Effect of h-BN and Nano-SiO2 Fillers on the High-Temperature Tribological Properties of PEEK/PI-Based Composites

Abstract

:1. Introduction

2. Materials and Experimental Procedure

2.1. Materials

2.2. Specimen Preparations

2.3. Measurements

3. Results

3.1. Thermal and Physical Properties of Composites

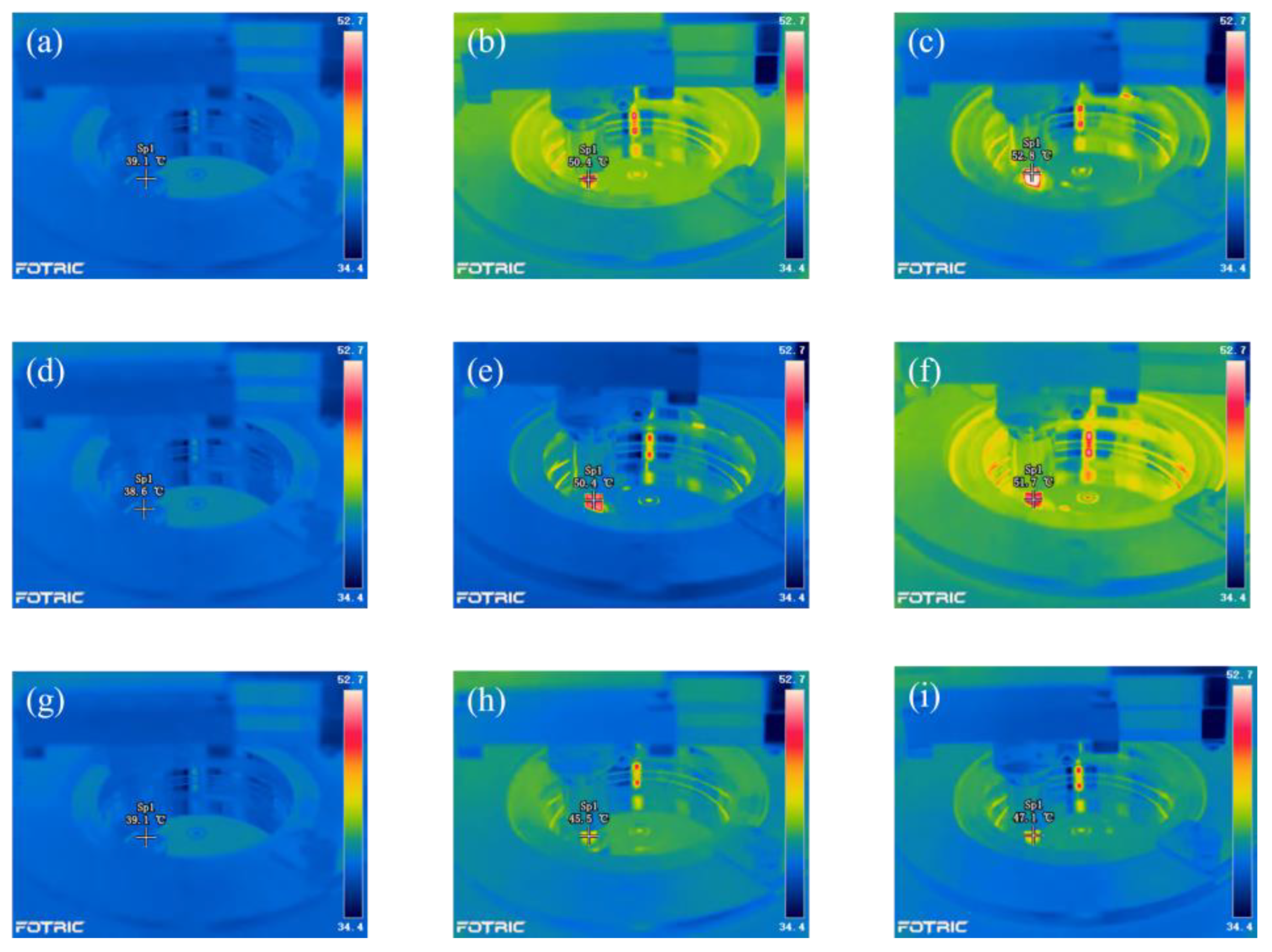

3.2. Friction and Wear Properties of Composites

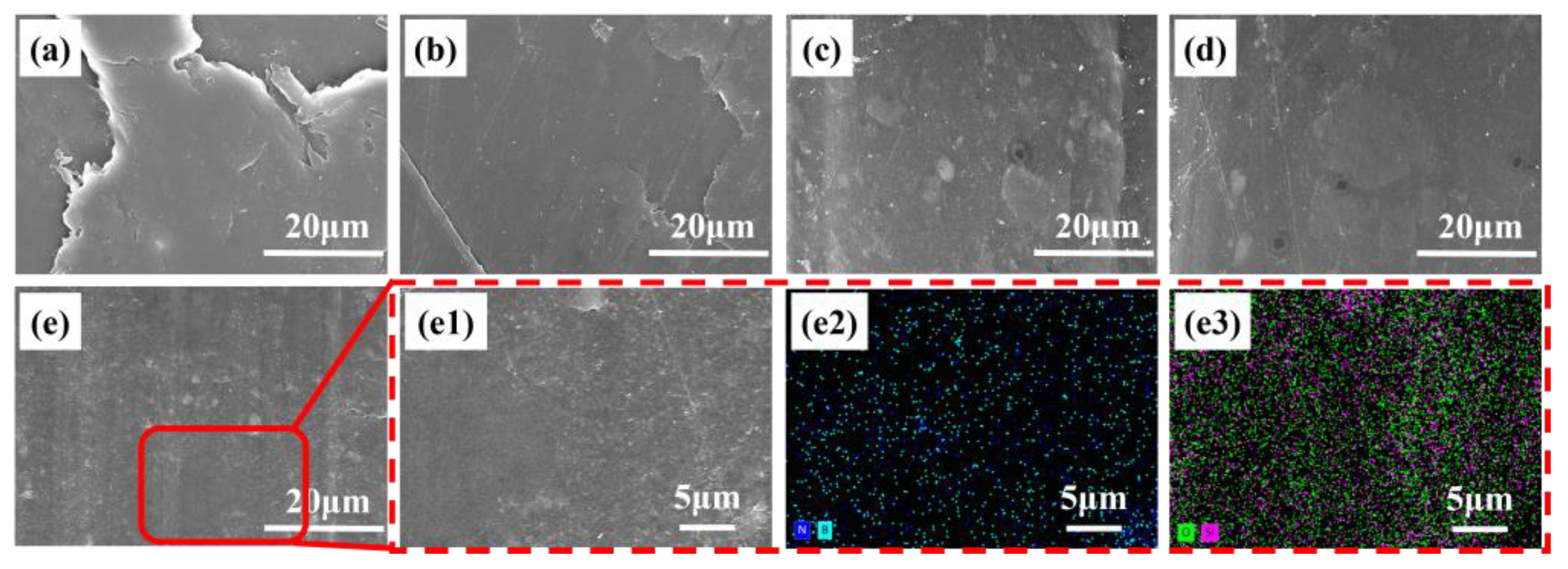

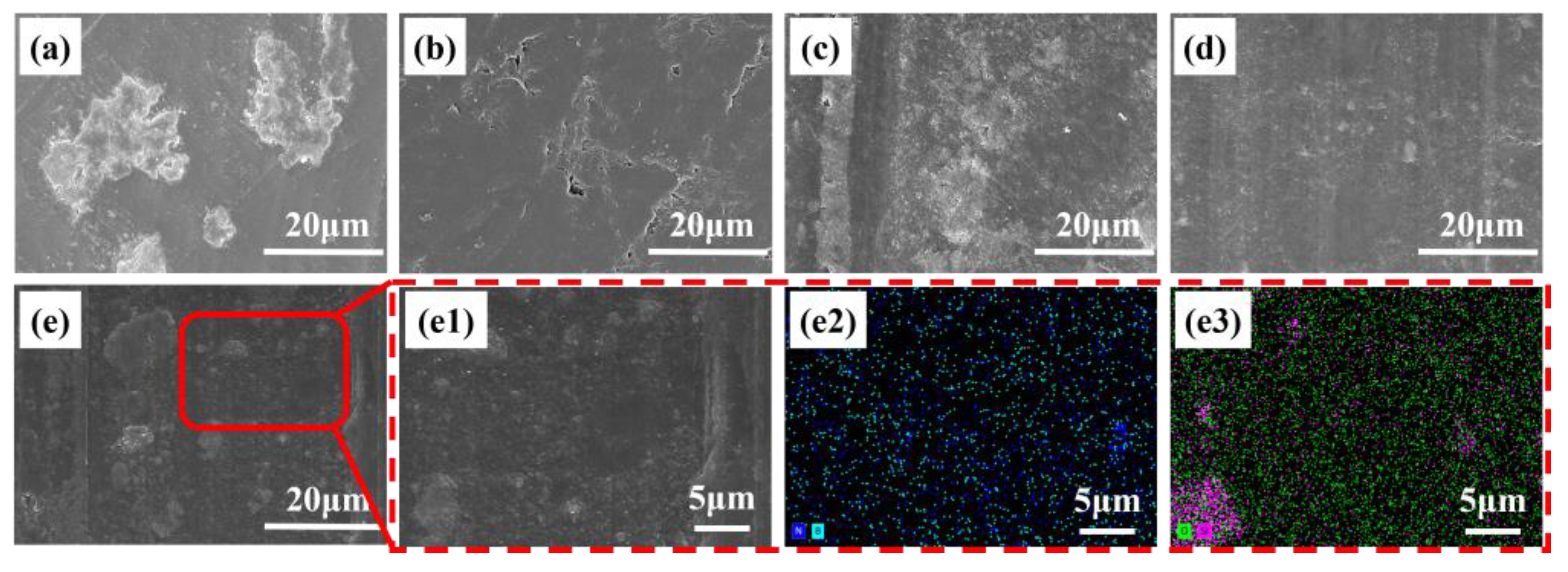

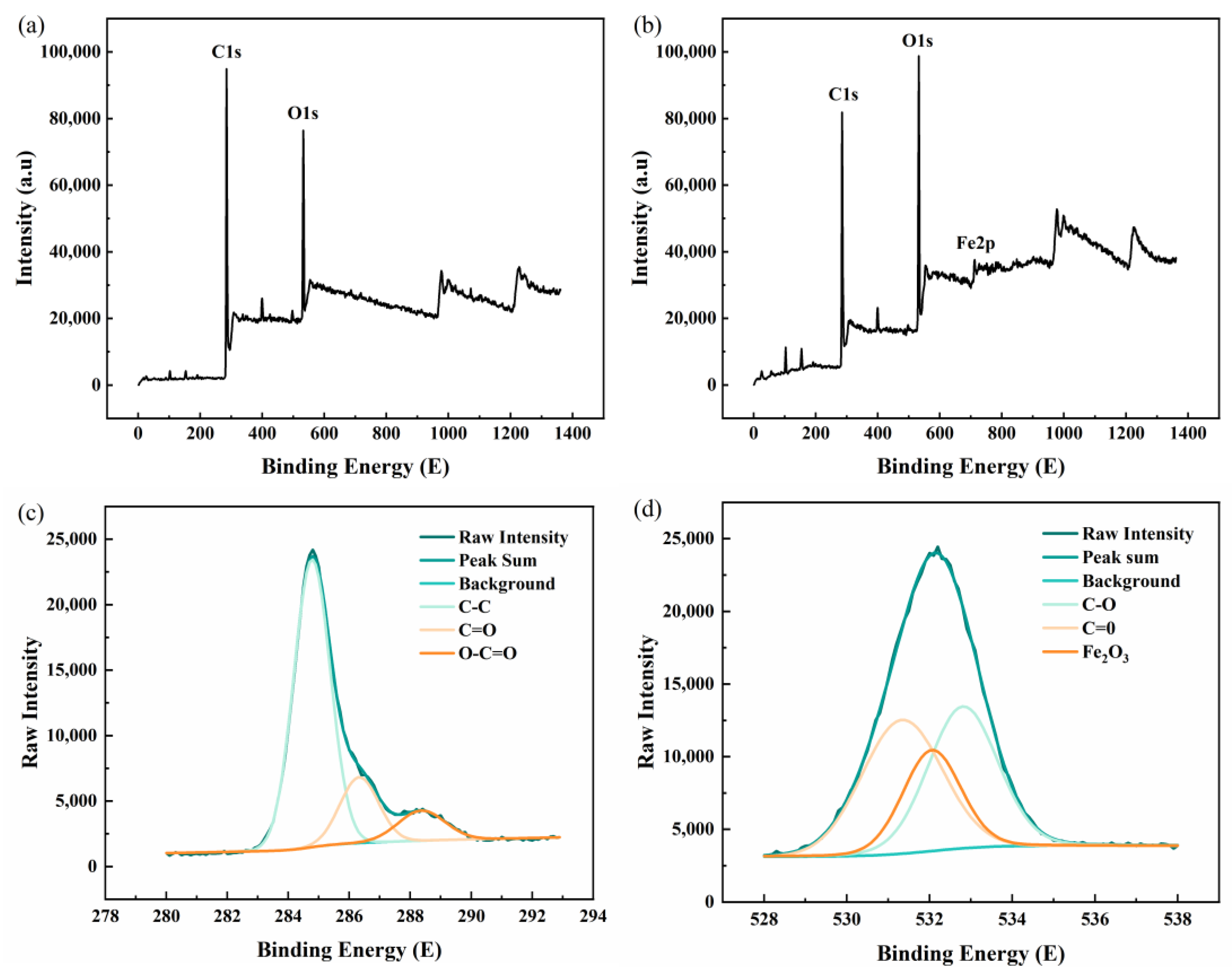

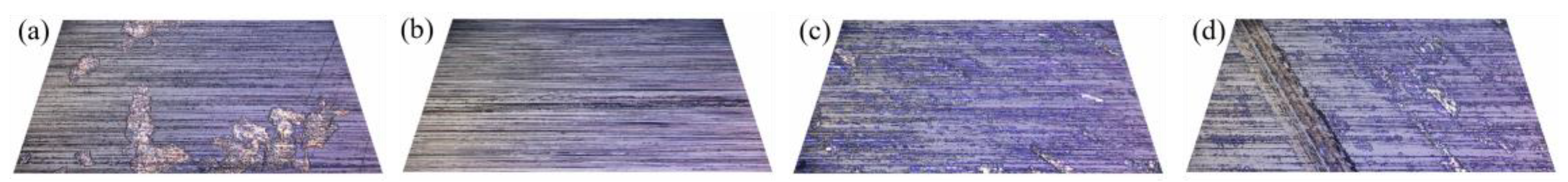

3.3. Microtopography and X-ray Photon Spectrum Analysis

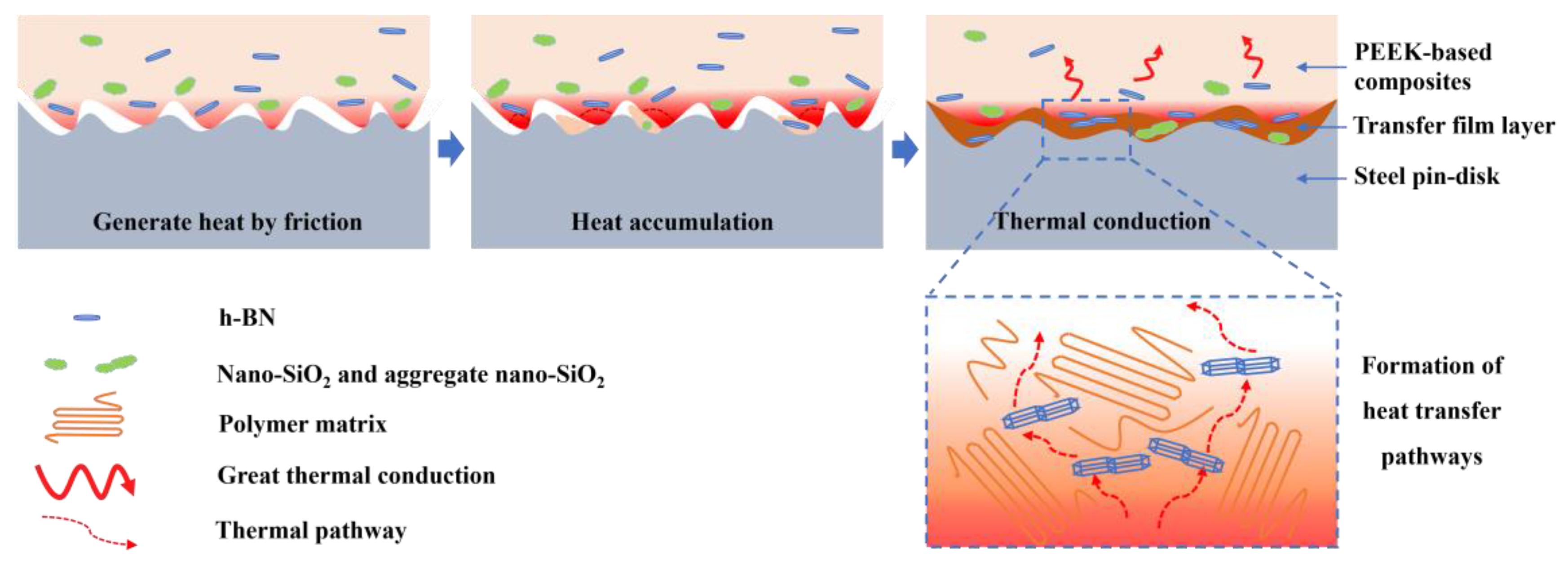

3.4. Role of TFL Formation on Friction and Wear

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Gackowski, B.M.; Phua, H.; Sharma, M.; Idapalapati, S. Hybrid additive manufacturing of polymer composites reinforced with buckypapers and short carbon fibres. Compos. Part Appl. Sci. Manuf. 2022, 154, 106794. [Google Scholar] [CrossRef]

- Sajan, S.; Philip Selvaraj, D. A review on polymer matrix composite materials and their applications. Mater. Today Proc. 2021, 47, 5493–5498. [Google Scholar] [CrossRef]

- Nunez, E.E.; Gheisari, R.; Polycarpou, A.A. Tribology review of blended bulk polymers and their coatings for high-load bearing applications. Tribol. Int. 2019, 129, 92–111. [Google Scholar] [CrossRef]

- Song, J.; Liao, Z.; Shi, H.; Xiang, D.; Liu, Y.; Liu, W.; Peng, Z. Fretting Wear Study of PEEK-Based Composites for Bio-implant Application. Tribol. Lett. 2017, 65, 150. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, X.; Chen, K.; Chen, Q.; Yu, Z.; Feng, C.; Qi, J.; Zhang, D. The antibacterial and wear-resistant nano-ZnO/PEEK composites were constructed by a simple two-step method. J. Mech. Behav. Biomed. Mater. 2022, 126, 104986. [Google Scholar] [CrossRef]

- Zhu, J.; Xie, F.; Dwyer-Joyce, R.S. PEEK Composites as Self-Lubricating Bush Materials for Articulating Revolute Pin Joints. Polymers 2020, 12, 665. [Google Scholar] [CrossRef]

- Hou, X.; Hu, Y.; Hu, X.; Jiang, D. Poly (ether ether ketone) composites reinforced by graphene oxide and silicon dioxide nanoparticles. High Perform. Polym. 2017, 30, 406–417. [Google Scholar] [CrossRef]

- Ghosh, S.; Dunnigan, R.; Gupta, S. Synthesis and tribological behavior of novel wear-resistant PEEK–Ti3SiC2 composites. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 231, 422–428. [Google Scholar] [CrossRef]

- Balaji, V.; Tiwari, A.N.; Goyal, R.K. Fabrication and properties of high performance PEEK/Si3N4 nanocomposites. J. Appl. Polym. Sci. 2011, 119, 311–318. [Google Scholar] [CrossRef]

- Guo, L.; Qi, H.; Zhang, G.; Wang, T.; Wang, Q. Distinct tribological mechanisms of various oxide nanoparticles added in PEEK composite reinforced with carbon fibers. Compos. Part A Appl. Sci. Manuf. 2017, 97, 19–30. [Google Scholar] [CrossRef]

- Zhang, G.; Schlarb, A.K.; Tria, S.; Elkedim, O. Tensile and tribological behaviors of PEEK/nano-SiO2 composites compounded using a ball milling technique. Compos. Sci. Technol. 2008, 68, 3073–3080. [Google Scholar] [CrossRef]

- Molazemhosseini, A.; Tourani, H.; Khavandi, A.; Eftekhari Yekta, B. Tribological performance of PEEK based hybrid composites reinforced with short carbon fibers and nano-silica. Wear 2013, 303, 397–404. [Google Scholar] [CrossRef]

- Zeng, H.; Zhi, C.; Zhang, Z.; Wei, X.; Wang, X.; Guo, W.; Bando, Y.; Golberg, D. “White Graphenes”: Boron Nitride Nanoribbons via Boron Nitride Nanotube Unwrapping. Nano Lett. 2010, 10, 5049–5055. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Xiao, L.; Li, M.; Zhang, X.; Chang, Y.; Shang, L.; Ao, Y. Effect of hexagonal boron nitride on high-performance polyether ether ketone composites. Colloid Polym. Sci. 2015, 294, 127–133. [Google Scholar] [CrossRef]

- Tharajak, J.; Palathai, T.; Sombatsompop, N. Recommendations for h-BN loading and service temperature to achieve low friction coefficient and wear rate for thermal-sprayed PEEK coatings. Surf. Coat. Technol. 2017, 321, 477–483. [Google Scholar] [CrossRef]

- Samyn, P.; Schoukens, G.; De Baets, P. Micro- to nanoscale surface morphology and friction response of tribological polyimide surfaces. Appl. Surf. Sci. 2010, 256, 3394–3408. [Google Scholar] [CrossRef]

- Xu, H.; Chen, W.; Wang, C.; Jia, T.; Wang, D.; Li, G.; Zhao, D.; Cui, B.; Fan, Z.; Fan, X.; et al. Ultralight and flexible silver nanoparticle-wrapped "scorpion pectine-like" polyimide hybrid aerogels as sensitive pressor sensors with wide temperature range and consistent conductivity response. Chem. Eng. J. 2023, 453, 139647. [Google Scholar] [CrossRef]

- He, M.; Tang, J.; Wang, Y.; Li, R.; Huang, L.; Wang, X.; Yu, J. Preparation and properties of PANI/PI composite fabrics with conductive nanofiber network structure. Polymer 2022, 240, 124498. [Google Scholar] [CrossRef]

- Lv, M.; Zheng, F.; Wang, Q.; Wang, T.; Liang, Y. Effect of proton irradiation on the friction and wear properties of polyimide. Wear 2014, 316, 30–36. [Google Scholar] [CrossRef]

- Yan, Y.; Meng, Z.; Xin, X.; Liu, H.; Yan, F. Tribological Behavior and Thermal Stability of Thermoplastic Polyimide/Poly (Ether Ether Ketone) Blends at Elevated Temperature. J. Macromol. Sci. Part B 2020, 60, 175–189. [Google Scholar] [CrossRef]

- Hu, C.; Qi, H.; Yu, J.; Zhang, G.; Zhang, Y.; He, H. Significant improvement on tribological performance of polyimide composites by tuning the tribofilm nanostructures. J. Mater. Process. Technol. 2020, 281, 116602. [Google Scholar] [CrossRef]

- Xie, C.; Wang, K. Synergistic modification of the tribological properties of polytetrafluoroethylene with polyimide and boron nitride. Friction 2020, 9, 1474–1491. [Google Scholar] [CrossRef]

- Wang, Q.; Xue, Q.; Shen, W. The friction and wear properties of nanometre SiO2. Tribol. Int. 1997, 30, 193–197. [Google Scholar] [CrossRef]

- Zhang, G.; Chang, L.; Schlarb, A.K. The roles of nano-SiO2 particles on the tribological behavior of short carbon fiber reinforced PEEK. Compos. Sci. Technol. 2009, 69, 1029–1035. [Google Scholar] [CrossRef]

- Bahadur, S.; Schwartz, C. The effect of nanoparticle fillers on transfer film formation and the tribological behavior of polymers. Frict. Wear Bulk Mater. Coat. 2013, 23–48. [Google Scholar]

- Guo, L.; Pei, X.; Zhao, F.; Zhang, L.; Li, G.; Zhang, G. Tribofilm growth at sliding interfaces of PEEK composites and steel at low velocities. Tribol. Int. 2020, 151, 106456. [Google Scholar] [CrossRef]

- Tanaka, K. Transfer of semicrystalline polymers sliding against a smooth steel surface. Wear 1982, 75, 183–199. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Hashimoto, M. Friction and wear of water lubricated PEEK and PPS sliding contacts. Wear 2004, 257, 181–189. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, C.; Nardin, P.; Li, W.Y.; Liao, H.; Coddet, C. Effects of sliding velocity and applied load on the tribological mechanism of amorphous poly-ether–ether–ketone (PEEK). Tribol. Int. 2008, 41, 79–86. [Google Scholar] [CrossRef]

- Bahadur, S.; Gong, D. The role of copper compounds as fillers in the transfer and wear behavior of polyetheretherketone. Wear 1992, 154, 151–165. [Google Scholar] [CrossRef]

- Kurdi, A.; Kan, W.H.; Chang, L. Tribological behaviour of high performance polymers and polymer composites at elevated temperature. Tribol. Int. 2019, 130, 94–105. [Google Scholar] [CrossRef]

- Wang, T.; Wang, M.; Fu, L.; Duan, Z.; Chen, Y.; Hou, X.; Wu, Y.; Li, S.; Guo, L.; Kang, R.; et al. Enhanced Thermal Conductivity of Polyimide Composites with Boron Nitride Nanosheets. Sci. Rep. 2018, 8, 1557. [Google Scholar] [CrossRef] [PubMed]

| Sample No. | PEEK (wt.%) | PI (wt.%) | h-BN (wt.%) | SiO2 (wt.%) |

|---|---|---|---|---|

| PEEK | 100 | - | - | - |

| +20P | 80 | 20 | - | - |

| +20P/2B/2Si | 76 | 20 | 2 | 2 |

| +20P/4B/2Si | 74 | 20 | 4 | 2 |

| +20P/4B/4Si | 72 | 20 | 4 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Yang, J.; Ma, S.; Liu, G.; Yang, H.; Yao, J. Effect of h-BN and Nano-SiO2 Fillers on the High-Temperature Tribological Properties of PEEK/PI-Based Composites. Lubricants 2023, 11, 416. https://doi.org/10.3390/lubricants11100416

Li M, Yang J, Ma S, Liu G, Yang H, Yao J. Effect of h-BN and Nano-SiO2 Fillers on the High-Temperature Tribological Properties of PEEK/PI-Based Composites. Lubricants. 2023; 11(10):416. https://doi.org/10.3390/lubricants11100416

Chicago/Turabian StyleLi, Mengjiao, Jingjing Yang, Shengqi Ma, Gang Liu, Hongru Yang, and Jianan Yao. 2023. "Effect of h-BN and Nano-SiO2 Fillers on the High-Temperature Tribological Properties of PEEK/PI-Based Composites" Lubricants 11, no. 10: 416. https://doi.org/10.3390/lubricants11100416

APA StyleLi, M., Yang, J., Ma, S., Liu, G., Yang, H., & Yao, J. (2023). Effect of h-BN and Nano-SiO2 Fillers on the High-Temperature Tribological Properties of PEEK/PI-Based Composites. Lubricants, 11(10), 416. https://doi.org/10.3390/lubricants11100416