Prediction of Surface Roughness Using Machine Learning Approach in MQL Turning of AISI 304 Steel by Varying Nanoparticle Size in the Cutting Fluid

Abstract

:1. Introduction

2. Materials and Methods

2.1. Machine Learning Models for Predicting Surface Roughness

2.1.1. Linear Regression

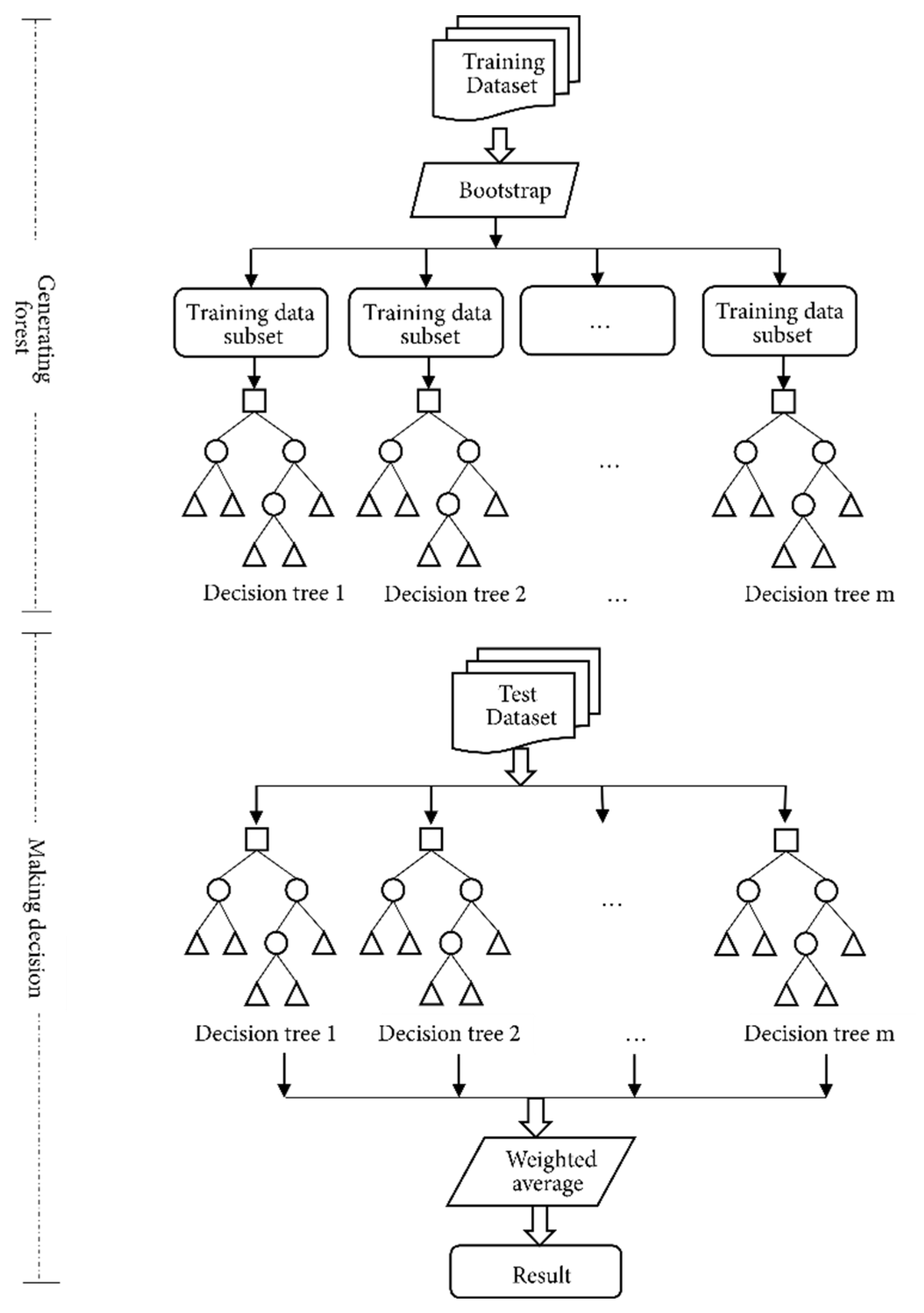

2.1.2. Random Forest

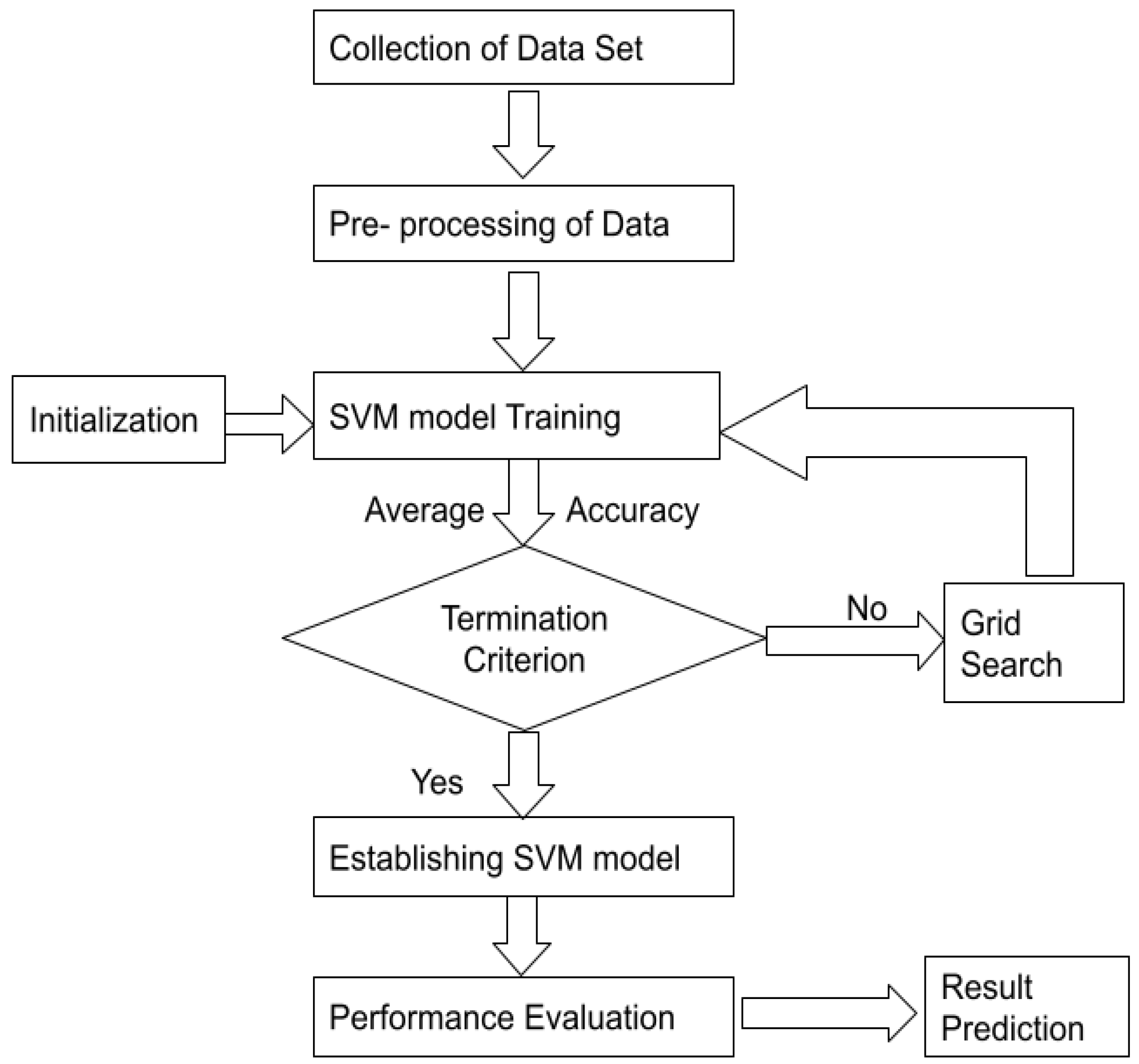

2.1.3. Support Vector Machines

2.2. Performance Indicators

2.3. Data Pre-Processing

3. Results and Discussions

3.1. Prediction of Response (Surface Roughness) by Different Machine Learning Models

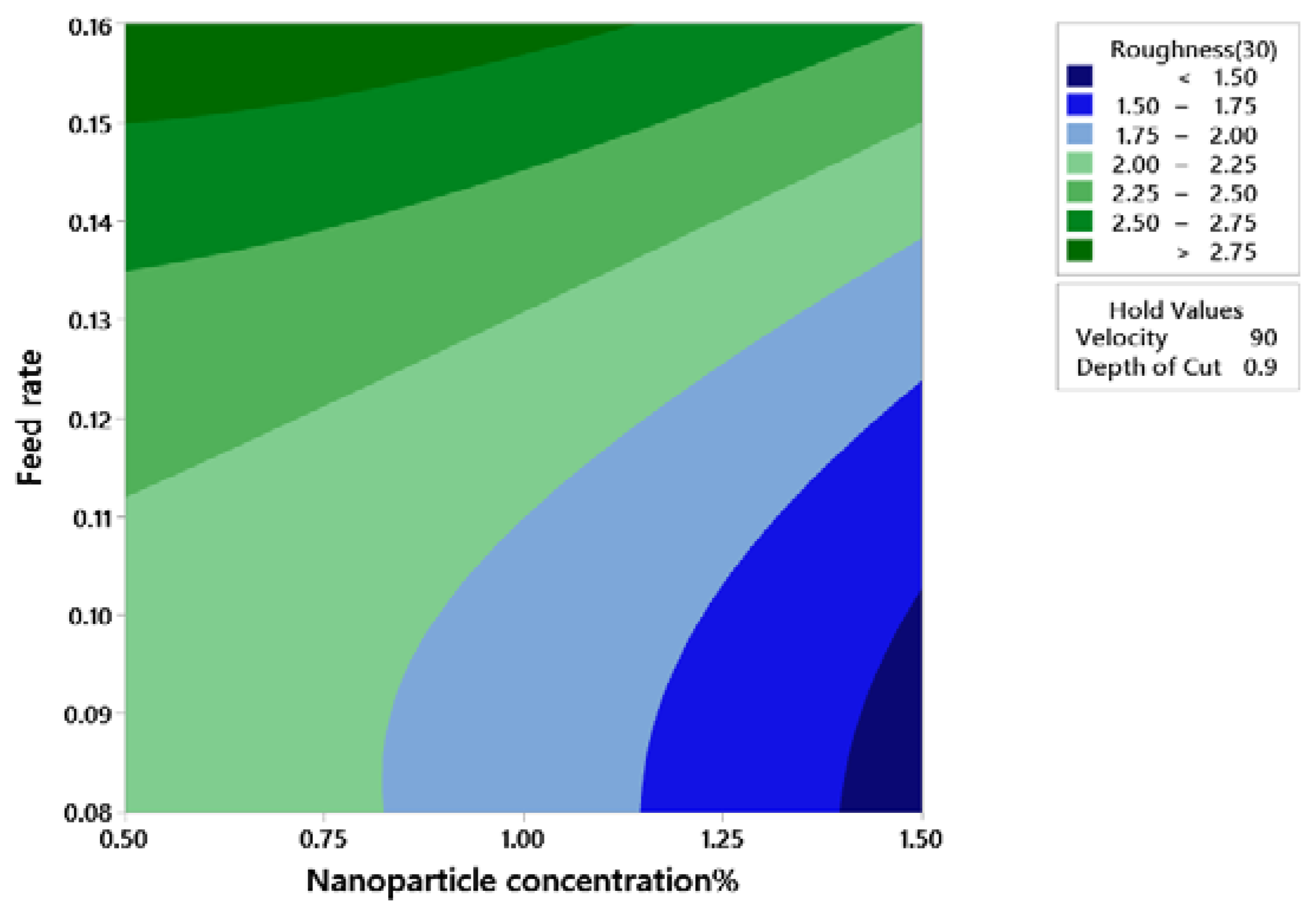

3.2. Analysis of Surface Roughness at Particle Size of 30 nm

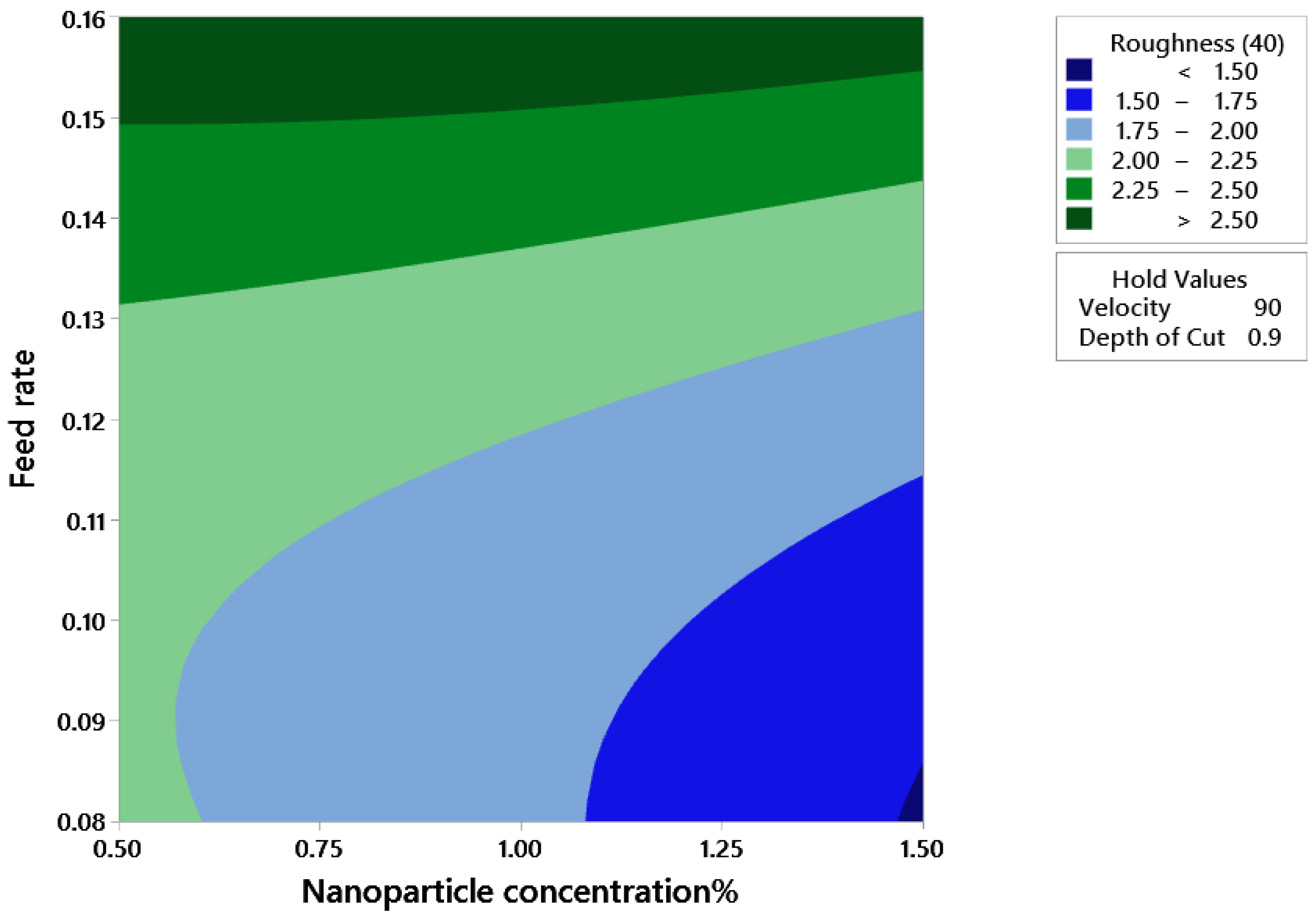

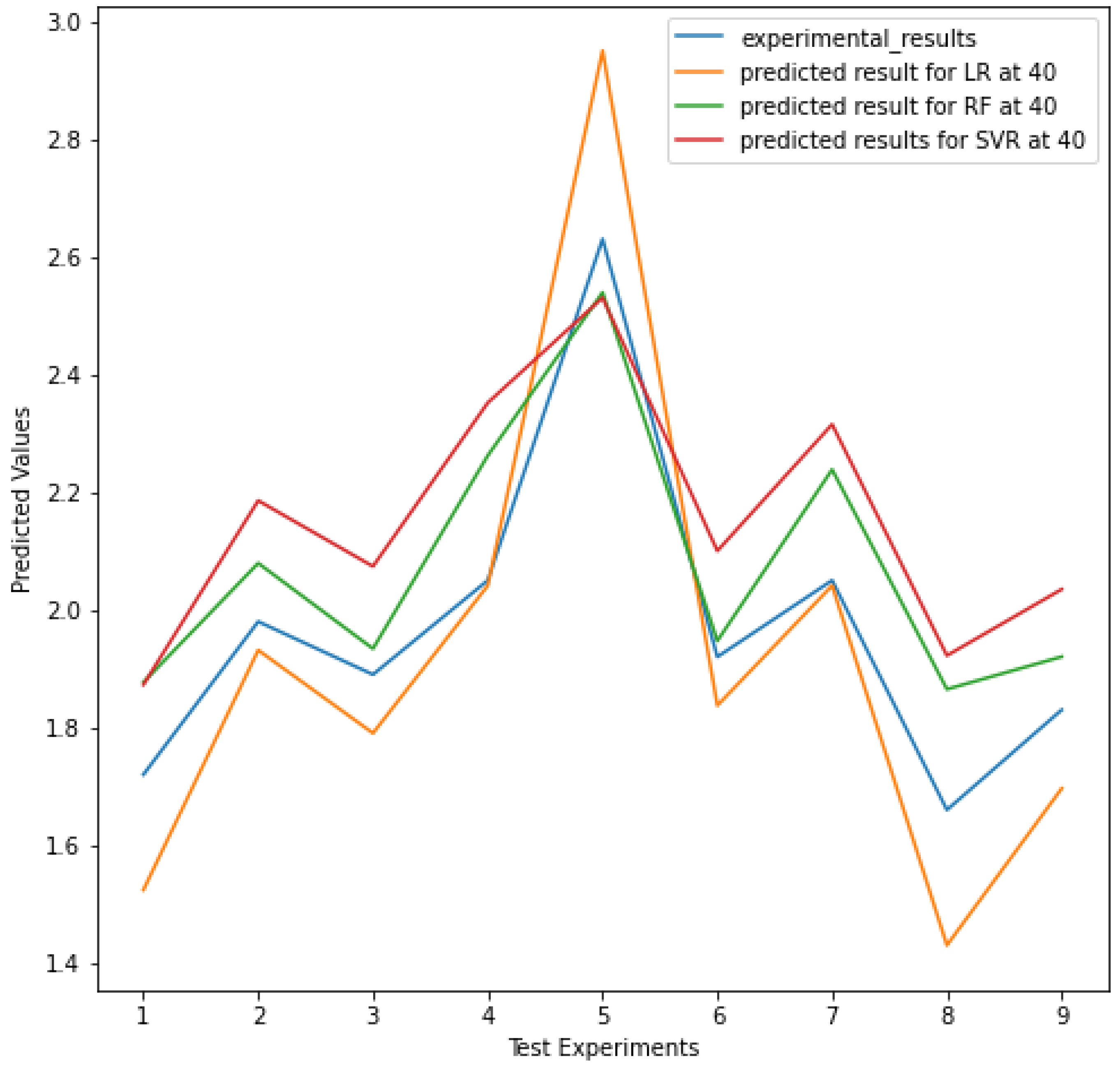

3.3. Analysis of Surface Roughness at Particle Size of 40 nm

4. Conclusions

- The experimental value of surface roughness obtained from 40 nm particle size of alumina is lower in comparison to 30 nm particle size.

- Among the three machine learning models used in this study, random forest outperformed the other two models as the errors obtained from the performance metrics in both the cases of average particle size were lower for random forest in comparison to errors obtained from the other two models.

- The R-squared value of the training errors in case of random forest for 30 and 40 nm size is 0.9710 and 0.7968, respectively.

- As per the application of the three machine learning models with both the particle sizes, it can be seen that models performed better with 30 nm particle size in comparison to 40 nm.

- The particle sizes of alumina used in this investigation can be used in further studies for hybridization purpose with other nanofluids to enhance the properties of the cutting fluid.

- It can be seen that there is a difference between train and test errors, which can be minimized if the data points are increased, as they were limited to 27 in this case.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| LR | Linear Regression |

| SVR | Support Vector Regression |

| RF | Random Forest |

| MSE | Mean Square Error |

| MAPE | Mean Absolute Percentage Error |

| ANN | Artificial Neural Network |

| DNN | Deep Neural Network |

| BPNN | Back Propagation Neural Network |

| Y | dependent variable |

| X | independent variable |

| ao | intercept of the line |

| a1 | linear regression coefficient |

| ε | random error |

| Yi | observed values |

| Ŷ | predicted values |

References

- Tsourveloudis, N.C. Predictive modeling of the Ti6Al4V alloy surface roughness. J. Intell. Robot. Syst. Theory Appl. 2010, 60, 513–530. [Google Scholar] [CrossRef]

- Varun, A.; Kumar, M.S.; Murumulla, K.; Sathvik, T. Surface roughness prediction using machine learning algorithms while turning under different lubrication conditions. J. Phys. Conf. Ser. 2021, 2070, 012243. [Google Scholar] [CrossRef]

- Elangovan, M.; Sakthivel, N.R.; Saravanamurugan, S.; Nair, B.B.; Sugumaran, V. Machine learning approach to the prediction of surface roughness using statistical features of vibration signal acquired in turning. Procedia Comput. Sci. 2015, 50, 282–288. [Google Scholar] [CrossRef] [Green Version]

- Raza, S.M.; Khan, A.M.; Farooq, M.U.; Iqbal, A.; Pimenov, D.Y.; Giasin, K.; Leksycki, K. Modelling and analysis of surface evolution on turning of hard-to-cut CLARM 30NiCrMoV14 steel alloy. Metals 2021, 11, 1751. [Google Scholar] [CrossRef]

- Dubey, V.; Sharma, A.K.; Vats, P.; Pimenov, D.Y.; Giasin, K.; Chuchala, D. Study of a multicriterion decision-making approach to the Mql turning of Aisi 304 steel using hybrid nanocutting fluid. Materials 2021, 14, 7207. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Abbas, A.T.; Gupta, M.K.; Soliman, M.S.; Mia, M.; Hegab, H.; Luqman, M.; Pimenov, D.Y. Sustainability assessment associated with surface roughness and power consumption characteristics in nanofluid MQL-assisted turning of AISI 1045 steel. Int. J. Adv. Manuf. Technol. 2019, 105, 1311–1327. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Singh, G.; Królczyk, G.; Pimenov, D.Y. An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J. Clean. Prod. 2018, 187, 1069–1081. [Google Scholar] [CrossRef]

- Sampaio, M.A.; Machado, Á.R.; Laurindo, C.A.H.; Torres, R.D.; Amorim, F.L. Influence of Minimum Quantity of Lubrication (MQL) when turning hardened SAE 1045 steel: A comparison with dry machining. Int. J. Adv. Manuf. Technol. 2018, 98, 959–968. [Google Scholar] [CrossRef]

- Gupta, M.K.; Boy, M.; Erdi Korkmaz, M.; Yaşar, N.; Günay, M.; Krolczyk, G.M. Measurement and analysis of machining induced tribological characteristics in dual jet minimum quantity lubrication assisted turning of duplex stainless steel. Meas. J. Int. Meas. Confed. 2022, 187, 110353. [Google Scholar] [CrossRef]

- Bonfá, M.M.; Costa, É.S.; Sales, W.F.; Amorim, F.L.; Maia, L.H.A.; Machado, Á.R. Evaluation of tool life and workpiece surface roughness in turning of AISI D6 hardened steel using PCBN tools and Minimum Quantity of Lubricant (MQL) applied at different directions. Int. J. Adv. Manuf. Technol. 2019, 103, 971–984. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; Sarikaya, M.; Pusavec, F. Energy consumption and ecological analysis of sustainable and conventional cutting fluid strategies in machining 15–5 PHSS. Sustain. Mater. Technol. 2022, 32, e00416. [Google Scholar] [CrossRef]

- Dubey, V.; Kumar Sharma, A.; Kumar Singh, R. Study of various cooling methodology used in machining processes. Mater. Today Proc. 2020, 21, 1572–1576. [Google Scholar] [CrossRef]

- Sizemore, N.E.; Nogueira, M.L.; Greis, N.P.; Davies, M.A. Application of machine learning to the prediction of surface roughness in diamond machining. Procedia Manuf. 2020, 48, 1029–1040. [Google Scholar] [CrossRef]

- Reddy, B.S.; Padmanabha, G.; Reddy, K.V.K. Surface roughness prediction techniques for CNC Turning. Asian J. Sci. Res. 2008, 1, 256–264. [Google Scholar] [CrossRef] [Green Version]

- Eser, A.; Aşkar Ayyildiz, E.; Ayyildiz, M.; Kara, F. Artificial intelligence-based surface roughness estimation modelling for milling of AA6061 alloy. Adv. Mater. Sci. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Manjunath, K.; Tewary, S.; Khatri, N.; Cheng, K. Monitoring and predicting the surface generation and surface roughness in ultraprecision machining: A critical review. Machines 2021, 9, 369. [Google Scholar] [CrossRef]

- Ross, N.S.; Gopinath, C.; Nagarajan, S.; Gupta, M.K.; Shanmugam, R.; Kumar, M.S.; Boy, M.; Korkmaz, M.E. Impact of hybrid cooling approach on milling and surface morphological characteristics of Nimonic 80A alloy. J. Manuf. Process. 2022, 73, 428–439. [Google Scholar] [CrossRef]

- Alajmi, M.S.; Almeshal, A.M. Prediction and optimization of surface roughness in a turning process using the ANFIS-QPSO method. Materials 2020, 13, 2986. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Bustillo, A.; Wojciechowski, S.; Sharma, V.S.; Gupta, M.K.; Kuntoğlu, M. Artificial intelligence systems for tool condition monitoring in machining: Analysis and critical review. J. Intell. Manuf. 2022, 1–43. [Google Scholar] [CrossRef]

- Pandey, K.; Dubey, V.; Sharma, A.K.; Mital, A. State of art on tribological behaviour of nanoparticle enriched cutting fluid. Mater. Today Proc. 2019, 26, 2586–2589. [Google Scholar] [CrossRef]

- Abbas, A.T.; Benyahia, F.; El Rayes, M.M.; Pruncu, C.; Taha, M.A.; Hegab, H. Towards optimization of machining performance and sustainability aspects when turning AISI 1045 steel under different cooling and lubrication strategies. Materials 2019, 12, 3023. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khanna, N.; Shah, P.; de Lacalle, L.N.L.; Rodríguez, A.; Pereira, O. In pursuit of sustainable cutting fluid strategy for machining Ti-6Al-4V using life cycle analysis. Sustain. Mater. Technol. 2021, 29, e00301. [Google Scholar] [CrossRef]

- Dubey, V.; Sharma, A.K.; Kumar, H.; Arora, P.K. Prediction of cutting forces in MQL turning of AISI 304 steel using machine learning algorithm. J. Eng. Res. 2022, 1–13. [Google Scholar] [CrossRef]

- Şap, S.; Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Salur, E.; Pimenov, D.Y. Investigation of the effects of cooling and lubricating strategies on tribological characteristics in machining of hybrid composites. Lubricants 2022, 10, 63. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Calleja-Ochoa, A.; Celaya, A.; de Lacalle, L.N.L.; Fernández-Valdivielso, A.; González, H. Simulation of cryo-cooling to improve super alloys cutting tools. Int. J. Precis. Eng. Manuf. Green Technol. 2022, 9, 73–82. [Google Scholar] [CrossRef]

- Magalhães, L.C.; Carlesso, G.C.; de Lacalle, L.N.L.; Souza, M.T.; de Palheta, F.O.; Binder, C. Tool wear effect on surface integrity in AISI 1045 steel dry turning. Materials 2022, 15, 2031. [Google Scholar] [CrossRef]

- Abrão, B.S.; Pereira, M.F.; da Silva, L.R.R.; Machado, Á.R.; Gelamo, R.V.; de Freitas, F.M.C.; Mia, M.; da Silva, R.B. Improvements of the Mql cooling-lubrication condition by the addition of multilayer graphene platelets in peripheral grinding of Sae 52100 steel. Lubricants 2021, 9, 79. [Google Scholar] [CrossRef]

- Baldin, V.; da Silva, L.R.R.; Houck, C.F.; Gelamo, R.V.; Machado, Á.R. Effect of graphene addition in cutting fluids applied by Mql in end milling of Aisi 1045 steel. Lubricants 2021, 9, 70. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Çamlı, K.Y.; Demirsöz, R.; Boy, M.; Korkmaz, M.E.; Yaşar, N.; Giasin, K.; Pimenov, D.Y. Performance of MQL and Nano-MQL lubrication in machining ER7 steel for train wheel applications. Lubricants 2022, 10, 48. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Boy, M.; Yaşar, N.; Krolczyk, G.M.; Günay, M. Influence of duplex jets MQL and Nano-MQL cooling system on machining performance of Nimonic 80A. J. Manuf. Process. 2021, 69, 112–124. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Korkmaz, M.E. Influence of hybrid cryo-MQL Lubri-cooling strategy on the machining and tribological characteristics of inconel 718. Tribol. Int. 2021, 163, 107178. [Google Scholar] [CrossRef]

- Tasdelen, B.; Thordenberg, H.; Olofsson, D. An Experimental investigation on contact length during Minimum Quantity Lubrication (MQL) machining. J. Mater. Process. Technol. 2008, 203, 221–231. [Google Scholar] [CrossRef]

- Cica, D.; Sredanovic, B.; Tesic, S.; Kramar, D. Predictive modeling of turning operations under different cooling/lubricating conditions for sustainable manufacturing with machine learning techniques. Appl. Comput. Inform. 2020. [CrossRef]

- Lin, W.J.; Lo, S.H.; Young, H.T.; Hung, C.L. Evaluation of deep learning neural networks for surface roughness prediction using vibration signal analysis. Appl. Sci. 2019, 9, 1462. [Google Scholar] [CrossRef] [Green Version]

- Dubey, V.; Sharma, A.K.; Singh, R.K. A technological review on temperature measurement techniques in various machining processes. In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Aggogeri, F.; Pellegrini, N.; Tagliani, F.L. Recent advances on machine learning applications in machining processes. Appl. Sci. 2021, 11, 8764. [Google Scholar] [CrossRef]

- Gupta, M.K.; Korkmaz, M.E.; Sarıkaya, M.; Krolczyk, G.M.; Günay, M.; Wojciechowski, S. Cutting forces and temperature measurements in cryogenic assisted turning of AA2024-T351 alloy: An experimentally validated simulation approach. Meas. J. Int. Meas. Confed. 2022, 188, 110594. [Google Scholar] [CrossRef]

- Chen, C.H.; Jeng, S.Y.; Lin, C.J. Prediction and analysis of the surface roughness in CNC end milling using neural networks. Appl. Sci. 2022, 12, 393. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, R.; Gao, Y.; Leopold, J. A nested-ANN prediction model for surface roughness considering the effects of cutting forces and tool vibrations. Meas. J. Int. Meas. Confed. 2017, 98, 25–34. [Google Scholar] [CrossRef]

- Bustillo, A.; Reis, R.; Machado, A.R.; Pimenov, D.Y. Improving the accuracy of machine-learning models with data from machine test repetitions. J. Intell. Manuf. 2022, 33, 203–221. [Google Scholar] [CrossRef]

- Azure, J.W.A.; Ayawah, P.E.A.; Kaba, A.G.A.; Kadingdi, F.A.; Frimpong, S. Hydraulic shovel digging phase simulation and force prediction using machine learning techniques. Mining Metall. Explor. 2021, 38, 2393–2404. [Google Scholar] [CrossRef]

- Cheng, J.; Li, G.; Chen, X. Developing a travel time estimation method of freeway based on floating car using random forests. J. Adv. Transp. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Jurkovic, Z.; Cukor, G.; Brezocnik, M.; Brajkovic, T. A comparison of machine learning methods for cutting parameters prediction in high speed turning process. J. Intell. Manuf. 2018, 29, 1683–1693. [Google Scholar] [CrossRef]

- Cervantes, J.; Garcia-Lamont, F.; Rodríguez-Mazahua, L.; Lopez, A. A comprehensive survey on support vector machine classification: Applications, challenges and trends. Neurocomputing 2020, 408, 189–215. [Google Scholar] [CrossRef]

- Bouacha, K.; Yallese, M.A.; Mabrouki, T.; Rigal, J.F. Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int. J. Refract. Met. Hard Mater. 2010, 28, 349–361. [Google Scholar] [CrossRef]

| Elements | S | P | C | Mo | Cu | Si | Mn | Ni | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Weight% | 0.02 | 0.027 | 0.065 | 0.13 | 0.14 | 0.3 | 1.78 | 8.1 | 18.2 | 71.2 |

| Levels/Factors | −1 | 0 | 1 |

|---|---|---|---|

| Depth of cut (mm) | 0.6 | 0.9 | 1.2 |

| Feed rate (mm/rev) | 0.08 | 0.12 | 0.16 |

| Cutting speed (m/min) | 60 | 90 | 120 |

| Nanofluid concentration (wt.%) | 0.5 | 1.0 | 1.5 |

| S.No. | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Nanoparticle Concentration (%) | Surface Roughness at 30 nm | Surface Roughness at 40 nm |

|---|---|---|---|---|---|---|

| 1 | 90 | 0.16 | 1.2 | 1 | 2.89 | 2.63 |

| 2 | 60 | 0.12 | 1.2 | 1 | 2.32 | 2.30 |

| 3 | 120 | 0.12 | 0.9 | 1.5 | 1.40 | 1.43 |

| 4 | 60 | 0.12 | 0.6 | 1 | 2.37 | 2.16 |

| 5 | 90 | 0.12 | 0.9 | 1 | 2.30 | 2.05 |

| 6 | 60 | 0.12 | 0.9 | 0.5 | 2.50 | 2.36 |

| 7 | 120 | 0.12 | 1.2 | 1 | 1.64 | 1.77 |

| 8 | 120 | 0.08 | 0.9 | 1 | 1.79 | 1.63 |

| 9 | 90 | 0.08 | 1.2 | 1 | 1.57 | 1.72 |

| 10 | 60 | 0.08 | 0.9 | 1 | 2.08 | 1.89 |

| 11 | 90 | 0.12 | 0.9 | 1 | 1.99 | 2.02 |

| 12 | 120 | 0.12 | 0.9 | 0.5 | 2.12 | 1.92 |

| 13 | 90 | 0.12 | 1.2 | 1.5 | 1.81 | 1.83 |

| 14 | 90 | 0.12 | 0.9 | 1 | 2.02 | 1.98 |

| 15 | 60 | 0.16 | 0.9 | 1 | 3.01 | 2.95 |

| 16 | 120 | 0.12 | 0.6 | 1 | 2.03 | 1.91 |

| 17 | 90 | 0.12 | 0.6 | 0.5 | 2.24 | 2.05 |

| 18 | 90 | 0.08 | 0.6 | 1 | 1.82 | 1.66 |

| 19 | 90 | 0.08 | 0.9 | 0.5 | 2.31 | 2.21 |

| 20 | 90 | 0.08 | 0.9 | 1.5 | 1.41 | 1.57 |

| 21 | 60 | 0.12 | 0.9 | 1.5 | 1.81 | 2.05 |

| 22 | 90 | 0.12 | 1.2 | 0.5 | 2.21 | 2.05 |

| 23 | 90 | 0.12 | 0.6 | 1.5 | 1.78 | 1.97 |

| 24 | 90 | 0.16 | 0.6 | 1 | 2.93 | 2.76 |

| 25 | 90 | 0.16 | 0.9 | 1.5 | 2.39 | 2.53 |

| 26 | 90 | 0.16 | 0.9 | 0.5 | 2.96 | 2.67 |

| 27 | 120 | 0.16 | 0.9 | 1 | 2.49 | 2.55 |

| Experiment Number | Experimented Value | Predicted SVR | Predicted RF | Predicted LR |

|---|---|---|---|---|

| 9 | 1.57 | 1.58 | 1.58 | 1.48 |

| 14 | 2.02 | 2.16 | 1.94 | 2.10 |

| 10 | 2.08 | 2.14 | 2.35 | 2.18 |

| 22 | 2.21 | 2.45 | 2.38 | 2.36 |

| 1 | 2.89 | 2.95 | 2.91 | 3.29 |

| 12 | 2.12 | 2.27 | 2.37 | 2.23 |

| 17 | 2.24 | 2.55 | 2.38 | 2.40 |

| 18 | 1.82 | 1.86 | 1.81 | 1.82 |

| 13 | 1.81 | 1.79 | 1.80 | 1.81 |

| Test Errors | Train Errors | |||||

|---|---|---|---|---|---|---|

| Models/Performance Metrics | R-Squared | MSE | MAPE | R-Squared | MSE | MAPE |

| SVR | 0.8053 | 0.0238 | 0.0547 | 0.9753 | 0.0057 | 0.0336 |

| RF | 0.8176 | 0.0223 | 0.0515 | 0.9710 | 0.0067 | 0.0322 |

| LR | 0.7660 | 0.0287 | 0.0547 | 1 | 4.6838 × 10−31 | 3.0185 × 10−16 |

| Experiment Number | Experimented Value | Predicted SVR | Predicted RF | Predicted LR |

|---|---|---|---|---|

| 9 | 1.72 | 1.87 | 1.87 | 1.52 |

| 14 | 1.98 | 2.18 | 2.07 | 1.93 |

| 10 | 1.89 | 2.07 | 1.93 | 1.79 |

| 22 | 2.05 | 2.35 | 2.26 | 2.04 |

| 1 | 2.63 | 2.53 | 2.53 | 2.95 |

| 12 | 1.92 | 2.10 | 1.94 | 1.83 |

| 17 | 2.05 | 2.31 | 2.23 | 2.04 |

| 18 | 1.66 | 1.92 | 1.86 | 1.43 |

| 13 | 1.83 | 2.03 | 1.92 | 1.69 |

| Test Errors | Train Errors | |||||

|---|---|---|---|---|---|---|

| Models/Performance Metrics | R-Squared | MSE | MAPE | R-Squared | MSE | MAPE |

| SVR | 0.3489 | 0.0459 | 0.1075 | 0.8497 | 0.0254 | 0.0642 |

| RF | 0.7231 | 0.0195 | 0.0645 | 0.7968 | 0.0344 | 0.0695 |

| LR | 0.6368 | 0.0256 | 0.0640 | 1 | 1.616 × 10−31 | 1.5186 × 10−16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubey, V.; Sharma, A.K.; Pimenov, D.Y. Prediction of Surface Roughness Using Machine Learning Approach in MQL Turning of AISI 304 Steel by Varying Nanoparticle Size in the Cutting Fluid. Lubricants 2022, 10, 81. https://doi.org/10.3390/lubricants10050081

Dubey V, Sharma AK, Pimenov DY. Prediction of Surface Roughness Using Machine Learning Approach in MQL Turning of AISI 304 Steel by Varying Nanoparticle Size in the Cutting Fluid. Lubricants. 2022; 10(5):81. https://doi.org/10.3390/lubricants10050081

Chicago/Turabian StyleDubey, Vineet, Anuj Kumar Sharma, and Danil Yurievich Pimenov. 2022. "Prediction of Surface Roughness Using Machine Learning Approach in MQL Turning of AISI 304 Steel by Varying Nanoparticle Size in the Cutting Fluid" Lubricants 10, no. 5: 81. https://doi.org/10.3390/lubricants10050081

APA StyleDubey, V., Sharma, A. K., & Pimenov, D. Y. (2022). Prediction of Surface Roughness Using Machine Learning Approach in MQL Turning of AISI 304 Steel by Varying Nanoparticle Size in the Cutting Fluid. Lubricants, 10(5), 81. https://doi.org/10.3390/lubricants10050081