Formability and Magnetic Properties of the Binary Nd-Co Amorphous Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klement, W.; Willens, R.H.; Duwez, P. Non-crystalline Structure in Solidified Gold–Silicon Alloys. Nat. Cell Biol. 1960, 187, 869–870. [Google Scholar] [CrossRef]

- Suzuki, K.; Sumiyama, K.; Homma, Y.; Amano, H.; Hihara, T. A heavy fermion-type behavior of Ce-based amorphous alloys. J. Non-Cryst. Solids 1993, 156-158, 328–331. [Google Scholar] [CrossRef]

- Ma, H.; Xu, J.; Ma, E. Mg-based bulk metallic glass composites with plasticity and high strength. Appl. Phys. Lett. 2003, 83, 2793–2795. [Google Scholar] [CrossRef]

- Li, W.; Chan, K.; Xia, L.; Liu, L.; He, Y. Thermodynamic, corrosion and mechanical properties of Zr-based bulk metallic glasses in relation to heterogeneous structures. Mater. Sci. Eng. A 2012, 534, 157–162. [Google Scholar] [CrossRef]

- Kim, K.-H.; Lee, S.-W.; Ahn, J.-P.; Fleury, E.; Kim, Y.-C.; Lee, J.-C. A Cu-based amorphous alloy with a simultaneous improvement in its glass forming ability and plasticity. Met. Mater. Int. 2007, 13, 21–24. [Google Scholar] [CrossRef]

- Wang, W.H. Bulk metallic glasses with functional physical properties. Adv. Mater. 2009, 21, 4524–4544. [Google Scholar] [CrossRef]

- Luo, Q.; Wang, W.H. Magnetocaloric effect in rare earth-based bulk metallic glasses. J. Alloys Compd. 2010, 495, 209–216. [Google Scholar] [CrossRef]

- Wang, X.; Ding, D.; Cui, L.; Xia, L. Compositional dependence of curie temperature and magnetic entropy change in the amorphous Tb–Co ribbons. Materials 2021, 14, 1002. [Google Scholar] [CrossRef]

- Zhang, H.; Li, R.; Zhang, L.; Zhang, T. Tunable magnetic and magnetocaloric properties in heavy rare-earth based metallic glasses through the substitution of similar elements. J. Appl. Phys. 2014, 115, 133903. [Google Scholar] [CrossRef]

- Wu, C.; Ding, D.; Xia, L.; Chan, K.C. Achieving tailorable magneto-caloric effect in the Gd-Co binary amorphous alloys. AIP Adv. 2016, 6, 035302. [Google Scholar] [CrossRef] [Green Version]

- Yuan, F.; Li, Q.; Shen, B. The effect of Fe/Al ratio on the thermal stability and magnetocaloric effect of Gd55FexAl45-x (x = 15–35) glassy ribbons. J. Appl. Phys. 2012, 111, 7. [Google Scholar] [CrossRef]

- Álvarez, P.; Gorria, P.; Marcos, J.S.; Barquín, L.F.; Blanco, J.A. The role of boron on the magneto-caloric effect of FeZrB metallic glasses. Intermetallics 2010, 18, 2464–2467. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Tang, B.Z.; Yu, P.; Xia, L.; Ding, D. Large magnetic entropy change and adiabatic temperature rise of a ternary Gd34Ni33Al33 metallic glass. J. Rare Earths 2021, 39, 998–1002. [Google Scholar] [CrossRef]

- Zhong, X.C.; Tian, H.C.; Wang, S.S.; Liu, Z.W.; Zheng, Z.G.; Zeng, D.C. Thermal, magnetic and magnetocaloric properties of Fe80-xMxB10Zr9Cu1 (M = Ni, Ta; x = 0, 3, 5) amorphous alloys. J. Alloys Compd. 2015, 633, 188–193. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Tang, B.Z.; Ding, D.; Li, C.; Xia, L. Magnetic and magneto-caloric properties of the amorphous Fe92-xZr8Bx ribbons. Materials 2020, 13, 5334. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.-B.; Zhang, L.-L.; Zhang, X.-F.; Li, Y.-F.; Zhao, Q.; Zhao, T.-Y.; Shen, B.-G. Tunable Curie temperature around room temperature and magnetocaloric effect in ternary Ce–Fe–B amorphous ribbons. J. Phys. D Appl. Phys. 2016, 50, 15002. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, T.; Zhang, W.; Takeuchi, A. Bulk Nd-Fe-Al amorphous alloys with hard magnetic properties. Mater. Trans. JIM 1996, 37, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Xia, L.; Ding, D.; Shan, S.T.; Dong, Y.D. Evaluation of the thermal stability of Nd60Al20Co20 bulk metallic glass. Appl. Phys. Lett. 2007, 90, 111903. [Google Scholar] [CrossRef]

- Xia, L.; Dong, Y.D. Glass forming ability and kinetic characters of paramagnetic Nd60Co40-xAlx(x = 5, 10, 15) bulk metallic glasses. Mod. Phys. Lett. B 2004, 18, 679–685. [Google Scholar] [CrossRef]

- Xia, L.; Fang, S.S.; Jo, C.L.; Dong, Y.D. Glass forming ability and microstructure of hard magnetic Nd60Al20Fe20 glass forming alloy. Intermetallics 2006, 14, 1098–1101. [Google Scholar] [CrossRef]

- Pan, M.X.; Wei, B.C.; Xia, L.; Wang, W.H.; Zhao, D.Q.; Zhang, Z.; Han, B.S. Magnetic properties and microstructural characteristics of bulk Nd–Al–Fe–Co glassy alloys. Intermetallics 2002, 10, 1215–1219. [Google Scholar]

- Lu, Y.; Bai, Q.; Bian, L.; Xu, H.; Xia, S. Effect of Ce addition on the glass-forming ability and hard-magnetic properties of the Nd-Fe-Al bulk metallic glasses. J. Non-Cryst. Solids 2016, 455, 24–28. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, B.; Chan, K.; Tang, M.; Ding, D.; Xia, L. Magnetocaloric effect and magnetostriction of a binary Nd50Co50 metallic glass. J. Non-Cryst. Solids 2021, 571, 121076. [Google Scholar] [CrossRef]

- Hussain, A.; Van Ende, M.A.; Kim, J.; Jung, I.H. Critical thermodynamic evaluation and optimization of the Co-Nd, Cu-Nd and Nd-Ni systems. Calphad 2013, 41, 26–41. [Google Scholar] [CrossRef]

- Turnbull, D. Under what conditions can a glass be formed? Contemp. Phys. 1969, 10, 473–488. [Google Scholar] [CrossRef]

- Lu, Z.P.; Liu, C.T. Glass formation criterion for various glass-forming systems. Phys. Rev. Lett. 2003, 91, 115505. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Ma, L.Y.; Tang, B.Z.; Chan, K.C.; Zhao, L.; Tang, M.B.; Ding, D.; Xia, L. Formability and magnetic properties of Dy-Co binary amorphous alloys. AIP Adv. 2018, 8, 075215. [Google Scholar] [CrossRef] [Green Version]

- Speliotis, T.; Niarchos, D. Extraordinary magnetization of amorphous TbDyFe films. Microelectron. Eng. 2013, 112, 183–187. [Google Scholar] [CrossRef]

- Luo, Q.; Schwarz, B.; Mattern, N.; Eckert, J. Irreversible and reversible magnetic entropy change in a Dy-based bulk metallic glass. Intermetallics 2012, 30, 76–79. [Google Scholar] [CrossRef]

- Wang, X.; Chan, K.C.; Zhao, L.; Ding, D.; Xia, L. Microstructure and its effect on the magnetic, magnetocaloric and magnetostrictive properties of Tb55Co30Fe15 glassy ribbons. Materials 2021, 14, 3068. [Google Scholar] [CrossRef] [PubMed]

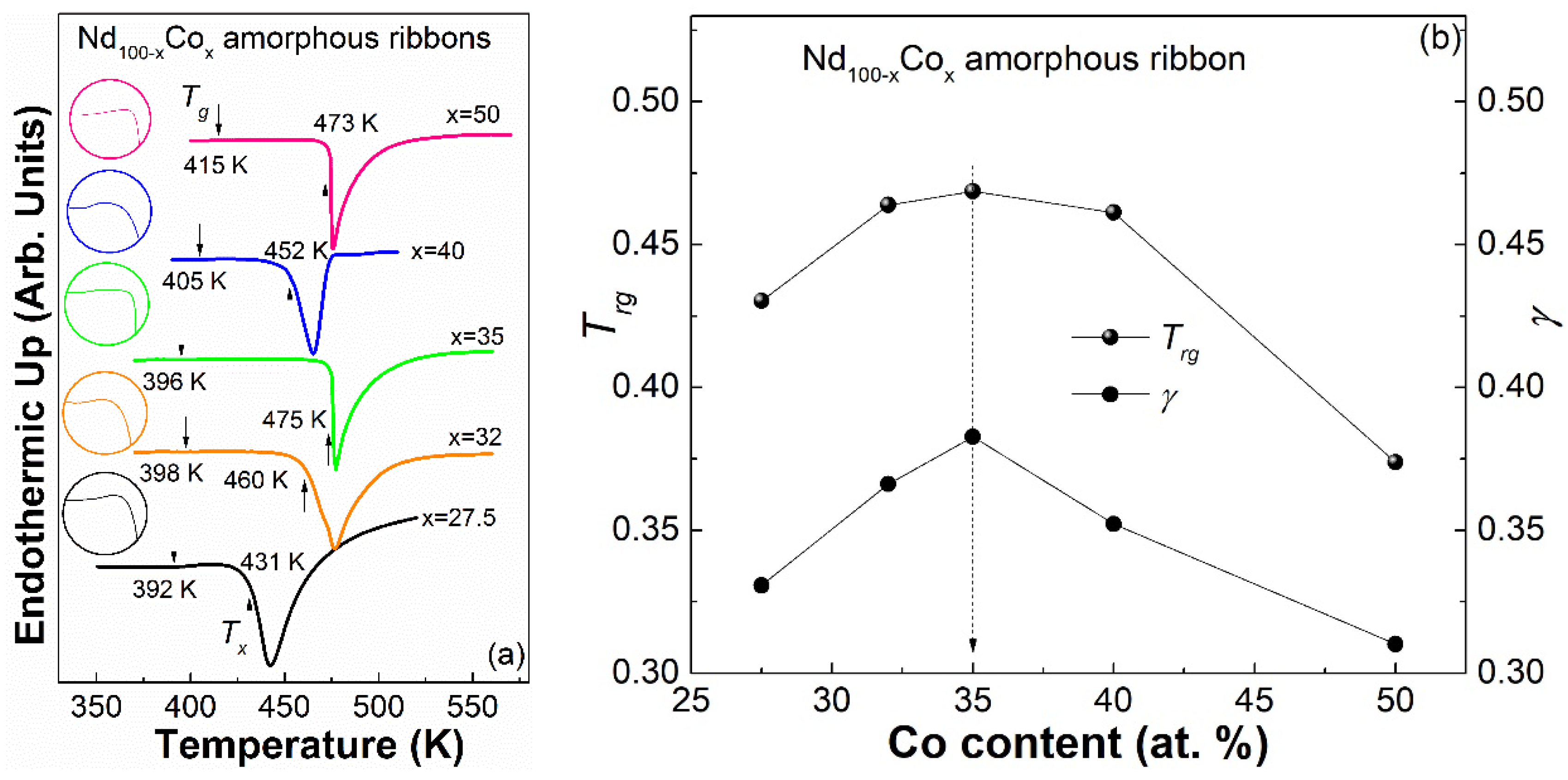

| Nd100−xCox Amorphous Ribbon | Tg (K) | Tx (K) | Tl (K) | Trg | γ |

|---|---|---|---|---|---|

| x = 27.5 | 392 | 431 | 911 | 0.430 | 0.331 |

| x = 32 | 398 | 460 | 858 | 0.464 | 0.366 |

| x = 35 | 396 | 475 | 845 | 0.469 | 0.383 |

| x = 40 | 405 | 452 | 878 | 0.461 | 0.352 |

| x = 50 | 415 | 473 | 1110 | 0.374 | 0.310 |

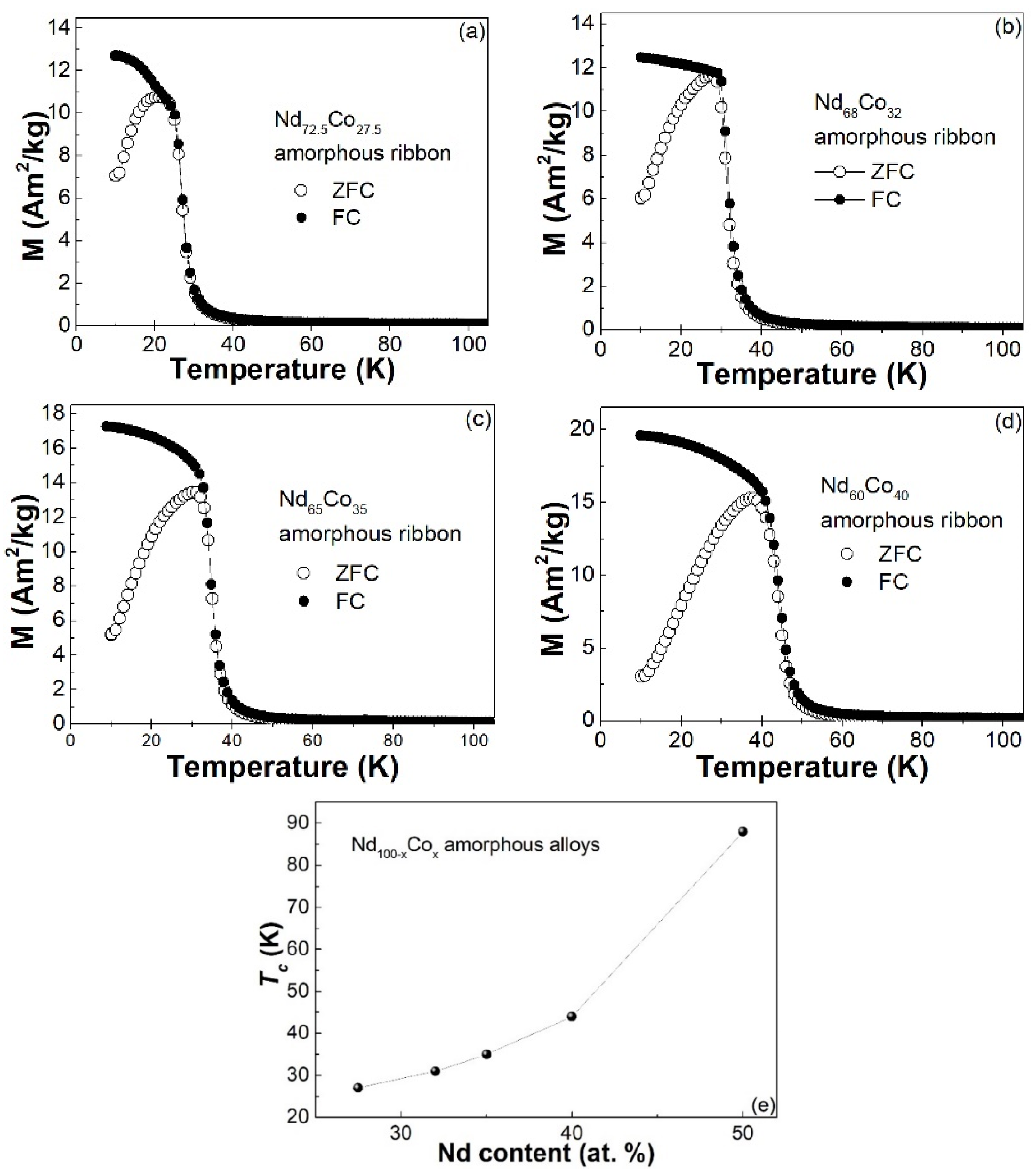

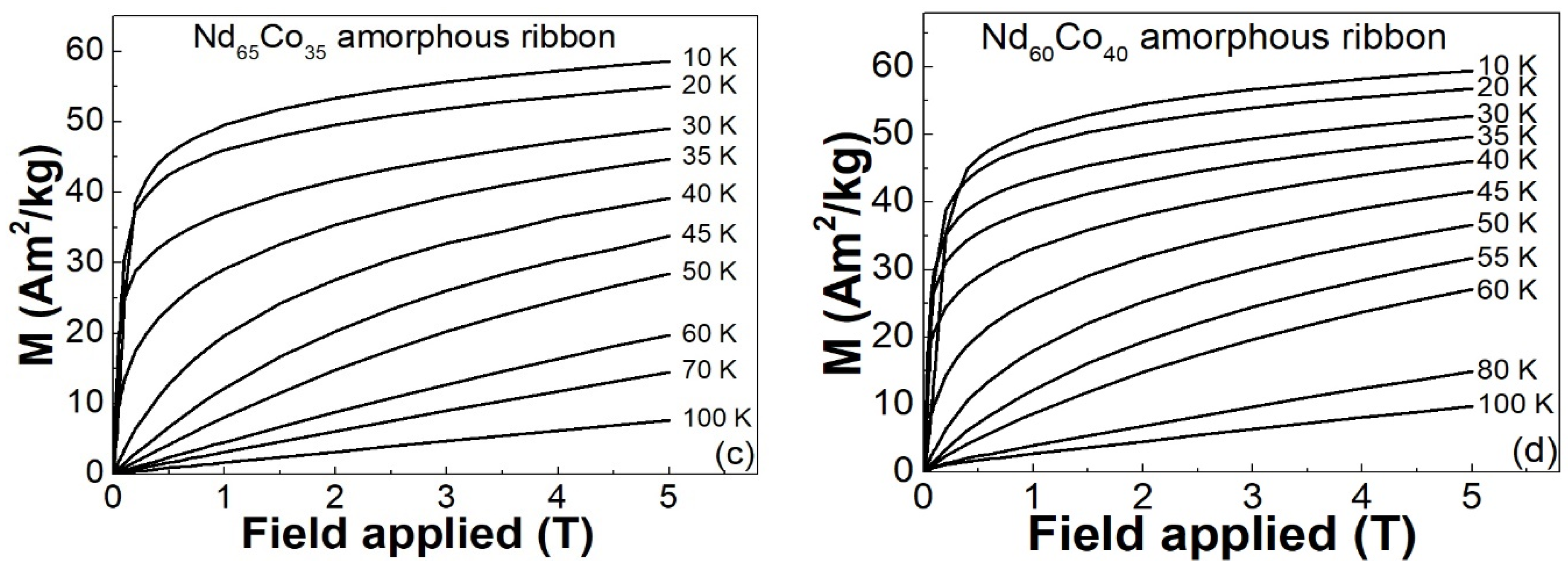

| Nd100−xCox Amorphous Ribbon | Tc (K) | Tf (K) | −ΔSmpeak (J/(kgK)) | RC under 5 T (J/kg) | |

|---|---|---|---|---|---|

| 1.5 T | 5 T | ||||

| x = 27.5 | 27 | 21 | 2.95 | 7.38 | 214.02 |

| x = 32 | 31 | 27 | 3.10 | 7.53 | 199.55 |

| x = 35 | 35 | 30 | 2.93 | 7.59 | 197.34 |

| x = 40 | 44 | 37 | 2.36 | 6.29 | 182.41 |

| x = 50 | 88 | 61 | 1.54 | 4.18 | 231.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Ding, D.; Xia, L. Formability and Magnetic Properties of the Binary Nd-Co Amorphous Alloys. Metals 2021, 11, 1730. https://doi.org/10.3390/met11111730

Wang Q, Ding D, Xia L. Formability and Magnetic Properties of the Binary Nd-Co Amorphous Alloys. Metals. 2021; 11(11):1730. https://doi.org/10.3390/met11111730

Chicago/Turabian StyleWang, Qiang, Ding Ding, and Lei Xia. 2021. "Formability and Magnetic Properties of the Binary Nd-Co Amorphous Alloys" Metals 11, no. 11: 1730. https://doi.org/10.3390/met11111730

APA StyleWang, Q., Ding, D., & Xia, L. (2021). Formability and Magnetic Properties of the Binary Nd-Co Amorphous Alloys. Metals, 11(11), 1730. https://doi.org/10.3390/met11111730