Using a Trial Sample on Stainless Steel 316L in a Direct Laser Deposition Process

Abstract

:1. Introduction

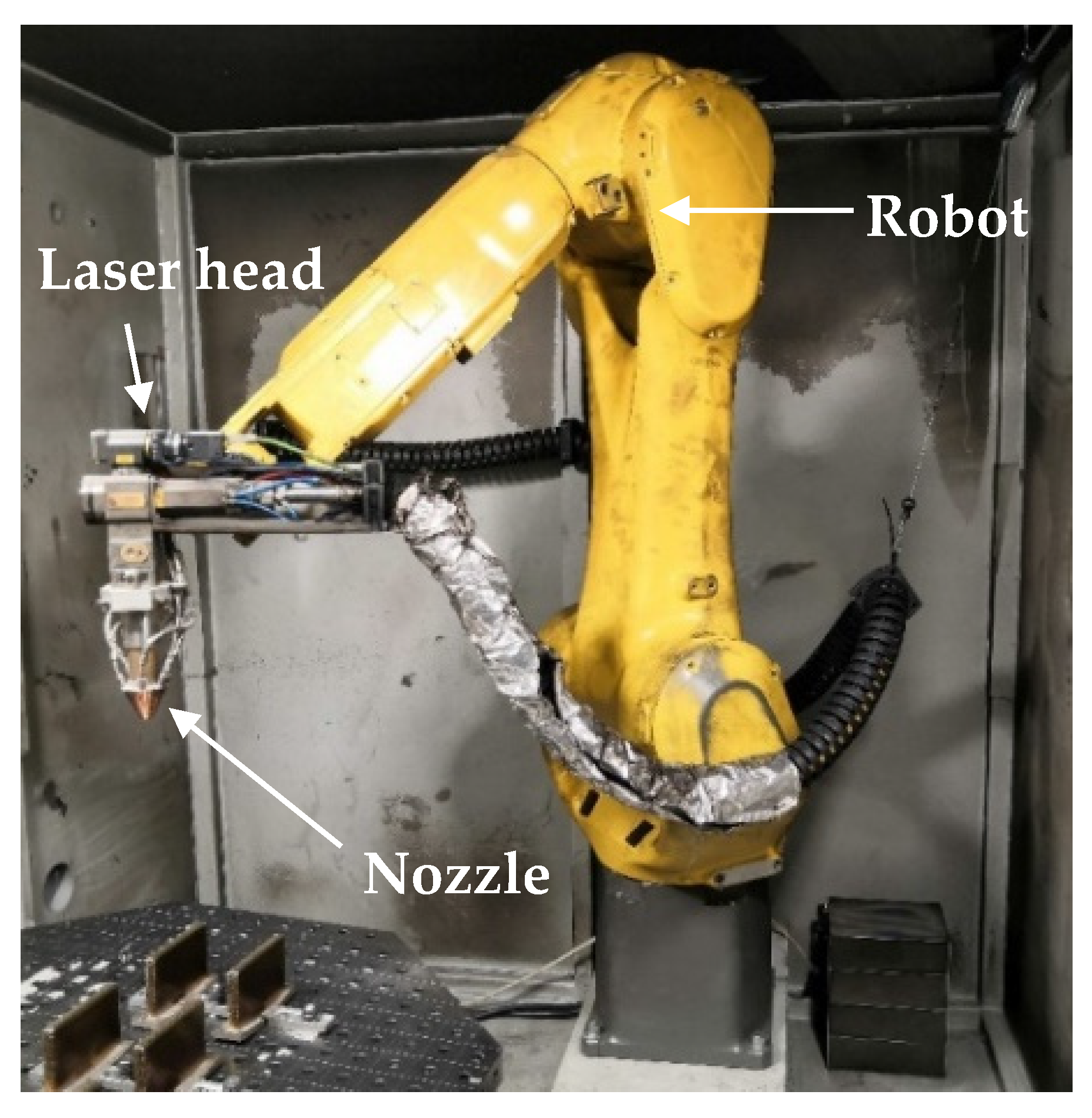

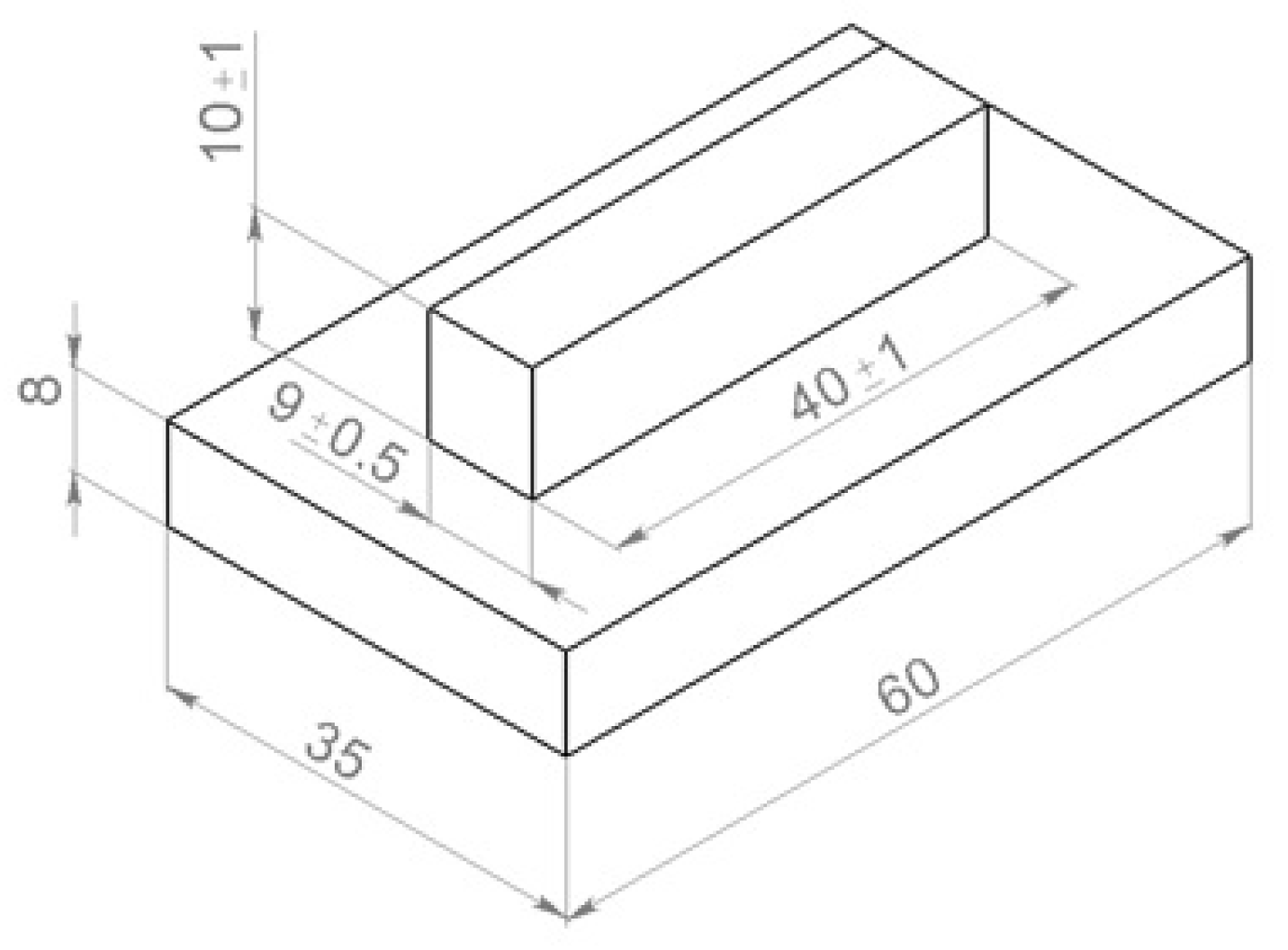

2. Materials and Methods

3. Results and Discussion

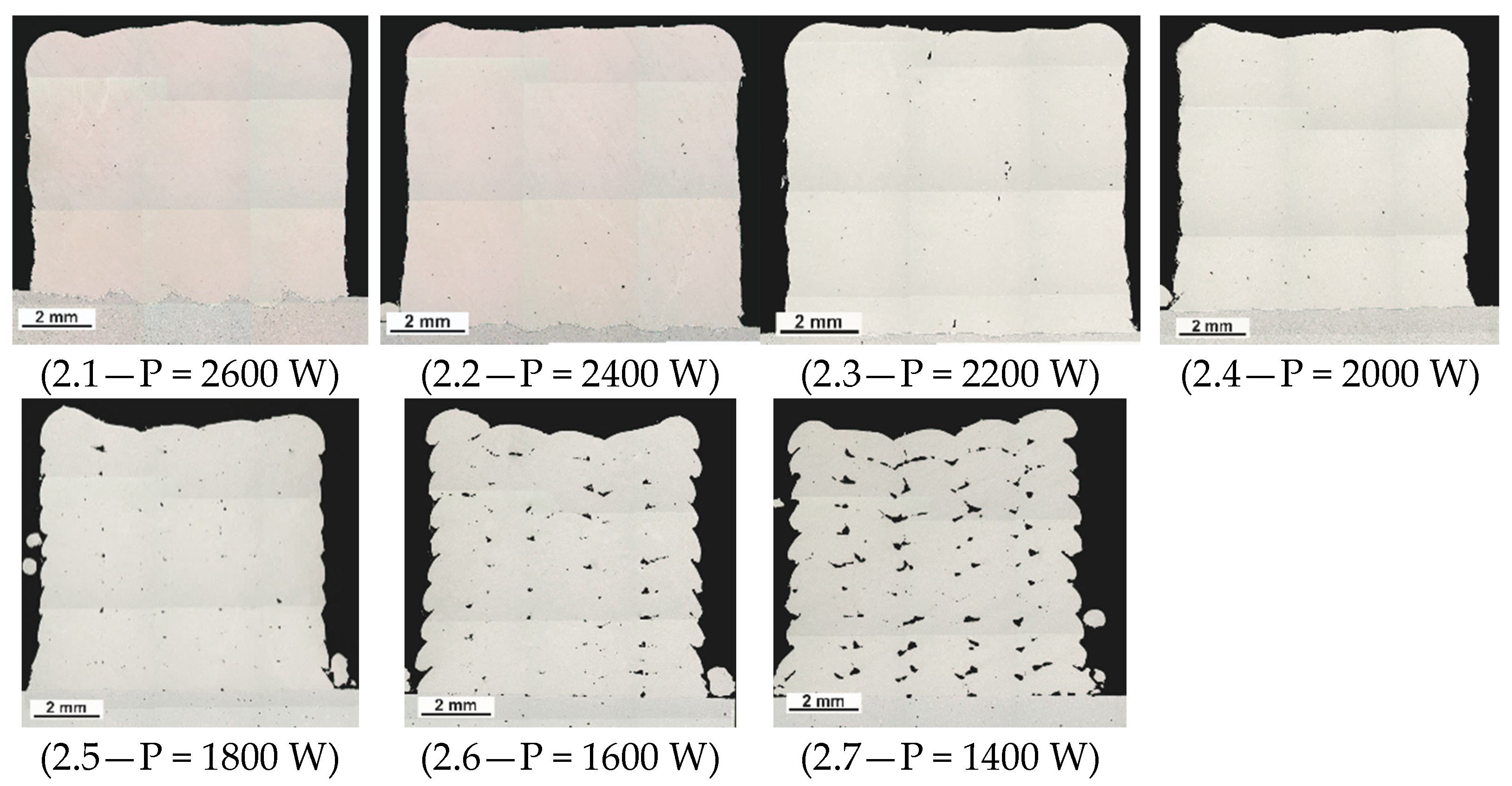

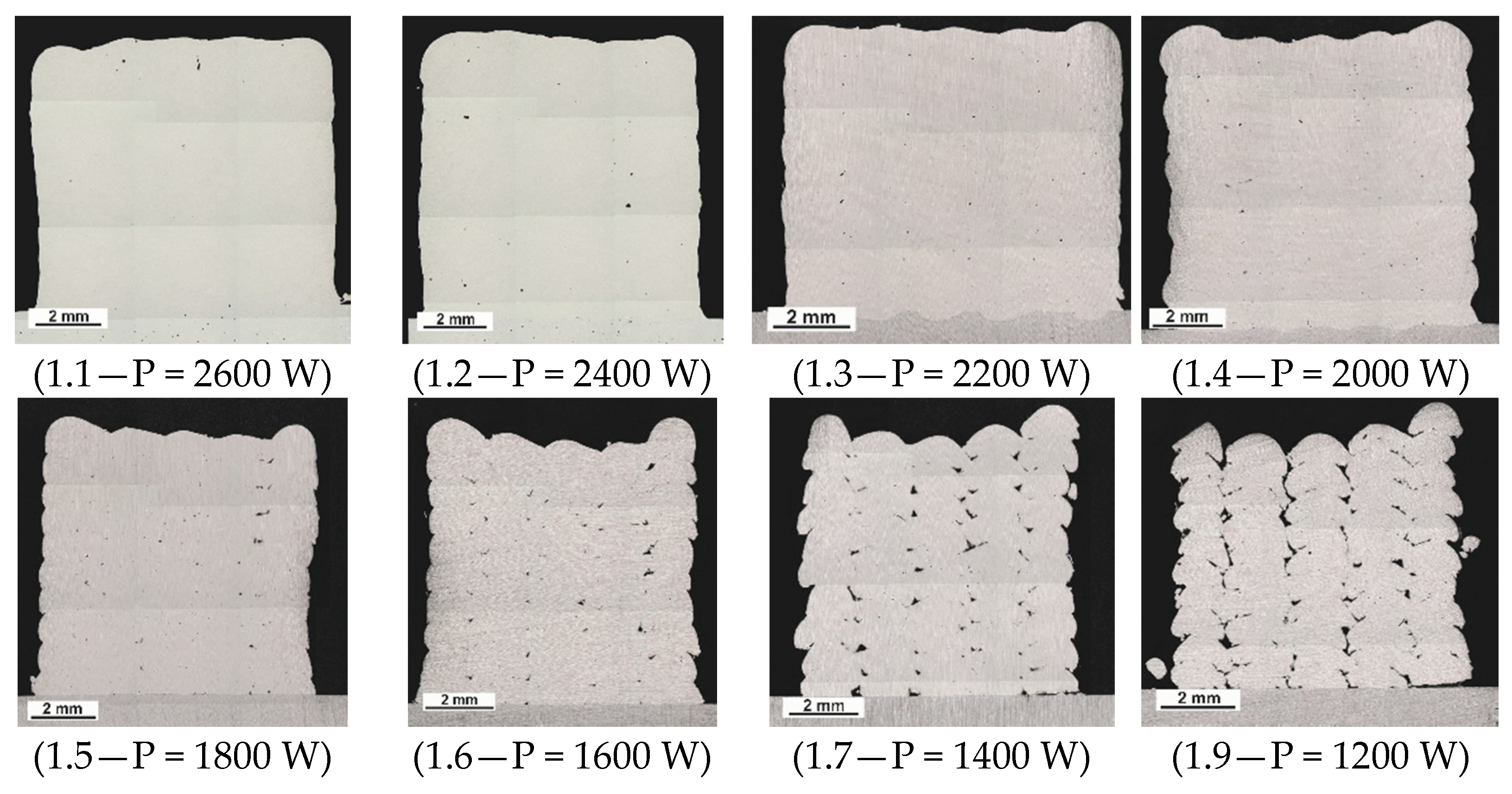

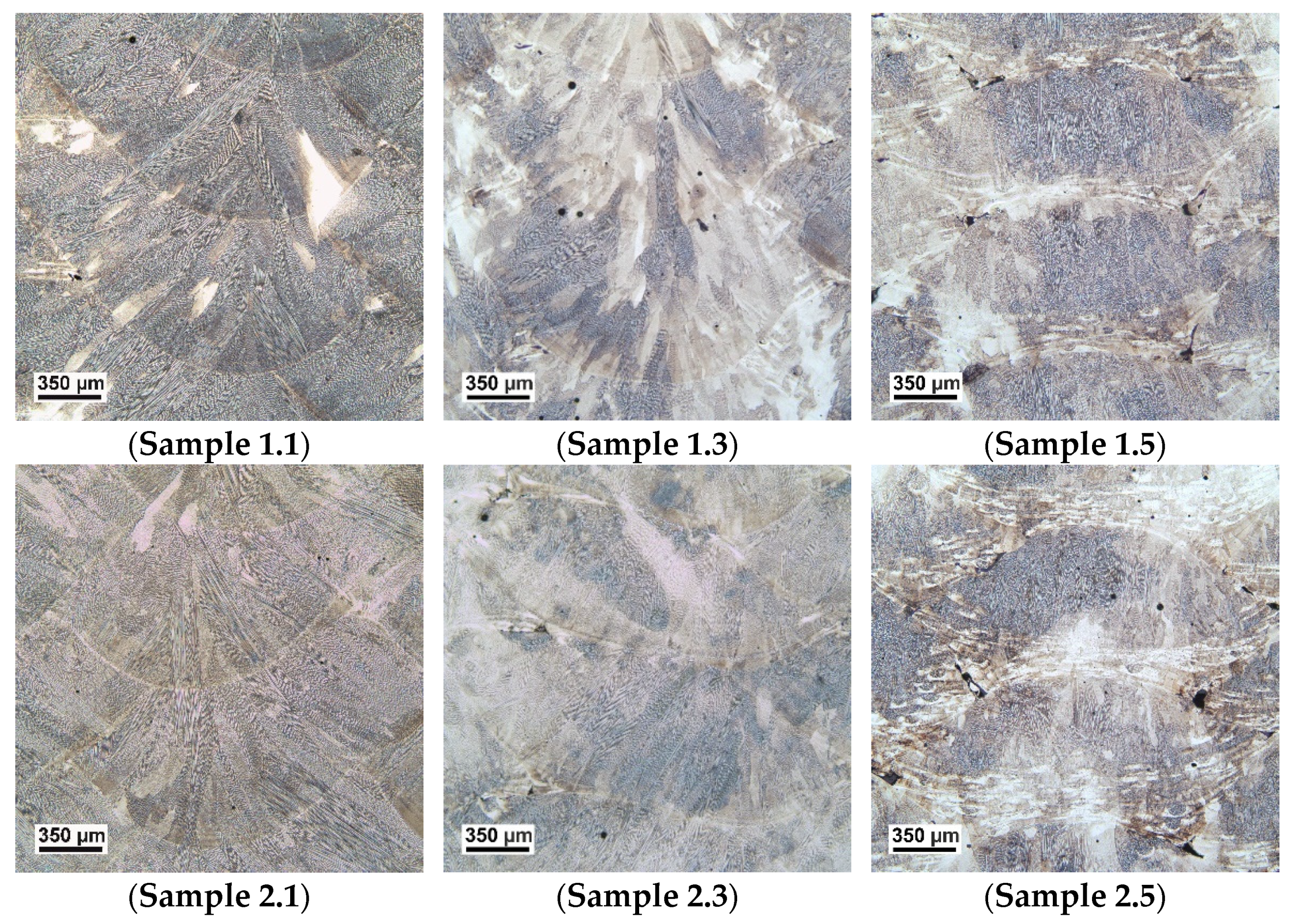

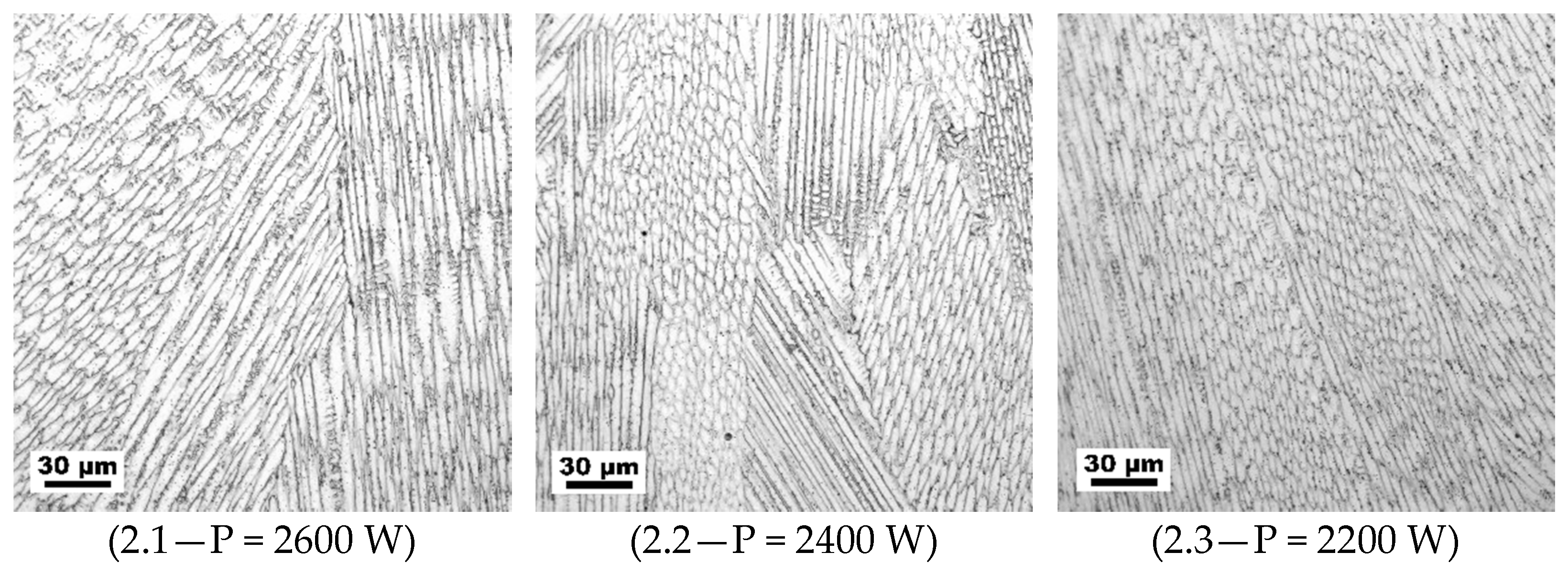

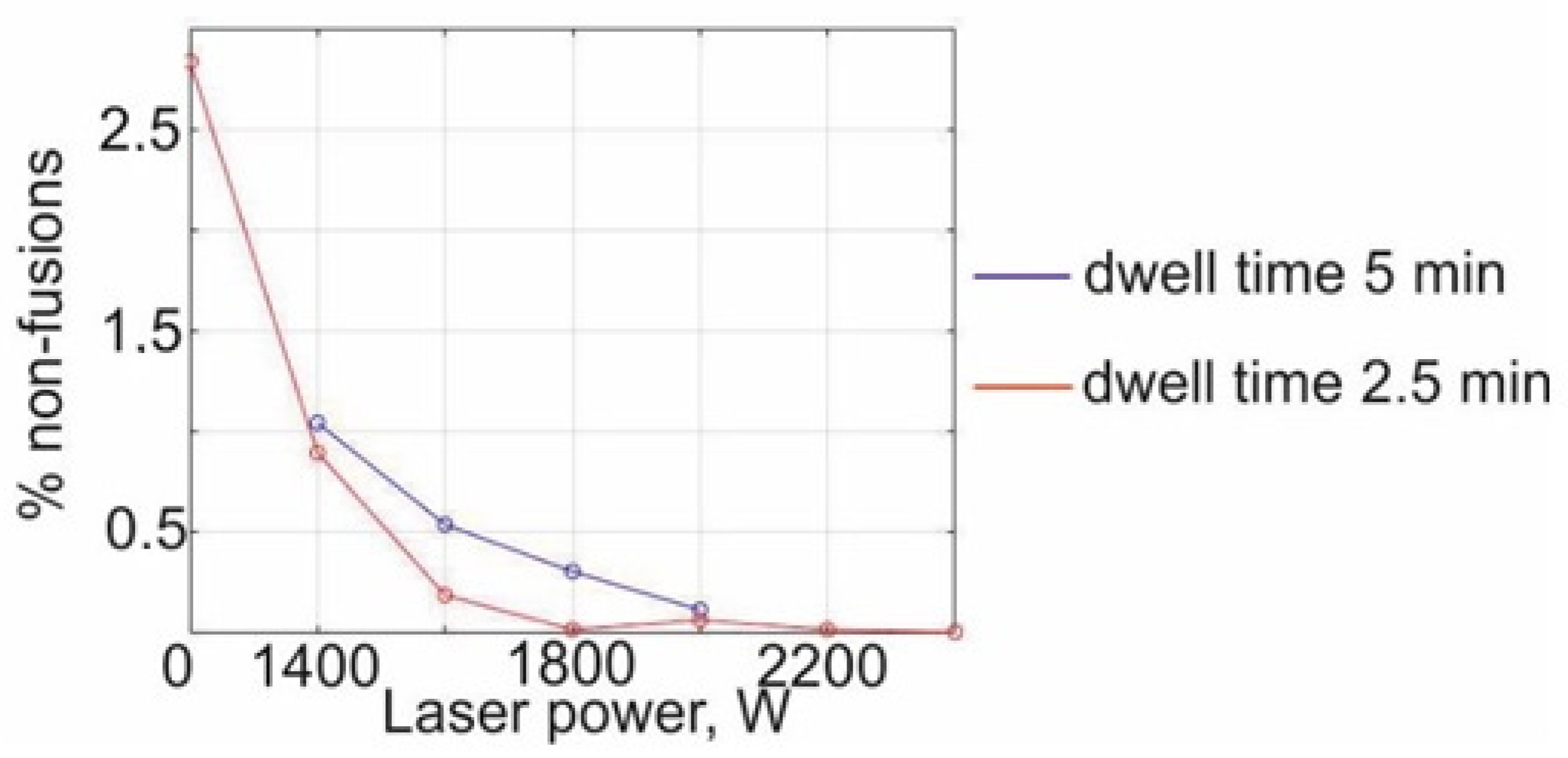

3.1. Metallographic Studies

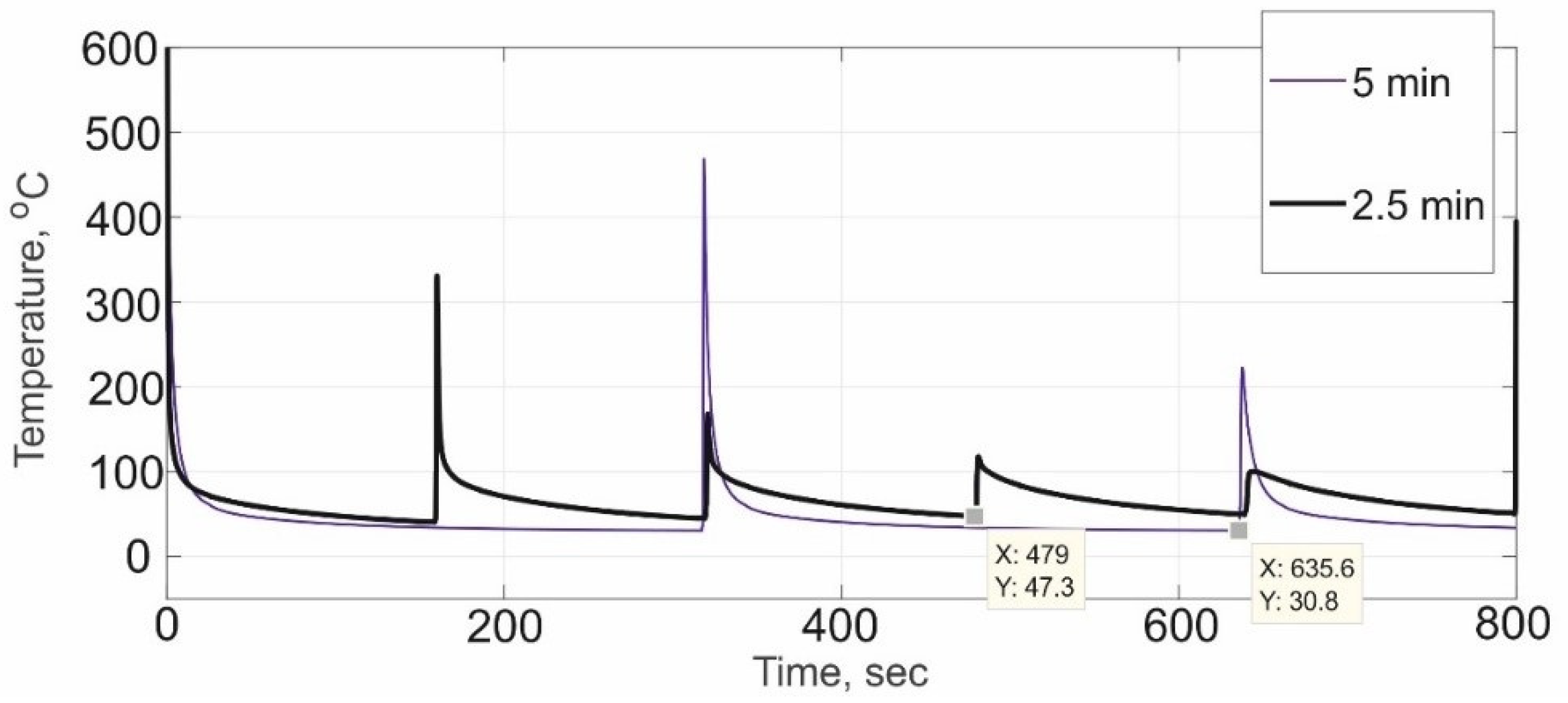

3.2. The Comparison of Thermal Cycles

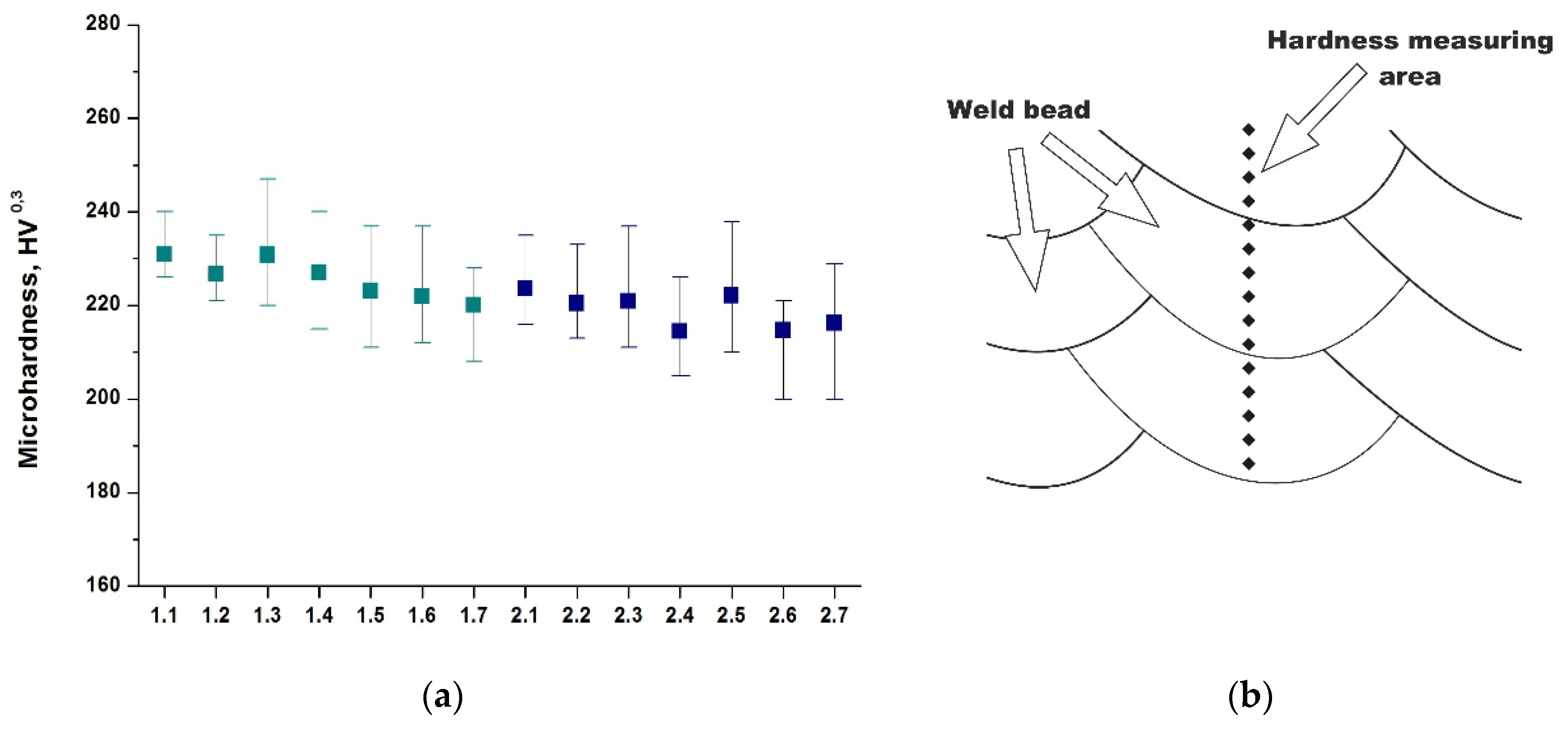

3.3. Mechanical Properties

4. Conclusions

- When manufacturing large-sized parts by direct laser deposition, it is necessary to set high power values, because low power values lead to the formation of non-fusion.

- To save time in determining the technological mode, it makes no sense to set the pause between the tracks on the model sample at more than 2.5 min, since the sample has time to cool down and simulate a large-sized part.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Turichin, G.A.; Zemlyakov, E.V.; Klimova, O.G.; Babkin, K.D.; Shamray, F.A.; Kolodiajniy, D.Y. Direct laser deposition–per-spective additive technology for aircraft engine. Svarka Diagn. 2015, 3, 54–57. [Google Scholar]

- Gu, D. New metallic materials development by laser additive manufacturing. In Laser Surface Engineering; Lawrence, J., Waugh, D.G., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 163–180. [Google Scholar]

- Gress, D.R.; Kalafsky, R.V. Geographies of production in 3D: Theoretical and research implications stemming from additive manufacturing. Geoforum 2015, 60, 43–52. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Gaytan, S.M.; Ramirez, D.A.; Machado, B.I.; Shindo, P.W.; Martinez, J.L.; Medina, F.; Wooten, J.; Ciscel, D.; et al. Microstructural Architecture, Microstructures, and Mechanical Properties for a Nickel-Base Superalloy Fabricated by Electron Beam Melting. Metals Mater. Trans. A 2011, 42, 3491–3508. [Google Scholar] [CrossRef] [Green Version]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Wei, H.; Mazumder, J.; Debroy, T. Evolution of solidification texture during additive manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sklyar, M.O.; Turichin, G.A.; Klimova, O.G.; Zotov, O.G.; Topalov, I.K. Microstructure of 316L stainless steel components produced by direct laser deposition. Steel Transl. 2016, 46, 883–887. [Google Scholar] [CrossRef]

- Santa-Aho, S.; Kiviluoma, M.; Jokiaho, T.; Gundgire, T.; Honkanen, M.; Lindgren, M.; Vippola, M. Additive Manufactured 316L Stainless-Steel Samples: Microstructure, Residual Stress and Corrosion Characteristics after Post-Processing. Metals 2021, 11, 182. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, P.; Li, W.; Liang, Y.; Liang, Y. Microstructure and Anisotropy of the Mechanical Properties of 316L Stainless Steel Fabricated by Selective Laser Melting. Metals 2021, 11, 775. [Google Scholar] [CrossRef]

- Qian, S.; Zhang, Y.; Dai, Y.; Guo, Y. Microstructure and Mechanical Properties of Nickel-Based Coatings Fabricated through Laser Additive Manufacturing. Metals 2020, 11, 53. [Google Scholar] [CrossRef]

- Ganesh, P.; Giri, R.; Kaul, R.; Sankar, P.R.; Tiwari, P.; Atulkar, A.; Porwal, R.; Dayal, R.; Kukreja, L. Studies on pitting corrosion and sensitization in laser rapid manufactured specimens of type 316L stainless steel. Mater. Des. 2012, 39, 509–521. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Shang, X. Characterization of stainless steel parts by Laser Metal Deposition Shaping. Mater. Des. 2014, 55, 104–119. [Google Scholar] [CrossRef]

- Turichin, G.A.; Klimova-Korsmik, O.G.; Gushchina, M.O.A.B.; Shalnova, S.A.; Korsmik, R.S.; Cheverikin, V.V.; Tataru, A.S. Features of structure formation in α + β titanium alloys. Procedia CIRP 2018, 74, 188–191. [Google Scholar] [CrossRef]

- Klimova-Korsmik, O.; Turichin, G.; Mendagaliyev, R.; Razorenov, S.; Garkushin, G.; Savinykh, A.; Korsmik, R. High-Strain Deformation and Spallation Strength of 09CrNi2MoCu Steel Obtained by Direct Laser Deposition. Metals 2021, 11, 1305. [Google Scholar] [CrossRef]

- Vallejo, N.D.; Lucas, C.; Ayers, N.; Graydon, K.; Hyer, H.; Sohn, Y. Process Optimization and Microstructure Analysis to Understand Laser Powder Bed Fusion of 316L Stainless Steel. Metals 2021, 11, 832. [Google Scholar] [CrossRef]

- Korsmik, R.; Tsybulskiy, I.; Rodionov, A.; Klimova-Korsmik, O.; Gogolukhina, M.; Ivanov, S.; Zadykyan, G.; Mendagaliev, R. The approaches to design and manufacturing of large-sized marine machinery parts by direct laser deposition. Procedia CIRP 2020, 94, 298–303. [Google Scholar] [CrossRef]

- El-Hadad, S.; Khalifa, W.; Nofal, A. Surface modification of investment cast-316L implants: Microstructure effects. Mater. Sci. Eng. C 2015, 48, 320–327. [Google Scholar] [CrossRef] [PubMed]

| Material Grade. | O | H | N | C | Si | Mn | Cr | Ni | Mo | S | P | Fe | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 316L ASTM A240 | ˂0.02 | ˂0.0002 | ˂0.02 | ≤0.03 | ≤1.0 | ≤2.0 | 16.0–18.0 | 10.0–14.0 | 2.0–3.0 | ≤0.03 | ≤0.045 | Bal. | ˂0.5 |

| 316L Powder | 0.021 | 0.32 | 1.32 | 16.52 | 10.05 | 2.08 | 0.022 | 0.041 | - |

| No.1 | Dwell time = 5 min, velocity = 25 mm/s, width track = 2.5 mm | ||||||||

| Samples | 1.1 | 1.2 | 1.3 | 1.4 | 1.5 | 1.6 | 1.7 | 1.8 | |

| Power, W | 2600 | 2400 | 2200 | 2000 | 1800 | 1600 | 1400 | 1200 | |

| No.2 | Dwell time = 2.5 min, velocity = 25 mm/s, width track = 2.5 mm | ||||||||

| Samples | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | |

| Power, W | 2600 | 2400 | 2200 | 2000 | 1800 | 1600 | 1400 | 1200 | |

| Samples Number | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 |

| % of Non-Fusions | 0.01 | 0.02 | 0.06 | 0.02 | 0.2 | 0.9 | 2.8 |

| Samples | Tensile Strength, (MPa) | Yield Strength, (MPa) | Elongation, (%) | Impact Strength, KCU, (J/cm2) |

|---|---|---|---|---|

| ASTM A240 | 485 | 170 | 40 | 160–180 |

| 1.3 | 570 | 272.5 | 41 | 160 |

| 2.3 | 556 | 269 | 39 | 150 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vildanov, A.; Babkin, K.; Mendagaliyev, R.; Arkhipov, A.; Turichin, G. Using a Trial Sample on Stainless Steel 316L in a Direct Laser Deposition Process. Metals 2021, 11, 1550. https://doi.org/10.3390/met11101550

Vildanov A, Babkin K, Mendagaliyev R, Arkhipov A, Turichin G. Using a Trial Sample on Stainless Steel 316L in a Direct Laser Deposition Process. Metals. 2021; 11(10):1550. https://doi.org/10.3390/met11101550

Chicago/Turabian StyleVildanov, Artur, Konstantin Babkin, Ruslan Mendagaliyev, Andrey Arkhipov, and Gleb Turichin. 2021. "Using a Trial Sample on Stainless Steel 316L in a Direct Laser Deposition Process" Metals 11, no. 10: 1550. https://doi.org/10.3390/met11101550

APA StyleVildanov, A., Babkin, K., Mendagaliyev, R., Arkhipov, A., & Turichin, G. (2021). Using a Trial Sample on Stainless Steel 316L in a Direct Laser Deposition Process. Metals, 11(10), 1550. https://doi.org/10.3390/met11101550