Tribological Properties of CNTs-Reinforced Nano Composite Materials

Abstract

:1. Introduction

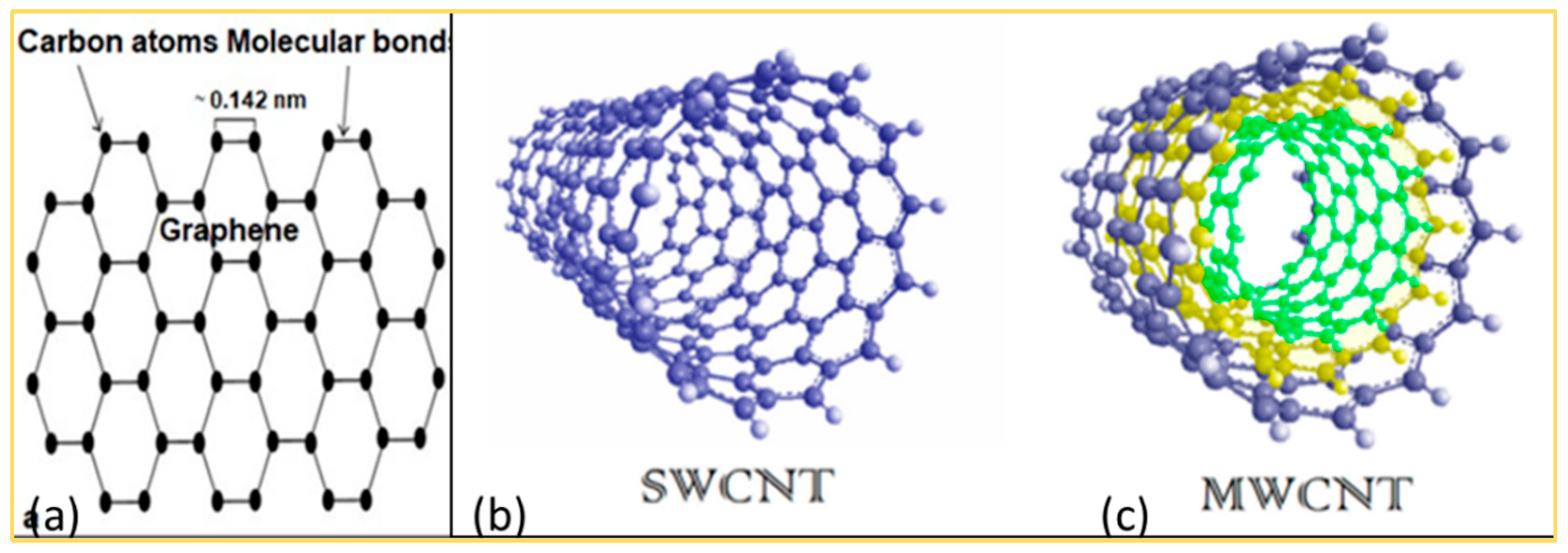

2. CNTs-Based Nano Materials

Wear and Friction Properties of Composites Developed with CNTs Reinforcement

3. Effects of Prevailing Conditions on Tribology of CNTs-Reinforced Composites

3.1. Response of CNTs-Reinforced Composites to Applied Load

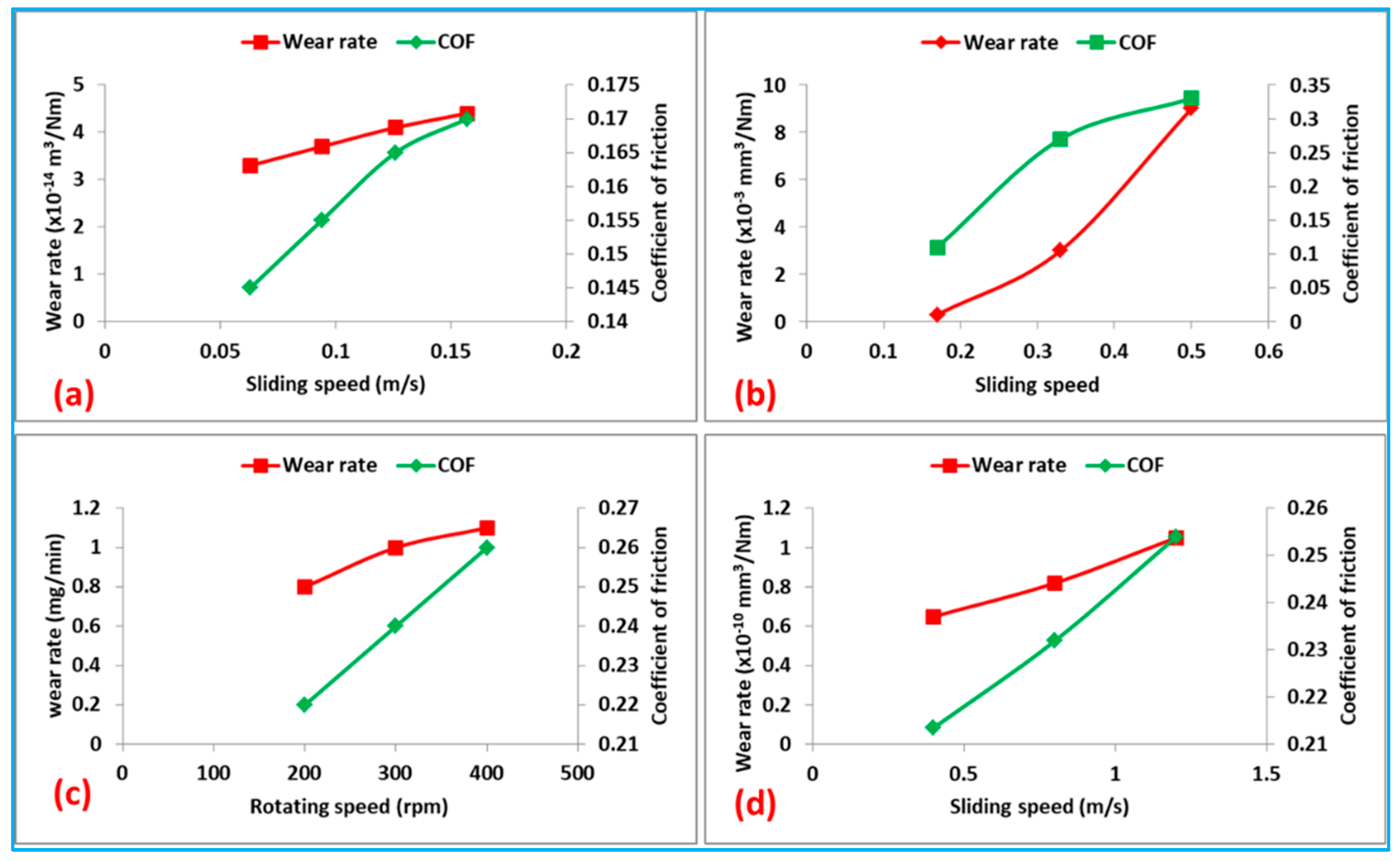

3.2. CNTs-Reinforced Composites’ Response to Sliding Speed

3.3. Effect of Temperature on CNTs-Reinforced Composites

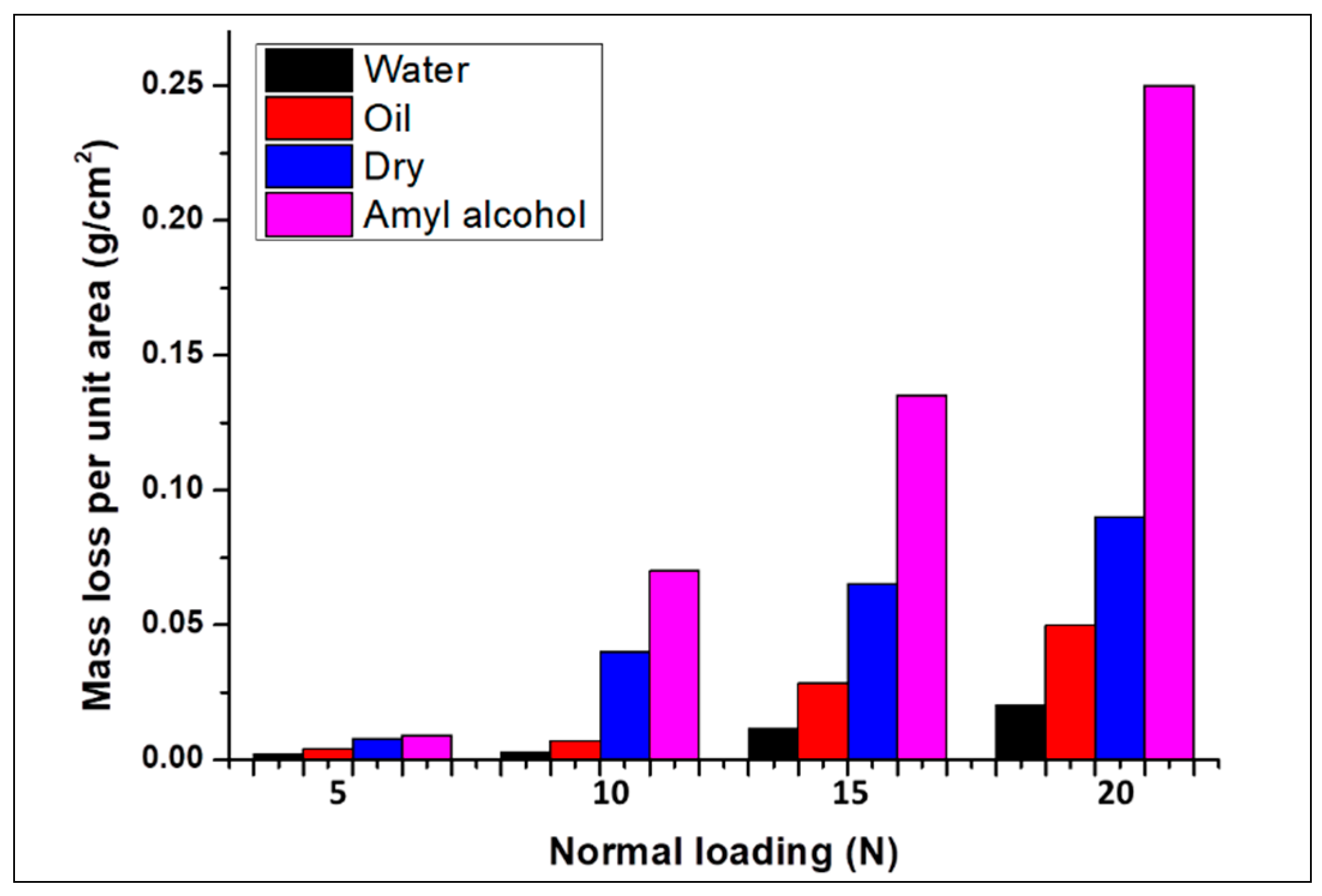

3.4. CNTs-Reinforced Composites’ Response to Various Media (Lubricants)

3.5. Effect of Volume Fraction of Reinforcement on CNTs-Reinforced Composites

3.6. Effect of Porosity on Tribology of CNTs-Reinforced Composites

3.7. Effect of Wettability on CNTs-Reinforced Composites

3.8. Effect of Dispersion of Reinforcement on CNTs-Reinforced Composites

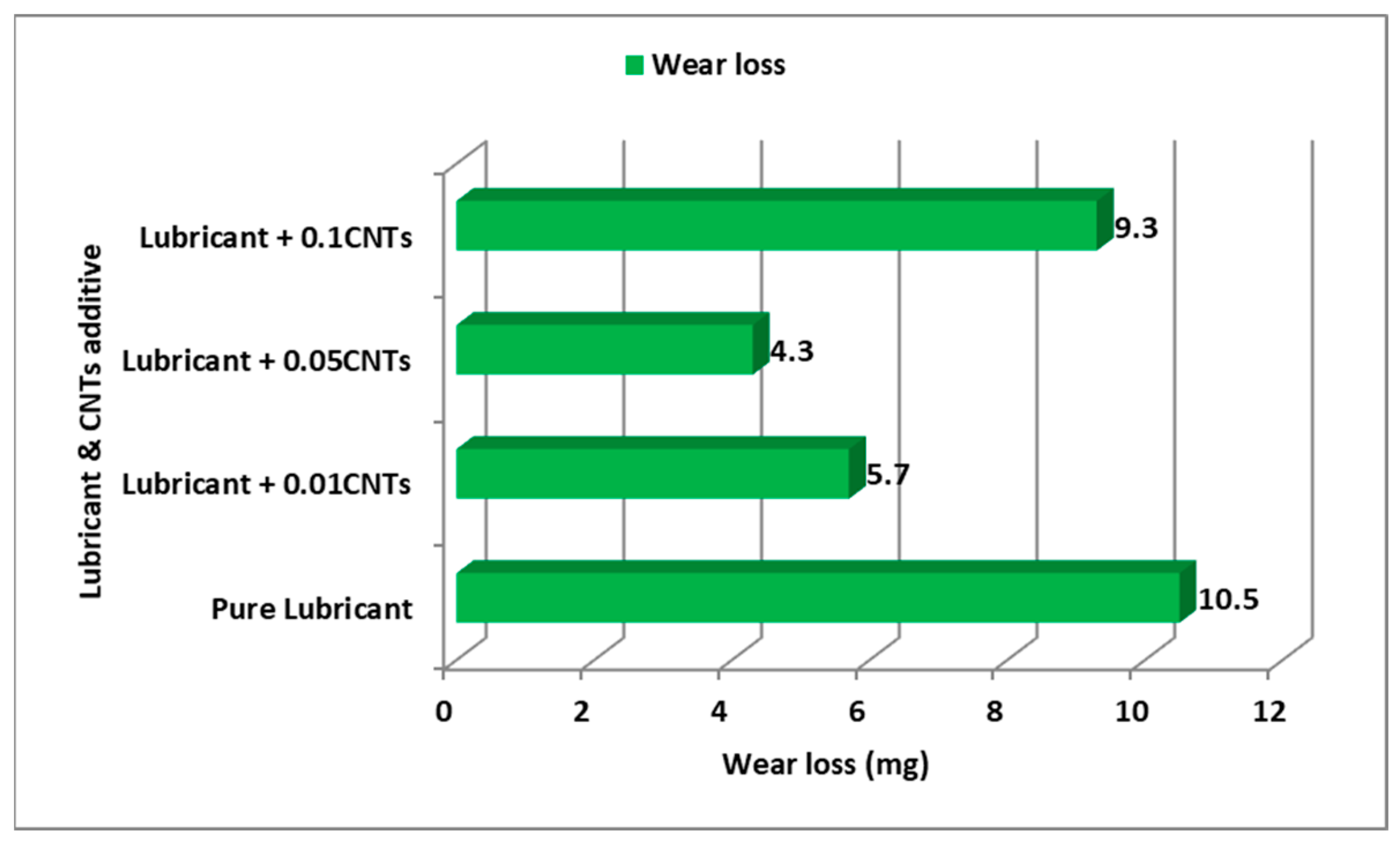

3.9. CNTs as Solid Lubricant and Lubrication Additive

4. Challenges and Remedies in the Development of CNTs-Reinforced Composites

5. Conclusions and Recommendations

- CNTs reinforcement increases the wear resistance and reduces the COF in MMCs and PMCs; for CMCs, it reduces their brittleness by increasing their fracture toughness besides reducing their COF.

- Wear loss transits from mild to severe when the critical temperature (usually 0.4 times the melting temperature of the constituent materials) is exceeded. CNTs possess high thermal conductivity and high melting temperature can delay such a transition by increasing the critical temperature of CNTs-reinforced composites.

- Incorporating CNTs reinforcement into metals, polymers or ceramics is challenging because of its high aspect ratio. It has low wettability, and so, the dispersion is difficult and can be improved by attaching functional groups to its unreactive covalent and hydrogen bonds via functionalization. More so, uniform dispersion can equally be achieved by coating it with Ni, Si, Cu, Li, Mg or Ca.

- CNTs solid lubricant is preferred to liquid and gaseous lubricants in certain applications such as food processing devices because it cannot contaminate foods. Additionally, devices that operate in a vacuum, in the space or at very high temperature vaporize liquid and gaseous lubricants, leaving only solid lubricants such as CNTs that possesses high melting temperature as the choice lubricant.

- CNTs lubricant is considered as the most effective for high temperature application as the temperature limit of CNTs (500 °C) is higher than other solid lubricants.

- Shortening the aspect ratio of CNTs through ball milling helps in dispersing it on matrices. However, ball milling distorts the morphology and structure of CNTs. So, by subjecting CNTs to ultrasonication and magnetic stirring before ball milling, the blending and dispersion will be more effective, innocuous and timely.

- CNTs-reinforced MMCs such as Al-CNTs can function better than steel-reinforced aluminum conductor in electricity transmission; polymer-CNTs composites have better properties than steel amours and shields used by military personnel; ceramic-CNTs composites can perform better than W and diamond for cutting tools. Conventional high temperature materials for producing boilers, nozzles and turbines will perform better if reinforced with CNTs.

- CNTs reinforcement has been confirmed to be useful in improving wear, friction and lubrication properties of MMCs, PMCs and CMCs.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tyagi, A.; Walia, R.; Murtaza, Q.; Pandey, S.M.; Tyagi, P.K.; Bajaj, B. A critical review of diamond like carbon coating for wear resistance applications. Int. J. Refract. Met. Hard Mater. 2019, 78, 107–122. [Google Scholar] [CrossRef]

- Awasthi, S.; Gaur, J.K.; Bobji, M. Advanced ferrogels with high magnetic response and wear resistance using carbon nanotubes. J. Alloys Compd. 2020, 848, 156259. [Google Scholar] [CrossRef]

- Shrivastava, R.; Singh, K. Interlaminar fracture toughness characterization of laminated composites: A review. Polym. Rev. 2020, 60, 542–593. [Google Scholar] [CrossRef]

- Makowiec, M.E.; Blanchet, T.A. Improved wear resistance of nanotube-and other carbon-filled PTFE composites. Wear 2017, 374, 77–85. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Ablyaz, T.R.; Shlykov, E.S.; Muratov, K.R.; Bhui, A.S.; Sidhu, S.S. Enhancing corrosion and wear resistance of Ti6Al4V alloy using CNTs mixed electro-discharge process. Micromachines 2020, 11, 850. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56. [Google Scholar] [CrossRef]

- Iijima, S. Carbon nanotubes. MRS Bull. 1994, 19, 43–49. [Google Scholar] [CrossRef]

- Obitayo, W.; Liu, T. A review: Carbon nanotube-based piezoresistive strain sensors. J. Sens. 2012, 2012, 652438. [Google Scholar] [CrossRef] [Green Version]

- Ujah, C.O.; Kallon, D.V.V. Trends in Aluminium Matrix Composite Development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Ismail, A.F.; Sharif, S.; Razzaghi, M.; Ramakrishna, S.; Berto, F. Carbon nanotubes (CNTs)-reinforced magnesium-based matrix composites: A comprehensive review. Materials 2020, 13, 4421. [Google Scholar] [CrossRef]

- Merchan-Merchan, W.; Saveliev, A.V.; Kennedy, L.; Jimenez, W.C. Combustion synthesis of carbon nanotubes and related nanostructures. Prog. Energy Combust. Sci. 2010, 36, 696–727. [Google Scholar] [CrossRef]

- Munoz, E.; Maser, W.; Benito, A.; Martinez, M.; De la Fuente, G.; Righi, A.; Sauvajol, J.; Anglaret, E.; Maniette, Y. Single-walled carbon nanotubes produced by cw CO2-laser ablation: Study of parameters important for their formation. Appl. Phys. A 2000, 70, 145–151. [Google Scholar]

- Laplaze, D.; Bernier, P.; Maser, W.; Flamant, G.; Guillard, T.; Loiseau, A. Carbon nanotubes: The solar approach. Carbon 1998, 36, 685–688. [Google Scholar] [CrossRef]

- Park, J.G.; Keum, D.H.; Lee, Y.H. Strengthening mechanisms in carbon nanotube-reinforced aluminum composites. Carbon 2015, 95, 690–698. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, O.M.; Popoola, A.P.; Aigbodion, V.S. Development and modelling of aluminium-carbon nanotubes-niobium composite conductor for high voltage transmission networks. In Chemical, Metallurgical and Materials Engineering; Tshwane University of Technology: Pretoria, South Africa, 2020. [Google Scholar]

- Sarina, B.; Kai, T.; Kvithyld, A.; Thorvald, E.; Tangstad, M. Wetting of pure aluminium on graphite, SiC and Al2O3 in aluminium filtration. Trans. Nonferrous Met. Soc. China 2012, 22, 1930–1938. [Google Scholar]

- Archard, J. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.; Popoola, O.; Aigbodion, V. Enhanced tribology, thermal and electrical properties of Al-CNT composite processed via spark plasma sintering for transmission conductor. J. Mater. Sci. 2019, 54, 14064–14073. [Google Scholar] [CrossRef]

- Mikhin, N.; Lyapin, K. Hardness dependence of the coefficient of friction. Sov. Phys. J. 1970, 13, 317–321. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, P.; Popoola, O.; Aigbodion, V. Enhanced mechanical, electrical and corrosion characteristics of Al-CNTs-Nb composite processed via spark plasma sintering for conductor core. J. Compos. Mater. 2019, 53, 3775–3786. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V.; Aikhuele, D.O.; Aigbodion, V.S. Advanced Composite Materials: A Panacea for Improved Electricity Transmission. Appl. Sci. 2022, 12, 8291. [Google Scholar] [CrossRef]

- Patil, A.; Walunj, G.; Ozdemir, F.; Gupta, R.K.; Borkar, T. Tribological Behavior of Carbon-Based Nanomaterial-Reinforced Nickel Metal Matrix Composites. Materials 2021, 14, 3536. [Google Scholar] [CrossRef]

- Watanabe, T. Wettability of ceramic surfaces-A wide range control of surface wettability from super hydrophilicity to super hydrophobicity, from static wettability to dynamic wettability. J. Ceram. Soc. Jpn. 2009, 117, 1285–1292. [Google Scholar] [CrossRef] [Green Version]

- Rajkumar, K.; Aravindan, S. Tribological studies on microwave sintered copper–carbon nanotube composites. Wear 2011, 270, 613–621. [Google Scholar] [CrossRef]

- Guiderdoni, C.; Estournès, C.; Peigney, A.; Weibel, A.; Turq, V.; Laurent, C. The preparation of double-walled carbon nanotube/Cu composites by spark plasma sintering, and their hardness and friction properties. Carbon 2011, 49, 4535–4543. [Google Scholar] [CrossRef] [Green Version]

- Dong, S.; Tu, J.; Zhang, X. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes. Mater. Sci. Eng. A 2001, 313, 83–87. [Google Scholar] [CrossRef]

- Chen, W.; Tu, J.; Wang, L.; Gan, H.; Xu, Z.; Zhang, X. Tribological application of carbon nanotubes in a metal-based composite coating and composites. Carbon 2003, 41, 215–222. [Google Scholar] [CrossRef]

- Zhou, S.-M.; Zhang, X.-B.; Ding, Z.-P.; Min, C.-Y.; Xu, G.-L.; Zhu, W.-M. Fabrication and tribological properties of carbon nanotubes reinforced Al composites prepared by pressureless infiltration technique. Compos. Part A Appl. Sci. Manuf. 2007, 38, 301–306. [Google Scholar] [CrossRef]

- Akbarpour, M.; Alipour, S.; Najafi, M. Tribological characteristics of self-lubricating nanostructured aluminum reinforced with multi-wall CNTs processed by flake powder metallurgy and hot pressing method. Diam. Relat. Mater. 2018, 90, 93–100. [Google Scholar] [CrossRef]

- Manikandan, P.; Sieh, R.; Elayaperumal, A.; Le, H.; Basu, S. Micro/nanostructure and tribological characteristics of pressureless sintered carbon nanotubes reinforced aluminium matrix composites. J. Nanomater. 2016, 2016, 9843019. [Google Scholar] [CrossRef] [Green Version]

- Ujah, C.O.; Popoola, P.; Popoola, O.; Ajenifuja, E. Effect of CNTs on the tribology and thermal behaviours of al nano-powder fabricated with SPS for industrial application. In Conference on Diversification of Developing Economies: Imperatives for Sustainable Environment and Technological Innovations; OAU Osun: Osun State, Nigeria, 2020. [Google Scholar]

- Mansoor, M.; Shahid, M. Tribological properties of MWCNTs strengthened aluminum composite fabricated by induction melting. Adv. Mater. Res. 2015, 1101, 62–65. [Google Scholar] [CrossRef]

- An, J.-W.; You, D.-H.; Lim, D.-S. Tribological properties of hot-pressed alumina–CNT composites. Wear 2003, 255, 677–681. [Google Scholar] [CrossRef]

- Yamamoto, G.; Omori, M.; Yokomizo, K.; Hashida, T.; Adachi, K. Structural characterization and frictional properties of carbon nanotube/alumina composites prepared by precursor method. Mater. Sci. Eng. B 2008, 148, 265–269. [Google Scholar] [CrossRef]

- Lim, D.-S.; You, D.-H.; Choi, H.-J.; Lim, S.-H.; Jang, H. Effect of CNT distribution on tribological behavior of alumina–CNT composites. Wear 2005, 259, 539–544. [Google Scholar] [CrossRef]

- Puchy, V.; Hvizdos, P.; Dusza, J.; Kovac, F.; Inam, F.; Reece, M. Wear resistance of Al2O3–CNT ceramic nanocomposites at room and high temperatures. Ceram. Int. 2013, 39, 5821–5826. [Google Scholar] [CrossRef]

- Zayed, A.S.; Kamel, B.M.; Abdelsadek Osman, T.; Elkady, O.A.; Ali, S. Experimental study of tribological and mechanical properties of aluminum matrix reinforced by Al2O3/CNTs. Fuller. Nanotub. Carbon Nanostruct. 2019, 27, 538–544. [Google Scholar] [CrossRef]

- Nie, P.; Min, C.; Song, H.-J.; Chen, X.; Zhang, Z.; Zhao, K. Preparation and tribological properties of polyimide/carboxyl-functionalized multi-walled carbon nanotube nanocomposite films under seawater lubrication. Tribol. Lett. 2015, 58, 7. [Google Scholar] [CrossRef]

- Yang, Z.; Shi, S.Q. Fabrication and tribological properties of polymer-carbon nanotubes nanocomposites. Key Eng. Mater. 2007, 334–335, 661–664. [Google Scholar] [CrossRef]

- Wang, C.; Dong, B.; Gao, G.-Y.; Xu, M.-W.; Li, H.-L. A study on microhardness and tribological behavior of carbon nanotubes reinforced AMMA-CNTs copolymer nanocomposites. Mater. Sci. Eng. A 2008, 478, 314–318. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Wang, S. A review on enhancement of mechanical and tribological properties of polymer composites reinforced by carbon nanotubes and graphene sheet: Molecular dynamics simulations. Compos. Part B Eng. 2019, 160, 348–361. [Google Scholar] [CrossRef]

- Campo, M.; Jiménez-Suárez, A.; Ureña, A. Effect of type, percentage and dispersion method of multi-walled carbon nanotubes on tribological properties of epoxy composites. Wear 2015, 324, 100–108. [Google Scholar] [CrossRef]

- Wang, H.-D.; He, P.-F.; Ma, G.-Z.; Xu, B.-S.; Xing, Z.-G.; Chen, S.-Y.; Liu, Z.; Wang, Y.-W. Tribological behavior of plasma sprayed carbon nanotubes reinforced TiO2 coatings. J. Eur. Ceram. Soc. 2018, 38, 3660–3672. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Singh, N.; Belokar, R. Tribological behavior of aluminum and magnesium-based hybrid metal matrix composites: A state-of-art review. Mater. Today Proc. 2021, 44, 460–466. [Google Scholar] [CrossRef]

- Chan, J.X.; Wong, J.F.; Petrů, M.; Hassan, A.; Nirmal, U.; Othman, N.; Ilyas, R.A. Effect of nanofillers on tribological properties of polymer nanocomposites: A review on recent development. Polymers 2021, 13, 2867. [Google Scholar] [CrossRef]

- Goswami, S.; Ghosh, R.; Hirani, H.; Mandal, N. Mechano-tribological performance of Graphene/CNT reinforced alumina nanocomposites–Review and quantitative insights. Ceram. Int. 2022, 48, 11879–11908. [Google Scholar] [CrossRef]

- Choudhary, M.; Sharma, A.; Raj, S.A.; Sultan, M.T.H.; Hui, D.; Shah, A.U.M. Contemporary review on carbon nanotube (CNT) composites and their impact on multifarious applications. Nanotechnol. Rev. 2022, 11, 2632–2660. [Google Scholar] [CrossRef]

- Demircan, O.; Al-Darkazali, A.; İnanç, İ.; Eskizeybek, V. Investigation of the effect of CNTs on the mechanical properties of LPET/glass fiber thermoplastic composites. J. Thermoplast. Compos. Mater. 2020, 33, 1652–1673. [Google Scholar] [CrossRef]

- Reddy, P.R.S.; Reddy, T.S.; Mogulanna, K.; Srikanth, I.; Madhu, V.; Rao, K.V. Ballistic impact studies on carbon and E-glass fibre based hybrid composite laminates. Procedia Eng. 2017, 173, 293–298. [Google Scholar] [CrossRef]

- Sastry, Y.S.; Budarapu, P.R.; Krishna, Y.; Devaraj, S. Studies on ballistic impact of the composite panels. Theor. Appl. Fract. Mech. 2014, 72, 2–12. [Google Scholar] [CrossRef]

- Chaurasia, A.; Mulik, R.S.; Parashar, A. Polymer-based nanocomposites for impact loading: A review. Mech. Adv. Mater. Struct. 2021, 29, 2581–2606. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.; Ansari, R. Thermomechanical investigation of unidirectional carbon fiber-polymer hybrid composites containing CNTs. Int. J. Mech. Mater. Des. 2019, 15, 471–488. [Google Scholar] [CrossRef]

- Boddu, V.M.; Brenner, M.W.; Patel, J.S.; Kumar, A.; Mantena, P.R.; Tadepalli, T.; Pramanik, B. Energy dissipation and high-strain rate dynamic response of E-glass fiber composites with anchored carbon nanotubes. Compos. Part B Eng. 2016, 88, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Zengin, E.; Ahlatci, H.; Zengin, H. Investigation of microstructure, tribological and corrosion properties of AISI 316 L stainless steel matrix composites reinforced by carbon nanotubes. Mater. Today Commun. 2021, 29, 102758. [Google Scholar] [CrossRef]

- Munnur, H.; Nagesh, S.; Siddaraju, C.; Rajesh, M.; Rajanna, S. Characterization & tribological behaviour of aluminium metal matrix composites–A review. Mater. Today Proc. 2021, 47, 2570–2574. [Google Scholar]

- Basha, G.; Bolleddu, V. Tribological Behavior of Carbon Nanotubes Reinforced High Velocity Oxy-Fuel Sprayed WC-20 wt.% Co Coatings. J. Therm. Spray Technol. 2021, 30, 1653–1665. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef] [Green Version]

- Arash, B.; Wang, Q.; Varadan, V. Mechanical properties of carbon nanotube/polymer composites. Sci. Rep. 2014, 4, 6479. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Sharma, K.; Dixit, A.R. Carbon nanotube-and graphene-reinforced multiphase polymeric composites: Review on their properties and applications. J. Mater. Sci. 2020, 55, 2682–2724. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube–polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Carneiro, Í.; Simões, S. Strengthening mechanisms in carbon nanotubes reinforced metal matrix composites: A review. Metals 2021, 11, 1613. [Google Scholar] [CrossRef]

- Kondoh, K.; Threrujirapapong, T.; Imai, H.; Umeda, J.; Fugetsu, B. Characteristics of powder metallurgy pure titanium matrix composite reinforced with multi-wall carbon nanotubes. Compos. Sci. Technol. 2009, 69, 1077–1081. [Google Scholar] [CrossRef] [Green Version]

- Nieto, A.; Agarwal, A.; Lahiri, D.; Bisht, A.; Bakshi, S.R. Carbon Nanotubes: Reinforced Metal Matrix Composites; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Meshalkin, V.P.; Belyakov, A.V. Methods used for the compaction and molding of ceramic matrix composites reinforced with carbon nanotubes. Processes 2020, 8, 1004. [Google Scholar] [CrossRef]

- Chan, K.F.; Zaid, M.H.M.; Mamat, M.S.; Liza, S.; Tanemura, M.; Yaakob, Y. Recent developments in carbon nanotubes-reinforced ceramic matrix composites: A review on dispersion and densification techniques. Crystals 2021, 11, 457. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V.; Aigbodion, V.S. Overview of Electricity Transmission Conductors: Challenges and Remedies. Materials 2022, 15, 8094. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of additive manufacturing applications towards environmental sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Dong, S.; Zhai, J. Biosensors: Microbial Sensors. In Reference Module in Biomedical Sciences; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Yu, T.; Liu, J.; He, Y.; Tian, J.; Chen, M.; Wang, Y. Microstructure and wear characterization of carbon nanotubes (CNTs) reinforced aluminum matrix nanocomposites manufactured using selective laser melting. Wear 2021, 476, 203581. [Google Scholar] [CrossRef]

- Kalangi, C.; Bolleddu, V.; Allasi, H.L. Tribological characteristics of carbon nanotubes-reinforced plasma-sprayed Al2O3-TiO2 ceramic coatings. Adv. Mater. Sci. Eng. 2021, 2021, 8094640. [Google Scholar] [CrossRef]

- Huang, S.J.; Abbas, A.; Ballokova, B. Effect of CNT on microstructure, dry sliding wear and compressive mechanical properties of AZ61 magnesium alloy. J. Mater. Res. Technol. 2019, 8, 4273–4286. [Google Scholar] [CrossRef]

- Ye, Z.; Li, J.; Liu, L.; Ma, F.; Zhao, B.; Wang, X. Microstructure and wear performance enhancement of carbon nanotubes reinforced composite coatings fabricated by laser cladding on titanium alloy. Opt. Laser Technol. 2021, 139, 106957. [Google Scholar] [CrossRef]

- Basha, G.T.; Bolleddu, V. Impact of Carbon Nanotubes Reinforcement on Microstructural and Tribological Characteristics of Air Plasma Sprayed Conventional Alumina-Titania (Al2O3-3wt% TiO2) Coatings. Iran. J. Mater. Sci. Eng. 2020, 17, 92–103. [Google Scholar]

- Xu, R.; Bian, D.; Zhao, Y.; Xu, X.; Liu, Y.; Zhou, W. Tribological behavior studies of chemically bonded phosphate ceramic coatings reinforced with modified multi-walled carbon nanotubes (MWCNTs). Int. J. Appl. Ceram. Technol. 2020, 17, 1010–1016. [Google Scholar] [CrossRef]

- Winarto, W.; Priadi, D.; Sofyan, N.; Wicaksono, A. Wear resistance and surface hardness of carbon nanotube reinforced alumina matrix nanocomposite by cold sprayed process. Procedia Eng. 2017, 170, 108–112. [Google Scholar] [CrossRef]

- Sharma, A.; Fujii, H.; Paul, J. Influence of reinforcement incorporation approach on mechanical and tribological properties of AA6061-CNT nanocomposite fabricated via FSP. J. Manuf. Process. 2020, 59, 604–620. [Google Scholar] [CrossRef]

- Shivaramu, H.; Nayak, V.; Umashankar, K. Dry sliding wear characteristics of multi-walled carbon nanotubes reinforced Al-Si (LM6) alloy nanocomposites produced by powder metallurgy technique. Mater. Res. Express 2020, 7, 045001. [Google Scholar]

- Popoola, P.; Popoola, O.; Aigbodion, V.; Oladijo, P. Improving tribological and thermal properties of Al alloy using CNTs and Nb nanopowder via SPS for power transmission conductor. Trans. Nonferrous Met. Soc. China 2020, 30, 333–343. [Google Scholar]

- Gbadeyan, O.J.; Kanny, K.; Mohan, T. Influence of the multi-walled carbon nanotube and short carbon fibre composition on tribological properties of epoxy composites. Tribol. -Mater. Surf. Interfaces 2017, 11, 59–65. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.; Popoola, O.; Uyor, U. Analysis of the Microstructure and Tribology of Ti36-Al16-V16-Fe16-Cr16 HEA Developed with SPS for Engineering Applications. JOM 2022, 74, 4239–4249. [Google Scholar] [CrossRef]

- Pan, Y.; Lu, X.; Volinsky, A.A.; Liu, B.; Xiao, S.; Zhou, C.; Li, Y.; Chen, M.; Qu, X. Tribological and mechanical properties of copper matrix composites reinforced with carbon nanotube and alumina nanoparticles. Mater. Res. Express 2019, 6, 116524. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.; Popoola, O.; Uyor, U. Investigating the Tribology, Vickers Hardness and Microstructure of Ti20–Al20–V20–Fe20–Ni20 HEA Developed with SPS. Trans. Indian Inst. Met. 2022, 75, 3029–3038. [Google Scholar] [CrossRef]

- Gao, J.; Luedtke, W.; Gourdon, D.; Ruths, M.; Israelachvili, J.; Landman, U. Frictional forces and Amontons’ law: From the molecular to the macroscopic scale. J. Phys. Chem. B 2004, 108, 3410–3425. [Google Scholar] [CrossRef]

- Kumar, S.; Balasubramanian, V. Developing a mathematical model to evaluate wear rate of AA7075/SiCp powder metallurgy composites. Wear 2008, 264, 1026–1034. [Google Scholar] [CrossRef]

- Wang, Y.; Rainforth, W.; Jones, H.; Lieblich, M. Dry wear behaviour and its relation to microstructure of novel 6092 aluminium alloy–Ni3Al powder metallurgy composite. Wear 2001, 251, 1421–1432. [Google Scholar] [CrossRef] [Green Version]

- Yu, S.Y.; Ishii, H.; Tohgo, K.; Cho, Y.T.; Diao, D. Temperature dependence of sliding wear behavior in SiC whisker or SiC particulate reinforced 6061 aluminum alloy composite. Wear 1997, 213, 21–28. [Google Scholar] [CrossRef]

- Daoud, A.; Abou-Elkhair, M.; Rohatgi, P. Wear and friction behavior of near eutectic Al–Si+ ZrO2 or WC particle composites. Compos. Sci. Technol. 2004, 64, 1029–1040. [Google Scholar] [CrossRef]

- He, P.; Jia, D.; Lin, T.; Wang, M.; Zhou, Y. Effects of high-temperature heat treatment on the mechanical properties of unidirectional carbon fiber reinforced geopolymer composites. Ceram. Int. 2010, 36, 1447–1453. [Google Scholar] [CrossRef]

- Srinivasan, R.; Shivananad, H. Studies on tribological characterization of carbon nanotube reinforced with 6061 aluminium alloy metal matrix composites coated with nickel. Int. J. Appl. Eng. Res. 2019, 14, 3721–3729. [Google Scholar]

- Venkatesan, M.; Palanikumar, K.; Boopathy, S.R. Experimental investigation and analysis on the wear properties of glass fiber and CNT reinforced hybrid polymer composites. Sci. Eng. Compos. Mater. 2018, 25, 963–974. [Google Scholar] [CrossRef]

- Özsarıkaya, B.; Yetgin, S.H.; Ünal, H. Tribological properties of carbon fiber and multi-walled carbon nanotube filled polyamide 66 composites. In Proceedings of the 10th International Scientific Conference BALTTRIB 2019, Kaunas, Lithuania, 14–16 November 2019; Vytautas Magnus University: Kaunas, Lithuania, 2019. [Google Scholar]

- Kumar, G.V.; Rao, C.; Selvaraj, N. Mechanical and tribological behavior of particulate reinforced aluminum metal matrix composites—A review. J. Miner. Mater. Charact. Eng. 2011, 10, 59. [Google Scholar] [CrossRef]

- Martin, A.; Martinez, M.; Llorca, J. Wear of SiC-reinforced Al-matrix composites in the temperature range 20–200 C. Wear 1996, 193, 169–179. [Google Scholar] [CrossRef]

- Martın, A.; Rodríguez, J.; Llorca, J. Temperature effects on the wear behavior of particulate reinforced Al-based composites. Wear 1999, 225, 615–620. [Google Scholar] [CrossRef]

- Rodriguez, J.; Poza, P.; Garrido, M.; Rico, A. Dry sliding wear behaviour of aluminium–lithium alloys reinforced with SiC particles. Wear 2007, 262, 292–300. [Google Scholar] [CrossRef]

- Vissutipitukul, P.; Aizawa, T. Wear of plasma-nitrided aluminum alloys. Wear 2005, 259, 482–489. [Google Scholar] [CrossRef]

- Gibson, P.; Clegg, A.; Das, A. Production and evaluation of squeeze-cast graphitic Al-Si alloys. Mater. Sci. Technol. 1985, 1, 559–567. [Google Scholar] [CrossRef]

- Hutchings, I.; Shipway, P. Tribology: Friction and Wear of Engineering Materials; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Barczak, L.M.; Batako, A.D. Application of minimum quantity lubrication in grinding. Mater. Manuf. Process. 2012, 27, 406–411. [Google Scholar] [CrossRef]

- Mertens, A.J.; Senthilvelan, S. Mechanical and tribological properties of carbon nanotube reinforced polypropylene composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2018, 232, 669–680. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.; Popoola, O.; Aigbodion, V.S. Influence of CNTs addition on the mechanical, microstructural, and corrosion properties of Al alloy using spark plasma sintering technique. Int. J. Adv. Manuf. Technol. 2020, 106, 2961–2969. [Google Scholar] [CrossRef]

- Guo, B.; Song, M.; Zhang, X.; Liu, Y.; Cen, X.; Chen, B.; Li, W. Exploiting the synergic strengthening effects of stacking faults in carbon nanotubes reinforced aluminum matrix composites for enhanced mechanical properties. Compos. Part B Eng. 2021, 211, 108646. [Google Scholar] [CrossRef]

- Gandhi, R.A.; Palanikumar, K.; Ragunath, B.; Davim, J.P. Role of carbon nanotubes (CNTs) in improving wear properties of polypropylene (PP) in dry sliding condition. Mater. Des. 2013, 48, 52–57. [Google Scholar] [CrossRef]

- Zhao, L.; Yao, P.; Zhou, H.; Gong, T.; Deng, M.; Zhang, Z.; Xiao, Y.; Deng, H.; Li, Y.; Luo, F. Effect of CNTs in copper matrix on mechanical characteristics and tribological behavior under dry sliding and boundary lubrication conditions. Materials 2019, 12, 2203. [Google Scholar] [CrossRef] [Green Version]

- Mindivan, H.; Efe, A.; Kosatepe, A.H.; Kayali, E.S. Fabrication and characterization of carbon nanotube reinforced magnesium matrix composites. Appl. Surf. Sci. 2014, 318, 234–243. [Google Scholar] [CrossRef]

- Choi, H.; Lee, S.; Bae, D. Wear characteristic of aluminum-based composites containing multi-walled carbon nanotubes. Wear 2010, 270, 12–18. [Google Scholar] [CrossRef]

- Savina, J.; Raghavendra, B.; Rangappa, D. Experimental investigation on mechanical and tribological behaviour of surfactant coated multi-walled carbon nano tubes reinforced aluminium 6065-silicon metal matrix composite. Lett. Mater. 2021, 11, 73–78. [Google Scholar] [CrossRef]

- Yoo, S.C.; Kang, B.; Van Trinh, P.; Phuong, D.D.; Hong, S.H. Enhanced mechanical and wear properties of Al6061 alloy nanocomposite reinforced by CNT-template-grown core–shell CNT/SiC nanotubes. Sci. Rep. 2020, 10, 12896. [Google Scholar] [CrossRef]

- Nafari, A.; Ghandvar, H.; Nekouee, K.; Nordin, N.A.; Torkamani, H. Microstructural characterization, mechanical and tribological properties of ZC71 hybrid composite einforced with SiC and MWCNT. J. Appl. Res. Technol. 2021, 19, 345–363. [Google Scholar] [CrossRef]

- Li, H.; Zong, H.; Li, S.; Jin, S.; Chen, Y.; Cabral, M.J.; Chen, B.; Huang, Q.; Ren, Y.; Yu, K. Uniting tensile ductility with ultrahigh strength via composition undulation. Nature 2022, 604, 273–279. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.; Popoola, O.; Afolabi, A.; Uyor, U. Mechanical and Oxidation Characteristics of Ti20-Al16-V16-Fe16-Ni16-Cr16 High-Entropy Alloy Developed via Spark Plasma Sintering for High-Temperature/Strength Applications. J. Mater. Eng. Perform. 2022, 32, 18–28. [Google Scholar] [CrossRef]

- German, R.M. Titanium sintering science: A review of atomic events during densification. Int. J. Refract. Met. Hard Mater. 2020, 89, 105214. [Google Scholar] [CrossRef]

- Franesqui, M.A.; Yepes, J.; García-González, C. Improvement of moisture damage resistance and permanent deformation performance of asphalt mixtures with marginal porous volcanic aggregates using crumb rubber modified bitumen. Constr. Build. Mater. 2019, 201, 328–339. [Google Scholar] [CrossRef]

- Thomson, K.; Jiang, D.; Yao, W.; Ritchie, R.; Mukherjee, A. Characterization and mechanical testing of alumina-based nanocomposites reinforced with niobium and/or carbon nanotubes fabricated by spark plasma sintering. Acta Mater. 2012, 60, 622–632. [Google Scholar] [CrossRef]

- Starke, E., Jr.; Rashed, H. Alloys: Aluminum. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 18–24. [Google Scholar]

- Yu, M.-F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 2000, 84, 5552. [Google Scholar] [CrossRef] [Green Version]

- Malaki, M.; Fadaei Tehrani, A.; Niroumand, B.; Gupta, M. Wettability in metal matrix composites. Metals 2021, 11, 1034. [Google Scholar] [CrossRef]

- James, J.; Annamalai, A.R.; Muthuchamy, A.; Jen, C.-P. Effect of Wettability and Uniform Distribution of Reinforcement Particle on Mechanical Property (Tensile) in Aluminum Metal Matrix Composite—A Review. Nanomaterials 2021, 11, 2230. [Google Scholar] [CrossRef]

- Huei-Long, L.; Wun-Hwa, L.; Chan, S.L.-I. Abrasive wear of powder metallurgy Al alloy 6061-SiC particle composites. Wear 1992, 159, 223–231. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M. The wettability of SiC particles by molten aluminium alloy. J. Mater. Process. Technol. 2001, 119, 324–328. [Google Scholar] [CrossRef]

- Tekmen, C.; Saday, F.; Cocen, U.; Ljungberg, L.Y. An investigation of the effect of SiC reinforcement coating on the wettability of Al/SiC system. J. Compos. Mater. 2008, 42, 1671–1679. [Google Scholar] [CrossRef]

- Zhou, W.; Xu, Z. Casting of SiC reinforced metal matrix composites. J. Mater. Process. Technol. 1997, 63, 358–363. [Google Scholar] [CrossRef]

- Jiang, L.; Fan, G.; Li, Z.; Kai, X.; Zhang, D.; Chen, Z.; Humphries, S.; Heness, G.; Yeung, W.Y. An approach to the uniform dispersion of a high volume fraction of carbon nanotubes in aluminum powder. Carbon 2011, 49, 1965–1971. [Google Scholar] [CrossRef]

- Riahi, A.; Alpas, A. The role of tribo-layers on the sliding wear behavior of graphitic aluminum matrix composites. Wear 2001, 251, 1396–1407. [Google Scholar] [CrossRef]

- So, K.P.; Jeong, J.C.; Park, J.G.; Park, H.K.; Choi, Y.H.; Noh, D.H.; Keum, D.H.; Jeong, H.Y.; Biswas, C.; Hong, C.H. SiC formation on carbon nanotube surface for improving wettability with aluminum. Compos. Sci. Technol. 2013, 74, 6–13. [Google Scholar] [CrossRef]

- Li, R.; Pan, Z.; Zeng, Q.; Xiaoli, Y. Influence of the Interface of Carbon Nanotube-Reinforced Aluminum Matrix Composites on the Mechanical Properties—A Review. Arch. Foundry Eng. 2022, 22, 23–36. [Google Scholar]

- He, R.; Wang, H. Fatigue crack nucleation and growth behaviors of laser melting deposited Ti–6Al–2Zr–Mo–V. Mater. Sci. Eng. A 2010, 527, 1933–1937. [Google Scholar] [CrossRef]

- Esawi, A.M.; Morsi, K.; Sayed, A.; Taher, M.; Lanka, S. Effect of carbon nanotube (CNT) content on the mechanical properties of CNT-reinforced aluminium composites. Compos. Sci. Technol. 2010, 70, 2237–2241. [Google Scholar] [CrossRef]

- Chen, H.; Jacobs, O.; Wu, W.; Rüdiger, G.; Schädel, B. Effect of dispersion method on tribological properties of carbon nanotube reinforced epoxy resin composites. Polym. Test. 2007, 26, 351–360. [Google Scholar] [CrossRef]

- Torralba, J.D.; Da Costa, C.; Velasco, F. P/M aluminum matrix composites: An overview. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Sapawe, N.; Hanafi, M.F.; Samion, S. The use of palm oil as new alternative biolubricant for improving anti-friction and anti-wear properties. Mater. Today Proc. 2019, 19, 1126–1135. [Google Scholar] [CrossRef]

- Scharf, T.; Prasad, S. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Slapnik, J.; Stiller, T.; Wilhelm, T.; Hausberger, A. Influence of Solid Lubricants on the Tribological Performance of Photocurable Resins for Vat Photopolymerization. Lubricants 2020, 8, 104. [Google Scholar] [CrossRef]

- Bastwros, M.M.; Esawi, A.M.; Wifi, A. Friction and wear behavior of Al–CNT composites. Wear 2013, 307, 164–173. [Google Scholar] [CrossRef]

- Zhang, X.; Luster, B.; Church, A.; Muratore, C.; Voevodin, A.A.; Kohli, P.; Aouadi, S.; Talapatra, S. Carbon nanotube− MoS2 composites as solid lubricants. ACS Appl. Mater. Interfaces 2009, 1, 735–739. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R.; Singh, R.K.; Singh, M. Novel uses of alumina/graphene hybrid nanoparticle additives for improved tribological properties of lubricant in turning operation. Tribol. Int. 2018, 119, 99–111. [Google Scholar] [CrossRef]

- Cornelio, J.A.C.; Cuervo, P.A.; Hoyos-Palacio, L.M.; Lara-Romero, J.; Toro, A. Tribological properties of carbon nanotubes as lubricant additive in oil and water for a wheel–rail system. J. Mater. Res. Technol. 2016, 5, 68–76. [Google Scholar] [CrossRef] [Green Version]

- Jang, I.; Joo, H.G.; Jang, Y.H. Effects of carbon nanotubes on electrical contact resistance of a conductive Velcro system under low frequency vibration. Tribol. Int. 2016, 104, 45–56. [Google Scholar] [CrossRef]

- Mao, F.; Wiklund, U.; Andersson, A.M.; Jansson, U. Graphene as a lubricant on Ag for electrical contact applications. J. Mater. Sci. 2015, 50, 6518–6525. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.; Tian, S.; Menezes, P.L.; Xiong, G. Carbon solid lubricants: Role of different dimensions. Int. J. Adv. Manuf. Technol. 2020, 107, 3875–3895. [Google Scholar] [CrossRef]

- Muzakkir, S.; Lijesh, K.; Hirani, H. Carbon Nanotubes as Solid Lubricant Additives for Anti-wear Performance Enhancement under Mixed Lubrication Conditions. Int. J. Mod. Eng. Res 2015, 5, 25–28. [Google Scholar]

- Chaudhuri, S.; Ghosh, A.; Chattopadhyay, S.K. Green synthetic approaches for medium ring–sized heterocycles of biological and pharmaceutical interest. In Green Synthetic Approaches for Biologically Relevant Heterocycles; Elsevier: Amsterdam, The Netherlands, 2021; pp. 617–653. [Google Scholar]

- Kolchugin, A.; Pikalova, E.Y.; Bogdanovich, N.; Bronin, D.; Pikalov, S.; Plaksin, S.; Ananyev, M.; Eremin, V. Structural, electrical and electrochemical properties of calcium-doped lanthanum nickelate. Solid State Ion. 2016, 288, 48–53. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Choi, H.; Shin, J.; Min, B.; Park, J.; Bae, D. Reinforcing effects of carbon nanotubes in structural aluminum matrix nanocomposites. J. Mater. Res. 2009, 24, 2610–2616. [Google Scholar] [CrossRef]

- Ma, P.C.; Wang, S.Q.; Kim, J.-K.; Tang, B.Z. In-situ amino functionalization of carbon nanotubes using ball milling. J. Nanosci. Nanotechnol. 2009, 9, 749–753. [Google Scholar] [CrossRef]

- Esawi, A.; Morsi, K.; Sayed, A.; Taher, M.; Lanka, S. The influence of carbon nanotube (CNT) morphology and diameter on the processing and properties of CNT-reinforced aluminium composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 234–243. [Google Scholar] [CrossRef]

- Tserengombo, B.; Jeong, H.; Dolgor, E.; Delgado, A.; Kim, S. Effects of Functionalization in Different Conditions and Ball Milling on the Dispersion and Thermal and Electrical Conductivity of MWCNTs in Aqueous Solution. Nanomaterials 2021, 11, 1323. [Google Scholar] [CrossRef]

- Oliver, U.C.; Sunday, A.V.; Christain, E.I.-E.I.; Elizabeth, M.M. Spark plasma sintering of aluminium composites—A review. Int. J. Adv. Manuf. Technol. 2021, 112, 1819–1839. [Google Scholar] [CrossRef]

- Chieh, K.; Te-Tan, L.; Kuo-Hwa, T.; Kuo-Ying, C.; Ming-Shuing, C. The influences of powder mixing process on the quality of W-cu composites. J. Trans. Can. Soc. Mech. Eng. 2009, 33, 361–375. [Google Scholar]

- Peng, T.; Chang, I. Uniformly dispersion of carbon nanotube in aluminum powders by wet shake-mixing approach. Powder Technol. 2015, 284, 32–39. [Google Scholar] [CrossRef]

- Chung, D.D. Composite Materials: Science and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Štengl, V. Preparation of graphene by using an intense cavitation field in a pressurized ultrasonic reactor. Chem. Eur. J. 2012, 18, 14047–14054. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Reis, M.A.; Vieira, M.F. Aluminum and nickel matrix composites reinforced by CNTs: Dispersion/mixture by ultrasonication. Metals 2017, 7, 279. [Google Scholar] [CrossRef]

- Thomas, S.; Pillari, L.K.; Umasankar, V.; Pious, J. Effect of sonication in enhancing the uniformity of MWCNT distribution in aluminium alloy AA2219 matrix. Mater. Today Proc. 2019, 18, 4058–4066. [Google Scholar] [CrossRef]

- Javadi, A.; Mirdamadi, S.; Faghihisani, M.; Shakhesi, S.; Soltani, R. Well-dispersion of multi-walled carbon nanotubes in aluminum matrix composites by controlling the mixing process. Fuller. Nanotub. Carbon Nanostruct. 2013, 21, 436–447. [Google Scholar] [CrossRef]

- Rais, L.; Sharma, D.R.; Sharma, D.V. Synthesis and structural characterization of Al-CNT metal matrix composite using physical mixing method. IOSR J. Appl. Phys. 2013, 5, 54–57. [Google Scholar] [CrossRef]

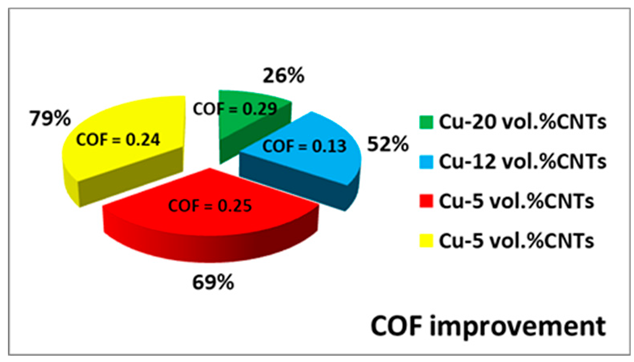

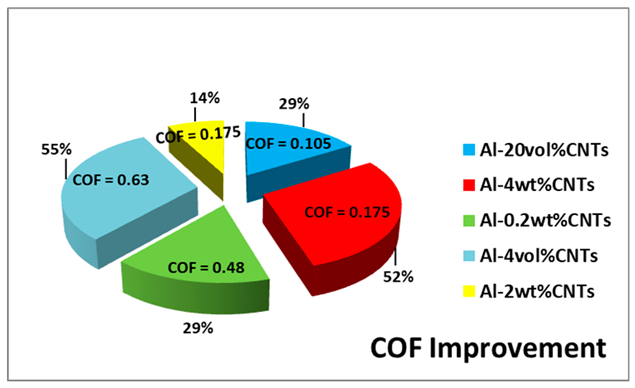

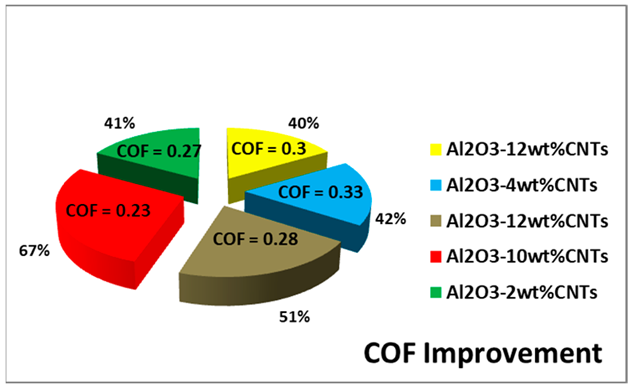

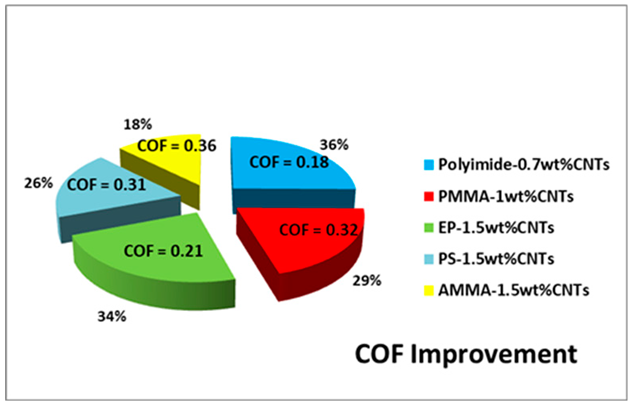

| Plots of COF Improvements | Remark | Ref. |

|---|---|---|

| 5 vol.% of CNTs gave the optimal COF improvement. As the concentration increased, the COF depreciated in the Cu alloy. | [24,25,26,27] |

| At a very low concentration of CNTs, the composite had low COF improvement; at too excessive a volume fraction, the improvement was still low. It was an optimal concentration (4 vol.%) that gave the highest improvement in Al alloys. | [28,29,30,31,32] |

| The COF improvement in Al2O3 ceramic-CNTs composite absorbed higher volume fraction of CNTs than in metals and polymers. An optimum value of 10 wt.% gave the highest COF improvement of 67%. | [33,34,35,36,37] |

| Polymer matrices can wet out only minute fraction of CNTs. Optimum concentration of CNTs that gave the highest COF improvement was 0.7 wt.%. (PMMA, polymethyl methacrylate; EP, epoxy; PS, polystyrene; AMMA, polyacrylonotrile). | [38,39,40] |

| Production Technique Sketches | Description | Remarks | Ref. |

|---|---|---|---|

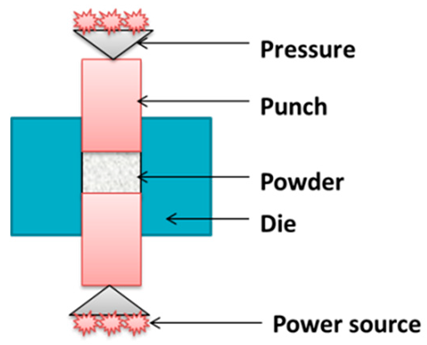

(a) Powder metallurgy | Powder metallurgy: This comprises spark plasma sintering, vacuum sintering, microwave sintering, hot pressing and conventional sintering. Prior to consolidation, matrix and reinforcement are blended via ball milling, tubular mixing and molecular mixing. Then, the application of heat and pressure is used to consolidate the composite. | In SPS and other forms of advanced sintering, heat and pressure are applied concurrently, while in conventional sintering, heat is applied after green compaction. There is zero waste of materials. | [67] |

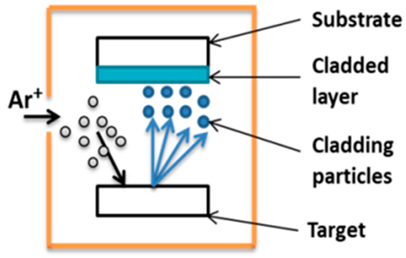

(b) Additive process | Additive manufacturing: This comprises laser cladding, sputtering, nanoscale dispersion, sandwich processing, plasma spraying and vapor deposition. | This technique reduces material wastes to the lowest level. | [68] |

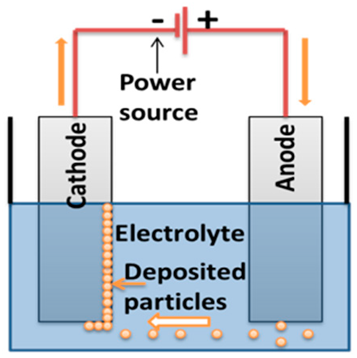

(c) Electrochemical method | Electrochemical technique: This comprises electro deposition via amperometry, potentiometry, conductometry, voltammetry or the galvanic cell technique. This involves the passing of electric current to initiate dissolution and deposition of materials. | The major advantages of this technique are its simplicity, low cost and speed. | [69] |

(d) Casting method | Casting method: This comprises stir casting, ultrasonic cavitation, squeeze casting, liquid casting etc. Casting involves melting of base material, addition of reinforcing phase, stirring and solidification. | Virtually every component can be casted, using metal composites, ceramics or polymer composites. It is cheap and uses simple tooling. | [67] |

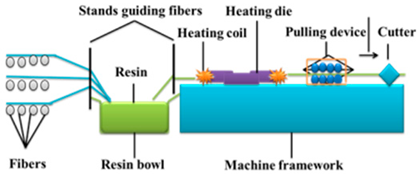

(e) Pultrusion/Extrusion | Low melting-point metals and polymer composite fabrication that comprises pultrusion and extrusion. This involves melting and pushing or pulling the melt through an orifice to assume specific shape. | This is used in the production of long components such as electric transmission conductors. It is very fast and economical. | [67] |

| CNTs/Composites | Tribology Properties | Remarks | Ref. |

|---|---|---|---|

| AlSi-10Mg-CNTs | Wear grove of composite = 150 μm2 Wear grove metal matrix = 224 μm2 Wear rate of composite is 33% lower | The improvement in wear rate is attributed to the fact that CNTs increased the hardness of the MMCs and improved the microstructure. Selective laser melting (SLM) was the technique employed. This composite is useful in automotive brake pad and lining, pistons and engine sleeves. | [70] |

| WC-20Co-6CNTs | Wear rate = 0.000307 ± 0.1 mm3/N.m COF = 0.08 ± 0.012 | The introduction of CNTs on WC-20Co improved the wear loss, wear rate and coefficient of friction greatly through improving the mechanical strength. The processing technique was high-velocity oxy-fuel (HVOF) spraying. This ceramic composite is useful in cutting tools and grinding wheels. | [57] |

| Al2O3-3%TiO2-3% CNT, | Wear resistance = 5800 Nm/mm3 Mass loss = 0.0035 g Average mass loss of unreinforced ceramics was 3.85 mg, while average mass loss of CNTs/ceramics was 3.45 mg (11.6% improvement). | Uniform CNTs dispersion and good adhesion of coatings with the substrate invoked the enhancement of the wear properties. The method was Plasma Spraying of Al2O3-3TiO2-CNTs on AISI 1020 steel substrate. This ceramic composite is replacing steel pipes in oil and gas industrial pipes. | [71] |

| 316 L Stainless steel-8CNT | Wear rate = 1.1 × 10−7 mm3/Nm (218% improvement) COF = 0.25 (60% improvement) The COF of unreinforced 316 L was 0.4, and the wear rate was 3.5 × 10−7 mm3/Nm. | The tribology improvement was made possible because the larger surface area of CNTs provided large surface roughing, thus having a better lubrication effect. Vacuum hot-press sintering was the technique applied. This steel composite is replacing conventional stainless steel in advanced applications. | [55] |

| AZ61Mg-0.5%CNTs | Volume loss = 0.81 mm3 (48% improvement) Mass loss = 0.008 g (38% improvement) COF = 0.3 (17% improvement) There was very low COF (0.22) at 1 wt%CNTs. The unrefined AZ61 had volume loss of 1.2 mm3, mass loss of 0.011 and COF of 0.35. | The strengthening and bonding characteristics of CNTs led to a reduction in mass loss. Additionally, the CNTs provided lubrication effect which led to enhancement of the tribology. Stir casting with annealing was the method used. This MMC is useful in electrical and electronics packaging. | [72] |

| Al3Ti-Cu-SiC-CNTs | Average COF = 0.46 Average COF of substrate = 0.57 This gives an improvement of 24% | The COF was enhanced by the dispersion strengthening and fine grain strengthening of CNTs. The production technique was laser cladding. This is an advanced hybrid composite which can compete favorably with high entropy alloy in aerospace applications. | [73] |

| Al2O3-3TiO2-6CNTs | Wear depth = 4 ± 0.8 μm Wear rate = 0.0003 ± 0.1 mm3/Nm COF = 0.11 ± 0.009 | The improvement was attributed to bridging of CNTs in between the splats of the ceramics matrix. The technique used was Plasma Spraying of the composite on AISI 1020 mild steel. This is replacing steel alloy in bridges, rails and other structural applications. | [74] |

| Polyimide-0.1CNTs | Wear rate = 0.0002 mm3/Nm COF = 0.26 | The functionalization of CNTs contributed to the improvement of the wear resistance. This polymer composite is used as high temperature structural glues and laminating resin. It is used in wood work, structural and car body parts applications. | [38] |

| Polyimide-0.7CNTs | Wear rate = 0.00065 mm3/Nm COF = 0.18 | There was strong interfacial bonding between PI matrix and MWCNTs-COOH nanofillers, which enhanced the transfer of load effectively from the matrix to the functionalized CNTs. So, this improved its hardness, which in turn reduced the wear rate and COF. It is now prominent in automotive industries. | [38] |

| Phosphate ceramic-0.75CNTs | Wear rate = 0.008 mm3/Nm COF = 0.39 | It was observed that at temperatures below 500 °C, the lubrication effect of CNTs was intact. However, when this temperature was exceeded, the tribology properties diminished. | [75] |

| Al2O3-2CNTs | Wear rate = 0.00000269 mm2/kg Wear rate of pristine Al2O3 = 0.00000294 mm2/kg | The improvement in wear rate was attributed to the uniform dispersion and the reinforcement efficiency of CNTs. The composite was produced with cold spraying. This is a high-temperature structural ceramic composite that is replacing BN, WC etc. | [76] |

| Al-CNTs | Specific wear rate of micro-sized channel reinforcement filling (MCRF) = 0.018 mm3/Nm Wear rate of pure Al = 0.022 mm3/Nm (20% improvement) | The improvement in wear rate was attributed to the uniform dispersion of CNTs in MCRF-fabricated composite, which formed a solid lubricant layer. Friction stir processing was the method applied. This MMC is useful in electrical, electronic and structural applications which can replace conventional steel conductors. | [77] |

| Al-Si-0.75CNTs | Wear rate = 0.00095 mm3/m Wear rate Al-Si = 0.0018 mm3/m (89% improvement) | The improvement was attributed to the formation of a carbon layer which acted as a solid lubricant at a higher speed. Powder metallurgy was employed in the fabrication. | [78] |

| Al-4CNTs | COF = 0.18 (52% improvement) Wear rate = 0.34 μm3/s (23% improvement) Wear volume = 20 μm3 (23% improvement) | The improvement was attributed to strong densification and refined microstructure influenced by spark plasma sintering technique. Useful for high temperature transmission conductor. | [18] |

| Al-8CNTs-8Nb | COF = 0.10 (79% improvement) Wear rate = 0.49 μm3/s (23% improvement) | The improvement was attributed to the solid lubrication property of CNTs and formation of Nb2O5 that acted as a solid lubricant too. This can conveniently replace steel-reinforced aluminum conductors. | [79] |

| Epoxy-10Carbon fibre-0.3CNTs | COF = 0.3 (97% improvement) Wear rate = 4 × 10−6 mm3/Nm (425% improvement) | The improvement in the tribological properties was attributed to the lubricating effect as well as strengthening action of C-C bond between CNTs and short carbon fibre. This polymer composite is useful in high-temperature applications. | [80] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ujah, C.O.; Kallon, D.V.V.; Aigbodion, V.S. Tribological Properties of CNTs-Reinforced Nano Composite Materials. Lubricants 2023, 11, 95. https://doi.org/10.3390/lubricants11030095

Ujah CO, Kallon DVV, Aigbodion VS. Tribological Properties of CNTs-Reinforced Nano Composite Materials. Lubricants. 2023; 11(3):95. https://doi.org/10.3390/lubricants11030095

Chicago/Turabian StyleUjah, Chika Oliver, Daramy Vandi Von Kallon, and Victor Sunday Aigbodion. 2023. "Tribological Properties of CNTs-Reinforced Nano Composite Materials" Lubricants 11, no. 3: 95. https://doi.org/10.3390/lubricants11030095

APA StyleUjah, C. O., Kallon, D. V. V., & Aigbodion, V. S. (2023). Tribological Properties of CNTs-Reinforced Nano Composite Materials. Lubricants, 11(3), 95. https://doi.org/10.3390/lubricants11030095