Ultra-High Temperature Creep of Ni-Based SX Superalloys at 1250 °C

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

2.2. Creep Tests

2.3. Microstructural Characterization

3. Results

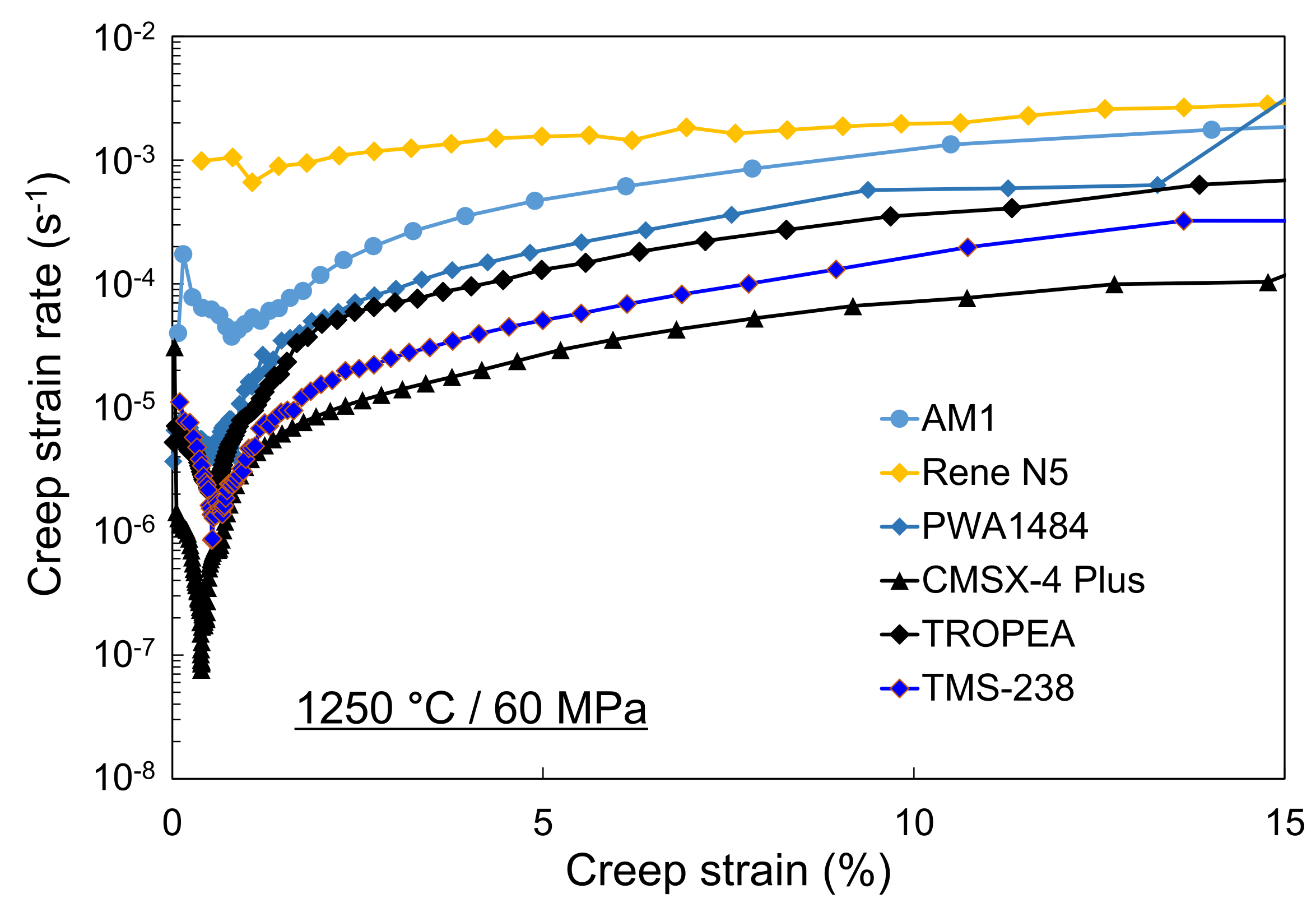

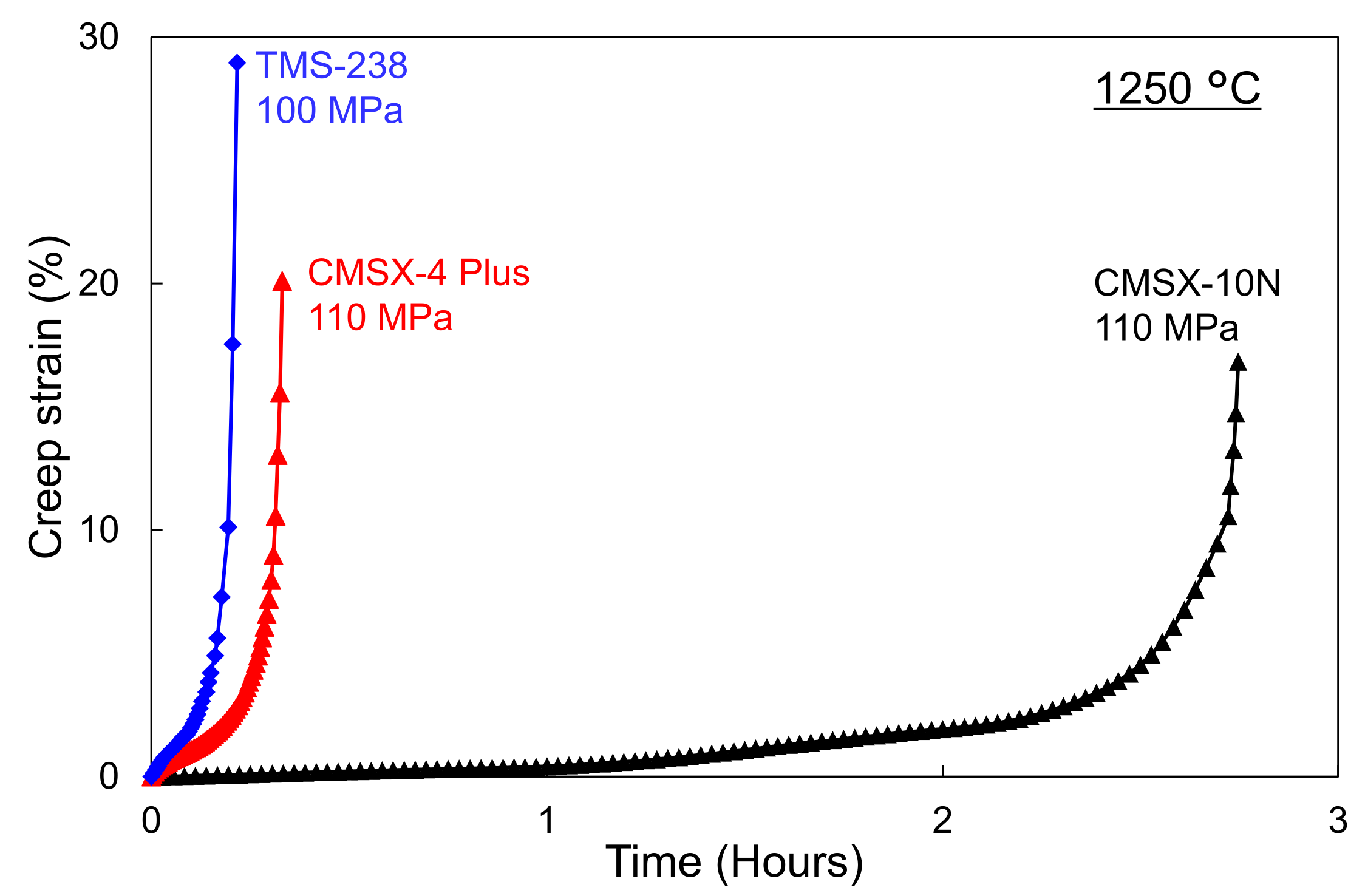

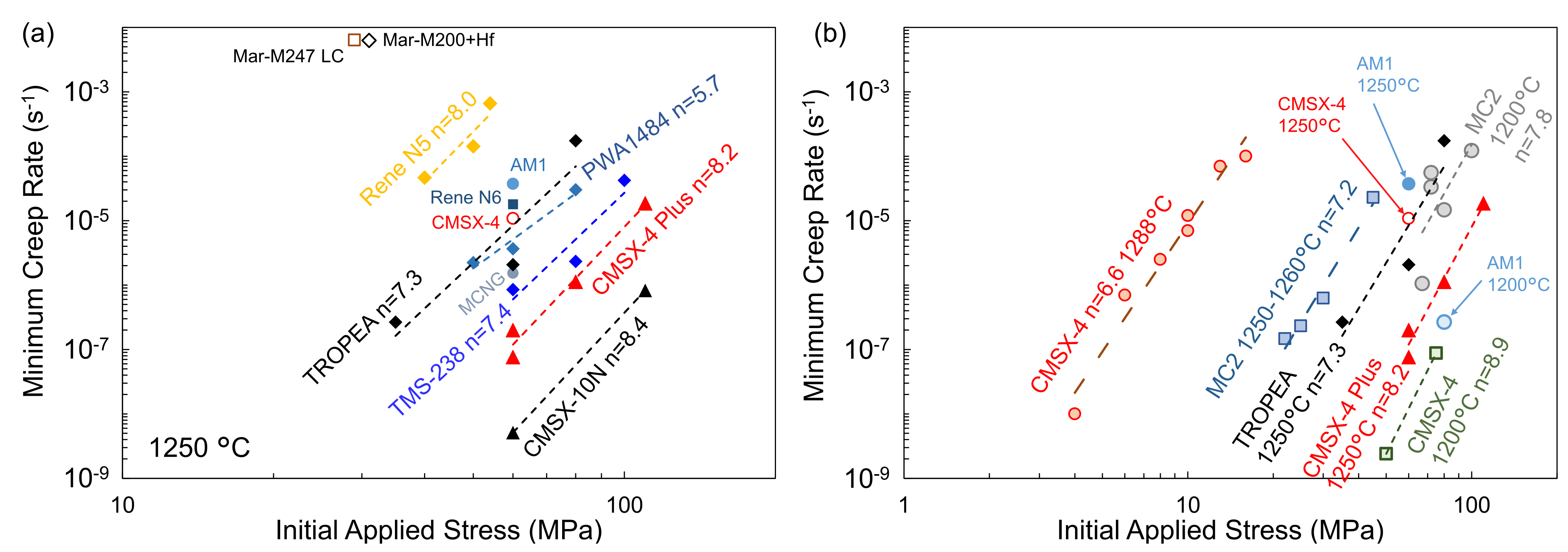

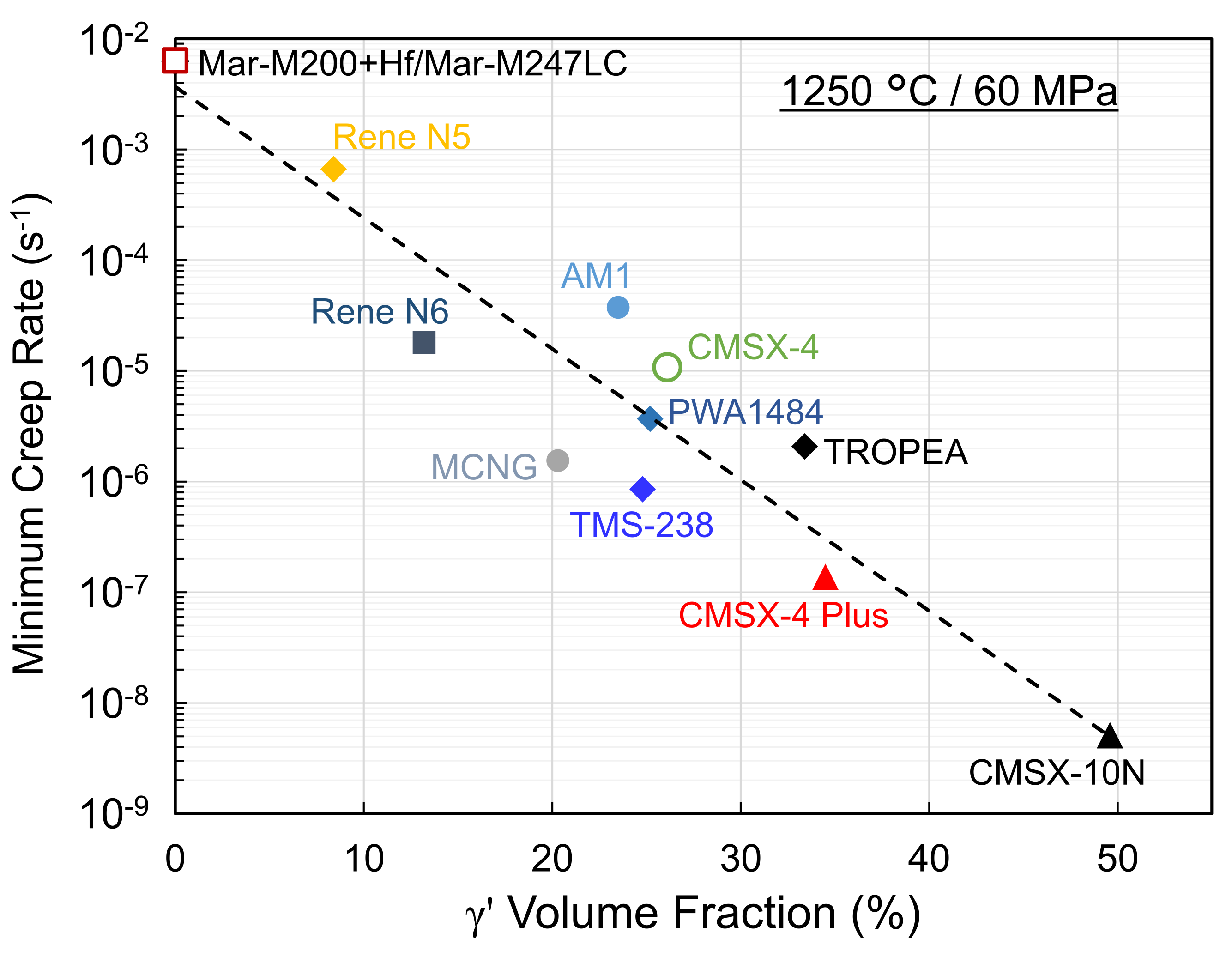

3.1. Creep Tests at 1250 °C

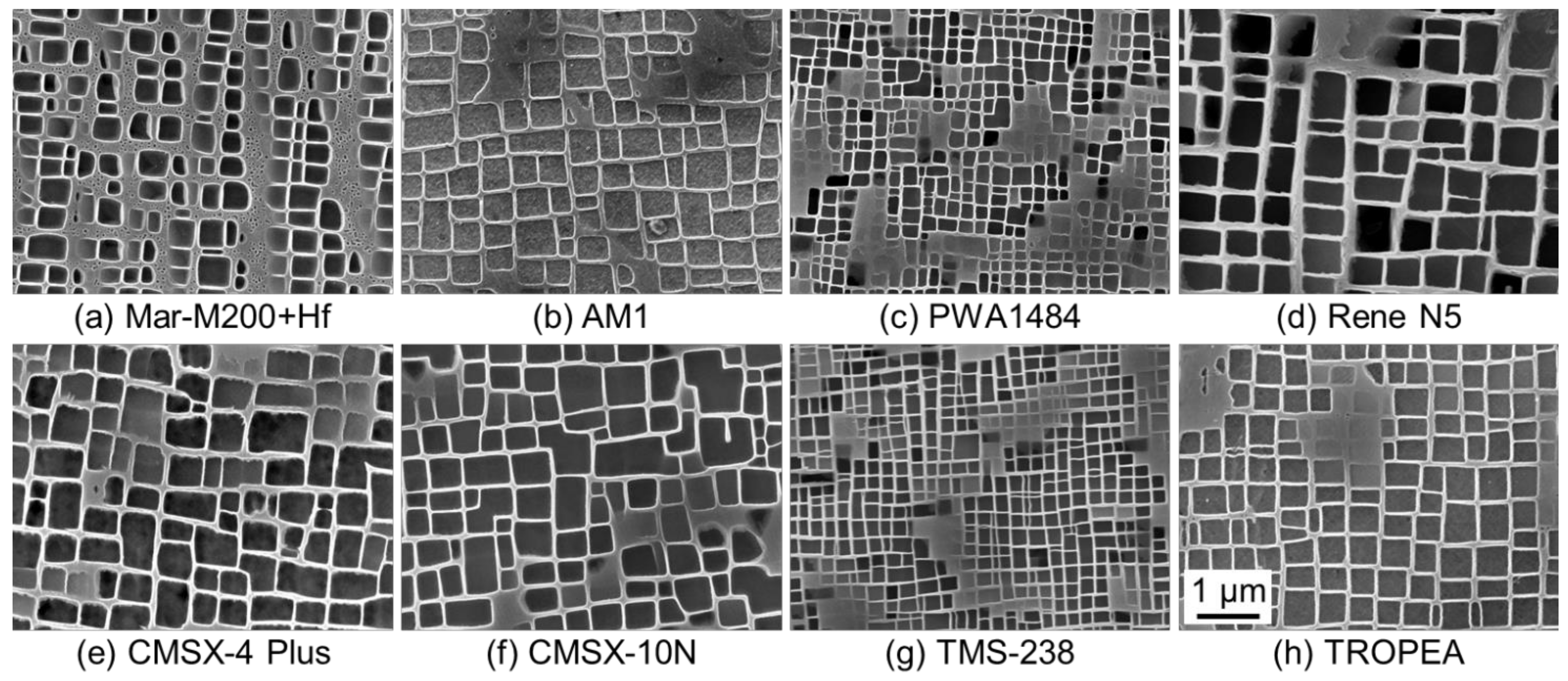

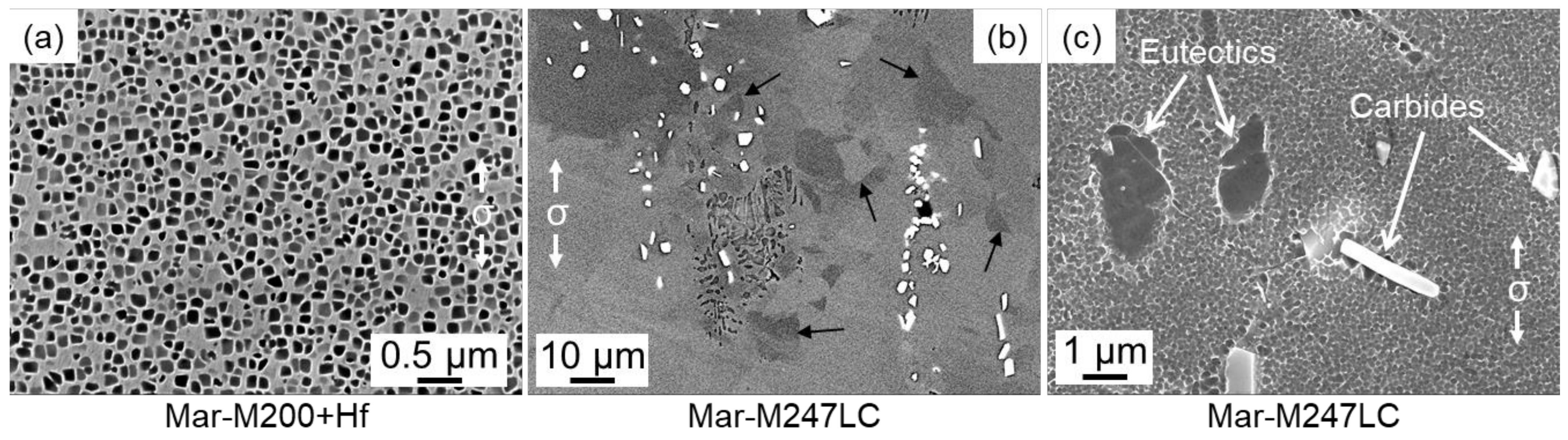

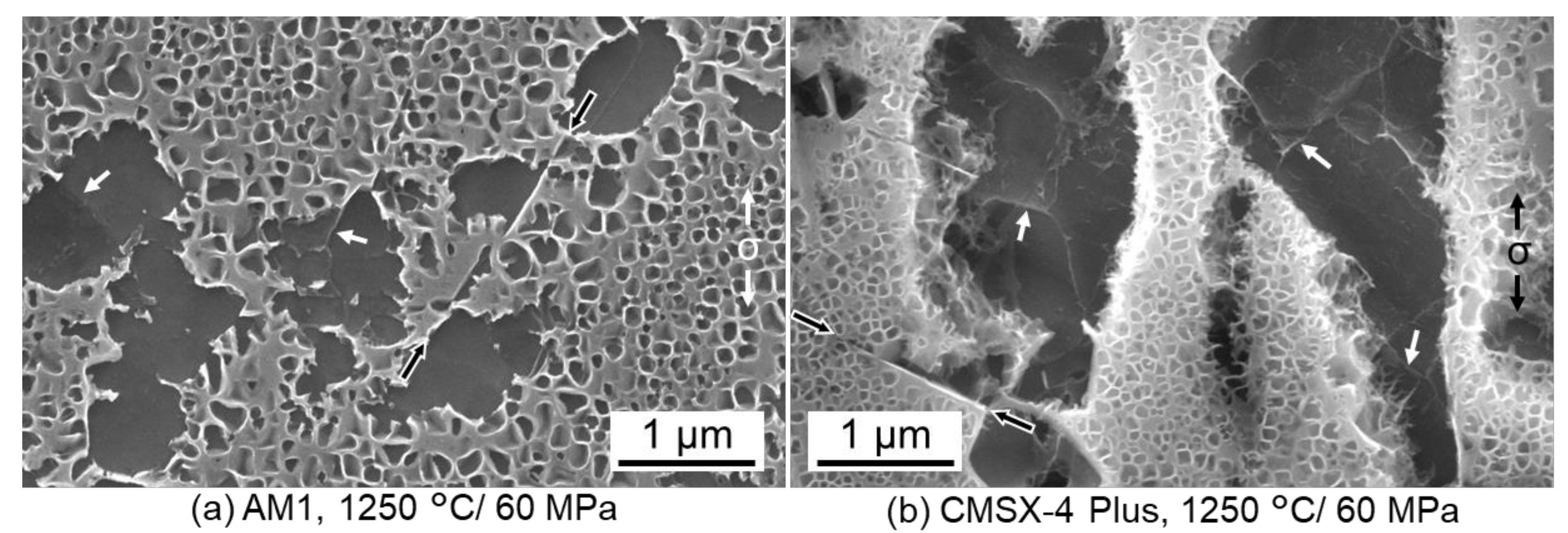

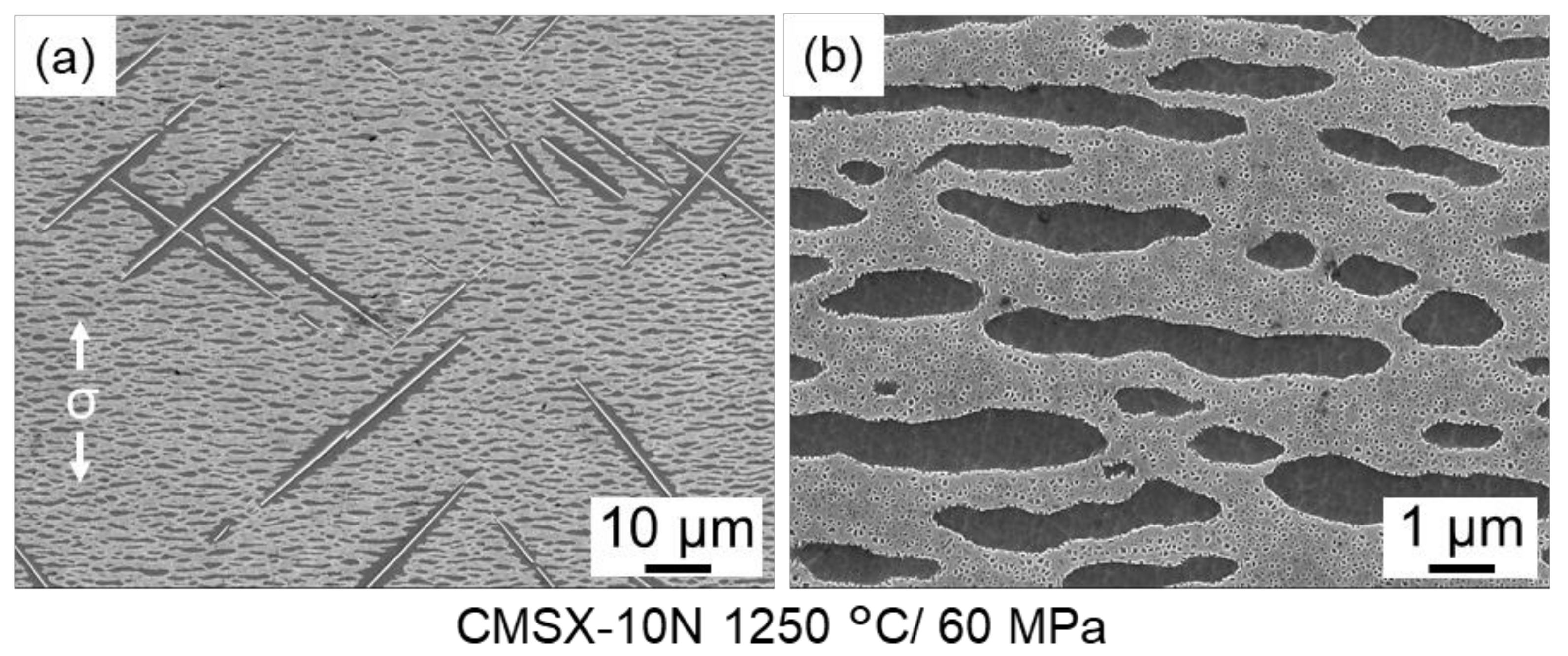

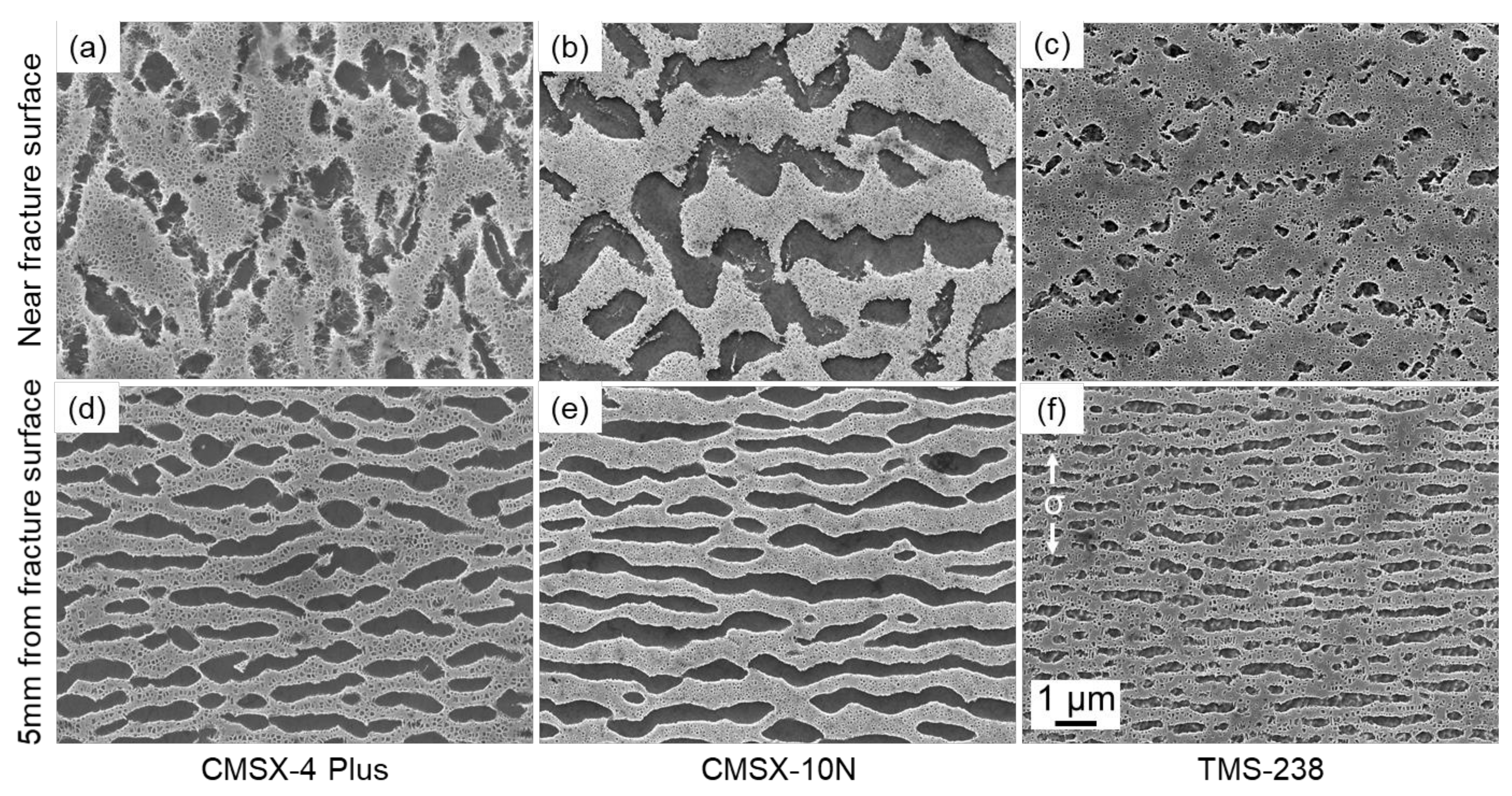

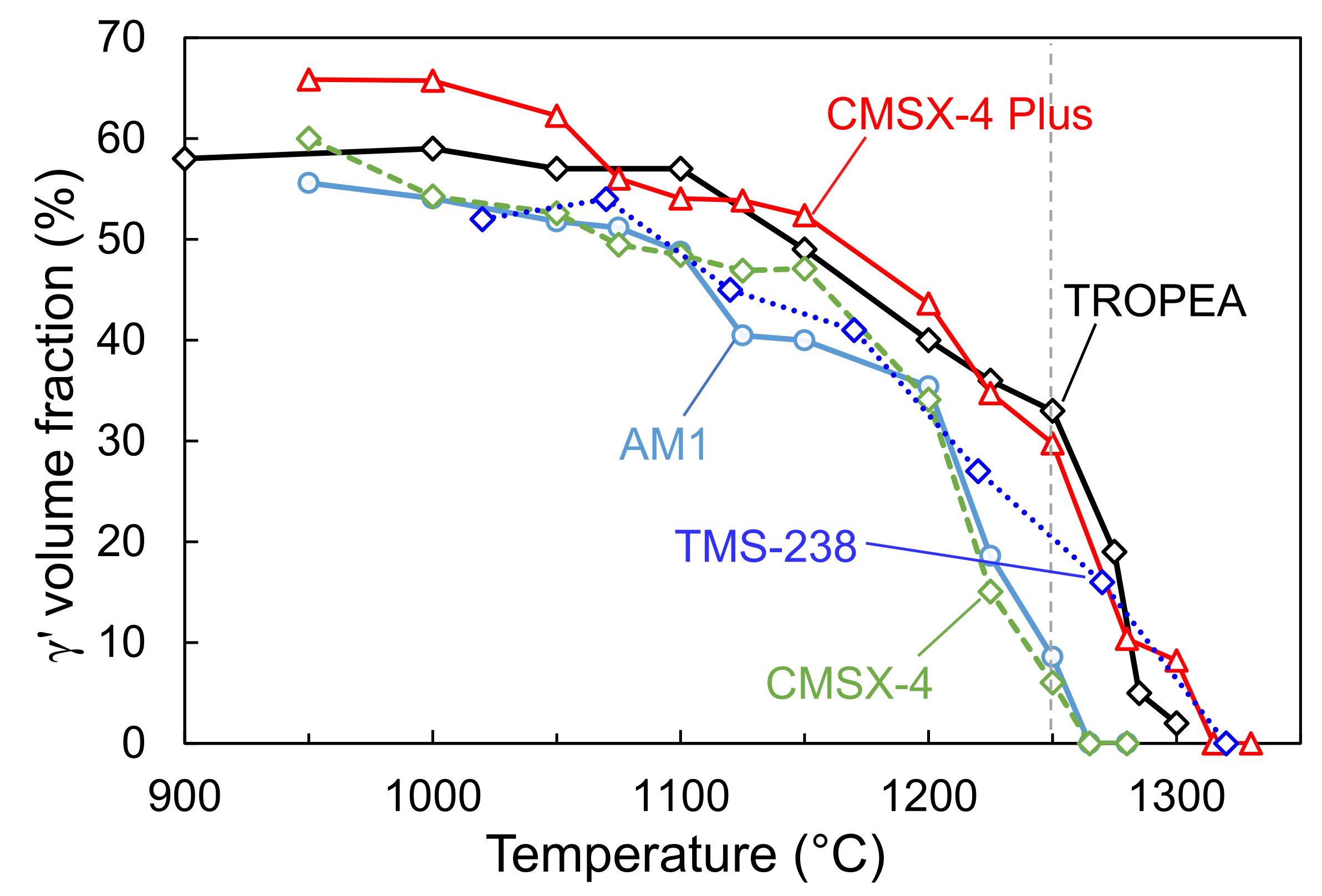

3.2. Mirostructure Analyses

4. Discussion

4.1. Creep Deformation Mechanisms of Ni-Based SX Superalloys at 1250 °C

4.2. Effect of Chemical Composition on the Damage Mechanisms

5. Conclusions

- The creep resistance of Ni-based single crystal superalloys at ultra-high temperature conditions at 1250 °C is mainly determined by the γ′ volume fraction that controls creep strain rate. Regardless of the alloy composition and the γ′ volume fraction at 1250 °C, the creep exponent in Norton’s power law is between 6 and 9, indicating that creep deformation mechanisms at this temperature are mainly by the glide of dislocations in the γ phase.

- Materials with similar γ′ volume fraction after creep tests at 1250 °C/ 60 MPa (MCNG, AM1, CMSX-4, PWA1484, TMS-238) exhibit different creep behavior. Alloy compositions influence the creep strength at 1250 °C by affecting the strength of the γ′ precipitates and the γ matrix and γ/γ′ lattice misfit.

- For most of the alloys, the main damage and failure mechanism in these conditions is accumulation of creep strain that leads to very severe necking. The exception is CMSX-10N, which shows damage mechanisms typical of those observed in the γ′-rafting regime, which are crack initiation and propagation from creep voids.

- With a relatively high applied stress, materials with a γ′ solvus temperature lower than 1250 °C (Mar-M200+Hf and Mar-M247LC) undergo dynamic recrystallization in a large area of the gauge section. Other creep ruptured materials also show recrystallization near the fracture surface. Recrystallization is presumed to occur during the last stages of creep failure due to the locally accumulated strain.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; ISBN 9780521070119. [Google Scholar]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Long, H.; Mao, S.; Liu, Y.; Zhang, Z.; Han, X. Microstructural and compositional design of Ni-based single crystalline superalloys—A review. J. Alloys Compd. 2018, 743, 203–220. [Google Scholar] [CrossRef]

- Reed, R.C.; Matan, N.; Cox, D.C.; Rist, M.A.; Rae, C.M.F. Creep of CMSX-4 superalloy single crystals: Effects of rafting at high temperature. Acta Mater. 1999, 47, 3367–3381. [Google Scholar] [CrossRef]

- Reed, R.C.; Cox, D.C.; Rae, C.M.F. Damage accumulation during creep deformation of a single crystal superalloy at 1150 °C. Mater. Sci. Eng. A 2007, 448, 88–96. [Google Scholar] [CrossRef]

- MacKay, R.A.; Maier, R.D. The influence of orientation on the stress rupture properties of nickel-base superalloy single crystals. Metall. Trans. A 1982, 13, 1747–1754. [Google Scholar] [CrossRef]

- Caron, P.; Henderson, P.J.; Khan, T.; McLean, M. On the effects of heat treatments on the creep behaviour of a single crystal superalloy. Scr. Metall. 1986, 20, 875–880. [Google Scholar] [CrossRef]

- Caron, P.; Ohta, Y.; Nakagawa, Y.G.; Khan, T. Creep deformation anisotropy in single crystal superalloys. In Proceedings of the Superalloys 1988; Reichman, S., Duhl, D.N., Maurer, G., Antolovich, S.D., Lund, C., Eds.; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 1988; pp. 215–224. [Google Scholar]

- Yuan, Y.; Kawagishi, K.; Koizumi, Y.; Kobayashi, T.; Yokokawa, T.; Harada, H. Creep deformation of a sixth generation Ni-base single crystal superalloy at 800 °C. Mater. Sci. Eng. A 2014, 608, 95–100. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall. Mater. 1992, 40, 1–30. [Google Scholar] [CrossRef]

- Zhang, J.X.; Murakumo, T.; Harada, H.; Koizumi, Y. Dependence of creep strength on the interfacial dislocations in a fourth generation SC superalloy TMS-138. Scr. Mater. 2003, 48, 287–293. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Reed, R.C. Primary creep in single crystal superalloys: Origins, mechanisms and effects. Acta Mater. 2007, 55, 1067–1081. [Google Scholar] [CrossRef]

- le Graverend, J.-B.; Adrien, J.; Cormier, J. Ex-situ X-ray tomography characterization of porosity during high-temperature creep in a Ni-based single-crystal superalloy: Toward understanding what is damage. Mater. Sci. Eng. A 2017, 695, 367–378. [Google Scholar] [CrossRef]

- Agudo Jácome, L.; Nörtershäuser, P.; Somsen, C.; Dlouhý, A.; Eggeler, G. On the nature of γ′ phase cutting and its effect on high temperature and low stress creep anisotropy of Ni-base single crystal superalloys. Acta Mater. 2014, 69, 246–264. [Google Scholar] [CrossRef]

- Ai, S.H.; Lupinc, V.; Maldini, M. Creep fracture mechanisms in single crystal superalloys. Scr. Metall. Mater. 1992, 26, 579–584. [Google Scholar] [CrossRef]

- Hamadi, S.; Hamon, F.; Delautre, J.; Cormier, J.; Villechaise, P.; Utada, S.; Kontis, P.; Bozzolo, N. Consequences of a Room-Temperature Plastic Deformation During Processing on Creep Durability of a Ni-Based SX Superalloy. Metall. Mater. Trans. A 2018, 49, 4246–4261. [Google Scholar] [CrossRef]

- Epishin, A.; Fedelich, B.; Nolze, G.; Schriever, S.; Feldmann, T.; Ijaz, M.F.; Viguier, B.; Poquillon, D.; Le Bouar, Y.; Ruffini, A.; et al. Creep of Single Crystals of Nickel-Based Superalloys at Ultra-High Homologous Temperature. Metall. Mater. Trans. A 2018, 49, 3973–3987. [Google Scholar] [CrossRef] [Green Version]

- Ru, Y.; Zhang, H.; Pei, Y.; Li, S.; Zhao, X.; Gong, S.; Xu, H. Improved 1200 °C stress rupture property of single crystal superalloys by γ′-forming elements addition. Scr. Mater. 2018, 147, 21–26. [Google Scholar] [CrossRef]

- Tan, X.P.; Liu, J.L.; Jin, T.; Hu, Z.Q.; Hong, H.U.; Choi, B.G.; Kim, I.S.; Jo, C.Y.; Mangelinck, D. Effect of Ru additions on very high temperature creep properties of a single crystal Ni-based superalloy. Mater. Sci. Eng. A 2013, 580, 21–35. [Google Scholar] [CrossRef]

- Epishin, A.I.; Fedelich, B.; Viguier, B.; Schriever, S.; Svetlov, I.L.; Petrushin, N.V.; Saillard, R.; Proietti, A.; Poquillon, D.; Chyrkin, A. Creep of single-crystals of nickel-base γ-alloy at temperatures between 1150 °C and 1288 °C. Mater. Sci. Eng. A 2021, 825, 141880. [Google Scholar] [CrossRef]

- Cormier, J.; Milhet, X.; Champion, J.-L.; Mendez, J. Simulation of Very High Temperature Overheating During Isothermal Creep of Single Crystal Ni-Base Superalloy. Adv. Eng. Mater. 2008, 10, 56–61. [Google Scholar] [CrossRef]

- Cormier, J.; Milhet, X.; Mendez, J. Non-isothermal creep at very high temperature of the nickel-based single crystal superalloy MC2. Acta Mater. 2007, 55, 6250–6259. [Google Scholar] [CrossRef]

- Guo, X.; Zheng, W.; Xiao, C.; Li, L.; Antonov, S.; Zheng, Y.; Feng, Q. Evaluation of microstructural degradation in a failed gas turbine blade due to overheating. Eng. Fail. Anal. 2019, 103, 308–318. [Google Scholar] [CrossRef]

- Guidance for 30-second and 2-minute one-engine-inoperative (OEI) ratings for rotercraft turbine engines. In Advisory Circulars; Federal Aviation Administration: Washington, DC, USA, 2009.

- Giraud, R.; Hervier, Z.; Cormier, J.; Saint-Martin, G.; Hamon, F.; Milhet, X.; Mendez, J. Strain Effect on the γ′ Dissolution at High Temperatures of a Nickel-Based Single Crystal Superalloy. Metall. Mater. Trans. A 2013, 44, 131–146. [Google Scholar] [CrossRef]

- Cormier, J.; Milhet, X.; Mendez, J. Effect of very high temperature short exposures on the dissolution of the γ′ phase in single crystal MC2 superalloy. J. Mater. Sci. 2007, 42, 7780–7786. [Google Scholar] [CrossRef]

- Cormier, J. Thermal Cycling Creep Resistance of Ni-Based Single Crystal Superalloys. In Proceedings of the Superalloys 2016; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 383–394. [Google Scholar]

- Bortoluci Ormastroni, L.M.; Utada, S.; Rame, J.; Mataveli Suave, L.; Kawagishi, K.; Harada, H.; Villechaise, P.; Cormier, J. Tensile, low cycle fatigue and very high cycle fatigue characterizations of advanced single crystal nickel-based superalloys. In Proceedings of the Superalloys 2020; Tin, S., Hardy, M., Clews, J., Cormier, J., Feng, Q., Marcin, J., O’Brien, C., Suzuki, A., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 341–351. [Google Scholar]

- Schwalbe, C.; Cormier, J.; Jones, C.N.; Galindo-Nava, E.; Rae, C.M.F. Investigating the Dislocation-Driven Micro-mechanical Response Under Non-isothermal Creep Conditions in Single-Crystal Superalloys. Metall. Mater. Trans. A 2018, 49, 3988–4002. [Google Scholar] [CrossRef] [Green Version]

- Cormier, J.; Jouiad, M.; Hamon, F.; Villechaise, P.; Milhet, X. Very high temperature creep behavior of a single crystal Ni-based superalloy under complex thermal cycling conditions. Philos. Mag. Lett. 2010, 90, 611–620. [Google Scholar] [CrossRef]

- Hähner, P.; Affeldt, E.; Beck, T.; Klingelhöffer, H.; Loveday, M.; Rinaldi, C. Final Version of the Validated Code-of-Practice for Strain-Controlled Thermo-Mechanical Fatigue Testing; Office for Official Publications of the European Communities: Luxembourg, 2006; ISBN 92-79-02216-4. [Google Scholar]

- Vaunois, J.-R.; Cormier, J.; Villechaise, P.; Devaux, A.; Flageolet, B. Influence of both γ′ distribution and grain size on the tensile properties of UDIMET 720Li at room temperature. In Proceedings of the 7th International Conference on Superalloys 718 and Derivatives, Pittsburg, PA, USA, 10–13 Octobe 2010; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 2010; pp. 199–213. [Google Scholar]

- Rame, J.; Utada, S.; Bortoluci Ormastroni, L.M.; Mataveli Suave, L.; Menou, E.; Després, L.; Kontis, P.; Cormier, J. Platinum containing new generation nickel-based superalloy for single crystalline application. In Proceedings of the Superalloys 2020; Tin, S., Hardy, M., Clews, J., Cormier, J., Feng, Q., Marcin, J., O’Brien, C., Suzuki, A., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 71–81. [Google Scholar]

- Cormier, J. Comportement en Fluage Anisotherme à Haute et Très Haute Température du Superalliage Monocristallin MC2; ISAE-ENSMA: Poitiers, France, 2006. [Google Scholar]

- Walston, W.S.; O’hara, K.S.; Ross, E.W.; Pollock, T.M.; Murphy, W.H. Rene’ N6: Third Generation Single Crystal Superalloy. In Proceedings of the Superalloys 1996; Kissinger, R.D., Deye, D.J., Anton, D.L., Cetel, A.D., Nathal, M.V., Pollock, T.M., Woodford, D.A., Eds.; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 1996; pp. 27–34. [Google Scholar]

- Mauget, F.; Marchand, D.; Benoit, G.; Morisset, M.; Bertheau, D.; Cormier, J.; Mendez, J.; Hervier, Z.; Ostoja-Kuczynski, E.; Moriconi, C. Development and use of a new burner rig facility to mimic service loading conditions of Ni-based single crystal superalloys. MATEC Web. Conf. 2014, 14, 20001. [Google Scholar] [CrossRef] [Green Version]

- Sponseller, D.L. Differential thermal analysis of nickel-base superalloys. In Proceedings of the Superalloys 1996; Kissinger, R.D., Deye, D.J., Anton, D.L., Cetel, A.D., Nathal, M.V., Pollock, T.M., Woodford, D.A., Eds.; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 1996; pp. 259–270. [Google Scholar]

- Nicolaÿ, A.; Fiorucci, G.; Franchet, J.M.; Cormier, J.; Bozzolo, N. Influence of strain rate on subsolvus dynamic and post-dynamic recrystallization kinetics of Inconel 718. Acta Mater. 2019, 174, 406–417. [Google Scholar] [CrossRef]

- Cormier, J.; Cailletaud, G. Constitutive modeling of the creep behavior of single crystal superalloys under non-isothermal conditions inducing phase transformations. Mater. Sci. Eng. A 2010, 527, 6300–6312. [Google Scholar] [CrossRef]

- Cormier, J.; Caccuri, V.; le Graverend, J.-B.; Villechaise, P. Comments on ‘Selective evolution of secondary γ′ precipitation in a Ni-based single crystal superalloy both in the γ matrix and at the dislocation nodes. Scr. Mater. 2017, 129, 100–103. [Google Scholar] [CrossRef]

- le Graverend, J.-B.; Cormier, J.; Jouiad, M.; Gallerneau, F.; Paulmier, P.; Hamon, F. Effect of fine γ′ precipitation on non-isothermal creep and creep-fatigue behaviour of nickel base superalloy MC2. Mater. Sci. Eng. A 2010, 527, 5295–5302. [Google Scholar] [CrossRef]

- Utada, S.; Rame, J.; Hamadi, S.; Delautre, J.; Villechaise, P.; Cormier, J. Kinetics of creep damage accumulation induced by a room-temperature plastic deformation introduced during processing of AM1 Ni-based single crystal superalloy. Mater. Sci. Eng. A 2020, 789, 139571. [Google Scholar] [CrossRef]

- Simonetti, M.; Caron, P. Role and behaviour of μ phase during deformation of a nickel-based single crystal superalloy. Mater. Sci. Eng. A 1998, 254, 1–12. [Google Scholar] [CrossRef]

- MacLachlan, D.W.; Knowles, D.M. Modelling and prediction of the stress rupture behaviour of single crystal superalloys. Mater. Sci. Eng. A 2001, 302, 275–285. [Google Scholar] [CrossRef]

- Moss, S.J.; Webster, G.A.; Fleury, E. Creep deformation and crack growth behavior of a single-crystal nickel-base superalloy. Metall. Mater. Trans. A 1996, 27, 829–837. [Google Scholar] [CrossRef]

- Matan, N.; Cox, D.C.; Rae, C.M.F.; Reed, R.C. On the kinetics of rafting in CMSX-4 superalloy single crystals. Acta Mater. 1999, 47, 2031–2045. [Google Scholar] [CrossRef]

- Caccuri, V.; Cormier, J.; Desmorat, R. γ′-Rafting mechanisms under complex mechanical stress state in Ni-based single crystalline superalloys. Mater. Des. 2017, 131, 487–497. [Google Scholar] [CrossRef]

- le Graverend, J.-B.; Jacques, A.; Cormier, J.; Ferry, O.; Schenk, T.; Mendez, J. Creep of a nickel-based single-crystal superalloy during very high-temperature jumps followed by synchrotron X-ray diffraction. Acta Mater. 2015, 84, 65–79. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Harada, H.; Koizumi, Y. The effect of lattice misfit on the dislocation motion in superalloys during high-temperature low-stress creep. Acta Mater. 2005, 53, 4623–4633. [Google Scholar] [CrossRef]

- Zhang, J.X.; Harada, H.; Koizumi, Y.; Kobayashi, T. Dislocation motion in the early stages of high-temperature low-stress creep in a single-crystal superalloy with a small lattice misfit. J. Mater. Sci. 2010, 45, 523–532. [Google Scholar] [CrossRef]

- Kamaraj, M. Rafting in single crystal nickel-base superalloys—An overview. Sadhana 2003, 28, 115–128. [Google Scholar] [CrossRef]

- Reed, R.C.; Cox, D.C.; Rae, C.M.F. Kinetics of rafting in a single crystal superalloy: Effects of residual microsegregation. Mater. Sci. Technol. 2007, 23, 893–902. [Google Scholar] [CrossRef]

- Zhang, J.X.; Murakumo, T.; Koizumi, Y.; Kobayashi, T.; Harada, H.; Masaki Jr, S. Interfacial dislocation networks strengthening a fourth-generation single-crystal TMS-138 superalloy. Metall. Mater. Trans. A 2002, 33, 3741–3746. [Google Scholar] [CrossRef]

- Kawagishi, K.; Yeh, A.; Yokokawa, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Development of an Oxidation-resistant High-Strength Sixth-Generation Single-Crystal Superalloy TMS-238. In Proceedings of the Superalloys 2012; Huron, E.S., Reed, R.C., Hardy, M.C., Mills, M.J., Montero, R.E., Portella, P.D., Telesman, J., Eds.; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 2012; pp. 189–195. [Google Scholar]

- Yokokawa, T.; Harada, H.; Mori, Y.; Kawagishi, K.; Koizumi, Y.; Kobayashi, T.; Yuyama, M.; Suzuki, S. Design of Next Generation Ni-base Single Crystal Superalloys Containing Ir: Towards 1150 °C Temperature Capability. In Proceedings of the Superalloys 2016; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 123–130. [Google Scholar]

- Epishin, A.; Link, T.; Klingelhöffer, H.; Fedelich, B.; Portella, P. Creep damage of single-crystal nickel base superalloys: Mechanisms and effect on low cycle fatigue. Mater. High Temp. 2010, 27, 53–59. [Google Scholar] [CrossRef]

- Epishin, A.; Link, T. Mechanisms of high-temperature creep of nickel-based superalloys under low applied stresses. Philos. Mag. 2004, 84, 1979–2000. [Google Scholar] [CrossRef]

- Charpagne, M.-A.; Billot, T.; Franchet, J.-M.; Bozzolo, N. Heteroepitaxial recrystallization: A new mechanism discovered in a polycrystalline γ-γ′ nickel based superalloy. J. Alloys Compd. 2016, 688, 685–694. [Google Scholar] [CrossRef] [Green Version]

- Medeiros, S.C.; Prasad, Y.V.R.; Frazier, W.G.; Srinivasan, R. Microstructural modeling of metadynamic recrystallization in hot working of IN 718 superalloy. Mater. Sci. Eng. A 2000, 293, 198–207. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Weaver, D.S.; Kramb, R.C.; Fagin, P.N.; Glavicic, M.G.; Goetz, R.L.; Frey, N.D.; Antony, M.M. Deformation and recrystallization behavior during hot working of a coarse-grain, nickel-base superalloy ingot material. Metall. Mater. Trans. A 2004, 35, 679–693. [Google Scholar] [CrossRef]

- Rettberg, L.H.; Pollock, T.M. Localized recrystallization during creep in nickel-based superalloys GTD444 and René N5. Acta Mater. 2014, 73, 287–297. [Google Scholar] [CrossRef]

- Murakumo, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction. Acta Mater. 2004, 52, 3737–3744. [Google Scholar] [CrossRef]

- Caron, P. High y’solvus new generation nickel-based superalloys for single crystal turbine blade applications. In Proceedings of the Superalloys 2000; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 2000; pp. 737–746. [Google Scholar]

- Royer, A.; Bastie, P.; Bellet, D.; Strudel, J.L. Temperature dependence of the lattice mismatch of the AM1 superalloy influence of the γ′ precipitates’ morphology. Philos. Mag. A 1995, 72, 669–689. [Google Scholar] [CrossRef]

- Huang, S.; An, K.; Gao, Y.; Suzuki, A. Determination of γ/γ′ Lattice Misfit in Ni-Based Single-Crystal Superalloys at High Temperatures by Neutron Diffraction. Metall. Mater. Trans. A 2018, 49, 740–751. [Google Scholar] [CrossRef]

- Pessah, M.; Caron, P.; Khan, T. Effect of µ Phase on the Mechanical Properties of a Nickel-Base Single Crystal Superalloy. In Proceedings of the Superalloys 1992; Antolovich, S.D., Stusrud, R.W., MacKay, R.A., Anton, D.L., Khan, T., Kissinger, R.D., Klarstrom, D.L., Eds.; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 1992; pp. 567–576. [Google Scholar]

- Rae, C.; Karunaratne, M.; Small, C.; Broomfield, R.; Jones, C.; Reed, R. Topologically Close Packed Phases in an Experimental Rhenium-Containing Single Crystal Superalloy. In Proceedings of the Superalloys 2000; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 2000; pp. 767–776. [Google Scholar]

- Utada, S.; Joh, Y.; Osawa, M.; Yokokawa, T.; Sugiyama, T.; Kobayashi, T.; Kawagishi, K.; Suzuki, S.; Harada, H. Creep Property and Phase Stability of Sulfur-Doped Ni-Base Single-Crystal Superalloys and Effectiveness of CaO Desulfurization. Metall. Mater. Trans. A 2018, 49, 4029–4041. [Google Scholar] [CrossRef]

- Koizumi, Y.; Yokokawa, T.; Sugiyama, T.; Yuyama, M.; Harada, H.; Kawagishi, K.; Takata, Y.; Kobayashi, T.; Sakamoto, M.; Suzuki, S. Creep and environmental properties of Ni-base single crystal superalloys, CMSX-4, CMSX-4 Plus, CMSX-10N and TMS-238. In Proceedings of the 46th Annual Conference of GTSJ; GTSJ: Kagoshima, Japan, 2018; p. B-13. [Google Scholar]

- Yeh, A.-C.; Sato, A.; Kobayashi, T.; Harada, H. On the creep and phase stability of advanced Ni-base single crystal superalloys. Mater. Sci. Eng. A 2008, 490, 445–451. [Google Scholar] [CrossRef]

- Yuan, Y.; Kawagishi, K.; Koizumi, Y.; Kobayashi, T.; Yokokawa, T.; Harada, H. Creep Deformation of a 6th Generation Ni-Base Single Crystal Superalloy at 800 °C and 735 MPa. In Proceedings of the Superalloys 2016; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2016; pp. 675–682. [Google Scholar]

- Hobbs, R.A.; Zhang, L.; Rae, C.M.F.; Tin, S. The effect of ruthenium on the intermediate to high temperature creep response of high refractory content single crystal nickel-base superalloys. Mater. Sci. Eng. A 2008, 489, 65–76. [Google Scholar] [CrossRef]

- Erickson, G.L. The Development and Application of CMSX®-10. In Proceedings of the Superalloys 1996; Kissinger, R.D., Deye, D.J., Anton, D.L., Cetel, A.D., Nathal, M.V., Pollock, T.M., Woodford, D.A., Eds.; The Minerals, Metals, & Materials Society: Pittsburg, PA, USA, 1996; pp. 35–44. [Google Scholar]

- Acharya, M.V.; Fuchs, G. The effect of long-term thermal exposures on the microstructure and properties of CMSX-10 single crystal Ni-base superalloys. Mater. Sci. Eng. A 2004, 381, 143–153. [Google Scholar] [CrossRef]

| Alloy | Co | Cr | Mo | W | Ta | Al | Ti | Nb | Re | Ru | Pt | Hf | C | B | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mar-M200+Hf | 10.0 | 9.0 | 12.5 | 5.0 | 2.0 | 1.0 | 1.6 | 0.15 | 0.015 | 0.05 | |||||

| Mar-M247LC | 9.0 | 8.0 | 0.5 | 10.0 | 3.2 | 5.6 | 0.7 | 1.4 | 0.07 | 0.015 | 0.01 | ||||

| AM1 | 6.7 | 7.6 | 2.0 | 5.6 | 8.0 | 5.3 | 1.2 | 0.05 | |||||||

| CMSX-4 | 9.7 | 6.4 | 0.6 | 6.4 | 6.5 | 5.6 | 1.1 | 2.9 | 0.10 | ||||||

| PWA1484 | 10.1 | 5.0 | 1.9 | 5.9 | 8.5 | 5.6 | 3.0 | 0.10 | |||||||

| Rene N5 | 7.5 | 7.0 | 1.5 | 5.0 | 6.5 | 6.2 | 3.0 | 0.16 | 0.05 | ||||||

| CMSX-4 Plus | 10.0 | 3.5 | 0.6 | 6.0 | 8.0 | 5.7 | 0.85 | 4.8 | 0.10 | ||||||

| Rene N6 | 12.0 | 4.0 | 1.1 | 5.9 | 6.9 | 5.6 | 5.3 | 0.19 | |||||||

| CMSX-10N | 3.0 | 1.5 | 0.4 | 5.0 | 8.0 | 5.8 | 0.1 | 0.05 | 7.0 | ||||||

| MCNG | 4.0 | 1.0 | 5.0 | 5.0 | 6.0 | 0.5 | 4.0 | 4.0 | 0.10 | ||||||

| TMS-238 | 6.5 | 4.6 | 1.1 | 4.0 | 7.6 | 5.9 | 6.4 | 5.0 | 0.10 | ||||||

| TROPEA | 8.9 | 6.4 | 0.6 | 6.1 | 9.1 | 5.4 | 1.0 | 1.0 | 1.95 | 0.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Utada, S.; Despres, L.; Cormier, J. Ultra-High Temperature Creep of Ni-Based SX Superalloys at 1250 °C. Metals 2021, 11, 1610. https://doi.org/10.3390/met11101610

Utada S, Despres L, Cormier J. Ultra-High Temperature Creep of Ni-Based SX Superalloys at 1250 °C. Metals. 2021; 11(10):1610. https://doi.org/10.3390/met11101610

Chicago/Turabian StyleUtada, Satoshi, Lucille Despres, and Jonathan Cormier. 2021. "Ultra-High Temperature Creep of Ni-Based SX Superalloys at 1250 °C" Metals 11, no. 10: 1610. https://doi.org/10.3390/met11101610

APA StyleUtada, S., Despres, L., & Cormier, J. (2021). Ultra-High Temperature Creep of Ni-Based SX Superalloys at 1250 °C. Metals, 11(10), 1610. https://doi.org/10.3390/met11101610