Effect of CH4 Flow Rate on the Tribological Behaviors of TiCN Films against Si3N4 Ceramic and Steel Ball

Abstract

:1. Introduction

2. Materials and Methods

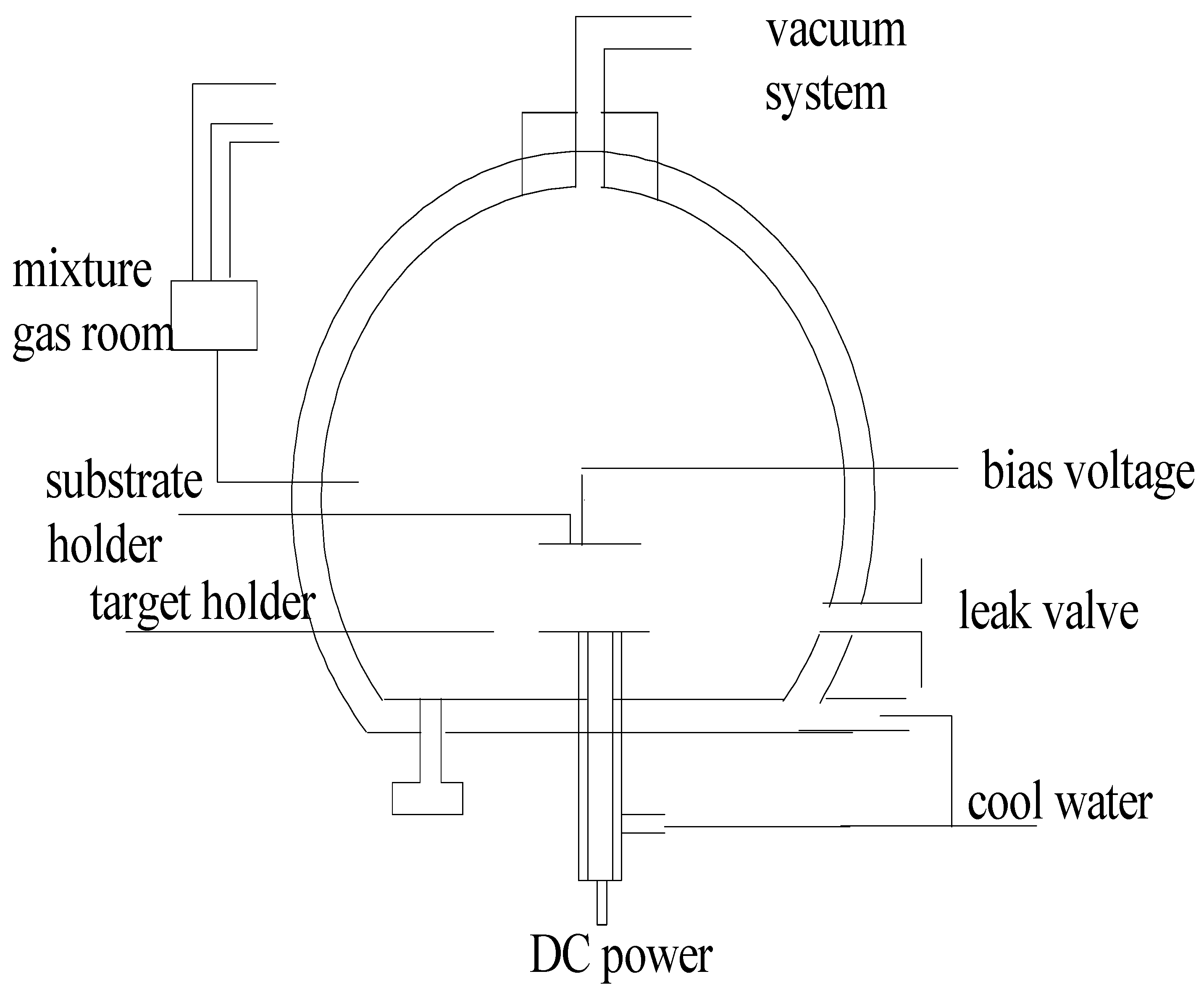

2.1. Film Deposition

2.2. Film Characterization

2.3. Tribological Tests

3. Results

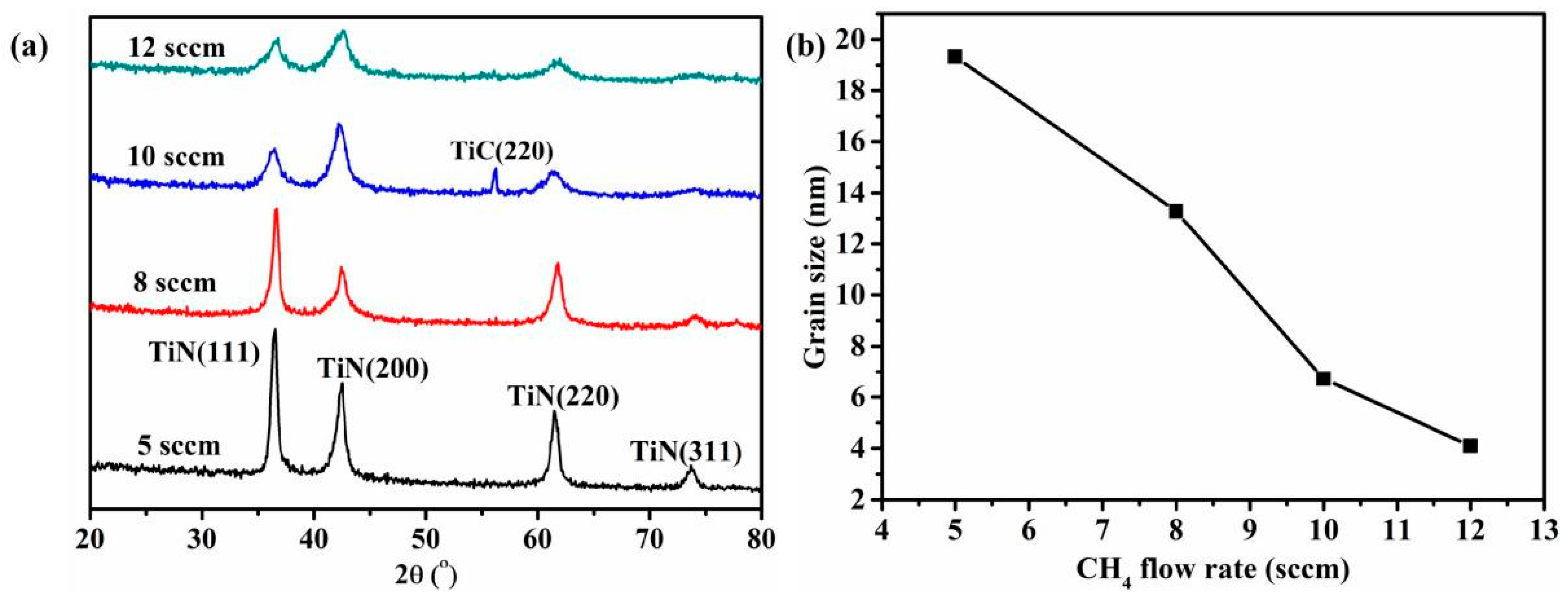

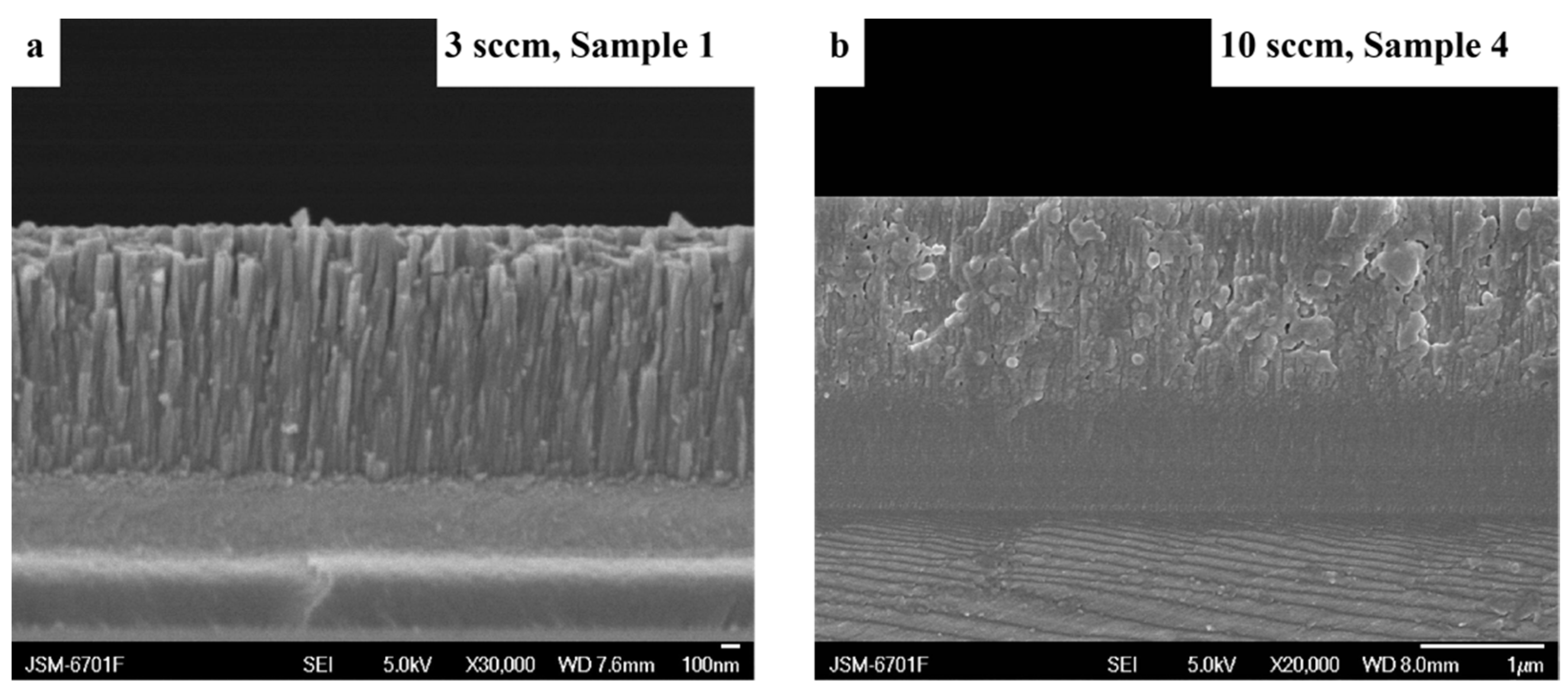

3.1. Composition and Microstructure

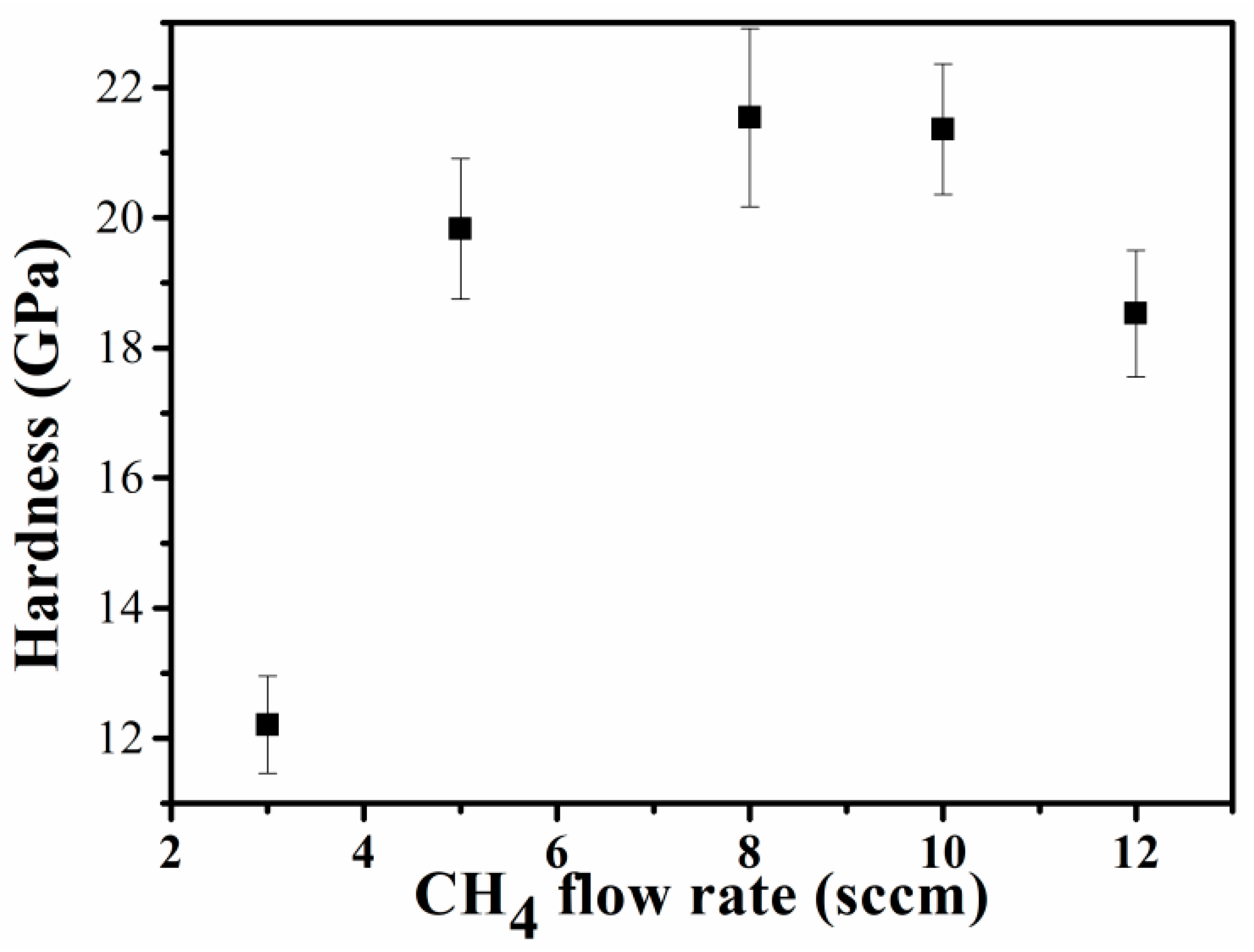

3.2. Nanoindentation Tests

3.3. Tribological Behavior

3.3.1. Against Steel Ball

3.3.2. Against Si3N4 Ball

3.3.3. Comparative Study

4. Conclusions

- The TiCN films displayed a gradual change in microstructure from loose and sharp pyramid-like to dense and globular nanostructure, with an increasing CH4 flow rate. The TiC phase was found in the TiCN film deposited at 10 sccm CH4 flow rates. Along with the rise in CH4 flow rates, the content of amorphous carbon raised. The grain size calculated by Scherrer’s formula decreased from 19.3 nm to 4.1 nm as the CH4 flow rate increased.

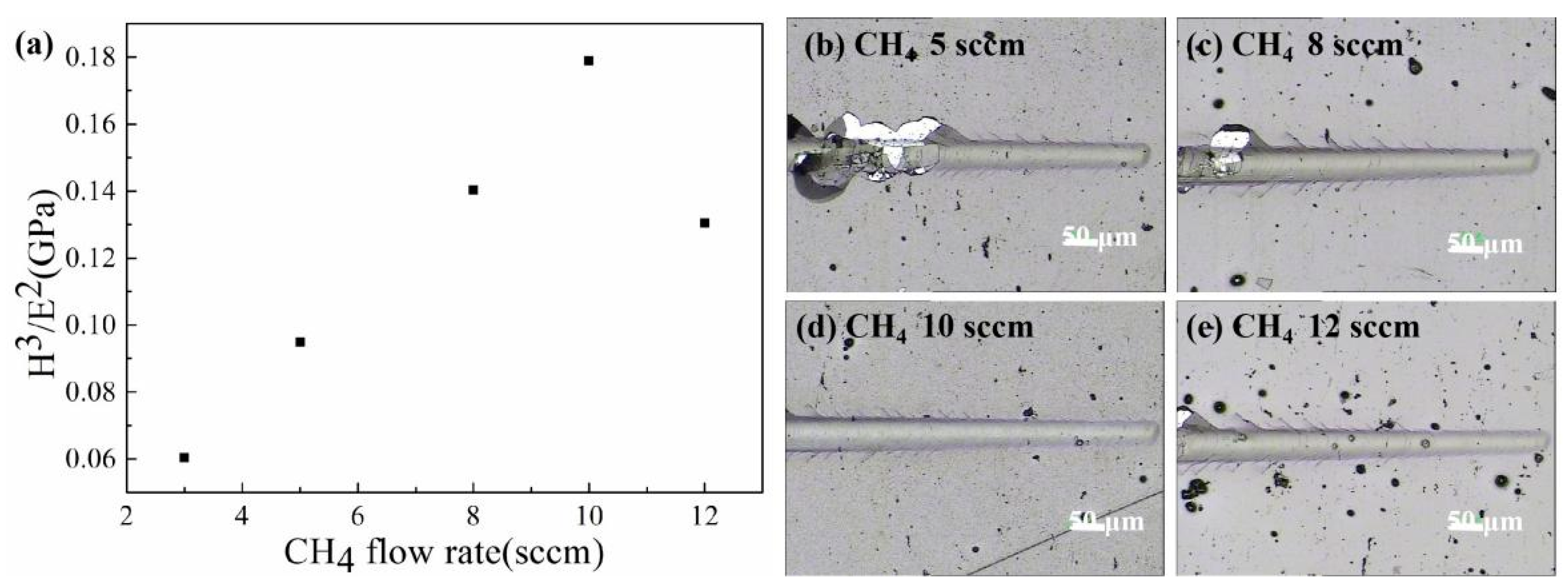

- The TiCN film deposited at 8 sccm CH4 flow rates had an optimal value of hardness. However, the value of H3/E2 of the film deposited under a 10 sccm CH4 flow rate was the uppermost value.

- The COF of the films firstly decreased and then increased by adding a CH4 flow rate while sliding against both the steel and the Si3N4 ball. The TiCN film obtained under a 10 sccm CH4 flow rate exhibited excellent tribological behaviors against both the steel ball and the Si3N4 ball.

- The films presented lower COF and shorter life span against the steel ball than the Si3N4 ball. However, the high hard films exhibited better wear resistance against the Si3N4 ball than the steel ball and vice versa.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, W.R.; Zhou, H.; Yang, S.Z. Nano-indentation and wear-resistance behaviors of TiCN films by pulsed plasma on cemented carbide cutting tool. Mater. Sci. Eng. A 2010, 527, 4767–4770. [Google Scholar] [CrossRef]

- Zhang, F.; He, J.; Chen, K.; Qin, Y.; Li, C.; Yin, F. Microstructure evolution and mechanical properties of TiCN-Cr nano/micro composite coatings prepared by reactive plasma spraying. Appl. Surf. Sci. 2018, 427, 905–914. [Google Scholar] [CrossRef]

- Kumar, T.S.; Jebaraj, A.V.; Shankar, E.; Tamiloli, N.; Sivakumar, K. Metallurgical and mechanical characterization of TiCN/TiAlN and TiAlN/TiCN bilayer nitride coatings. Surf. Inter. 2019, 15, 256–264. [Google Scholar]

- Cheng, Y.H.; Browne, T.; Heckerman, B. Influence of CH4 fraction on the composition, structure, and internal stress of the TiCN coatings deposited by LAFAD technique. Vacuum 2010, 85, 89–94. [Google Scholar] [CrossRef]

- Hsieh, J.; Li, C.; Wu, W.; Tan, A. Synthesis of TiC, N, O coatings by unbalanced magnetron sputtering. J. Mater. Process. Technol. 2003, 140, 662–667. [Google Scholar] [CrossRef]

- Balaceanu, M.; Braic, M.; Braic, V.; Pavelescu, G. Properties of arc plasma deposited TiCN/ZrCN superlattice coatings. Surf. Coat. Technol. 2005, 200, 1084–1087. [Google Scholar] [CrossRef]

- Podchernyaeva, I.A.; Lavrenko, V.A.; Umanskii, A.P.; Koror, A.A.; Timofeeva, I.I.; Yuga, A.I. Electric-spark alloying of structural alloys with a composite based on TiCN-AlN. Powder Metall. Met. Ceram. 2000, 39, 232–238. [Google Scholar] [CrossRef]

- Lackner, J.M.; Waldhauser, W.; Ebner, R.; Bakker, R.J. Chemistry and microstructure of PLD Ti, AlCxN1-x coatings deposited at room temperature. Appl. Phys. A 2004, 79, 1469–1471. [Google Scholar] [CrossRef]

- Bemporad, E.; Pecchio, C.; De Rossi, S.; Carassiti, F. Characterization and hardness modelling of alternate TiN/TiCN multilayer cathodic arc PVD coating on tool steel. Surf. Coat. Technol. 2001, 146, 363–370. [Google Scholar] [CrossRef]

- Huber, P.; Manova, D.; Mandl, S.; Rauschenbach, B. Formation of TiN, TiC and TiCN by metal plasma immersion ion implantation and deposition. Surf. Coat. Technol. 2003, 174, 1243–1247. [Google Scholar] [CrossRef]

- Zheng, J.Y.; Hao, J.Y.; Liu, X.Q.; Gong, Q.Y.; Liu, W.M. TiN/TiCN Multilayer Films Modified by Argon Plasma Treatment. Appl. Surf. Sci. 2013, 280, 764. [Google Scholar] [CrossRef]

- Zheng, J.Y.; Ren, X.D.; Hao, H.Y.; Li, A.; Liu, W.M. Carbon nanohoops as attractive toughening and lubricant agents in TiN porous films. Appl. Surf. Sci. 2017, 393, 60–66. [Google Scholar] [CrossRef]

- Wang, Q.; Jin, X.; Zhou, F. Comparison of mechanical and tribological properties of CrBN coatings modified by Ni or Cu incorporation. Friction 2022, 10, 516. [Google Scholar] [CrossRef]

- Serro, A.P.; Completo, C.; Colaço, R.; dos Santos, F.; Lobato da Silva, C.; Cabral, J.M.S.; Araújo, H.; Pires, E.; Saramago, B. A comparative study of titanium nitrides, TiN, TiNbN and TiCN, as coatings for biomedical applications. Surf. Coat. Technol. 2009, 203, 3701–3707. [Google Scholar] [CrossRef]

- Yang, Y.L.; Yao, W.M.; Zhang, H.Z. Phase constituents and mechanical properties of laser in-situ synthesized TiCN/TiN composite coating on Ti-6Al-4V. Surf. Coat. Technol. 2010, 205, 620–624. [Google Scholar] [CrossRef]

- Canteli, J.A.; Cantero, J.L.; Marín, N.C.; Gómez, B.; Gordo, E.; Miguélez, M.H. Cutting performance of TiCN-HSS cermet in dry machining. J. Mater. Process. Technol. 2010, 210, 122–128. [Google Scholar] [CrossRef]

- Guruvenket, S.; Li, D.; Klemberg-Sapieha, J.E.; Martinu, L.; Szpunar, J. Mechanical and tribological properties of duplex treated TiN, nc-TiN/a-SiNx and nc-TiCN/a-SiCN coatings deposited on 410 low alloy stainless steel. Surf. Coat. Technol. 2009, 203, 2905–2911. [Google Scholar] [CrossRef]

- Su, Y.L.; Kao, W.H. Tribological behavior and wear mechanisms of TiN/TiCN/TiN multilayer coatings. J. Mater. Eng. Perform. 1998, 7, 601–612. [Google Scholar] [CrossRef]

- Eizenberg, M.; Littau, L.; Ghanayem, S.; Liao, M.; Mosely, R.; Sinha, A.K. Chemical vapor deposited TiCN: A new barrier metallization for submicron via and contact applications. J. Vac. Sci. Technol. A 1995, 13, 590–595. [Google Scholar] [CrossRef]

- Klemberg-Sapieha, J.E.; Jedrzejowski, P.; Martinu, L. Mechanical and optical characteristics of superhard nanocomposite TiN/a-Si3N4 and TiCN/a-SiCN coatings produced by PECVD. J. Superhard Mater. 2007, 29, 147–152. [Google Scholar] [CrossRef]

- Escobar-Alarcón, L.; Camps, E.; Romero, S.; Muhl, S.; Camps, I.; Haro-Poniatowski, E. TiCN thin films grown by reactive crossed beam pulsed laser deposition. Appl. Phys. A Mater. Sci. Process. 2010, 101, 771–775. [Google Scholar] [CrossRef]

- Deng, J.G.; Braun, M.; Gudowska, I. Properties of TiCN coatings prepared by magnetron sputtering. J. Vac. Sci. Technol. A 1994, 12, 733–736. [Google Scholar] [CrossRef]

- Rabiei, M.; Palevicius, A.; Monshi, A.; Nasiri, S.; Vilkauskas, A.; Janusas, G. Comparing Methods for Calculating Nano Crystal Size of Natural Hydroxyapatite Using X-Ray Diffraction. Nanomaterials 2020, 10, 1627. [Google Scholar] [CrossRef] [PubMed]

- Klug, H.P.; Alexander, L.E. X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials; Wiley-Interscience: New York, NY, USA, 1974. [Google Scholar]

- Morant, C.; Prieto, P.; Forn, A.; Picas, J.A.; Elizalde, E.; Sanz, J.M. Hardness enchancement by CN/TiCN/TiN multilayer films. Surf. Coat. Technol. 2004, 180, 512–518. [Google Scholar] [CrossRef]

- Caicedo, J.C.; Amaya, C.; Yate, L.; Gómez, M.E.; Zambrano, G.; Alvarado-Rivera, J.; Muñoz-Saldaña, J.; Prieto, P. TiCN/TiNbCN multilayer coatings with enhanced mechanical properties. Appl. Surf. Sci. 2010, 256, 5898–5904. [Google Scholar] [CrossRef]

- Zukerman, I.; Raveh, A.; Landau, Y.; Weiss, R.; Shneck, R.; Shneor, Y.; Kalman, H.; Klemberg-Saphieha, J.E.; Martinu, L. Tribological properties of duplex treated TiN/TiCN coatings on plasma nitrided PH15-5 steel. Surf. Coat. Technol. 2007, 201, 6171–6175. [Google Scholar] [CrossRef]

- Polcar, T.; Novák, R.; Široký, P. The tribological characteristics of TiCN coating at elevated temperatures. Wear 2006, 260, 40–49. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H. Sliding tribological behaviors of PVD CrN and AlCrN coatings against Si3N4 ceramic and pure titanium. Wear 2009, 267, 874–881. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Lei, B.; Leng, Y.X.; Huang, N. Comparison of tribological behaviours of AlCrN and TiAlN coatings deposited by physical vapor deposition. Wear 2007, 263, 1423–1429. [Google Scholar] [CrossRef]

- Hager, C.H., Jr.; Sanders, J.; Sharma, S.; Voevodin, A. Gross slip fretting wear of CrCN, TiAlN, Ni, and CuNiIn coatings on Ti6Al4V interfaces. Wear 2007, 263, 430–443. [Google Scholar] [CrossRef]

| CH4 (sccm) | Ti (at.%) | C (at.%) | N (at.%) | O (at.%) |

|---|---|---|---|---|

| 3 | 26.70 | 29.05 | 22.95 | 21.30 |

| 5 | 21.49 | 37.17 | 20.08 | 21.26 |

| 8 | 11.69 | 65.75 | 10.79 | 11.77 |

| 10 | 9.28 | 69.96 | 7.66 | 13.10 |

| 12 | 7.32 | 70.42 | 10.13 | 12.13 |

| Samples | CH4 (sccm) | Wear Rate (10−6 mm3/N·m) | |

|---|---|---|---|

| Against Steel Ball | Against Si3N4 Ball | ||

| 2 | 5 | 3.35 | 3.52 |

| 3 | 8 | 5.90 | 2.33 |

| 4 | 10 | 2.43 | 2.08 |

| 5 | 12 | 4.12 | 5.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, Y.; Zheng, J.; Sun, H.; Deng, X.; Liu, Y.; Zhang, Q. Effect of CH4 Flow Rate on the Tribological Behaviors of TiCN Films against Si3N4 Ceramic and Steel Ball. Lubricants 2023, 11, 209. https://doi.org/10.3390/lubricants11050209

Lyu Y, Zheng J, Sun H, Deng X, Liu Y, Zhang Q. Effect of CH4 Flow Rate on the Tribological Behaviors of TiCN Films against Si3N4 Ceramic and Steel Ball. Lubricants. 2023; 11(5):209. https://doi.org/10.3390/lubricants11050209

Chicago/Turabian StyleLyu, Yanhong, Jianyun Zheng, Huilian Sun, Xinrong Deng, Yang Liu, and Qiaoyu Zhang. 2023. "Effect of CH4 Flow Rate on the Tribological Behaviors of TiCN Films against Si3N4 Ceramic and Steel Ball" Lubricants 11, no. 5: 209. https://doi.org/10.3390/lubricants11050209

APA StyleLyu, Y., Zheng, J., Sun, H., Deng, X., Liu, Y., & Zhang, Q. (2023). Effect of CH4 Flow Rate on the Tribological Behaviors of TiCN Films against Si3N4 Ceramic and Steel Ball. Lubricants, 11(5), 209. https://doi.org/10.3390/lubricants11050209