Dissimilar Laser Welding of a NiTi Shape Memory Alloy to Ti2AlNb

Abstract

:1. Introduction

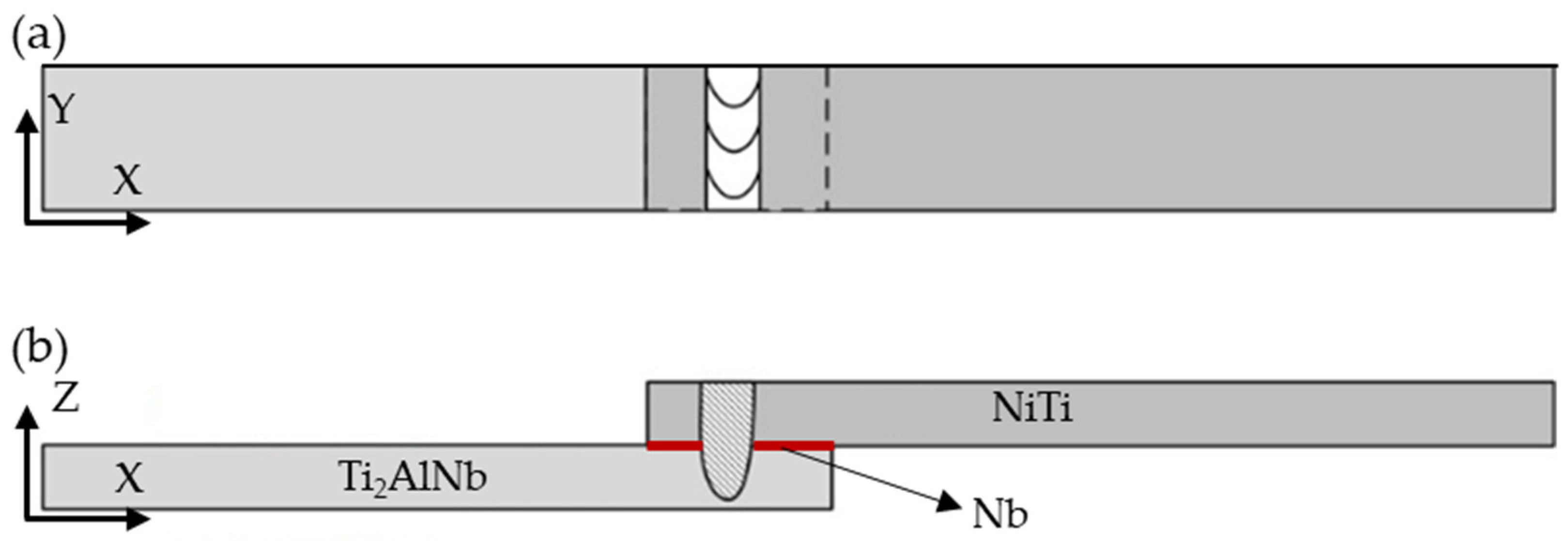

2. Materials and Methods

3. Results and Discussion

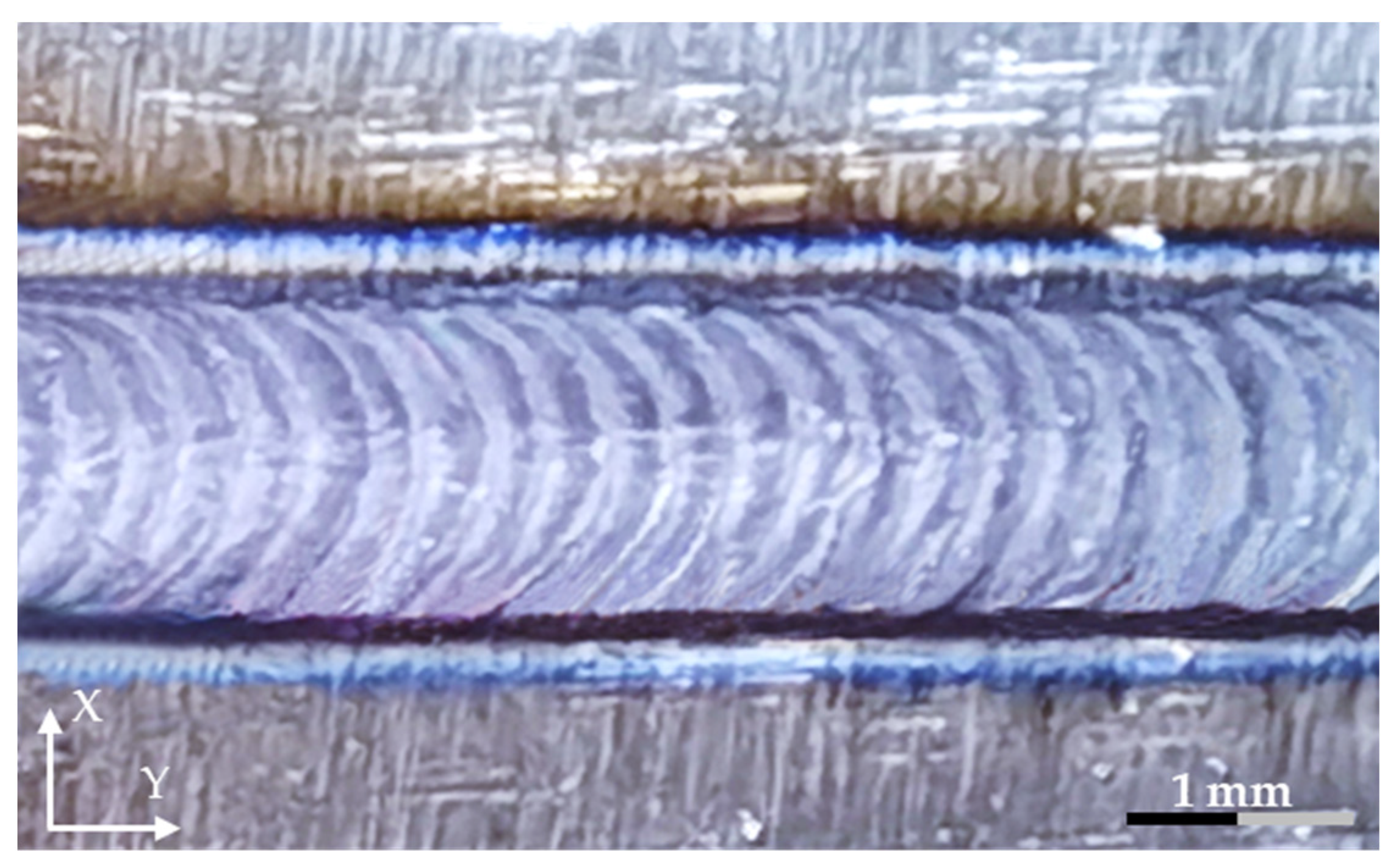

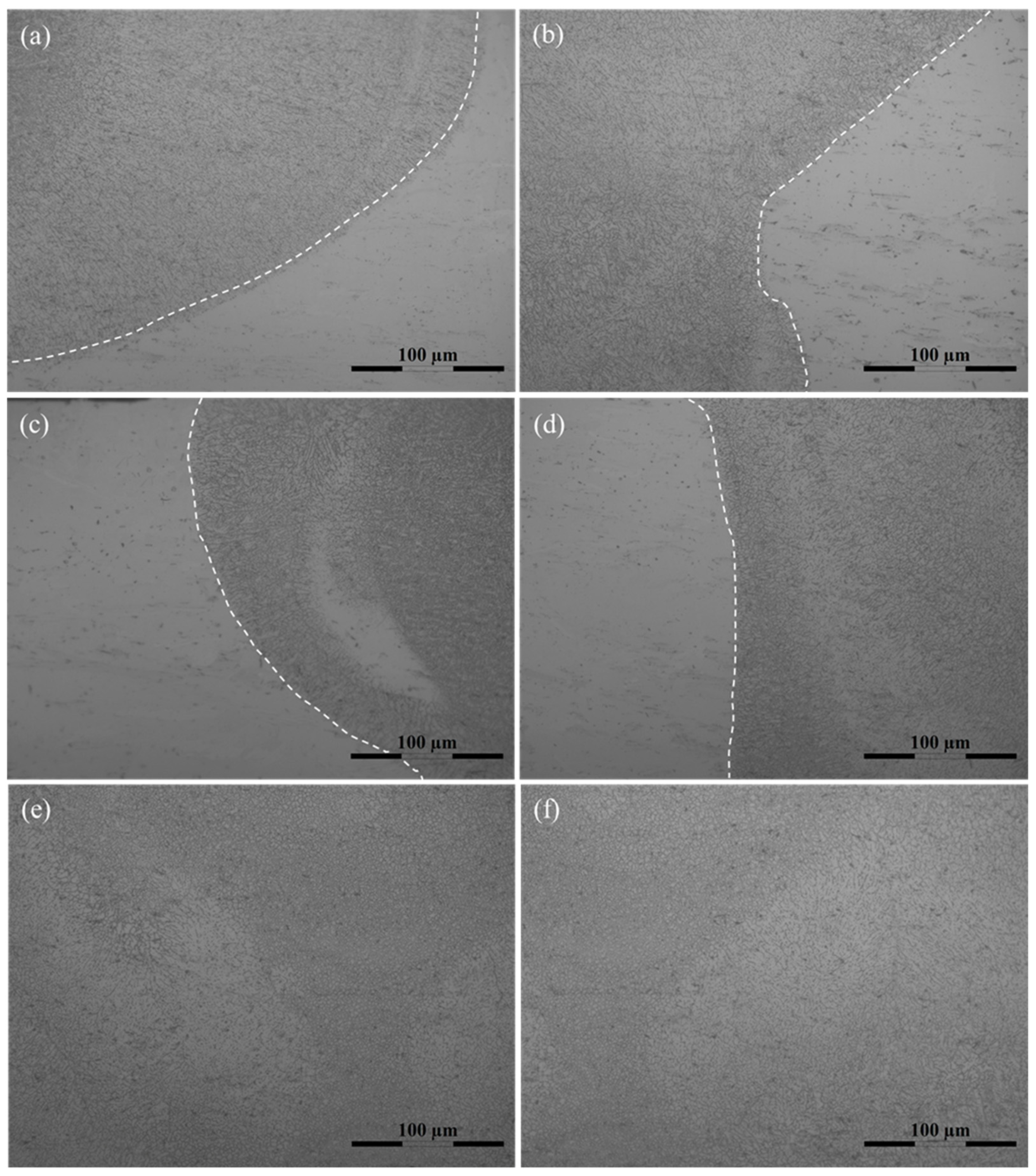

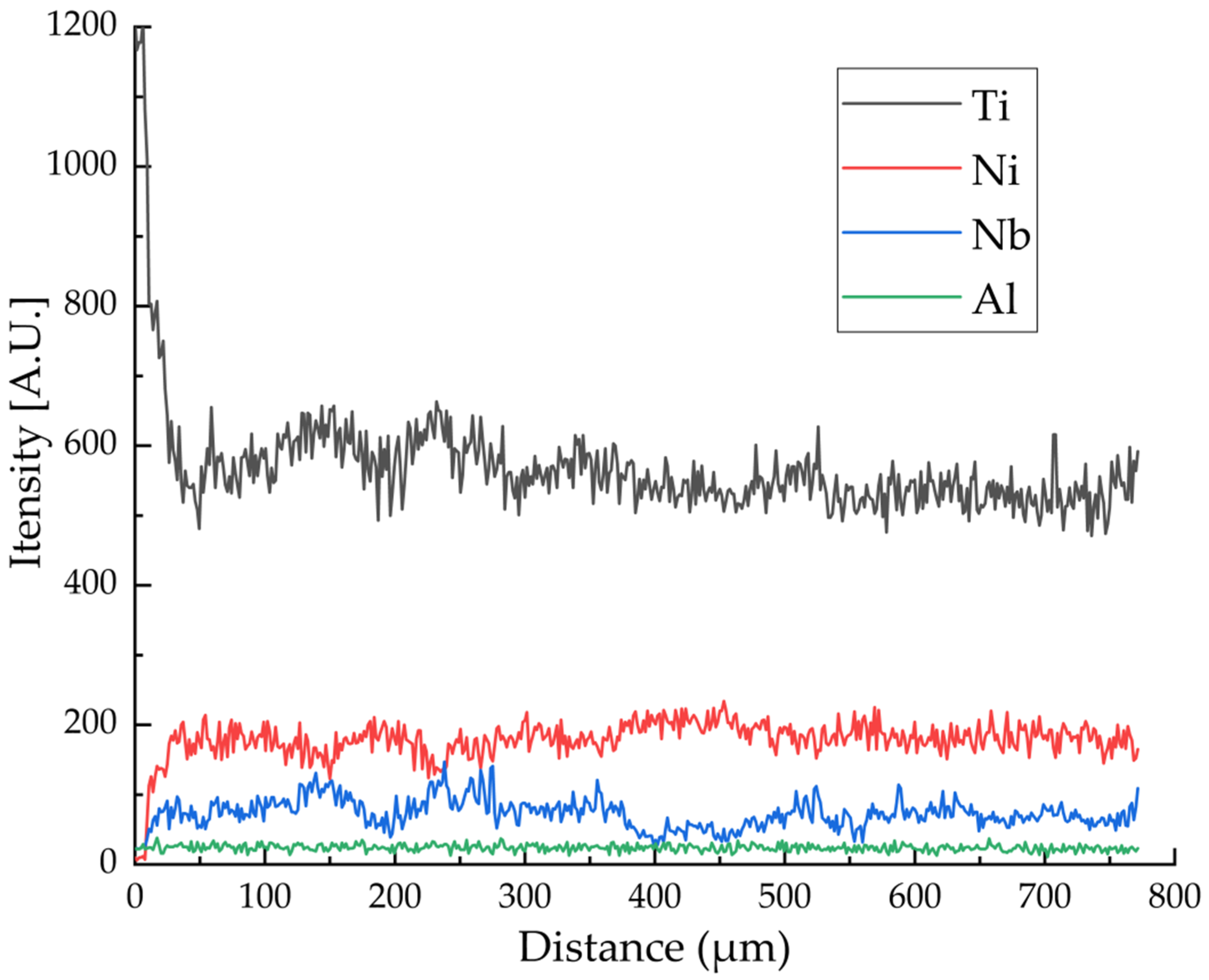

3.1. Macro Morphology and Microstructure of Welded Joint

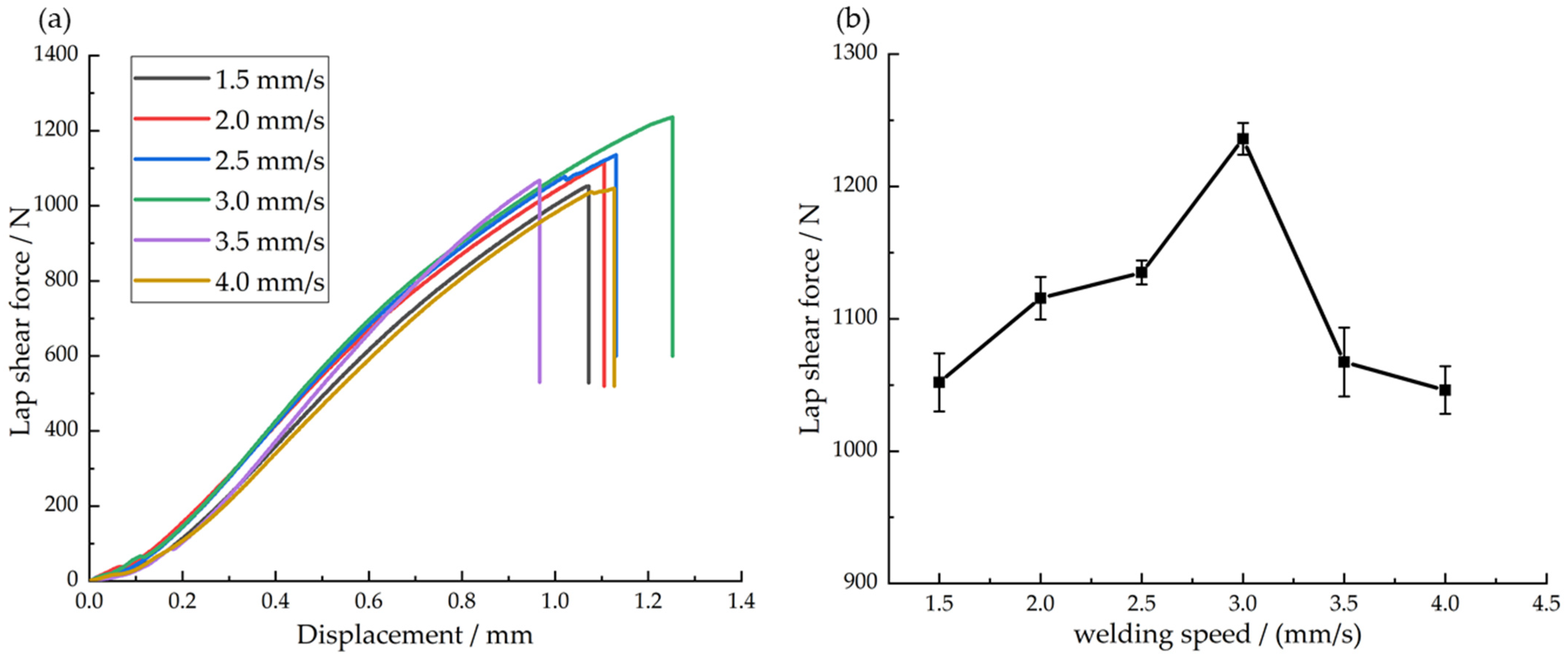

3.2. Mechanical Properties of Lap Joint Tensile

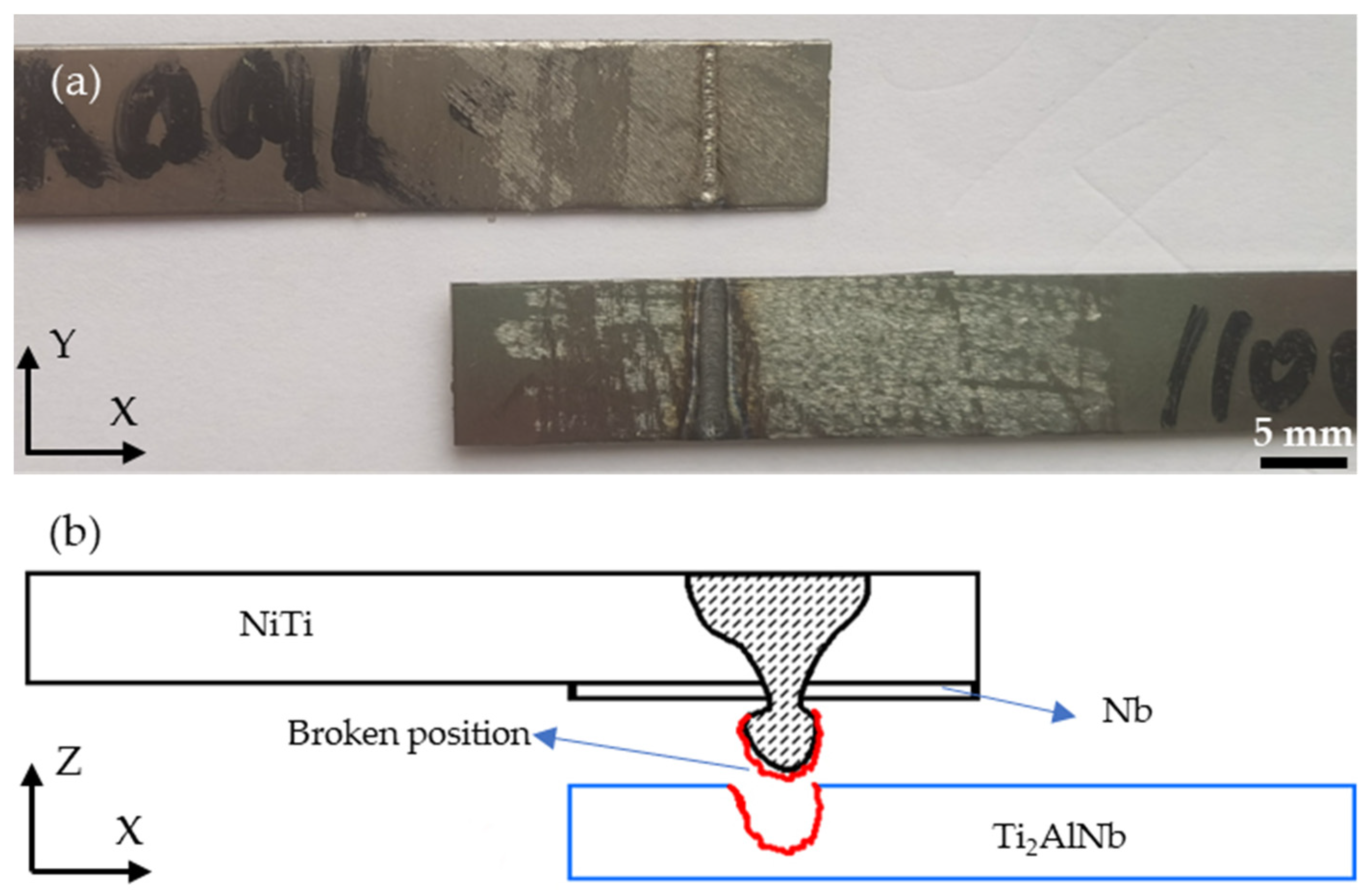

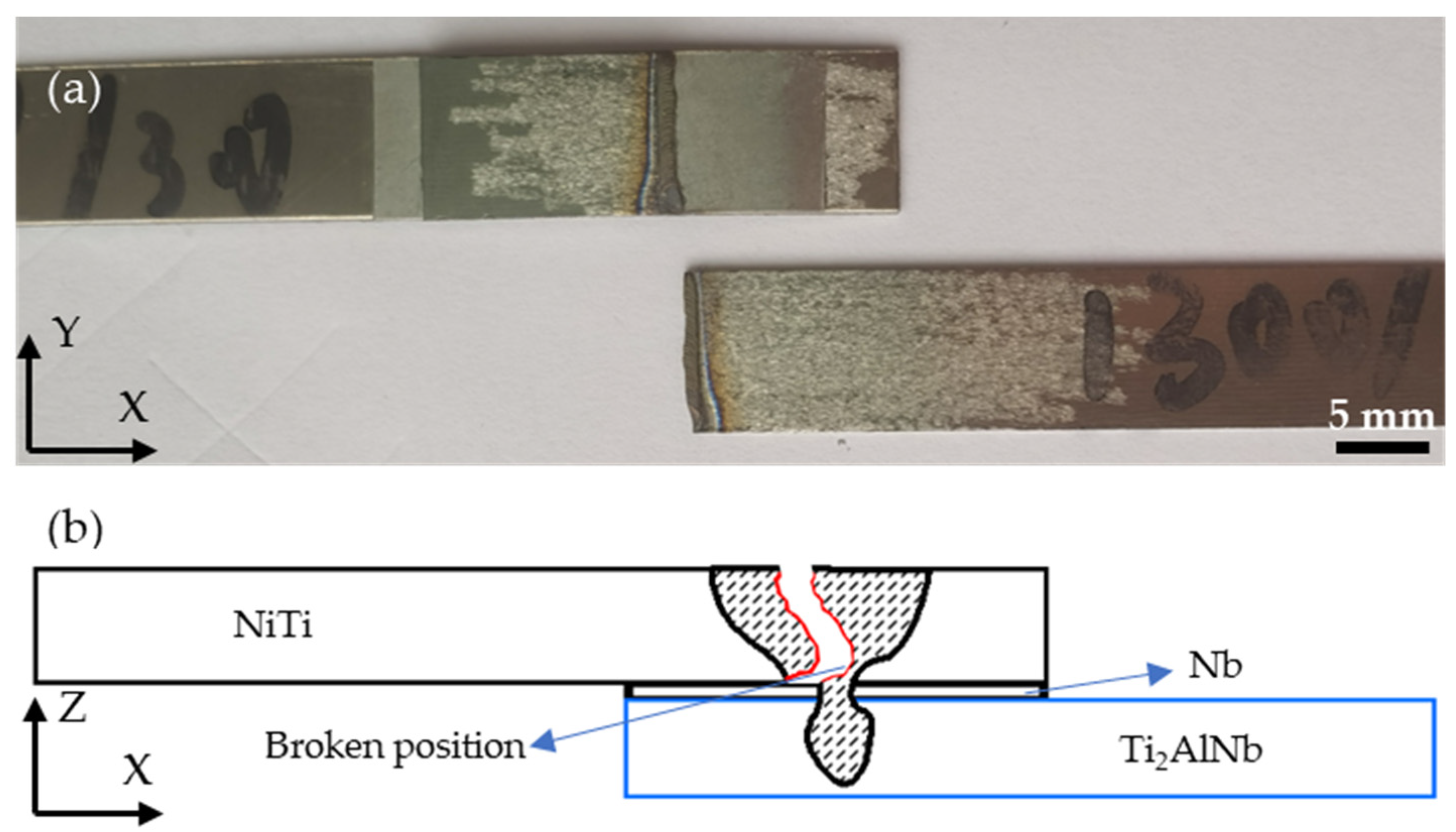

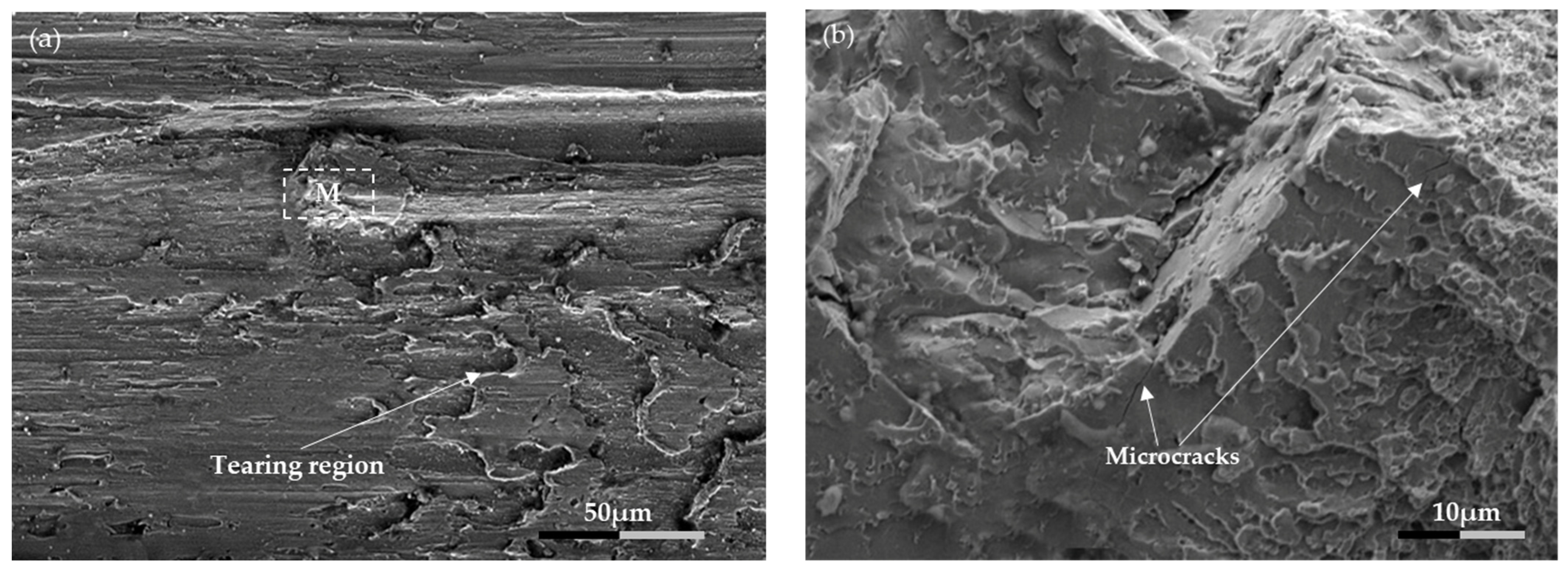

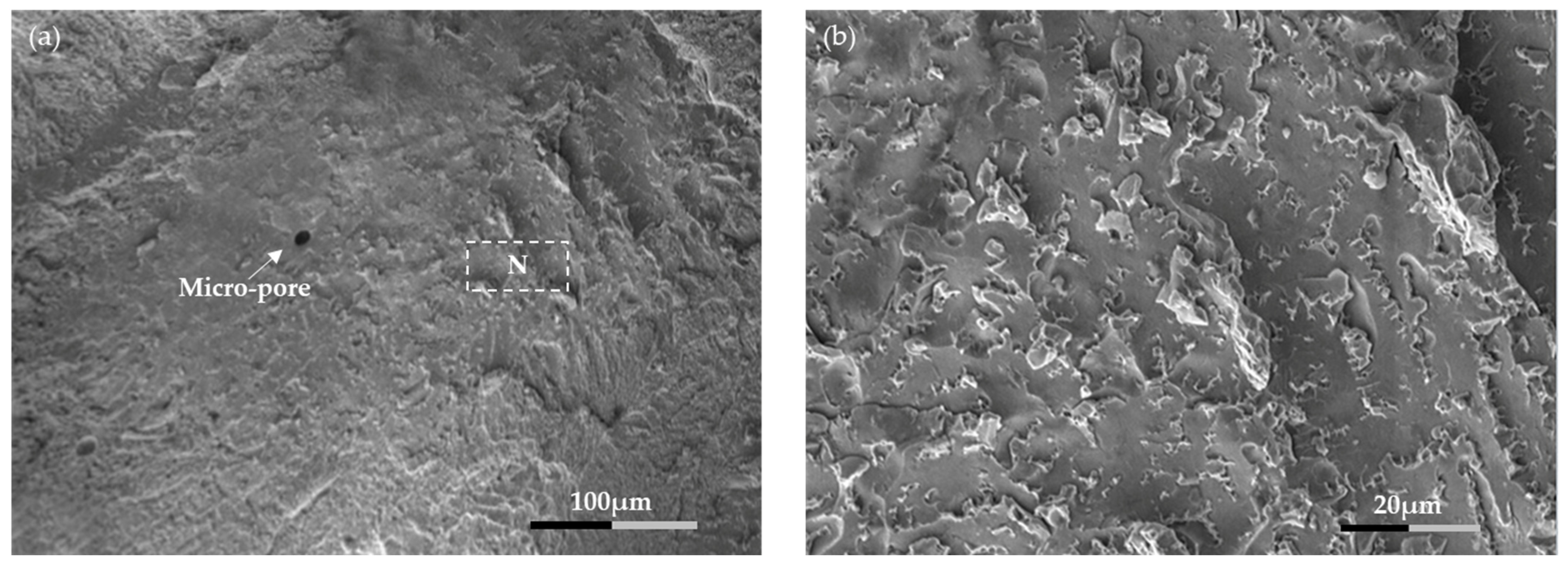

3.3. Fracture Characteristics of Lap Joint

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saadat, S.; Salichs, J.; Noori, M. An overview of vibration and seismic applications of NiTi shape memory alloy. Smart Mater. Struct. 2002, 11, 218–229. [Google Scholar] [CrossRef]

- Jani, M.J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Hartl, D.J.; Lagoudas, D.C. Aerospace applications of shape memory alloys. Proc. Inst. Mech. Eng.-Part G 2014, 221, 535–552. [Google Scholar] [CrossRef] [Green Version]

- Appel, F.; Wagner, R. Intermetallics: Titanium Aluminides. Encycl. Mater. Sci. Technol. 2001, 4246–4264. [Google Scholar]

- Dimiduk, D.M.; Miracle, D.B.; Ward, C.H. Development of intermetallic materials for aerospace systems. Mater. Sci. Technol. 1992, 8, 367–375. [Google Scholar] [CrossRef]

- Lutjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Baden-Württemberg, Germany, 2003. [Google Scholar]

- Hagiwara, M.; Emura, S.; Araoka, A. Enhanced Mechanical Properties of Orthorhombic Ti2AlNb-based Intermetallic Alloy. Met. Mater. Int. 2003, 9, 265–272. [Google Scholar] [CrossRef]

- Oh, J.; Pyo, S.G.; Lee, S. Fabrication of multilayered titanium aluminide sheets by self-propagating high-temperature synthesis reaction using hot rolling and heat treatment. J. Mater. Sci. 2003, 38, 3647–3651. [Google Scholar] [CrossRef]

- Chen, X.; Xie, F.Q.; Ma, T.J. Microstructure evolution and mechanical properties of linear friction welded Ti2AlNb alloy. J. Alloys Compd. 2015, 646, 4–496. [Google Scholar] [CrossRef]

- Cui, Y.; Yang, D.; Liu, B. Microstructure and mechanical properties of Ti-23Al-14Nb-3Valuminide’s electron beam weld-ed joint. Trans. China Weld. Inst. 1998, 19, 130–139. [Google Scholar]

- Chaturvedi, M.C.; Xu, Q.; Richards, N.L. Development of crack-free welds in a TiAl-based alloy. J. Mater. Process. Technol. 2001, 118, 74–78. [Google Scholar] [CrossRef]

- Wu, Y.T.; Wei, W.S.; Koo, C.H. Diffusion bonding of Ti–25Al–10Nb alloy. Sci. Technol. Weld. Join. 1998, 3, 97–104. [Google Scholar] [CrossRef]

- Herrmann, D.; Appel, F. Diffusion bonding of γ(TiAl) alloys: Influence of composition, microstructure, and mechanical properties. Metall. Mater. Trans. A 2009, 40, 1881–1902. [Google Scholar] [CrossRef]

- Pan, H.; Wei, M. Key factors effecting on properties of Ti_3Al braze joints. J. Mater. Eng. 2009, (Suppl. 1), 201–205. [Google Scholar]

- Shi, M.; Xiong, J.; Zhang, G. Monitoring process stability in GTA additive manufacturing based on vision sensing of arc length. Measurement 2021, 185, 110001. [Google Scholar] [CrossRef]

- Xue, J.L.; Peng, P.; Guo, W. HAZ Characterization and Mechanical Properties of QP980-DP980 Laser Welded Joints. Chin. J. Mech. Eng. 2021, 34, 80. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, Z.; Qin, C. Elevated temperature properties of the welding interface for Ti3Al/TC11 alloy. Rare Met. Mater. Eng. 2012, 41, 1828–1832. [Google Scholar]

- Zeng, Z.; Cong, B.Q.; Oliveira, J.P. Wire and arc additive manufacturing of a Ni-rich NiTi shape memory alloy: Microstructure and mechanical properties. Addit. Manuf. 2020, 32, 101051. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Panton, B.; Zeng, Z. Laser joining of NiTi to Ti6Al4V using a Niobium interlayer. Acta Mater. 2016, 105, 9–15. [Google Scholar] [CrossRef]

- Zeng, Z.; Yang, M.; Oliveira, J.P. Laser welding of NiTi shape memory alloy wires and tubes for multi-functional design applications. Smart Mater. Struct. 2016, 25, 085001. [Google Scholar] [CrossRef]

- Sun, Z.; Ion, J. Laser welding of dissimilar metal combinations. J. Mater. Sci. 1995, 30, 4205–4214. [Google Scholar] [CrossRef]

- Miranda, R.M.; Assuncao, E.; Silva, R.J.C. Fiber laser welding of NiTi to Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2015, 81, 1533–1538. [Google Scholar] [CrossRef]

- Zoeram, A.S.; Mousavi, S. Laser welding of Ti–6Al–4V to Nitinol–ScienceDirect. Mater. Des. 2014, 61, 185–190. [Google Scholar] [CrossRef]

- Song, P.; Zhu, Y.; Guo, W.; Qu, P.; Kang, H.; Wen, K. Mechanism of crack formation in the laser welded joint between NiTi shape memory alloy and TC4. Rare Met. Mater. Eng. 2013, 42, 6–9. [Google Scholar]

- Shiue, R.H.; Wu, S.K. Infrared brazing Ti50Ni50 and Ti-6Al-4V using the BAg-8braze alloy. Mater. Trans. 2005, 46, 2057–2066. [Google Scholar] [CrossRef] [Green Version]

- Zhi, Z.; Panton, B.; Oliveira, J.P. Dissimilar laser welding of NiTi shape memory alloy and copper. Smart Mater. Struct. 2015, 24, 125036. [Google Scholar]

- Oliveira, J.P.; Fernandes, F.; Miranda, R.M. Residual stress analysis in laser welded NiTi sheets using synchrotron X-ray diffraction. Mater. Des. 2016, 100, 180–187. [Google Scholar] [CrossRef] [Green Version]

- Penner, P.; Liu, L.; Gerlich, A. Dissimilar resistance spot welding of aluminum to magnesium with Zn-coated steel interlayers. Weld. J. 2014, 93, 225–231. [Google Scholar]

- Penner, P.; Liu, L.; Gerlich, A. Feasibility study of resistance spotwelding of dissimilar Al/Mg combinations with Ni based interlayers. Sci. Technol. Weld. Join. 2013, 18, 541–550. [Google Scholar] [CrossRef]

- Sun, M.; Niknejad, S.T.; Zhang, G. Microstructure and mechanical properties of resistance spot welded AZ31/AA5754 using a nickel interlayer. Mater. Des. 2015, 87, 905–913. [Google Scholar] [CrossRef]

- Chen, Y.H.; Ge, J.W.; Liu, F.C. Micro laser welding of dissimilar materials between TiNi shape memory alloy and titanium alloy. Opt. Precis. Eng. 2014, 22, 2075–2080. [Google Scholar] [CrossRef]

- Yuan, B.G.; Yu, H.P.; Li, C.F. Effect of hydrogen on fracture behavior of Ti–6Al–4V alloy by in-situ tensile test. Int. J. Hydrogen Energy 2010, 35, 1829–1838. [Google Scholar] [CrossRef]

- Gale, W.F.; Totemeier, T.C. Smithells Metals Reference Book, 8th ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Shaw, J. Simulations of localized thermo-mechanical behavior in a NiTi shape memory alloy. Int. J. Plast. 2000, 16, 541–562. [Google Scholar] [CrossRef]

- Wu, J.; Guo, R.P.; Xu, L. Effect of Hot Isostatic Pressing Loading Route on Microstructure and Mechanical Properties of Powder Metallurgy Ti2AlNb Alloys. J. Mater. Sci. Technol. 2017, 33, 172–178. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of TiNi-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Servant, C.; Ansara, I. Thermodynamic assessment of the Al-Nb-Ti system. Ber. Bunsenges. Phys. Chem. 1998, 102, 1189–1205. [Google Scholar] [CrossRef]

- Zhao, X.; Lan, L.; Sun, H. Mechanical properties of additive laser-welded NiTi alloy. Mater. Lett. 2010, 64, 628–631. [Google Scholar] [CrossRef]

- Wu, A.; Zou, G.; Ren, J. The development status of Ti3Al alloy and its connection technology. Aeronaut. Manuf. Technol. 2007, 6, 30–35. [Google Scholar]

- Zhao, X.; Yan, X.; Yang, Y. Wide hysteresis NiTi(Nb) shape memory alloys with low Nb content (4.5at.%). Mater. Sci. Eng. A 2006, 438, 575–578. [Google Scholar] [CrossRef]

- Zhao, L.C.; Duerig, T.W.; Justi, S. The study of niobium-rich precipitates in a NiTiNb shape memory alloy. Scr. Metall. Mater. 1990, 24, 221–225. [Google Scholar] [CrossRef]

- Wang, R.R.; Welsch, G.E. Joining titanium materials with tungsten inert gas welding, laser welding, and infrared brazing. J. Prosthet. Dent. 1995, 74, 521–530. [Google Scholar] [CrossRef]

- Li, X.; Xie, J.; Zhou, Y. Effects of oxygen contamination in the argon shielding gas in laser welding of commercially pure titanium thin sheet. J. Mater. Sci. 2005, 40, 3437–3443. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Cavaleiro, A.J.; Schell, N. Effects of laser processing on the transformation characteristics of NiTi: A contribute to additive manufacturing. Scr. Mater. 2018, 152, 122–126. [Google Scholar] [CrossRef]

- Yan, X.J.; Yang, D.Z.; Liu, X.P. Corrosion behavior of a laser-welded NiTi shape memory alloy. Mater. Charact. 2007, 58, 623–628. [Google Scholar] [CrossRef]

- Chan, C.W.; Man, H.C. Laser welding of thin foil nickel-titanium shape memory alloy. Opt. Lasers Eng. 2011, 49, 121–126. [Google Scholar] [CrossRef]

| Experiment No. | Laser Power (W) | Welding Speed (mm/s) |

|---|---|---|

| 1 | 900 | 3.0 |

| 2 | 1000 | 3.0 |

| 3 | 1100 | 3.0 |

| 4 | 1200 | 3.0 |

| 5 | 1300 | 3.0 |

| 6 | 1100 | 1.5 |

| 7 | 1100 | 2.0 |

| 8 | 1100 | 2.5 |

| 9 | 1100 | 3.5 |

| 10 | 1100 | 4.0 |

| Region | Ti | Ni | Nb |

|---|---|---|---|

| 1 | 51.80 | 45.90 | 2.30 |

| 2 | 51.15 | 47.22 | 1.63 |

| 3 | 53.15 | 42.26 | 4.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, F.; Peng, B.; Oliveira, J.P.; Ke, W.; Teshome, F.B.; Li, Y.; Zeng, Z. Dissimilar Laser Welding of a NiTi Shape Memory Alloy to Ti2AlNb. Metals 2021, 11, 1578. https://doi.org/10.3390/met11101578

Ge F, Peng B, Oliveira JP, Ke W, Teshome FB, Li Y, Zeng Z. Dissimilar Laser Welding of a NiTi Shape Memory Alloy to Ti2AlNb. Metals. 2021; 11(10):1578. https://doi.org/10.3390/met11101578

Chicago/Turabian StyleGe, Fuguo, Bei Peng, João Pedro Oliveira, Wenchao Ke, Fissha Biruke Teshome, Yongmei Li, and Zhi Zeng. 2021. "Dissimilar Laser Welding of a NiTi Shape Memory Alloy to Ti2AlNb" Metals 11, no. 10: 1578. https://doi.org/10.3390/met11101578

APA StyleGe, F., Peng, B., Oliveira, J. P., Ke, W., Teshome, F. B., Li, Y., & Zeng, Z. (2021). Dissimilar Laser Welding of a NiTi Shape Memory Alloy to Ti2AlNb. Metals, 11(10), 1578. https://doi.org/10.3390/met11101578