Asymmetrical Rolling of Aluminum Alloys and Steels: A Review

Abstract

1. Introduction

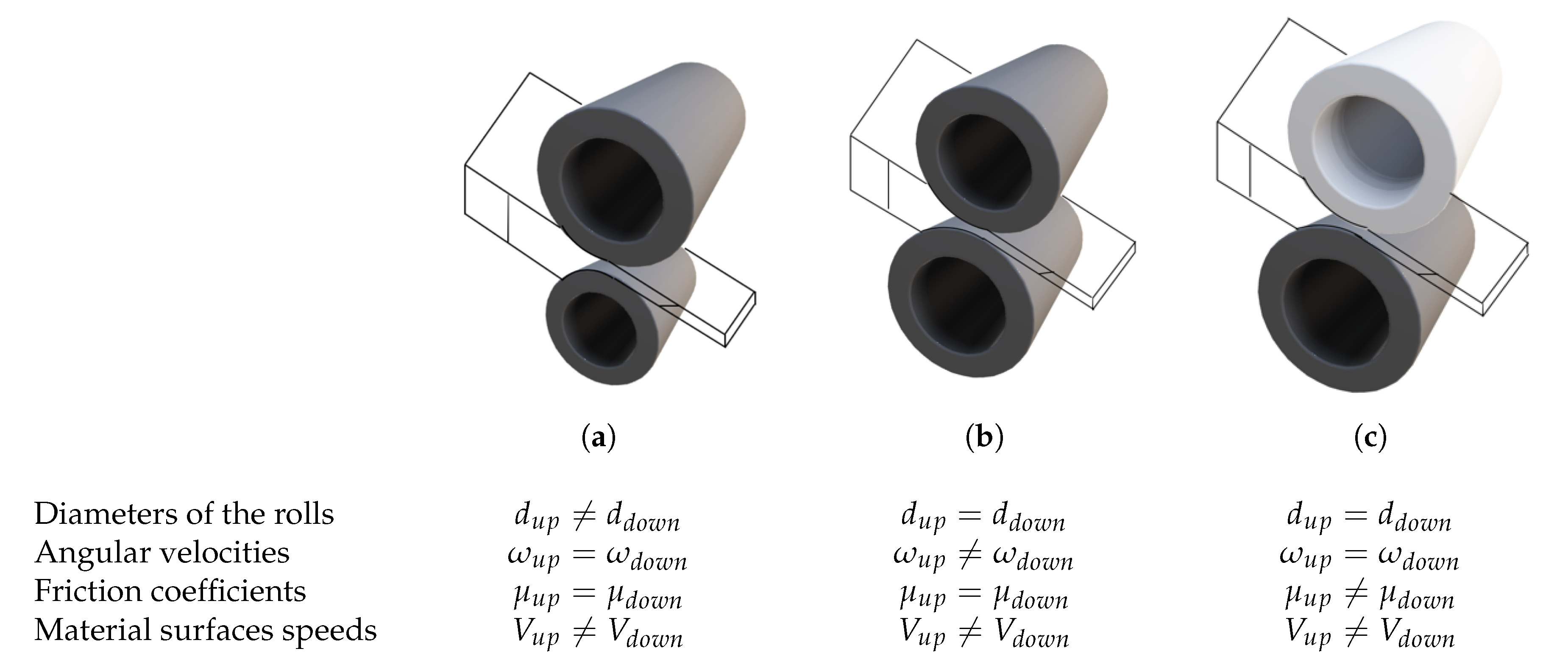

2. Methodology of Asymmetric Rolling

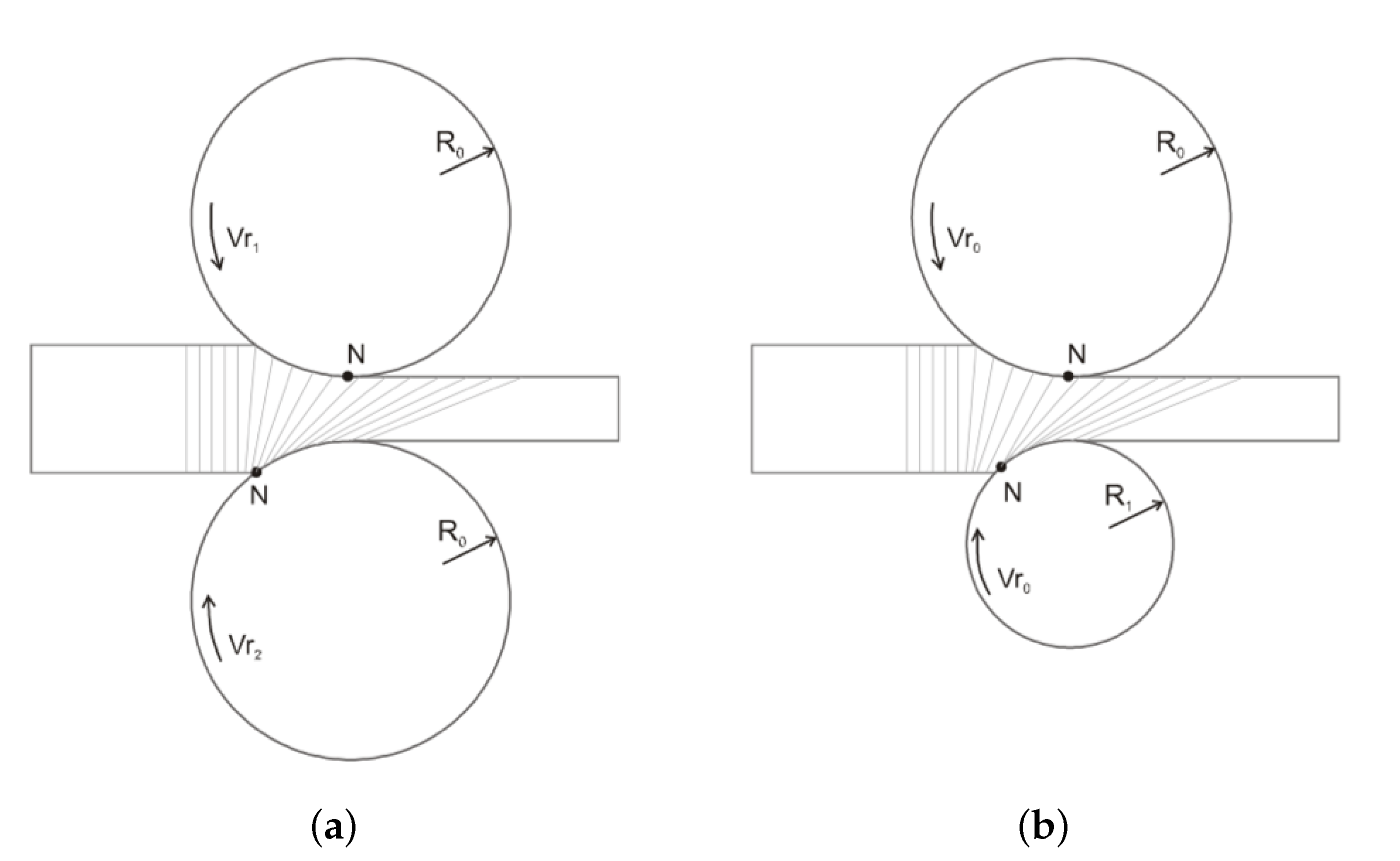

2.1. Circumferential Speed Ratio

2.2. Dissimilarity of Friction Conditions

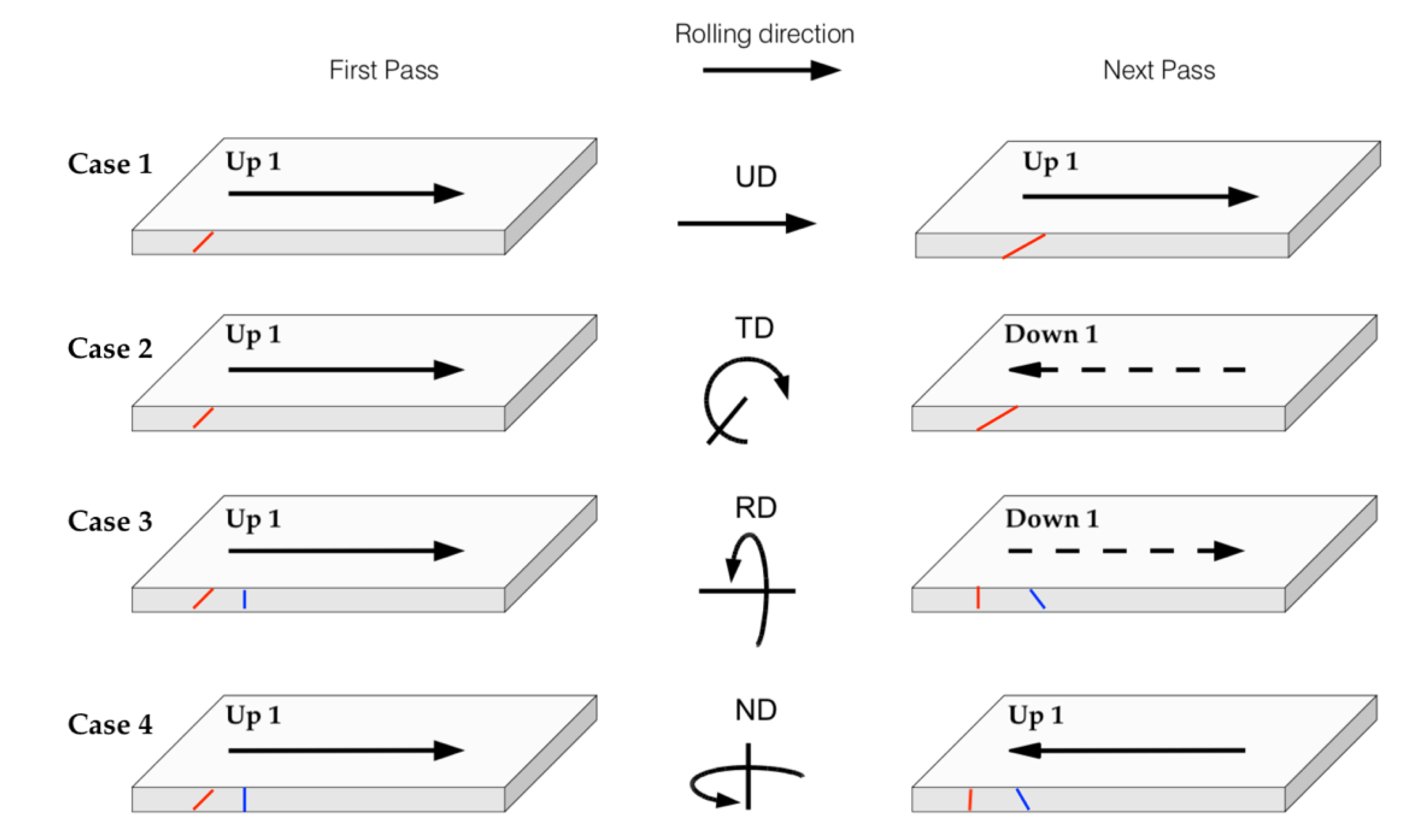

2.3. Rolling Routes

- Case 1:

- no rotation between 2 subsequent passes occurs; in this case the shear deformation increases with the increase of the number of passes; the Up and Down surfaces of the sheet are kept.

- Case 2:

- rotation relative to transverse direction (TD) between 2 subsequent passes; in this case the shear deformation increases with the increase of the number of passes; the Up and Down surfaces are switched.

- Case 3:

- rotation relative to rolling direction (RD) between 2 subsequent passes; the shear deformation is reversed; the increase of number of passes is equivalent to cyclic shear; the Up and Down surfaces are switched.

- Case 4:

- rotation relative to normal direction (ND) between 2 subsequent passes; the shear deformation is reversed; the increase of number of passes is equivalent to cyclic shear; the Up and Down surfaces of the sheet are kept.

3. Texture

3.1. Texture of Aluminium Alloys

3.2. Texture of Steels

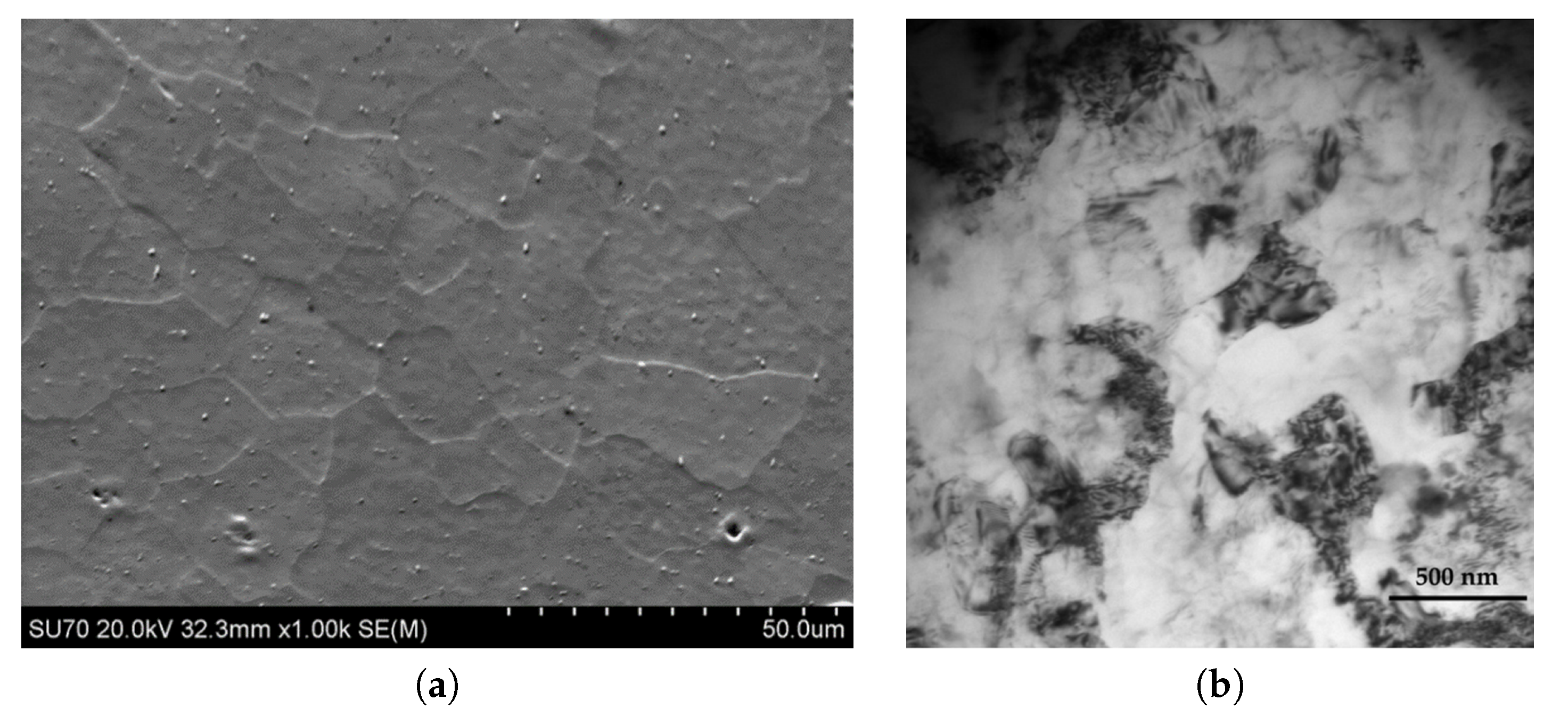

4. Microstructure Evolution

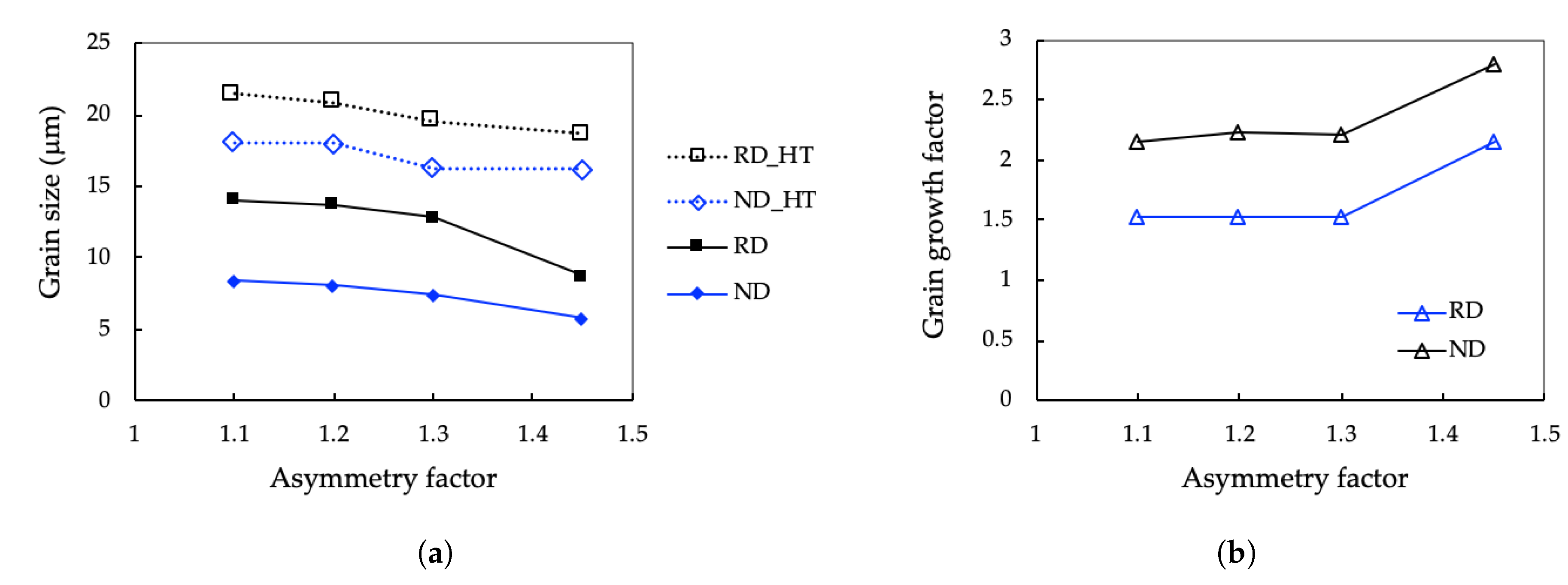

4.1. Microstructure of Aluminum Alloys

4.2. Microstructure of Steels

5. Mechanical Behavior

5.1. Aluminum Alloys

5.2. Steels

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ASR | Asymmetric rolling |

| CR | Conventional rolling |

| bcc | body-centered cubic |

| fcc | face-centered cubic |

| hcp | hexagonal close-packed |

| ND | normal direction |

| RD | rolling direction |

| TD | transverse direction |

| RC | rotated cube |

| TWIP | twinning-induced plasticity |

| IF | interstitial-free |

| HSLA | high-strength low-alloy |

| r | anisotropy coefficient |

| LABs | low angle boundaries |

| HABs | high angle boundaries |

| RPP | thickness reduction per pass |

| KAM | Kernel Average Misorientation parameter |

References

- Sachs, G.; Klingler, L.J. The flow of metals through tools of circular contour. J. Appl. Mech. 1947, 14, 88. [Google Scholar]

- Holbrook, R.L.; Zorowski, C.F. Effects of Nonsymmetry in Strip Rolling on Single-Roll Drive Mills. J. Eng. Ind. 1966, 88, 401–408. [Google Scholar] [CrossRef]

- Johnson, W.; Needham, G. Further experiments in asymmetrical rolling. Int. J. Mech. Sci. 1966, 8, 443–455. [Google Scholar] [CrossRef]

- Zorowski, C.; Shutt, A. Analysis of the Load and Torque Characteristics of Single-Roll Drive Mills; International Research in Product Engineering ASME: Pittsburgh, PA, USA, 1963; p. 380. [Google Scholar]

- Johnson, W.N.G. An experimental study of asymmetrical rolling. In Applied Mechanics Convention; Institution of Mechanical Engineering: Cambridge, UK, 1966. [Google Scholar]

- Richelsen, A. Elastic-plastic analysis of the stress and strain distributions in asymmetric rolling. Int. J. Mech. Sci. 1997, 39, 1199–1211. [Google Scholar] [CrossRef]

- Richelsen, A.B. Numerical analysis of asymmetric rolling accounting for differences in friction. J. Mater. Process. Technol. 1994, 45, 149–154. [Google Scholar] [CrossRef]

- Skorokhodov, V.; Polyakov, M.; Skorokhodov, S. Study of Metal Flow During Asymmetric Rolling. ISSLEDOVANIE TECHENIYA METALLA PRI NESIMMETRICHNOI PROKATKE. Izv. Vyss. Uchebnykh Zaved. Chernaya Metall. 1977, 73–76. [Google Scholar]

- Skorokhodov, V.; Polyakov, M.; Skorokhodov, S. Metal flow during asymmetric rolling. Steel USSR 1978, 7, 457–458. [Google Scholar]

- Pavlov, I.; Karelin, F.; Portnaya, Z. Relationship between the geometrical parameters of blanks and finished products with asymmetric rolling. Russ. Metall. 1985, 3, 100–104. [Google Scholar]

- Potapkin, V.; Satonin, A.; Dobronosov, Y. Deformation of metal in asymmetric rolling of thin strips. Russ. Metall. 1987, 62–66. [Google Scholar]

- Gorelik, V.; Nalcha, G.; Rudnev, A.; Klimenko, I.; Feofilaktov, A. Improvement of service properties of plates by utilization of asymmetric rolling. Steel USSR 1991, 11, 41–44. [Google Scholar]

- Gorelik, V.; Klimenko, I. Classification and analysis of strip rolling with asymmetric deformation zone. Izv. Akad. Nauk. SSSR Metall. 1997, 3, 34–42. [Google Scholar]

- Tibar, H.; Jiang, Z. Improving Thin Strip Profile Using Work Roll Cross and Work Roll Shifting Methods in Cold Strip Rolling. Int. J. Met. 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Aljabri, A.; Jiang, Z.; Wei, D. Analysis of thin strip profile by work roll crossing and shifting in asymmetrical cold rolling. Int. J. Mod. Phys. B 2015, 29, 1540032. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D. Shear texture development and grain refinement in asymmetrically rolled aluminum alloy sheets: Effects of shear combinations. In Ultrafine Grained Materials III; Wiley: Charlotte, NC, USA, 2004; pp. 303–308. [Google Scholar]

- Sidor, J.; Miroux, A.; Petrov, R.; Kestens, L. Controlling the plastic anisotropy in asymmetrically rolled aluminium sheets. Philos. Mag. 2008, 88, 3779–3792. [Google Scholar] [CrossRef]

- Lee, J.K.; Lee, D.N. Texture control and grain refinement of AA1050 Al alloy sheets by asymmetric rolling. Int. J. Mech. Sci. 2008, 50, 869–887. [Google Scholar] [CrossRef]

- Jiang, J.; Ding, Y.; Zuo, F.; Shan, A. Mechanical properties and microstructures of ultrafine-grained pure aluminum by asymmetric rolling. Scr. Mater. 2009, 60, 905–908. [Google Scholar] [CrossRef]

- Ko, Y.G. Microstructure evolution and mechanical properties of severely deformed Al alloy processed by differential speed rolling. J. Alloy. Compd. 2012, 536, S122–S125. [Google Scholar] [CrossRef]

- Wronski, S.; Bacroix, B. Microstructure evolution and grain refinement in asymmetrically rolled aluminium. Acta Mater. 2014, 76, 404–412. [Google Scholar] [CrossRef]

- Yu, H.L.; Lu, C.; Tieu, A.K.; Li, H.J.; Godbole, A.; Zhang, S.H. Special rolling techniques for improvement of mechanical properties of ultrafine-grained metal sheets: A review. Adv. Eng. Mater. 2016, 18, 754–769. [Google Scholar] [CrossRef]

- Wroński, S.; Wierzbanowski, K.; Wroński, M.; Bacroix, B. Three dimensional analysis of asymmetric rolling with flat and inclined entry. Arch. Metall. Mater. 2014, 59, 585–591. [Google Scholar] [CrossRef]

- Feng, Y.; Liu, W.; Yang, T.; Du, F.; Sun, J. Theoretical and experimental analysis of the deformation zone and minimum thickness in single-roll-driven asymmetric ultrathin strip rolling. Int. J. Adv. Manuf. Technol. 2019, 104, 2925–2937. [Google Scholar] [CrossRef]

- Simões, F.J.P. Asymmetrical Rolling of an Aluminum Alloy 1050. Ph.D. Thesis, University of Aveiro, Aveiro, Portugal, 2008. [Google Scholar]

- Halloumi, A.; Desrayaud, C.; Bacroix, B.; Rauch, E.; Montheillet, F. A simple analytical model of asymmetric rolling. Arch. Metall. Mater. 2012, 57, 425–435. [Google Scholar] [CrossRef]

- Halloumi, A.; Desrayaud, C.; Montheillet, F. A simple modeling of asymmetric rolling. AIP Conf. Proc. 2010, 1252, 269–277. [Google Scholar] [CrossRef]

- Alexa, V.; Raţiu, S.; Kiss, I. Metal rolling—Asymmetrical rolling process. IOP Conf. Ser. Mater. Sci. Eng. 2016, 106. [Google Scholar] [CrossRef]

- Salimi, M.; Sassani, F. Modified slab analysis of asymmetrical plate rolling. Int. J. Mech. Sci. 2002, 44, 1999–2023. [Google Scholar] [CrossRef]

- Salimi, M.; Kadkhodaei, M. Slab analysis of asymmetrical sheet rolling. J. Mater. Process. Technol. 2004, 150, 215–222. [Google Scholar] [CrossRef]

- Qwamizadeh, M.; Kadkhodaei, M.; Salimi, M. Asymmetrical sheet rolling analysis and evaluation of developed curvature. Int. J. Adv. Manuf. Technol. 2012, 61, 227–235. [Google Scholar] [CrossRef]

- Dyja, H.; Korczak, P.; Pilarczyk, J.W.; Grzybowski, J. Theoretical and experimental analysis of plates asymmetric rolling. J. Mater. Process. Tech. 1994, 45, 167–172. [Google Scholar] [CrossRef]

- Richelsen, A.B. Comparison of a numerical analysis of rolling with experimental data. J. Mater. Process. Technol. 1996, 57, 70–78. [Google Scholar] [CrossRef]

- Ji, Y.; Park, J. Development of severe plastic deformation by various asymmetric rolling processes. Mater. Sci. Eng. A 2009, 499, 14–17. [Google Scholar] [CrossRef]

- Grydin, O.; Andreiev, A.; Briukhanov, A.; Briukhanova, Z.; Schaper, M. Evolution of Microstructure, Properties and Texture of a Two-Phase Low-Carbon Steel at Cold Asymmetric Rolling. Steel Res. Int. 2017, 88, 1–9. [Google Scholar] [CrossRef]

- Roumina, R.; Sinclair, C.W. Deformation geometry and through-thickness strain gradients in asymmetric rolling. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2008, 39, 2495–2503. [Google Scholar] [CrossRef]

- Li, L.; Matsumoto, R.; Utsunomiya, H. Curling of sheet in asymmetric rolling investigated by profile measurement of partly rolled sheet. ISIJ Int. 2019, 59, 489–495. [Google Scholar] [CrossRef]

- Lu, J.S.; Harrer, O.K.; Schwenzfeier, W.; Fischer, F.D. Analysis of the bending of the rolling material in asymmetrical sheet rolling. Int. J. Mech. Sci. 2000, 42, 49–61. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, D.N. Analysis of deformation textures of asymmetrically rolled steel sheets. Int. J. Mech. Sci. 2001, 43, 1997–2015. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, D.N. Analysis of deformation textures of asymmetrically rolled aluminum sheets. Acta Mater. 2001, 49, 2583–2595. [Google Scholar] [CrossRef]

- Ghobrial, M. A photoelastic investigation on the contact stresses developed in rolls during asymmetrical flat rolling. Int. J. Mech. Sci. 1989, 31, 751–764. [Google Scholar] [CrossRef]

- Pesin, A.M.; Pustovoitov, D.O.; Biryukova, O.D. The effect of speed asymmetry on the strain state in aluminium bimetals during accumulative rolling. IOP Conf. Ser. Mater. Sci. Eng. 2018, 447. [Google Scholar] [CrossRef]

- Jin, H.; Lloyd, D.J. The different effects of asymmetric rolling and surface friction on formation of shear texture in aluminium alloy AA5754. Mater. Sci. Technol. 2010, 26, 754–760. [Google Scholar] [CrossRef]

- Lequeu, P.; Jonas, J.J. Modeling of the plastic anisotropy of textured sheet. Metall. Trans. A 1988, 19, 105–120. [Google Scholar] [CrossRef]

- Jonas, J.J.; Butron-Guillen, M.P.; Savoie, J. Transformation Textures in Steels. ISIJ Int. 1994, 34, 927–942. [Google Scholar] [CrossRef]

- Engler, O.; Kim, H.C.; Huh, M.Y. Formation of {111} fibre texture in recrystallised aluminium sheet. Mater. Sci. Technol. 2001, 17, 75–86. [Google Scholar] [CrossRef]

- Choi, C.H.; Kim, K.H.; Lee, D.N. The Effect of Shear Texture Development on the Formability in Rolled Aluminum Alloys Sheets. Mater. Sci. Forum 1998, 273-275, 391–396. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, D.N.; Choi, C.H.; Szpunar, J.A. The Deformation Textures and Lankford Values of Asymmetrically Rolled Aluminum Alloy Sheet. In Proceedings of the 12th International Conference on Textures of Materials, Montreal, QC, Canada, 9–13 August 1999; Volume 1, pp. 755–760. [Google Scholar]

- Sakai, T.; Hamada, S.; Saito, Y. Improvement of the r-value in 5052 aluminum alloy sheets having through-thickness shear texture by 2-pass single-roll drive unidirectional shear rolling. Scr. Mater. 2001, 44, 2569–2573. [Google Scholar] [CrossRef]

- Jin, H.; Lloyd, D.J. The reduction of planar anisotropy by texture modification through asymmetric rolling and annealing in AA5754. Mater. Sci. Eng. A 2005, 399, 358–367. [Google Scholar] [CrossRef]

- Lomana, M.; Rodríguez, A.; Tamayo, J.; Zubillaga, C.; García-Rosales, C.; Gil Sevillano, J. Modificación de las texturas y de los índices de embutibilidad de chapas de aleaciones de aluminio Al 1050 y Al-Mg 5754 mediante laminación asimétrica. Boletín de la Sociedad Española de Cerámica y Vidrio 2004, 43, 175–178. [Google Scholar] [CrossRef]

- Kim, I.; Akramov, S.; Jeong, H.B. Texture and formability development of asymmetry rolled AA 3003 AL alloy sheet. Int. J. Mod. Phys. B 2008, 22, 5895–5900. [Google Scholar] [CrossRef]

- Kang, S.B.; Min, B.K.; Kim, H.W.; Wilkinson, D.S.; Kang, J. Effect of asymmetric rolling on the texture and mechanical properties of AA6111-aluminum sheet. Metall. Mater. Trans. A 2005, 36, 3141–3149. [Google Scholar] [CrossRef]

- Zanchetta, B.D.; Da Silva, V.K.; Sordi, V.L.; Rubert, J.B.; Kliauga, A.M. Effect of asymmetric rolling under high friction coefficient on recrystallization texture and plastic anisotropy of AA1050 alloy. Trans. Nonferr. Met. Soc. China (Engl. Ed.) 2019, 29, 2262–2272. [Google Scholar] [CrossRef]

- Cho, J.H.; Kim, H.W.; Lim, C.Y.; Kang, S.B. Microstructure and mechanical properties of Al-Si-Mg alloys fabricated by twin roll casting and subsequent symmetric and asymmetric rolling. Met. Mater. Int. 2014, 20, 647–652. [Google Scholar] [CrossRef]

- Nam, S.K.; Lee, J.H.; Kim, G.H.; Lee, D.N.; Kim, I. Texture Analysis for Enhancement of R-value in Asymmetrically Rolled Al Alloy Sheet. J. Mater. Eng. Perform. 2019, 28, 5186–5194. [Google Scholar] [CrossRef]

- Simões, F.J.; de Sousa, R.J.; Grácio, J.J.; Barlat, F.; Yoon, J.W. Effect of asymmetrical rolling and annealing on the mechanical response of an AA1050-O sheet. Int. J. Mater. Form. 2009, 2, 891–894. [Google Scholar] [CrossRef]

- Shore, D.; Kestens, L.A.; Sidor, J.; Van Houtte, P.; Van Bael, A. Process parameter influence on texture heterogeneity in asymmetric rolling of aluminium sheet alloys. Int. J. Mater. Form. 2018, 11, 297–309. [Google Scholar] [CrossRef]

- Kraner, J.; Fajfar, P.; Palkowski, H.; Kugler, G.; Godec, M.; Paulin, I. Microstructure and texture evolution with relation to mechanical properties of compared symmetrically and asymmetrically cold rolled aluminum alloy. Metals 2020, 10, 156. [Google Scholar] [CrossRef]

- Jin, H.; Lloyd, D.J. Evolution of texture in AA6111 aluminum alloy after asymmetric rolling with various velocity ratios between top and bottom rolls. Mater. Sci. Eng. A 2007, 465, 267–273. [Google Scholar] [CrossRef]

- Suzuki, Y.; Noguchi, O.; Miki, Y.; Ueno, Y.; Koyama, K.; Komatsubara, T. Evolution of Recrystallization Texture in Aluminum Alloy Sheets by Asymmetric-Warm-Rolling. In Proceedings of the 12th International Conference on Aluminium Alloys, Yokohama, Japan, 5–9 September 2010; The Japan Institute of Light Metals: Tokyo, Japan, 2010; pp. 137–142. [Google Scholar]

- Miki, Y.; Noguchi, O.; Ueno, Y.; Suzuki, Y.; Koyama, K.; Komatsubara, T. Improvement of Deep Drawability of Al-Mg-Si Alloy Sheets for Automotive Panel by Asymmetric Warm Rolling. In Proceedings of the 12th International Conference on Aluminium Alloys, Yokohama, Japan, 5–9 September 2010; The Japan Institute of Light Metals: Tokyo, Japan, 2010; pp. 1225–1230. [Google Scholar]

- Ren, X.; Huang, Y.; Liu, Y.; Zhao, Y.; Li, H. Evolution of microstructure, texture, and mechanical properties in a twin-roll cast AA6016 sheet after asymmetric rolling with various velocity ratios between top and bottom rolls. Mater. Sci. Eng. A 2020, 788, 139448. [Google Scholar] [CrossRef]

- Cheon, B.H.; Kim, H.W.; Lee, J.C. Asymmetric rolling of strip-cast Al-5.5Mg-0.3Cu alloy sheet: Effects on the formability and mechanical properties. Mater. Sci. Eng. A 2011, 528, 5223–5227. [Google Scholar] [CrossRef]

- Son, S.G.; Kim, H.K.; Cho, J.H.; Kim, H.W.; Lee, J.C. Differential speed rolling of twin-roll-cast 6xxx al alloy strips and its influence on the sheet formability. Met. Mater. Int. 2016, 22, 108–117. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, X.; Huang, Y.; Liu, Y.; Zhao, L.; Zhou, W. Evolution of shear texture during the asymmetric rolling and its annealing behavior in a twin-roll casting AA6016 sheet: An ex-situ electron backscatter diffraction study. J. Mater. Res. Technol. 2020, 9, 6420–6433. [Google Scholar] [CrossRef]

- Wroński, S.; Wierzbanowski, K.; Bacroix, B.; Chauveau, T.; Wróbel, M. Effect of asymmetric rolling on mechanical characteristics, texture and misorientations in ferritic steel. J. Cent. South Univ. 2013, 20, 1443–1455. [Google Scholar] [CrossRef]

- Orlov, D.; Lapovok, R.; Toth, L.S.; Timokhina, I.B.; Hodgson, P.D.; Haldar, A.; Bhattacharjee, D. Asymmetric rolling of interstitial-free steel using differential roll diameters. Part II: Microstructure and annealing effects. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 447–454. [Google Scholar] [CrossRef]

- Tóth, L.S.; Beausir, B.; Orlov, D.; Lapovok, R.; Haldar, A. Analysis of texture and R value variations in asymmetric rolling of if steel. J. Mater. Process. Technol. 2012, 212, 509–515. [Google Scholar] [CrossRef]

- Lapovok, R.; Orlov, D.; Timokhina, I.B.; Pougis, A.; Toth, L.S.; Hodgson, P.D.; Haldar, A.; Bhattacharjee, D. Asymmetric rolling of interstitial-free steel using one idle roll. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 1328–1340. [Google Scholar] [CrossRef]

- Wauthier, A.; Regle, H.; Formigoni, J.; Herman, G. The effects of asymmetrical cold rolling on kinetics, grain size and texture in IF steels. Mater. Charact. 2009, 60, 90–95. [Google Scholar] [CrossRef]

- Tamimi, S.; Gracio, J.J.; Lopes, A.B.; Ahzi, S.; Barlat, F. Asymmetric rolling of interstitial free steel sheets: Microstructural evolution and mechanical properties. J. Manuf. Process. 2018, 31, 583–592. [Google Scholar] [CrossRef]

- Dhinwal, S.S.; Toth, L.S.; Lapovok, R.; Hodgson, P.D. Tailoring one-pass asymmetric rolling of extra low carbon steel for shear texture and recrystallization. Materials 2019, 12, 1935. [Google Scholar] [CrossRef]

- Dong, F.; Xue, F.; Du, L.; Liu, X. Promoting Ti4C2S2 strain induced precipitation during asymmetrical hot rolling to improve r value and advantaged texture in Ti stabilized IF steel. J. Alloy. Compd. 2015, 620, 240–248. [Google Scholar] [CrossRef]

- Barella, S.; Mapelli, C. Mechanical properties and textures of duplex stainless steel rolled worked by asymmetric rolling. Int. J. Mater. Form. 2011, 4, 379–388. [Google Scholar] [CrossRef][Green Version]

- Amininejad, A.; Jamaati, R.; Hosseinipour, S.J. Achieving superior strength and high ductility in AISI 304 austenitic stainless steel via asymmetric cold rolling. Mater. Sci. Eng. A 2019, 767, 138433. [Google Scholar] [CrossRef]

- Chen, S.D.; Liu, X.H.; Liu, L.Z. Symmetric and asymmetric rolling pure copper foil: Crystal plasticity finite element simulation and experiments. Acta Metall. Sin. Engl. Lett. 2015, 28, 1024–1033. [Google Scholar] [CrossRef]

- Berrenberg, F.; Wang, J.; Timokhina, I.; Haase, C.; Lapovok, R.; Molodov, D.A. Influence of rolling asymmetry on the microstructure, texture and mechanical behavior of high-manganese twinning-induced plasticity steel. Mater. Sci. Eng. A 2018, 709, 172–180. [Google Scholar] [CrossRef]

- Brasche, F.; Wang, J.; Timokhina, I.; Haase, C.; Lapovok, R.; Molodov, D.A. Mechanical twinning and texture evolution during asymmetric warm rolling of a high manganese steel. Mater. Sci. Eng. A 2019, 764, 138183. [Google Scholar] [CrossRef]

- Sha, Y.; Zhang, F.; Zhou, S.; Pei, W.; Zuo, L. Improvement of recrystallization texture and magnetic property in non-oriented silicon steel by asymmetric rolling. J. Magn. Magn. Mater. 2008, 320, 393–396. [Google Scholar] [CrossRef]

- Chen, S.; Butler, J.; Melzer, S. Effect of asymmetric hot rolling on texture, microstructure and magnetic properties in a non-grain oriented electrical steel. J. Magn. Magn. Mater. 2014, 368, 342–352. [Google Scholar] [CrossRef]

- Cui, Q.; Ohori, K. Grain refinement of high purity aluminium by asymmetric rolling. Mater. Sci. Technol. 2000, 16, 1095–1101. [Google Scholar] [CrossRef]

- Jin, H.; Lloyd, D.J. The tensile response of a fine-grained AA5754 alloy produced by asymmetric rolling and annealing. Metall. Mater. Trans. A 2004, 35, 997–1006. [Google Scholar] [CrossRef]

- Ding, Y.; Jiang, J.; Shan, A. Plastic instability and strain rate sensitivity of ultrafine-grained iron. J. Alloy. Compd. 2009, 487, 517–521. [Google Scholar] [CrossRef]

- Sidor, J.J.; Petrov, R.H.; Kestens, L.A. Microstructural and texture changes in severely deformed aluminum alloys. Mater. Charact. 2011, 62, 228–236. [Google Scholar] [CrossRef]

- Wroński, S.; Bacroix, B. Texture and microstructure variation in asymmetrically rolled steel. Mater. Charact. 2016, 118, 235–243. [Google Scholar] [CrossRef]

- Ma, C.; Hou, L.; Zhang, J.; Zhuang, L. Influence of thickness reduction per pass on strain, microstructures and mechanical properties of 7050 Al alloy sheet processed by asymmetric rolling. Mater. Sci. Eng. A 2016, 650, 454–468. [Google Scholar] [CrossRef]

- Bintu, A.; Vincze, G.; Picu, R.; Lopes, A. Effect of symmetric and asymmetric rolling on the mechanical properties of AA5182. Mater. Des. 2016, 100, 151–156. [Google Scholar] [CrossRef]

- Ma, B.; Li, C.; Wang, J.; Cai, B.; Sui, F. Influence of asymmetric hot rolling on through-thickness microstructure gradient of Fe–20Mn–4Al–0.3C non-magnetic steel. Mater. Sci. Eng. A 2016, 671, 190–197. [Google Scholar] [CrossRef]

- Hamad, K.; Ko, Y.G. Annealing Characteristics of Ultrafine Grained Low-Carbon Steel Processed by Differential Speed Rolling Method. Metall. Mater. Trans. A 2016, 47, 2319–2334. [Google Scholar] [CrossRef]

- Cai, M.H.; Singh Dhinwal, S.; Han, Q.H.; Chao, Q.; Hodgson, P.D. Gradient ultrafine ferrite and martensite structure and its tensile properties by asymmetric rolling in low carbon microalloyed steel. Mater. Sci. Eng. A 2013, 583, 205–209. [Google Scholar] [CrossRef]

- Kudrathon, B. Asymmetric Rolling of Aluminium 1050. Master’s Thesis, Universidade de Aveiro, Aveiro, Portugal, 2010. [Google Scholar]

- Orlov, D.; Pougis, A.; Lapovok, R.; Toth, L.S.; Timokhina, I.B.; Hodgson, P.D.; Haldar, A.; Bhattacharjee, D. Asymmetric Rolling of Interstitial-Free Steel Using Differential Roll Diameters. Part I: Mechanical Properties and Deformation Textures. Metall. Mater. Trans. A 2013, 44, 4346–4359. [Google Scholar] [CrossRef]

- Knight, C.W.; Hardy, S.J.; Lees, A.W.; Brown, K.J. Investigations into the influence of asymmetric factors and rolling parameters on strip curvature during hot rolling. J. Mater. Process. Technol. 2003, 134, 180–189. [Google Scholar] [CrossRef]

- Markowski, J.; Dyja, H.; Knapiński, M.; Kawałek, A. Theoretical analysis of the asymmetric rolling of sheets on leader and finishing stands. J. Mater. Process. Technol. 2003, 138, 183–188. [Google Scholar] [CrossRef]

- Kawałek, A. Forming of band curvature in asymmetrical rolling process. J. Mater. Process. Technol. 2004, 155–156, 2033–2038. [Google Scholar] [CrossRef]

- Shatalov, R.L.; Maksimov, E.A.; Babkin, A.G. Adjustment of rolling mills to produce flatter steel strip. Steel Transl. 2011, 41, 845–848. [Google Scholar] [CrossRef]

- Grácio, J.J.; Vincze, G.; Yoon, J.W.; Cardoso, R.P.R.; Rauch, E.F.; Barlat, F.G. Modeling the Effect of Asymmetric Rolling on Mechanical Properties of Al-Mg Alloys. Steel Res. Int. 2015, 86, 922–931. [Google Scholar] [CrossRef]

- Gracio, J.J.; Kim, H.J.; Vincze, G.; Panigrahi, B.B.; Barlat, F.; Rauch, E.F.; Yoon, J.W.; Barlat, F.; Moon, Y.H.; Lee, M.G. Effect of Asymmetric Rolling on Plastic Anisotropy of Low Carbon Steels during Simple Shear Tests. In Proceedings of the 10th International Conference on Numerical Methods in Industrial Forming Processes (NUMIFORM 2010), Pohang, Korea, 13–17 June 2010; pp. 181–184. [Google Scholar] [CrossRef]

- Ren, J.; Chen, Z.; Peng, J.; Ma, W.; Ringer, S.P. An initial report on achieving high comprehensive performance in an Al-Mg-Si alloy via novel thermomechanical processing. J. Alloy. Compd. 2018, 764, 679–683. [Google Scholar] [CrossRef]

| Type | Component | {hkl}<uvw> | Euler Angles (Bunge) | ||

|---|---|---|---|---|---|

| Deformation | Brass | {011}<211> | 35 | 45 | 0 |

| S | {123}<634> | 55 | 35 | 65 | |

| Copper | {112}<111> | 90 | 30 | 45 | |

| Dillamore | {4411}<11118> | 90 | 27 | 45 | |

| Shear | Rotated Cube (RC) | {001}<110> | 0 | 0 | 45 |

| E | {111}<110> | 0 | 55 | 45 | |

| F | {111}<112> | 90 | 55 | 45 | |

| I | {112}<110> | 0 | 35 | 45 | |

| Recrystallization | Goss | {011}<001> | 0 | 45 | 0 |

| Cube | {001}<100> | 0 | 0 | 0 | |

| Rotated Cube RD1 | {013}<100> | 0 | 20 | 0 | |

| Rotated Cube RD2 | {023}<100> | 0 | 35 | 0 | |

| Rotated Cube ND1 | {001}<310> | 20 | 0 | 0 | |

| Rotated Cube ND2 | {001}<320> | 35 | 0 | 0 | |

| P | {011}<122> | 70 | 45 | 0 | |

| Q | {013}<231> | 55 | 20 | 0 | |

| R | {124}<211> | 55 | 75 | 25 | |

| Material | N° Passes | Total Reduction | Asymmetry Ratio | Asymmetric Rolling Grain Size | Symmetric Rolling Grain Size | Ref |

|---|---|---|---|---|---|---|

| AA1xxx | 3 | 91.3% | 1.4 | 2 m | - | [82] |

| AA1050 | 5 | 93.7 % | 1.36 | 2 m | 2 m | [25] |

| AA6061 | 1 | 36% | 1.5 | 4 m | 9 m | [21] |

| AA5052 | 2 | 75% | 1:4 | 0.5 m | no refinement | [20] |

| AA5754 | 10 | 88% | 2 | 1 m | - | [83] |

| AA7050 | 10 | 75% (∼475 °C) | 1.25 | <0.5 m | - | [87] |

| AA5182 | 2 | 50% | 1.36 | 20 m | - | [88] |

| AA5182 | 6 | 90% | 1.36 | 0.3 m | - | [88] |

| IF steel | 1 | 36.8% | 1.45 | 8.7 m (RD) 5.8 m (TD) | 14.1 m (RD) 8.4 m (TD) | [71] |

| IF steel | 3 | 60% | 1.15/1.3 | 50 m | 80 m | [86] |

| TWIP | - | 60% (∼1000 °C) | 1.1/1.2/1.3 | 5 m (surface) 9 m (center) | - | [89] |

| Low Carbon Steel | 4 | 75% | 1:4 | 0.4 m | - | [90] |

| Low Carbon Steel | 4 | 60% | 1.5 | 1.5 m | - | [72] |

| Low carbon microalloyed steel | 1 | 50% (800 °C) | 1:2 | 0.92 m (surface) 1.09 m (center) | 1.02 m (surface) 1.44 m (center) | [91] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vincze, G.; Simões, F.J.P.; Butuc, M.C. Asymmetrical Rolling of Aluminum Alloys and Steels: A Review. Metals 2020, 10, 1126. https://doi.org/10.3390/met10091126

Vincze G, Simões FJP, Butuc MC. Asymmetrical Rolling of Aluminum Alloys and Steels: A Review. Metals. 2020; 10(9):1126. https://doi.org/10.3390/met10091126

Chicago/Turabian StyleVincze, Gabriela, Fábio J.P. Simões, and Marilena C. Butuc. 2020. "Asymmetrical Rolling of Aluminum Alloys and Steels: A Review" Metals 10, no. 9: 1126. https://doi.org/10.3390/met10091126

APA StyleVincze, G., Simões, F. J. P., & Butuc, M. C. (2020). Asymmetrical Rolling of Aluminum Alloys and Steels: A Review. Metals, 10(9), 1126. https://doi.org/10.3390/met10091126