New Optimized Lubricating Blend of Peanut Oil and Naphthenic Oil Additivated with Graphene Nanoparticles and MoS2: Stability Time and Thermal Conductivity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Hybrid Graphene–MoS2 Nanoparticles

2.3. Sample Preparation

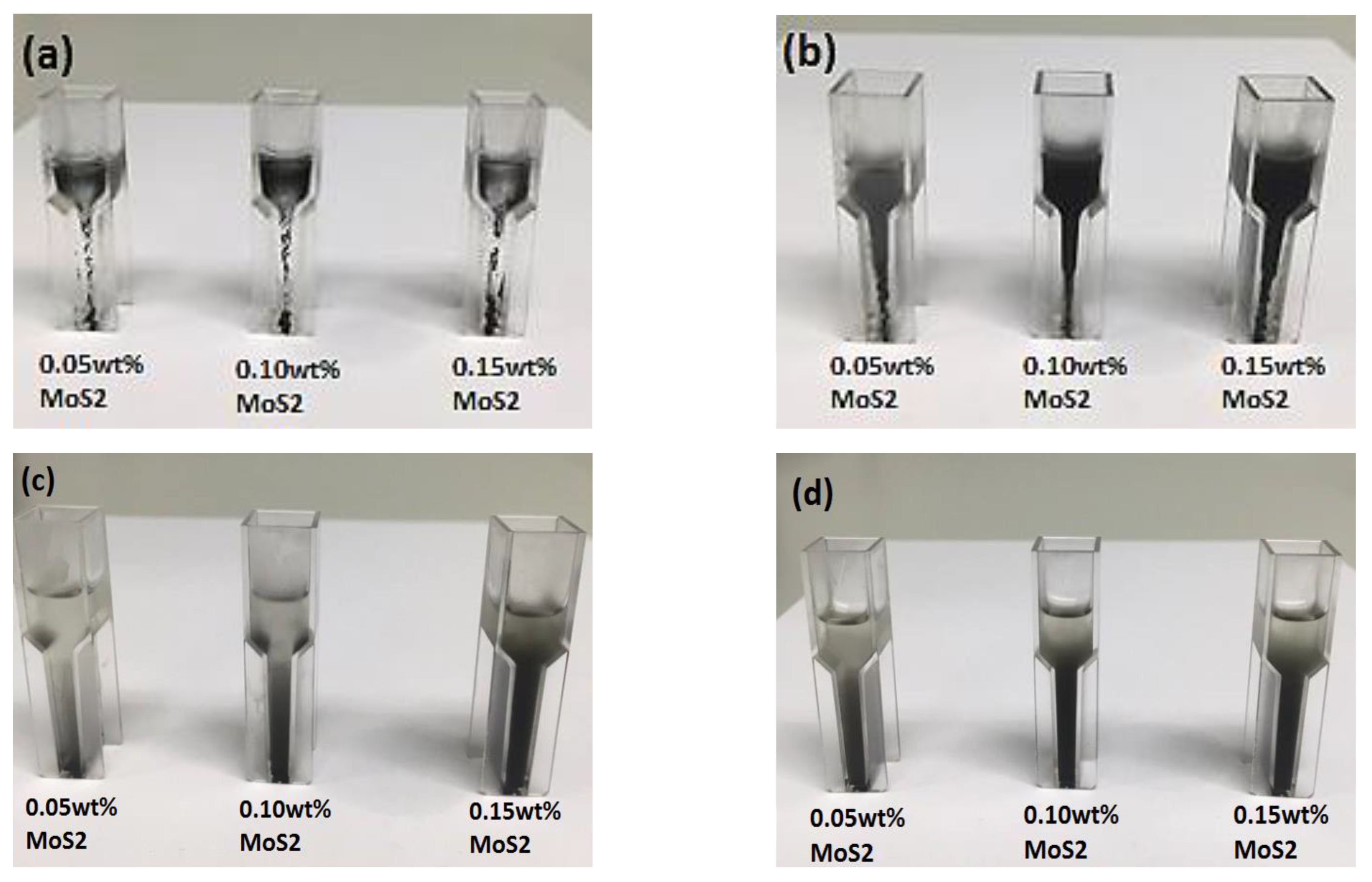

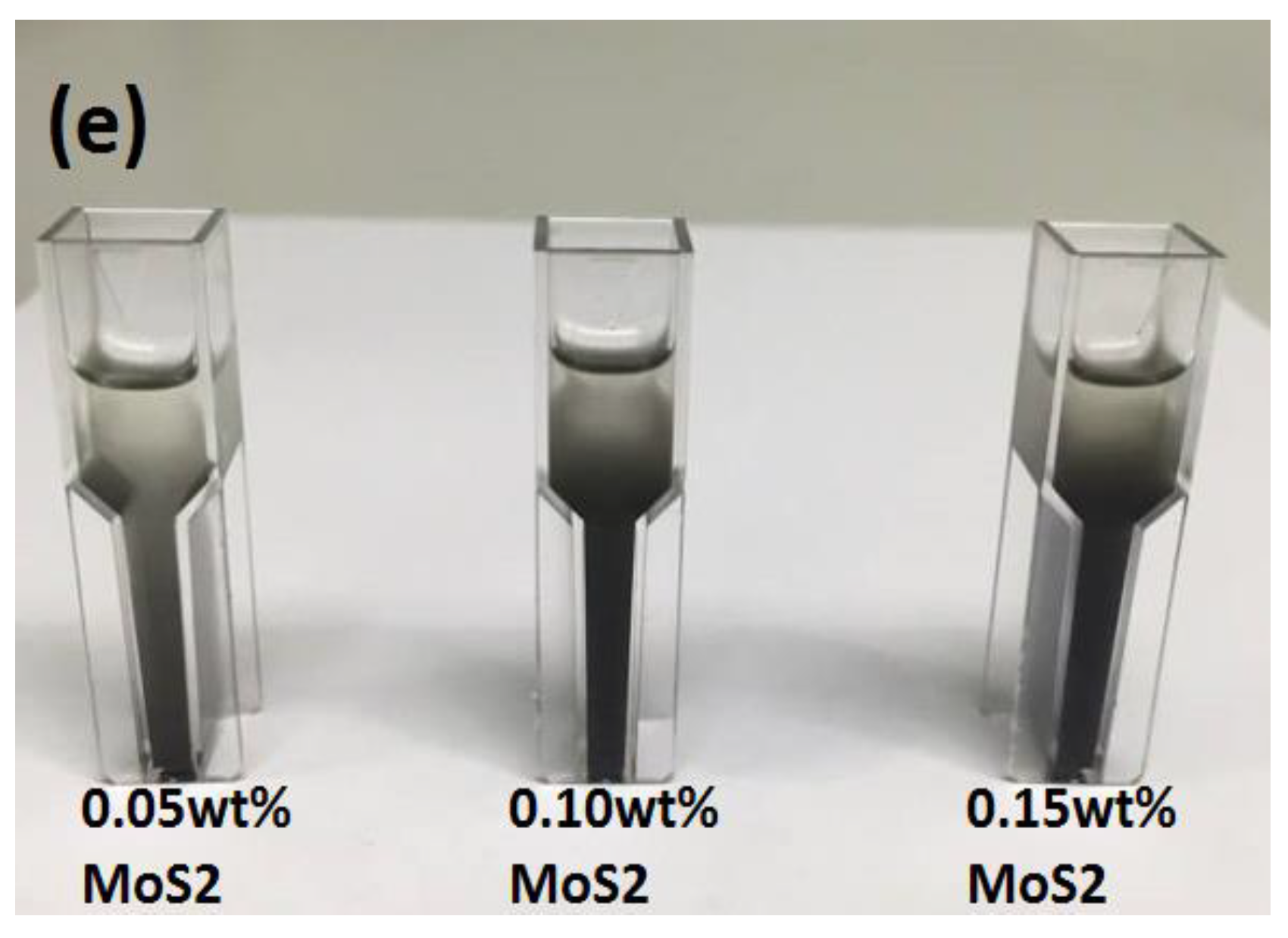

2.4. Stability Studies of Graphene–MoS2-Based Hybrid Nanolubricant

2.5. Thermophysical Property Analysis

2.6. Using Artificial Neural Network Models for Parametric Investigation

3. Results and Discussions

3.1. Stability Analysis of Nanofluids

Effect of MoS2

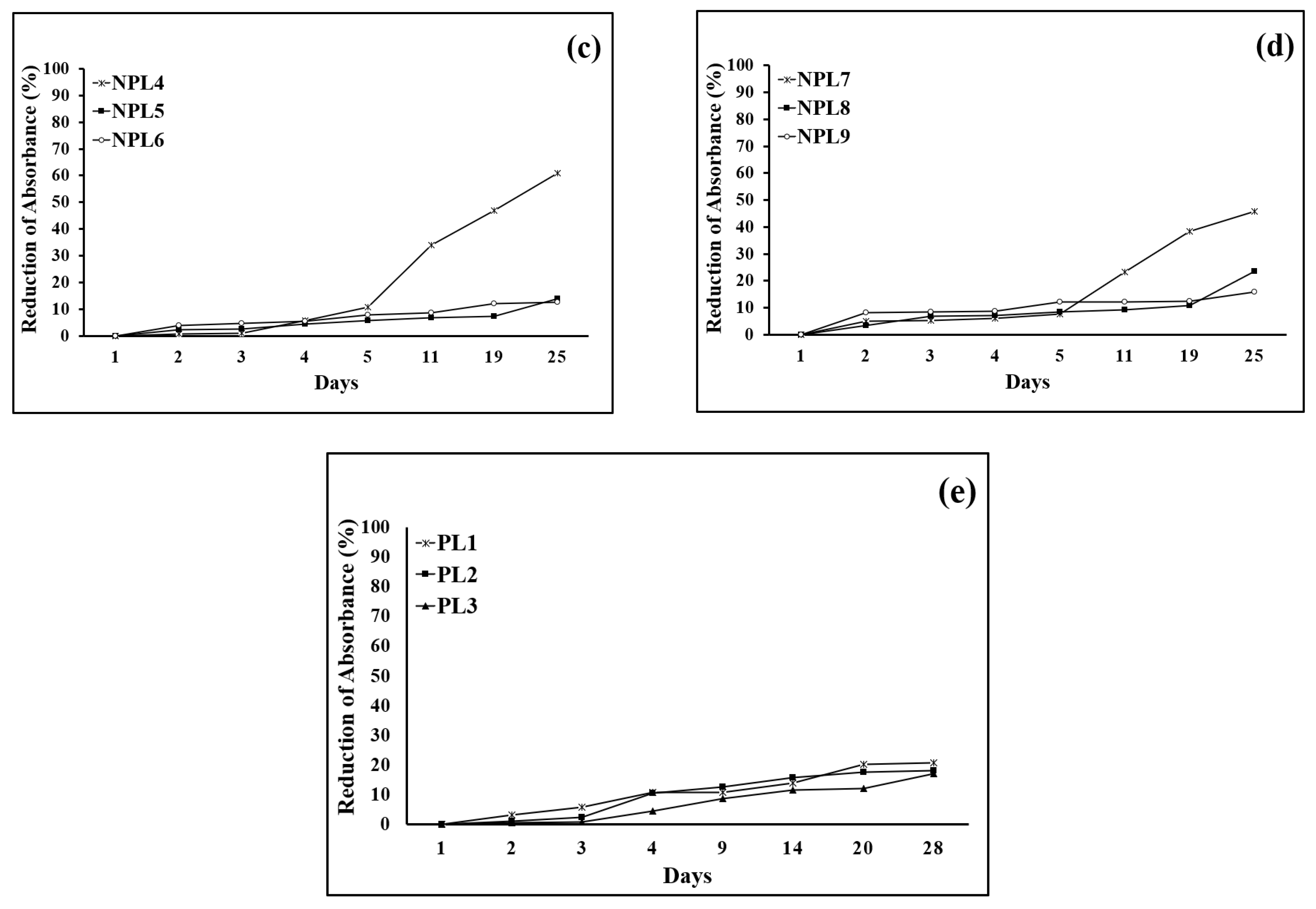

3.2. Thermophysical Property Analysis of Nanofluids

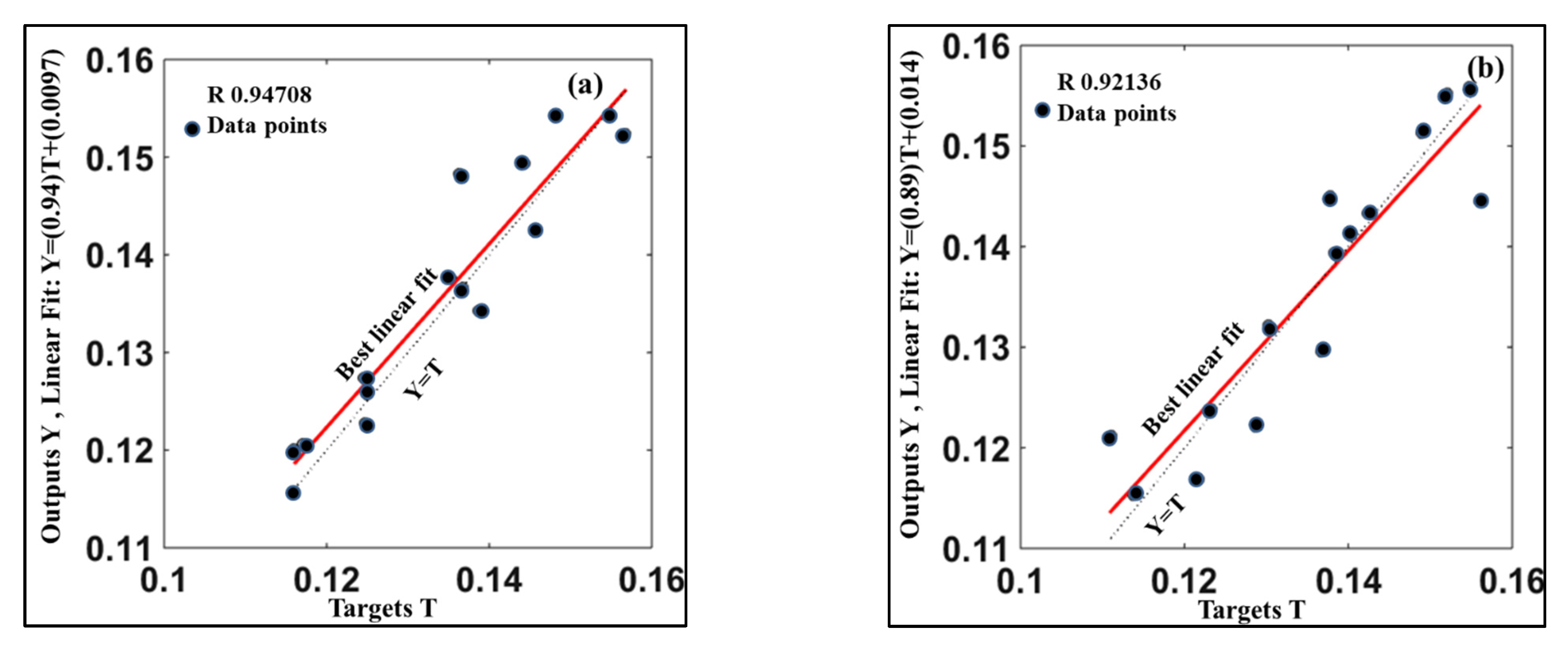

4. Understanding the Influencing Parameters from Experimental Data Using Artificial Neural Network

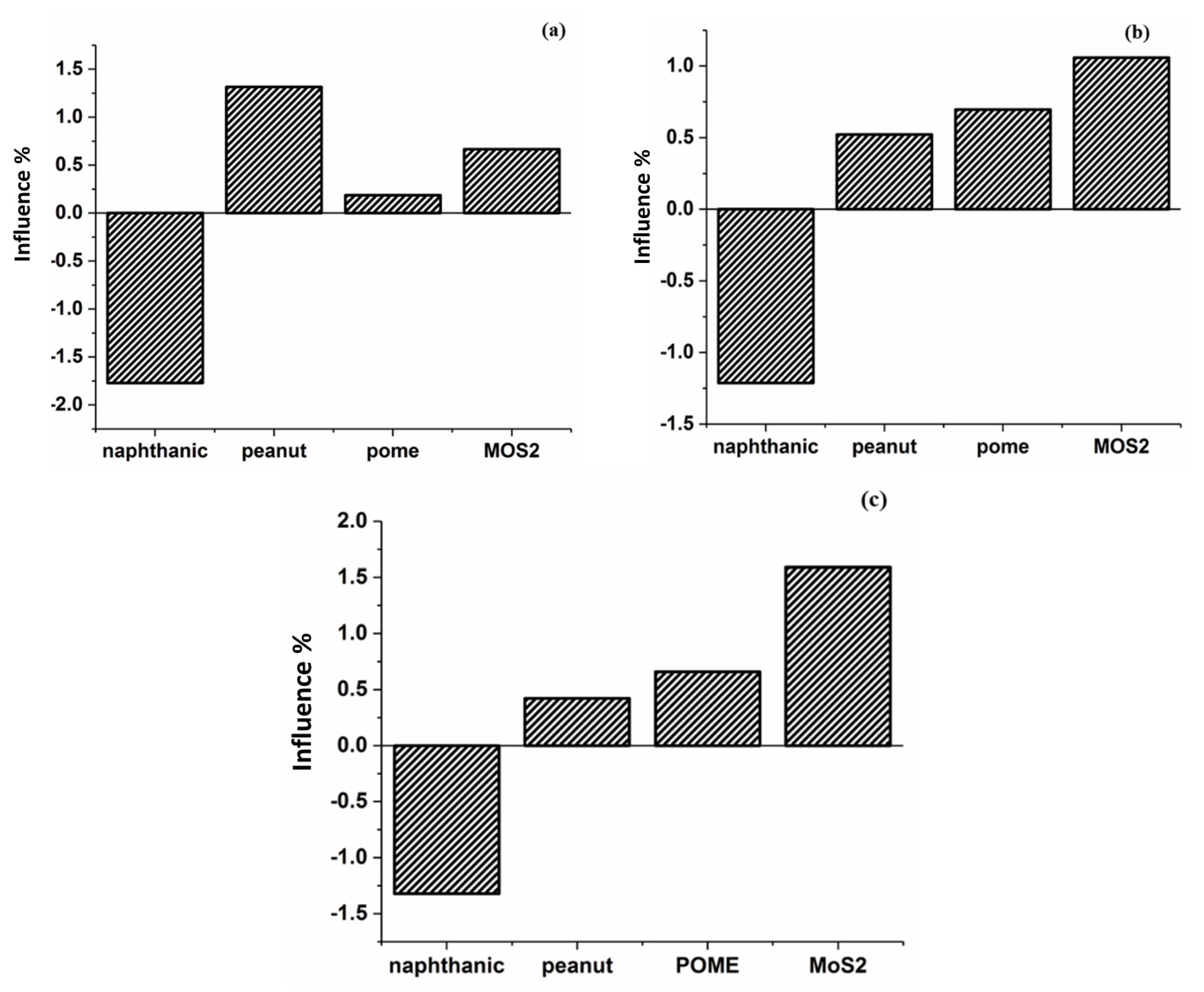

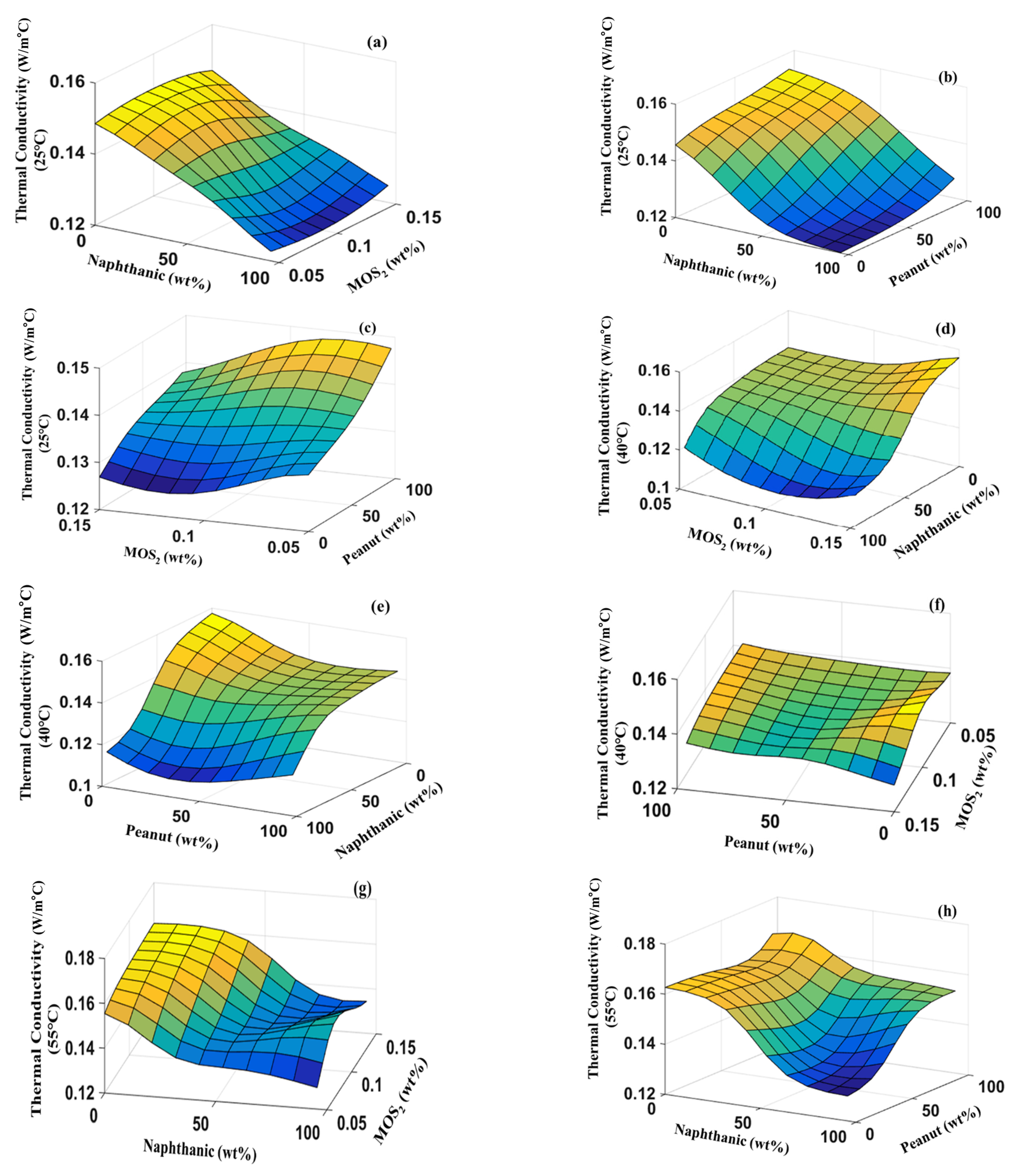

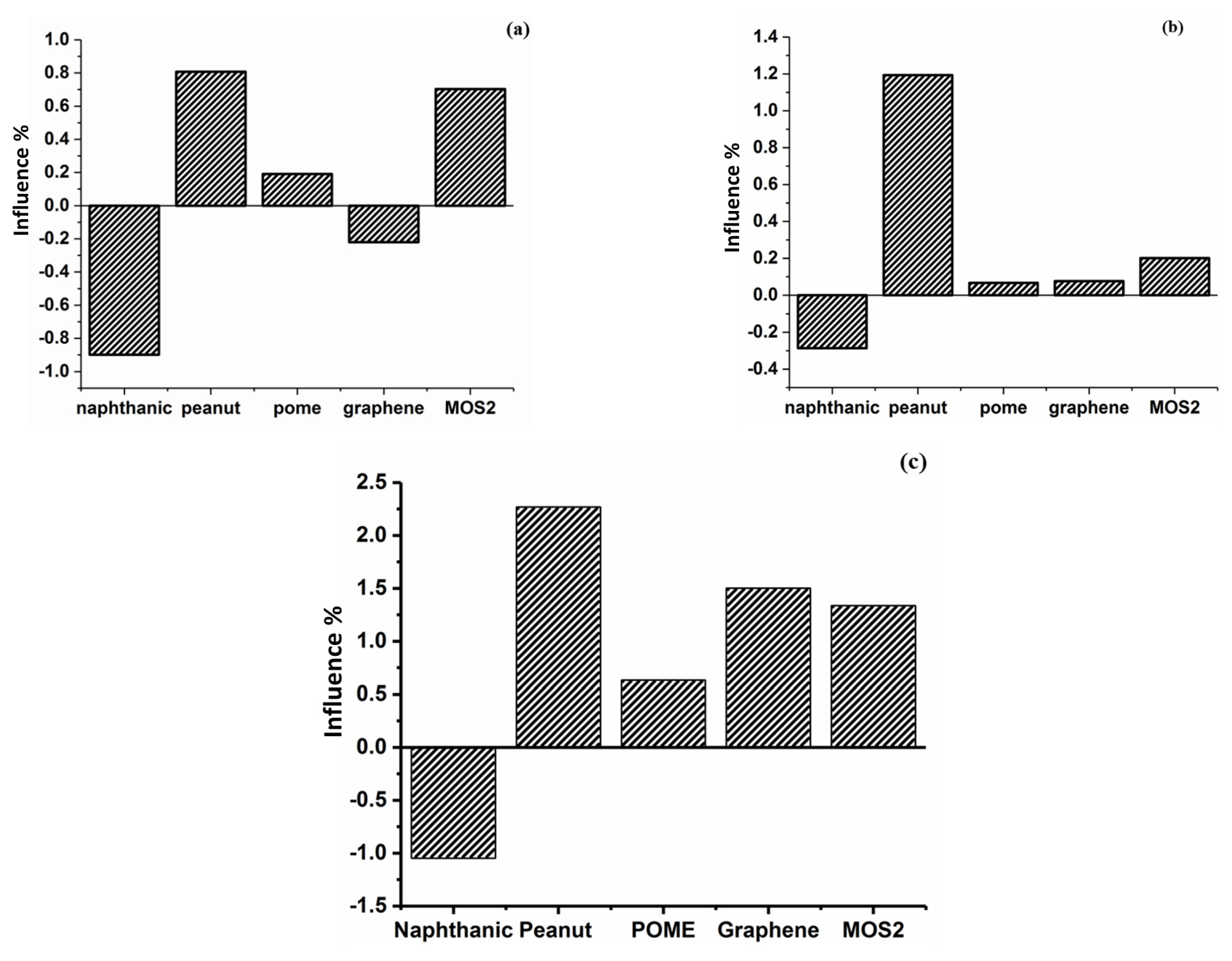

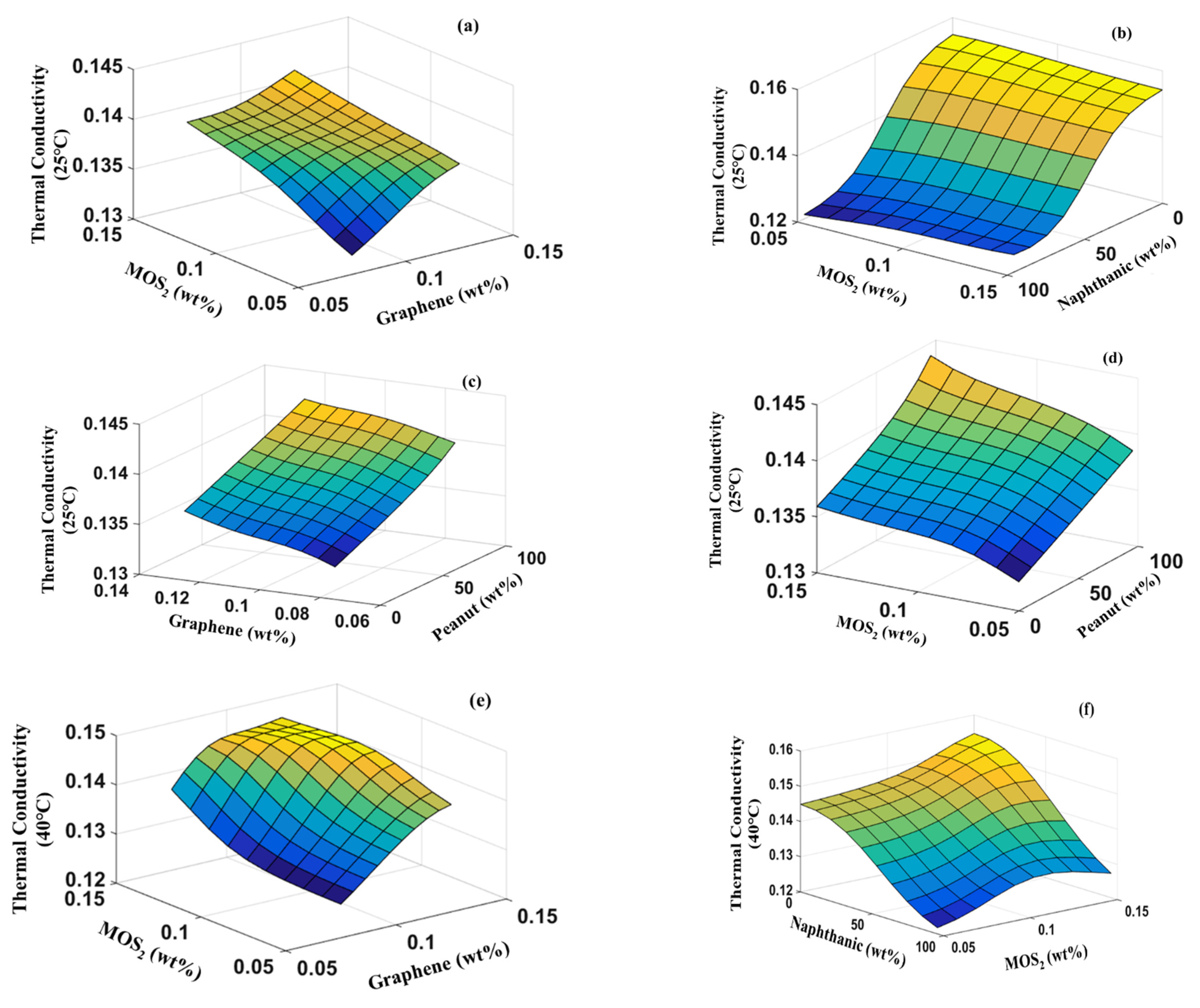

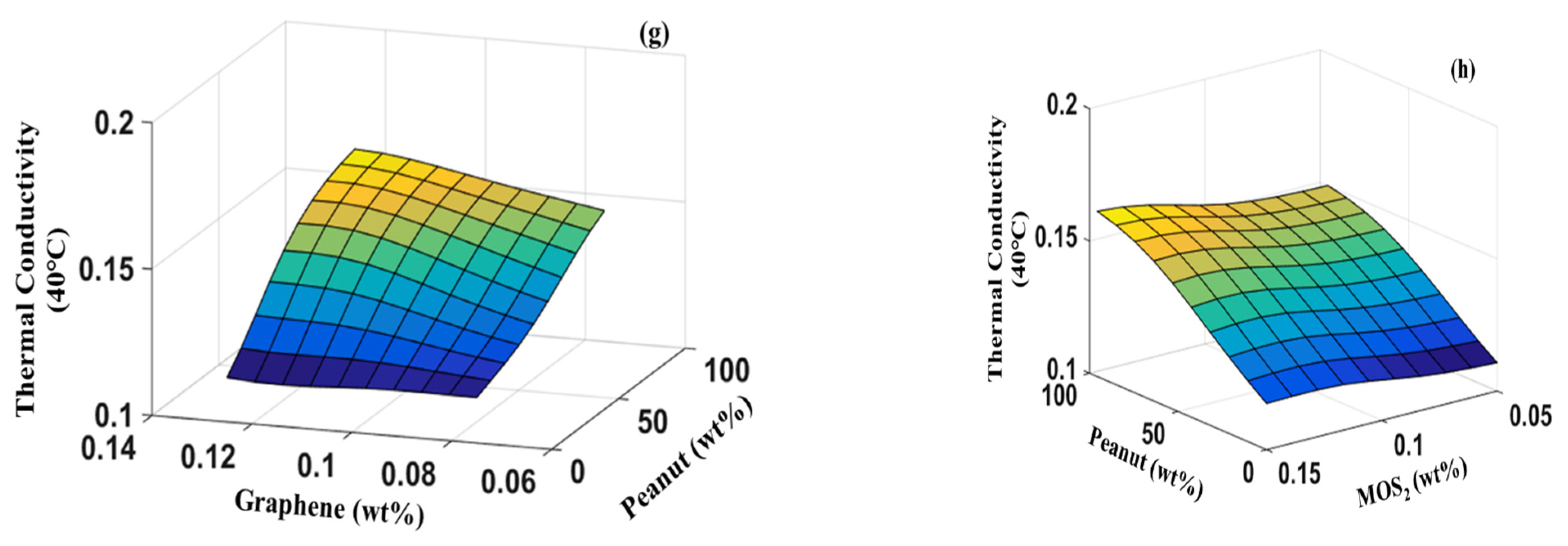

5. Sensitivity Analysis and Surface Plots

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nazma Sultana, M.; Ranjan Dhar, N.; Binte Zaman, P. A Review on Different Cooling/Lubrication Techniques in Metal Cutting. Am. J. Mech. Appl. 2019, 7, 71. [Google Scholar] [CrossRef]

- Thampi, A.D.; Prasanth, M.A.; Anandu, A.P.; Sneha, E.; Sasidharan, B.; Rani, S. The Effect of Nanoparticle Additives on the Tribological Properties of Various Lubricating Oils—Review. Mater. Today Proc. 2021, 47, 4919–4924. [Google Scholar] [CrossRef]

- Rawat, S.S.; Harsha, A.P. Recent Progress in Vegetable Oil-Based Lubricants for Tribological Applications. In Tribology and Sustainability; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-1-00-309216-2. [Google Scholar]

- Sankaranarayanan, R.; Rajesh Jesudoss Hynes, N.; Senthil Kumar, J.; Krolczyk, G.M. A Comprehensive Review on Research Developments of Vegetable-Oil Based Cutting Fluids for Sustainable Machining Challenges. J. Manuf. Process. 2021, 67, 286–313. [Google Scholar] [CrossRef]

- Huang, X.; Zhi, C.; Lin, Y.; Bao, H.; Wu, G.; Jiang, P.; Mai, Y.-W. Thermal Conductivity of Graphene-Based Polymer Nanocomposites. Mater. Sci. Eng. R Rep. 2020, 142, 100577. [Google Scholar] [CrossRef]

- Fang, H.; Bai, S.-L.; Wong, C.P. Microstructure Engineering of Graphene towards Highly Thermal Conductive Composites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 216–238. [Google Scholar] [CrossRef]

- Zeng, W.; Tao, X.-M.; Lin, S.; Lee, C.; Shi, D.; Lam, K.; Huang, B.; Wang, Q.; Zhao, Y. Defect-Engineered Reduced Graphene Oxide Sheets with High Electric Conductivity and Controlled Thermal Conductivity for Soft and Flexible Wearable Thermoelectric Generators. Nano Energy 2018, 54, 163–174. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Liu, Y.; Yang, L.; Chen, L. 2D Nano-Materials beyond Graphene: From Synthesis to Tribological Studies. Appl. Nanosci. 2020, 10, 3353–3388. [Google Scholar] [CrossRef]

- Sun, J.; Du, S. Application of Graphene Derivatives and Their Nanocomposites in Tribology and Lubrication: A Review. RSC Adv. 2019, 9, 40642–40661. [Google Scholar] [CrossRef]

- Arenas, M.A.; Ahuir-Torres, J.I.; García, I.; Carvajal, H.; de Damborenea, J. Tribological Behaviour of Laser Textured Ti6Al4V Alloy Coated with MoS2 and Graphene. Tribol. Int. 2018, 128, 240–247. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Joseph, A.; Gautham, V.; Akshay, K.S.; Sajith, V. 2D MoS2-HBN Hybrid Coatings for Enhanced Corrosion Resistance of Solid Lubricant Coatings. Surf. Coat. Technol. 2022, 443, 128612. [Google Scholar] [CrossRef]

- Thachnatharen, N.; Khalid, M.; Shahabuddin, S.; Anwar, A.; Sridewi, N. Tribological Analysis of Advanced Microwave Synthesized Molybdenum Disulfide (MoS2) as Anti-Friction Additives in Diesel Engine Oil for Military Vehicles. Mater. Today Proc. 2022, 62, 7243–7247. [Google Scholar] [CrossRef]

- Nagarajan, T.; Khalid, M.; Srid, N.; Jagadish, P.; Shahabuddin, S.; Muthoosamy, K.; Walvekar, R. Tribological, Oxidation and Thermal Conductivity Studies of Microwave Synthesised Molybdenum Disulfide (MoS 2) Nanoparticles as Nano-Additives in Diesel Based Engine Oil. Sci. Rep. 2022, 12, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Nagarajan, T.; Khalid, M.; Srid, N.; Jagadish, P.; Walvekar, R. Microwave Synthesis of Molybdenum Disulfide Nanoparticles Using Response Surface Methodology for Tribological Application. Nanomaterials 2022, 12, 3369. [Google Scholar] [CrossRef] [PubMed]

- Upadhyay, R.K.; Kumar, A. Epoxy-Graphene-MoS2 Composites with Improved Tribological Behavior under Dry Sliding Contact. Tribol. Int. 2019, 130, 106–118. [Google Scholar] [CrossRef]

- Ahmad, K.; Shinde, M.A.; Kim, H. Molybdenum Disulfide/Reduced Graphene Oxide: Progress in Synthesis and Electro-Catalytic Properties for Electrochemical Sensing and Dye Sensitized Solar Cells. Microchem. J. 2021, 169, 106583. [Google Scholar] [CrossRef]

- Su, W.; Wang, P.; Cai, Z.; Yang, J.; Wang, X. One-Pot Hydrothermal Synthesis of Al-Doped MoS2@graphene Aerogel Nanocomposite Electrocatalysts for Enhanced Hydrogen Evolution Reaction. Results Phys. 2019, 12, 250–258. [Google Scholar] [CrossRef]

- Lv, Y.; Pan, H.; Lin, J.; Chen, Z.; Li, Y.; Li, H.; Shi, M.; Yin, R.; Zhu, S. One-Pot Hydrothermal Approach towards 2D/2D Heterostructure Based on 1 T MoS2 Chemically Bonding with GO for Extremely High Electrocatalytic Performance. Chem. Eng. J. 2022, 428, 132072. [Google Scholar] [CrossRef]

- Rashmi, W.; Osama, M.; Khalid, M.; Rasheed, A.; Bhaumik, S.; Wong, W.Y.; Datta, S.; Tcsm, G. Tribological Performance of Nanographite-Based Metalworking Fluid and Parametric Investigation Using Artificial Neural Network. Int. J. Adv. Manuf. Technol. 2019, 104, 359–374. [Google Scholar] [CrossRef]

- Senapati, S.K.; Mishra, B.P.; Biswal, S.K. A Study on Tribological Properties of Mixture of Fatty Acid Methyl Ester (FAME) Derived from Various Vegetable Oils. Indian J. Tribol. 2019, 7, 23–26. [Google Scholar]

- Prakash, P.; Seethraman, M.; Kumar, L.S.; Jayaprakash, S.; Bakrutheen, M. Performance Characteristics of Mineral Oil Blended with Vegetable Oil. In Proceedings of Fifth International Conference on Inventive Material Science Applications; Advances in Sustainability Science and Technology; Bindhu, V., Tavares, J.M.R.S., Chen, J.I.-Z., Eds.; Springer Nature Singapore: Singapore, 2023; pp. 17–25. ISBN 978-981-19430-3-4. [Google Scholar]

- Virdi, R.L.; Chatha, S.S.; Singh, H. Machining Performance of Inconel-718 Alloy under the Influence of Nanoparticles Based Minimum Quantity Lubrication Grinding. J. Manuf. Process. 2020, 59, 355–365. [Google Scholar] [CrossRef]

- Hamidian, P.; Alidoust, P.; Golafshani, E.M.; Niavol, K.P.; Behnood, A. Introduction of a Novel Evolutionary Neural Network for Evaluating the Compressive Strength of Concretes: A Case of Rice Husk Ash Concrete. J. Build. Eng. 2022, 61, 105293. [Google Scholar] [CrossRef]

- Onukwuli, O.D.; Nnaji, P.C.; Menkiti, M.C.; Anadebe, V.C.; Oke, E.O.; Ude, C.N.; Ude, C.J.; Okafor, N.A. Dual-Purpose Optimization of Dye-Polluted Wastewater Decontamination Using Bio-Coagulants from Multiple Processing Techniques via Neural Intelligence Algorithm and Response Surface Methodology. J. Taiwan Inst. Chem. Eng. 2021, 125, 372–386. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of Nanoparticles in Lubricating Oil: A Critical Review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Wu, P.; Chen, X.; Zhang, C.; Zhang, J.; Luo, J.; Zhang, J. Modified Graphene as Novel Lubricating Additive with High Dispersion Stability in Oil. Friction 2021, 9, 143–154. [Google Scholar] [CrossRef]

- Wu, H.; Al-Rashed, A.A.A.A.; Barzinjy, A.A.; Shahsavar, A.; Karimi, A.; Talebizadehsardari, P. Curve-Fitting on Experimental Thermal Conductivity of Motor Oil under Influence of Hybrid Nano Additives Containing Multi-Walled Carbon Nanotubes and Zinc Oxide. Phys. A Stat. Mech. Its Appl. 2019, 535, 122128. [Google Scholar] [CrossRef]

- Olden, J.D.; Joy, M.K.; Death, R.G. An accurate comparison of methods for quantifying variable importance in artificial neural networks using simulated data. Ecol. Model. 2004, 178, 389–397. [Google Scholar] [CrossRef]

- Bhaumik, S.; Paleu, V.; Chowdhury, D.; Batham, A.; Sehgal, U.; Bhattacharya, B.; Ghosh, C.; Datta, S. Tribological Investigation of Textured Surfaces in Starved Lubrication Conditions. Materials 2022, 15, 8445. [Google Scholar] [CrossRef]

| Weight Percentage, % | |||

|---|---|---|---|

| Base Fluids | Naphthalene Oil | Peanut Oil | Ratio |

| NL | 100 | 0 | 1:0 |

| NPL1 | 75 | 25 | 3:1 |

| NPL2 | 50 | 50 | 1:1 |

| NPL3 | 25 | 75 | 1:3 |

| PL | 0 | 100 | 0:1 |

| Weight (%) | ||||

|---|---|---|---|---|

| Samples | Naphthenic Oil | Peanut Oil | POME | MoS2 |

| NL1 | 95.66 | 0 | 4.34 | 0.05 |

| NL2 | 95.66 | 0 | 4.34 | 0.10 |

| NL3 | 95.66 | 0 | 4.34 | 0.15 |

| NPL1 | 71.75 | 23.92 | 4.34 | 0.05 |

| NPL2 | 71.75 | 23.92 | 4.34 | 0.10 |

| NPL3 | 71.75 | 23.92 | 4.34 | 0.15 |

| NPL4 | 47.83 | 47.83 | 4.34 | 0.05 |

| NPL5 | 47.83 | 47.83 | 4.34 | 0.10 |

| NPL6 | 47.83 | 47.83 | 4.34 | 0.15 |

| NPL7 | 23.92 | 71.75 | 4.34 | 0.05 |

| NPL8 | 23.92 | 71.75 | 4.34 | 0.10 |

| NPL9 | 23.92 | 71.75 | 4.34 | 0.15 |

| PL1 | 0 | 95.66 | 4.34 | 0.05 |

| PL2 | 0 | 95.66 | 4.34 | 0.10 |

| PL3 | 0 | 95.66 | 4.34 | 0.15 |

| Weight (%) | |||||

|---|---|---|---|---|---|

| Samples | Naphthenic Oil | Peanut Oil | POME | MoS2 | Graphene |

| NGL1 | 95.66 | 0 | 4.34 | 0.05 | 0.075 |

| NGL2 | 95.66 | 0 | 4.34 | 0.10 | 0.075 |

| NGL3 | 95.66 | 0 | 4.34 | 0.15 | 0.075 |

| NGL4 | 95.66 | 0 | 4.34 | 0.05 | 0.010 |

| NGL5 | 95.66 | 0 | 4.34 | 0.10 | 0.010 |

| NGL6 | 95.66 | 0 | 4.34 | 0.15 | 0.010 |

| NGL7 | 95.66 | 0 | 4.34 | 0.05 | 0.015 |

| NGL8 | 95.66 | 0 | 4.34 | 0.10 | 0.015 |

| NGL9 | 95.66 | 0 | 4.34 | 0.15 | 0.015 |

| NPGL1 | 71.75 | 23.92 | 4.34 | 0.05 | 0.075 |

| NPGL2 | 71.75 | 23.92 | 4.34 | 0.10 | 0.075 |

| NPGL3 | 71.75 | 23.92 | 4.34 | 0.15 | 0.075 |

| NPGL4 | 71.75 | 23.92 | 4.34 | 0.05 | 0.010 |

| NPGL5 | 71.75 | 23.92 | 4.34 | 0.10 | 0.010 |

| NPGL6 | 71.75 | 23.92 | 4.34 | 0.15 | 0.010 |

| NPGL7 | 71.75 | 23.92 | 4.34 | 0.05 | 0.015 |

| NPGL8 | 71.75 | 23.92 | 4.34 | 0.10 | 0.015 |

| NPGL9 | 71.75 | 23.92 | 4.34 | 0.15 | 0.015 |

| NPGL10 | 47.83 | 47.83 | 4.34 | 0.05 | 0.075 |

| NPGL11 | 47.83 | 47.83 | 4.34 | 0.10 | 0.075 |

| NPGL12 | 47.83 | 47.83 | 4.34 | 0.15 | 0.075 |

| NPGL13 | 47.83 | 47.83 | 4.34 | 0.05 | 0.010 |

| NPGL14 | 47.83 | 47.83 | 4.34 | 0.10 | 0.010 |

| NPGL15 | 47.83 | 47.83 | 4.34 | 0.15 | 0.010 |

| NPGL16 | 47.83 | 47.83 | 4.34 | 0.05 | 0.015 |

| NPGL17 | 47.83 | 47.83 | 4.34 | 0.10 | 0.015 |

| NPGL18 | 47.83 | 47.83 | 4.34 | 0.15 | 0.015 |

| NPGL19 | 23.92 | 71.75 | 4.34 | 0.05 | 0.075 |

| NPGL20 | 23.92 | 71.75 | 4.34 | 0.10 | 0.075 |

| NPGL21 | 23.92 | 71.75 | 4.34 | 0.15 | 0.075 |

| NPGL22 | 23.92 | 71.75 | 4.34 | 0.05 | 0.010 |

| NPGL23 | 23.92 | 71.75 | 4.34 | 0.10 | 0.010 |

| NPGL24 | 23.92 | 71.75 | 4.34 | 0.15 | 0.010 |

| NPGL25 | 23.92 | 71.75 | 4.34 | 0.05 | 0.015 |

| NPGL26 | 23.92 | 71.75 | 4.34 | 0.10 | 0.015 |

| NPGL27 | 23.92 | 71.75 | 4.34 | 0.15 | 0.015 |

| PGL1 | 0 | 95.66 | 4.34 | 0.05 | 0.075 |

| PGL2 | 0 | 95.66 | 4.34 | 0.10 | 0.075 |

| PGL3 | 0 | 95.66 | 4.34 | 0.15 | 0.075 |

| PGL4 | 0 | 95.66 | 4.34 | 0.05 | 0.010 |

| PGL5 | 0 | 95.66 | 4.34 | 0.10 | 0.010 |

| PGL6 | 0 | 95.66 | 4.34 | 0.15 | 0.010 |

| PGL7 | 0 | 95.66 | 4.34 | 0.05 | 0.015 |

| PGL8 | 0 | 95.66 | 4.34 | 0.10 | 0.015 |

| PGL9 | 0 | 95.66 | 4.34 | 0.15 | 0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walvekar, R.; Bhaumik, S.; Nagarajan, T.; Khalid, M.; Rasheed, A.K.; Gupta, T.C.S.M.; Paleu, V. New Optimized Lubricating Blend of Peanut Oil and Naphthenic Oil Additivated with Graphene Nanoparticles and MoS2: Stability Time and Thermal Conductivity. Lubricants 2023, 11, 71. https://doi.org/10.3390/lubricants11020071

Walvekar R, Bhaumik S, Nagarajan T, Khalid M, Rasheed AK, Gupta TCSM, Paleu V. New Optimized Lubricating Blend of Peanut Oil and Naphthenic Oil Additivated with Graphene Nanoparticles and MoS2: Stability Time and Thermal Conductivity. Lubricants. 2023; 11(2):71. https://doi.org/10.3390/lubricants11020071

Chicago/Turabian StyleWalvekar, Rashmi, Shubrajit Bhaumik, Thachnatharen Nagarajan, Mohammad Khalid, Abdul Khaliq Rasheed, Thummalapalli Chandra Sekhara Manikyam Gupta, and Viorel Paleu. 2023. "New Optimized Lubricating Blend of Peanut Oil and Naphthenic Oil Additivated with Graphene Nanoparticles and MoS2: Stability Time and Thermal Conductivity" Lubricants 11, no. 2: 71. https://doi.org/10.3390/lubricants11020071

APA StyleWalvekar, R., Bhaumik, S., Nagarajan, T., Khalid, M., Rasheed, A. K., Gupta, T. C. S. M., & Paleu, V. (2023). New Optimized Lubricating Blend of Peanut Oil and Naphthenic Oil Additivated with Graphene Nanoparticles and MoS2: Stability Time and Thermal Conductivity. Lubricants, 11(2), 71. https://doi.org/10.3390/lubricants11020071