Effect of Grease Viscosity on Channeling Properties of Ball Bearings

Abstract

:1. Introduction

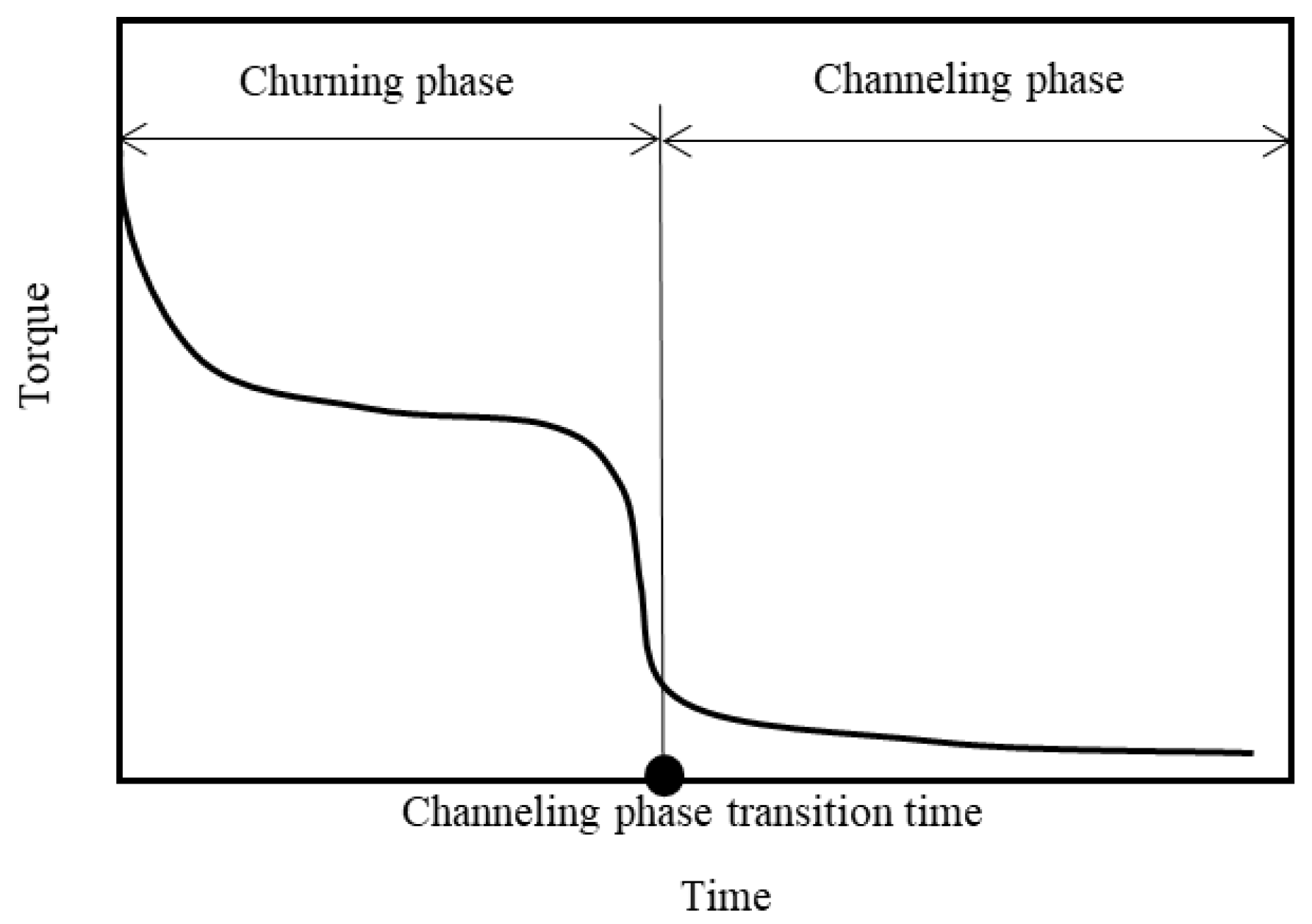

2. Proposed Mechanism of Transition to Channeling Phase in Bearings

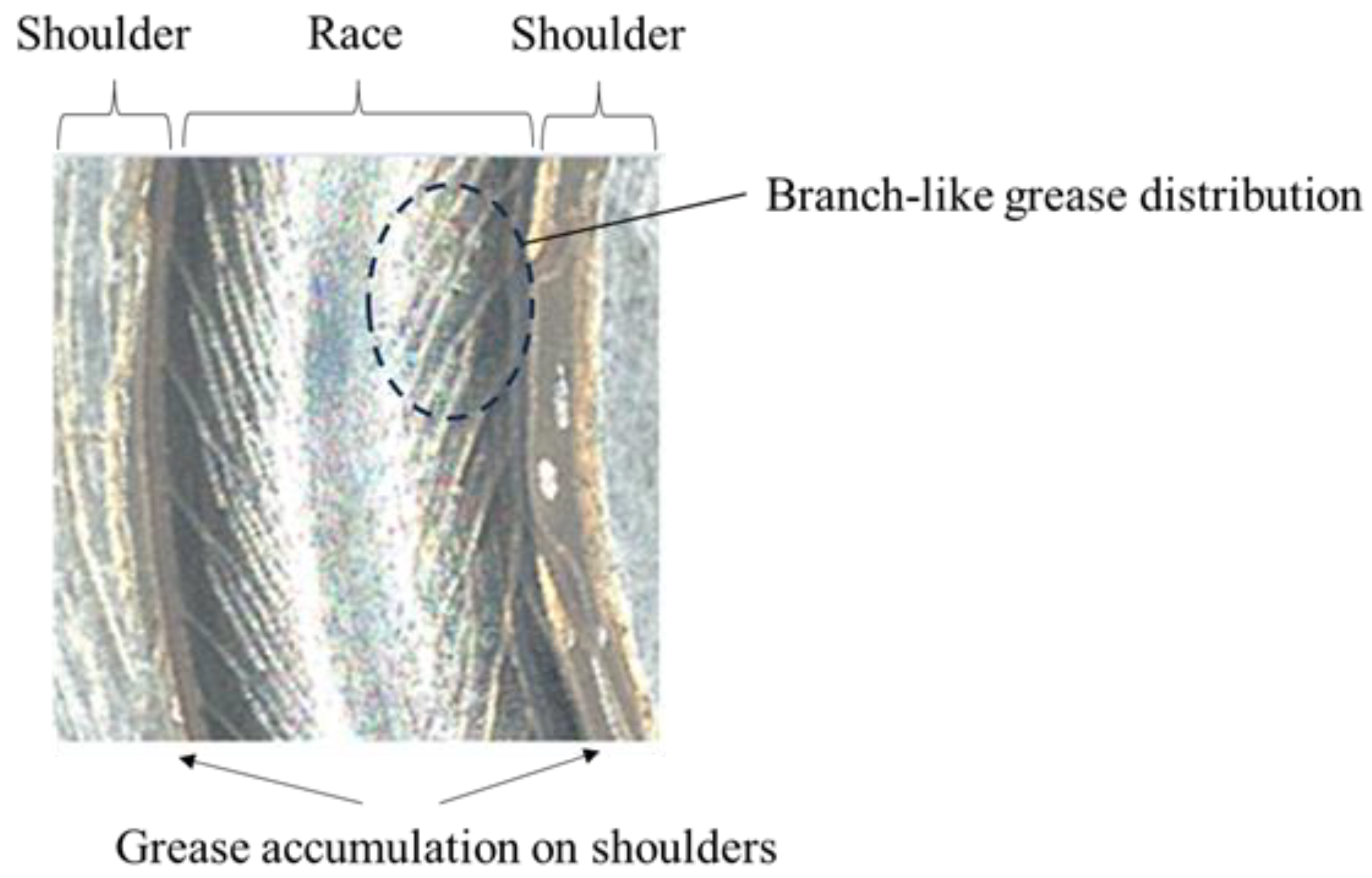

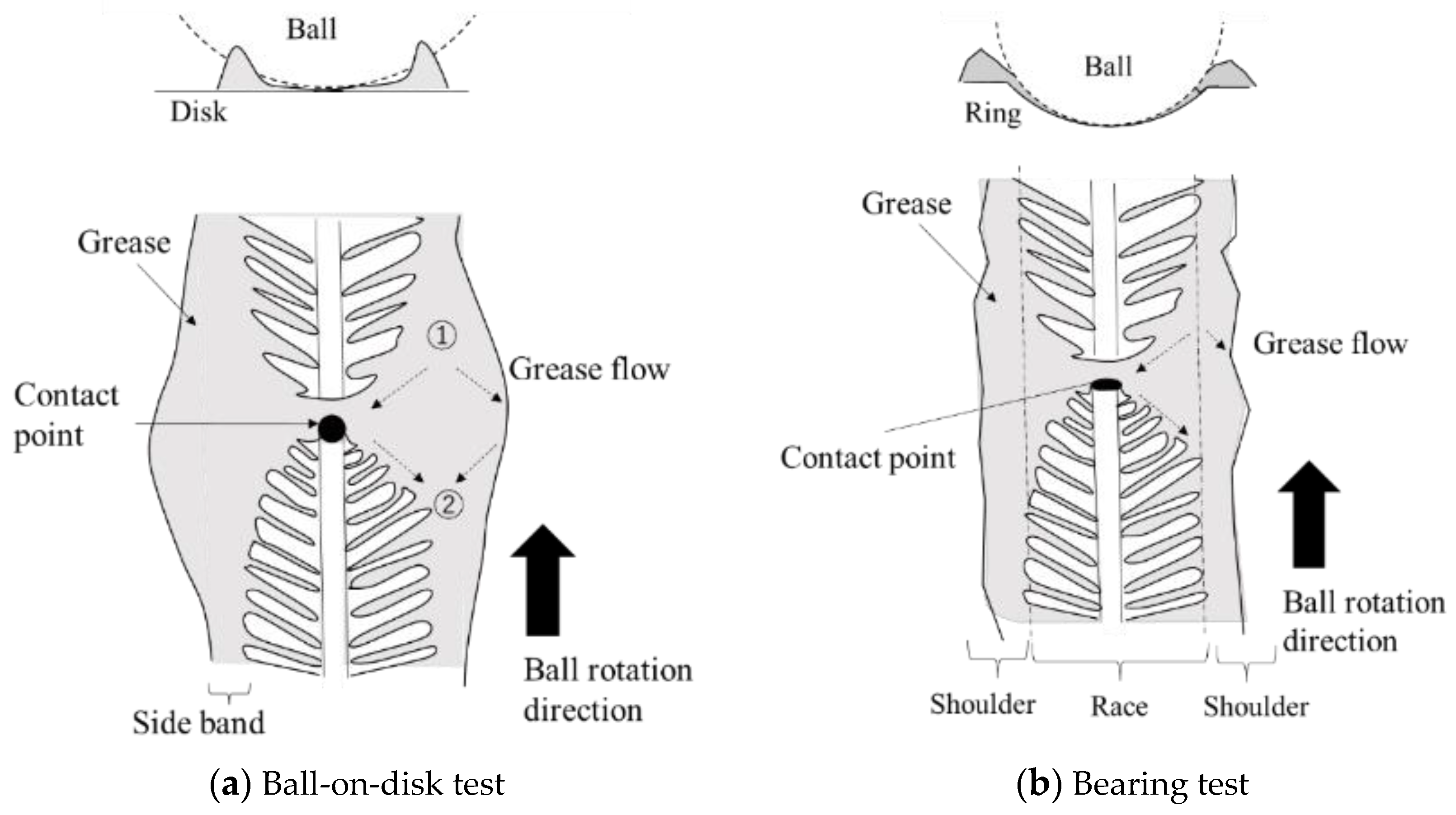

2.1. Observation of Grease Flow in Bearing

2.2. Effect of Bearing Shoulders on Grease Flow

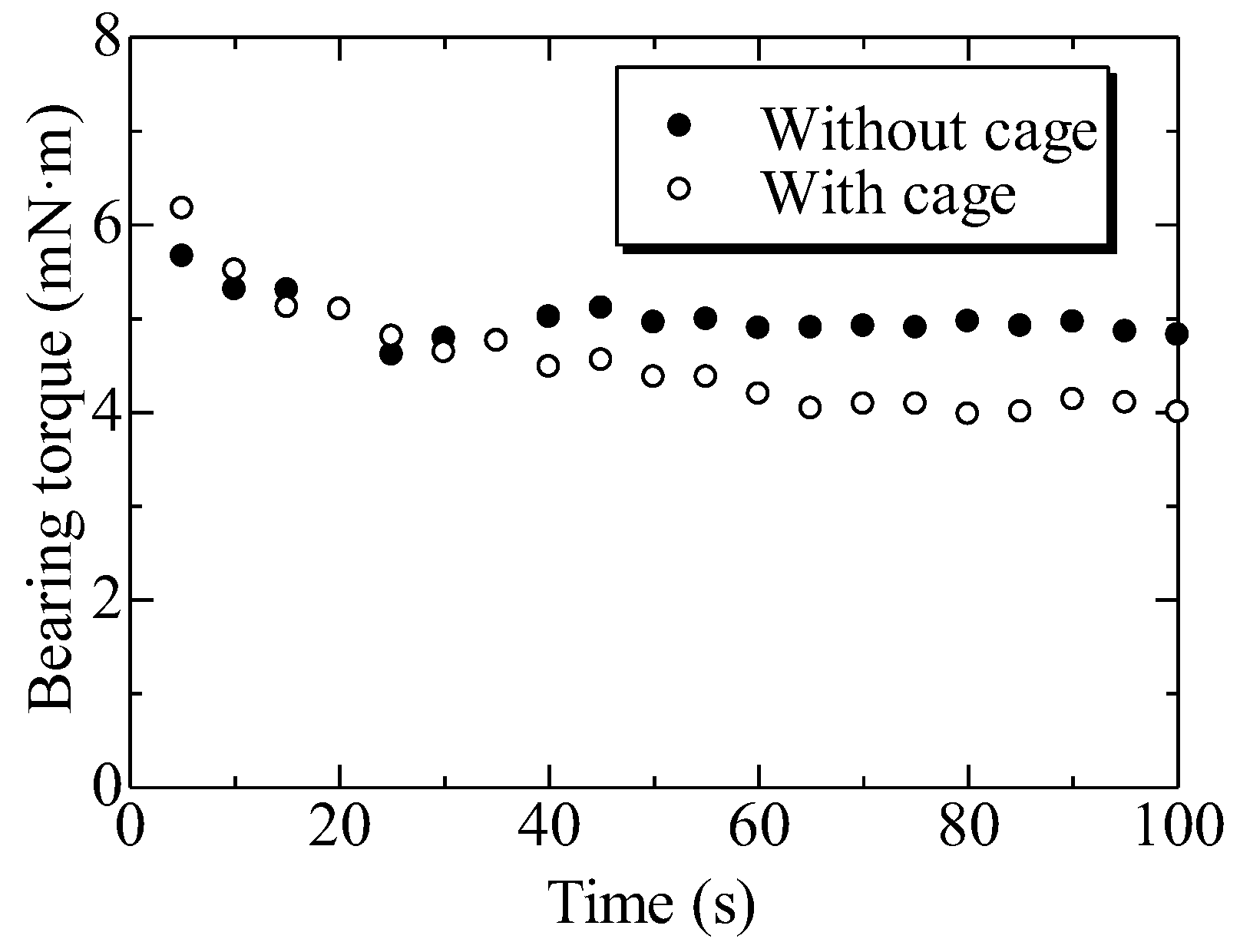

2.3. Effect of Cage on Grease Flow

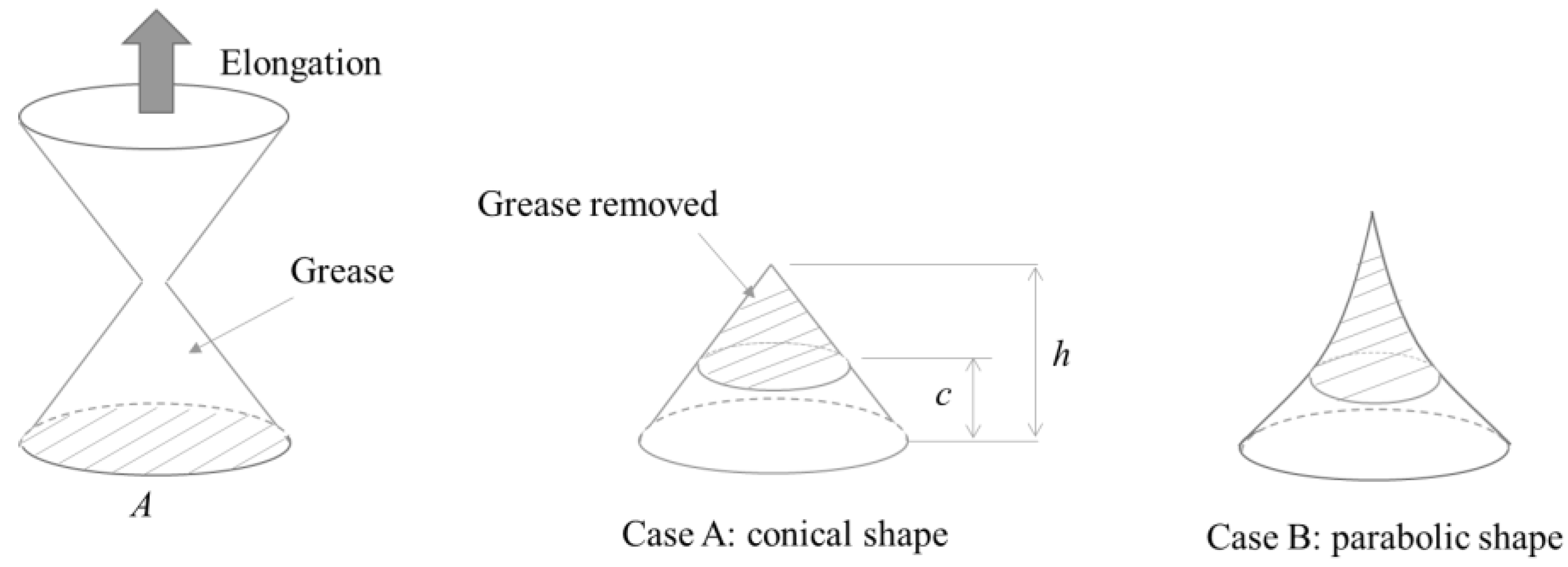

2.4. Mechanism of Grease Reduction on Lubricated Surfaces

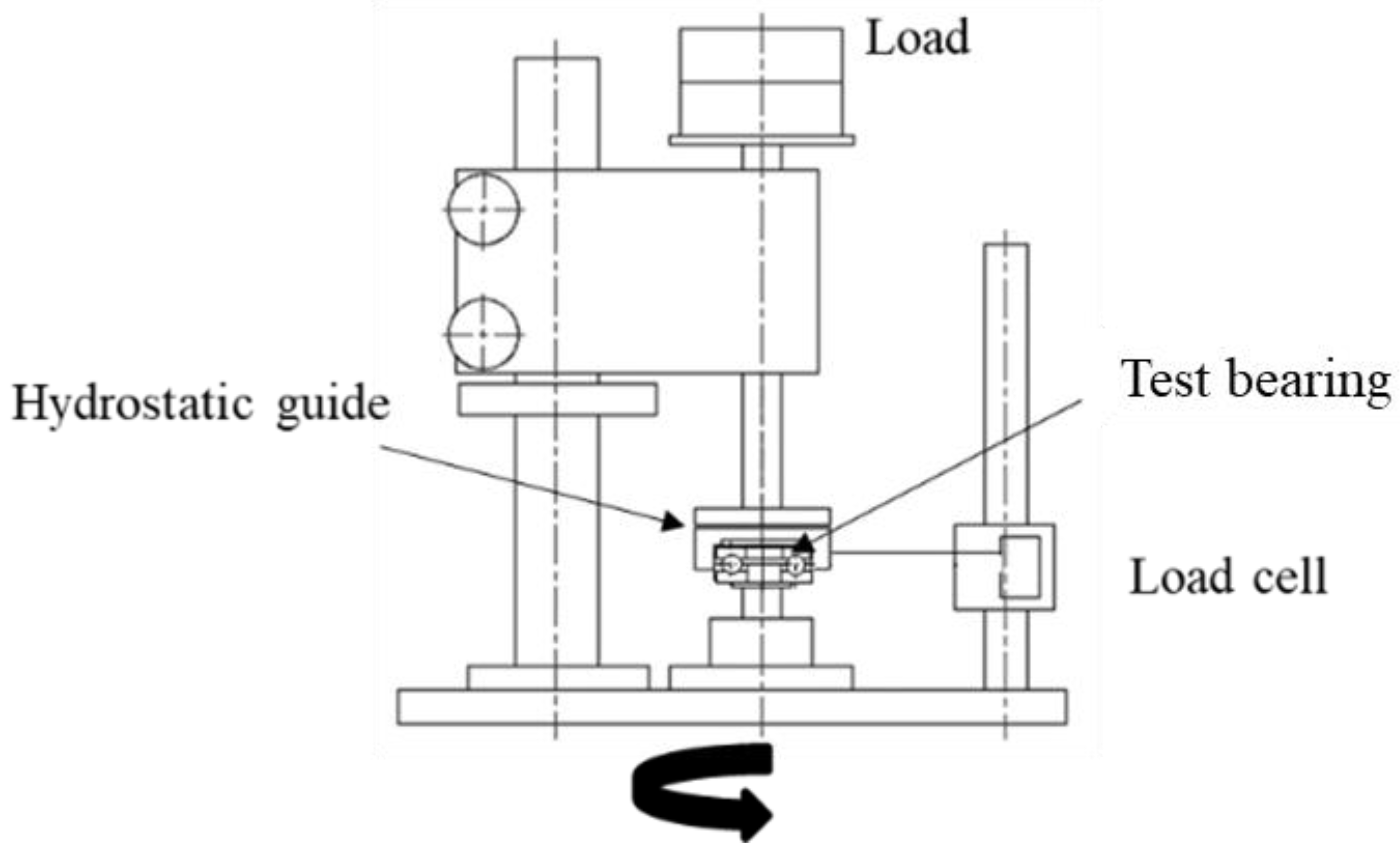

3. Material and Method

3.1. Grease Properties for Flow during Elongation

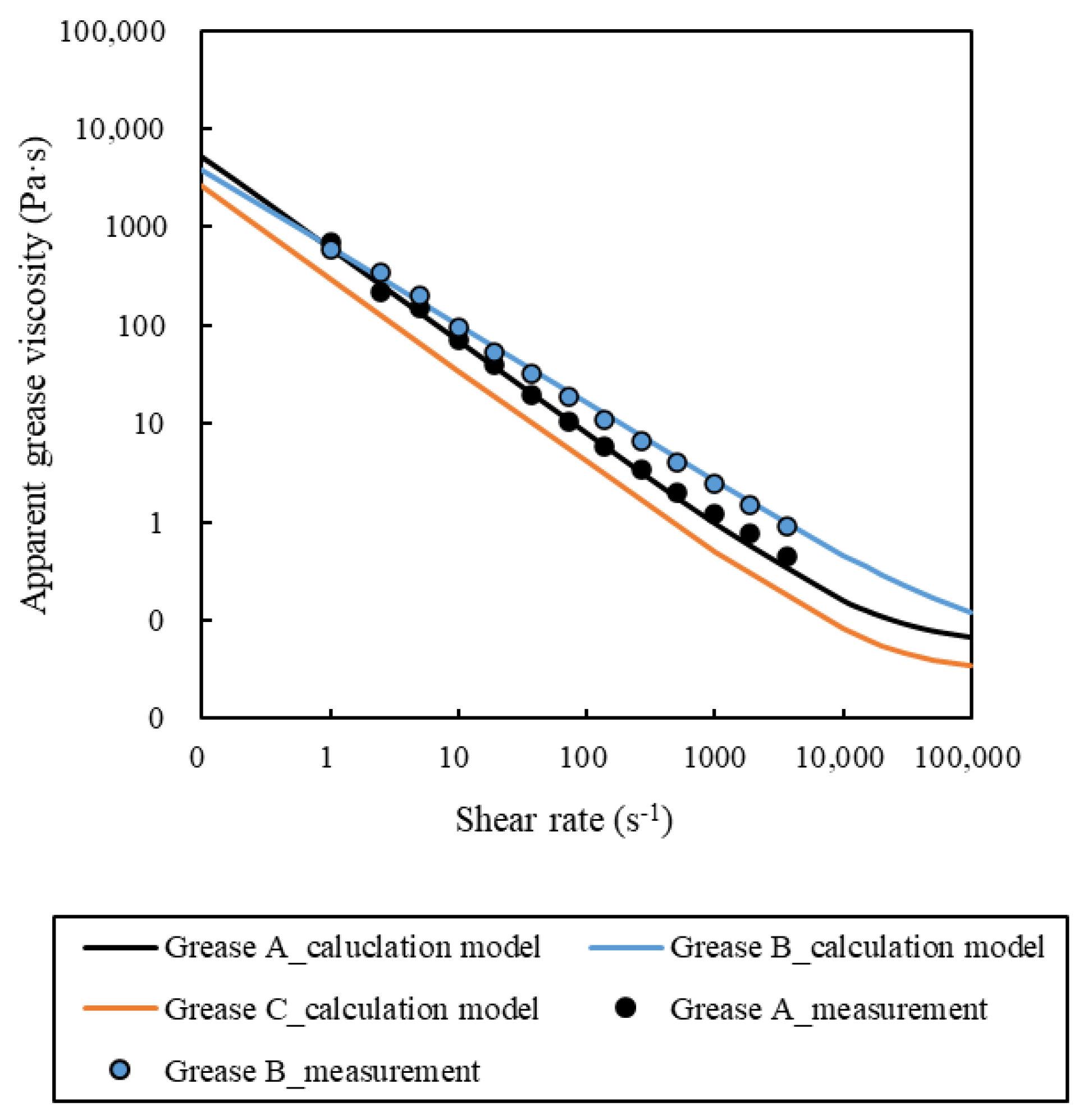

3.1.1. Grease Model

3.1.2. Grease Elongation Model

3.2. Channeling Properties of Bearings

3.2.1. Sample Grease

3.2.2. Operating Conditions for Bearings

4. Result and Discussion

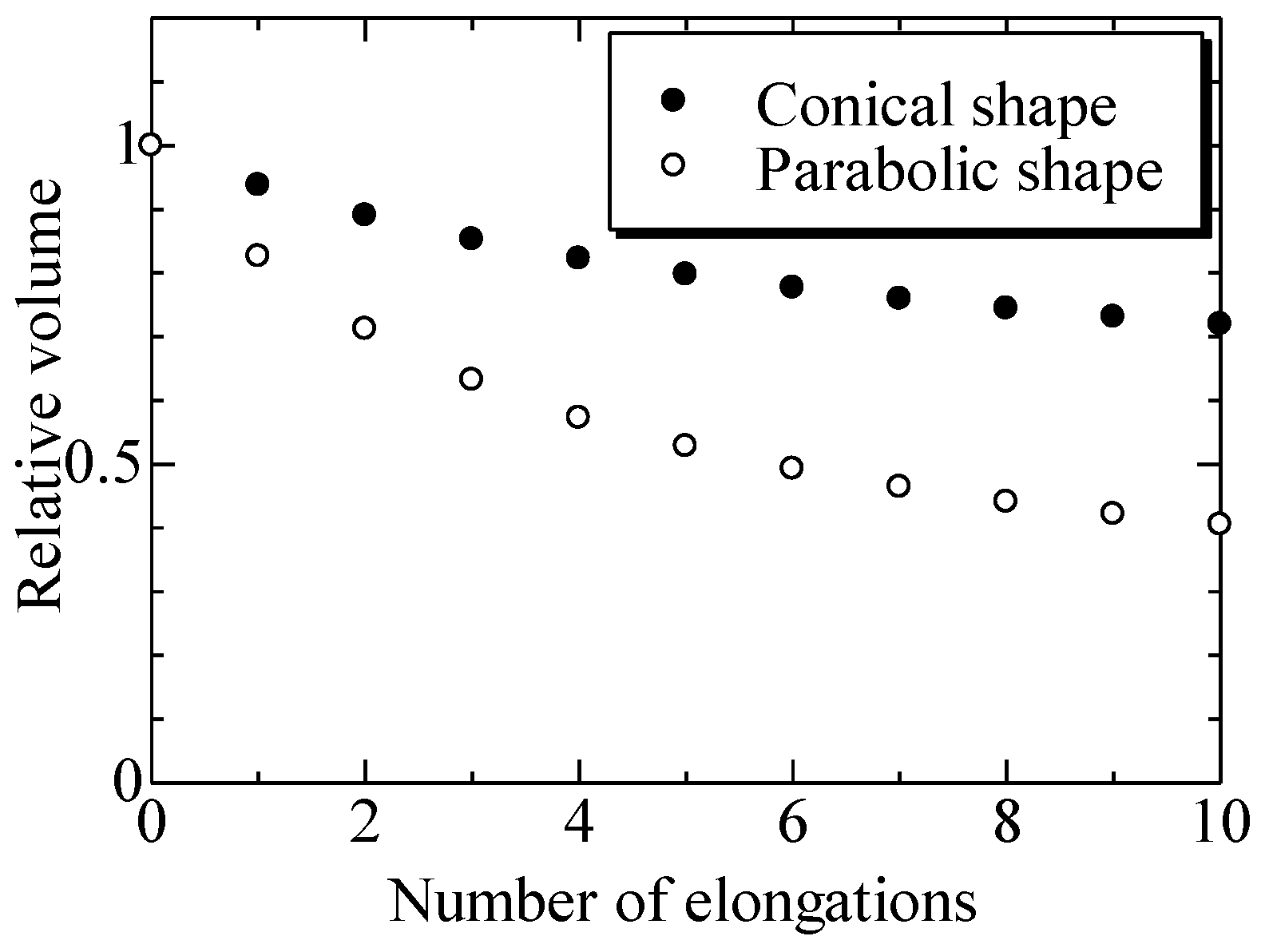

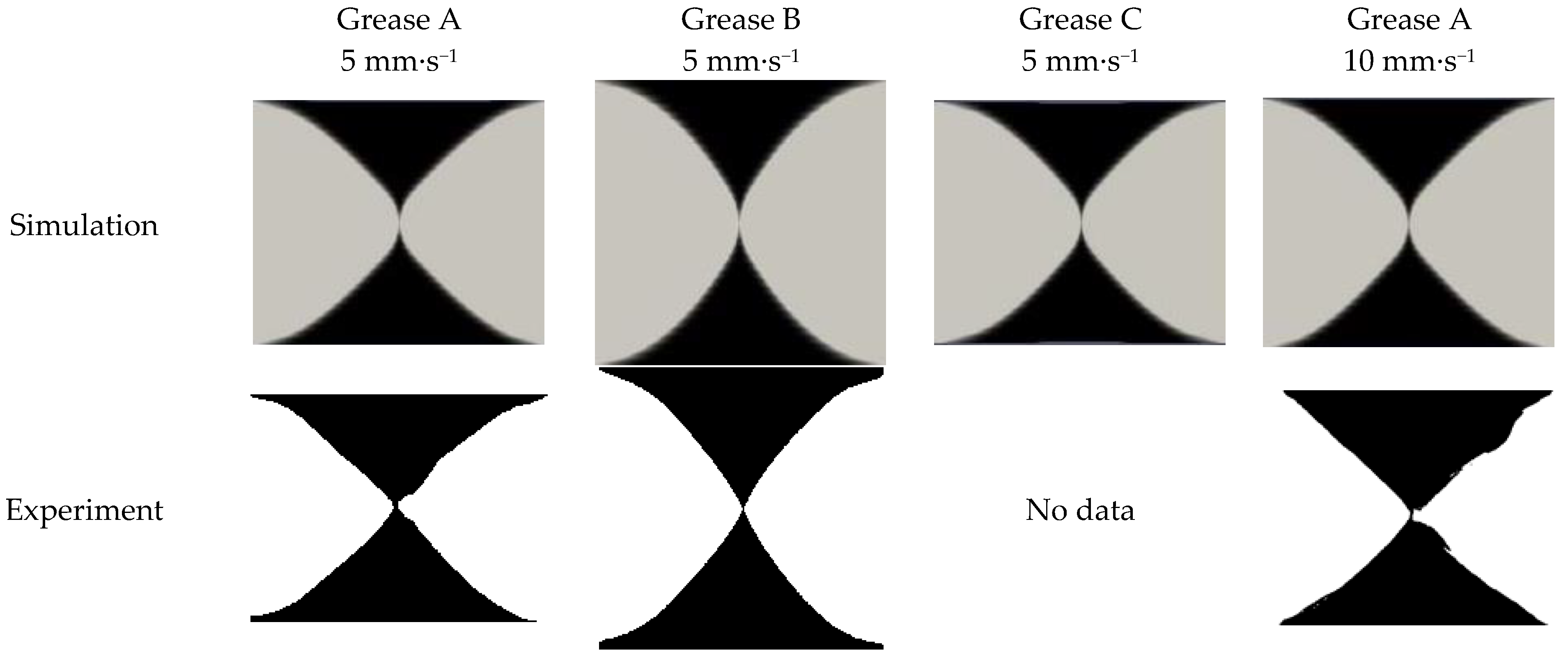

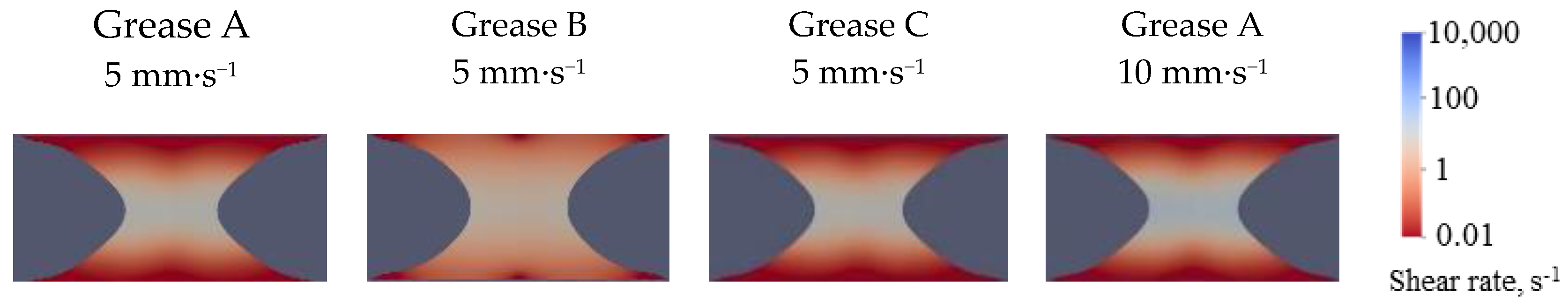

4.1. Grease Flow Analysis during Elongation

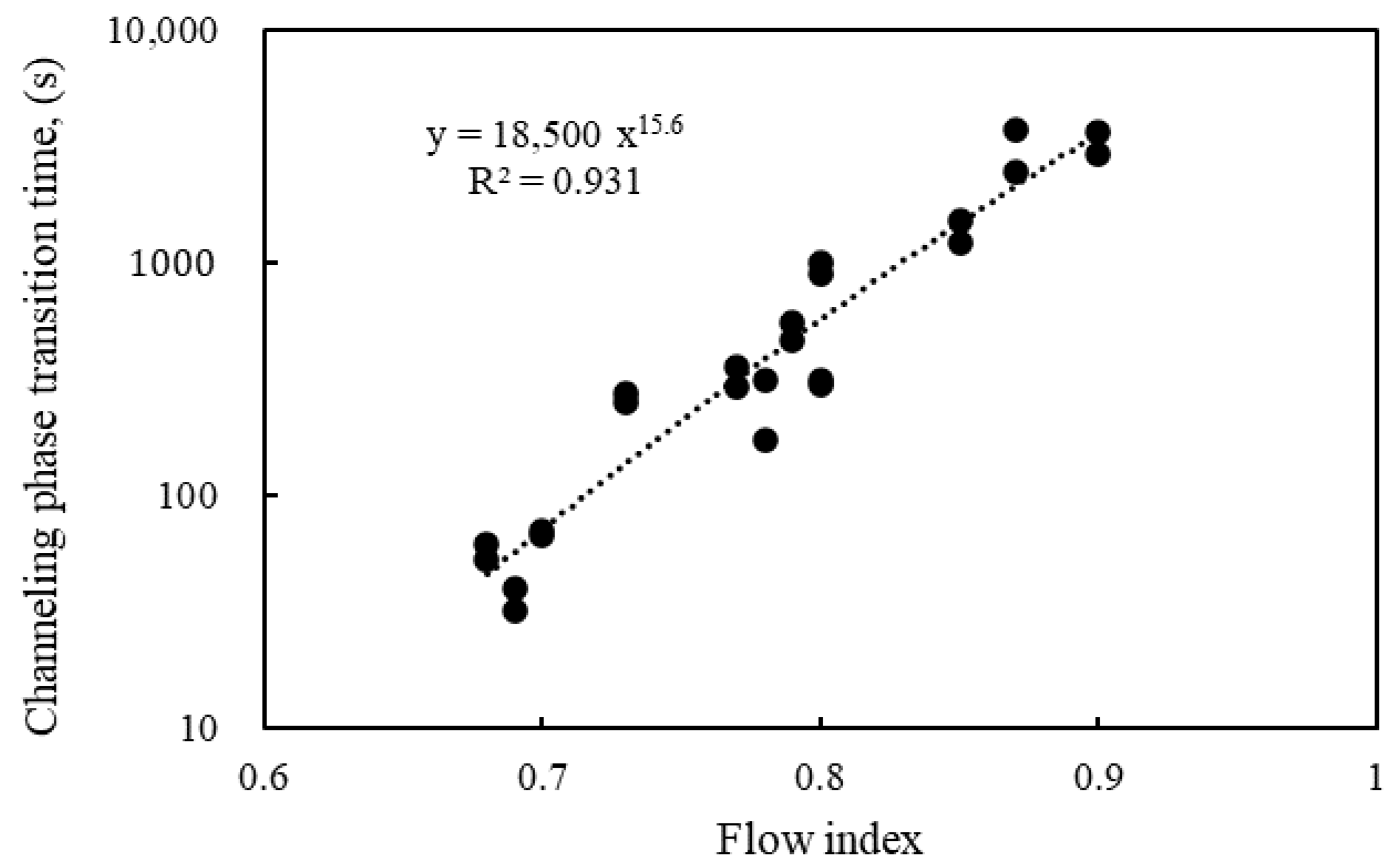

4.2. Evaluation of Channeling Properties of Bearings

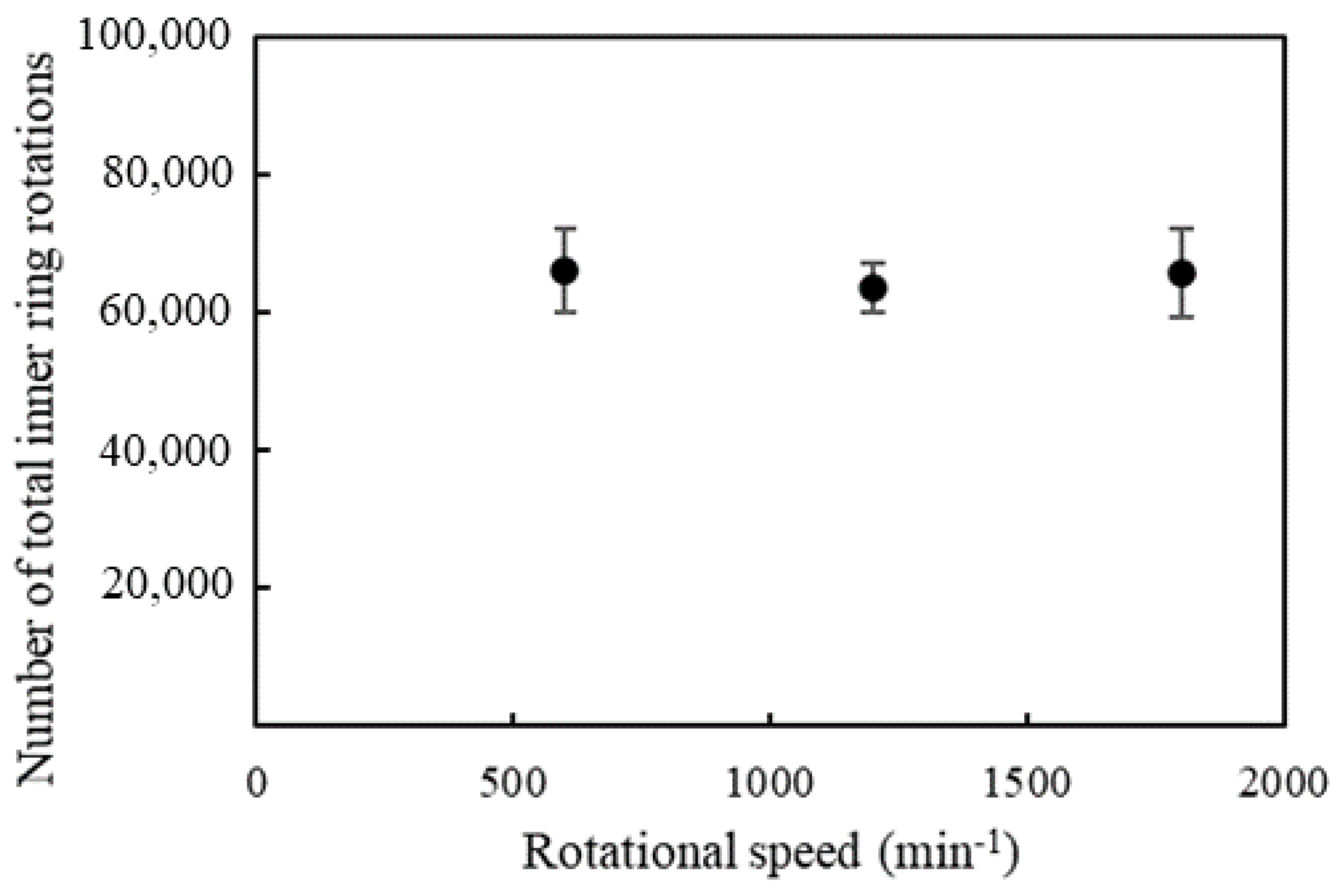

4.3. Relationship between Channeling Phase Transition Time and Rotational Speed

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qiang, H.; Anling, L.; Yuan, S.; Lili, L.; Zeqiang, L.; Benliu, P. Design and application on experimental platform for high-speed bearing with grease lubrication. Adv. Mech. Eng. 2015, 7, 1687814015618640. [Google Scholar] [CrossRef]

- Akutsu, T.; Masuko, M.; Suzuki, A. Structural Change of Lubricating Grease Considered from Viscous Reduction by Shear. J. Jpn. Soc. Tribol. 2007, 52, 445–452. (In Japanese) [Google Scholar]

- Cousseau, T.; Graça, B.M.; Campos, A.V.; Seabra, J.H. Influence of grease rheology on thrust ball bearings friction torque. Tribol. Int. 2012, 46, 106–113. [Google Scholar] [CrossRef]

- Cousseau, T.; Graça, B.; Campos, A.; Seabra, J. Friction torque in grease lubricated thrust ball bearings. Tribol. Int. 2011, 44, 523–531. [Google Scholar] [CrossRef]

- Horth, A.C.; Norton, J.H.; Paltenden, W.C. Temperature rise characteristics of greases in rolling element bearings. Lubr. Eng. 1971, 27, 380–385. [Google Scholar]

- Lugt, P.M. Grease Lubrication in Rolling Bearings; Wiley: Hoboken, NJ, USA, 2012; ISBN 9781118353912. [Google Scholar]

- Sakai, K.; Kostal, D.; Shitara, Y.; Kaneta, M.; Krupka, I.; Hartl, M. Influence of Li Grease Thickener Types on Film Thicknesses Formed between Smooth and Dented Surfaces. Tribol. Online 2017, 12, 262–273. [Google Scholar] [CrossRef]

- Noda, T.; Shibasaki, K.; Miyata, S.; Taniguchi, M. X-ray CT Imaging of Grease Behavior in Ball Bering and Numerical Vali-dation of Multi-Phase Flows Simulation. Tribol. Online 2020, 15, 36–44. [Google Scholar] [CrossRef]

- Oikawa, E.; Inami, N.; Hokao, M.; Yokouchi, A.; Sugimura, J. Bearing torque characteristics of lithium soap greases with some synthetic base oils. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 226, 575–583. [Google Scholar] [CrossRef]

- Hoshino, M. Flow properties of lubricating greases and Torque in Rolling Bearings. J. Jpn. Soc. Lubr. Eng. 1980, 25, 547–561. (In Japanese) [Google Scholar]

- Lugt, P.M. A Review on Grease Lubrication in Rolling Bearings. Tribol. Trans. 2009, 52, 470–480. [Google Scholar] [CrossRef]

- Chatra, K.S.; Osara, J.A.; Lugt, P.M. Impact of grease churning on grease leakage, oil bleeding and grease rheology. Tribol. Int. 2022, 176, 107926. [Google Scholar] [CrossRef]

- Miyanaga, N.; Nihei, M.; Tomioka, J. Effects of Flow Properties of Lithium Soap Greases on Bearing Torque. Key Eng. Mater. 2019, 823, 123–127. [Google Scholar] [CrossRef]

- Cann, P. Grease degradation in a bearing simulation device. Tribol. Int. 2006, 39, 1698–1706. [Google Scholar] [CrossRef]

- Chatra, K.R.; Lugt, P.M. Channeling behavior of lubricating greases in rolling bearings: Identification and characterization. Tribol. Int. 2019, 143, 106061. [Google Scholar] [CrossRef]

- Chatra, K.R.; Lugt, P.M. The process of churning in a grease lubricated rolling bearing: Channeling and clearing. Tribol. Int. 2021, 153, 106661. [Google Scholar] [CrossRef]

- Chatra, K.R.; Osara, J.A.; Lugt, P.M. Thermo-mechanical aging during churning in grease lubricated bearings and its impact on grease life. Tribol. Int. 2023, 181, 108248. [Google Scholar] [CrossRef]

- Acar, N.; Franco, J.M.; Kuhn, E. On the shear-induced structural degradation of lubricating greases and associated activation energy: An experimental rheological study. Tribol. Int. 2019, 144, 106105. [Google Scholar] [CrossRef]

- Zhou, Y.; Lugt, P.M. On the application of the mechanical aging Master Curve for lubricating greases to rolling bearings. Tribol. Int. 2020, 141, 105918. [Google Scholar] [CrossRef]

- Osara, J.A.; Chatra, S.; Lugt, P.M. Grease material properties from first principles thermodynamics. Lubr. Sci. 2023, 36, 36–50. [Google Scholar] [CrossRef]

- Cen, H.; Lugt, P.M. Replenishment of the EHL conatacts in a grease lubricated ball bearing. Tribol. Int. 2020, 146, 106064. [Google Scholar] [CrossRef]

- Cann, P.; Damiens, B.; Lubrecht, A. The transition between fully flooded and starved regimes in EHL. Tribol. Int. 2004, 37, 859–864. [Google Scholar] [CrossRef]

- Åström, H.; Östensen, J.O.; Höglund, E. Lubricating Grease Replenishment in an Elastohydrodynamic Point Contact. J. Tribol. 1993, 115, 501–506. [Google Scholar] [CrossRef]

- Obata, T.; Itoigawa, F. Quantitative Observation of Grease Behavior for Rolling Bearings Using Splitting Phenomena of Colorant. J. Jpn. Soc. Tribol. 2022, 67, 54–60. (In Japanese) [Google Scholar]

- Delgado, M.A.; Secouard, S.; Valencia, C.; Franco, J.M. On the Steady-State Flow and Yielding Behaviour of Lubricating Greases. Fluids 2019, 4, 6. [Google Scholar] [CrossRef]

- Hodapp, A.; Conrad, A.; Hochstein, B.; Jacob, K.-H.; Willenbacher, N. Effect of Base Oil and Thickener on Texture and Flow of Lubricating Greases: Insights from Bulk Rheometry, Optical Microrheology and Electron Microscopy. Lubricants 2022, 10, 55. [Google Scholar] [CrossRef]

- Abdulrazaq, M.; Shahmardi, A.; Rosti, M.E.; Brandt, L. Numerical modelling of the extensional dynamics in elastovisco-plastic fluids. J. Nonnewton Fluid Mech. 2023, 318, 105060. [Google Scholar] [CrossRef]

- Nelson, A.Z.; Ewoldt, R.H. Design of yield-stress fluids: A rheology-to-structure inverse problem. Soft Matter 2017, 13, 7578–7594. [Google Scholar] [CrossRef]

- Mubashshir, M.; Shaukat, A. The Role of Grease Composition and Rheology in Elastohydrodynamic Lubrication. Tribol. Lett. 2019, 67, 104. [Google Scholar] [CrossRef]

- Cross, M.M. Rheology of non-Newtonian fluids: A new flow equation for pseudoplastic systems. J. Colloid Sci. 1965, 20, 417–437. [Google Scholar] [CrossRef]

- OpenFOAM Foundation. OpenFOAM User Guide. Available online: http://www.openfoam.org/docs/user/ (accessed on 15 November 2023).

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

| Bearing | 51204 |

| Rotational speed (min−1) | 1200 |

| Time (s) | 100 |

| Axial load (N) | 20 |

| Grease amount (g) | 0.1 |

| Room temperature (°C) | 25 |

| Sample | Grease A | Grease B | Grease C |

|---|---|---|---|

| ηγ=0 (Pa·s) | 130,000 | 70,000 | 65,000 |

| ηγ=∞ (Pa·s) | 0.056 | 0.056 | 0.028 |

| m | 300 | 350 | 300 |

| n | 0.94 | 0.8 | 0.94 |

| Sample Grease | Kinetic Viscosity of Base Oil (mm2·s−1 @40 °C) | Thickener | Worked Penetration | Flow Index, n | |

|---|---|---|---|---|---|

| Type | Content Rate (mass%) | ||||

| A1 | 32 | Lithium soap | 7.0 | 241 | 0.90 |

| A2 | 72 | Lithium soap | 7.0 | 230 | 0.85 |

| A3 | 104 | Lithium soap | 7.0 | 234 | 0.80 |

| A4 | 167 | Lithium soap | 7.0 | 215 | 0.79 |

| B1 | 32 | Alicyclic diurea | 16.0 | 244 | 0.80 |

| B2 | 72 | Alicyclic diurea | 16.0 | 236 | 0.73 |

| B3 | 104 | Alicyclic diurea | 16.0 | 206 | 0.70 |

| B4 | 167 | Alicyclic diurea | 16.0 | 175 | 0.68 |

| C1 | 32 | Aliphatic diurea | 9.0 | 251 | 0.87 |

| C2 | 167 | Aliphatic diurea | 9.0 | 223 | 0.78 |

| D1 | 32 | Aromatic diurea | 21.4 | 298 | 0.77 |

| D2 | 167 | Aromatic diurea | 21.4 | 262 | 0.69 |

| Bearing | 6204 |

| Rotational speed (min−1) | 1200 |

| Axial load (N) | 20 |

| Room temperature (°C) | 25 |

| Number of tests | 2 |

| Bearing | 6204 |

| Rotational speed (min−1) | 600, 1200, 1800 |

| Axial load (N) | 20 |

| Room temperature (°C) | 25 |

| Number of tests | 2 |

| Grease | A1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obata, T.; Fujiwara, H.; Itoigawa, F.; Maegawa, S. Effect of Grease Viscosity on Channeling Properties of Ball Bearings. Lubricants 2024, 12, 13. https://doi.org/10.3390/lubricants12010013

Obata T, Fujiwara H, Itoigawa F, Maegawa S. Effect of Grease Viscosity on Channeling Properties of Ball Bearings. Lubricants. 2024; 12(1):13. https://doi.org/10.3390/lubricants12010013

Chicago/Turabian StyleObata, Tomohiko, Hiroki Fujiwara, Fumihiro Itoigawa, and Satoru Maegawa. 2024. "Effect of Grease Viscosity on Channeling Properties of Ball Bearings" Lubricants 12, no. 1: 13. https://doi.org/10.3390/lubricants12010013

APA StyleObata, T., Fujiwara, H., Itoigawa, F., & Maegawa, S. (2024). Effect of Grease Viscosity on Channeling Properties of Ball Bearings. Lubricants, 12(1), 13. https://doi.org/10.3390/lubricants12010013