Effect of Nb Addition on the Corrosion and Wear Resistance of Laser Clad AlCr2FeCoNi High-Entropy Alloy Coatings

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure and Hardness

3.1.1. Microstructure Evolution

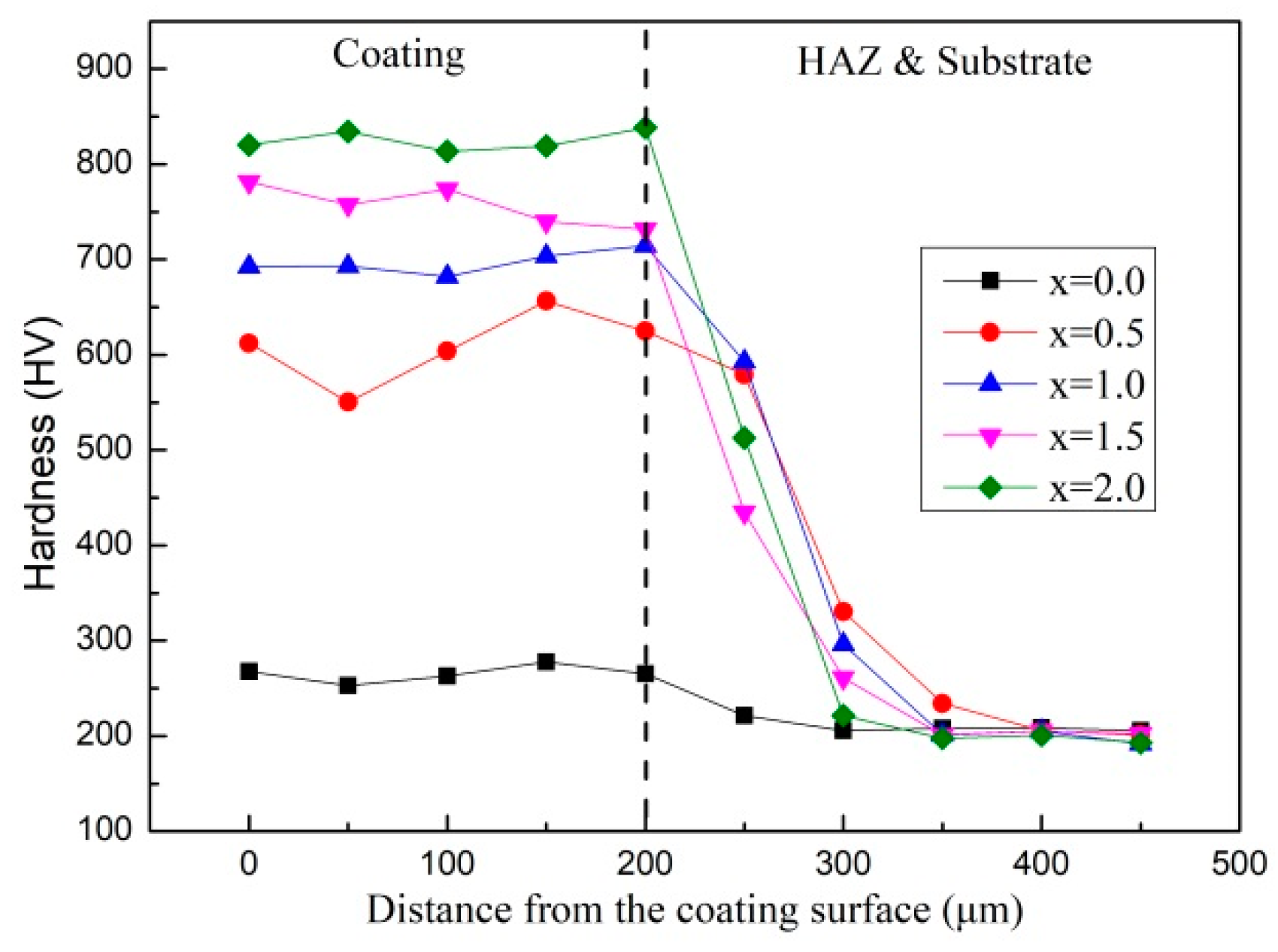

3.1.2. Hardness Evolution

3.2. Corrosion Resistance

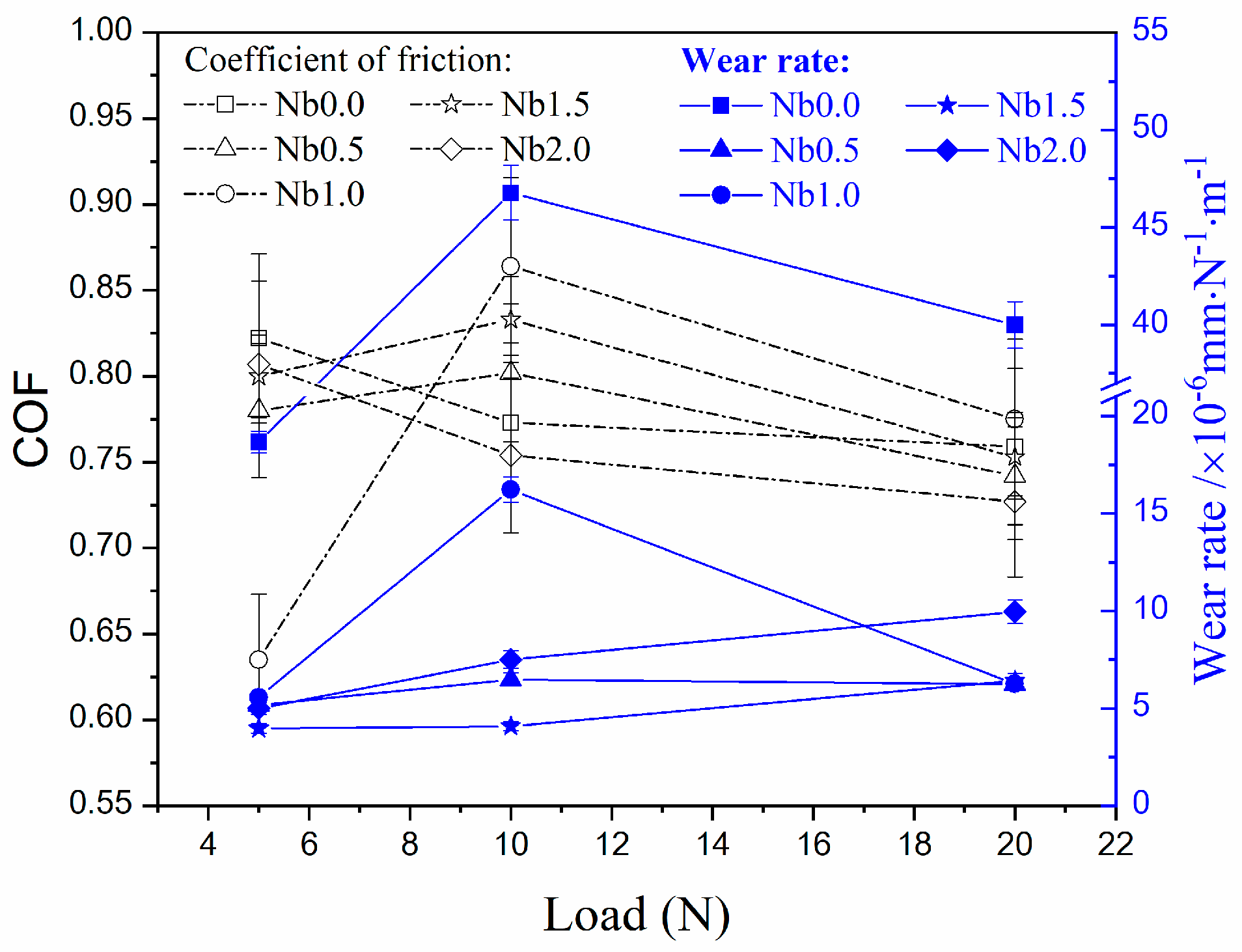

3.3. Sliding Wear Resistance

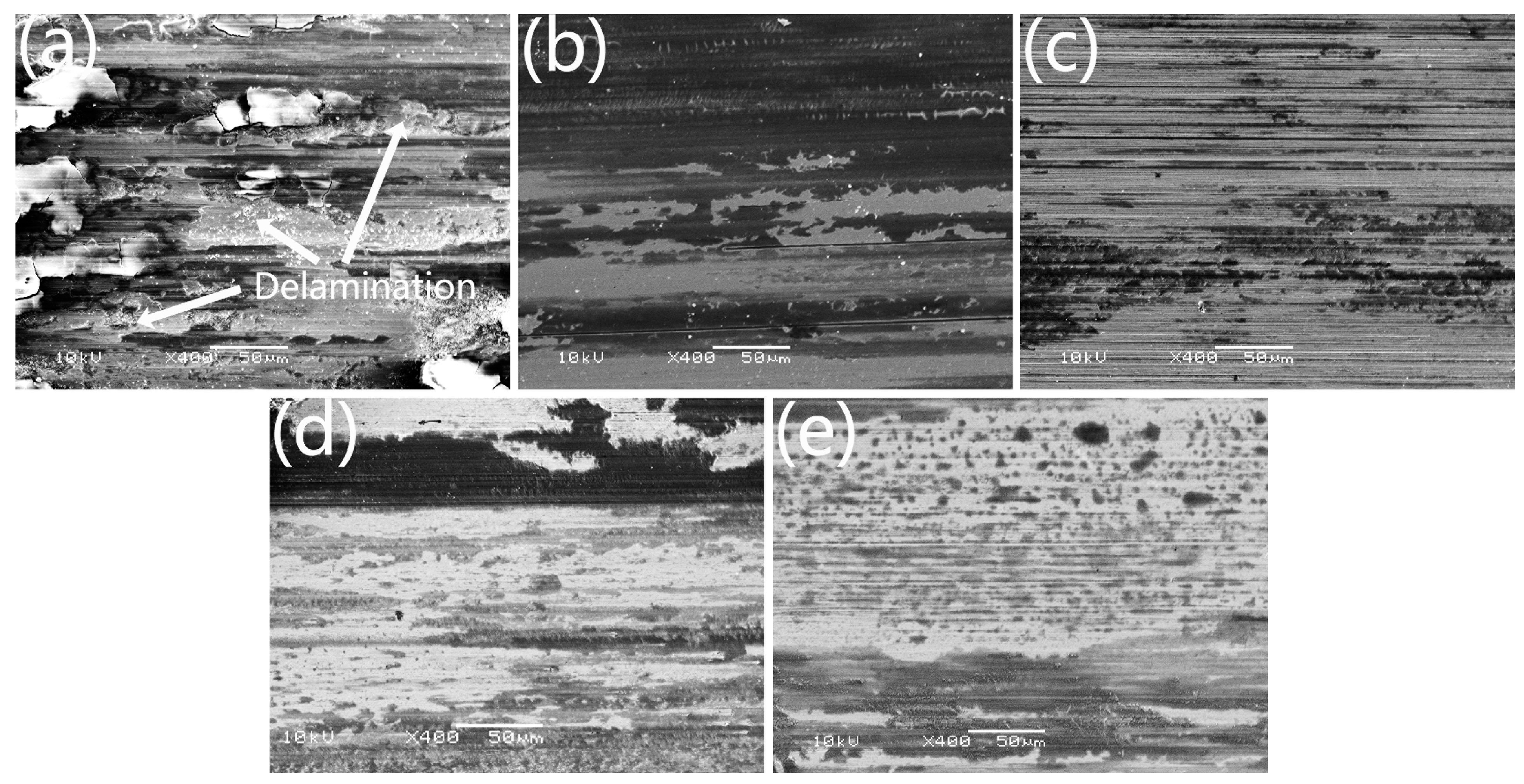

3.4. Wear Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Chen, W.P.; Wu, B.Y.; Cao, X.Y.; Liu, L.S.; Fu, Z.Q. Effects of Co and Ti on microstructure and mechanical behavior of Al0.75FeNiCrCo high entropy alloy prepared by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A-Struct. 2015, 648, 217–224. [Google Scholar] [CrossRef]

- Ji, X.; Duan, H.; Zhang, H.; Ma, J. Slurry Erosion Resistance of Laser Clad NiCoCrFeAl3 High-Entropy Alloy Coatings. Tribol. Trans. 2015, 58, 1119–1123. [Google Scholar] [CrossRef]

- Ye, Q.F.; Feng, K.; Li, Z.G.; Lu, F.G.; Li, R.F.; Huang, J.; Wu, Y.X. Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating. Appl. Surf. Sci. 2017, 396, 1420–1426. [Google Scholar] [CrossRef]

- Kumar, D. Recent advances in tribology of high entropy alloys: A critical review. Prog. Mater. Sci. 2023, 136, 101106. [Google Scholar] [CrossRef]

- Wu, W.H.; Yang, C.C.; Yeh, J.W. Industrial development of high-entropy alloys. In Annales de Chimie-Science des Materiaux; Masson: Paris, NY, USA, 2006; Volume 31, pp. 737–747. [Google Scholar]

- Lin, Y.C.; Cho, Y.H. Elucidating the microstructural and tribological characteristics of NiCrAlCoCu and NiCrAlCoMo multicomponent alloy clad layers synthesized. Surf. Coat. Technol. 2009, 203, 1694–1701. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.; Jiao, H. Microstructure and properties of Al2CrFeCoxCuNiTi high-entropy alloy coating prepared by laser cladding. Mater. Sci. Eng. Powder Met. 2013, 18, 735–740. [Google Scholar]

- Ji, X.; Alavi, S.H.; Harimkar, S.P.; Zhang, Y. Sliding Wear of Spark Plasma Sintered CrFeCoNiCu High-Entropy Alloy Coatings: Effect of Aluminum Addition. J. Mater. Eng. Perform. 2018, 27, 5815–5822. [Google Scholar] [CrossRef]

- Kar, S.; Meena, L.K.; Srivastava, V.C.; Mandal, G.K. Microstructural, Mechanical, and Corrosion Behaviour of Ni-Fe-Cr-Al and Ni-Fe-Cr-Al-Co Alloys. Trans. Indian Inst. Met. 2023. [Google Scholar] [CrossRef]

- Rogal, L.; Szklarz, Z.; Bobrowski, P.; Kalita, D.; Garzel, G.; Tarasek, A.; Kot, M.; Szlezynger, M. Microstructure and Mechanical Properties of Al-Co-Cr-Fe-Ni Base High Entropy Alloys Obtained Using Powder Metallurgy. Met. Mater. Int. 2019, 25, 930–945. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Y.X.; Cui, S.G.; Yi, Y.L.; Xing, X.W.; Wang, X.J.; Li, W. Effect of Mo Element on the Mechanical Properties and Tribological Responses of CoCrFeNiMo High-Entropy Alloys. Metals 2021, 11, 486. [Google Scholar] [CrossRef]

- Ma, S.G.; Zhang, Y. Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. Mater. Sci. Eng. A-Struct. 2012, 532, 480–486. [Google Scholar] [CrossRef]

- Liu, W.H.; He, J.Y.; Huang, H.L.; Wang, H.; Lu, Z.P.; Liu, C.T. Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi high-entropy alloys. Intermetallics 2015, 60, 1–8. [Google Scholar] [CrossRef]

- Jiang, H.; Jiang, L.; Qiao, D.; Lu, Y.; Wang, T.; Cao, Z.; Li, T. Effect of Niobium on Microstructure and Properties of the CoCrFeNbxNi High Entropy Alloys. J. Mater. Sci. Technol. 2017, 33, 712–717. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, Q.; Zhou, F. Microsturcture and wear resistance of high-melting-point AlCrFeMoNbxTiW high-entropy alloy coating by laser cladding. Rare Met. 2017, 41, 1327–1332. [Google Scholar] [CrossRef]

- Liang, H.; Yao, H.; Qiao, D.; Nie, S.; Lu, Y.; Deng, D.; Cao, Z.; Wang, T. Microstructures and Wear Resistance of AlCrFeNi2W0.2Nbx High-Entropy Alloy Coatings Prepared by Laser Cladding. J. Therm. Spray Technol. 2019, 28, 1318–1329. [Google Scholar] [CrossRef]

- Lin, D.; Zhang, N.; He, B.; Gong, X.; Zhang, Y.; Li, D.; Dong, F. Structural Evolution and Performance Changes in FeCoCrNiAlNbx High-Entropy Alloy Coatings Cladded by Laser. J. Therm. Spray Technol. 2017, 26, 2005–2012. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, W. Laser surface cladding: The state of the art and challenges. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2010, 224, 1041–1060. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, T.; Kovacevic, R. Erosion and corrosion resistance of laser cladded AISI 420 stainless steel reinforced with VC. Appl. Surf. Sci. 2017, 410, 225–240. [Google Scholar] [CrossRef]

- Wang, Y.P.; Li, B.S.; Fu, H.Z. Solid Solution or Intermetallics in a High-Entropy Alloy. Adv. Eng. Mater. 2009, 11, 641–644. [Google Scholar] [CrossRef]

- Zhuang, Y.X.; Liu, W.J.; Chen, Z.Y.; Xue, H.D.; He, J.C. Effect of elemental interaction on microstructure and mechanical properties of FeCoNiCuAl alloys. Mater. Sci. Eng. A-Struct. 2012, 556, 395–399. [Google Scholar] [CrossRef]

- Fu, Z.Q.; Chen, W.P.; Chen, Z.; Wen, H.M.; Lavernia, E.J. Influence of Ti addition and sintering method on microstructure and mechanical behavior of a medium-entropy Al0.6CoNiFe alloy. Mater. Sci. Eng. A-Struct. 2014, 619, 137–145. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Wang, W.R.; Lin, S.J.; Yeh, J.W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Ji, X.; Bao, Y.; Zhao, J.; Gu, P. Erosion wear resistance of laser cladding AlCr2FeCoNiNbx high-entropy alloy coatings. In Asia International Conference on Tribology 2018; Abdollah, M.F.B., Ed.; Malaysia Tribology Society: Kuching, Malaysia, 2018; pp. 3–5. [Google Scholar]

- Yang, W.; Luo, J.; Fu, H.; Cheung, C.F.; Ruan, H.; Yang, X.-S. bcc → hcp phase transition significantly enhancing the wear resistance of metastable refractory high-entropy alloy. Scr. Mater. 2022, 221, 114966. [Google Scholar] [CrossRef]

- Wu, C.L.; Zhang, S.; Zhang, C.H.; Zhang, H.; Dong, S.Y. Phase evolution and cavitation erosion-corrosion behavior of FeCoCrAlNiTix high entropy alloy coatings on 304 stainless steel by laser surface alloying. J. Alloys Compd. 2017, 698, 761–770. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Raghavan, R.; Kumar, K.C.H.; Murty, B.S. Analysis of phase formation in multi-component alloys. J. Alloys Compd. 2012, 544, 152–158. [Google Scholar] [CrossRef]

- Pi, J.H.; Pan, Y. Thermodynamic Analysis for Microstructure of High-Entropy Alloys. Rare Met. Mater. Eng. 2013, 42, 232–237. [Google Scholar] [CrossRef]

- Praveen, S.; Murty, B.S.; Kottada, R.S. Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng. A-Struct. 2012, 534, 83–89. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Jiang, H.; Han, K.M.; Gao, X.X.; Lu, Y.P.; Cao, Z.Q.; Gao, M.C.; Hawk, J.A.; Li, T.J. A new strategy to design eutectic high-entropy alloys using simple mixture method. Mater. Des. 2018, 142, 101–105. [Google Scholar] [CrossRef]

- Lu, Y.P.; Jiang, H.; Guo, S.; Wang, T.M.; Cao, Z.Q.; Li, T.J. A new strategy to design eutectic high-entropy alloys using mixing enthalpy. Intermetallics 2017, 91, 124–128. [Google Scholar] [CrossRef]

- Nayak, S.K.; Kumar, A.; Sarkar, K.; Pathak, A.; Banerjee, A.; Laha, T. A Study on the Corrosion Inhibition of Fe-Based Amorphous/Nanocrystalline Coating Synthesized by High-Velocity Oxy-Fuel Spraying in an Extreme Environment. J. Therm. Spray Technol. 2019, 28, 1433–1447. [Google Scholar] [CrossRef]

- Fan, J.; Liu, X.; Pu, J.; Shi, Y. Anti-friction mechanism of VAlTiCrMo high-entropy alloy coatings through tribo-oxidation inducing layered oxidic surface. Tribol. Int. 2022, 171, 107523. [Google Scholar] [CrossRef]

| x | Al | Cr | Fe | Ni | Co | Nb |

|---|---|---|---|---|---|---|

| 0.00 | 8.87 | 34.16 | 18.34 | 19.28 | 19.35 | / |

| 0.50 | 7.69 | 29.63 | 15.91 | 16.72 | 16.79 | 13.26 |

| 1.00 | 6.79 | 26.17 | 14.05 | 14.77 | 14.83 | 23.39 |

| 1.50 | 6.08 | 24.43 | 12.58 | 13.22 | 13.28 | 30.41 |

| 2.00 | 5.51 | 21.21 | 11.39 | 11.97 | 12.02 | 37.90 |

| x | Zone | Al | Cr | Fe | Co | Ni | Nb |

|---|---|---|---|---|---|---|---|

| 0 | A | 4.91 | 19.52 | 51.67 | 12.68 | 11.21 | / |

| B | 9.02 | 21.33 | 45.77 | 13.95 | 9.93 | / | |

| 0.5 | A | 3.52 | 14.46 | 52.75 | 8.23 | 9.92 | 11.11 |

| B | 8.20 | 15.36 | 55.01 | 8.73 | 7.21 | 5.49 | |

| 1.0 | A | 3.10 | 8.86 | 56.15 | 6.23 | 5.82 | 19.84 |

| B | 6.09 | 7.96 | 63.73 | 5.95 | 5.73 | 10.53 | |

| 1.5 | A | 2.78 | 7.78 | 58.99 | 4.43 | 5.19 | 20.83 |

| B | 0.72 | 6.72 | 51.78 | 4.74 | 5.39 | 30.65 | |

| 2.0 | A | 2.14 | 8.15 | 46.74 | 3.37 | 2.18 | 37.41 |

| B | 1.11 | 8.00 | 61.11 | 5.59 | 5.28 | 18.90 |

| HEA Coatings | Nb0 | Nb0.5 | Nb1.0 | Nb1.5 | Nb2.0 |

|---|---|---|---|---|---|

| Ecorr(V) | −0.423 | −0.520 | −0.795 | −0.608 | −0.602 |

| icorr(μA cm−2) | 0.857 | 2.990 | 3.293 | 2.427 | 2.708 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Guan, K.; Bao, Y.; Mao, Z.; Wang, F.; Dai, H. Effect of Nb Addition on the Corrosion and Wear Resistance of Laser Clad AlCr2FeCoNi High-Entropy Alloy Coatings. Lubricants 2024, 12, 5. https://doi.org/10.3390/lubricants12010005

Ji X, Guan K, Bao Y, Mao Z, Wang F, Dai H. Effect of Nb Addition on the Corrosion and Wear Resistance of Laser Clad AlCr2FeCoNi High-Entropy Alloy Coatings. Lubricants. 2024; 12(1):5. https://doi.org/10.3390/lubricants12010005

Chicago/Turabian StyleJi, Xiulin, Kunpeng Guan, Yayun Bao, Zhongfa Mao, Fengtao Wang, and Houfu Dai. 2024. "Effect of Nb Addition on the Corrosion and Wear Resistance of Laser Clad AlCr2FeCoNi High-Entropy Alloy Coatings" Lubricants 12, no. 1: 5. https://doi.org/10.3390/lubricants12010005

APA StyleJi, X., Guan, K., Bao, Y., Mao, Z., Wang, F., & Dai, H. (2024). Effect of Nb Addition on the Corrosion and Wear Resistance of Laser Clad AlCr2FeCoNi High-Entropy Alloy Coatings. Lubricants, 12(1), 5. https://doi.org/10.3390/lubricants12010005