Microstructure Evolution of Selective Laser Melted Inconel 718: Influence of High Heating Rates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thermal Analysis

2.3. Microstructural Investigations

3. Results and Discussion

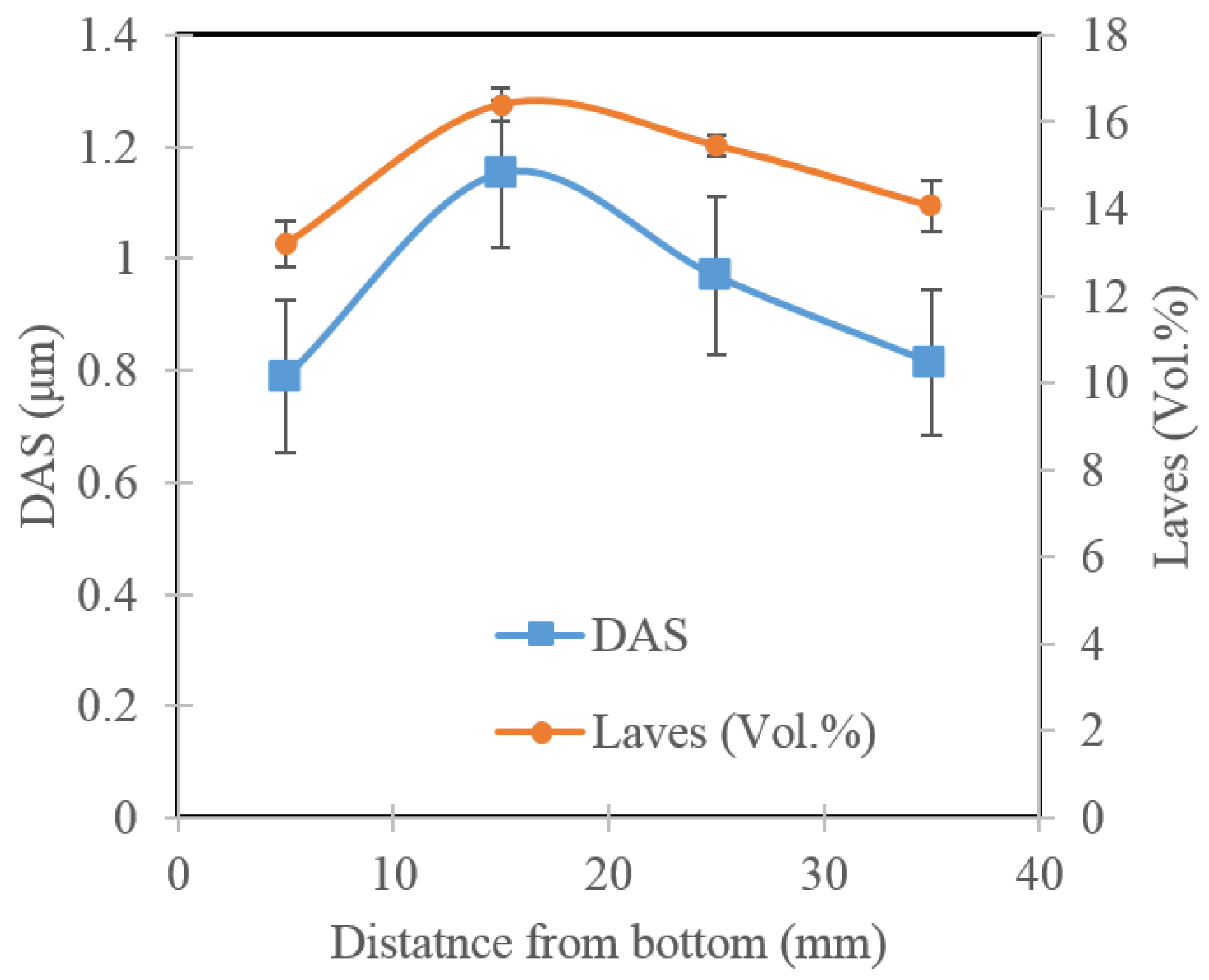

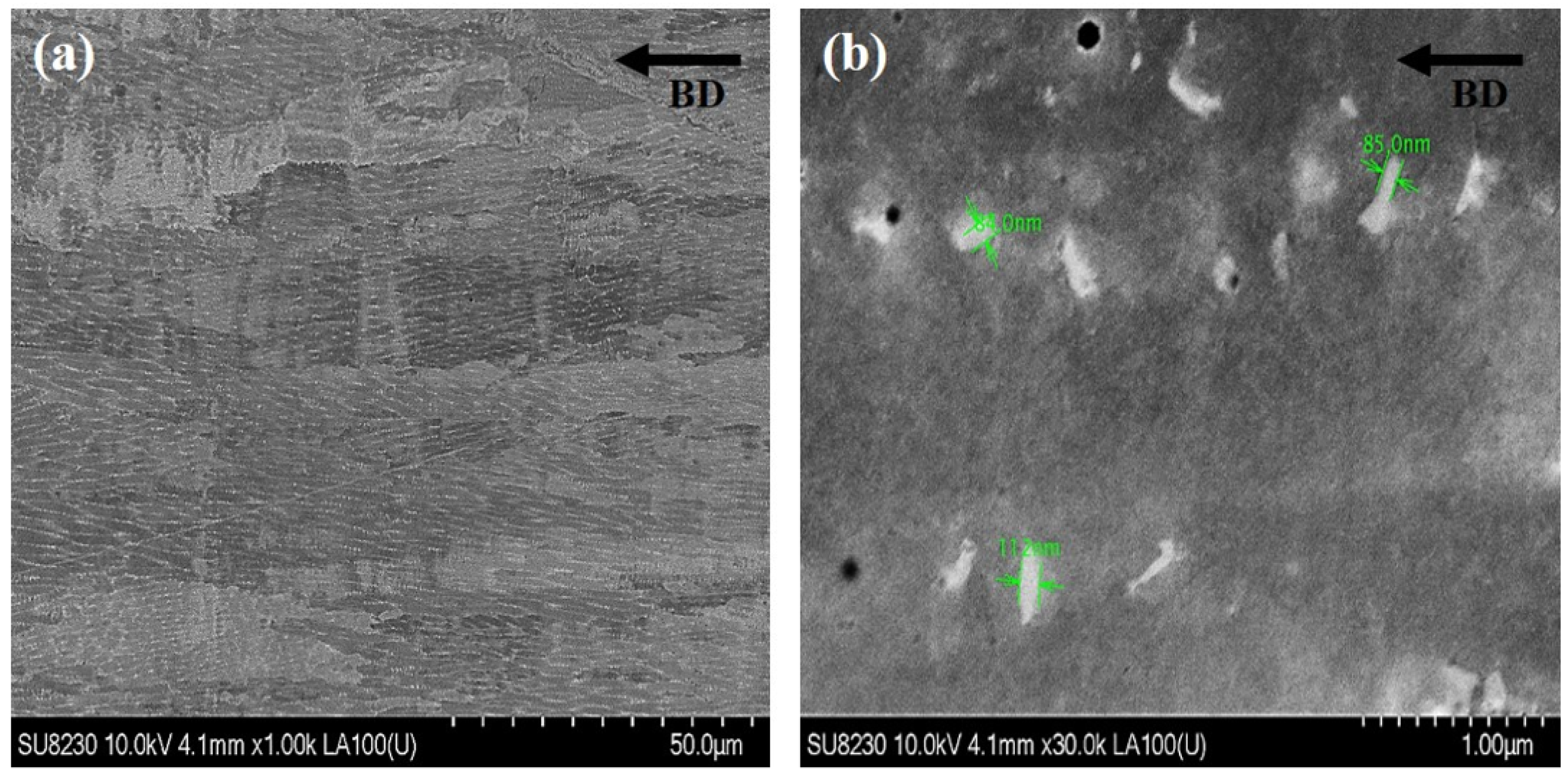

3.1. Characterization of the As-SLM Samples

3.2. Low Heating Rate Tests

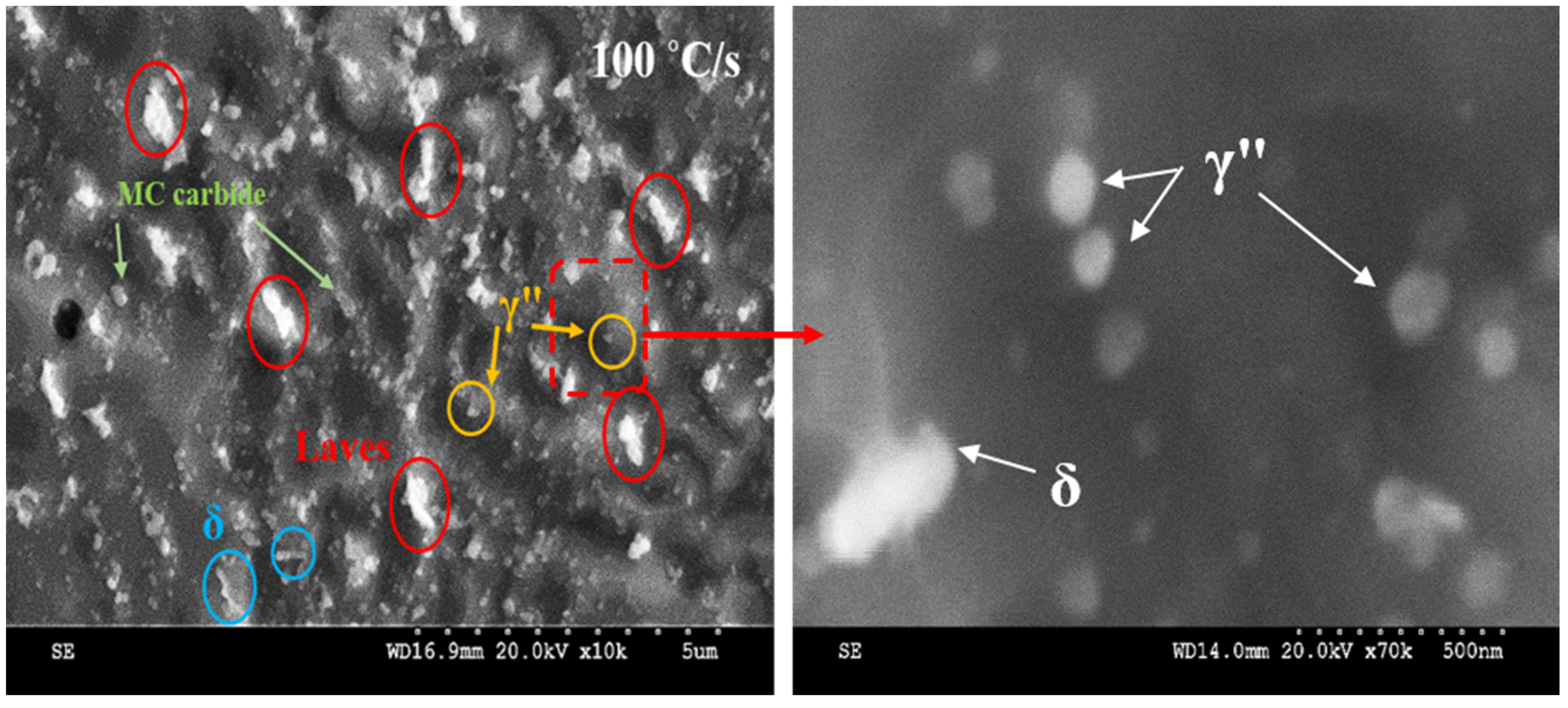

3.3. High Heating Rate Tests

3.4. Hardness Variations

4. Conclusions

- (1)

- A transitional zone characterized with the presence of blocky zones was identified in the subsurface region of the samples.

- (2)

- It was demonstrated that the transitional zone was not due to a thermal gradient in the sample but to microstructural changes.

- (3)

- The evolution of γ″ and δ phases in the SLM samples is different when compared to wrought materials when submitted to high heating rates.

- (4)

- The solubility of Nb is based on the diffusion rate of this element in different heating rates and stability of all phases (Laves, δ, and γ״) which contained Nb. The diffusion rate and/or the solubility of Nb in the γ phase increased at higher heating rates. The remaining Nb content in the interdendritic areas was determined to be insufficient for the Laves phase to form. The morphology of the Laves phase changed from fine and granular for 100 °C/s to long-striped for 400 °C/s, demonstrating that less time was available for Nb dissolution of in the matrix and/or precipitation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Petersen-Øverleir, E. Effect of 3D printing on the Microstructure and Mechanical Properties of an Inconel 718 Nickel-alloy. Master’s Thesis, University of Stavanger, Stavanger, Norway, 2015. [Google Scholar]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.Y.; Weaver, M.; Guo, Y.B. Microstructure evolution characteristics of Inconel 625 alloy from selective laser melting to heat treatment. Mater. Sci. Eng. A 2017, 705, 20–31. [Google Scholar] [CrossRef]

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (Lm) technologies, state of the art and future perspectives. CIRP Ann. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Kruth, J.P.; Leu, M.C.; Nakagawa, T. Progress in additive manufacturing and rapid prototyping. CIRP Ann. 1998, 47, 525–540. [Google Scholar] [CrossRef]

- Knapp, G.L.; Raghavan, N.; Plotkowski, A.; DebRoy, T. Experiments and simulations on solidification microstructure for Inconel 718 in powder bed fusion electron beam additive manufacturing. Addit. Manuf. 2019, 25, 511–521. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloy. Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Sufiiarov, V.S.; Borisov, E.V.; Polozov, I.A. Selective laser melting of the Inconel 718 nickel superalloy. Appl. Mech. Mater. 2014, 698, 333–338. [Google Scholar] [CrossRef]

- Raza, T.; Hurtig, K.; Asala, G.; Andersson, J.; Svensson, L.E.; Ojo, O.A. Influence of heat treatments on heat affected zone cracking of gas tungsten arc welded additive manufactured alloy 718. Metals 2019, 9, 881. [Google Scholar] [CrossRef] [Green Version]

- Owczarski, W.A.; Duvall, D.S.; Sullivan, C.P. Model for heat-affected zone cracking in nickel-base superalloys. Weld J. 1966, 45, 145–155. [Google Scholar]

- Raza, T.; Andersson, J.; Svensson, L.-E. Varestraint weldability testing of additive manufactured alloy 718. Sci. Technol. Weld. Join. 2018, 23, 606–611. [Google Scholar] [CrossRef] [Green Version]

- Manikandan, S.G.K.; Sivakumar, D.; Prasad Rao, K.; Kamaraj, M. Laves phase in alloy 718 fusion zone—Microscopic and calorimetric studies. Mater. Charact. 2015, 100, 192–206. [Google Scholar] [CrossRef]

- Radhakrishnan, B.; Thompson, R.G. The effect of weld Heat-Affected zone (HAZ) liquation kinetics on the hot cracking susceptibility of alloy 718. Metall. Mater. Trans. A 1993, 24, 1409–1422. [Google Scholar] [CrossRef]

- Manikandan, S.G.K.; Sivakumar, D.; Kamaraj, M.; Rao, K.P. Laves phase control in Inconel 718 weldments. Mater. Sci. Forum 2012, 710, 614–619. [Google Scholar] [CrossRef]

- Mary, C.; Jahazi, M. Linear friction welding of IN-718 process optimization and microstructure evolution. Adv. Mater. Res. 2006, 15–17, 357–362. [Google Scholar] [CrossRef]

- Huang, Z.W.; Li, H.Y.; Preuss, M.; Karadge, M.; Bowen, P.; Bray, S.; Baxter, G. Inertia friction welding dissimilar nickel-based superalloys alloy 720Li to IN718. Metall. Mater. Trans. A 2007, 38, 1608–1620. [Google Scholar] [CrossRef]

- Chamanfar, A.; Jahazi, M.; Cormier, J. A review on inertia and linear friction welding of Ni-based superalloys. Metall. Mater. Trans. A 2015, 46, 1639–1669. [Google Scholar] [CrossRef]

- Sui, S.; Chen, J.; Ma, L.; Fan, W.; Tan, H.; Liu, F.; Lin, X. Microstructures and stress rupture properties of pulse laser repaired Inconel 718 superalloy after different heat treatments. J. Alloy. Compd. 2019, 770, 125–135. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, F.; Zhang, K.; Nie, P.; Elmi Hosseini, S.R.; Feng, K.; Li, Z. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling. J. Alloy. Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Kumara, C.; Deng, D.; Hanning, F.; Raanes, M.; Moverare, J.; Nylén, P. Predicting the microstructural evolution of electron beam melting of alloy 718 with phase-field modeling. Metall. Mater. Trans. A 2019, 50, 2527–2537. [Google Scholar] [CrossRef] [Green Version]

- Qian, M.; Lippold, J.C. The effect of annealing twin-generated special grain boundaries on HAZ liquation cracking of nickel-base superalloys. Acta Mater. 2003, 51, 3351–3361. [Google Scholar] [CrossRef]

- VishwakAarma, K.R.; Ojo, O.A.; Wanjara, P.; Chaturvedi, M.C. Microstructural analysis of linear friction-welded 718 plus superalloy. J. Miner. Met. Mater. Soc. (TMS) 2014, 66, 2525–2534. [Google Scholar] [CrossRef]

- Zhang, H.R.; Ojo, O.A. Non-equilibrium liquid phase dissolution of δ phase precipitates in a nickel-based superalloy. Philos. Mag. Lett. 2009, 89, 787–794. [Google Scholar] [CrossRef]

- Tharappel, J.T.; Babu, J. Welding processes for Inconel 718- A brief review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330. [Google Scholar] [CrossRef]

- Muralidharan, B.G.; Shankar, V.; Gill, T.P.S. Weldability of Inconel 718—A Review; 29018458; Indira Gandhi Centre for Atomic Research: Kalpakkam, India, 1996; p. 61. [Google Scholar]

- Roder, O.; Helm, D.; Neft, S.; Albrecht, J.; Luetjering, G. Mixed Inconel Alloy 718 Inertia Welds for Rotating Applications: Microstructures and Mechanical Properties. In Proceedings of the Superalloys 718, 625, 706 and Various Derivatives, Pittsburgh, PA, USA, 2–5 October 2005; pp. 649–658. [Google Scholar]

- Niang, A.; Viguier, B.; Lacaze, J. Some features of anisothermal solid-state transformations in alloy 718. Mater. Charact. 2010, 61, 525–534. [Google Scholar] [CrossRef] [Green Version]

- Antonsson, T.; Fredriksson, H. The effect of cooling rate on the solidification of INCONEL 718. Metall. Mater. Trans. B 2005, 36, 85–96. [Google Scholar] [CrossRef]

- Knorovsky, G.A.; Cieslak, M.J.; Headley, T.J.; Romig, A.D.; Hammetter, W.F. INCONEL 718: A solidification diagram. Metall. Trans. A 1989, 20, 2149–2158. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Mirzadeh, H. Revisiting the diffusion of niobium in an as-cast nickel-based superalloy during annealing at elevated temperatures. Met. Mater. Int. 2019. [Google Scholar] [CrossRef]

- Huang, W.; Yang, J.; Yang, H.; Jing, G.; Wang, Z.; Zeng, X. Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 750, 98–107. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Z.; Bai, P.; Qu, H.; Liu, B.; Li, L.; Wu, L.; Guan, R.; Liu, H.; Guo, Z. Microstructural evolution and mechanical properties of IN718 alloy fabricated by selective laser melting following different heat treatments. J. Alloy. Compd. 2019, 772, 861–870. [Google Scholar] [CrossRef]

- Piec, M.; Dobrzański, L.A.; Labisz, K.; Jonda, E.; Klimpel, A. Laser alloying with WC ceramic powder in hot work tool steel using a high power diode laser (HPDL). Adv. Mater. Res. 2006, 15–17, 193–198. [Google Scholar] [CrossRef]

- Mostafa, A.; Picazo Rubio, I.; Brailovski, V.; Jahazi, M.; Medraj, M. Structure, texture and phases in 3D printed IN718 alloy subjected to homogenization and HIP treatments. Metals 2017, 7, 196. [Google Scholar] [CrossRef] [Green Version]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Tucho, W.M.; Cuvillier, P.; Sjolyst-Kverneland, A.; Hansen, V. Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater. Sci. Eng. A 2017, 689, 220–232. [Google Scholar] [CrossRef]

- Cao, G.H.; Sun, T.Y.; Wang, C.H.; Li, X.; Liu, M.; Zhang, Z.X.; Hu, P.F.; Russell, A.M.; Schneider, R.; Gerthsen, D.; et al. Investigations of γ′, γ″ and δ precipitates in heat-treated Inconel 718 alloy fabricated by selective laser melting. Mater. Charact. 2018, 136, 398–406. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y.; Bai, P.; Liu, F.; Hou, X. Investigation on the precipitates of IN718 alloy fabricated by selective laser melting. Metals 2019, 9, 1128. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Guo, Y.; Xu, M.; Ma, C.; Zhang, Q.; Wang, L.; Yao, J.; Li, Z. Study on the element segregation and laves phase formation in the laser metal deposited IN718 superalloy by flat top laser and gaussian distribution laser. Mater. Sci. Eng. A 2019, 754, 339–347. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of selective laser melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef] [Green Version]

- Bayerlein, F.; Bodensteiner, F.; Zeller, C.; Hofmann, M.; Zaeh, M.F. Transient development of residual stresses in laser beam melting—A neutron diffraction study. Addit. Manuf. 2018, 24, 587–594. [Google Scholar] [CrossRef]

- Masoumi, F.; Shahriari, D.; Jahazi, M.; Cormier, J.; Devaux, A. Kinetics and mechanisms of gamma’ reprecipitation in a Ni-based superalloy. Sci. Rep. 2016, 6, 28650. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.-Y.; Wen, Z.-X.; Cheng, H.; Gu, S.-N.; Lu, G.-X. Influences of the heating and cooling rates on the dissolution and precipitation behavior of a nickel-based single-crystal superalloy. Metals 2019, 9, 360. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chou, K. Microstructure simulations of Inconel 718 during selective laser melting using a phase field model. Int. J. Adv. Manuf. Technol. 2018, 100, 2147–2162. [Google Scholar] [CrossRef]

- Chrostek, T. The Influence of The Heating and Cooling Rates on The Temperature of The Phase Transformation; University of Warmia an Mazury in Olsztyn: Olsztyn, Poland, 2016. [Google Scholar]

- Soucail, M.; Bienvenu, Y. Dissolution of the γ′ phase in a nickel base superalloy at equilibrium and under rapid heating. Mater. Sci. Eng. A 1996, 220, 215–222. [Google Scholar] [CrossRef]

- Soucail, M.; Moal, A.; Naze, L.; Massoni, E.; Levaillant, C.; Bienvenu, Y. Microstructural study and numerical-simulation of inertia friction welding of astroloy. Superalloys 1992, 1992, 847–856. [Google Scholar]

- Sui, S.; Tan, H.; Chen, J.; Zhong, C.; Li, Z.; Fan, W.; Gasser, A.; Huang, W. The influence of Laves phases on the room temperature tensile properties of Inconel 718 fabricated by powder feeding laser additive manufacturing. Acta Mater. 2019, 164, 413–427. [Google Scholar] [CrossRef]

- Lalvani, H.M.; Brooks, J.W. Hot forging of IN718 with solution-treated and delta-containing initial microstructures. Metallogr. Microstruct. Anal. 2016, 5, 392–401. [Google Scholar] [CrossRef] [Green Version]

- Beaubois, V.; Huez, J.; Coste, S.; Brucelle, O.; Lacaze, J. Short term precipitation kinetics of delta phase in strain free Inconel* 718 alloy. Mater. Sci. Technol. 2004, 20, 1019–1026. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Mahaffey, D.W.; Levkulich, N.C.; Senkov, O.N. The radial temperature gradient in the Gleeble® hot-torsion test and its effect on the interpretation of plastic-flow behavior. Metall. Mater. Trans. A 2017, 48, 5357–5367. [Google Scholar] [CrossRef]

- Keller, B.P.; Nelson, S.E.; Walton, K.L.; Ghosh, T.K.; Tompson, R.V.; Loyalka, S.K. Total hemispherical emissivity of Inconel 718. Nucl. Eng. Design 2015, 287, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Rafiei, M.; Mirzadeh, H.; Malekan, M.; Sohrabi, M.J. Homogenization kinetics of a typical nickel-based superalloy. J. Alloy. Compd. 2019, 793, 277–282. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Mirzadeh, H. Numerical and analytical solutions for determination of interdiffusion coefficients in superalloys during homogenization. Mater. Today Commun. 2019, 21. [Google Scholar] [CrossRef]

- Sui, S.; Chen, J.; Li, Z.; Li, H.; Zhao, X.; Tan, H. Investigation of dissolution behavior of laves phase in inconel 718 fabricated by laser directed energy deposition. Addit. Manuf. 2020, 32. [Google Scholar] [CrossRef]

| P (W) | v (mm/s) | H (μm) | t (μm) |

|---|---|---|---|

| 275 | 760 | 120 | 50 |

| Ni | Fe | Cr | Co | Al | Ti | Nb | Mo | C | B | Zr | Si |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bal. | 15.7 | 20.54 | 0.1 | 0.34 | 1.17 | 5.1 | 3.13 | 0.04 | 0.002 | 0.018 | 0.01 |

| Heating Rate (˚C/min) | Temperature (°C) | |||||

| γ′–p | γ′–d | γ″–p | γ″–d | δ–p | δ–d | |

| 10 | 540 | 589 | 736 | 801 | 886 | 984 |

| 15 | 557 | 595 | 741 | 817 | 926 | 1008 |

| 25 | 560 | 614 | 754 | 831 | 962 | 1024 |

| 50 | 572 | 663 | 761 | 840 | 948 | 1035 |

| 80 | 596 | 678 | 776 | 860 | 965 | 1051 |

| 100 | 600 | 700 | 798 | 873 | 990 | 1057 |

| Elements | Ni | Cr | Fe | Nb | Mo | Ti | Al | |

|---|---|---|---|---|---|---|---|---|

| Phases | ||||||||

| Matrix in blocky zone | Bal. | 16.56 | 16.21 | 4.98 | 2.89 | 1.28 | 0.31 | |

| Laves in interdendritic region | Bal. | 10.98 | 10.80 | 34.05 | 5.85 | 3.98 | 0.0 | |

| MC carbide | Bal. | 3.08 | 2.96 | 47.71 | 6.10 | 10.78 | 0.0 | |

| δ–precipitate | Bal. | 17.93 | 17.26 | 9.09 | 5.06 | 1.68 | 0.06 | |

| γ″–precipitate | Below the EDS detection limits | |||||||

| Heating Rate (°C/s) | Thickness (µm) | Area of Blocky Zones (µm2) | Laves (wt.%) | NbLaves (wt.%) | Shape of Laves Phase |

|---|---|---|---|---|---|

| 100 | 12.08 ± 2.01 | 13.5 ± 10.24 | 5.45 ± 0.67 | 15 ± 3.8 | Fine and granular |

| 200 | 9.61 ± 1.97 | 6.65 ± 3.64 | 4.14 ± 0.28 | 14 ± 4.6 | Fine and granular |

| 400 | 4.23 ± 1.01 | 5.76 ± 4.49 | 3.25 ± 0.53 | 17 ± 3.9 | Irregular and long-striped |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabaie, S.; Rézaï-Aria, F.; Jahazi, M. Microstructure Evolution of Selective Laser Melted Inconel 718: Influence of High Heating Rates. Metals 2020, 10, 587. https://doi.org/10.3390/met10050587

Tabaie S, Rézaï-Aria F, Jahazi M. Microstructure Evolution of Selective Laser Melted Inconel 718: Influence of High Heating Rates. Metals. 2020; 10(5):587. https://doi.org/10.3390/met10050587

Chicago/Turabian StyleTabaie, Seyedmohammad, Farhad Rézaï-Aria, and Mohammad Jahazi. 2020. "Microstructure Evolution of Selective Laser Melted Inconel 718: Influence of High Heating Rates" Metals 10, no. 5: 587. https://doi.org/10.3390/met10050587

APA StyleTabaie, S., Rézaï-Aria, F., & Jahazi, M. (2020). Microstructure Evolution of Selective Laser Melted Inconel 718: Influence of High Heating Rates. Metals, 10(5), 587. https://doi.org/10.3390/met10050587