Tube Drawing Process with Diameter Expansion for Effectively Reducing Thickness

Abstract

:1. Introduction

2. Materials and Methods

2.1. Method for Estimating Frictional Property by Tube Flaring

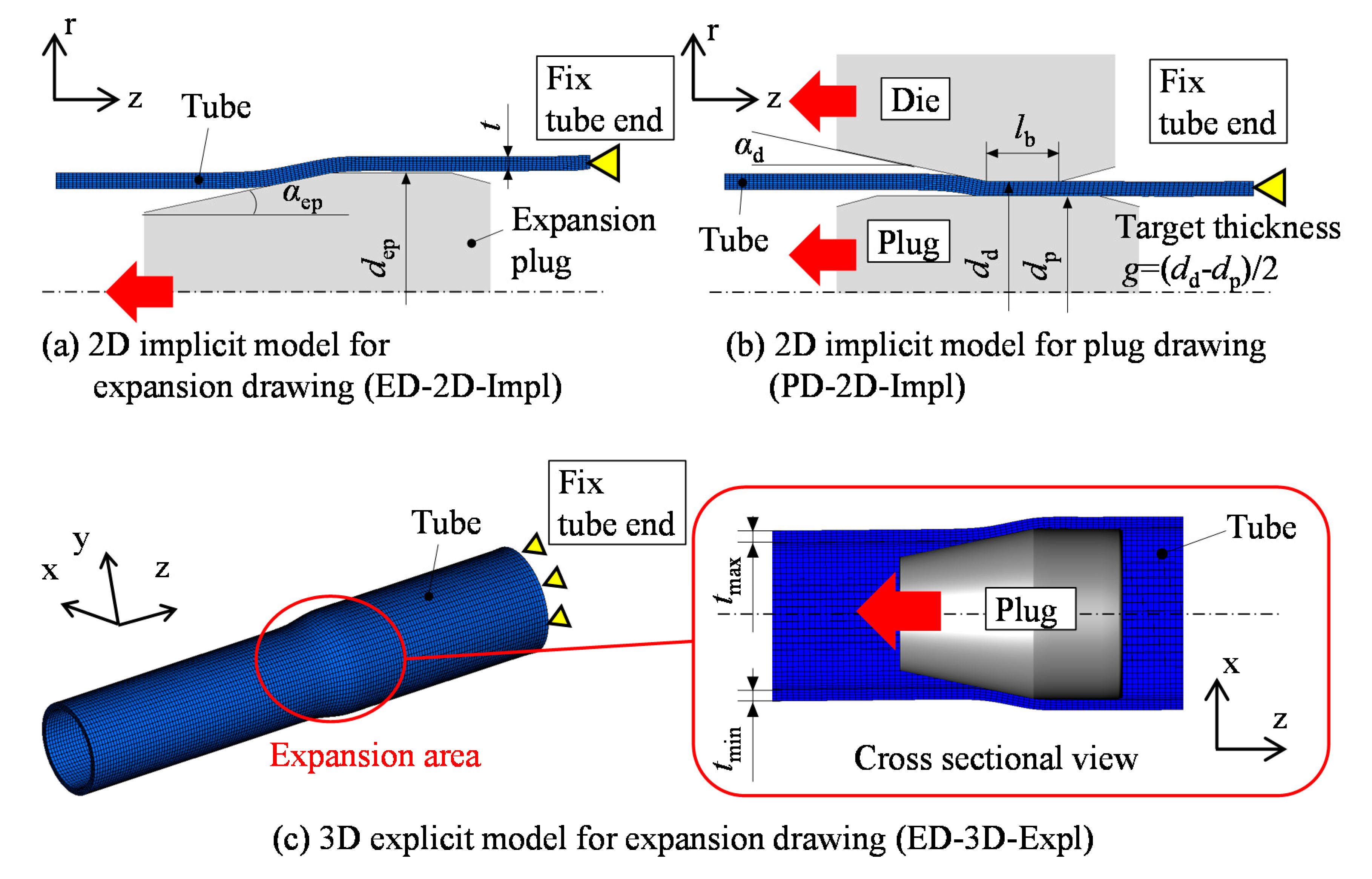

2.2. Expansion Drawing Method and Conditions

3. Results and Discussions

3.1. Identification of Friction Coefficient

3.2. Investigation of Thickness Reduction Efficiency by FEM Analysis

3.3. Experimental Investigation of Expansion Drawing

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kuboki, T.; Nishida, K.; Sakaki, T.; Murata, M. Effect of plug on levelling of residual stress in tube drawing. J. Mater. Process. Technol. 2008, 204, 162–168. [Google Scholar] [CrossRef]

- Kuboki, T.; Tasaka, S.; Kajikawa, S. Examination of working condition for reducing thickness variation in tube drawing with plug. In COMPLAS XIV, Proceedings of the XIV International Conference on Computational Plasticity: Fundamentals and Applications, Barcelona, Spain, 5–7 September 2017; CIMNE: Barcelona, Spain, 2017; pp. 63–71. [Google Scholar]

- Foadian, F.; Carradó, A.; Palkowski, H. Precision tube production: Influencing the eccentricity and residual stresses by tilting and shifting. J. Mater. Process. Technol. 2015, 222, 155–162. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, W.; Long, J.; Lei, Z. Surface roughening analysis of cold drawn tube based on macro–micro coupling finite element method. J. Mater. Process. Technol. 2015, 224, 189–199. [Google Scholar] [CrossRef]

- Łuksza, J.; Burdek, M. The influence of the deformation mode on the final mechanical properties of products in multi-pass drawing and flat rolling. J. Mater. Process. Technol. 2002, 125–126, 725–730. [Google Scholar] [CrossRef]

- Prakash, R.; Singhal, R.P. Shear spinning technology for manufacture of long thin wall tubes of small bore. J. Mater. Process. Technol. 1995, 54, 186–192. [Google Scholar] [CrossRef]

- Chi, J.; Cai, Z.; Li, L. Optimization of spinning process parameters for long thin-walled cylinder of TC11 alloy based on processing map. Int. J. Adv. Manuf. Technol. 2018, 97, 1961–1969. [Google Scholar] [CrossRef]

- Abe, H.; Iwamoto, T.; Yamamoto, Y.; Nishida, S.; Komatsu, R. Dimensional accuracy of tubes in cold pilgering. J. Mater. Process. Technol. 2016, 231, 277–287. [Google Scholar] [CrossRef]

- Yasui, H.; Miyagawa, T.; Yoshihara, S.; Furushima, T.; Yamada, R.; Ito, Y. Influence of Internal Pressure and Axial Compressive Displacement on the Formability of Small-Diameter ZM21 Magnesium Alloy Tubes in Warm Tube Hydroforming. Metals 2020, 10, 674. [Google Scholar] [CrossRef]

- Tamura, S.; Iguchi, K.; Mizumura, M. Effect of Punch Shape on Multiprocess Tube Flaring for Eccentric Parts. J. Jpn Soc. Technol. Plast. 2019, 60, 182–186. (In Japanese) [Google Scholar] [CrossRef]

- Avalle, M.; Priarone, P.C.; Scattina, A. Experimental and numerical characterization of a mechanical expansion process for thin-walled tubes. J. Mater. Process. Technol. 2014, 214, 1143–1152. [Google Scholar] [CrossRef] [Green Version]

- Al-Abri, O.S.; Pervez, T. Structural behavior of solid expandable tubular undergoes radial expansion process–Analytical, numerical, and experimental approaches. Int. J. Solids Struct. 2013, 50, 2980–2994. [Google Scholar] [CrossRef] [Green Version]

- Seibi, A.C.; Barsoum, I.; Molki, A. Experimental and Numerical Study of Expanded Aluminum and Steel Tubes. Procedia Eng. 2011, 10, 3049–3055. [Google Scholar] [CrossRef]

- Karrech, A.; Seibi, A. Analytical model for the expansion of tubes under tension. J. Mater. Process. Technol. 2010, 210, 356–362. [Google Scholar] [CrossRef]

- Seibi, A.C.; Al-Hiddabi, S.; Pervez, T. Structural Behavior of a Solid Tubular Under Large Radial Plastic Expansion. J. Energy Resour. Technol. 2005, 127, 323–327. [Google Scholar] [CrossRef]

- Yang, J.; Luo, M.; Hua, Y.; Lu, G. Energy absorption of expansion tubes using a conical–cylindrical die: Experiments and numerical simulation. Int. J. Mech. Sci. 2010, 52, 716–725. [Google Scholar] [CrossRef]

- De Souza Neto, E.A.; Peric, D.; Dutko, M.; Owen, D.R.J. Design of simple low order finite elements for large strain analysis of nearly incompressible solids. Int. J. Solids Struct. 1996, 33, 3277–3296. [Google Scholar] [CrossRef]

| Tube | Material | Carbon Steel (STKM13C) Aluminum Alloy (AA1070) |

| Initial diameter d0 (mm) | 30 | |

| Initial thickness t0 (mm) | 2 | |

| Initial length l0 (mm) | 200 | |

| Initial flared length lf0 (mm) | 100 | |

| Element size for flaring region (FEM) | 8 elements in thickness 0.5 mm/div along the z axis | |

| Expansion plug | Material | SKD11 (Experiment) Rigid (FEM) |

| Half angle αep (°) | 12 | |

| Lubricant (Experiment) | Stamping and Forming Lubricant G-3344 (Nihon Kohsakuyu Co., Ltd., Minato-ku, Japan) | |

| Friction coefficient μ (FEM) | 0.1–0.3 | |

| Property | STKM13C | AA1070 |

|---|---|---|

| Young’s modulus (GPa) | 200 | 66 |

| Poisson ratio | 0.3 | 0.34 |

| Yield stress (MPa) | 637 | 88 |

| Swift equation σeq = F(εeq + ε0)n | σeq = 725(εeq + 0.0032)0.023 | σeq = 121(εeq + 0.0013)0.048 |

| Tube (FEM and experiment) | Material | Carbon Steel (STKM13C) Aluminum Alloy (AA1070) | |

| Initial diameter d0 (mm) | 30 | ||

| Initial thickness t0 (mm) | 2, 4 | ||

| Initial length l0 (mm) | Exp. | 200 | |

| 2D FEM | 160 | ||

| 3D FEM | 170 | ||

| Element size for flaring region (FEM) | 2D FEM | 0.5 mm/div along the z axis 8 elements in thickness | |

| 3D FEM | 1 mm/div along the z axis 4 elements in thickness 64 elements in hoop | ||

| Plug for expansion drawing (FEM and experiment) | Material | SKD11 (Experiment) Rigid (FEM) | |

| Half angle αep (°) | 12 | ||

| Diameter dep (mm) (Expansion ratio κd) | 24–38 (0.07–0.46) | ||

| Die for plug drawing (FEM) | Material | Rigid | |

| Half angle αd (°) | 12 | ||

| Diameter dd (mm) | 28 | ||

| Bearing length lb (mm) | 9 | ||

| Plug for plug drawing (FEM) | Material | Rigid | |

| Diameter dp (mm) (Target thickness g (mm)) | t0 = 2.0 mm | 24–25 (1.5–2.0) | |

| t0 = 4.0 mm | 20–22 (3.0–4.0) | ||

| Lubricant (Experiment) | Stamping and Forming Lubricant G-3344 (Nihon Kohsakuyu Co., Ltd., Minato-ku, Japan) | ||

| Friction coefficient μ (FEM) | 0.1 (STKM13C) 0.25 (AA1070) | ||

| Material | Expansion Ratio κd | ||||

|---|---|---|---|---|---|

| 0.08 | 0.15 | 0.23 | 0.31 | 0.38 | |

| STKM13C | s | s | s | c | - |

| AA1070 | s | s | s | s | c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kajikawa, S.; Kawaguchi, H.; Kuboki, T.; Akasaka, I.; Terashita, Y.; Akiyama, M. Tube Drawing Process with Diameter Expansion for Effectively Reducing Thickness. Metals 2020, 10, 1642. https://doi.org/10.3390/met10121642

Kajikawa S, Kawaguchi H, Kuboki T, Akasaka I, Terashita Y, Akiyama M. Tube Drawing Process with Diameter Expansion for Effectively Reducing Thickness. Metals. 2020; 10(12):1642. https://doi.org/10.3390/met10121642

Chicago/Turabian StyleKajikawa, Shohei, Hikaru Kawaguchi, Takashi Kuboki, Isamu Akasaka, Yuzo Terashita, and Masayoshi Akiyama. 2020. "Tube Drawing Process with Diameter Expansion for Effectively Reducing Thickness" Metals 10, no. 12: 1642. https://doi.org/10.3390/met10121642