Correlation between the Mechanical and Tribological Properties of Rutile Reinforced LM27 Alloy Composite

Abstract

:1. Introduction

2. Preparation of Samples

3. Characterization of Composites

3.1. Structural Analysis

3.2. Microhardness Measurement

3.3. Wear Rate Measurements

3.4. Compressive Strength Measurements

3.5. Fracture Studies

4. Results and Discussion

4.1. XRD Analysis

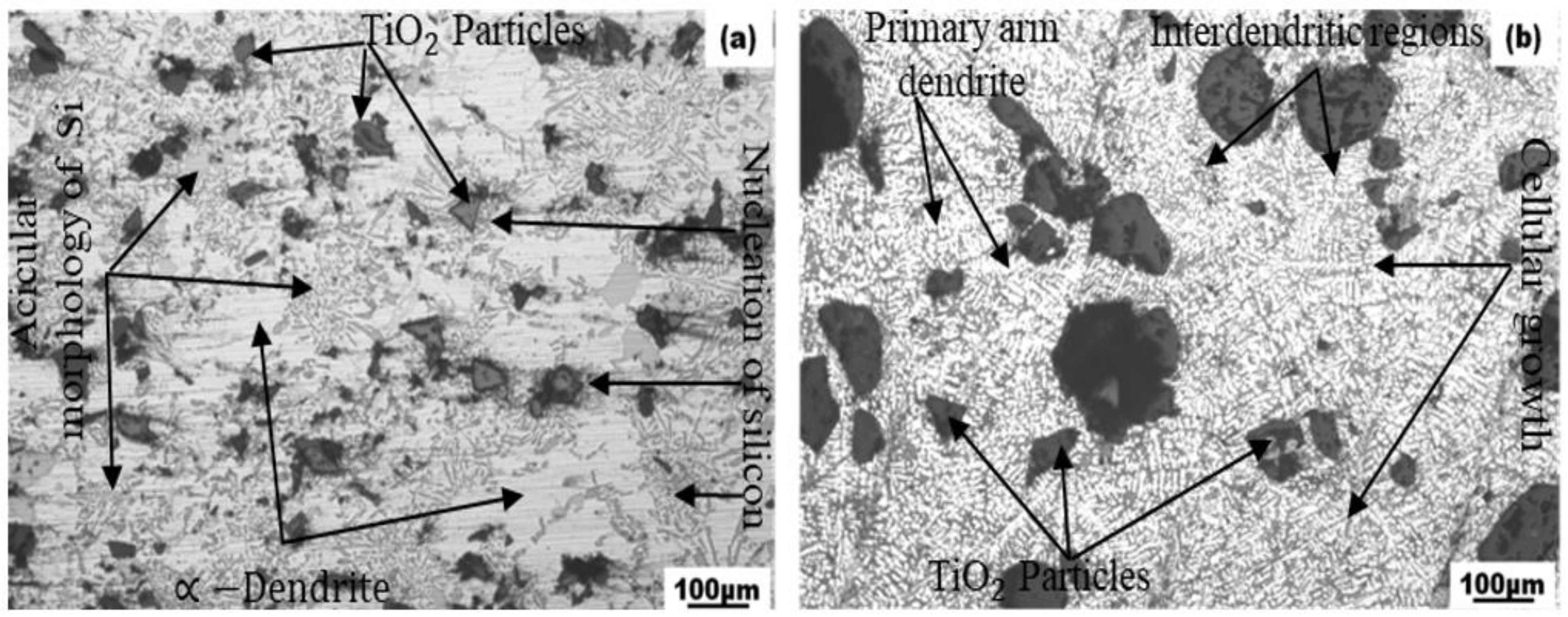

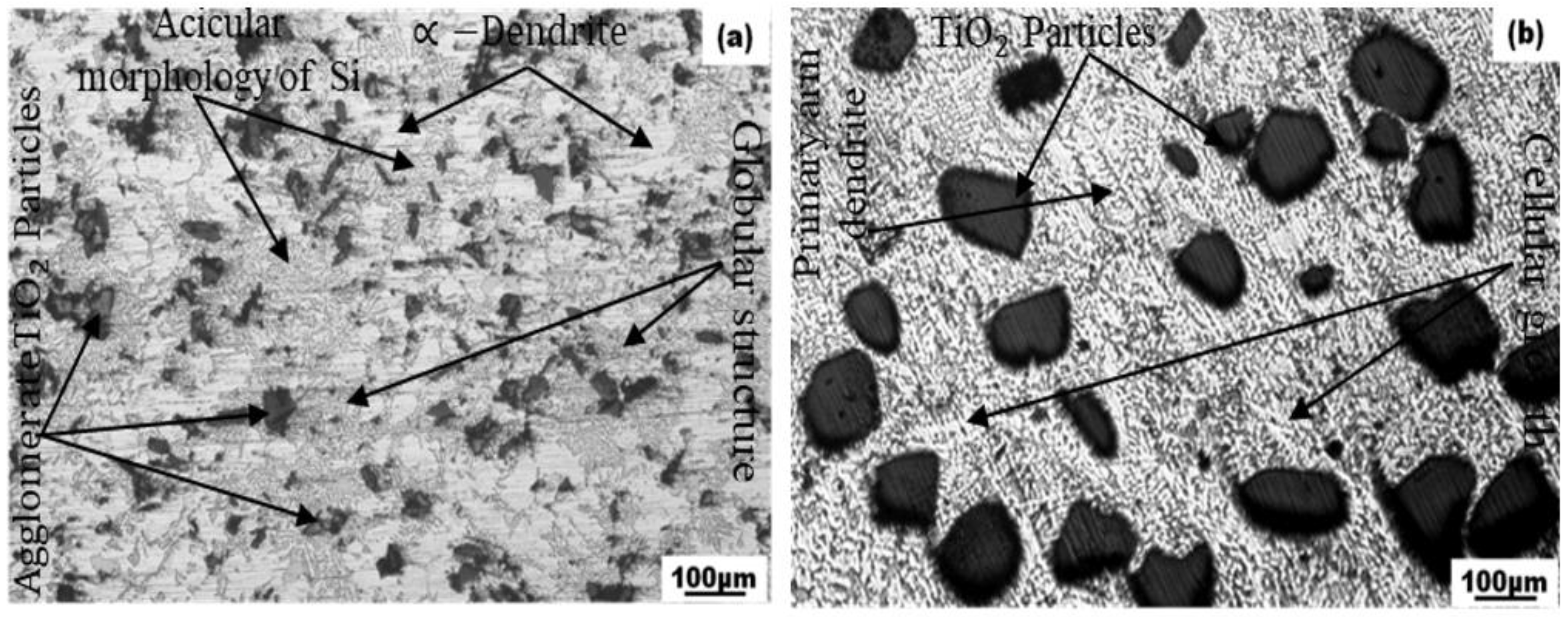

4.2. Microstructural Analysis

4.3. Microhardness Analysis

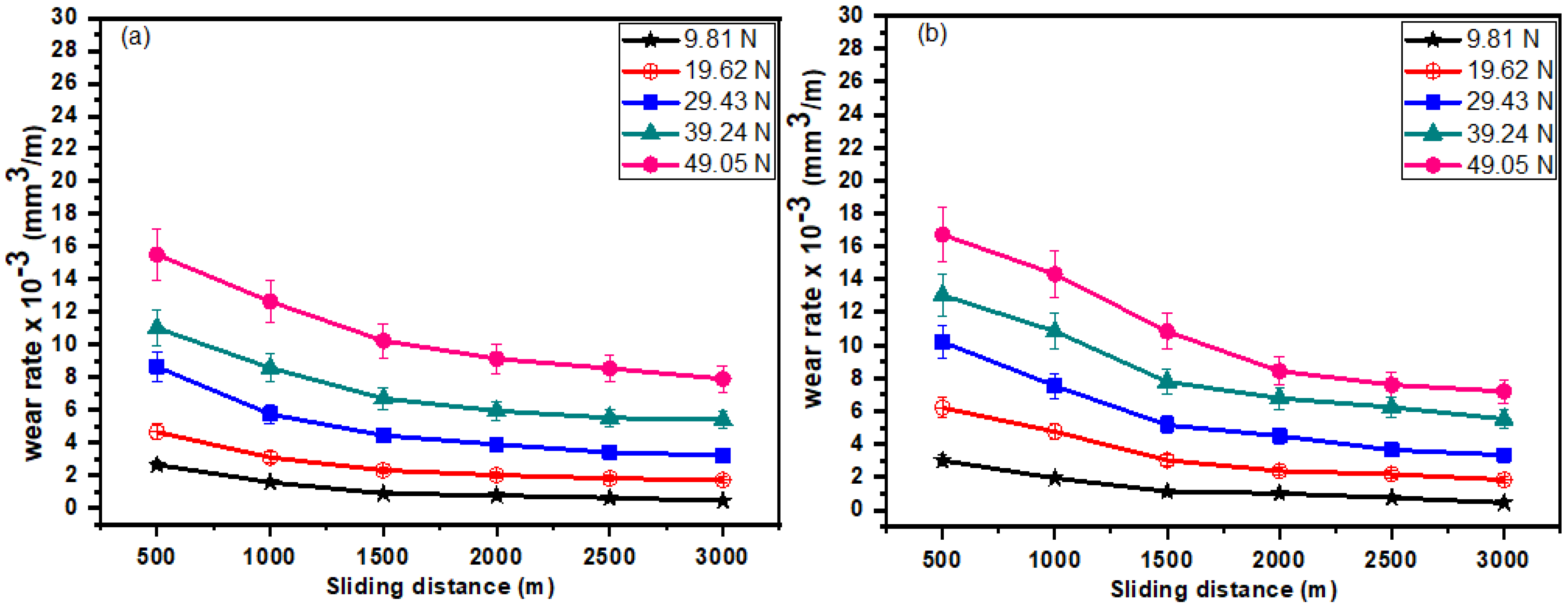

4.4. Wear Behaviour Analysis

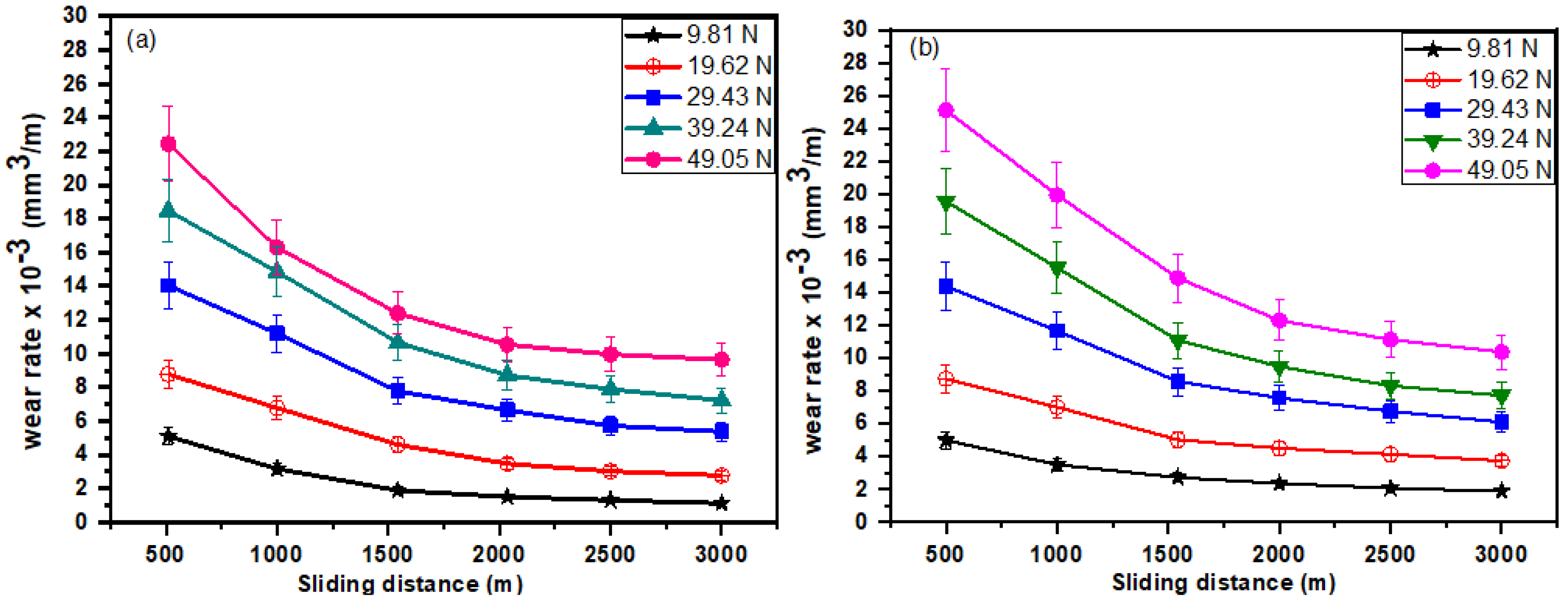

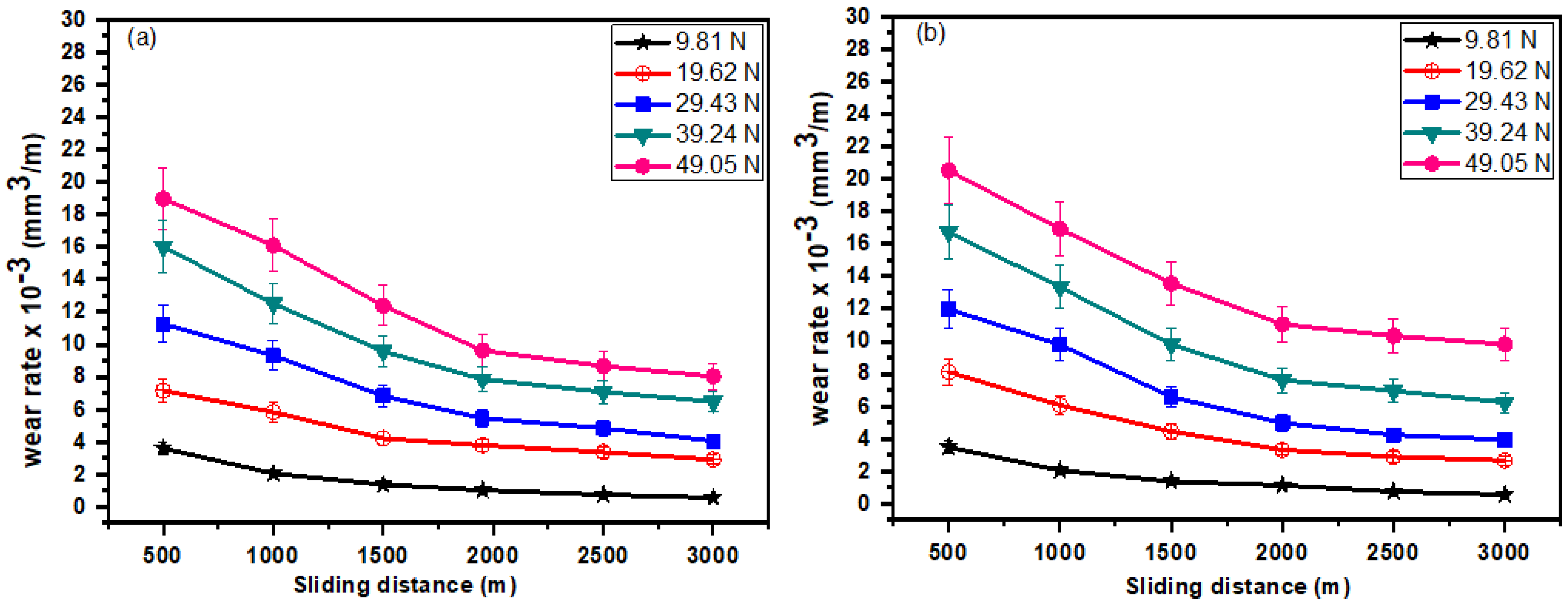

4.4.1. Effect of Rutile Reinforcement on Wear Rate

4.4.2. Effect of Particle Size on Wear Rate

4.4.3. Effect of Load on Wear Rate

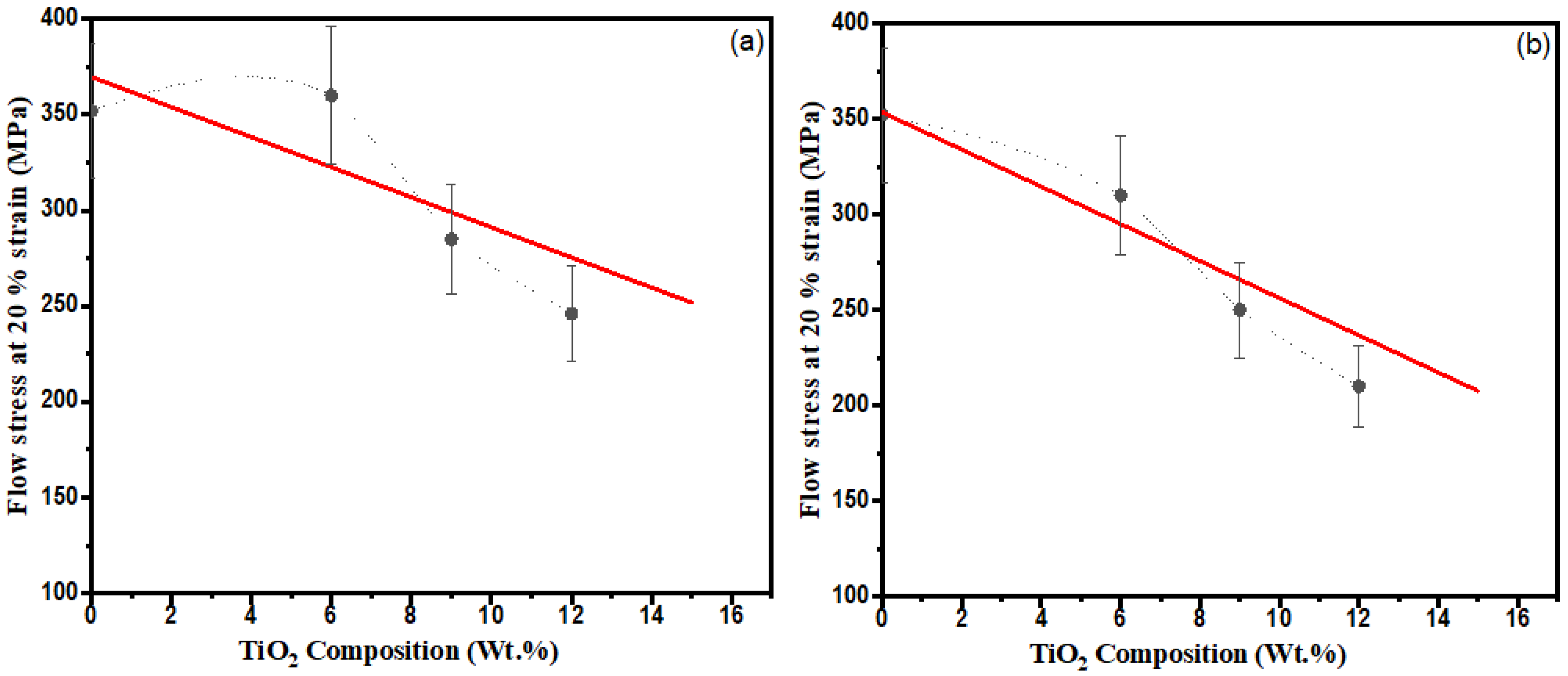

4.5. Compressive Strength

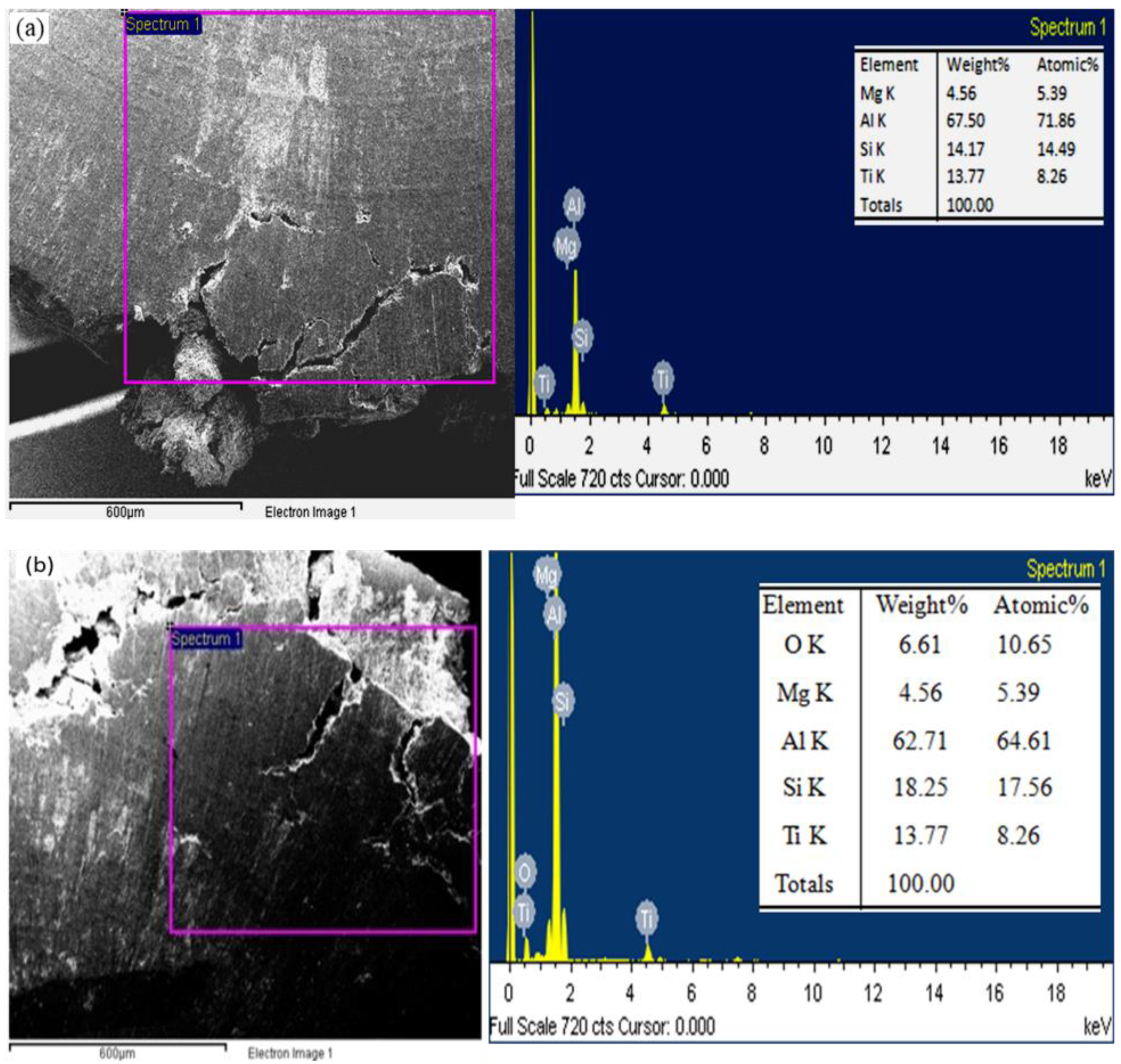

4.6. Fracture Studies

5. Conclusions

- Because of the uniform distribution of the rutile particles in the microstructure of the LM27 alloy composites, the mechanical and tribological properties have been significantly improved.

- Fine size reinforced particles are responsible for the delayed cooling rate near the particles, which restricted the diffusion within the melt and it served as a center for the development of silicon with fuzzy morphological changes.

- This composite has higher microhardness, wear resistance, and compressive strength because the fine-sized rutile reinforcement particles are evenly distributed throughout the matrix. There is a decrease in the wear rate difference observed between composites with different reinforcement size ranges as the loads increase.

- A limited amount of fine size rutile particle addition in the matrix enhances the compressive strength as compared to coarse size rutile particles at the same weight percentage of reinforcement.

- The higher compressive strength is achieved with 6 wt.% fine size reinforced composite material.

- A higher amount of reinforced particle contains higher interfacial micro-voids, which disturbs the stress concentration in the composite. In this condition, the higher stress concentration on the voids is responsible for the nucleation of cracks and their ultimate fracture.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Surappa, M.K. Aluminium matrix composites: Challenges and opportunities. Sadhana 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, A.; Arora, A.; Pandey, O.P. The microstructure and wear behaviour of garnet particle reinforced Al matrix composites. J. Mater. Res. Technol. 2019, 8, 5443–5455. [Google Scholar] [CrossRef]

- Prabhu, S.R.; Shettigar, A.K.; Herbert, M.A.; Rao, S.S. Microstructure and mechanical properties of rutile-reinforced AA6061 matrix composites produced via stir casting process. Trans. Nonferr. Met. Soc. China 2019, 29, 2229–2236. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Laoui, T.; Haseeb, A.S.M.A.; Celis, J.P.; Froyen, L. Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: A comparative study. J. Mater. Process. Technol. 2003, 142, 738–743. [Google Scholar] [CrossRef]

- Sharma, S.C. The sliding wearbehavior of Al6061-garnet particulate composites. Wear 2001, 249, 1036–1045. [Google Scholar] [CrossRef]

- Sharma, S.; Nanda, T.; Pandey, O.P. Heat treatment T4 and T6 effects on the tribological properties of sillimanite mineral-reinforced LM30 aluminium alloy composites at elevated temperatures. Proceed. Int. Mech. Eng. J.-J. Eng. 2022, 236, 946. [Google Scholar] [CrossRef]

- Badran, A.H.; Alamro, T.; Bazuhair, R.W.; Gad El-Mawla, A.A.; El-Adben, S.Z.; Fouly, A. Investigation of the mechanical behavior of synthesized Al6061/TiO2 microcomposites using an innovative stir casting method. J. Nanomater. 2022, 12, 1646. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Li, Y.F.; Zhang, Y.Z.; Wang, Y.M.; Wang, Y.J. High-temperature solid lubricants and self-lubricating composites: A critical review. Lubricants 2022, 10, 177. [Google Scholar] [CrossRef]

- Akbari, M.K.; Baharvandi, H.; Shirvanimoghaddam, K. Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater. Des. 2015, 66, 150–161. [Google Scholar] [CrossRef]

- Wang, J.; Zafar, M.Q.; Chen, Y.; Pan, P.; Zuo, L.; Zhao, H.; Zhang, X. Tribological properties of brake disc material for a high-speed train and the evolution of debris. Lubricants 2022, 10, 168. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, R.; Panwar, R.P.; Pandey, O.P. Effect of particle size on wear of particulate reinforced aluminum alloy composites at elevated temperatures. J. Mater. Eng. Perform. 2013, 22, 3550–3560. [Google Scholar] [CrossRef]

- Bhoi, N.K.; Singh, H.; Pratap, S. Developments in the aluminum metal matrix composites reinforced by micro/nano particles-A review. J. Compos. Mater. 2020, 54, 813–833. [Google Scholar] [CrossRef]

- Alagarsamy, S.V.; Ravichandran, M. Synthesis, microstructure and properties of TiO2 reinforced AA7075 matrix composites via stir casting route. Mater. Res. Express. 2019, 6, 6519. [Google Scholar] [CrossRef]

- Rodiouchkina, M.; Berglund, K.; Forsberg, F.; Rodushkin, I.; Hardell, J. Influence of counter surface roughness and lay on the tribological behaviour of self-lubricating bearing materials in dry sliding conditions at high contact pressures. Lubricants 2022, 10, 167. [Google Scholar] [CrossRef]

- Chern, S.Y.; Chen, Y.Y.; Liu, W.L.; Horng, J.H. Contact characteristics at interface in three-body contact conditions with rough surfaces and foreign particles. Lubricants 2022, 10, 164. [Google Scholar] [CrossRef]

- Lhermerout, R.; Perkin, S. The influence of mechanical deformations on surface force measurements. Lubricants 2021, 9, 69. [Google Scholar] [CrossRef]

- Lata, S.; Pandey, A.; Labhansh; Sharma, A.; Meena, K.; Rana, R.; Lal, R. An experimental study and analysis of the mechanical properties of titanium dioxide reinforced aluminum (AA5051) composite. Mater. Today Proceed. 2018, 5, 6090–6097. [Google Scholar] [CrossRef]

- Donelan, P. Modelling microstructural and mechanical properties of ferritic ductile cast iron. Mater. Sci. Technol. 2000, 16, 261–269. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–31. [Google Scholar]

- Bonatti, R.S.; Siqueira, R.R.; Padilha, G.S.; Bortolozo, A.D.; Osorio, W.R. Distinct Alp/Sip composites affecting its densification and mechanical behavior. J. Alloys Compd. 2018, 757, 434–447. [Google Scholar] [CrossRef]

- Gnjidic, Z.; Bozic, D.; Mitkov, M. The influence of SiC particles on the compressive properties of metal matrix composites. Mater. Charact. 2001, 47, 129–138. [Google Scholar] [CrossRef]

- Sudarshan; Surappa, M.K. Dry sliding wear of fly ash particle reinforced A356 Al composites. Wear 2008, 265, 349–360. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Tribological behaviour of semisolid-semisolid compocast Al-Si matrix composites reinforced with TiB2 coated B4C particulates. Ceram. Int. 2012, 38, 1887–1895. [Google Scholar] [CrossRef]

- Wang, B.; Janowski, G.M.; Patterson, B.R. Particle cracking in P/M processed SiC reinforced aluminum matrix composite materials. Metall. Mater. Trans. A 1995, 26A, 2457. [Google Scholar] [CrossRef]

- Doel, T.J.A.; Bowen, P. Tensile properties of particulate reinforced metal matrix composites. Compos. Part A 1996, 27A, 655. [Google Scholar] [CrossRef]

- Rees, D.W.A. Deformation and fracture of metal matrix particulate composites under combined loading. Compos. Part A 1998, 29A, 171. [Google Scholar] [CrossRef]

- Miller, W.S.; Humphreys, F.J. Strengthening mechanisms in metal matrix composites. Scr. Metall. Mater. 1991, 25, 33. [Google Scholar] [CrossRef]

| Details of Composite Specimens | Rutile Particle Size (μm) | Rutile Concentration (%) |

|---|---|---|

| LM27 alloy | - | 0 |

| Composite ‘6F’ | 50–75 | 6 |

| Composite ‘9F’ | 50–75 | 9 |

| Composite ‘12F’ | 50–75 | 12 |

| Composite ‘6C’ | 106–125 | 6 |

| Composite ‘9C’ | 106–125 | 9 |

| Composite ‘12C’ | 106–125 | 12 |

| Details of Composite Specimens | Specimen Diameter, D (mm) | Specimen Thickness, L (mm) | L/D |

|---|---|---|---|

| LM27 alloy | 10 | 5 | 0.5 |

| Composite ‘6F’ | 10 | 5 | 0.5 |

| Composite ‘9F’ | 10 | 5 | 0.5 |

| Composite ‘12F’ | 10 | 5 | 0.5 |

| Composite ‘6C’ | 10 | 5 | 0.5 |

| Composite ‘9C’ | 10 | 5 | 0.5 |

| Composite ‘12C’ | 10 | 5 | 0.5 |

| Composite | Microhardness [Hv] | ||

|---|---|---|---|

| at Matrix | at Interface | at Particle | |

| (Composite ‘6F’) | 81 ± 1 | 121 ± 1 | 706 ± 1 |

| (Composite ‘6C’) | 78 ± 1 | 119 ± 1 | 702 ± 1 |

| (Composite ‘9F’) | 88 ± 1 | 127 ± 1 | 711 ± 1 |

| (Composite ‘9C’) | 85 ± 1 | 122 ± 1 | 704 ± 1 |

| (Composite ‘12F’) | 96 ± 1 | 138 ± 1 | 718 ± 1 |

| (Composite ‘12C’) | 94 ± 1 | 131 ± 1 | 709 ± 1 |

| Test Series | Reinforced Particle Size (µm) | Rutile Concentration (%) | Flow Stress at 20% Strain (MPa) |

|---|---|---|---|

| LM27 | Base Alloy | 0 | 352 ± 2 |

| Composite ‘6F’ | 50–75 ± 5 | 6 | 360 ± 2 |

| Composite ‘9F’ | 50–75 ± 5 | 9 | 285 ± 2 |

| Composite ‘12F’ | 50–75 ± 5 | 12 | 246 ± 2 |

| Test Series | Reinforced Particle Size (µm) | Rutile Concentration (%) | Flow Stress at 20% Strain (MPa) |

|---|---|---|---|

| LM27 | Base Alloy | 0 | 352 ± 2 |

| Composite ‘6C’ | 106–125 ± 5 | 6 | 310 ± 2 |

| Composite ‘9C’ | 106–125 ± 5 | 9 | 250 ± 2 |

| Composite ‘12C’ | 106–125 ± 5 | 12 | 210 ± 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagpal, P.K.; Kumar, S.; Sharma, J.D.; Mahla, S.K.; Salunkhe, S.; Hussein, H.M.A. Correlation between the Mechanical and Tribological Properties of Rutile Reinforced LM27 Alloy Composite. Lubricants 2022, 10, 251. https://doi.org/10.3390/lubricants10100251

Nagpal PK, Kumar S, Sharma JD, Mahla SK, Salunkhe S, Hussein HMA. Correlation between the Mechanical and Tribological Properties of Rutile Reinforced LM27 Alloy Composite. Lubricants. 2022; 10(10):251. https://doi.org/10.3390/lubricants10100251

Chicago/Turabian StyleNagpal, Pardeep Kumar, Suresh Kumar, Jagmohan Datt Sharma, Sunil Kumar Mahla, Sachin Salunkhe, and Hussein Mohamed Abdelmoneam Hussein. 2022. "Correlation between the Mechanical and Tribological Properties of Rutile Reinforced LM27 Alloy Composite" Lubricants 10, no. 10: 251. https://doi.org/10.3390/lubricants10100251

APA StyleNagpal, P. K., Kumar, S., Sharma, J. D., Mahla, S. K., Salunkhe, S., & Hussein, H. M. A. (2022). Correlation between the Mechanical and Tribological Properties of Rutile Reinforced LM27 Alloy Composite. Lubricants, 10(10), 251. https://doi.org/10.3390/lubricants10100251