Development of a High Strength Magnesium Alloy for Wire Arc Additive Manufacturing

Abstract

:1. Introduction

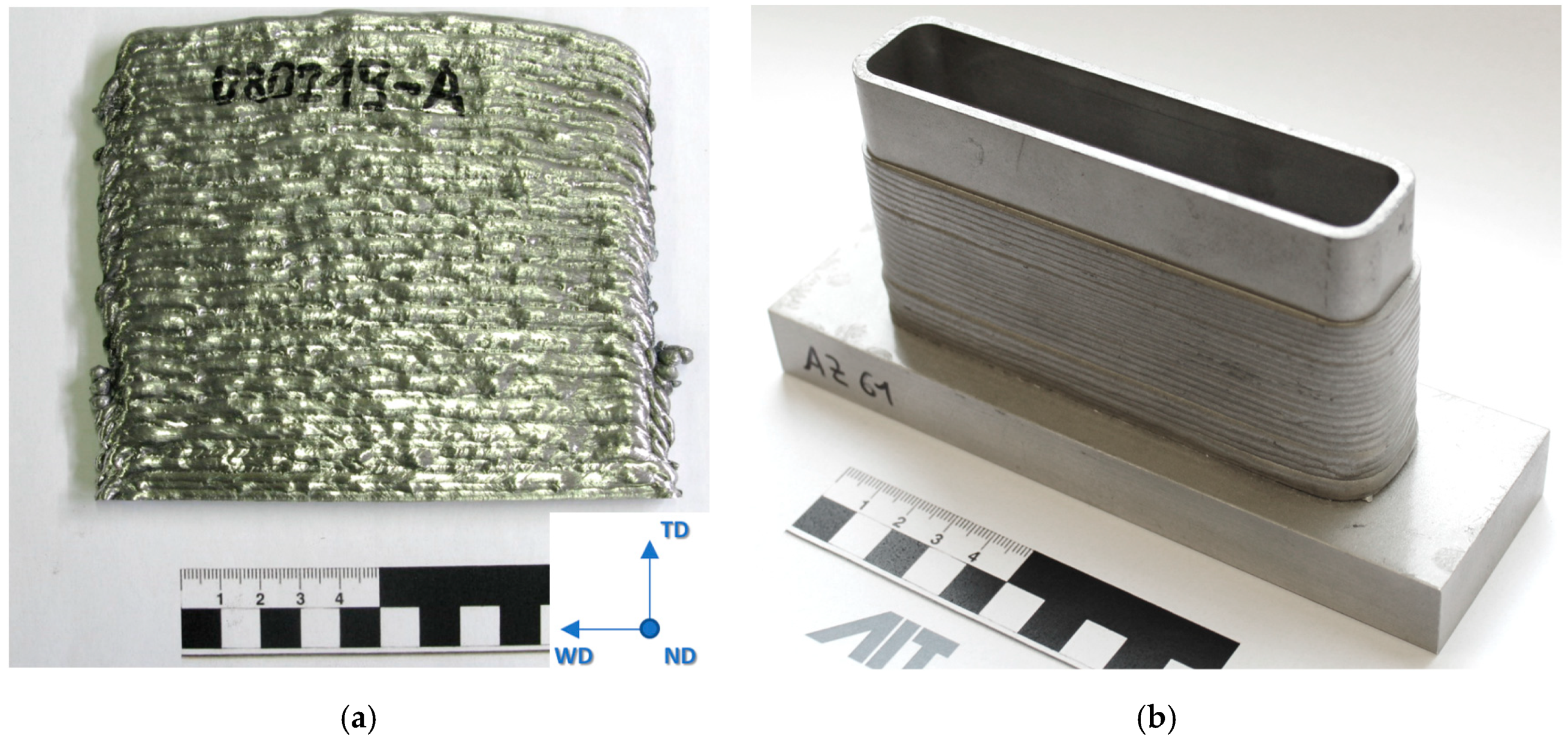

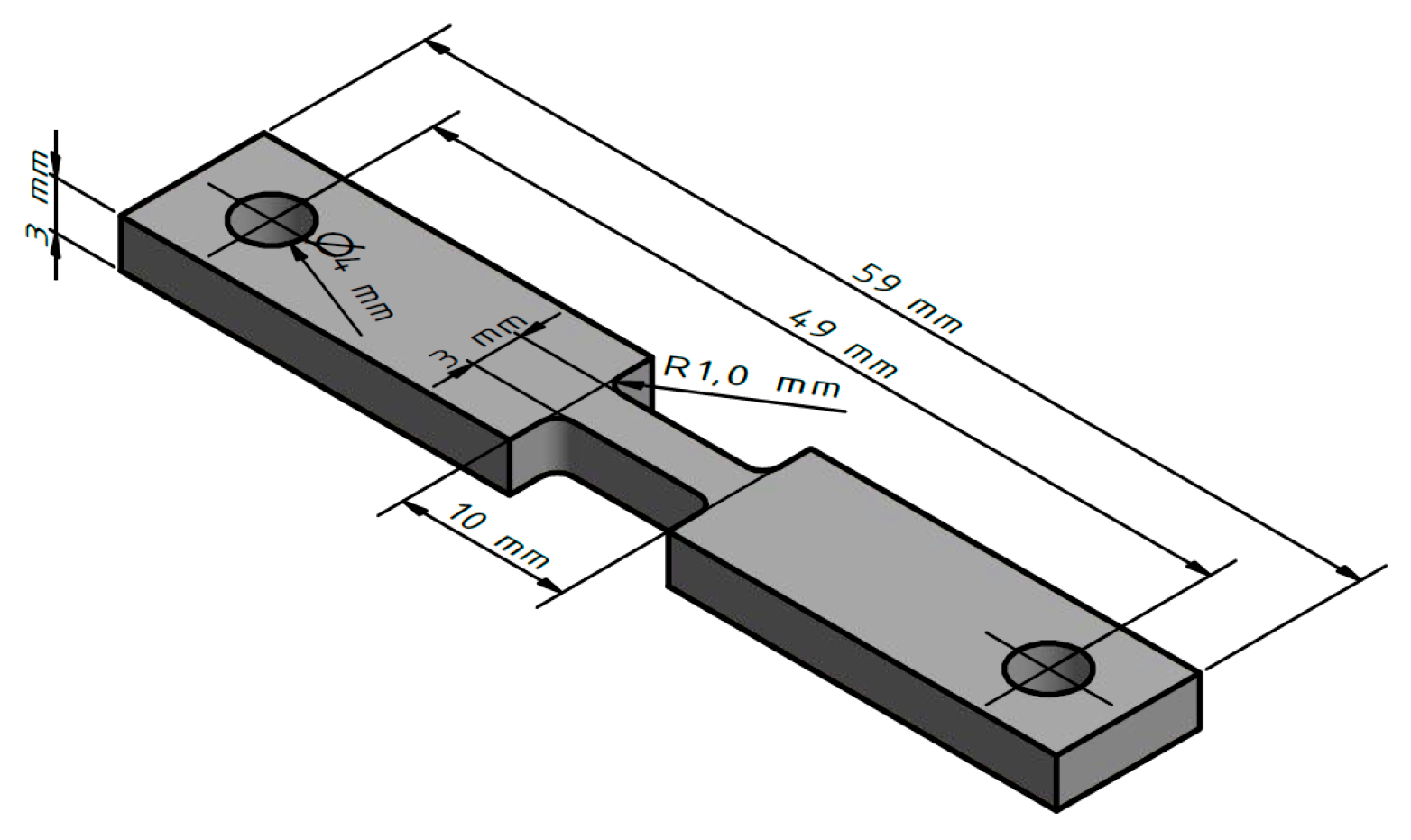

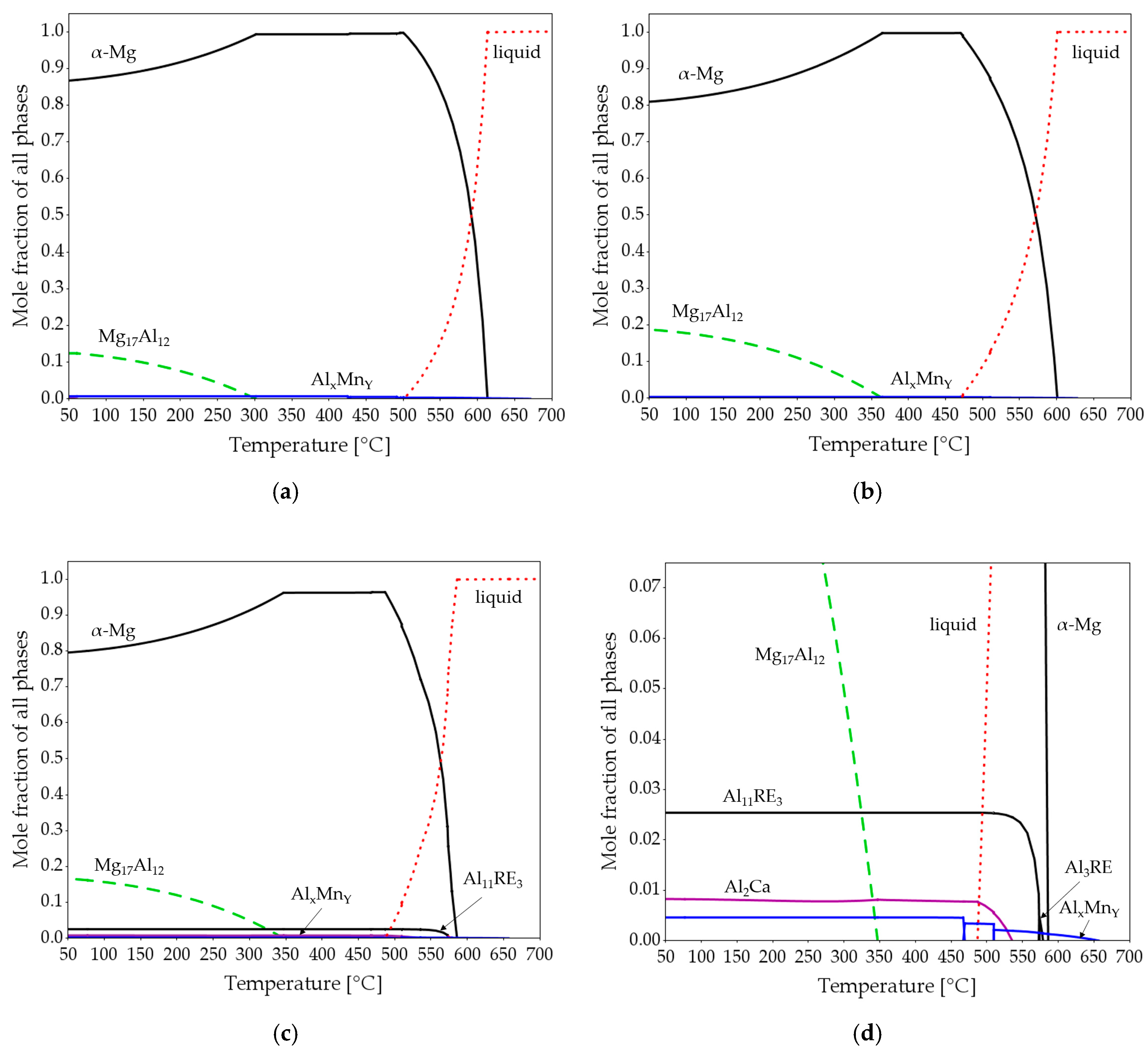

2. Materials and Methods

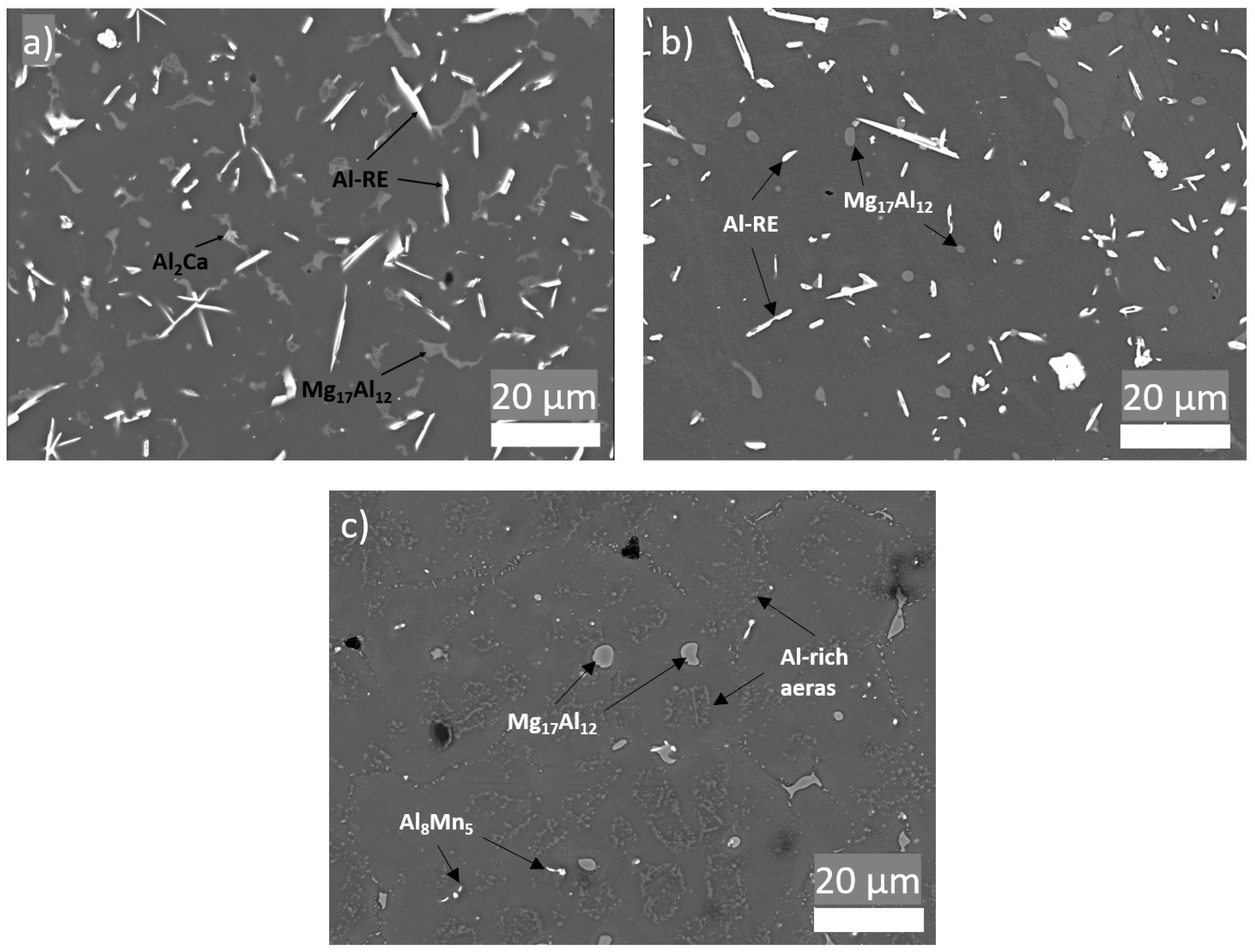

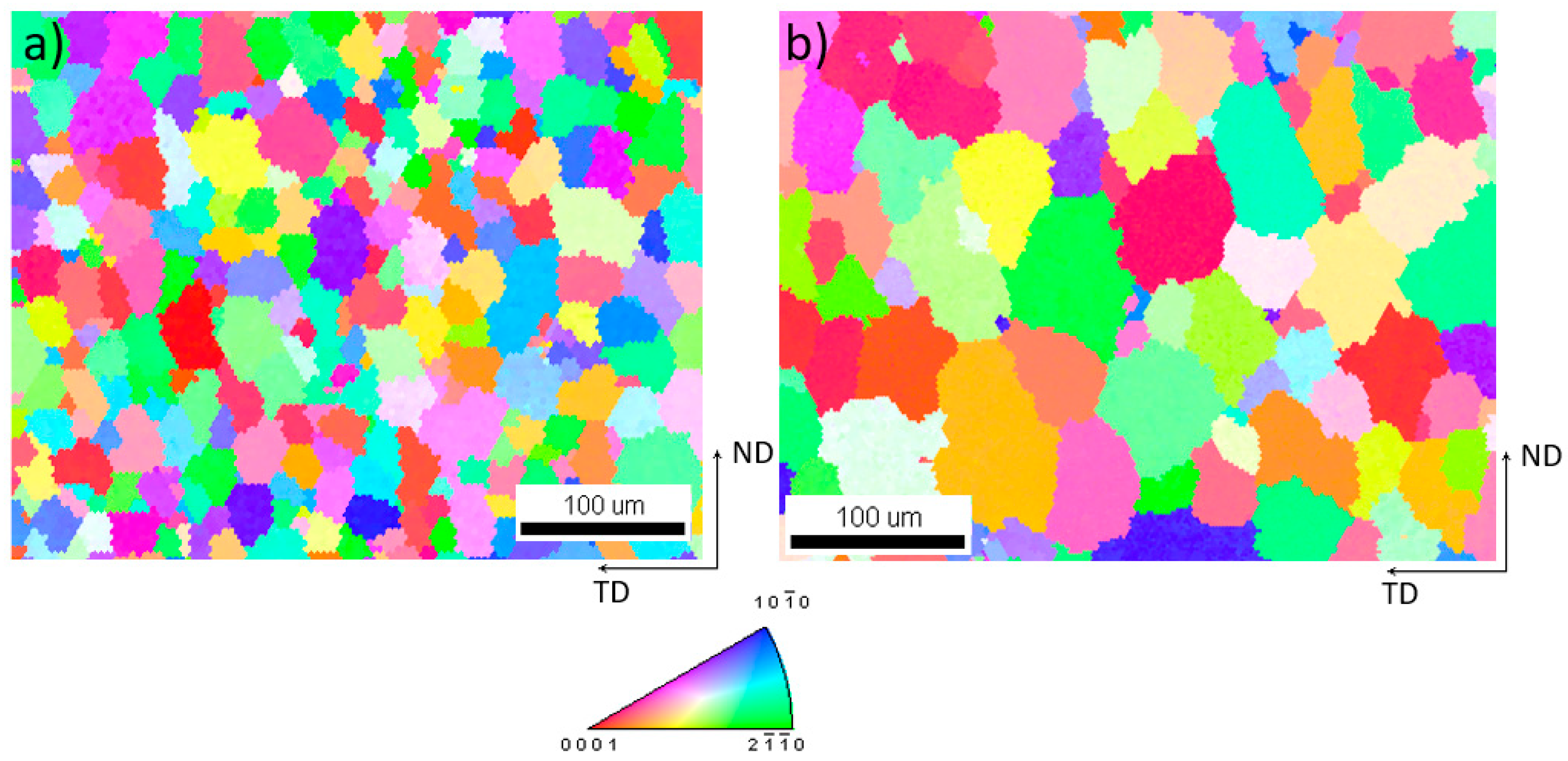

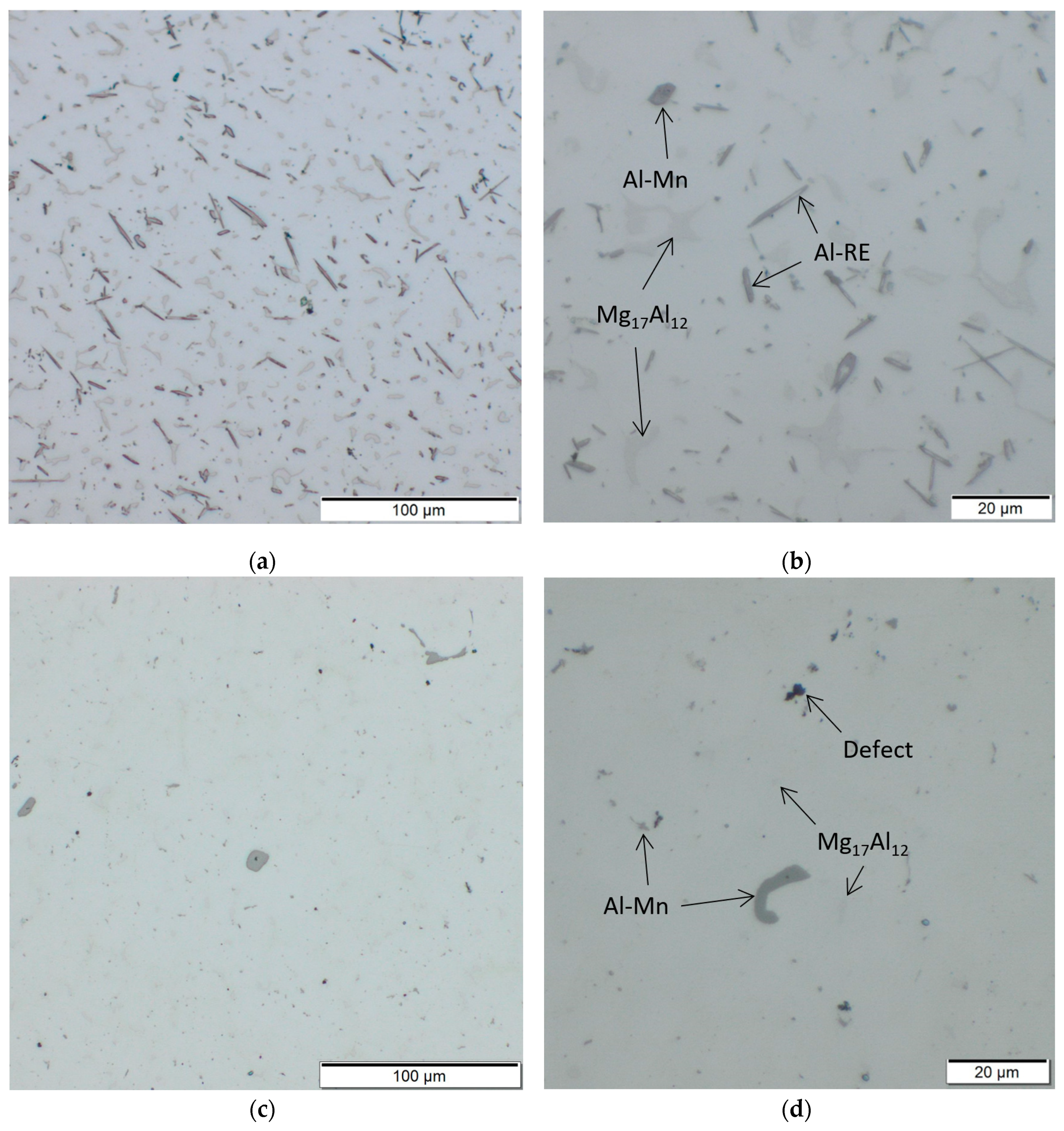

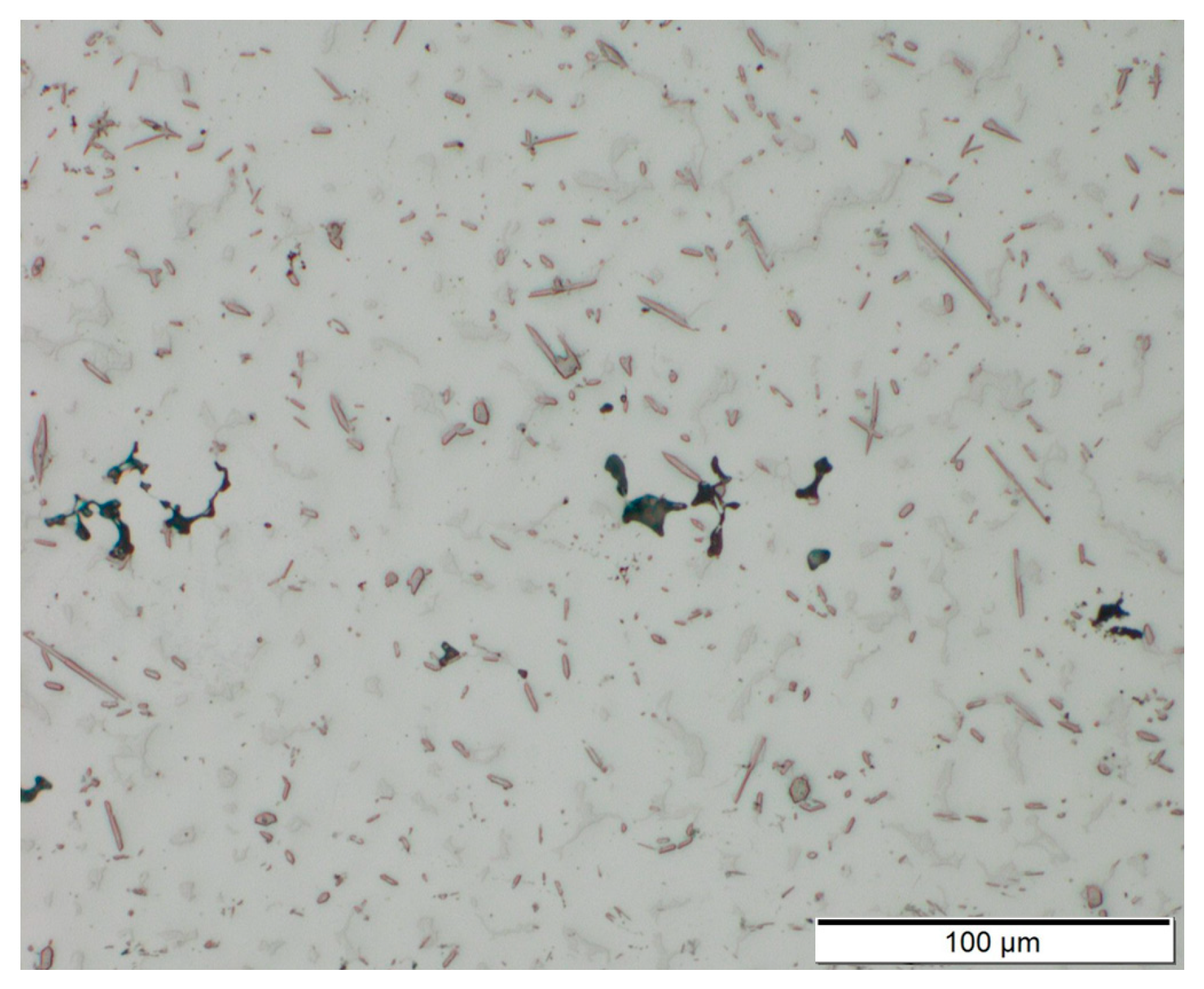

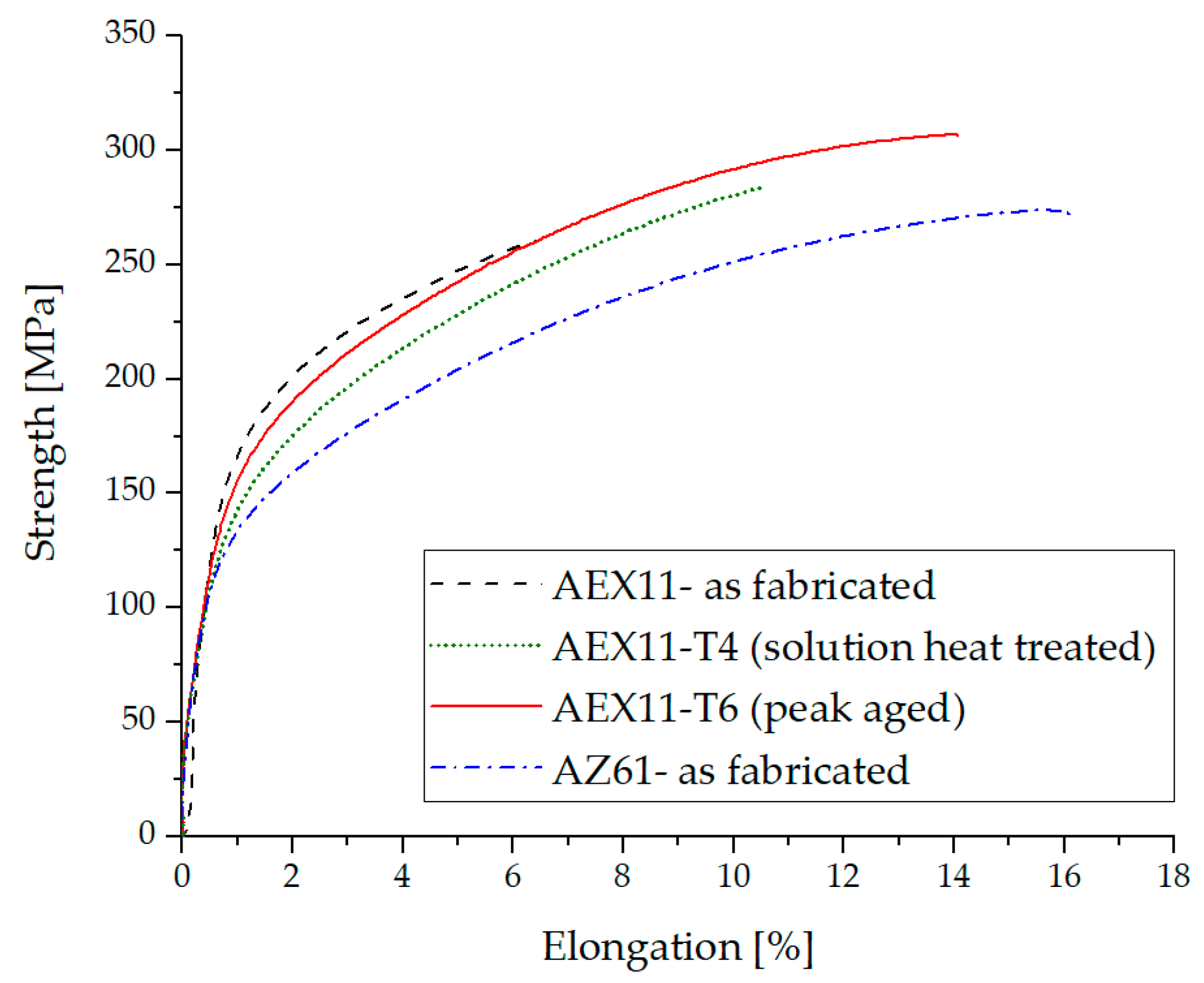

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mordike, B.L.; Ebert, T. Magnesium: Properties—Applications—Potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Emmelmann, C.; Sander, P.; Kranz, J.; Wycisk, E. Laser Additive Manufacturing and Bionics: Redefining Lightweight Design. Phys. Procedia 2011, 12, 364–368. [Google Scholar] [CrossRef] [Green Version]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Windhagen, H.; Radtke, K.; Weizbauer, A.; Diekmann, J.; Noll, Y.; Kreimeyer, U.; Schavan, R.; Stukenborg-Colsman, C.; Waizy, H. Biodegradable magnesium-based screw clinically equivalent to titanium screw in hallux valgus surgery: Short term results of the first prospective, randomized, controlled clinical pilot study. Biomed. Eng. OnLine 2013, 12, 62. [Google Scholar] [CrossRef] [Green Version]

- Gieseke, M.; Kiesow, T.; Noelke, C.; Kaierle, S.; Maier, H.J.; Matena, J.; Kampmann, A.; Nolte, I.; Gellrich, N.-C.; Haferkamp, H. Challenges of Processing Magnesium and Magnesium Alloys by Selective Laser Melting. In Proceedings of the World PM 2016 Congress and Exhibition. European Powder Metallurgy Association (EPMA), Hamburg, Germany, 9–13 October 2016. [Google Scholar]

- Jauer, L.; Meiners, W.; Vervoort, S.; Gayer, C.; Zumdick, N.A.; Zander, D. Selective Laser Melting of Magnesium Alloys. In Proceedings of the World Powder Metallurgy Conference 2016, Hamburg, Germany, 9–13 October 2016. [Google Scholar]

- Gieseke, M.; Noelke, C.; Kaierle, S.; Wesling, V.; Haferkamp, H. Selective Laser Melting of Magnesium and Magnesium Alloys. In Magnesium Technology 2013; Hort, N., Mathaudhu, S.N., Neelameggham, N.R., Alderman, M., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 65–68. ISBN 978-3-319-48150-0. [Google Scholar]

- Manakari, V.; Parande, G.; Gupta, M. Selective Laser Melting of Magnesium and Magnesium Alloy Powders: A Review. Metals 2017, 7, 2. [Google Scholar] [CrossRef] [Green Version]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Tandon, R.; Palmer, T.; Gieseke, M.; Noelke, C.; Kaierle, S. Additive manufacturing of magnesium alloy powders: Investigations into process development using elektron®MAP+43 via laser powder bed fusion and directed energy deposition. In Proceedings of the World PM 2016 Congress and Exhibition; European Powder Metallurgy Association (EPMA), Hamburg, Germany, 9–13 October 2016. [Google Scholar]

- Avedesian, M.M.; Baker, H. ASM Specialty Handbook: Magnesium and Magnesium Alloys; ASM International: Russel Township, OH, USA, 1999; ISBN 978-0-87170-657-7. [Google Scholar]

- Products–Mag Specialties. Available online: https://www.magspecialtiesinc.com/products/ (accessed on 10 July 2019).

- Magnesium Alloys|Products|Washington Alloy Company. Available online: https://weldingwire.com/products/Magnesium-Alloys (accessed on 10 July 2019).

- Magnesium-DRATEC. Available online: http://www.dratec.de/magnesium.html (accessed on 10 July 2019).

- Guo, J.; Zhou, Y.; Liu, C.; Wu, Q.; Chen, X.; Lu, J. Wire Arc Additive Manufacturing of AZ31 Magnesium Alloy: Grain Refinement by Adjusting Pulse Frequency. Materials 2016, 9, 823. [Google Scholar] [CrossRef] [Green Version]

- Takagi, H.; Sasahara, H.; Abe, T.; Sannomiya, H.; Nishiyama, S.; Ohta, S.; Nakamura, K. Material-property evaluation of magnesium alloys fabricated using wire-and-arc-based additive manufacturing. Addit. Manuf. 2018, 24, 498–507. [Google Scholar] [CrossRef]

- Han, S.; Zielewski, M.; Martinez Holguin, D.; Michel Parra, M.; Kim, N. Optimization of AZ91D Process and Corrosion Resistance Using Wire Arc Additive Manufacturing. Appl. Sci. 2018, 8, 1306. [Google Scholar] [CrossRef] [Green Version]

- Holguin, D.A.M.; Han, S.; Kim, N.P. Magnesium Alloy 3D Printing by Wire and Arc Additive Manufacturing (WAAM). MRS Adv. 2018, 3, 2959–2964. [Google Scholar] [CrossRef]

- Graf, M.; Hälsig, A.; Höfer, K.; Awiszus, B.; Mayr, P. Thermo-Mechanical Modelling of Wire-Arc Additive Manufacturing (WAAM) of Semi-Finished Products. Metals 2018, 8, 1009. [Google Scholar] [CrossRef] [Green Version]

- Marker, T. Evaluating the Flammability of Various Magnesium Alloys During Laboratory- and Full-Scale Aircraft Fire Test; US Department of Transportation, Federal Aviation Administration: Atlantic City, NJ, USA, 2013.

- Marker, T.R. Development of a Laboratory-Scale Flammability Test for Magnesium Alloys Used in Aircraft Seat Construction; Federal Aviation Administration: Washington, DC, USA, 2014.

- Gneiger, S.; Frank, S.; Betz, A. Untersuchung des Elementeinflusses von Ca und Y auf Magnesiumlegierungen. In Proceedings of the 9th Ranshofener Leichtmetalltage, Bad Ischl, Austria, 9–10 November 2016. [Google Scholar]

- Gneiger, S.; Gradinger, R.; Betz, A. Manufacturing route for producing tailor-made magnesium wires for welding and ALM purposes. In Proceedings of the 2017 World Magnesium Conference, Singapore, 21–23 May 2017. [Google Scholar]

- Bakke, P.; Westengen, H. The Role of Rare Earth Elements in Structure and Property Control of Magnesium Die Casting Alloys. In Essential Readings in Magnesium Technology; Springer: Berlin/Heidelberg, Germany, 2016; pp. 313–318. ISBN 978-3-319-48588-1. [Google Scholar]

- Rokhlin, L.L. Magnesium Alloys Containing Rare Earth Metals: Structure and Properties; CRC Press: Boca Raton, FL, USA, 2003; ISBN 978-0-429-17922-8. [Google Scholar]

- Li, P.; Tang, B.; Kandalova, E.G. Microstructure and properties of AZ91D alloy with Ca additions. Mater. Lett. 2005, 59, 671–675. [Google Scholar] [CrossRef]

- Nami, B.; Shabestari, S.G.; Razavi, H.; Mirdamadi, S.; Miresmaeili, S.M. Effect of Ca, RE elements and semi-solid processing on the microstructure and creep properties of AZ91 alloy. Mater. Sci. Eng. A 2011, 528, 1261–1267. [Google Scholar] [CrossRef]

- Dini, H.; Andersson, N.-E.; Jarfors, A. Effect of Mg17Al12 Fraction on Mechanical Properties of Mg-9%Al-1%Zn Cast Alloy. Metals 2016, 6, 251. [Google Scholar] [CrossRef] [Green Version]

- Cai, H.; Guo, F.; Su, J. Combined effects of cerium and cooling rate on microstructure and mechanical properties of AZ91 magnesium alloy. Mater. Res. Express 2018, 5, 016503. [Google Scholar] [CrossRef]

- Zhu, T.; Chen, Z.W.; Gao, W. Effect of cooling conditions during casting on fraction of β-Mg17Al12 in Mg–9Al–1Zn cast alloy. J. Alloys Compd. 2010, 501, 291–296. [Google Scholar] [CrossRef]

- Cui, X.; Liu, H.; Meng, J.; Zhang, D. Microstructure and mechanical properties of die-cast AZ91D magnesium alloy by Pr additions. Trans. Nonferrous Met. Soc. China 2010, 20, s435–s438. [Google Scholar] [CrossRef]

- Easton, M.; Zhu, S.; Gibson, M.; Abbott, T.; Ang, H.Q.; Chen, X.; Birbilis, N.; Savage, G. Performance Evaluation of High-Pressure Die-Cast Magnesium Alloys. In Magnesium Technology 2017; Solanki, K.N., Orlov, D., Singh, A., Neelameggham, N.R., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 123–129. ISBN 978-3-319-52391-0. [Google Scholar]

- Zhu, S.; Easton, M.A.; Abbott, T.B.; Nie, J.-F.; Dargusch, M.S.; Hort, N.; Gibson, M.A. Evaluation of Magnesium Die-Casting Alloys for Elevated Temperature Applications: Microstructure, Tensile Properties, and Creep Resistance. Metall. Mater. Trans. A 2015, 46, 3543–3554. [Google Scholar] [CrossRef] [Green Version]

- Klein, T.; Schnall, M. Control of macro-/microstructure and mechanical properties of a wire-arc additive manufactured aluminum alloy. Int. J. Adv. Manuf. Technol. 2020. [Google Scholar] [CrossRef]

- Monteiro, W.A. New Features on Magnesium Alloys; InTech: Rijeka, Croatia, 2012; ISBN 978-953-51-0668-5. [Google Scholar]

- Liu, L.; Song, G.; Liang, G.; Wang, J. Pore formation during hybrid laser-tungsten inert gas arc welding of magnesium alloy AZ31B—Mechanism and remedy. Mater. Sci. Eng. A 2005, 390, 76–80. [Google Scholar] [CrossRef]

- Javadi, Y.; MacLeod, C.N.; Pierce, S.G.; Gachagan, A.; Lines, D.; Mineo, C.; Ding, J.; Williams, S.; Vasilev, M.; Mohseni, E.; et al. Ultrasonic phased array inspection of a Wire + Arc Additive Manufactured (WAAM) sample with intentionally embedded defects. Addit. Manuf. 2019, 29, 100806. [Google Scholar] [CrossRef]

- Kaufman, J.G. Properties of Aluminum Alloys: Tensile, Creep, and Fatigue Data at High and Low Temperatures; ASM International: Russel Township, OH, USA, 1999; ISBN 978-0-87170-632-4. [Google Scholar]

- Kammer, C. Magnesium-Taschenbuch; Aluminium-Verlag: Düsseldorf, Germany, 2000; ISBN 978-3-87017-264-0. [Google Scholar]

- Jo, S.M.; Go, Y.; You, B.S.; Kim, Y.M. Precipitation Behavior of Mg–Al–Sn–Zn–(Na) Alloy. In Magnesium Technology 2017; Solanki, K.N., Orlov, D., Singh, A., Neelameggham, N.R., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 203–207. [Google Scholar]

- Manivannan, S.; Gopalakrishnan, S.K.; Saravana Murthy, L.N.; Babu, K.; Sundarrajan, S. Microstructure and Mechanical Properties of Cast Mg-6Al- 1Zn-xRE Alloy with Additions of Yttrium at Different Ageing Temperature. Eur. J. Sci. Res. 2014, 122, 381–391. [Google Scholar]

- Papenberg, N.P.; Gneiger, S.; Weißensteiner, I.; Uggowitzer, P.J.; Pogatscher, S. Mg-Alloys for Forging Applications—A Review. Materials 2020, 13, 985. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gneiger, S.; Papenberg, N.; Frank, S.; Gradinger, R. Investigations on Microstructure and Mechanical Properties of Non-flammable Mg–Al–Zn–Ca–Y Alloys. In Proceedings of the Magnesium Technology 2018; Orlov, D., Joshi, V., Solanki, K.N., Neelameggham, N.R., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 105–113. [Google Scholar]

- ASM Handbook Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials-ASM International. Available online: https://www.asminternational.org/materials-resources/results/-/journal_content/56/10192/06182G/PUBLICATION (accessed on 24 September 2019).

- Zeng, Z.; Stanford, N.; Davies, C.H.J.; Nie, J.-F.; Birbilis, N. Magnesium extrusion alloys: A review of developments and prospects. Int. Mater. Rev. 2019, 64, 27–62. [Google Scholar] [CrossRef]

| Alloy | Al (wt.%) | Zn (wt.%) | Ce-Mischmetal (wt.%) | Ca (wt.%) | Mn (wt.%) | Mg (wt.%) |

|---|---|---|---|---|---|---|

| AZ61A | 5.8–7.2 | 0.40–1.5 | - | - | 0.15–0.5 | Rem. |

| AZ91D | 8.5–9.5 | 0.45–0.9 | - | - | ≥0.17 | Rem. |

| AEX11 | 10.1–11.5 | 0.3–0.6 | 2.5–3.5 | 0.2–0.44 | 0.15–0.5 | Rem. |

| Alloy | State | Direction | UTS (MPa) | SD (MPa) | Elongation (%) | SD (%) |

|---|---|---|---|---|---|---|

| AZ61A | as fabricated | WD | 275 | 1.0 | 16.8 | 0.4 |

| TD | 272 | 4.5 | 17.2 | 1.3 | ||

| AEX11 | as fabricated | WD | 243 | 17.3 | 4.5 | 2.3 |

| TD | 233 | 12.3 | 5.2 | 0.7 | ||

| T6 | WD | 299 | 8.0 | 12.6 | 1.5 | |

| TD | 298 | 6.3 | 11.0 | 0.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gneiger, S.; Österreicher, J.A.; Arnoldt, A.R.; Birgmann, A.; Fehlbier, M. Development of a High Strength Magnesium Alloy for Wire Arc Additive Manufacturing. Metals 2020, 10, 778. https://doi.org/10.3390/met10060778

Gneiger S, Österreicher JA, Arnoldt AR, Birgmann A, Fehlbier M. Development of a High Strength Magnesium Alloy for Wire Arc Additive Manufacturing. Metals. 2020; 10(6):778. https://doi.org/10.3390/met10060778

Chicago/Turabian StyleGneiger, Stefan, Johannes A. Österreicher, Aurel R. Arnoldt, Alois Birgmann, and Martin Fehlbier. 2020. "Development of a High Strength Magnesium Alloy for Wire Arc Additive Manufacturing" Metals 10, no. 6: 778. https://doi.org/10.3390/met10060778

APA StyleGneiger, S., Österreicher, J. A., Arnoldt, A. R., Birgmann, A., & Fehlbier, M. (2020). Development of a High Strength Magnesium Alloy for Wire Arc Additive Manufacturing. Metals, 10(6), 778. https://doi.org/10.3390/met10060778