Cavitation Peening: A Review

Abstract

:1. Introduction

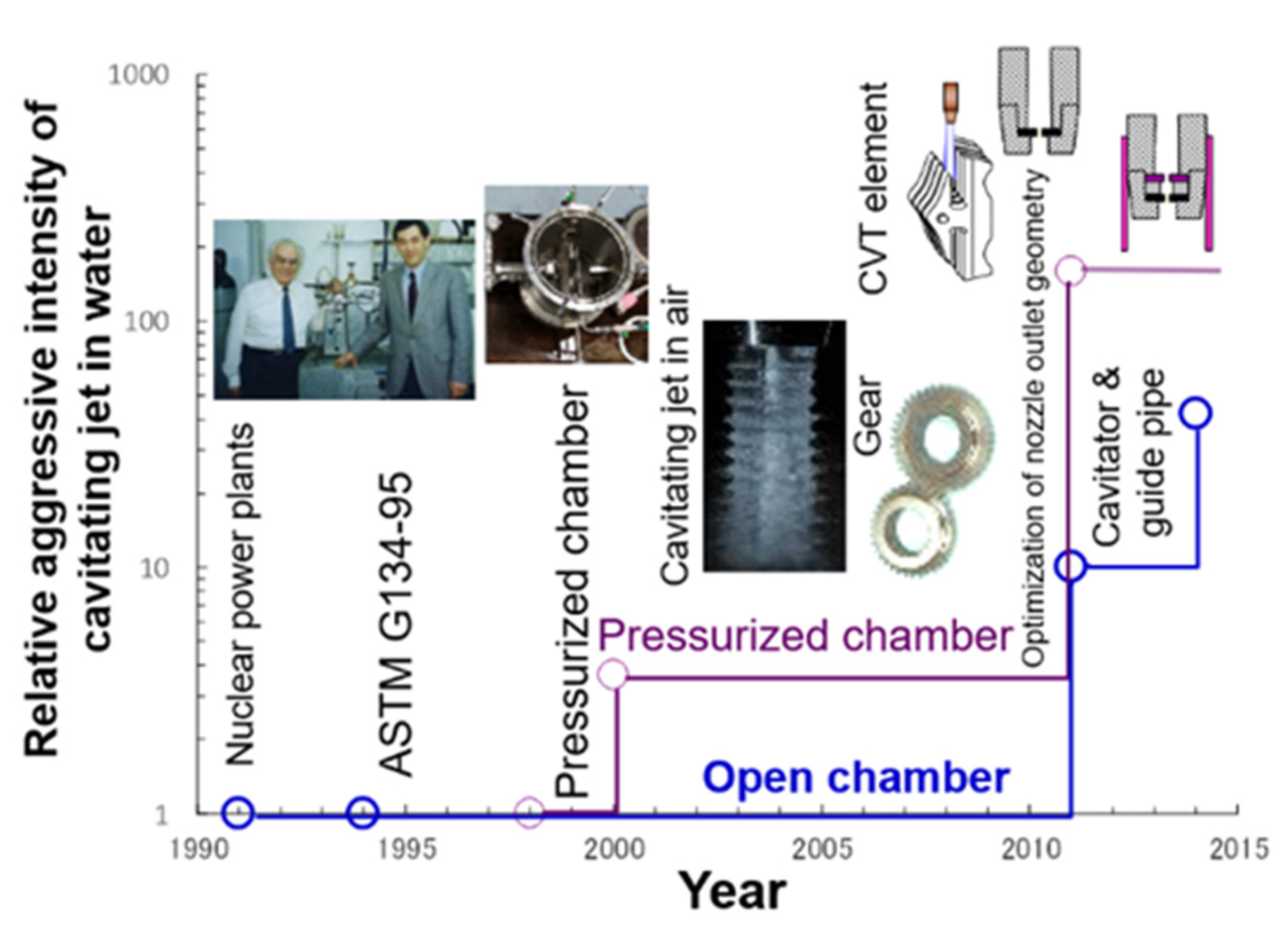

2. History of Cavitation Peening

3. Cavitation

3.1. What Is Cavitation?

3.2. How To Generate Cavitation

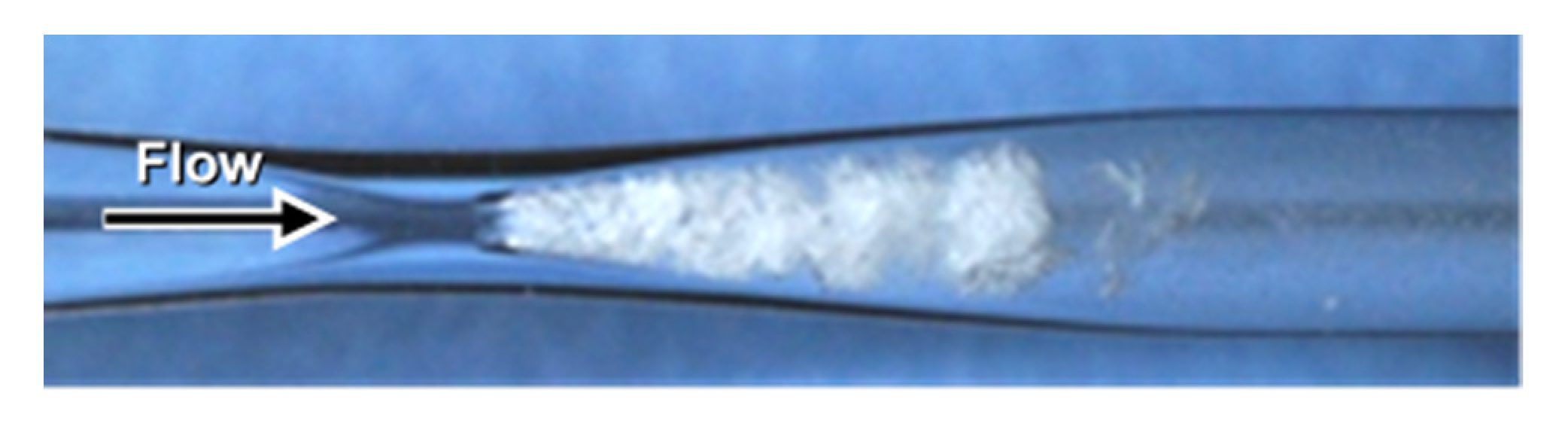

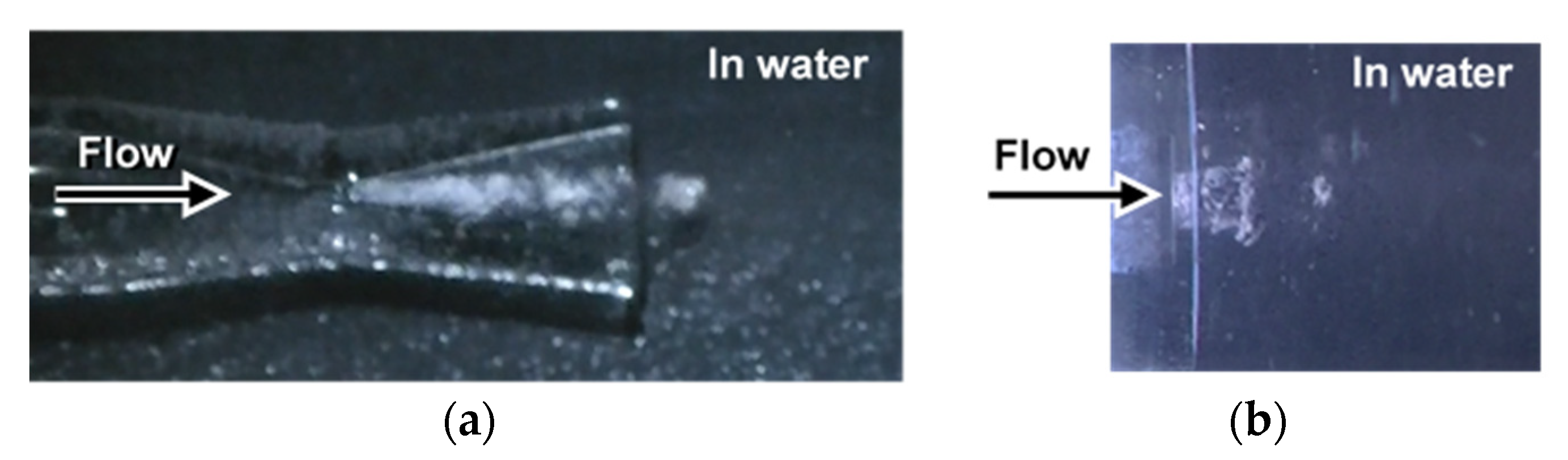

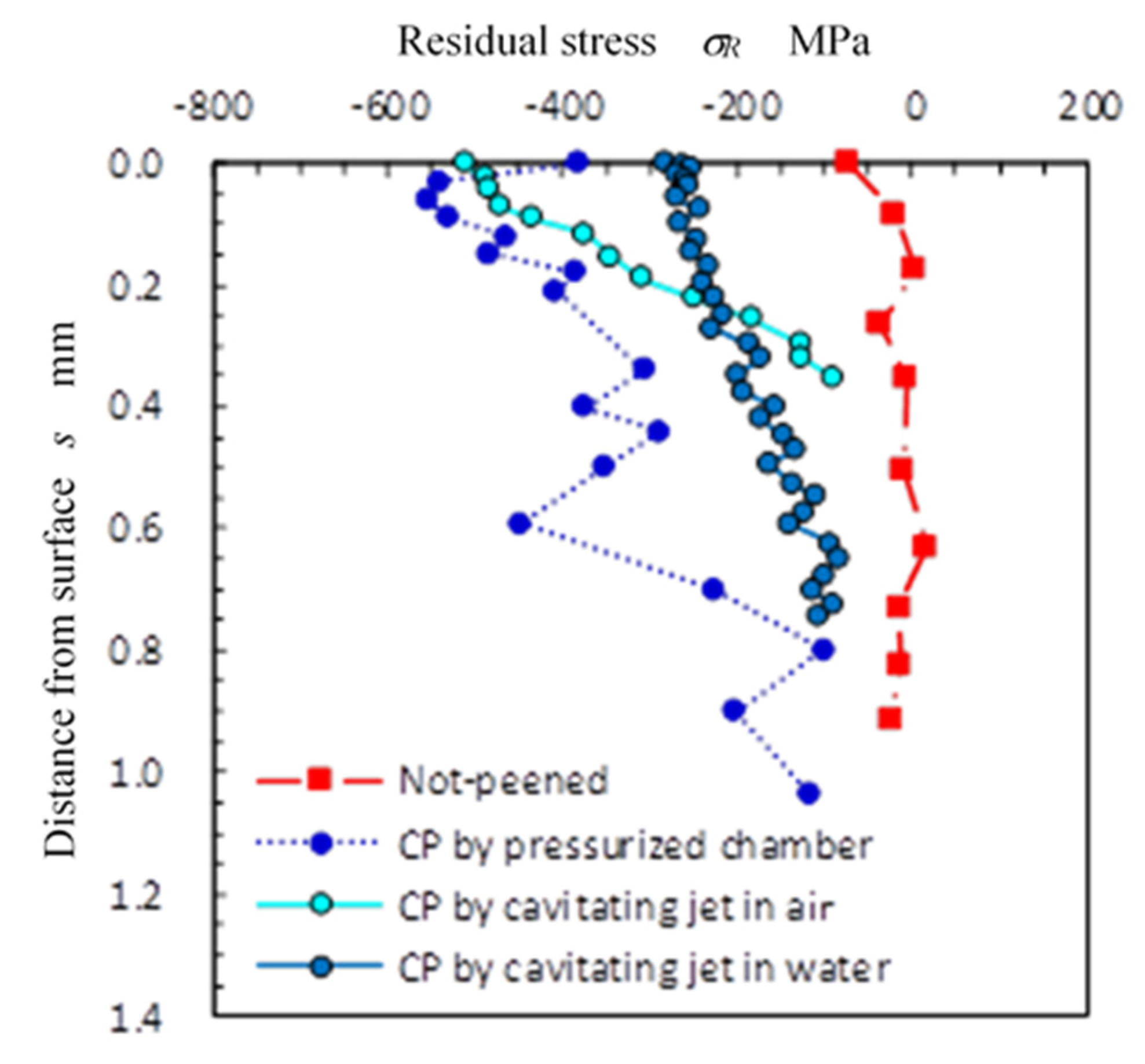

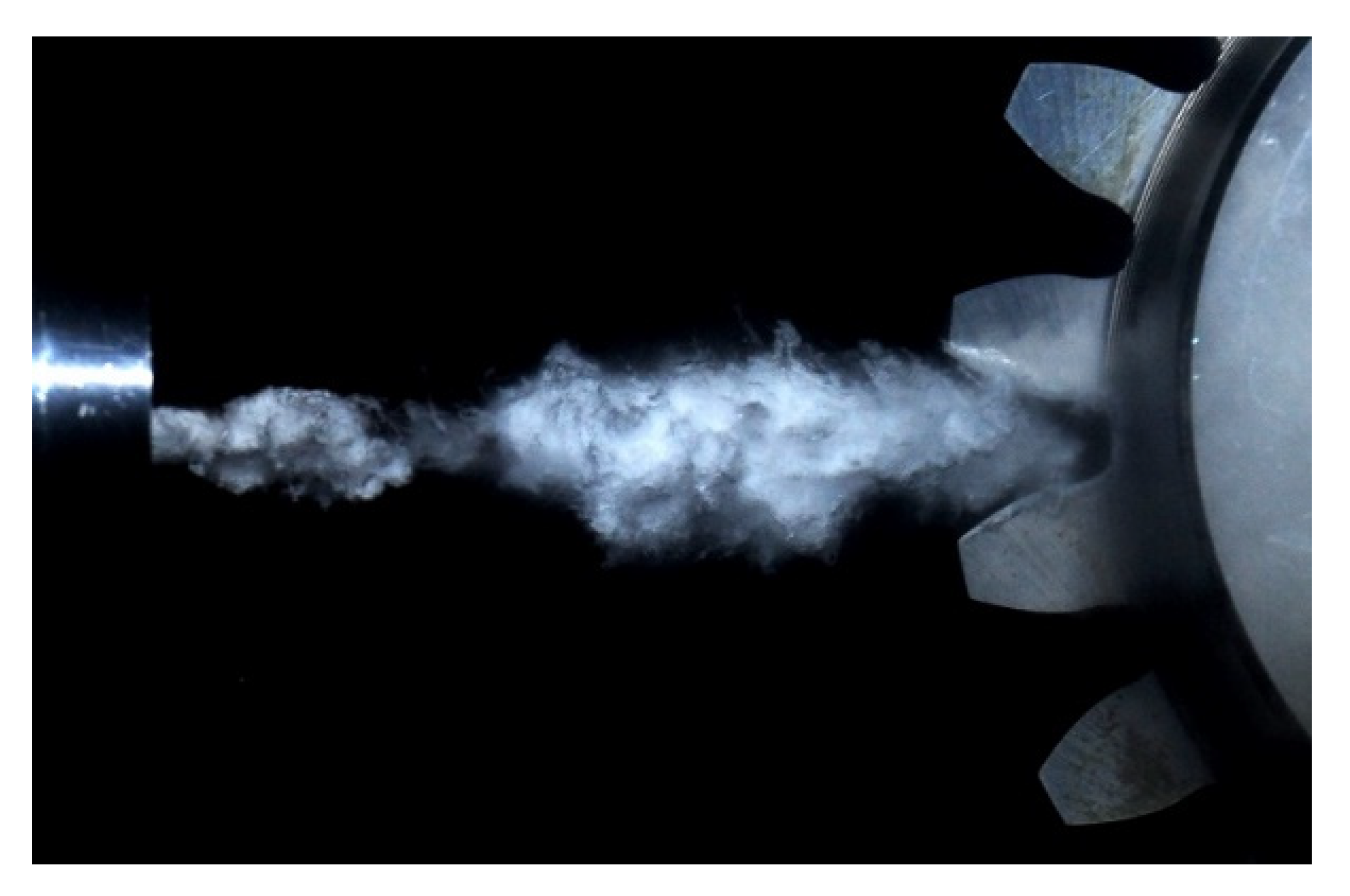

3.2.1. Hydraulic Cavitation

3.2.2. Ultrasonic Cavitation

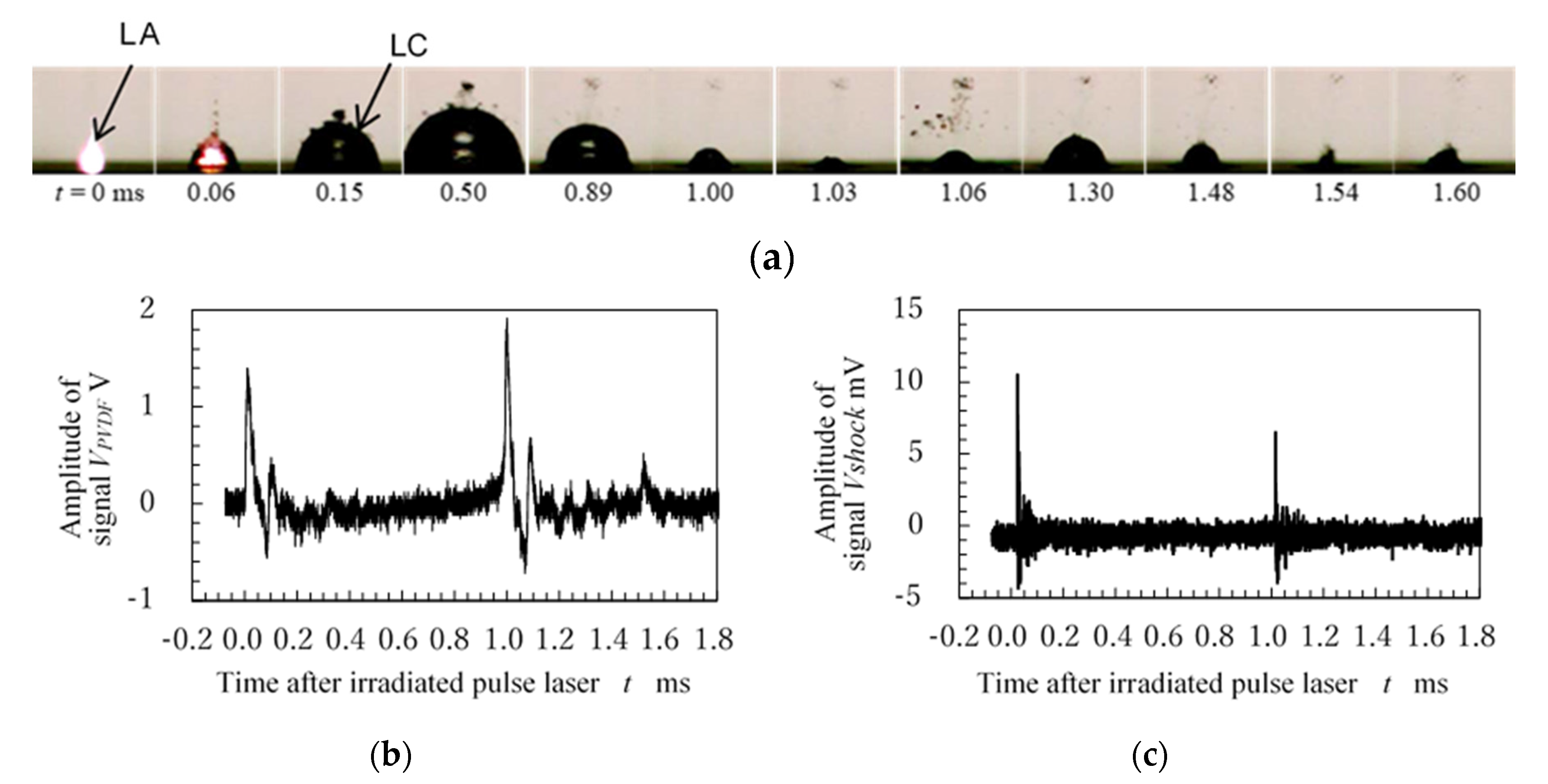

3.2.3. Laser Cavitation

4. Key Parameters of Cavitation Peening

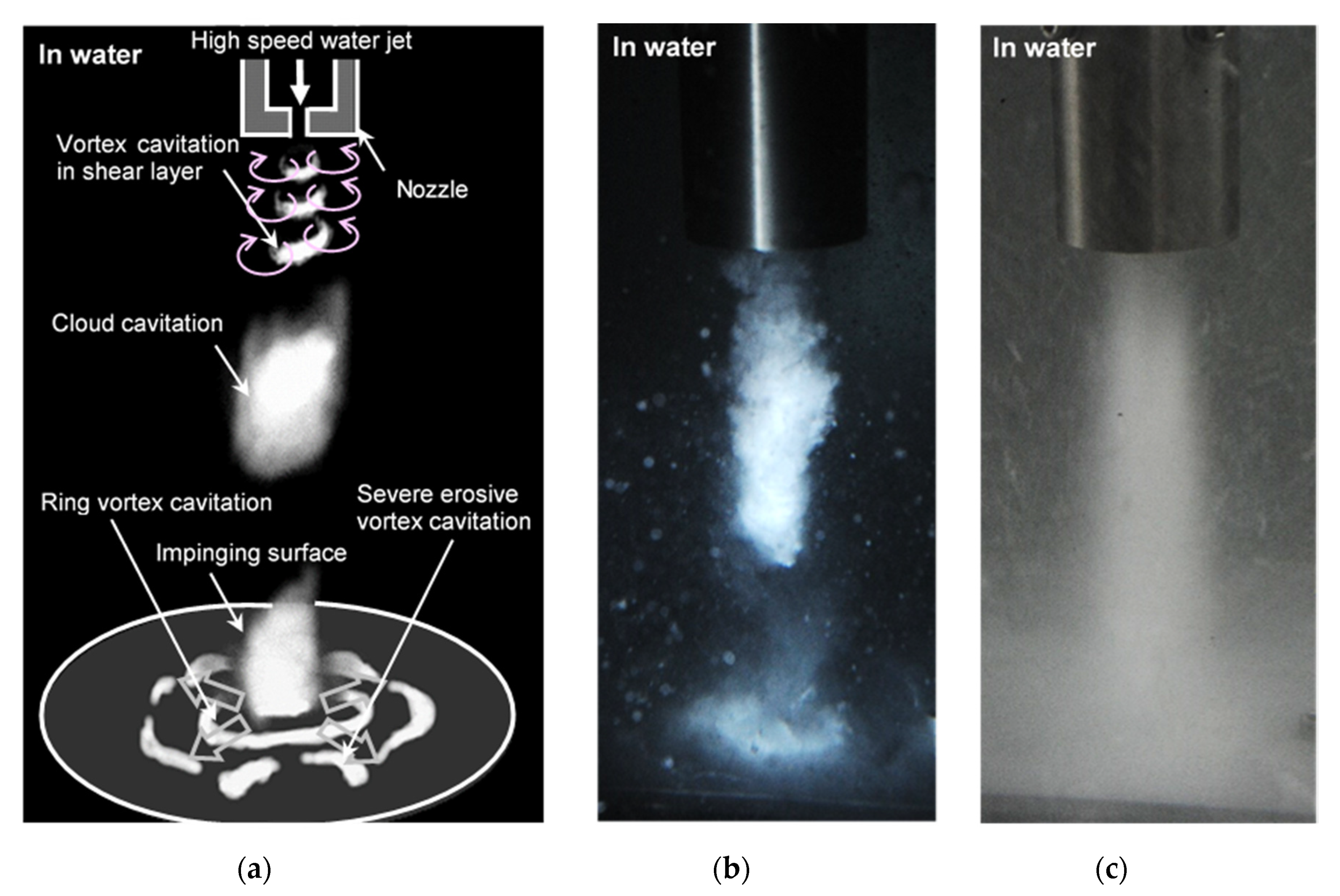

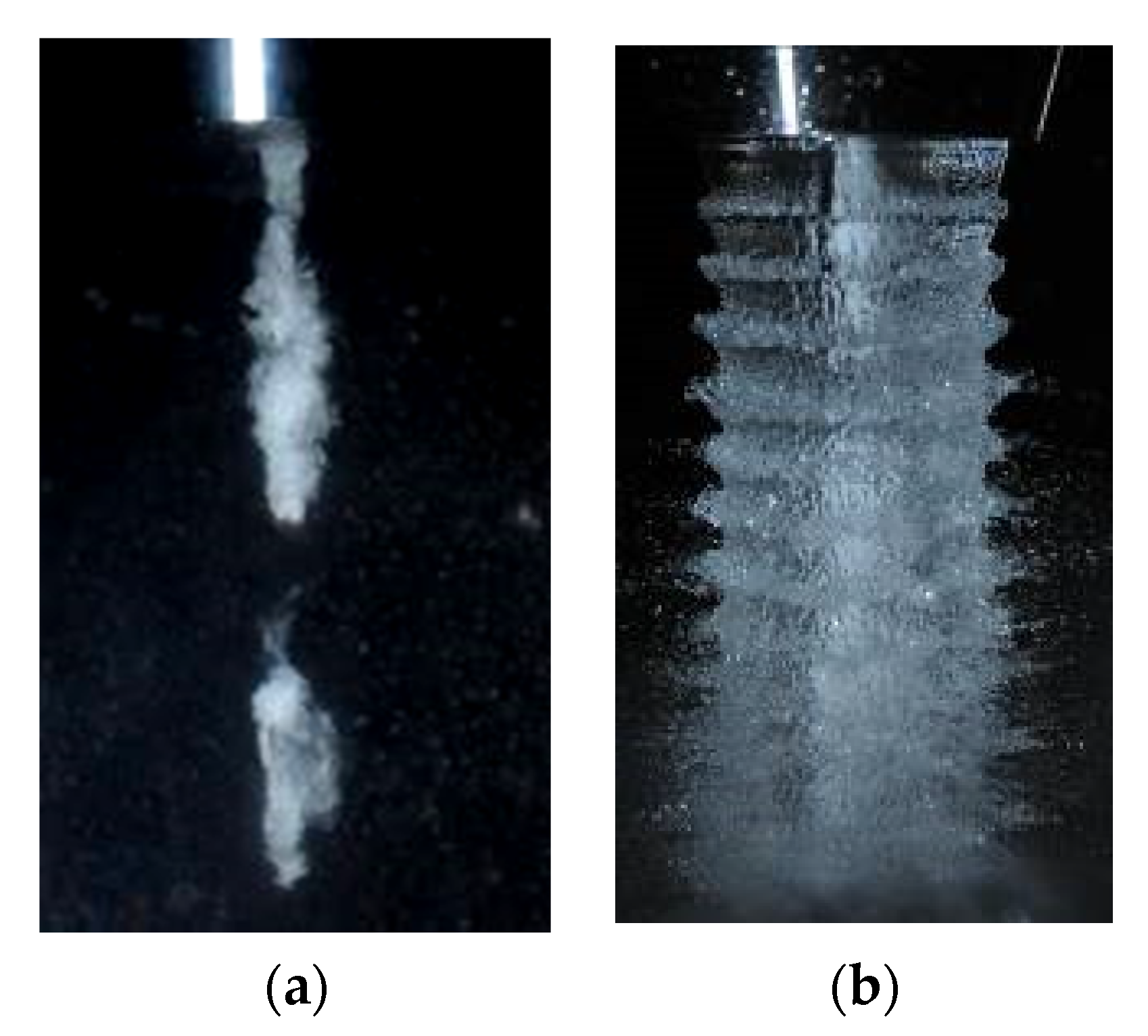

4.1. Type of Cavitating Jet

4.2. Standoff Distance

4.3. Nozzle Geometry and Diameter

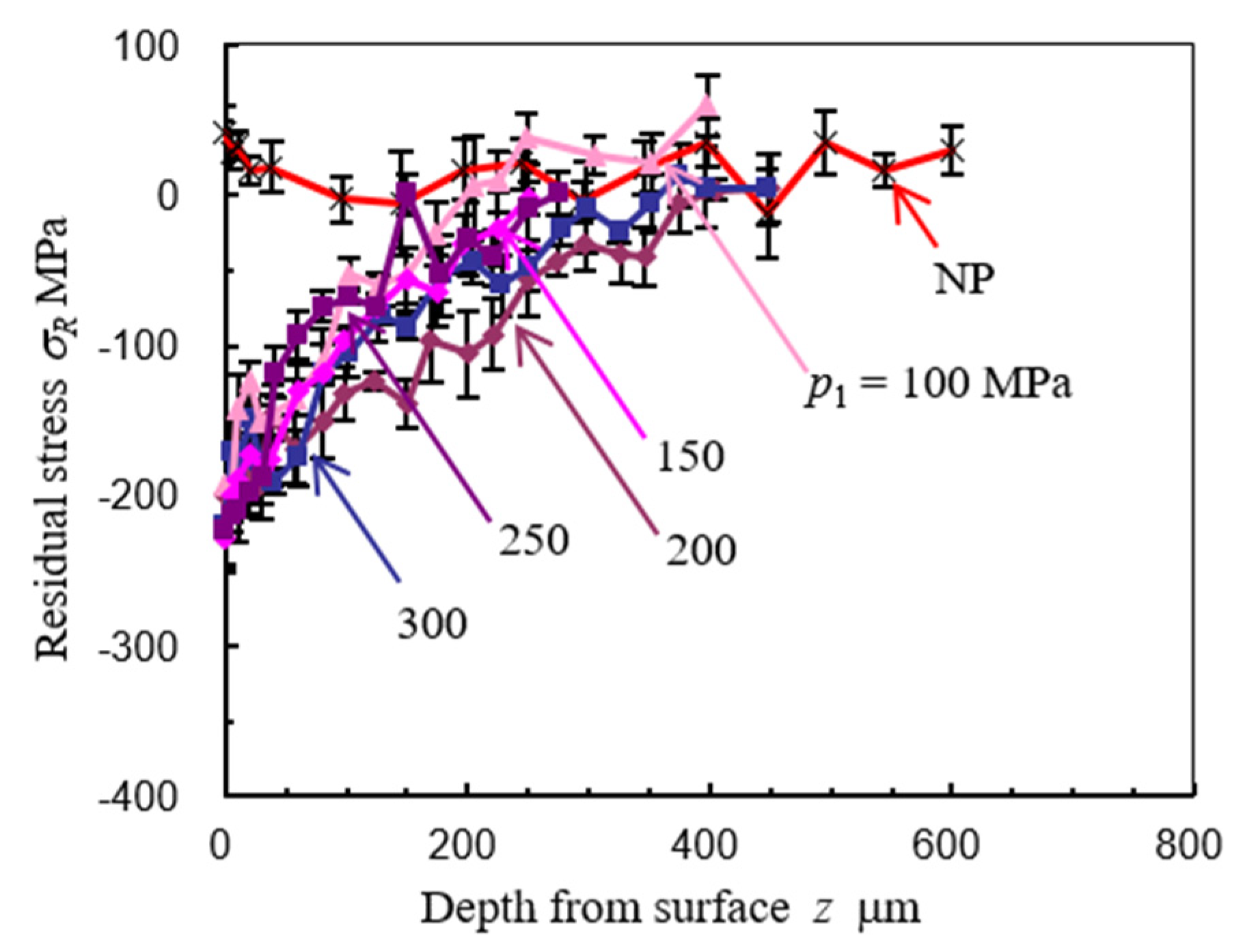

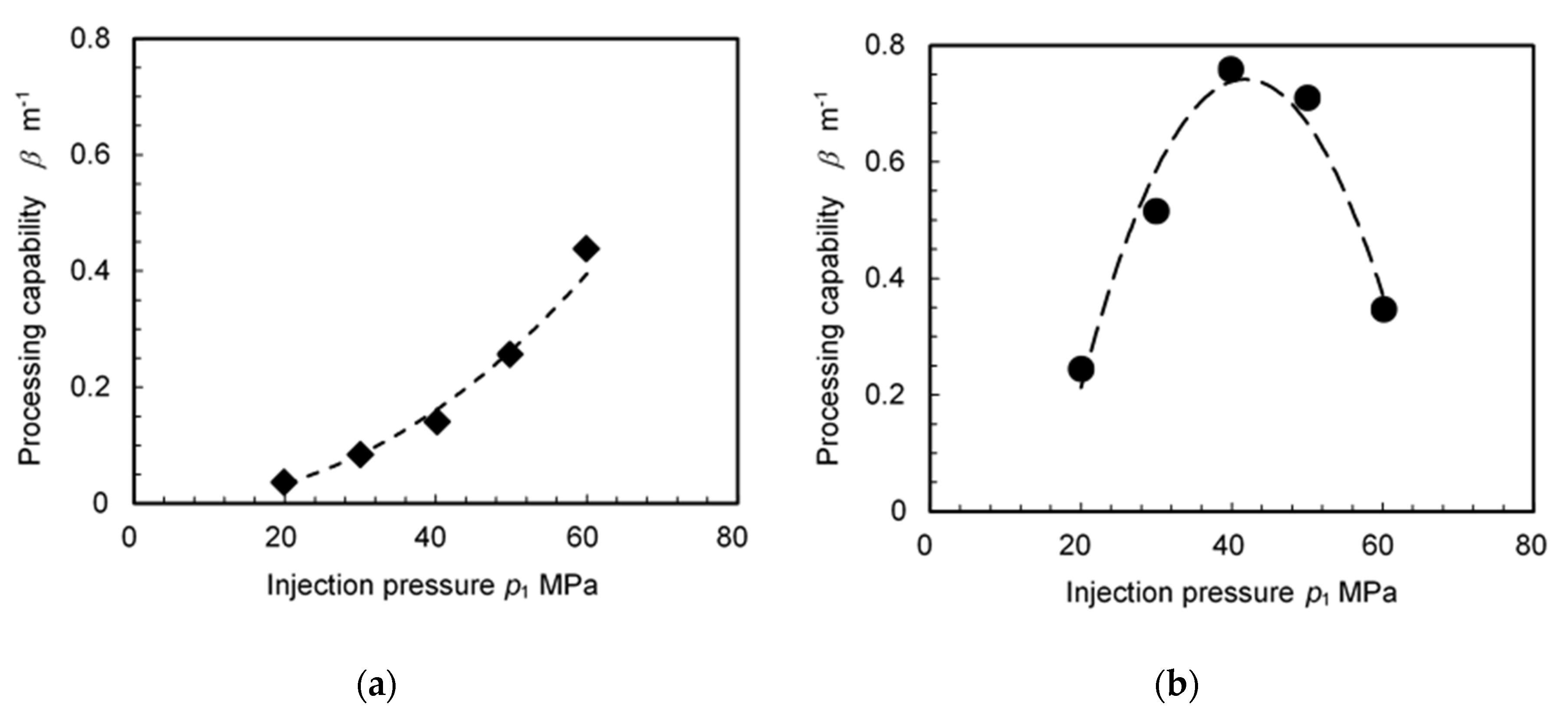

4.4. Injection Pressure

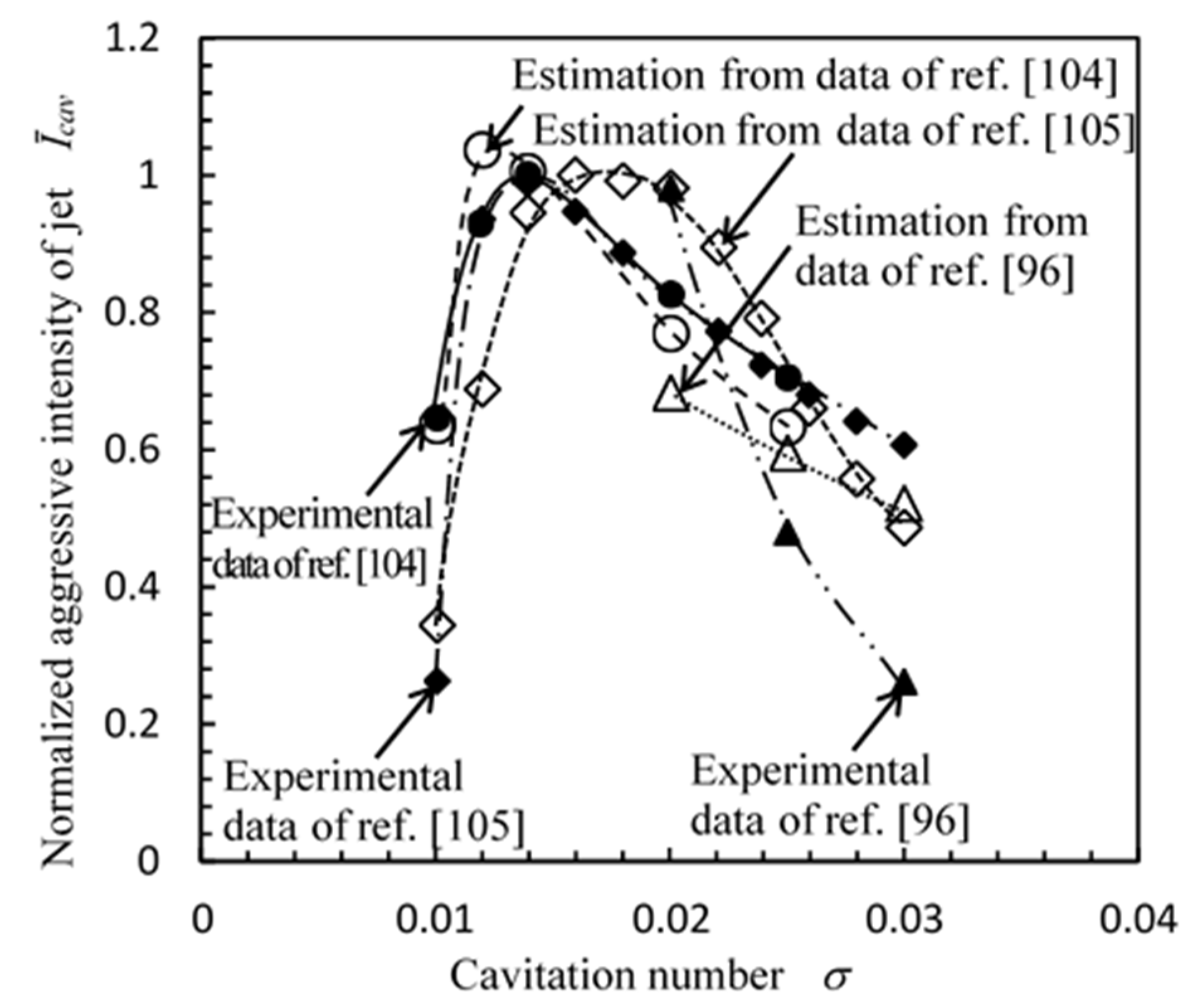

4.5. Cavitation Number

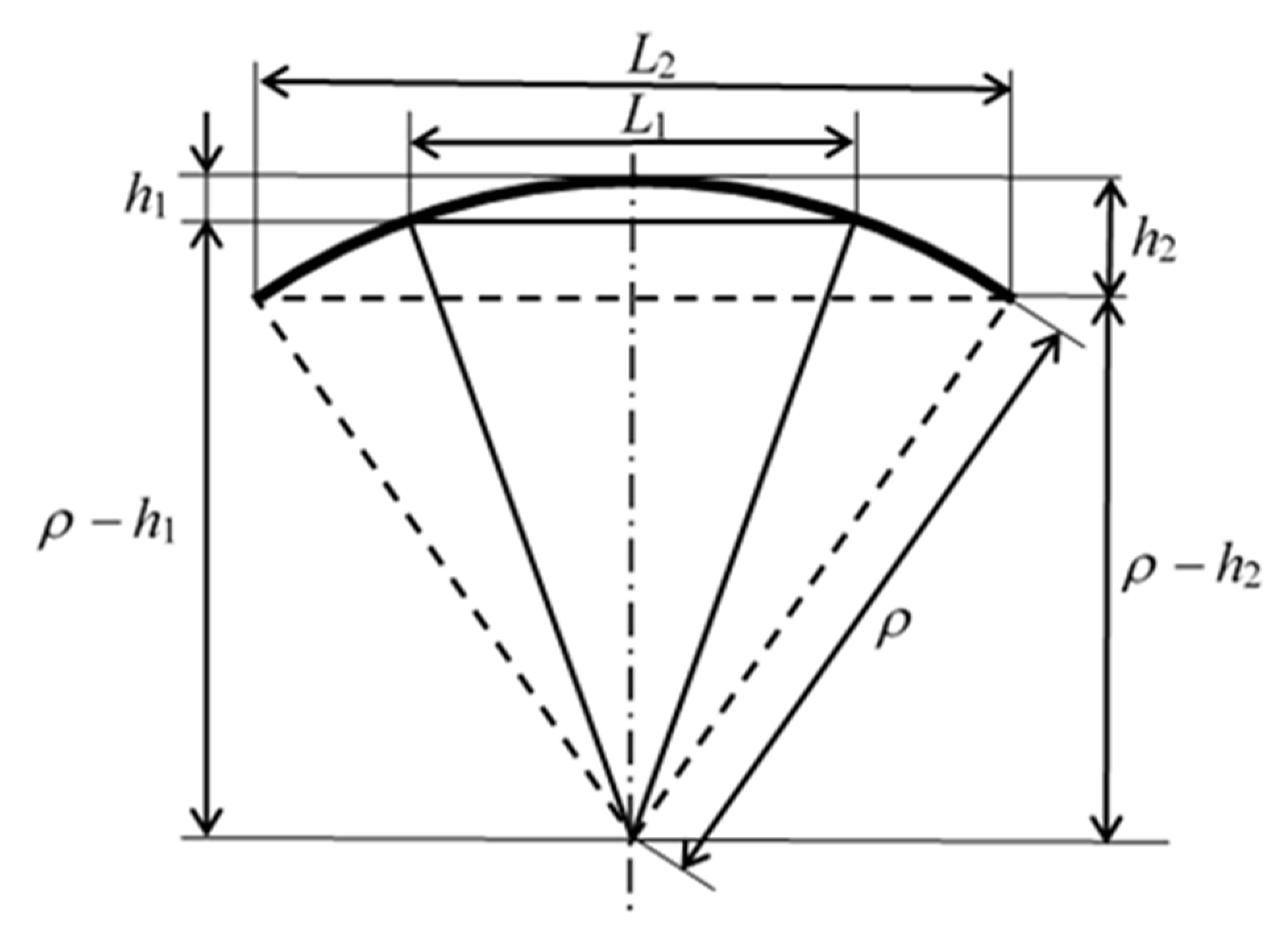

4.6. Geotrty Effect of Treatment Section

4.7. Scanning Pitch and Speed

4.8. Water Qualities

4.9. Material Properties

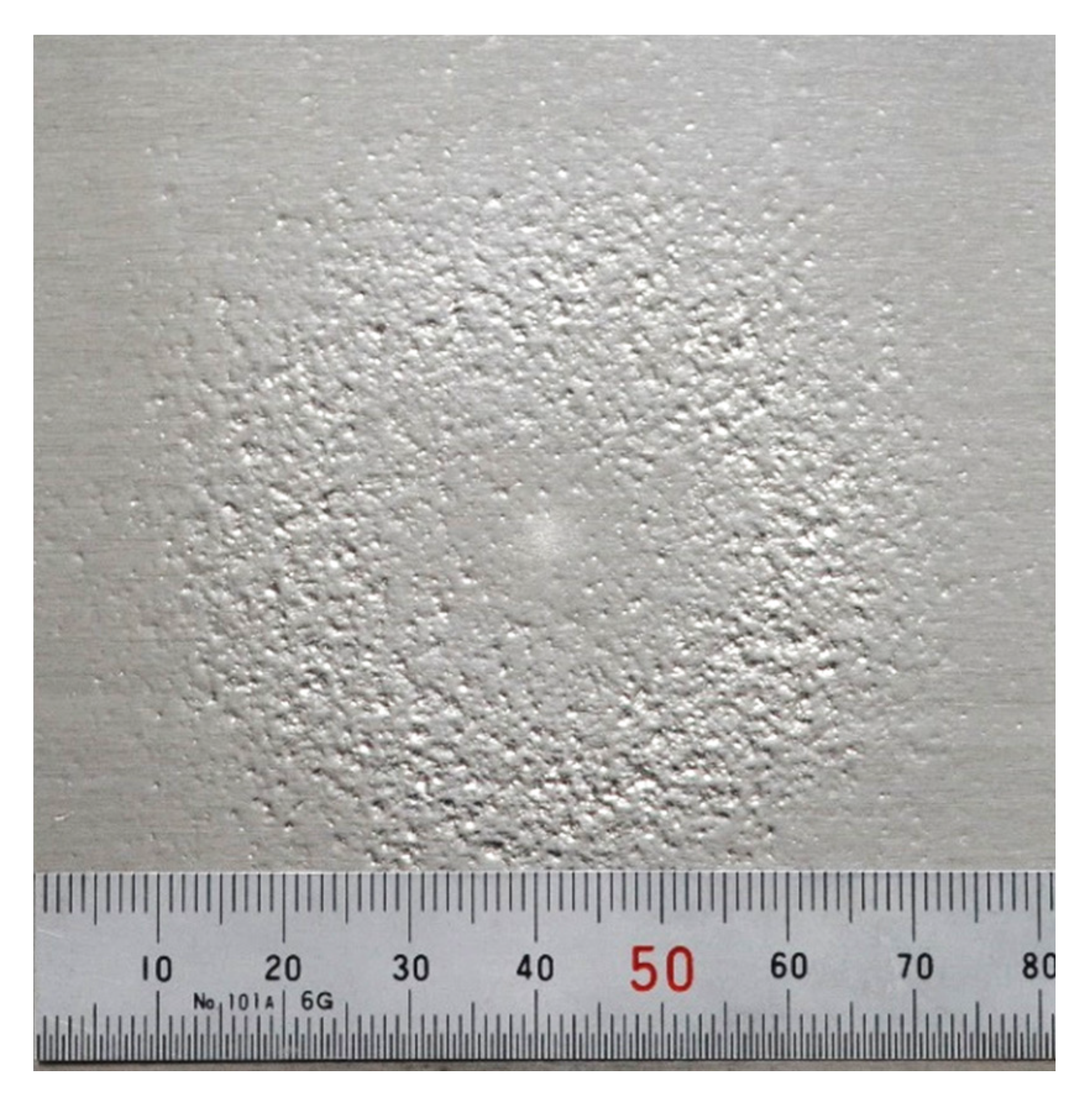

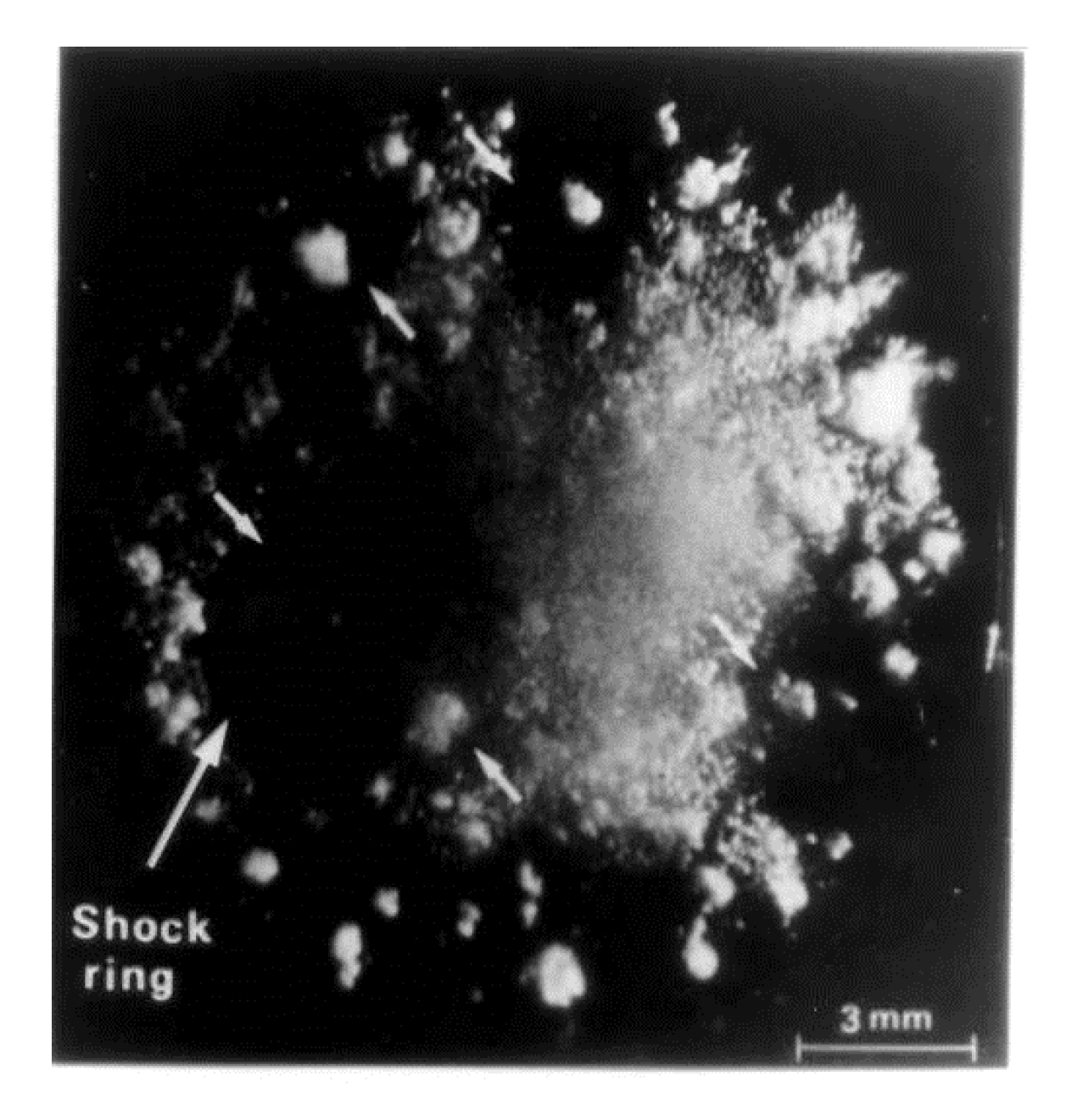

5. Estimation of Aggressive Intensity of Cavitation Peening

6. Difference between Cavitation Peening and Water Jet Peening

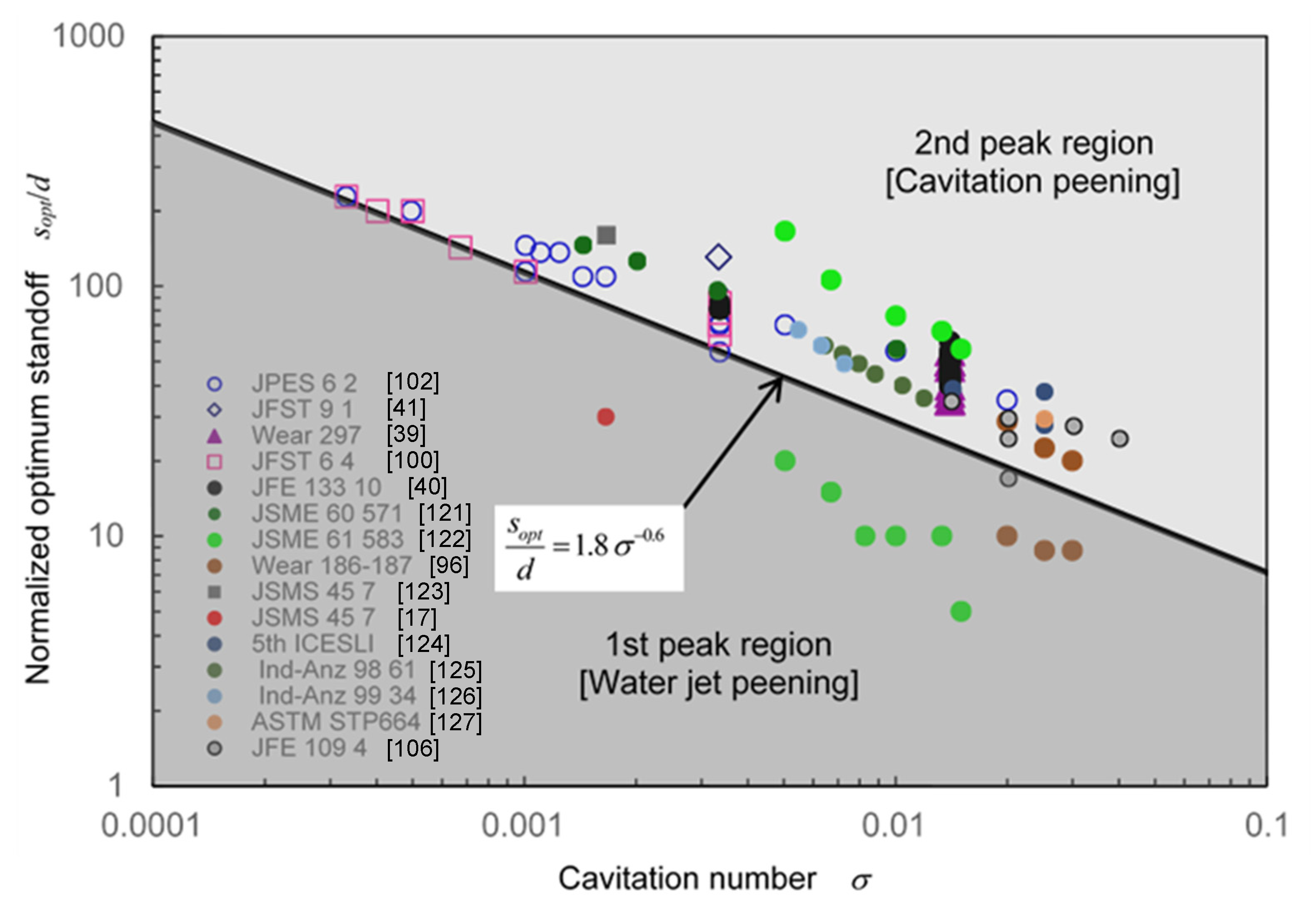

6.1. Standoff Distance

- (1)

- Find the optimum standoff distance sopt changes with distance from the nozzle to the target using experiments.

- (2)

- Calculate sopt/d.

- (3)

- Calculate 1.8 σ−0.6 using Equation (2). Note that p1 and p2 in Equation (2) are absolute pressures.

- (4)

- If experimental sopt/d is larger than the sopt/d obtained in step (3), the peening is cavitation peening.

- (5)

- If experimental sopt/d is smaller than the sopt/d obtained in step (3), the peening is water jet peening. If cavitation peening is desired, find the other optimum standoff distance on the far side of the nozzle using experiments.

6.2. Peening Intensity

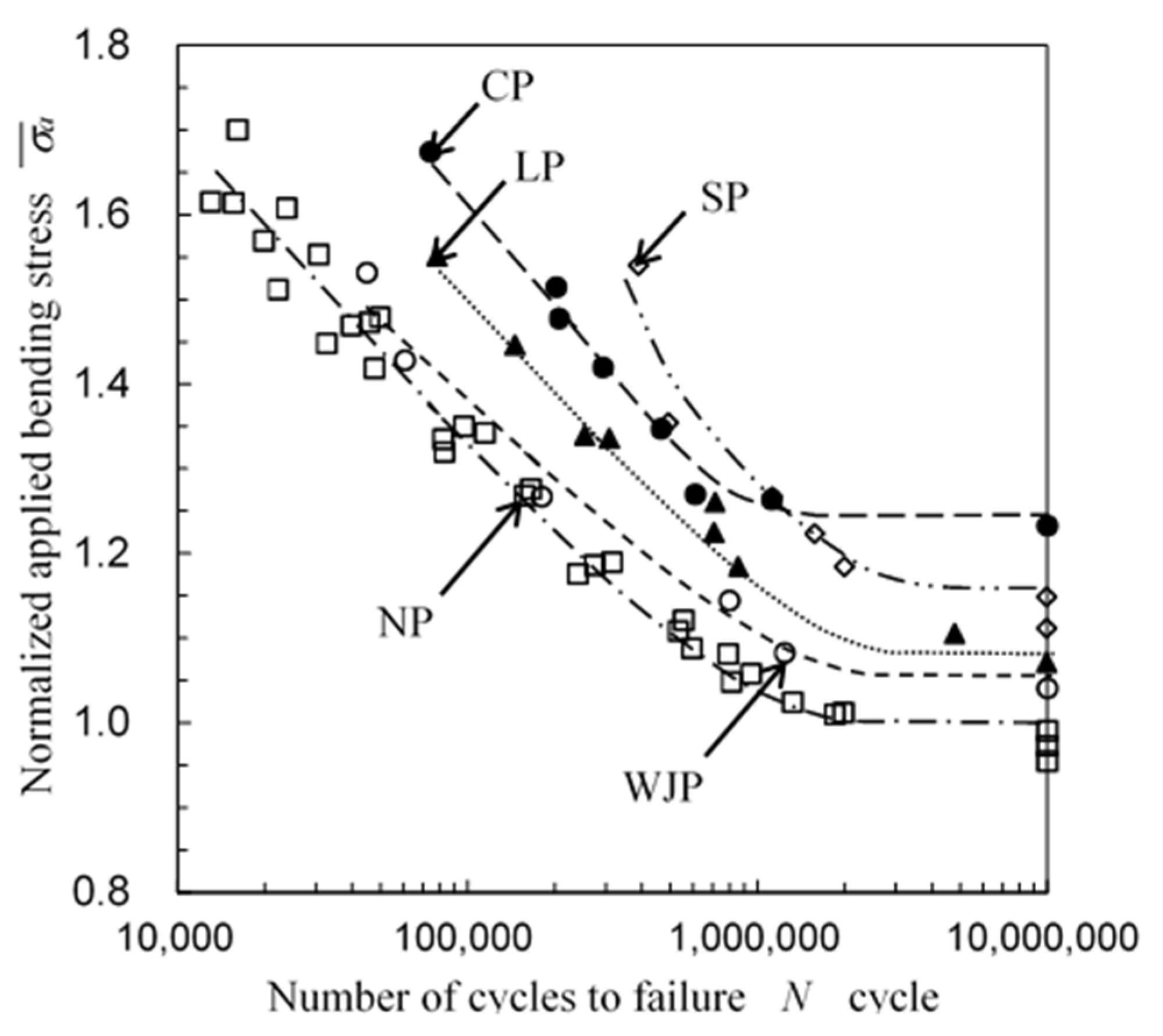

7. Comparison between Cavitation Peening and Other Peening Methods

8. Application of Cavitation Peening

8.1. Suppression of Environmental Assisted Cracking

8.2. Improvement of Fatigue Properites

8.3. Improvement in Triborogical Properties

8.4. Gettering Effect of Silicon Wafer

9. Conclusions

- (1)

- Cavitation peening can mitigate environmentally assisted cracking, such as stress corrosion cracking, hydrogen belittlement, and delayed fracture. It is also applied for the improvement of fatigue strength and tribological properties of metallic materials.

- (2)

- For conventional cavitation peening, a submerged high-speed water jet is used. However, the peening mechanisms of cavitation peening and water jet peening are different. Cavitation peening uses the impacts of bubble collapses. Water jet peening uses water column impacts. Note that submerged high-speed water can also treat the target by water jet peening.

- (3)

- For cavitation peening using an open water-filled chamber, peening intensity has a maximum at a certain injection pressure of about 40 MPa. The peening intensity of cavitation peening at 40 MPa is larger than that of water jet peening at 60 MPa.

- (4)

- Cavitation peening and water jet peening are classified by the relationship between cavitation number and the normalized distance from the nozzle to the target.

- (5)

- Submerged laser peening is a kind of cavitation peening using the impact at the collapse of the bubble, which develops after the laser ablation when it is optimized.

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Soyama, H.; Oba, R.; Kato, H. Cavitation observations of severely erosive vortex cavitation arising in a centrifugal pump. In Proceedings of the Institution of Mechanical Engineers, 3rd International Conference on Cavitation, London, UK, 17–19 March 1992; pp. 103–110. [Google Scholar]

- Brennen, C.E. Cavitation and Bubble Dynamics; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Soyama, H. Key factors and applications of cavitation peening. Inter. J. Peen. Sci. Technol. 2017, 1, 3–60. [Google Scholar]

- Soyama, H.; Saito, K.; Saka, M. Improvement of fatigue strength of aluminum alloy by cavitation shotless peening. J. Eng. Mater. Technol. 2002, 124, 135–139. [Google Scholar] [CrossRef]

- Thiruvengadam, A.; Preseir, H.S. On testing materials for cavitation damage resistance. J. Ship Res. 1964, 8, 39–56. [Google Scholar]

- G32-16 Standard test method for cavitation erosion using vibratory apparatus1. ASTM Stand. 2016, 03.02, 1–20.

- G134-17 Standard test method for erosion of solid materials by a cavitating liquid jet. ASTM Stand. 2017, 03.02, 1–17.

- Soyama, H.; Kumano, H. The fundamental threshold level—A new parameter for predicting cavitation erosion resistance. J. Test. Eval. 2002, 30, 421–431. [Google Scholar]

- Soyama, H.; Park, J.D.; Saka, M. Use of cavitating jet for introducing compressive residual stress. J. Manuf. Sci. Eng. Trans. ASME 2000, 122, 83–89. [Google Scholar] [CrossRef]

- Soyama, H.; Yamauchi, Y.; Ikohagi, T.; Oba, R.; Sato, K.; Shindo, T.; Oshima, R. Marked peening effects by highspeed submerged-water-jets-residual stress change on sus304. J. Jet Flow Eng. 1996, 13, 25–32. [Google Scholar]

- Saitou, N.; Enomoto, K.; Kurosawa, K.; Morinaka, R.; Hayashi, E.; Ishikwa, T.; Yoshimura, T. Development of water jet peening technique for reactor internal components of nuclear power plant. J. Jet Flow Eng. 2003, 20, 4–12. [Google Scholar]

- Odhiambo, D.; Soyama, H. Cavitation shotless peening for improvement of fatigue strength of carbonized steel. Int. J. Fatigue 2003, 25, 1217–1222. [Google Scholar] [CrossRef]

- Soyama, H.; Shimizu, M.; Hattori, Y.; Nagasawa, Y. Improving the fatigue strength of the elements of a steel belt for cvt by cavitation shotless peening. J. Mater. Sci. 2008, 43, 5028–5030. [Google Scholar] [CrossRef]

- Soyama, H.; Sekine, Y. Sustainable surface modification using cavitation impact for enhancing fatigue strength demonstrated by a power circulating-type gear tester. Int. J. Sustain. Eng. 2010, 3, 25–32. [Google Scholar] [CrossRef]

- Seki, M.; Nishie, N.; Kozai, S.; Kakuda, M.; Soyama, H.; Naito, A.; Fujii, M. Fatigue strength of steel rollers and gears treated by cavitation peening with short processing time. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 33–43. [Google Scholar] [CrossRef] [Green Version]

- Soyama, H.; Sanders, D. Use of an abrasive water cavitating jet and peening process to improve the fatigue strength of titanium alloy 6al-4v manufactured by the electron beam powder bed melting (ebpb) additive manufacturing method. JOM 2019, 71, 4311–4318. [Google Scholar] [CrossRef] [Green Version]

- Enomoto, K.; Hirano, K.; Mochizuki, M.; Kurosawa, K.; Saito, H.; Hayashi, E. Improvement of residual stress on material surface by water jet peening. J. Soc. Mater. Soc. Jpn. 1996, 45, 734–739. [Google Scholar] [CrossRef]

- Daniewicz, S.R.; Cummings, S.D. Characterization of a water peening process. J. Eng. Mater. Technol. 1999, 121, 336–340. [Google Scholar] [CrossRef]

- Chillman, A.; Ramulu, M.; Hashish, M. Waterjet peening and surface preparation at 600 mpa: A preliminary experimental study. J. Fluids Eng. Trans. ASME 2007, 129, 485–490. [Google Scholar] [CrossRef]

- Ishiguro, T.; Shimazaki, T.; Terayama, K.; Yoneguchi, A. Effect of hard shot peening with water-jet on surface residual-stress distribution of carburized steels. Tetsu Hagane J. Iron Steel Inst. Jpn. 1994, 80, 131–136. [Google Scholar] [CrossRef] [Green Version]

- Sano, Y.; Mukai, N.; Okazaki, K.; Obata, M. Residual stress improvement in metal surface by underwater laser irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1997, 121, 432–436. [Google Scholar] [CrossRef]

- Yoda, M.; Chida, I.; Okada, S.; Ochiai, M.; Sano, Y.; Mukai, N.; Komotori, G.; Saeki, R.; Takagi, T.; Sugihara, M.; et al. Development and application of laser peening system for pwr power plants. In Proceedings of the 4th International Conference on Nuclear Engineering, Istanbul, Turkey, 25–26 May 2006; pp. 419–424. [Google Scholar]

- Sato, K.; Soyama, H.; Yamauchi, Y.; Ikohagi, T.; Oba, R.; Oshima, R. A study on peening by submerged ultra-high-speed water-jets. In Proceeding of 11th International Conference on Jet Cutting Technology, St. Andrews, Scotland, 8–10 September 1992; pp. 413–424. [Google Scholar]

- Lichtarowicz, A. Use of a simple cavitating nozzle for cavitation erosion testing and cutting. Nat. Phys. Sci. 1972, 239, 63–64. [Google Scholar] [CrossRef]

- Blickwedel, H.; Haferkamp, H.; Louis, H.; Tai, P.T. Modification of material structure by cavitation and liquid impact and their influence on mechanical properties. In Proceedings of the 7th International Conference on Erosion by Liquid and Solid Impact, Cambridge, UK, 7–10 September 1987; pp. 31–36. [Google Scholar]

- Rawers, J.C.; McCune, R.A.; Dunning, J.S. Ultrasound treatment of centrifugally atomized 316 stainless steel powders. Metall. Trans. A 1991, 22A, 3025–3033. [Google Scholar] [CrossRef]

- Soyama, H. Introduction of compressive residual stress using a cavitating jet in air. J. Eng. Mater. Technol. 2004, 126, 123–128. [Google Scholar] [CrossRef]

- Soyama, H. Improvement of fatigue strength by using cavitating jets in air and water. J. Mater. Sci. 2007, 42, 6638–6641. [Google Scholar] [CrossRef]

- Fukuda, S.; Matsui, K.; Ishigami, H.; Ando, K. Cavitation peening to improve the fatigue strength of nitrocarburized steel. Fatigue Fract. Eng. Mater. Struct. 2008, 31, 857–862. [Google Scholar] [CrossRef]

- Marcon, A.; Melkote, S.N.; Castle, J.; Sanders, D.G.; Yoda, M. Effect of jet velocity in co-flow water cavitation jet peening. Wear 2016, 360, 38–50. [Google Scholar] [CrossRef]

- Marcon, A.; Melkote, S.N.; Yoda, M. Effect of nozzle size scaling in co-flow water cavitation jet peening. J. Manuf. Process. 2018, 31, 372–381. [Google Scholar] [CrossRef]

- Soyama, H. Improvement in fatigue strength of silicon manganese steel sup7 by using a cavitating jet. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2000, 43, 173–178. [Google Scholar] [CrossRef] [Green Version]

- Soyama, H.; Takeo, F. Comparison between cavitation peening and shot peening for extending the fatigue life of a duralumin plate with a hole. J. Mater. Process. Technol. 2016, 227, 80–87. [Google Scholar] [CrossRef]

- Takakuwa, O.; Takeo, F.; Sato, M.; Soyama, H. Using cavitation peening to enhance the fatigue strength of duralumin plate containing a hole with rounded edges. Surf. Coat. Technol. 2016, 307, 200–205. [Google Scholar] [CrossRef]

- Han, B.; Ju, D.Y.; Jia, W.P. Influence of water cavitation peening with aeration on fatigue behaviour of sae1045 steel. Appl. Surf. Sci. 2007, 253, 9342–9346. [Google Scholar] [CrossRef]

- Soyama, H.; Macodiyo, D.O. Fatigue strength improvement of gears using cavitation shotless peening. Tribol. Lett. 2005, 18, 181–184. [Google Scholar] [CrossRef]

- Seki, M.; Soyama, H.; Fujii, M.; Yoshida, A. Rolling contact fatigue life of cavitation-peened steel gear. Tribol. Online 2008, 3, 116–121. [Google Scholar] [CrossRef] [Green Version]

- Takakuwa, O.; Nakai, M.; Narita, K.; Niinomi, M.; Hasegawa, K.; Soyama, H. Enhancing the durability of spinal implant fixture applications made of ti-6al-4v eli by means of cavitation peening. Int. J. Fatigue 2016, 92, 360–367. [Google Scholar] [CrossRef]

- Soyama, H. Effect of nozzle geometry on a standard cavitation erosion test using a cavitating jet. Wear 2013, 297, 895–902. [Google Scholar] [CrossRef]

- Soyama, H. Enhancing the aggressive intensity of a cavitating jet by means of the nozzle outlet geometry. J. Fluids Eng. 2011, 133, 1–11. [Google Scholar] [CrossRef]

- Soyama, H. Enhancing the aggressive intensity of a cavitating jet by introducing a cavitator and a guide pipe. J. Fluid Sci. Technol. 2014, 9, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Soyama, H.; Uranishi, K.; Ito, Y.; Kato, H.; Ichioka, T.; Oba, R. Hard-erosion-progress in a typical centrifugal pump (1st report, marked effects of upstream cavitators). Turbomachinery 1990, 18, 691–698. [Google Scholar]

- Kamisaka, H.; Soyama, H. Enhancement of an aggressive intensity of a cavitating jet by water flow holes near nozzle outlet. Trans. JSME 2019. [Google Scholar] [CrossRef]

- Soyama, H.; Okura, Y. The use of various peening methods to improve the fatigue strength of titanium alloy ti6al4v manufactured by electron beam melting. AIMS Mater. Sci. 2018, 5, 1000–1015. [Google Scholar] [CrossRef]

- Okura, Y.; Sasaki, H.; Soyama, H. Effect of meczhanical properties on fatigue life enhancement of additive manufactured titanium alloy treated by various peening methods. In Advanced Surface Enhancement, INCASE 2019, Lecture Notes in Mechanical Engineering; Springer Nature Singapore Pte Ltd.: Singapore, 2020; pp. 88–96. [Google Scholar]

- Nagalingam, A.P.; Yeo, S.H. Effects of combined wear mechanisms in internal surface finishing using controlled hydrodynamic cavitation abrasive finishing process. In Advanced Surface Enhancement, INCASE 2019, Lecture Notes in Mechanical Engineering; Springer Nature Singapore Pte Ltd.: Singapore, 2020; pp. 244–253. [Google Scholar]

- Soyama, H.; Hoshino, J. Enhancing the aggressive intensity of hydrodynamic cavitation through a venturi tube by increasing the pressure in the region where the bubbles collapse. AIP Adv. 2016, 6, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Soyama, H.; Ohba, K.; Takeda, S.; Oba, R. High-speed observations of highly erosive vortex cavitation around butterfly valve. Trans. JSME 1994, 60B, 1133–1138. [Google Scholar] [CrossRef]

- Reisman, G.E.; Wang, Y.C.; Brennen, C.E. Observations of shock waves in cloud cavitation. J. Fluid Mech. 1998, 355, 255–283. [Google Scholar] [CrossRef] [Green Version]

- Plesset, M.S.; Chapman, R.B. Collapse of an initially spherical vapour cavity in neighbourhood of a solid boundary. J. Fluid Mech. 1971, 47, 283–290. [Google Scholar] [CrossRef] [Green Version]

- Crum, L.A. Surface oscillations and jet development in pulsating bubbles. J. De Phys. Colloq. 1979, 40, 285–288. [Google Scholar] [CrossRef] [Green Version]

- Lauterborn, W.; Bolle, H. Experimental investigations of cavitation-bubble collapse in neighborhood of a solid boundary. J. Fluid Mech. 1975, 72, 391–399. [Google Scholar] [CrossRef]

- Dominguez Cortazar, M.A.; Franc, J.P.; Michel, J.M. The erosive axial collapse of a cavitating vortex: An experimental study. J. Fluids Eng. 1997, 119, 686–691. [Google Scholar] [CrossRef]

- Soyama, H. Fundamentals and applications of cavitation peening comparing with shot peening and laser peening. In Advanced Surface Enhancement, INCASE 2019, Lecture Notes in Mechanical Engineering; Springer Nature Singapore Pte Ltd.: Singapore, 2020; pp. 76–87. [Google Scholar]

- Philipp, A.; Lauterborn, W. Cavitation erosion by single laser-produced bubbles. J. Fluid Mech. 1998, 361, 75–116. [Google Scholar] [CrossRef]

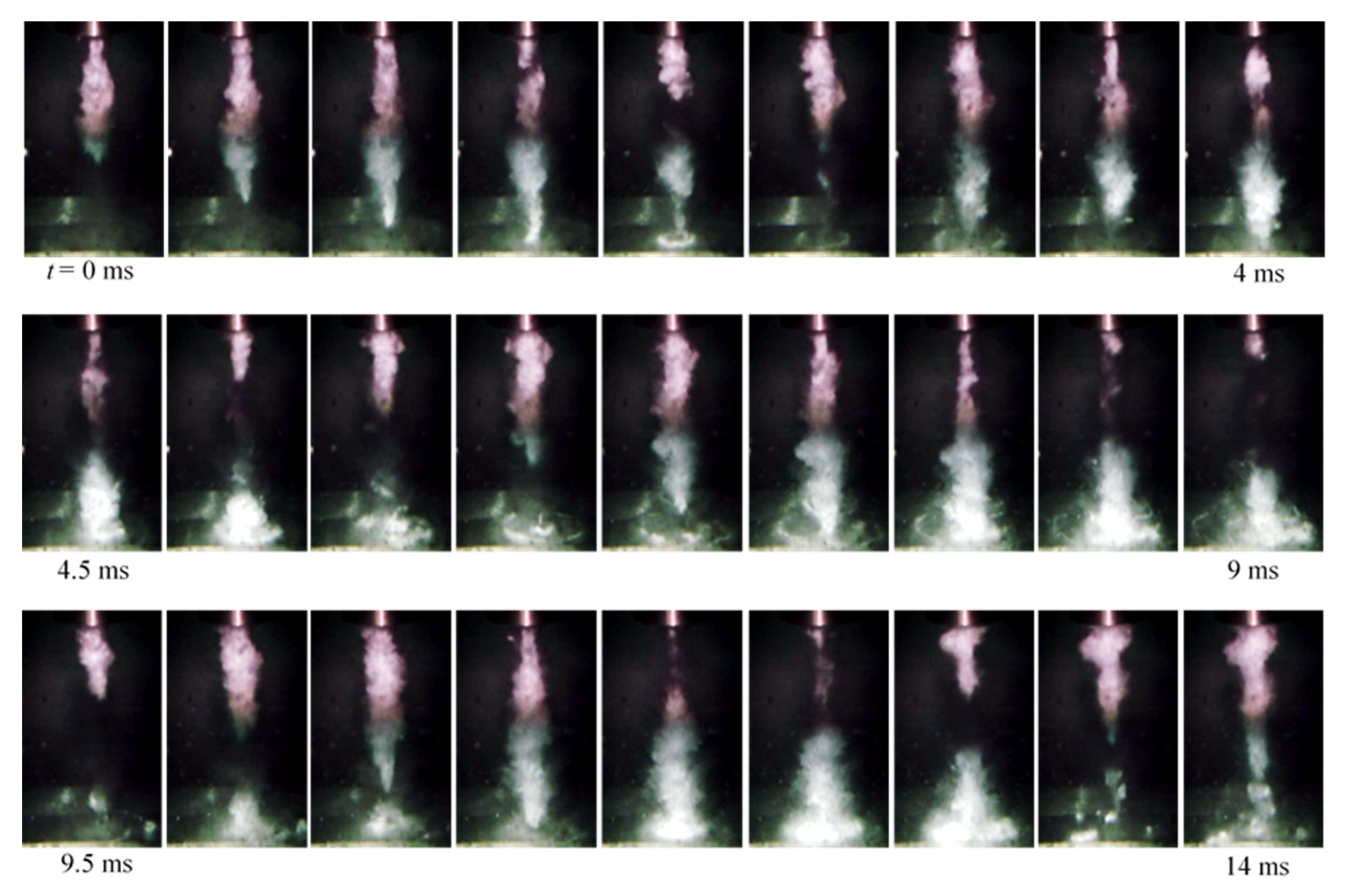

- Soyama, H.; Yamauchi, Y.; Adachi, Y.; Sato, K.; Shindo, T.; Oba, R. High-speed observations of the cavitation cloud around a high-speed submerged water-jet. JSME Int. J. 1995, 38B, 245–251. [Google Scholar] [CrossRef] [Green Version]

- Kamisaka, H.; Soyama, H. Periodical shedding of cavitation cloud induced by a cavitating jet. Proc. 23rd Int. Conf. Water Jet. 2018, 111–123. [Google Scholar]

- Soyama, H.; Lichtarowicz, A.; Momma, T. Vortex cavitation in a submerged jet. In Proceedings of the 1996 ASME Fluids Engineering Division Summer Meeting, San Diego, CA, USA, 7–11 July 1996; FED-236. pp. 415–422. [Google Scholar]

- Soyama, H.; Lichtarowicz, A. Cavitating jets—Similarity correlations. Jet Flow Eng. 1996, 13, 9–19. [Google Scholar]

- Ohya, T.; Okimura, K.; Ohta, T.; Ichioka, T. Residual stress improved by water jet peening for small-diameter pipe inner surfaces. Mitsubishi Heavy Ind. Ltd. Tech. Rev. 2000, 37, 52–55. [Google Scholar]

- Demma, A.; Frederick, G. Program on technology innovation: An evaluation of surface stress improvement technologies for pwscc mitigation of alloy 600 nuclear components. In Mater. Reliab. Program (MRP-162); Electric Power Research Institute EPRI: Palo Alto, CA, USA, 2006; Volume 1011806, pp. 1–104. [Google Scholar]

- Crooker, P.; Lian, T. Technical basis for primary water stress corrosion cracking mitigation by surface stress improvement. In Mater. Reliab. Program (MRP-267, Revision 1); Electric Power Research Institute EPRI: Palo Alto, CA, USA, 2012; Volume 1025839, pp. 1–296. [Google Scholar]

- Nishimura, S.; Takakuwa, O.; Soyama, H. Similarity law on shedding frequency of cavitation cloud induced by a cavitating jet. J. Fluid Sci. Technol. 2012, 7, 405–420. [Google Scholar] [CrossRef] [Green Version]

- Soyama, H. High-speed observation of a cavitating jet in air. J. Fluids Eng. 2005, 127, 1095–1108. [Google Scholar] [CrossRef]

- Soyama, H.; Kikuchi, T.; Nishikawa, M.; Takakuwa, O. Introduction of compressive residual stress into stainless steel by employing a cavitating jet in air. Surf. Coat. Technol. 2011, 205, 3167–3174. [Google Scholar] [CrossRef]

- Soyama, H.; Mikami, M. Cavitating jet in air using multiple nozzles. In Proceedings of the 2005 WJTA American Waterjet Conference, Houston, TX, USA, 21–23 August 2005. Paper 6B-2. [Google Scholar]

- Soyama, H. Opposed cavitating jets and their application for cavitation peening of wall surrounding hole. In Proceedings of the 23rd International Conference on Water Jetting, Seattle, DC, USA, 16–18 November 2016; pp. 201–208. [Google Scholar]

- Ley, S.V.; Low, C.M.R. Ultrasound in Synthesis; Springer: Berlin, Germany, 1989. [Google Scholar]

- Nakashima, K.; Ebi, Y.; Shibasaki-Kitakawa, N.; Soyama, H.; Yonemoto, T. Hydrodynamic cavitation reactor for efficient pretreatment of lignocellulosic biomass. Ind. Eng. Chem. Res. 2016, 55, 1866–1871. [Google Scholar] [CrossRef]

- Kikuchi, K.; Ahmed, S.M.; Hiraiwa, T.; Ito, Y.; Oba, R. An indirect vibratory method capable of simulating several cavitating states. JSME Int. J. Ser. B Fluids Therm. Eng. 1991, 34, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Yamaguchi, H.; Shinmura, T.; Kasai, K.; Aizawa, T. Study of micro-machining process applying cavitation based on ultrasonic vibration. Trans. JSME 2002, 68, 2777–2782. [Google Scholar] [CrossRef] [Green Version]

- Nakagawa, M.; Watanabe, T. Introducing compressive residual stress on metal surfaces by irradiating ultrasonic wave with a horn in water: Surface modification by irradiating ultrasonic wave in liquid (report 1). Q. J. Jpn. Weld. Soc. 2004, 22, 587–594. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.B.; Wu, B.X.; Liu, Z.; Zhou, Y.; Shen, N.G.; Ding, H.T. Ultrasonic cavitation peening of stainless steel and nickel alloy. J. Manuf. Sci. Eng. Trans. ASME 2014, 136, 6. [Google Scholar] [CrossRef]

- Sasaki, T.; Yoshida, K.; Nakagawa, M.; Yoshida, S. Effect of horn tip geometry on ultrasonic cavitation peening. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems; Conference Proceedings of the Society for Experimental Mechanics Series; Springer International Publishing: Cham, Switzerland, 2016; Volume 9, pp. 139–146. [Google Scholar]

- Bai, F.; Long, Y.Y.; Saalbach, K.A.; Twiefel, J. Theoretical and experimental investigations of ultrasonic sound fields in thin bubbly liquid layers for ultrasonic cavitation peening. Ultrasonics 2019, 93, 130–138. [Google Scholar] [CrossRef]

- Tan, K.L.; Yeo, S.H. Surface modification of additive manufactured components by ultrasonic cavitation abrasive finishing. Wear 2017, 378–379, 90–95. [Google Scholar] [CrossRef]

- Nagalingam, A.P.; Yeo, S.H. Controlled hydrodynamic cavitation erosion with abrasive particles for internal surface modification of additive manufactured components. Wear 2018, 414, 89–100. [Google Scholar] [CrossRef]

- Toh, C.K. The use of ultrasonic cavitation peening to improve micro-burr-free surfaces. Int. J. Adv. Manuf. Technol. 2007, 31, 688–693. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R.; Merrien, P.; Lieurade, H.P. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 1996, 210, 102–113. [Google Scholar] [CrossRef]

- Nalla, R.K.; Altenberger, I.; Noster, U.; Liu, G.Y.; Scholtes, B.; Ritchie, R.O. On the influence of mechanical surface treatments-deep rolling and laser shock peening-on the fatigue behavior of ti-6al-4v at ambient and elevated temperatures. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2003, 355, 216–230. [Google Scholar] [CrossRef]

- Hatamleh, O.; Lyons, J.; Forman, R. Laser and shot peening effects on fatigue crack growth in friction stir welded 7075-t7351 aluminum alloy joints. Int. J. Fatigue 2007, 29, 421–434. [Google Scholar] [CrossRef]

- Liu, K.K.; Hill, M.R. The effects of laser peening and shot peening on fretting fatigue in ti-6al-4v coupons. Tribol. Int. 2009, 42, 1250–1262. [Google Scholar] [CrossRef]

- Trdan, U.; Grum, J. Evaluation of corrosion resistance of aa6082-t651 aluminium alloy after laser shock peening by means of cyclic polarisation and eis methods. Corros. Sci. 2012, 59, 324–333. [Google Scholar] [CrossRef]

- Gill, A.; Telang, A.; Mannava, S.R.; Qian, D.; Pyoun, Y.-S.; Soyama, H.; Vasudevan, V.K. Comparison of mechanisms of advanced mechanical surface treatments in nickel-based superalloy. Mater. Sci. Eng. A 2013, 576, 346–355. [Google Scholar] [CrossRef]

- Sano, Y.; Obata, M.; Kubo, T.; Mukai, N.; Yoda, M.; Masaki, K.; Ochi, Y. Retardation of crack initiation and growth in austenitic stainless steels by laser peening without protective coating. Mater. Sci. Eng. A 2006, 417, 334–340. [Google Scholar] [CrossRef]

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Technol. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- Soyama, H. Improvement of fatigue strength of additive manufactured metals by solid-liquid-gas interfacial phenomena induced by pulse laser. IOP Conf. Ser. Mater. Sci. Eng. 2019, 611, 012002. [Google Scholar] [CrossRef]

- Sasoh, A.; Watanabe, K.; Sano, Y.; Mukai, N. Behavior of bubbles induced by the interaction of a laser pulse with a metal plate in water. Appl. Phys. A 2005, 80, 1497–1500. [Google Scholar] [CrossRef]

- Soyama, H.; Lichtarowicz, A.; Momma, T.; Williams, E.J. A new calibration method for dynamically loaded transducers and its application to cavitation impact measurement. J. Fluids Eng. 1998, 120, 712–718. [Google Scholar] [CrossRef]

- Soyama, H.; Sekine, Y.; Saito, K. Evaluation of the enhanced cavitation impact energy using a PVDF transducer with an acrylic resin backing. Measurement 2011, 44, 1279–1283. [Google Scholar] [CrossRef]

- Soyama, H. Surface mechanics design by cavitation peening using submerged pulse laser. In Proceedings of the Abstracts of 7th International Conference on Laser Peening and Related Phenomena, Singapore, 17–22 June 2018; p. 57. [Google Scholar]

- Soyama, H.; Sasaki, H.; Endo, S.; Iga, Y. Mechanical surface treatment of duralumin plate by bubble induced by pulse laser. J. Phys. Conf. Ser. 2015, 656, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Ogawa, M. Development and commercialization of advanced cleaning system for skin pass mill work roll, type cavitating jet in air: Realization of high-quality and high-productivity in hot dip continuous galvanizing line. Nippon Steel Sumikin Eng. Co. Ltd. Tech. Rev. 2014, 5, 14–20. [Google Scholar]

- Soyama, H.; Takano, Y.; Ishimoto, M. Peening of forging die by cavitation. Tech. Rev. Forg. Technol. Inst. Jpn. 2000, 25, 53–57. [Google Scholar]

- Soyama, H. Surface mechanics design of metallic materials on mechanical surface treatments. Mech. Eng. Rev. 2015, 2, 1–20. [Google Scholar]

- Momma, T.; Lichtarowicz, A. A study of pressure and erosion produced by collapsing cavitation. Wear 1995, 186, 425–436. [Google Scholar] [CrossRef]

- Kamisaka, H.; Soyama, H. Effect of injection pressure on mechanical surface treatment using a submerged water jet. J. Jet Flow Eng. 2018, 33, 4–10. [Google Scholar]

- Lichtarowicz, A. Erosion testing with cavitating jet. In Proceedings of the Cavitation Erosion in Fluid Systems, ASME Fluids Engineering Conference, Boulder, Colorado, 22–24 June 1981; pp. 153–161. [Google Scholar]

- Hutli, E.; Nedeljkovic, M.S.; Bonyar, A.; Legrady, D. Experimental study on the influence of geometrical parameters on the cavitation erosion characteristics of high speed submerged jets. Exp. Therm. Fluid Sci. 2017, 80, 281–292. [Google Scholar] [CrossRef] [Green Version]

- Soyama, H.; Takakuwa, O. Enhancing the aggressive strength of a cavitating jet and its practical application. J. Fluid Sci. Technol. 2011, 6, 510–521. [Google Scholar] [CrossRef] [Green Version]

- Soyama, H. Power law of injection pressure and nozzle diameter on aggressive intensity of a cavitating jet. In Proceedings of the 21st International Conference on Water Jetting, Ottawa, ON, Canada, 19–21 September 2012; pp. 343–354. [Google Scholar]

- Soyama, H.; Nagasaka, K.; Takakuwa, O.; Naito, A. Optimum injection pressure of a cavitating jet for introducing compressive residual stress into stainless steel. J. Power Energy Syst. 2012, 6, 63–75. [Google Scholar] [CrossRef] [Green Version]

- Shimizu, S.; Tanioka, K.; Ikegami, N. Erosion due to ultra-high-speed cavitating jet. J. Jpn. Hydraul. Pneum. Soc. 1997, 28, 778–784. [Google Scholar]

- Soyama, H. Material testing and surface modification by using cavitating jet. J. Soc. Mater. Sci. Jpn. 1998, 47, 381–387. [Google Scholar] [CrossRef] [Green Version]

- Soyama, H.; Takakuwa, O.; Naito, A. Effect of nozzle shape for high injection pressure on aggressivity of cavitating jet. In Proceedings of the 21st International Conference on Water Jetting: Looking to the Future, Learning from the Past, Ottawa, ON, Canada, 19–22 September 2012; pp. 367–378. [Google Scholar]

- Yamaguchi, A.; Shimizu, S. Erosion due to impingement of cavitating jet. J. Fluids Eng. Trans. ASME 1987, 109, 442–447. [Google Scholar] [CrossRef]

- Liu, H.; Kang, C.; Soyama, H. Experimental study of the influence of test chamber dimensions on aggressive intensity of the cavitating jet. J. Test. Eval. 2020, 48, 1–14. [Google Scholar] [CrossRef]

- Qin, M.; Ju, D.Y.; Oba, R. Investigation of the influence of incidence angle on the process capability of water cavitation peening. Surf. Coat. Technol. 2006, 201, 1409–1413. [Google Scholar] [CrossRef]

- Yamauchi, Y.; Soyama, H.; Adachi, Y.; Sato, K.; Oba, R. Curveture effects upon peening action on working surfaces by impiging high-speed submerged waterjets. Trans. JSME 1994, 60B, 2671–2677. [Google Scholar] [CrossRef]

- Takakuwa, O.; Soyama, H. The effect of scanning pitch of nozzle for a cavitating jet during overlapping peening treatment. Surf. Coat. Technol. 2012, 206, 4756–4762. [Google Scholar] [CrossRef]

- Singer, B.G.; Harvey, S.J. Gas content and temperature effects in vibratory cavitation tests. Wear 1979, 52, 147–160. [Google Scholar] [CrossRef]

- Iwai, Y.; Okada, T.; Hammitt, F.G. Effect of temperature on the cavitation erosion of cast-iron. Wear 1983, 85, 181–191. [Google Scholar] [CrossRef] [Green Version]

- Kwok, C.T.; Man, H.C.; Leung, L.K. Effect of temperature, pH and sulphide on the cavitation erosion behaviour of super duplex stainless steel. Wear 1997, 211, 84–93. [Google Scholar] [CrossRef]

- Hattori, S.; Goto, Y.; Fukuyama, T. Influence of temperature on erosion by a cavitating liquid jet. Wear 2006, 260, 1217–1223. [Google Scholar] [CrossRef]

- Hutli, E.A.F.; Nedeljkovic, M.S.; Radovic, N.A. Mechanics of submerged jet cavitating action: Material properties, exposure time and temperature effects on erosion. Arch. Appl. Mech. 2008, 78, 329–341. [Google Scholar] [CrossRef]

- Dular, M. Hydrodynamic cavitation damage in water at elevated temperatures. Wear 2016, 346, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Grinspan, A.S.; Gnanamoorthy, R. Effect of nozzle-traveling velocity on oil cavitation jet peening of aluminum alloy, aa 6063-t6. J. Eng. Mater. Technol. Trans. ASME 2007, 129, 609–613. [Google Scholar] [CrossRef]

- Hattori, S.; Ishikura, R. Revision of cavitation erosion database and analysis of stainless steel data. Wear 2010, 268, 109–116. [Google Scholar] [CrossRef]

- Lecoffre, Y. Cavitation erosion, hydrodyanmimc scaling laws, practical method of long term damage predicition. Proc. Int. Symp. Cavitation 1995, 249–256. [Google Scholar]

- Sasaki, H.; Iga, Y.; Soyama, H. Effect of bubble radius on ability of submerged laser peening. In Advanced Surface Enhancement, INCASE 2019, Lecture Notes in Mechanical Engineering; Springer Nature Singapore Pte Ltd.: Singapore, 2020; pp. 283–291. [Google Scholar]

- Yamauchi, Y.; Soyama, H.; Sato, K.; Ikohagi, T.; Oba, R. Development of erosion in high-speed submerged water jets. Trans. JSME 1994, 60B, 736–743. [Google Scholar] [CrossRef] [Green Version]

- Yamauchi, Y.; Asami, K.; Soyama, H.; Sato, K.; Ikohagi, T.; Oba, R. Marked effects of ambient pressure on impinging erosion induced by high-speed submerged water jets. Trans. JSME 1995, 61B, 785–792. [Google Scholar] [CrossRef] [Green Version]

- Hirano, K.; Enomoto, K.; Hayashi, E.; Kurosawa, K. Effect of water jet peening on corrosion resistance and fatigue strength of type 304 stainless steel. J. Soc. Mater. Soc. Jpn. 1996, 45, 740–745. [Google Scholar] [CrossRef]

- Lichtarowicz, A.; Scott, P.J. Erosion testing with cavitating jet. In Proceedings of the 5th International Conference on Erosion by Liquid and Solid Impact, Cambridge, UK, 3–6 September 1979. paper No. 69. [Google Scholar]

- Kleinbreuer, W. Werkstoffzerstorung durch kavitation in olhydralishen systemen. Ind. Anz. 1976, 98, 1096–1100. [Google Scholar]

- Kleinbreuer, W. Kavitationserosion in hydraulischen systemen. Ind. Anz. 1977, 99, 609–613. [Google Scholar]

- Lichtarowicz, A. Cavitating jet apparatus for cavitation erosion testing, erosion: Prevention and useful applications. ASTM STP 1979, 669, 530–549. [Google Scholar]

- Soyama, H.; Yamada, N. Relieving micro-strain by introducing macro-strain in a polycrystalline metal surface by cavitation shotless peening. Mater. Lett. 2008, 62, 3564–3566. [Google Scholar] [CrossRef]

- Sekine, Y.; Soyama, H. Surface modification of alloy tool steel for forging dies by cavitation peening. Rev. Automot. 2009, 30, 393–399. [Google Scholar]

- Taira, S. X-ray-diffraction approach for studies on fatigue and creep. Exp. Mech. 1973, 13, 449–463. [Google Scholar] [CrossRef]

- Quesnel, D.J.; Meshii, M.; Cohen, J.B. Residual-stresses in high-strength low-alloy steel during low-cycle fatigue. Mater. Sci. Eng. 1978, 36, 207–215. [Google Scholar] [CrossRef]

- Ostrovskii, I.; Ostrovskaya, N.; Korotchenkov, O.; Reidy, J. Radiation defects manipulation by ultrasound in ionic crystals. Ieee Trans. Nucl. Sci. 2005, 52, 3068–3073. [Google Scholar] [CrossRef]

- Takakuwa, O.; Chiba, A.; Soyama, H. Movement of dislocations in the sub-surface of a polycrystalline metal by cavitation peening observed by transmission electron microscopy. Mater. Sci. Appl. 2015, 6, 140–144. [Google Scholar] [CrossRef] [Green Version]

- Turski, M.; Clitheroe, S.; Evans, A.D.; Rodopoulos, C.; Hughes, D.J.; Withers, P.J. Engineering the residual stress state and microstructure of stainless steel with mechanical surface treatments. Appl. Phys. A Mater. Sci. Process. 2010, 99, 549–556. [Google Scholar] [CrossRef] [Green Version]

- Telang, A.; Gili, A.S.; Mannava, S.R.; Qian, D.; Vasudevan, V.K. Effect of temperature on microstructure and residual stresses induced by surface treatments in inconel 718 spf. Surf. Coat. Technol. 2018, 344, 93–101. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Soyama, H.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Martinez, S.; Khripta, N.I.; Lamikiz, A. Mechanical surface treatments of AISI 304 stainless steel: Effects on surface microrelief, residual stress, and microstructure. J. Mater. Eng. Perform. 2019, 28, 5307–5322. [Google Scholar] [CrossRef]

- Kai, A.; Soyarna, H. Visualization of the plastic deformation area beneath the surface of carbon steel induced by cavitation impact. Scr. Mater. 2008, 59, 272–275. [Google Scholar] [CrossRef]

- Kanou, S.; Takakuwa, O.; Mannava, S.R.; Qian, D.; Vasudevan, V.K.; Soyama, H. Effect of the impact energy of various peening techniques on the induced plastic deformation region. J. Mater. Process. Technol. 2012, 212, 1998–2006. [Google Scholar] [CrossRef]

- Soyama, H.; Asahara, M. Improvement of the corrosion resistance of a carbon steel surface by a cavitating jet. J. Mater. Sci. Lett. 1999, 18, 1953–1955. [Google Scholar] [CrossRef]

- Kim, S.J.; Hyun, K.Y.; Jang, S.K. Effects of water cavitation peening on electrochemical characteristic by using micro-droplet cell of Al-Mg alloy. Curr. Appl. Phys. 2012, 12, S24–S30. [Google Scholar] [CrossRef]

- Takakuwa, O.; Soyama, H. Suppression of hydrogen-assisted fatigue crack growth in austenitic stainless steel by cavitation peening. Int. J. Hydrog. Energy 2012, 37, 5268–5276. [Google Scholar] [CrossRef]

- Kumagi, N.; Takakuwa, O.; Soyama, H. Improvement of delayed fracture resistance on chrome molybdenum steel bolt by cavitation peening. Trans. JSME 2016, 82, 1–13. [Google Scholar]

- Takahashi, K.; Osedo, H.; Suzuki, T.; Fukuda, S. Fatigue strength improvement of an aluminum alloy with a crack-like surface defect using shot peening and cavitation peening. Eng. Fract. Mech. 2018, 193, 151–161. [Google Scholar] [CrossRef]

- Masaki, K.; Ochi, Y.; Soyama, H. Fatigue property improvement of type 316l steel by cavitation shotless peening. In Proceeding of 10th International Conference on Shot Peening, Tokyo, Japan, 15–18 September 2008. paper No. 053. [Google Scholar]

- Soyama, H. Comparison between shot peening, cavitation peening and laser peening by observation of crack initiation and crack growth in stainless steel. Metals 2020, 10, 63. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Mall, S.; Soyama, H. Fretting fatigue behavior of cavitation shotless peened Ti–6Al–4V. Tribol. Lett. 2009, 36, 89–94. [Google Scholar] [CrossRef]

- Lee, H.; Mall, S. Analysis of fretting fatigue of cavitation shotless peened Ti-6Al-4V. Tribol. Lett. 2010, 38, 125–133. [Google Scholar] [CrossRef]

- Seki, M.; Soyama, H.; Kobayashi, Y.; Gowa, D.; Fujii, M. Rolling contact fatigue life of steel rollers treated by cavitation peening and shot peening. J. Solid Mech. Mater. Eng. 2012, 6, 478–486. [Google Scholar] [CrossRef] [Green Version]

- Okada, T.; Hattori, S.; Shimizu, M. A fundamental-study of cavitation erosion using a magnesium-oxide single crystal (intensity and distribution of bubble collapse impact loads). Wear 1995, 186, 437–443. [Google Scholar] [CrossRef]

- Soyama, H. Distribution of residual stress around plastic deformation pit induced by cavitation shotless peening. Prepr. JSME 2005, 05-9, 361–362. [Google Scholar]

- Goetzberger, A.; Shockley, W. Metal precipitates in silicon p-n junctions. J. Appl. Phys. 1960, 31, 1821–1824. [Google Scholar] [CrossRef]

- Tice, W.K.; Tan, T.Y. Nucleation of cusi precipitate colonies in oxygen-rich silicon. Appl. Phys. Lett. 1976, 28, 564–565. [Google Scholar] [CrossRef]

- Kang, J.S.; Schroder, D.K. Gettering in silicon. J. Appl. Phys. 1989, 65, 2974–2985. [Google Scholar] [CrossRef]

- Istratov, A.A.; Hieslmair, H.; Weber, E.R. Iron contamination in silicon technology. Appl. Phys. A Mater. Sci. Process. 2000, 70, 489–534. [Google Scholar] [CrossRef]

- Battaglia, C.; Cuevas, A.; De Wolf, S. High-efficiency crystalline silicon solar cells: Status and perspectives. Energy Environ. Sci. 2016, 9, 1552–1576. [Google Scholar] [CrossRef] [Green Version]

- Mikkelsen, J.C. Gettering of oxygen in si wafers damaged by ion-implantation and mechanical abrasion. Appl. Phys. Lett. 1983, 42, 695–697. [Google Scholar] [CrossRef]

- Sawada, R. Durability of mechanical damage gettering effect in Si wafers. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 1984, 23, 959–964. [Google Scholar] [CrossRef]

- Kumano, H.; Sasaki, T.; Soyama, H. Evaluation of the effectiveness of back-side damage gettering in silicon introduced by a cavitating jet. Appl. Phys. Lett. 2004, 85, 3935–3937. [Google Scholar] [CrossRef]

| Method | Mechanism of Impact | Source of Impact |

|---|---|---|

| Wet shot peening | Solid collision | Shot |

| Water jet peening | Liquid collision | Water droplet |

| Cavitation peening | Shockwave | Cavitation collapse |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soyama, H. Cavitation Peening: A Review. Metals 2020, 10, 270. https://doi.org/10.3390/met10020270

Soyama H. Cavitation Peening: A Review. Metals. 2020; 10(2):270. https://doi.org/10.3390/met10020270

Chicago/Turabian StyleSoyama, Hitoshi. 2020. "Cavitation Peening: A Review" Metals 10, no. 2: 270. https://doi.org/10.3390/met10020270

APA StyleSoyama, H. (2020). Cavitation Peening: A Review. Metals, 10(2), 270. https://doi.org/10.3390/met10020270