Cyclic Stress Response Behavior of Near β Titanium Alloy and Deformation Mechanism Associated with Precipitated Phase

Abstract

:1. Introduction

2. Materials and Methods

3. Results

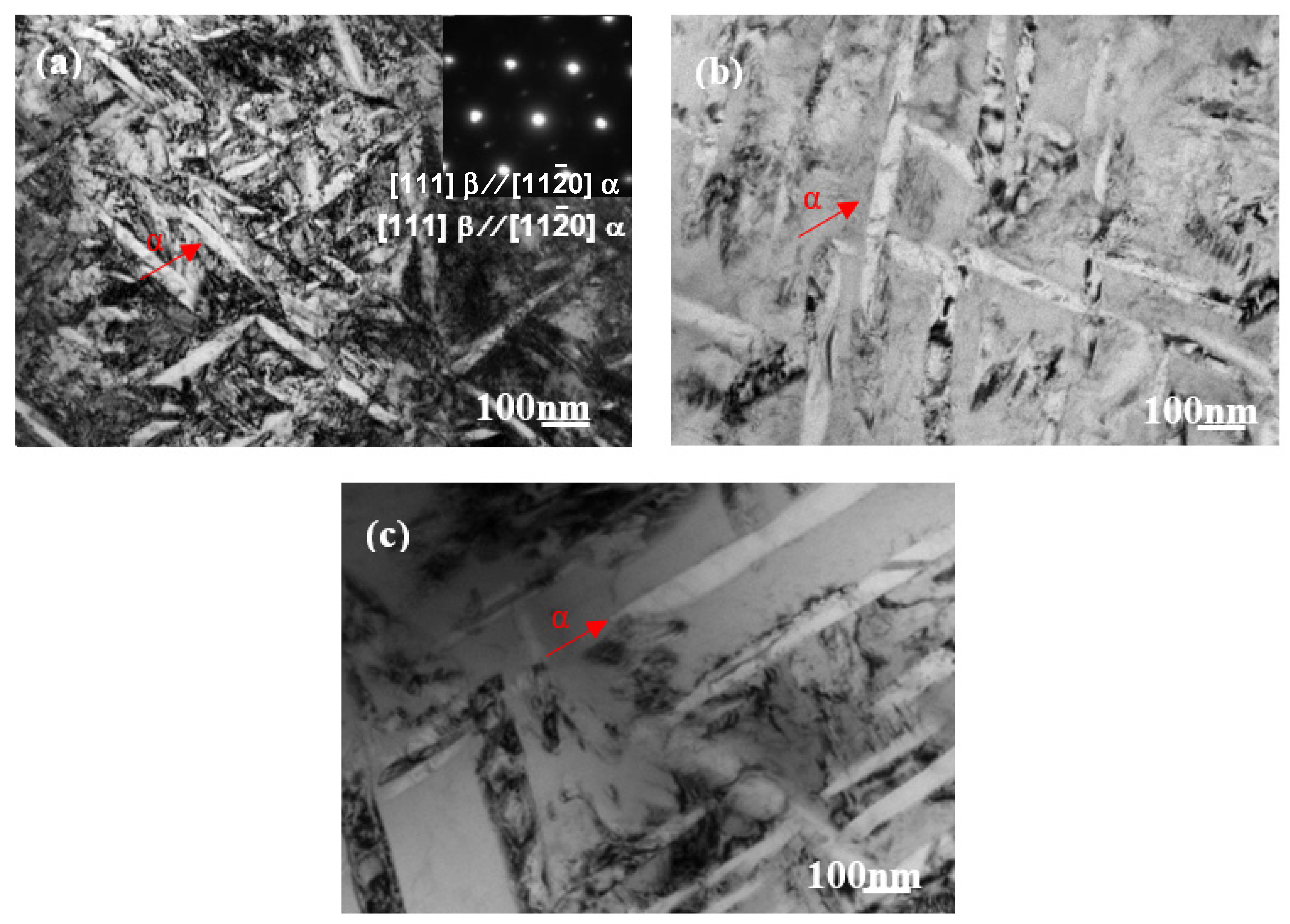

3.1. Microstructure before Fatigue Deformation

3.2. Tensile Properties

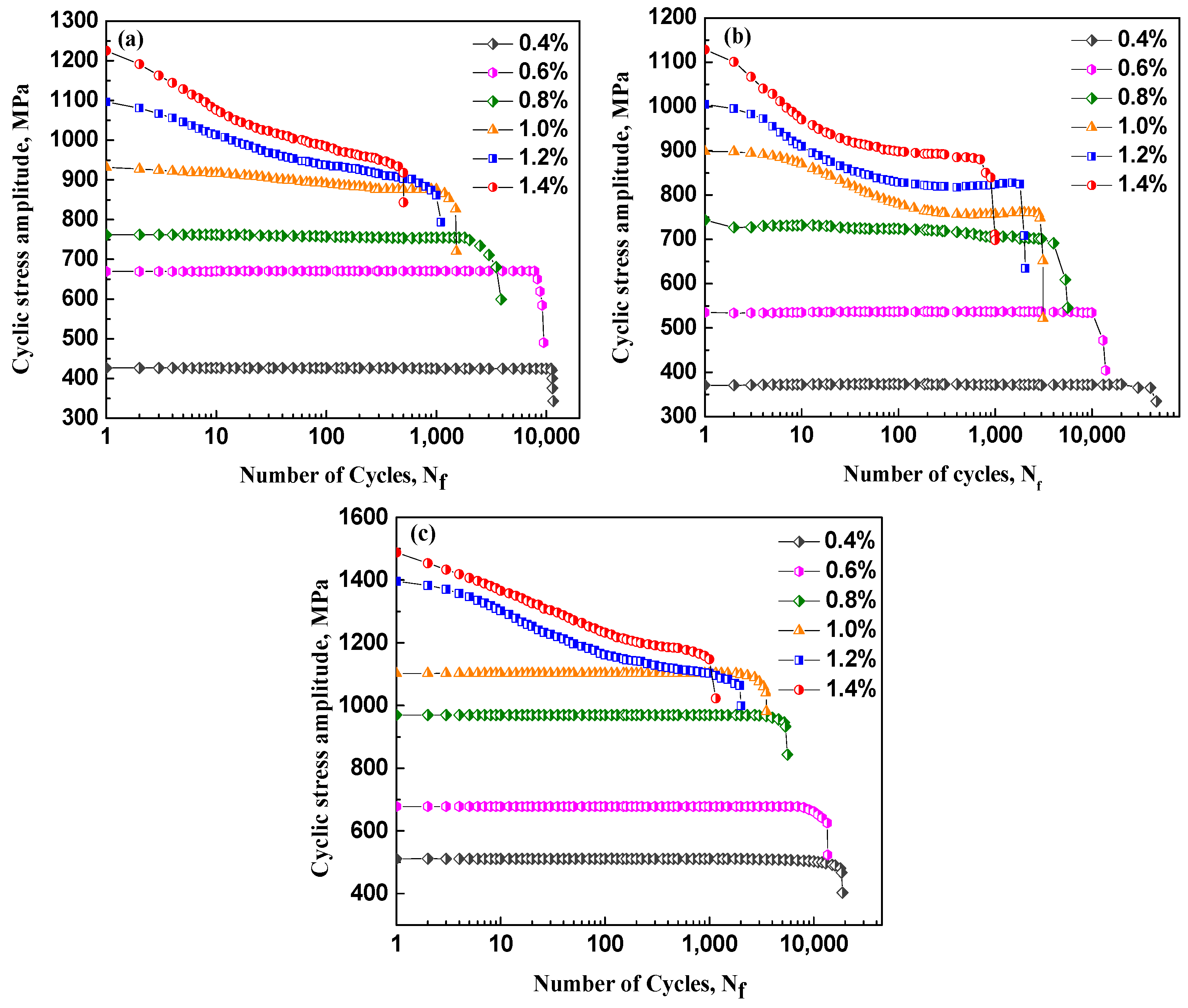

3.3. Strain Amplitude in Fatigue

3.4. Cyclic Stress Response Behaviour

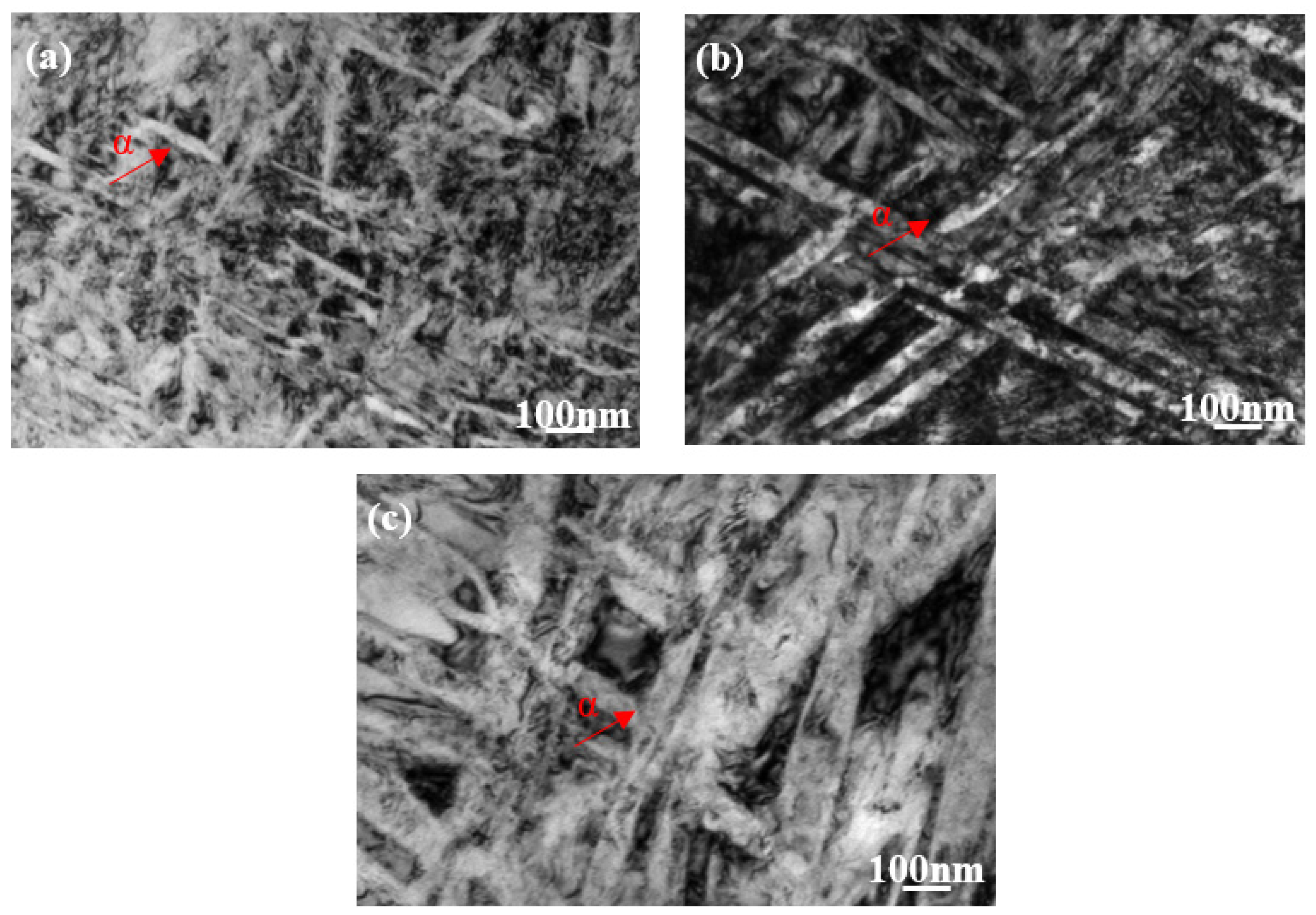

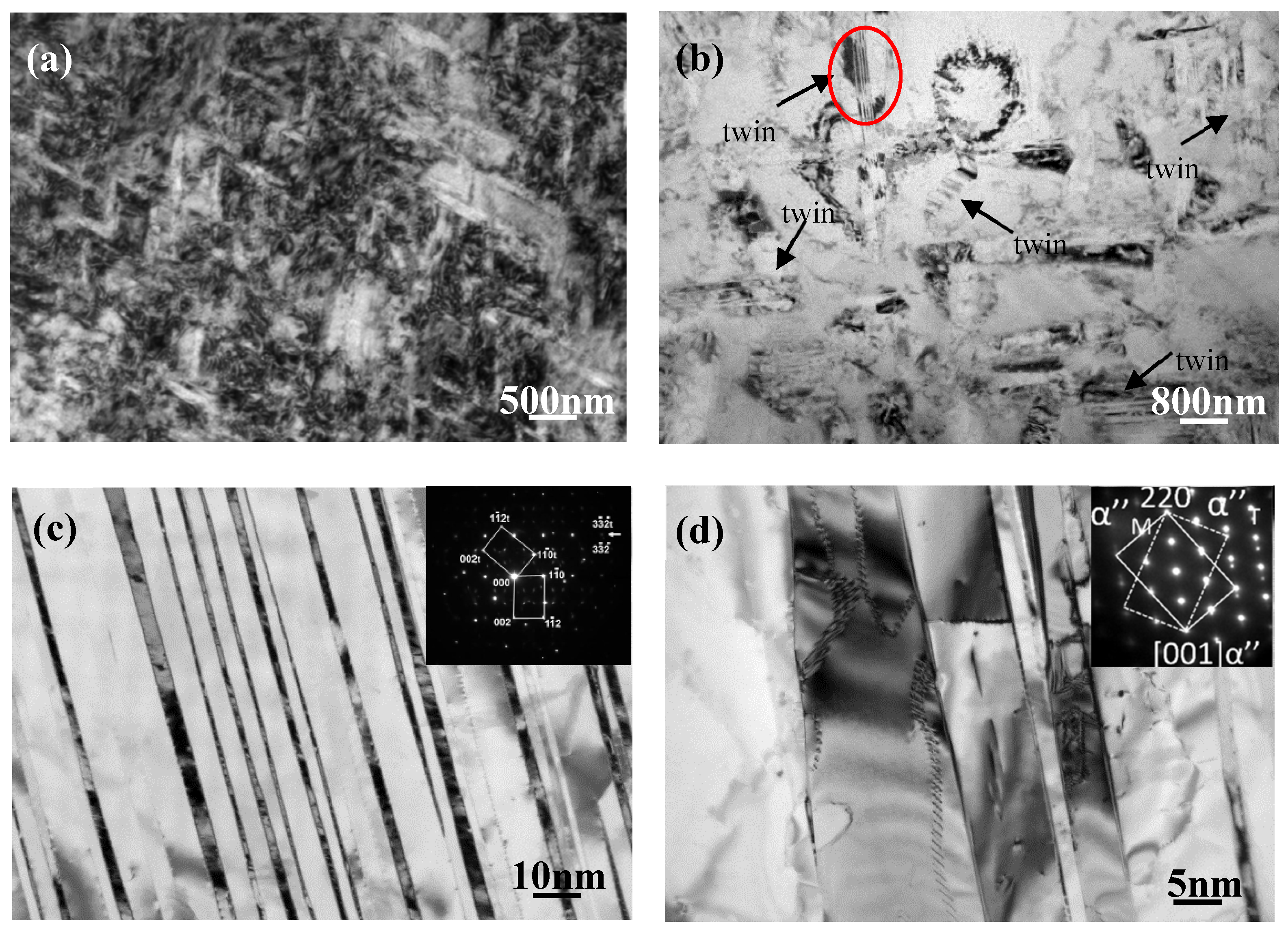

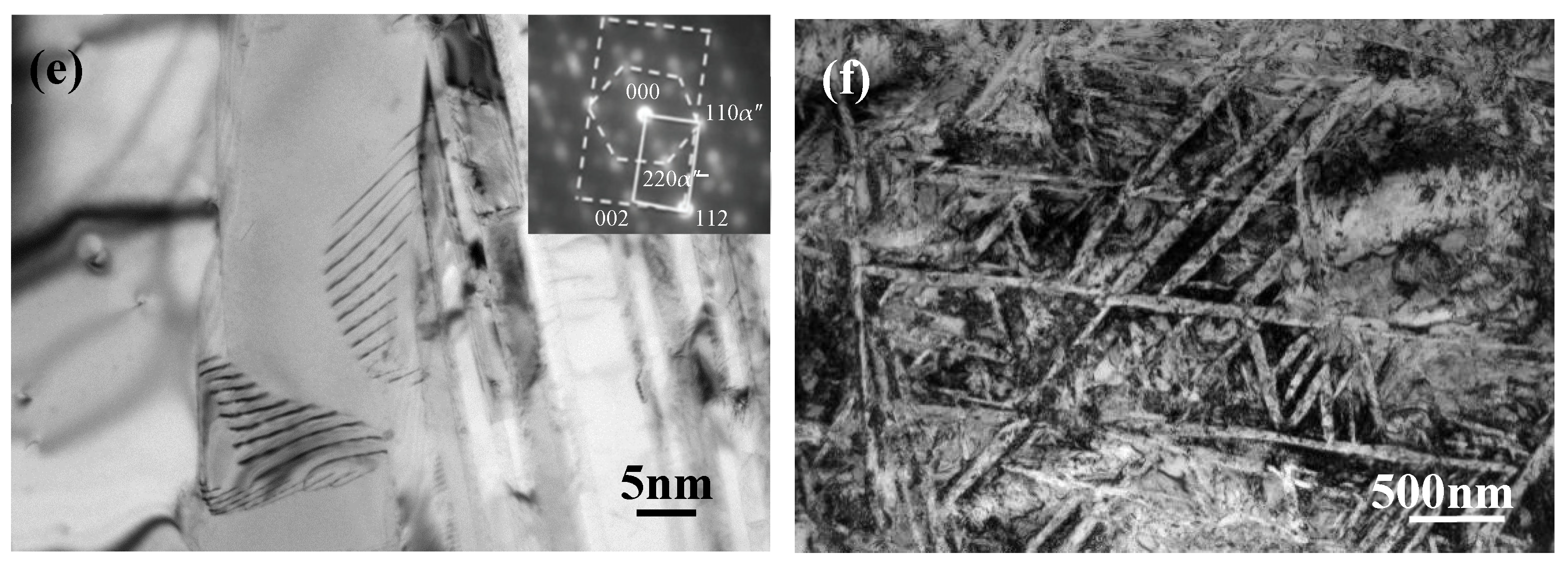

3.5. Microstructure after Fatigue Deformation

4. Discussion

5. Conclusions

- (1)

- The alloy aging for 12 h possessed the optimal α/β morphology and exhibited the best tensile and LCF properties.

- (2)

- At low strain amplitude, an obvious cyclic saturation stage was revealed until fracture for all three alloys.

- (3)

- At high strain amplitude, three alloys all displayed an initial striking cyclic softening. However, for alloy aging for 12 h, a cyclic saturation stage was obtained after an initial cyclic softening.

- (4)

- The deformation of {332}<113> twin and precipitation of α″ martensite were found to have a crucial influence on the cyclic stress response behavior.

Author Contributions

Funding

Conflicts of Interest

References

- Koizumi, H.; Takeuchi, Y.; Imai, H.; Kawai, T.; Yoneyama, T. Application of titanium and titanium alloys to fixed dental prostheses. J. Prosthodont. Res. 2019, 63, 266–270. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.H.; Hwang, Y.J.; Park, S.W.; Park, C.H.; Yeom, J.-T.; Park, J.M.; Kim, K. Low-cost beta titanium cast alloys with good tensile properties developed with addition of commercial material. J. Alloys Compd. 2019, 793, 271–276. [Google Scholar] [CrossRef]

- Bin Asim, U.; Siddiq, A.; Kartal, M.E. A CPFEM based study to understand the void growth in high strength dual-phase titanium alloy (Ti-10V-2Fe-3Al). Int. J. Plast. 2019, 122, 188–211. [Google Scholar] [CrossRef]

- Srivatsan, T.; Soboyejo, W.; Lederich, R. The cyclic fatigue and fracture behavior of a titanium alloy metal matrix composite. Eng. Fract. Mech. 1995, 52, 467–491. [Google Scholar] [CrossRef]

- Grosdidier, T.; Combress, Y.; Gautier, E.; Philippe, M.J. Effect of microstructure variations on the formation of deformation-induced martensite and associated tensile properties in a b metastable Ti alloy. Metall. Mater. Trans. A 2000, 31A, 1095–1106. [Google Scholar] [CrossRef]

- Hua, K.; Zhang, Y.; Gan, W.; Kou, H.; Beausir, B.; Li, J.; Esling, C. Hot deformation behavior originated from dislocation activity and β to α phase transformation in a metastable β titanium alloy. Int. J. Plast. 2019, 119, 200–214. [Google Scholar] [CrossRef]

- Sun, Q.Y.; Song, S.J.; Zhu, R.H.; Gu, H.C. Toughening of titanium alloys by twinning and martensite transformation. J. Mater. Sci. 2002, 37, 2543–2547. [Google Scholar] [CrossRef]

- Gouthama, N.S.; Singh, V. Low cycle fatigue behaviour of Ti alloy Timetal 834 at 873K. Int. J. Fatigue 2007, 29, 843–851. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Z.; Qu, S.J.; Feng, A.; Mi, G.; Shen, J.; Huang, X.; Chen, D. Microstructure and cyclic deformation behavior of a 3D-printed Ti–6Al–4V alloy. J. Alloys Compd. 2020, 825, 153971. [Google Scholar] [CrossRef]

- Ibrahim, A.M.H.; Balog, M.; Krizik, P.; Novy, F.; Cetin, Y.; Svec, P.; Bajana, O.; Drienovsky, M. Partially biodegradable Ti-based composites for biomedical applications subjected to intense and cyclic loading. J. Alloys Compd. 2020, 839, 155663. [Google Scholar] [CrossRef]

- Luquiau, D.; Feaugas, X.; Clavel, M. Cyclic softenimg of the Ti-10V-2Fe-3Al titanium alloy. Mater. Sci. Eng. A. 1997, 224, 146–156. [Google Scholar] [CrossRef]

- Cottrell, A.H. Dislocations and Plastic Flow in Crystals; Oxford University Press: Oxford, London, 1953. [Google Scholar]

- Béranger, A.; Feaugas, X.; Clavel, M. Low cycle fatigue behavior of an α + β titanium alloy: Ti6246. Mater. Sci. Eng. A 1993, 172, 31–41. [Google Scholar] [CrossRef]

- Giugliano, D.; Cho, N.-K.; Chen, H.; Gentile, L. Cyclic plasticity and creep-cyclic plasticity behaviours of the SiC/Ti-6242 particulate reinforced titanium matrix composites under thermo-mechanical loadings. Compos. Struct. 2019, 218, 204–216. [Google Scholar] [CrossRef] [Green Version]

- Santos, P.F.; Niinomi, M.; Cho, K.; Liu, H.; Nakai, M.; Narushima, T.; Ueda, K.; Itoh, Y. Effects of Mo Addition on the Mechanical Properties and Microstructures of Ti-Mn Alloys Fabricated by Metal Injection Molding for Biomedical Applications. Mater. Trans. 2017, 58, 271–279. [Google Scholar] [CrossRef] [Green Version]

- Du, Z.; Ma, Y.; Liu, F.; Zhao, X.; Chen, Y.; Li, G.; Liu, G.; Chen, Y. Improving mechanical properties of near beta titanium alloy by high-low duplex aging. Mater. Sci. Eng. A 2019, 754, 702–707. [Google Scholar] [CrossRef]

- Bertrand, E.; Castany, P.; Péron, I.; Gloriant, T. Twinning system selection in a metastable β-titanium alloy by Schmid factor analysis. Scr. Mater. 2011, 64, 1110–1113. [Google Scholar] [CrossRef] [Green Version]

- Lee, B.-S.; Im, Y.-D.; Kim, H.G.; Kim, K.; Kim, W.-Y.; Lim, S.-H. Stress-Induced α″ Martensitic Transformation Mechanism in Deformation Twinning of Metastable β-Type Ti-27Nb-0.5Ge Alloy under Tension. Mater. Trans. 2016, 57, 1868–1871. [Google Scholar] [CrossRef] [Green Version]

- Blackburn, M.J.; Feeny, J.A. Stress-induced transformations in Ti-Mo alloys. J. Inst. Met. 1971, 99, 132–134. [Google Scholar]

- Lai, M.J.; Tasan, C.C.; Raabe, D. On the mechanism of {332} twinning in metastable β titanium alloys. Acta Mater. 2016, 111, 173–186. [Google Scholar] [CrossRef]

- Gao, Y.; Zheng, Y.; Fraser, H.; Wang, Y. Intrinsic coupling between twinning plasticity and transformation plasticity in metastable β Ti-alloys: A symmetry and pathway analysis. Acta Mater. 2020, 196, 488–504. [Google Scholar] [CrossRef]

- Gong, M.Y.; Xu, S.; Capolungo, L.; Tomé, C.N.; Wang, J. Interactions between <a>dislocations and three-dimensional {1122} twin in Ti. Acta Mater. 2020, 195, 597–610. [Google Scholar] [CrossRef]

- Chen, N.; Aldareguia, J.M.M.; Kou, H.C.; Qiang, F.M.; Wu, Z.H.; Li, J.S. Reversion martensitic phase transformation induced {3 3 2}<1 1 3> twinning in metastable β-Ti alloys. Mater. Lett. 2020, 272, 127883. [Google Scholar] [CrossRef]

- Ren, L.; Xiao, W.; Kent, D.; Wan, M.; Ma, C.; Zhou, L. Simultaneously enhanced strength and ductility in a metastable β-Ti alloy by stress-induced hierarchical twin structure. Scr. Mater. 2020, 184, 6–11. [Google Scholar] [CrossRef]

- Cao, S.; Zhou, X.; Lim, C.V.S.; Boyer, R.R.; Williams, J.C.; Wu, X. A strong and ductile Ti-3Al-8V-6Cr-4Mo-4Zr (Beta-C) alloy achieved by introducing trace carbon addition and cold work. Scr. Mater. 2020, 178, 124–128. [Google Scholar] [CrossRef]

- Shin, S.; Zhu, C.Y.; Vecchio, K.S. Observations on {332}<113> twinning- induced softening in Ti-Nb Gum Metal. Mater. Sci. Eng. A. 2018, 724, 189–198. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Chen, B.; Sun, W. Transitional structure of {332}<113> β twin boundary in a deformed metastable β-type Ti-Nb-based alloy, revealed by atomic resolution electron microscopy. Scr. Mater. 2018, 150, 115–119. [Google Scholar] [CrossRef]

- Castany, P.; Yang, Y.; Bertrand, E.; Gloriant, T. Reversion of a parent {130}<310>α’’ martensitic Twinning system at the origin of {332}<113> β twins observed in metastable β titanium alloys. Phys. Rev. Lett. 2016, 117, 245501. [Google Scholar] [CrossRef] [PubMed]

- Qu, L.; Yang, Y.; Lu, Y.F.; Feng, L.; Ju, J.H.; Ge, P.; Zhou, W.; Han, D.; Ping, D.H. A detwinning process of {332}<113> twins in beta titanium alloys. Scr. Mater. 2013, 69, 389–392. [Google Scholar] [CrossRef]

- Idrissi, H.; Renard, K.; Schryvers, D.; Jacques, P. On the relationship between the twin internal structure and the work-hardening rate of TWIP steels. Scr. Mater. 2010, 63, 961–964. [Google Scholar] [CrossRef]

- Cho, K.; Morioka, R.; Harjo, S.; Kawasaki, T.; Yasuda, H.Y. Study on formation mechanism of {332}<113> deformation twinning in metastable β-type Ti alloy focusing on stress-induced α″ martensite phase. Scr. Mater. 2020, 177, 106–111. [Google Scholar] [CrossRef]

| Alloy | Al | V | Cr | Mo | Zr | Ti |

|---|---|---|---|---|---|---|

| Ti-3Al-8V-6Cr-4Mo-4Zr | 2.9 | 7.8 | 6.1 | 3.9 | 4.0 | Bal. |

| Heat Treatment States | σb/MPa | σ0.2/MPa | φ(Elongation at Maximum Tensile Strength) | ψ(Reduction of Area) |

|---|---|---|---|---|

| 800 °C/30 min + 500 °C/4 h | 1205.2 | 1137.8 | 12.98% | 16.94% |

| 800 °C/30 min + 500 °C/12 h | 1452.1 | 1436.9 | 12.75% | 15.85% |

| 800 °C/30 min + 500 °C/24 h | 1115.6 | 1088.6 | 12.67% | 15.18% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Zhang, H.; Hao, J.; Liu, J.; Sun, J.; Chen, L. Cyclic Stress Response Behavior of Near β Titanium Alloy and Deformation Mechanism Associated with Precipitated Phase. Metals 2020, 10, 1482. https://doi.org/10.3390/met10111482

Zhang S, Zhang H, Hao J, Liu J, Sun J, Chen L. Cyclic Stress Response Behavior of Near β Titanium Alloy and Deformation Mechanism Associated with Precipitated Phase. Metals. 2020; 10(11):1482. https://doi.org/10.3390/met10111482

Chicago/Turabian StyleZhang, Siqian, Haoyu Zhang, Junhong Hao, Jing Liu, Jie Sun, and Lijia Chen. 2020. "Cyclic Stress Response Behavior of Near β Titanium Alloy and Deformation Mechanism Associated with Precipitated Phase" Metals 10, no. 11: 1482. https://doi.org/10.3390/met10111482

APA StyleZhang, S., Zhang, H., Hao, J., Liu, J., Sun, J., & Chen, L. (2020). Cyclic Stress Response Behavior of Near β Titanium Alloy and Deformation Mechanism Associated with Precipitated Phase. Metals, 10(11), 1482. https://doi.org/10.3390/met10111482