Friction Coefficient of Wet Clutches as a Function of Service Mileage

Abstract

:1. Introduction

2. Experiment

2.1. Apparatus

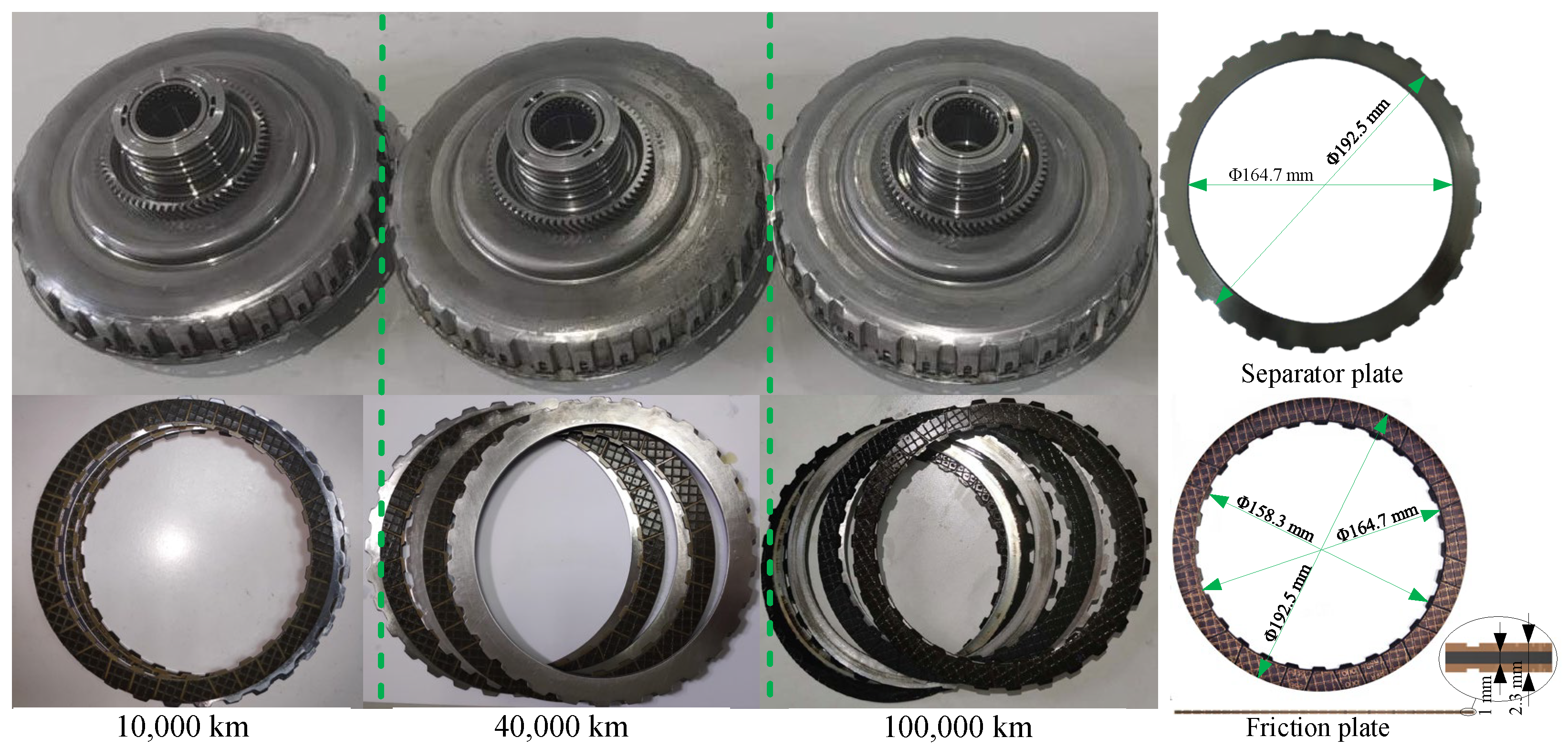

2.2. Experimental Subjects

2.3. Experimental Methods

3. Theoretical Analysis

4. Results and Discussion

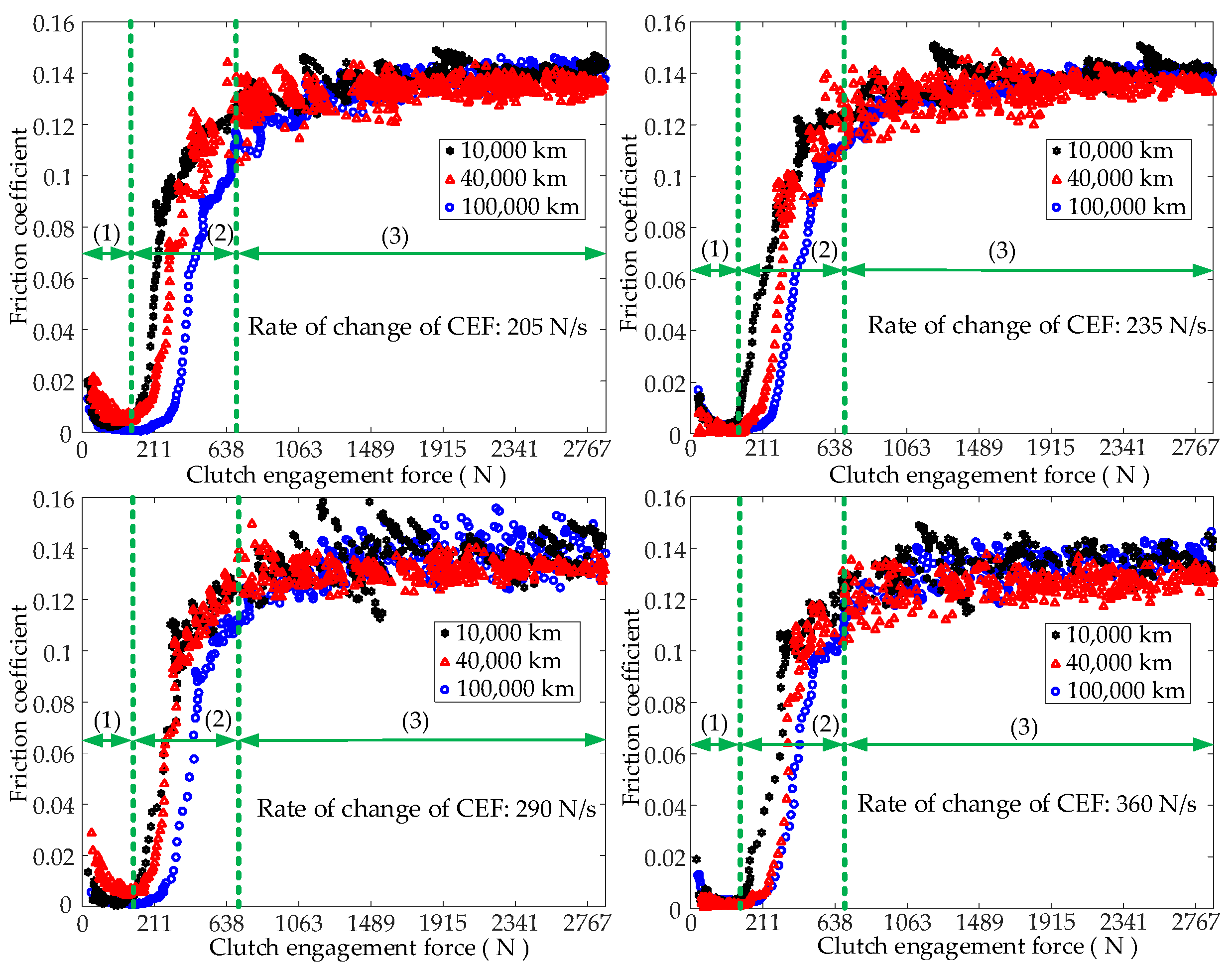

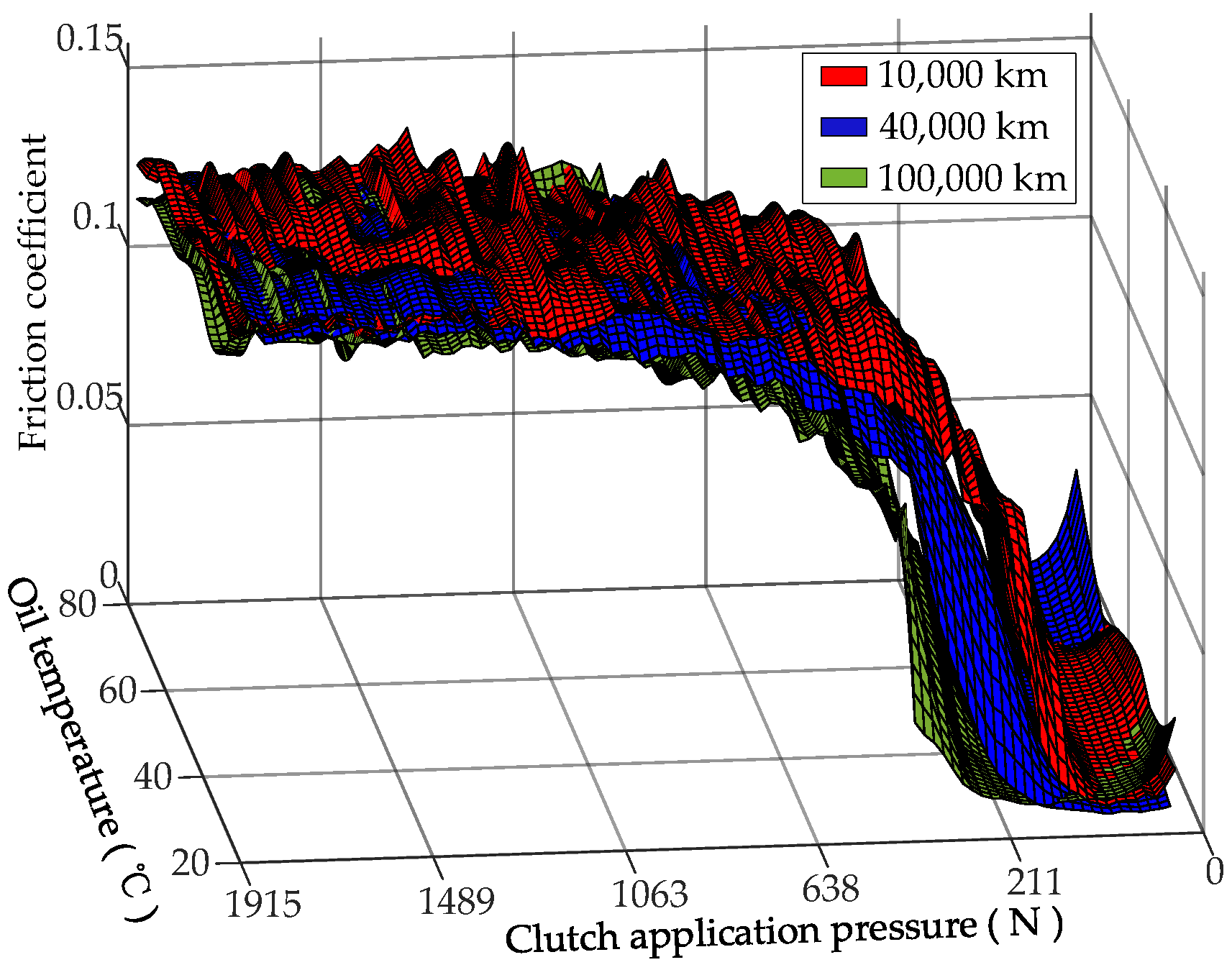

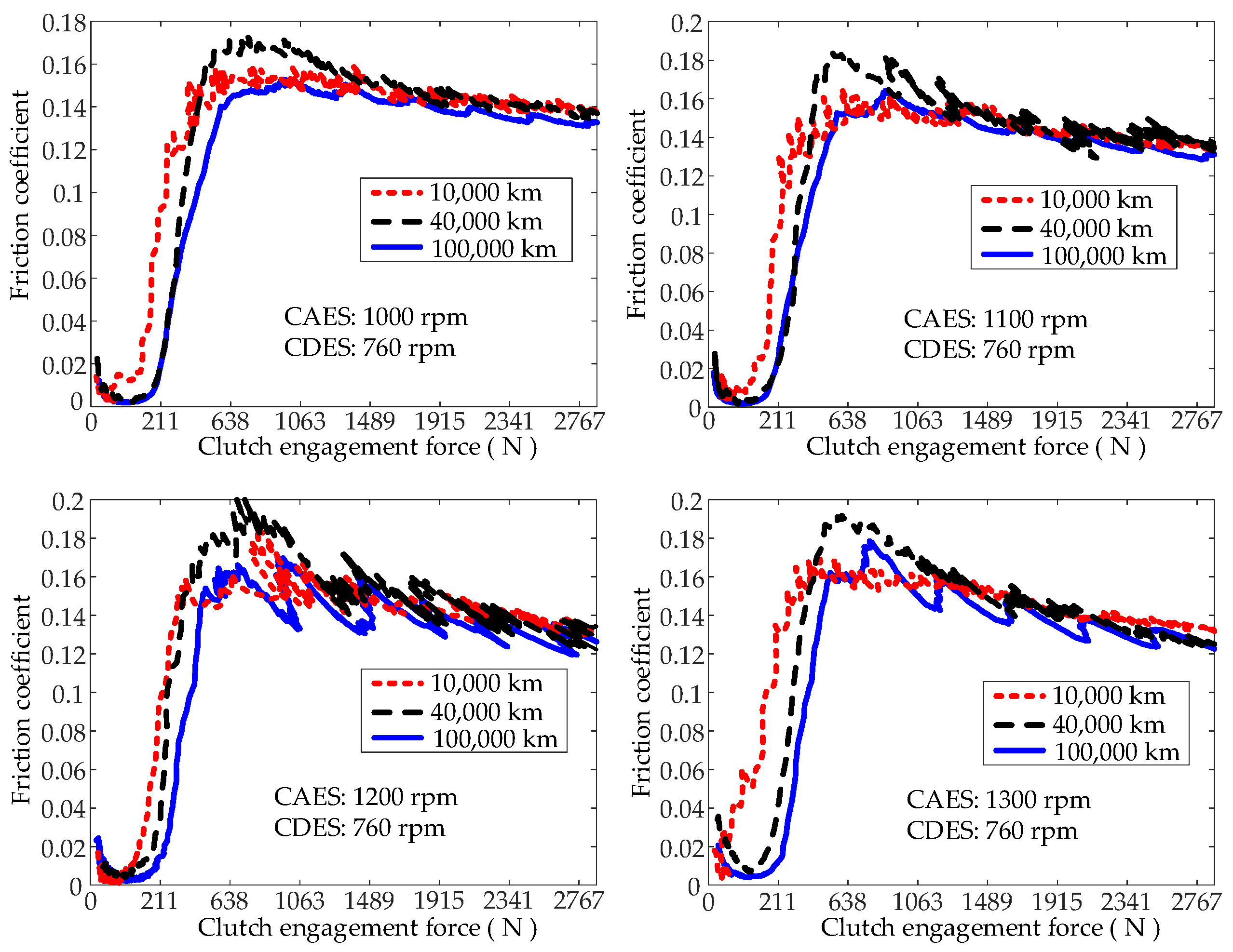

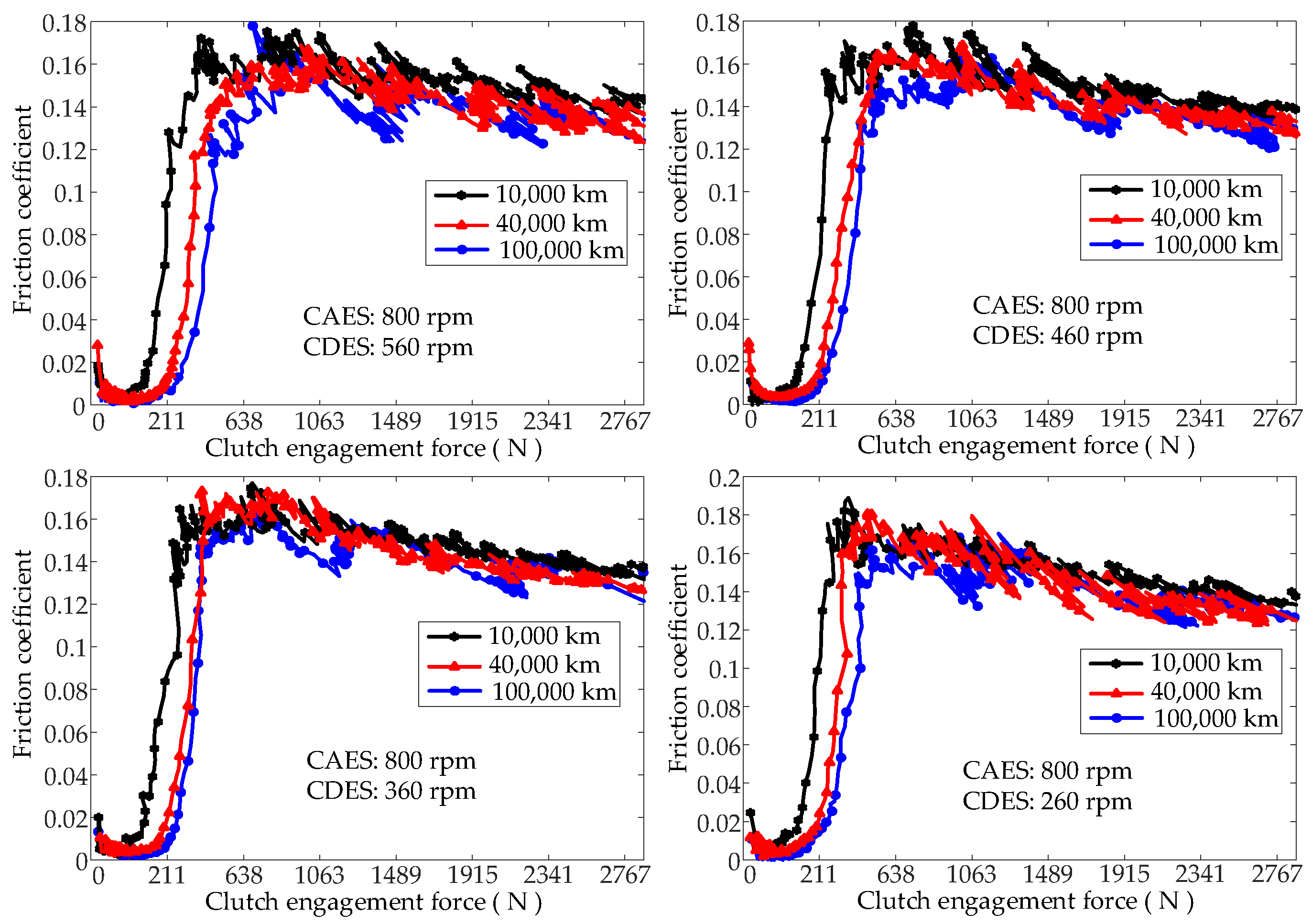

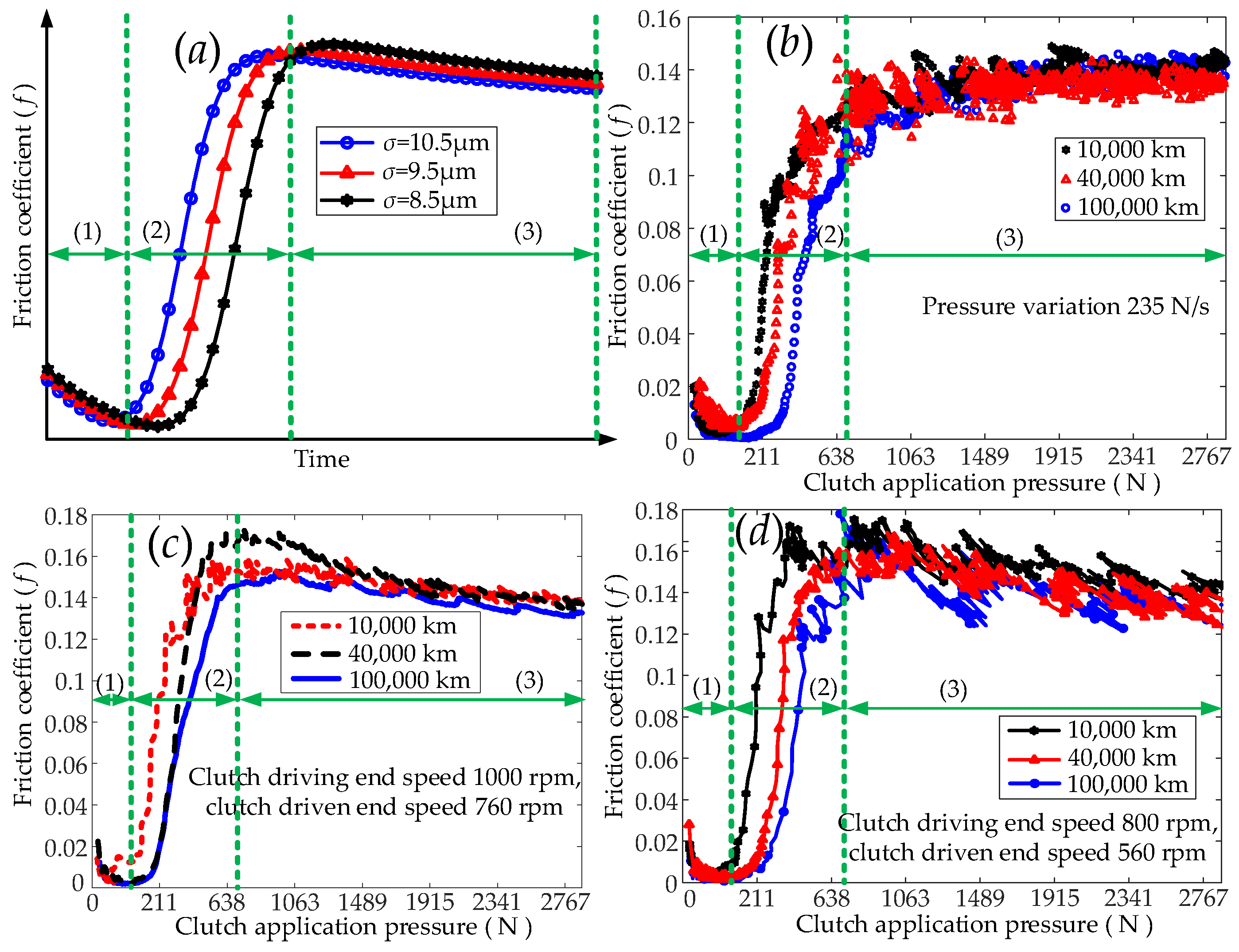

4.1. Service Characteristics of Wet Clutch Friction Coefficient

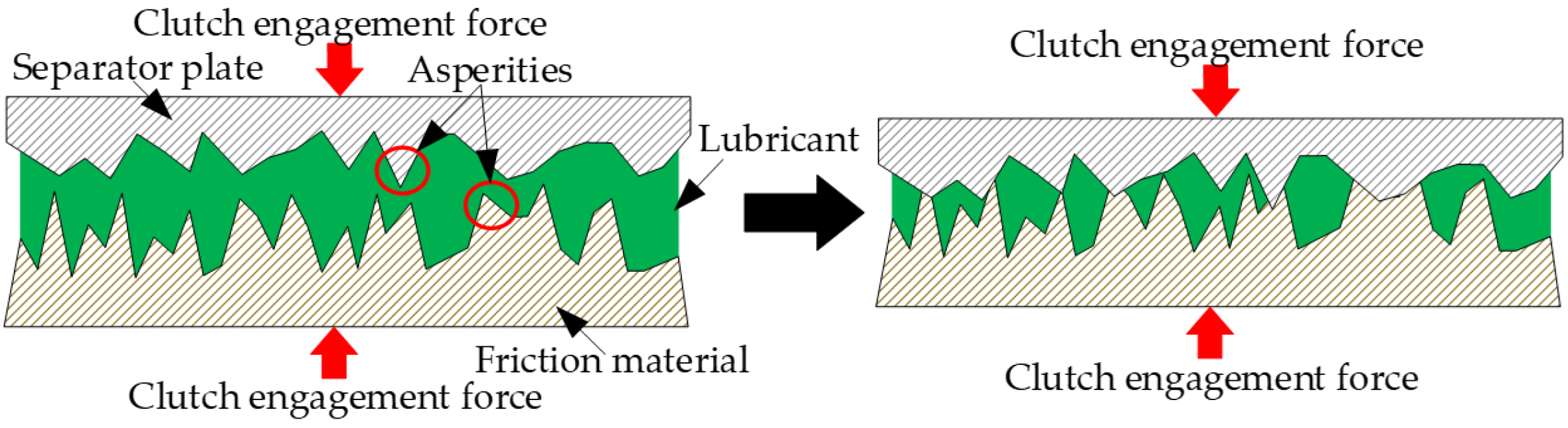

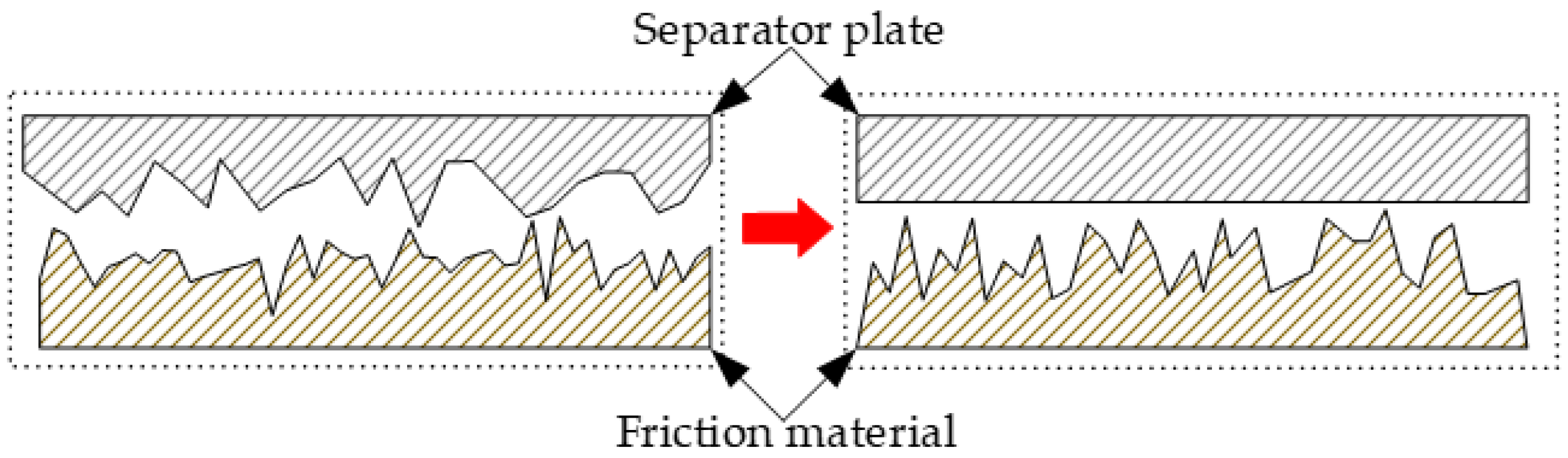

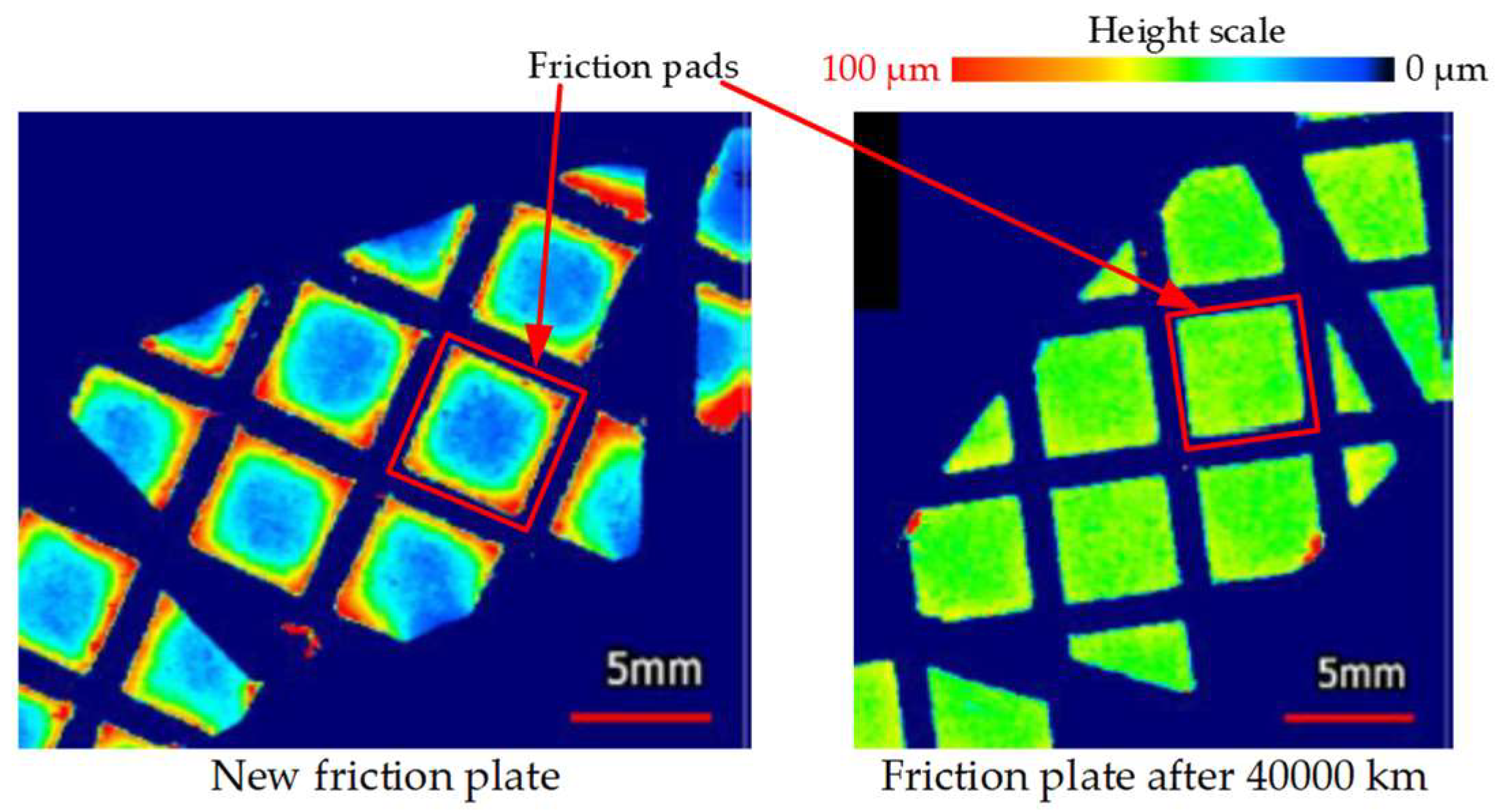

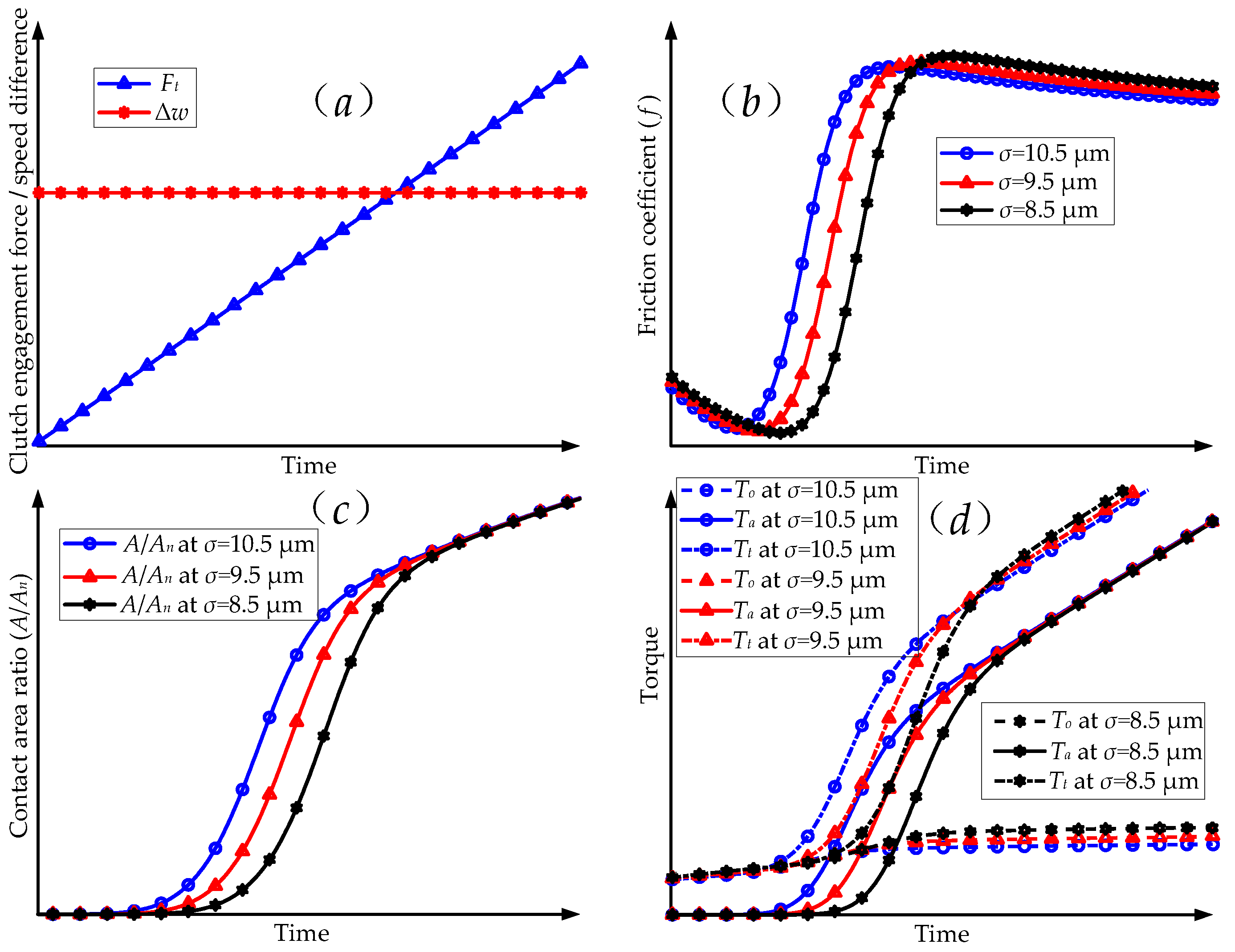

4.2. Mechanistic Analysis of Service Characteristics of Wet Clutch Friction Coefficients

5. Conclusions

- (1)

- The friction coefficient decreases as the service mileage of the wet clutch increases from initial contact to full contact between the asperities on the surfaces of the separator plate and the friction plate.

- (2)

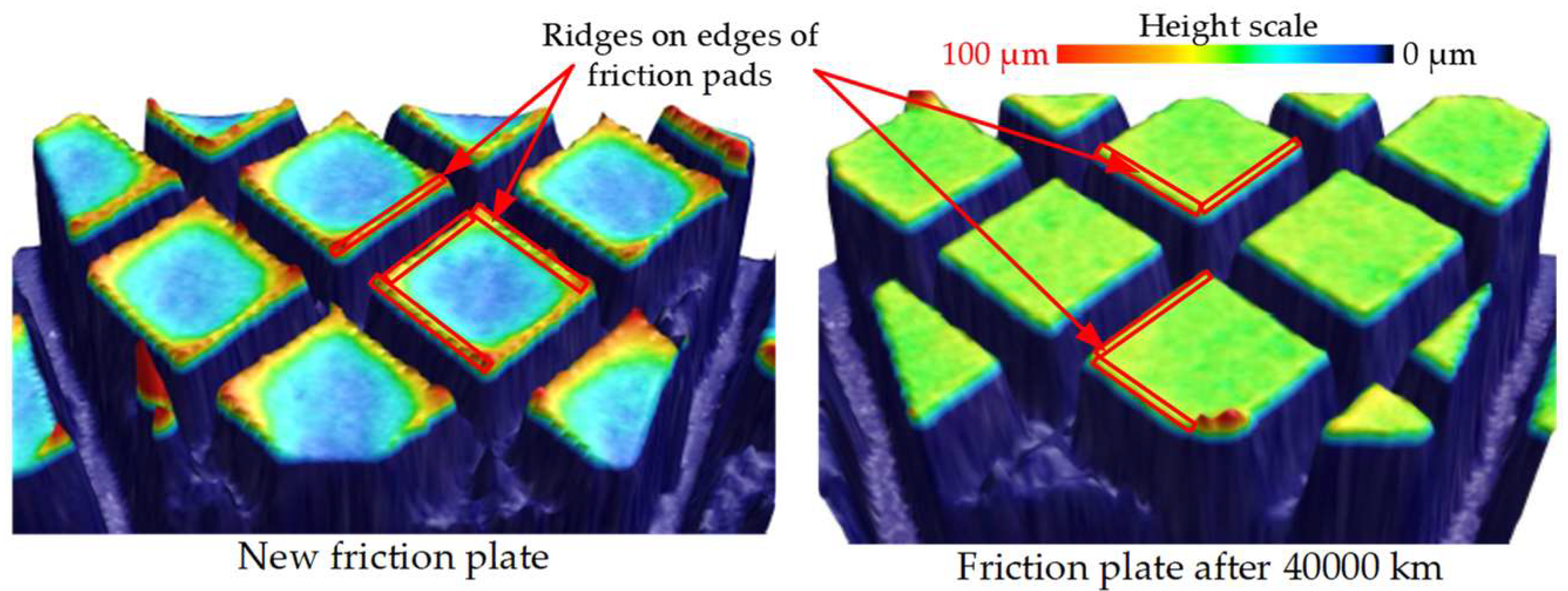

- The surface roughness of the friction plate becomes progressively smaller with the increase in service mileage. This enhances the dynamic pressure lubrication effect between the separator plate and the friction plate, and also increases the engagement pressure when the asperities on the surfaces of the separator plate and the friction plate come into contact. Ultimately, the friction coefficient decreases from initial contact to full contact between the asperities on the surfaces of the separator plate and the friction plate.

- (3)

- The variation law of the friction coefficient of the wet clutch with service mileage can be theoretically analyzed by changing the standard deviation of the combined roughness of the different friction surfaces in the asperities elastic contact model and the dynamic pressure lubrication model.

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, Z.; Li, H.; Lei, H.; Xie, M.; Wang, L. Study of the Judder Characteristics of Friction Material for an Automobile Clutch and Test Verification. Chin. J. Mech. Eng. 2023, 36, 53. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, Z.; Qian, Y. Research on Wet Clutch Switching Quality in the Shifting Stage of an Agricultural Tractor Transmission System. Agriculture 2022, 12, 1174. [Google Scholar] [CrossRef]

- Yu, L.; Ma, B.; Chen, M.; Xue, J.; Zhao, P. Variation mechanism of the friction torque in a Cu-based wet clutch affected by operating parameters. Tribol. Int. 2020, 147, 106–169. [Google Scholar] [CrossRef]

- Peng, Z.; Yuan, S. Mathematical Model of Drag Torque with Surface Tension in Single-Plate Wet Clutch. Chin. J. Mech. Eng. 2019, 32, 25. [Google Scholar] [CrossRef]

- Wu, B.; Qin, D.; Hu, J.; Liu, Y. Experimental Data Mining Research on Factors Influencing Friction Coefficient of Wet Clutch. ASME J. Tribol. 2021, 143, 121802. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Y.; Gao, Z.; Ye, F.; Tang, P. Transient Temperature Characteristics of Friction Clutch Disc Considering Thermal Contact Conductance Under Sliding Conditions. Friction 2023, 11, 2253–2263. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Kuciej, M.; Grzes, P.; Ilyushchanka, A.; Liashok, A. Influence of the Additive of Ceramic and Intermetallic Powders on the Friction Properties and Temperature of the Wet Clutch Disc. Materials 2022, 15, 5384. [Google Scholar] [CrossRef] [PubMed]

- Farfan-Cabrera, L.I.; Gallardo-Hernández, E.A.; Vite-Torres, M.; Godínez-Salcedo, J.G. Influence of Oxidation of Automatic Transmission Fluids (ATFs) and Sliding Distance on Friction Coefficients of a Wet Clutch in the Running-in Stage. Friction 2021, 9, 401–414. [Google Scholar] [CrossRef]

- Schneider, T.; Voelkel, K.; Pflaum, H.; Stahl, K. Failure Modes of Spontaneous Damage of Wet-Running Multi-Plate Clutches with Carbon Friction Linings. Tribol. Trans. 2022, 65, 813–826. [Google Scholar] [CrossRef]

- Li, M.; Khonsari, M.M.; Mccarthy, D.M.C.; Lundin, J. Parametric Analysis for a Paper-Based Wet Clutch with Groove Consideration. Tribol. Int. 2014, 80, 222–233. [Google Scholar] [CrossRef]

- Bao, H.; Huang, W.; Lu, F. Investigation of Engagement Characteristics of a Multi-Disc Wet Friction Clutch. Tribol. Int. 2021, 159, 10694. [Google Scholar]

- Chen, L.; Li, R.; Xie, F.; Wang, Y. Load-Bearing Capacity Research in Wet Clutches with Surface Texture. Measurement 2019, 142, 96–104. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G.; Zhang, D.; Chin, K. A Mixed Lubrication Model for Studying Tribological Behaviors of Surface Texturing. Tribol. Int. 2016, 93, 583–592. [Google Scholar] [CrossRef]

- Chen, S.; Han, Z.; Zeng, Q.; Wang, B.; Wang, L.; Guo, L.; Shao, Y. Influence of Manufacturing Surface Topography on Torque and Load Bearing Capacity of Hydro-Viscous Drive Clutch Under Mixed Lubrication Stage. Ind. Lubr. Tribol. 2024, 76, 81–90. [Google Scholar] [CrossRef]

- Li, S.; Di, Z.; Cheng, L.; Liu, Z.; Piao, J.; Huang, D.; Zhao, Z.; Cui, H.; Li, Y. Surface Chemical Characterization of Steel Clutch Plate in ATF. Tribol. Int. 2016, 102, 319–325. [Google Scholar] [CrossRef]

- Wirkner, J.; Baese, M.; Lebel, A.; Pflaum, H.; Voelkel, K.; Pointner-Gabriel, L.; Besser, C.; Schneider, T.; Stahl, K. Influence of Water Contamination, Iron Particles, and Energy Input on the NVH Behavior of Wet Clutches. Lubricants 2023, 11, 459. [Google Scholar] [CrossRef]

- Fatima, N.; Minami, I.; Holmgren, A.; Marklund, P.; Larsson, R. Surface chemistry of wet clutch influenced by water contamination in automatic transmission fluids. Tribol. Int. 2016, 96, 395–401. [Google Scholar] [CrossRef]

- Farfán-Cabrera, L.; Gallardo-Hernández, E.; Vite-Torres, M.; Laguna-Camacho, J. Frictional Behavior of a Wet Clutch Using Blends of Automatic Transmission Fluid (ATF) and Biolubricant (Jatropha Oil) in a Pin-on-Disk Tester. Tribol. Trans. 2015, 58, 941–946. [Google Scholar] [CrossRef]

- Fei, J.; Li, H.; Fu, Y.; Qi, L.; Zhang, Y. Effect of Phenolic Resin Content on Performance of Carbon Fiber Reinforced Paper-Based Friction Material. Wear 2010, 269, 534–540. [Google Scholar] [CrossRef]

- Zhang, X.; Li, K.; Li, H.; Fu, Y.; Fei, J. Tribological and Mechanical Properties of Glass Fiber Reinforced Paper-Based Composite Friction Material. Tribol. Int. 2014, 69, 156–167. [Google Scholar] [CrossRef]

- Ingram, M.; Noles, J.; Watts, R.; Harris, S.; Spikes, H.A. Frictional Properties of Automatic Transmission Fluids: Part Ⅱ-Origins of Friction-Sliding Speed Behavior. Tribol. Trans. 2010, 54, 154–167. [Google Scholar] [CrossRef]

- Ma, B.; Wang, Q.; Zheng, C.; Yu, L.; Wang, G.; Zheng, L. Effect of ATF Temperature on the Friction-Wear Characteristic of a Wet Multi-Disc Clutch during the Running-in Process. Ind. Lubr. Tribol. 2022, 74, 714–721. [Google Scholar] [CrossRef]

- Li, W.; Huang, J.; Fei, J.; Liang, Z.; Cao, L.; Yao, C. Study on Tribological Properties as a Function of Operating Conditions for Carbon Fabric Wet Clutch. Tribol. Int. 2016, 94, 428–436. [Google Scholar]

- Cui, H.; Wang, Q.; Lian, Z.; Li, L. Theoretical Model and Experimental Research on Friction and Torque Characteristics of Hydro-Viscous Drive in Mixed Friction Stage. Chin. J. Mech. Eng. 2019, 32, 80. [Google Scholar] [CrossRef]

- Wu, J.; Cui, J.; Shu, W.; Wang, L.; Li, H. Coupling Mechanism and Data-Driven Approaches for High Power Wet Clutch Torque Modeling and Analysis. Tribol. Int. 2024, 191, 109166. [Google Scholar] [CrossRef]

- Ost, W.; Baets, P.; Degrieck, J. The Tribological Behaviour of Paper Friction Plates for Wet Clutch Application Investigated on SAE#II and Pin-On-Disk Test Rigs. Wear 2001, 249, 361–371. [Google Scholar]

- Fei, J.; Li, W.; Huang, J.; Cao, L.; Yao, C. Variation of the Tribological Properties of Carbon Fabric Composites in Their Whole Service Life. Tribol. Int. 2016, 99, 29–37. [Google Scholar]

- Voelkel, K.; Pflaum, H.; Stahl, K. Running-in Behavior of Wet Multi-Plate Clutches: Introduction of a New Test Method for Investigation and Characterization. Chin. J. Mech. Eng. 2020, 33, 34. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, B.; Yu, L.; Xiong, C.; Zheng, L. Effects of Operating Conditions on the Tribological Behavior of a Wet Multi-Disc Clutch during the Running-in Process. Tribol. Int. 2023, 179, 108096. [Google Scholar] [CrossRef]

- Dong, H.; Fu, J.; Zhao, Z.; Liu, Q.; Li, Y.; Liu, J. A Comparative Study on the Energy Flow of a Conventional Gasoline-Powered Vehicle and a New Dual Clutch Parallel-Series Plug-in Hybrid Electric Vehicle Under NEDC. Energy Convers. Manag. 2020, 218, 113019–113026. [Google Scholar] [CrossRef]

- Wu, B.; Qin, D.; Hu, J.; Wang, X.; Wang, Y.; Lv, H. Analysis of Influencing Factors and Changing Laws on Friction Behavior of Wet Clutch. Tribol. Int. 2021, 162, 107125. [Google Scholar] [CrossRef]

- Greenwood, J.; Tripp, J. The Contact of Two Nominally Flat Rough Surfaces. Proc. Inst. Mech. Eng. 1970, 185, 625–634. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H. Application of Average Flow Model to Lubrication Between Rough Sliding Surfaces. ASME J. Tribol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

| Component | Characteristic Parameter |

|---|---|

| Drive motor | Power 132 kW, Rated speed 3000 rpm |

| Thermocouple | Model TT-K-36-SLE, Temperature range −267–260 °C |

| Dynamometer | Power 250 kW, Rated speed 3000 rpm |

| Inertia flywheel | Inertia 120 kg·m2 |

| Control system | MicroAutoBox II 1401 |

| Torque and speed sensor | Model HBM T40B, Rated torque 500 Nm and 3000 Nm |

| Oil temperature control system | Temperature range 10–90 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, B. Friction Coefficient of Wet Clutches as a Function of Service Mileage. Lubricants 2024, 12, 147. https://doi.org/10.3390/lubricants12050147

Wu B. Friction Coefficient of Wet Clutches as a Function of Service Mileage. Lubricants. 2024; 12(5):147. https://doi.org/10.3390/lubricants12050147

Chicago/Turabian StyleWu, Bangzhi. 2024. "Friction Coefficient of Wet Clutches as a Function of Service Mileage" Lubricants 12, no. 5: 147. https://doi.org/10.3390/lubricants12050147

APA StyleWu, B. (2024). Friction Coefficient of Wet Clutches as a Function of Service Mileage. Lubricants, 12(5), 147. https://doi.org/10.3390/lubricants12050147