Low Cycle Fatigue Behavior of Elbows with Local Wall Thinning

Abstract

1. Introduction

2. Test Specimens and Procedures

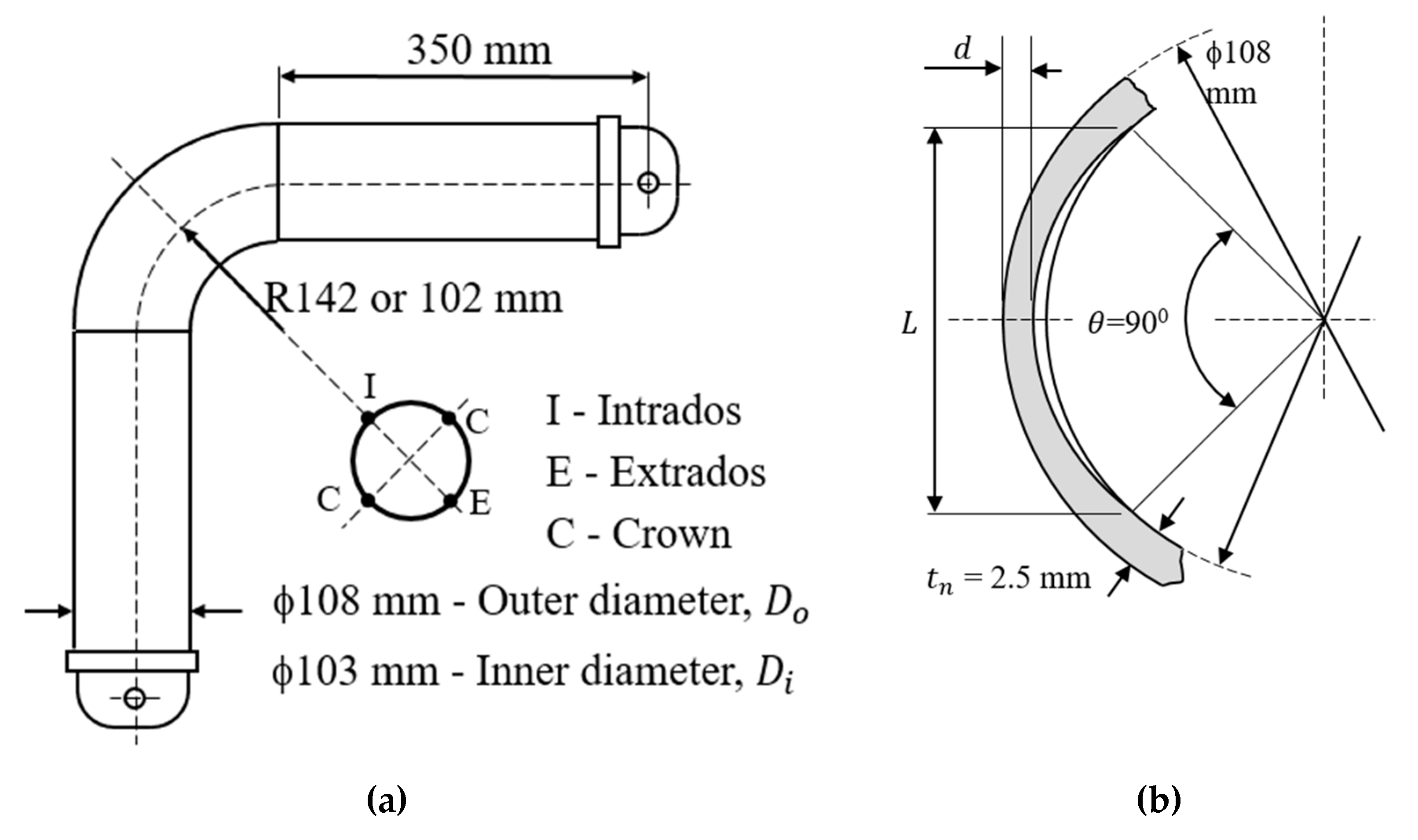

2.1. Material and Specimens

2.2. Testing Apparatus

3. Results and Discussion

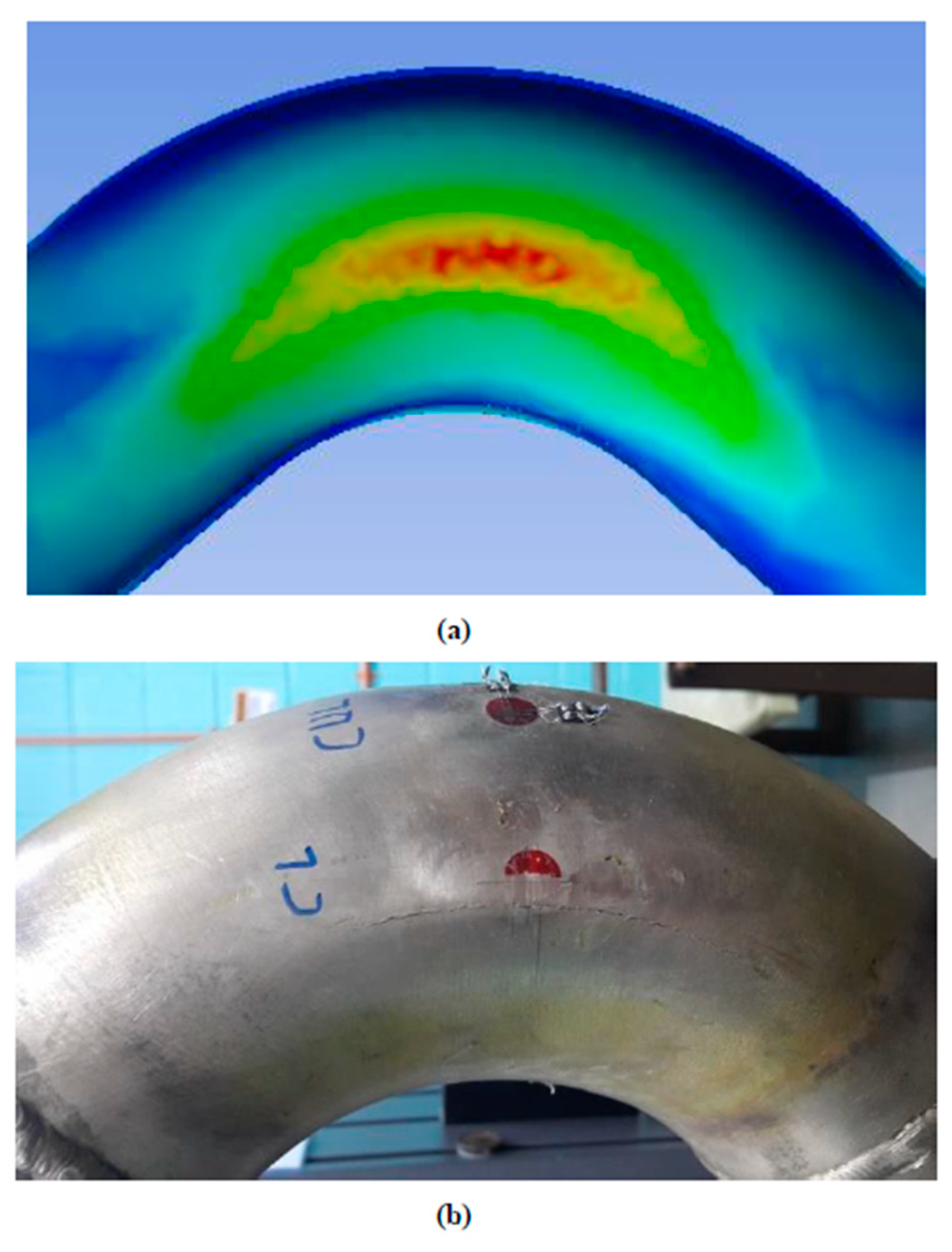

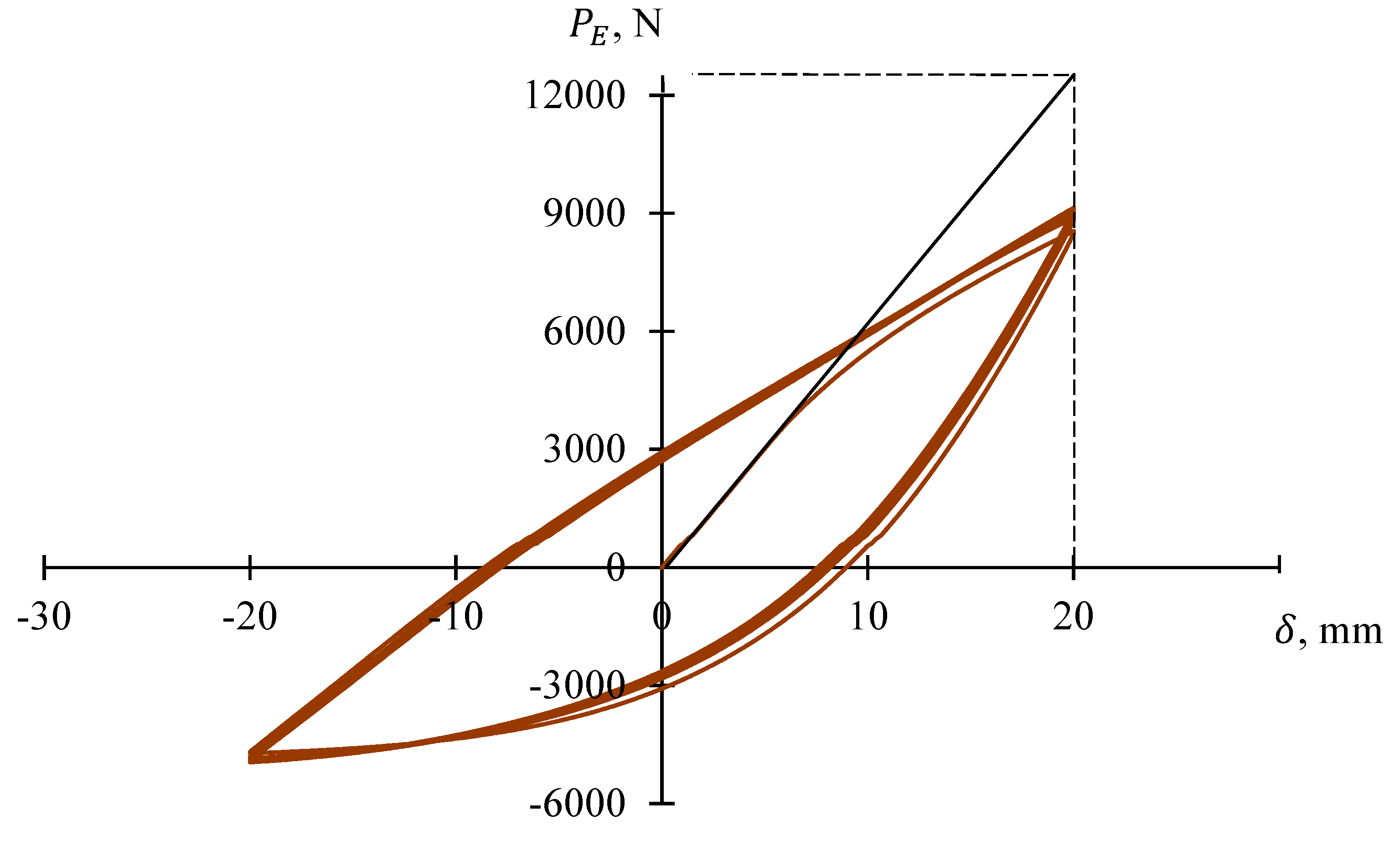

3.1. Low Cycle Behavior of Sound Elbows

3.2. Low Cycle Behavior of Elbows with Local Wall Thinning

4. Safety Margin Evaluation

5. Conclusions

- (1)

- Local wall thinning at extrados and intrados regions does not significantly affect low cycle fatigue life of damaged elbows. Fatigue cracks do not initiate at the weakened locations even at large eroded ratios;

- (2)

- In most cases and regardless of the applied inner pressure, fatigue cracks initiate at the crown regions, and the presence of local wall thinning defect at this location only marginally reduces low cycle fatigue life;

- (3)

- When the allowable stress is assumed as the material yield stress, and the applied stress level is calculated based on the ASME Boiler and Pressure Vessel Code, Section III, the elbow with wall thinning defects withstood 6–7 times of the allowable stress level, even when the eroded ratio has reached the extreme value of 0.75. This result indicates a sufficiently large safety margin against occasional loading.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Varelis, G.E.; Karamanos, S. Low-cycle fatigue of pressurized steel elbows under in-plane bending. ASME J. Press. Vessel Technol. 2015, 137. [Google Scholar] [CrossRef]

- Sobel, L.H.; Newman, S.Z. Comparison of Experimental and Simplified Analytical Results for the In-Plane Plastic Bending and Buckling of an Elbow. J. Press. Vessel. Technol. 1980, 102, 400–409. [Google Scholar] [CrossRef]

- Hilsenkopf, P.; Boneh, B.; Sollogoub, P. Experimental study of behavior and functional capability of ferritic steel elbows and austenitic stainless steel thin-walled elbows. Int. J. Press. Vessel. Pip. 1988, 33, 111–128. [Google Scholar] [CrossRef]

- Gresnigt, A.M.; Van Foeken, R. Strength and deformation capacity of bends in pipelines. Int. J. Offshore Polar Eng. 1995, 5, 294–307. [Google Scholar]

- Karamanos, S.A.; Giakoumatos, E.; Gresnigt, A.M. Nonlinear Response and Failure of Steel Elbows Under In-Plane Bending and Pressure. J. Press. Vessel. Technol. 2003, 125, 393–402. [Google Scholar] [CrossRef]

- Kim, J.-W.; Na, Y.-S.; Lee, S.-H. Experimental Evaluation of the Bending Load Effect on the Failure Pressure of Wall-Thinned Elbows. J. Press. Vessel. Technol. 2009, 131. [Google Scholar] [CrossRef]

- Takahashi, K.; Watanabe, S.; Ando, K.; Urabe, Y.; Hidaka, A.; Hisatsune, M.; Miyazaki, K. Low cycle fatigue behaviors of elbow pipe with local wall thinning. Nucl. Eng. Des. 2009, 239, 2719–2727. [Google Scholar] [CrossRef]

- Nagamori, H.; Takahashi, K. The Revised Universal Slope Method to Predict the Low-Cycle Fatigue Lives of Elbow and Tee Pipes. J. Press. Vessel. Technol. 2017, 139. [Google Scholar] [CrossRef]

- Foroutan, M.; Ahmadzadeh, G.; Varvani-Farahani, A. Axial and hoop ratcheting assessment in pressurized steel elbow pipes subjected to bending cycles. Thin-Walled Struct. 2018, 123, 317–323. [Google Scholar] [CrossRef]

- Jeon, B.-G.; Kim, S.-W.; Choi, H.-S.; Park, N.-U.; Kim, N.-S. A Failure Estimation Method of Steel Pipe Elbows under In-plane Cyclic Loading. Nucl. Eng. Technol. 2017, 49, 245–253. [Google Scholar] [CrossRef]

- Kim, S.-W.; Choi, H.-S.; Jeon, B.-G.; Hahm, D.-G. Low-cycle fatigue behaviors of the elbow in a nuclear power plant piping system using the moment and deformation angle. Eng. Fail. Anal. 2019, 96, 348–361. [Google Scholar] [CrossRef]

- Kiran, A.R.; Reddy, G.; Agrawal, M. Experimental and numerical studies of inelastic behavior of thin walled elbow and tee joint under seismic load. Thin-Walled Struct. 2018, 127, 700–709. [Google Scholar] [CrossRef]

- Liu, C.; Shi, S.; Cai, Y.; Chen, X. Ratcheting behavior of pressurized-bending elbow pipe after thermal aging. Int. J. Press. Vessel. Pip. 2019, 169, 160–169. [Google Scholar] [CrossRef]

- Udagawa, M.; Li, Y.; Nishida, A.; Nakamura, I. Failure behavior analyses of piping system under dynamic seismic loading. Int. J. Press. Vessel. Pip. 2018, 167, 2–10. [Google Scholar] [CrossRef]

- Kiran, A.R.; Reddy, G.; Agrawal, M. Seismic fragility analysis of pressurized piping systems considering ratcheting: A case study. Int. J. Press. Vessel. Pip. 2019, 169, 26–36. [Google Scholar] [CrossRef]

- Firoozabad, E.S.; Jeon, B.-G.; Choi, H.-S.; Kim, N.-S. Failure criterion for steel pipe elbows under cyclic loading. Eng. Fail. Anal. 2016, 66, 515–525. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers. Process Piping, B31.3. In ASME Code for Pressure Piping; American Society of Mechanical Engineers: New York, NY, USA, 2006. [Google Scholar]

- Comité Européen de Normalisation. Metallic Industrial Piping—Part 3: Design and Calculation, EN13480-3; Comité Européen de Normalisation: Brussels, Belgium, 2002. [Google Scholar]

- Urabe, Y.; Takahashi, K.; Ando, K. Low Cycle Fatigue Behavior and Seismic Assessment for Elbow Pipe Having Local Wall Thinning. J. Press. Vessel. Technol. 2012, 134, 041801. [Google Scholar] [CrossRef]

- Takahashi, K.; Ando, K.; Matsuo, K.; Urabe, Y. Estimation of Low-Cycle Fatigue Life of Elbow Pipes Considering the Multi-Axial Stress Effect. J. Press. Vessel. Technol. 2014, 136, 041405. [Google Scholar] [CrossRef]

- Harun, M.F.; Mohammad, R.; Kotousov, A. Effect of wall thinning on deformation and failure of copper-nickel alloy elbows subjected to low cycle fatigue. Mater. Des. Process. Commun. 2019. [Google Scholar] [CrossRef]

| Mechanical Properties | |

|---|---|

| Young’s modulus | 125 GPa |

| Poisson’s ratio | 0.3 |

| Ultimate strength | 300 MPa |

| Yield strength | 110 MPa |

| Hardness | 80 HB |

| Test Conditions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Defect Location | Pressure, MPa | ||||||||

| Extrados | 0.25 | 80 | 90° | 0 | 0.5 | 1.0 | 1.5 | 2.0 | ± 20 |

| 0.5 | 0 | 0.5 | 1.0 | 1.5 | - | ||||

| 0.75 | 0 | 0.5 | 1.0 | 1.5 | - | ||||

| Crown | 0.25 | 0 | 0.5 | 1.0 | 1.5 | 2.0 | |||

| 0.5 | 0 | 0.5 | 1.0 | 1.5 | - | ||||

| 0.75 | 0 | 0.5 | 1.0 | 1.5 | - | ||||

| Intrados | 0.25 | 60 | 0 | 0.5 | 1.0 | 1.5 | 2.0 | ||

| 0.5 | 0 | 0.5 | 1.0 | 1.5 | - | ||||

| 0.75 | 0 | 0.5 | 1.0 | 1.5 | - | ||||

| Types of Elbow Radius | Long Radius Elbows | Short Radius Elbows | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inner Pressure, MPa | 0 | 1 | 2 | 3 | 4 | 0 | 1 | 2 | 3 | 4 |

| Cycles to Failure | 208 C | 220 C | 210 C | 204 C | 196 C | 165 C | 166 C | 166 C | 166 C | 166 C |

| Location of | Inner Pressure, MPa | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Defects | Long Bend Radius Elbows | Short Bend Radius Elbows | |||||||||

| 0.0 | 0.5 | 1.0 | 1.5 | 2.0 | 0.0 | 0.5 | 1.0 | 1.5 | 2.0 | ||

| Extrados | 0.25 | 193 C | 195 C | 196 C | 198 C | 200 C | 176 C | 179 C | 181 C | 185 C | 188 C |

| 0.5 | 187 C | 188 C | 188 C | 189 C | - | 171 C | 171 C | 172 C | 173 C | - | |

| 0.75 | 197 C | 179 C | 180 C | 175 E/T | - | 174 C | 175 E/T | 176 E/T | 175 E/T | - | |

| Crown | 0.25 | 184 C | 187 C | 191 C | 195 C | 190 C | 169 C | 170 C | 170 C | 171 C | 172 C |

| 0.5 | 172 C | 173 C | 174 C | 175 C/T | - | 166 C | 167 C | 168 C | 168 C/T | - | |

| 0.75 | 166 C/T | 166 C | 166 C/T | 165 C/T | - | 163 C | 163 C | 160 C | 155 C/T | - | |

| Intrados | 0.25 | 194 C | 195 C | 196 C | 198 C | 200 C | 176 C | 177 C | 178 C | 178 C | 179 C |

| 0.5 | 198 C | 199 C | 200 C | 201 C | - | 177 C | 178 C | 179 C | 180 C | - | |

| 0.75 | 201 C | 196 C | 192 I/T | 189 I/T | - | 170 C | 170 C | 169 I/T | 166 I/T | - | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harun, M.F.; Mohammad, R.; Kotousov, A. Low Cycle Fatigue Behavior of Elbows with Local Wall Thinning. Metals 2020, 10, 260. https://doi.org/10.3390/met10020260

Harun MF, Mohammad R, Kotousov A. Low Cycle Fatigue Behavior of Elbows with Local Wall Thinning. Metals. 2020; 10(2):260. https://doi.org/10.3390/met10020260

Chicago/Turabian StyleHarun, Muhammad Faiz, Roslina Mohammad, and Andrei Kotousov. 2020. "Low Cycle Fatigue Behavior of Elbows with Local Wall Thinning" Metals 10, no. 2: 260. https://doi.org/10.3390/met10020260

APA StyleHarun, M. F., Mohammad, R., & Kotousov, A. (2020). Low Cycle Fatigue Behavior of Elbows with Local Wall Thinning. Metals, 10(2), 260. https://doi.org/10.3390/met10020260