Abstract

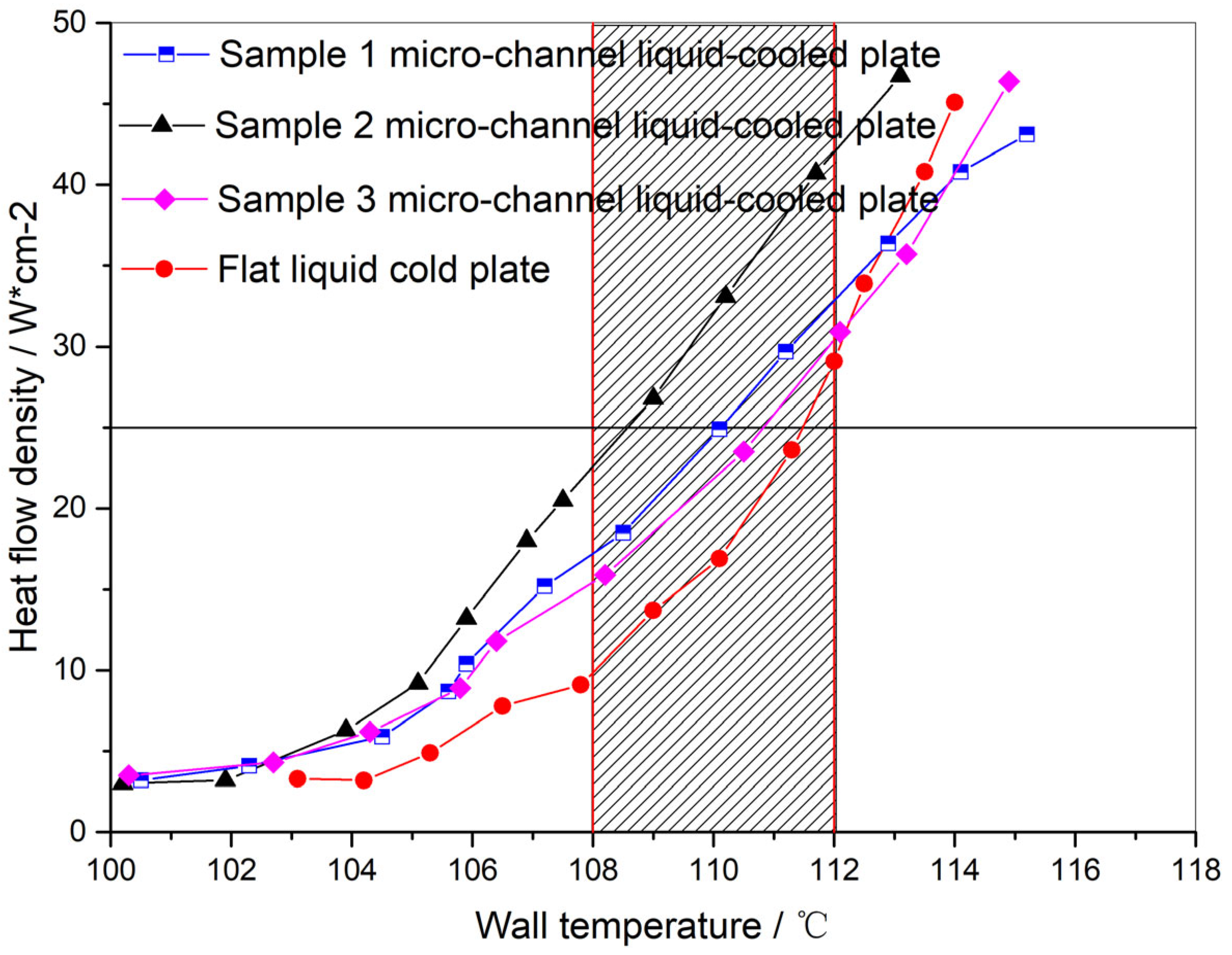

The additive manufacturing technology of laser-based powder bed fusion (L-PBF), which is used to produce boiling heat transfer structures, offers a high processing flexibility and can provide lattice structures with a high surface-to-volume ratio. As an important part of the phased array radar, the plentiful transmit/receive (T/R) modules can generate considerable heat. Targeting this local overheating problem, this study discusses the pass design, the optimal formation process, and boiling heat transfer performance of microchannel liquid-cooled plates based on L-PBF additive manufacturing technology. The optimum design and process parameters were obtained by performing basic channel experiments. On this basis, the design and formation experiments of the microchannel structure were performed, and then the porosity and pore morphology of microchannel liquid-cooled plate samples were analysed. The boiling heat transfer experiments were conducted with deionised water, and the boiling heat transfer characteristics were compared with the saturated boiling curve of a traditional copper-tube liquid-cooled plate. The average wall temperature of the designed samples decreased by 4% compared with that of the traditional liquid-cooled plate under the same heat flow density the value reduced from 111.9 °C to 108.2 °C. Furthermore, within the same optimal boiling temperature range, the average heat flow densities of all the prepared samples increased by >60% compared with those of the traditional liquid-cooled plate the value increased from minimum 16 W∙cm−2 to maximum 34 W∙cm−2. The self-supporting microchannel structure can considerably improve the heat dissipation effect of T/R modules and solve the local overheating problem.

1. Introduction

In the past few decades, considerable progress has been made in the field of heat exchangers/radiators, but many problems persist in heat dissipation for small devices mainly due to an increase in power density [1]. Gas/liquid two-phase boiling heat transfer can remove more heat than single-phase convective heat transfer and has become a primary research direction of heat dissipation [2]. With rising requirements for heat dissipation, liquid cooling technology is increasingly used. Traditional single-phase liquid cooling technology exhibits nonideal performance under high heat fluxes. By contrast, pool boiling, phase-change liquid cooling technology, presents a high heat transfer efficiency and plays a critical role in high-power equipment cooling [3]. In recent years, with its high machining flexibility, laser-based powder bed fusion (L-PBF), a type of additive manufacturing technology, is used to form radiators with a modified structural design [4]. Additive manufacturing technology follows a designed digital model and is used to print various parts and products through the superposition of different materials [5]. It is advanced manufacturing technology based on the principle of layered manufacturing. As a product of multi-disciplinary integration of information technology, new material technology, and manufacturing technology, additive manufacturing is avidly pursued by manufacturing powers worldwide [6,7]. Additive manufacturing offers outstanding advantages in the customisation of structural parts, complex structure manufacturing, and rapid development [8,9,10]. L-PBF [11,12] powder additive manufacturing is advanced manufacturing technology developed in the 1990s. In L-PBF, according to the additive manufacturing principle, a computer aided design (CAD) model is sliced and layered, and a numerical control system controls the laser to scan according to the path determined using layering software. By melting metal powders with a high-power laser and stacking them layer by layer, die-free, rapid, completely dense, and near-net formation can be realised for high-performance metal parts with complex structures [13,14]. Parts formed using L-PBF have a higher surface roughness than those manufactured by following traditional methods. These characteristics make L-PBF uniquely advantageous in radiator manufacturing. For the manufacturing of complex microporous structures, the L-PBF process can achieve an extreme fine feature with a diameter of 90 mu m in stable process control, and the process parameters with their control strategies as well as the printing process planning have an important impact on the printing results. Ding L P [15] first studied the manufacturability of the ultra-fine pore structure of SLM, and discussed the manufacturability analysis of the fine porous structure and the control method of printing parameters.

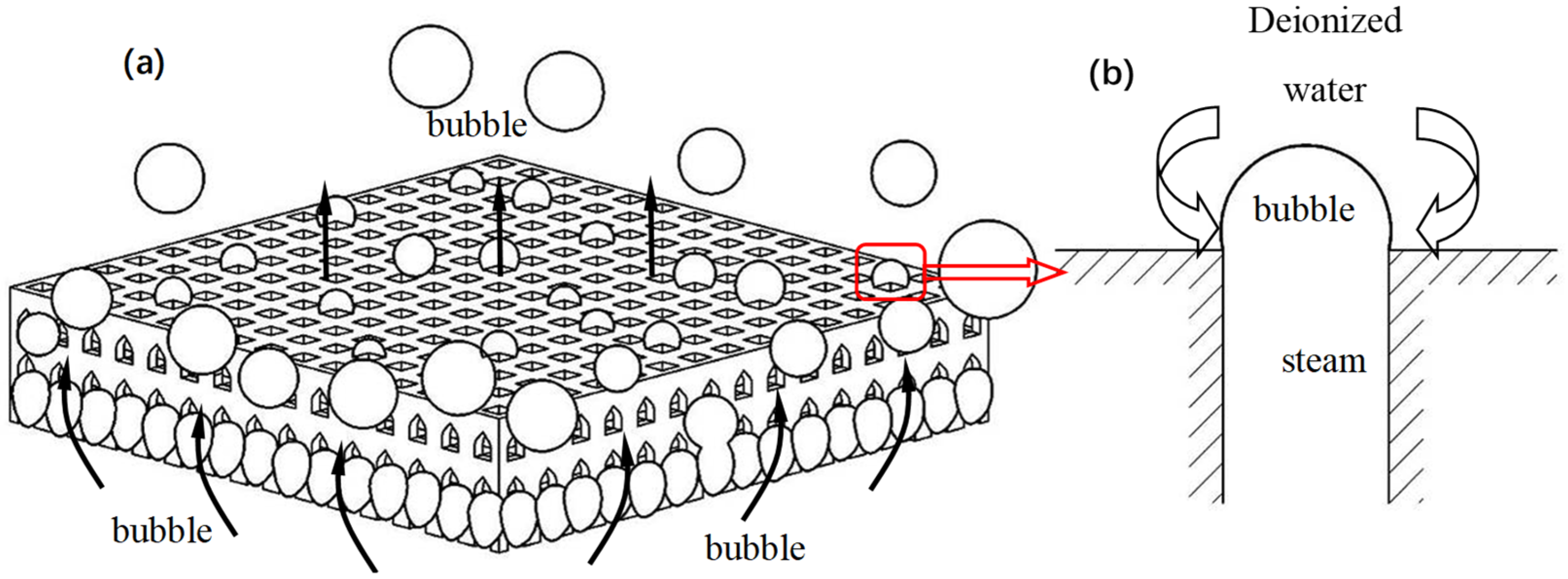

With a high surface-to-volume ratio, the microchannel structure can increase the solid–liquid contact area and form highly potential nucleation sites, which reduce initial boiling temperature and considerably enhance the pool boiling heat transfer effect. Furthermore, microchannels can serve as bubble-escaping and liquid-replenishing paths, thereby delaying the critical heat flux (CHF) [16]. The activated holes in the porous layer produce bubble nuclei, and a liquid film layer is formed between the bubble nuclei and solid. When heat is transferred from the solid contact surface to liquid film layer, this liquid film layer absorbs the heat and evaporates, which facilitates bubble growth until the bubble escapes from the hole and transfers the heat to the liquid. Afterwards, the liquid comes into contact with the heating surface, and then the next bubble nucleus forms in the activated hole, followed by bubble nucleation and growth, that is, cycle completion [17,18].

With the rapid development of large-scale integration, heat generated per unit surface area of electronic devices sharply increases, making thermal design challenging. With their poor working environment, high reliability requirements, small volume, and light weight, military radars and weapon systems, in particular, have a strict demand for circuit integration and thermal design. Under these circumstances, microchannel heat dissipation structures exhibit substantial application advantages. Microchannel heat dissipation technology plays an important role in solving the heat dissipation problem of highly integrated electronic equipment and improving the performance and reliability of microelectronic devices. In a phased array radar, nearly 1000 transmit/receive (T/R) modules are distributed on an antenna array. The T/R module is equipped with power amplifier components having different transmission powers, and the maximum heat consumption of a single T/R module can be as high as 30 W. Limited by the antenna box size, the inside layout is considerably compact, which results in harsh ventilation and heat dissipation conditions. Therefore, a reasonable heat dissipation design is essential to ensure the normal operation of T/R modules. Traditional copper-tube liquid-cooled plates, which are prepared with a restricted method described below, have poor heat transfer performance. First, the general frame of the component is milled from thick metal materials, the flow channel shape is milled on the rib plate in the middle, and then the channel cover plate is brazed. Large-area brazing is costly and increases the coolant leakage risk. To minimise the cost of the coolant channel while improving its pressure bearing capacity and corrosion resistance, red copper tube is embedded in the cooling plate to avoid direct contact between the aluminium alloy and coolant. Red copper has excellent corrosion resistance and can ensure long-term stable operation of the system. Compared with the structures of the parts prepared using the traditional method, the porous structure formed with L-PBF has an accurate and controllable interior. In addition, powders bonded on the structure surface can generate numerous potential nucleation sites. Many scholars have conducted detailed research on this topic. Ameli M et al. [19] used L-PBF technology to produce an entire heat transfer tube in one step, including the end cap, tube wall, and lattice core structure, verifying its feasibility in controlling the thickness, porosity, permeability, and pore diameter of different areas in the heat pipe core. However, the heat transfer effect of the heat pipe was not explored further. The material used for the heat pipe was Al6061, which was previously not used to manufacture heat pipe cores as aluminium powder sintering was highly complex. Ho J Y et al. [20] employed AlSi10 Mg powders for L-PBF to obtain microcavities/fin surfaces and performed the boiling heat transfer experiment with FC-72 as the working medium. Compared with those of the Al6061 plate, the heat transfer coefficient and CHF of the L-PBF-formed microstructure surface substantially improved. Specifically, the maximum heat transfer coefficient of the L-PBF-formed surface was 1.27 W∙(cm2∙°C)−1, and its average heat transfer coefficient was over 70% higher than that of the Al6061 plate. The highest CHF of the L-PBF-formed surface was 47.90 W∙cm−2, which was enhanced by 76%. Currently, in the heat transfer field, L-PBF is applied to single-phase heat transfer, with limited studies on L-PBF-formed porous structures for boiling heat transfer.

Therefore, to solve the problem of local overheating in T/R modules and contribute to flexible manufacturing processes in the complex internal structures of new liquid-cooled plates, this study investigated the preparation and heat dissipation and transfer performance of microchannel liquid-cooled plates based on L-PBF additive manufacturing. Through comparison, efficient heat transfer and dissipation structures with high strength under the volume limit were determined. The optimised self-supporting microchannel structure and design parameters were adopted to ensure the overall strength when realising efficient fluid heat transfer. First, the basic channel experiment was conducted to obtain the optimum design and process parameters. On the basis of these, the design and formation experiments of the microchannel structure were conducted, followed by the analysis of the porosity and pore morphology of the samples. The boiling heat transfer experiment was performed with deionised water, and the results were compared with the saturated boiling curve of plates. Furthermore, the influences of process parameters on the enhancement of boiling heat transfer were studied.

The use of L-PBF technology to form microchannel liquid-cooled structures for boiling heat transfer presents considerable study values. However, the porous structures formed with L-PBF are currently mostly used as medical implants or lightweight parts for aerospace [21], and the research is focused on the improvement of mechanical properties [22,23] and the lightweight structure forming process and structure optimization [24,25] with few studies on L-PBF-formed porous structures for boiling heat transfer. Therefore, this study, the first systematic investigation on the application of L-PBF-formed controllable microchannel structures in the boiling heat transfer process, combined the L-PBF formation of microchannel liquid-cooled structures with the requirements of boiling heat transfer. Considering the requirements for strengthening boiling heat transfer, the design of microchannel structures formed using L-PBF was explored. The effects of the structure on bubble-escape and liquid-replenishment processes during boiling heat transfer were analysed to explain why different structures exhibit varying levels of boiling heat transfer enhancement. Furthermore, the porous liquid-cooled structure with high CHF was obtained, and the optimal structure under different heat flux requirements was acquired, which provided a comprehensive reference for manufacturing liquid-cooled plates in T/R modules.

2. Experimental Method and Material

2.1. L-PBF Experimental Facility

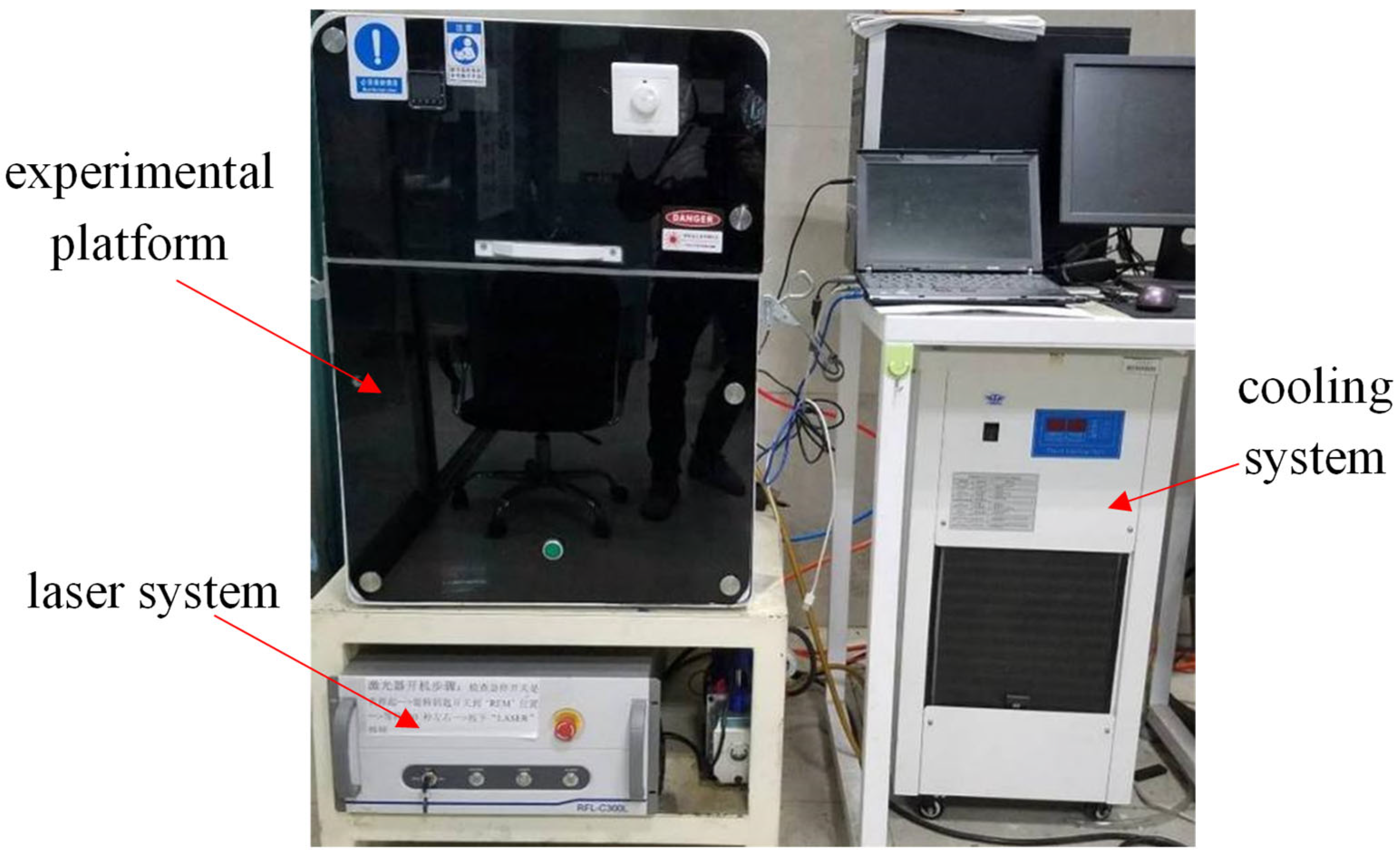

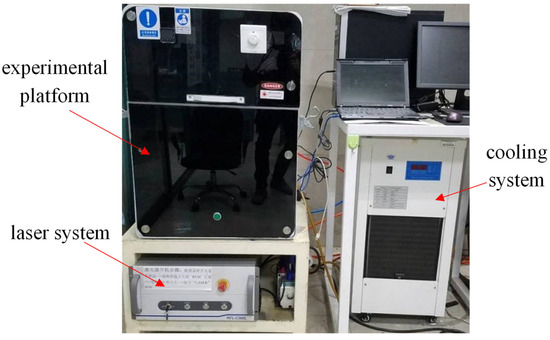

As shown in Figure 1, the L-PBF experimental platform constituted a host, a laser system, a cooling system, a control system, and a gas protection system. The laser was an RFL-C300L continuous-wave fibre laser (Raycuslaser Ltd., Wuhan, China). Its parameters are presented in Table 1. The printer had a formation size of 80 mm × 80 mm × 60 mm and adopted the impact powder dropping mode.

Figure 1.

L-PBF experimental facility.

Table 1.

Primary working parameters of the laser machine.

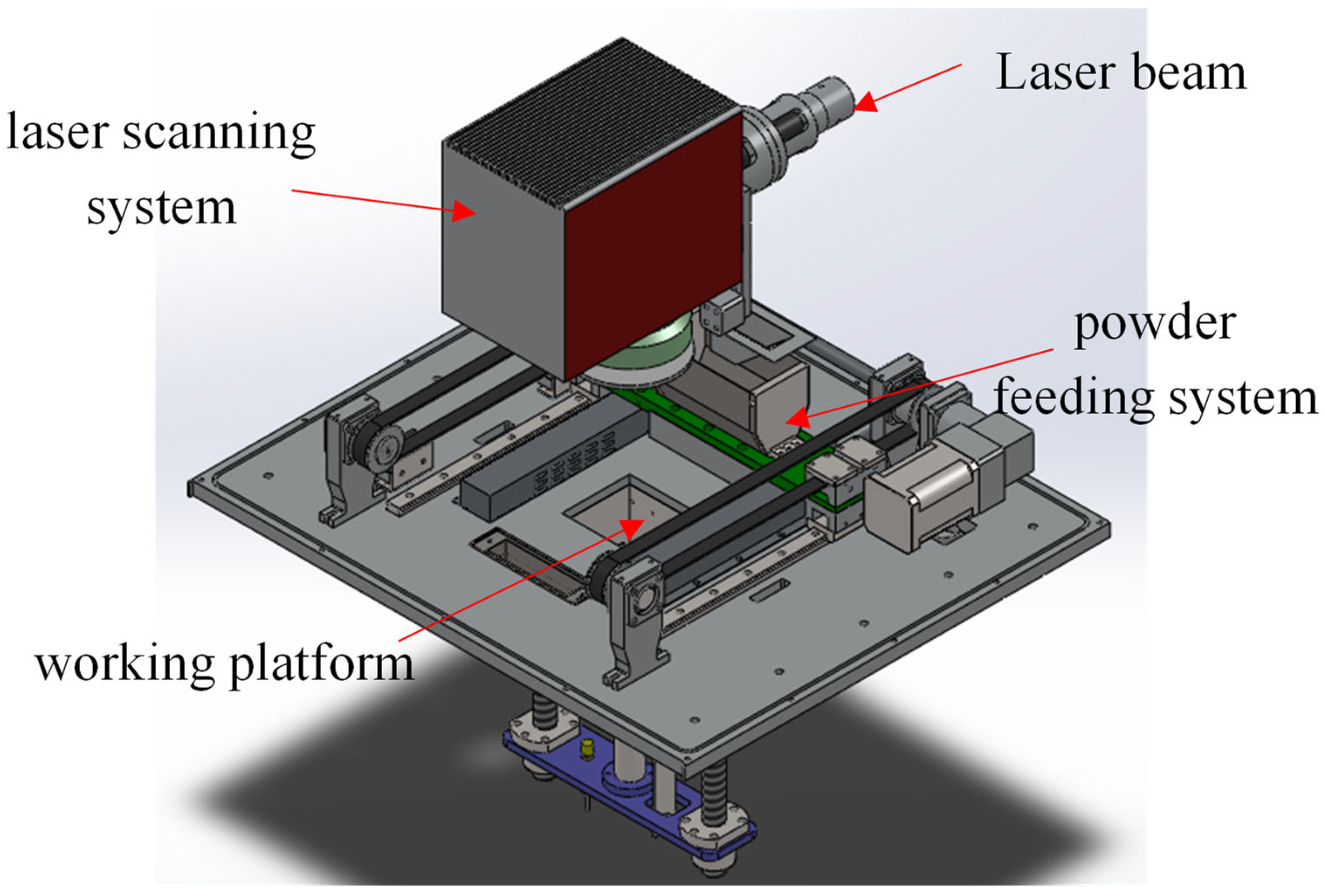

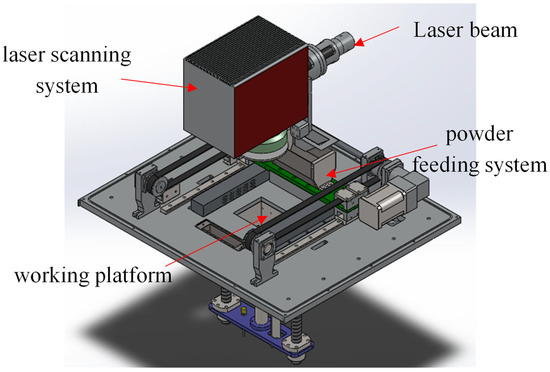

The schematic diagram of the host is shown in Figure 2. The host constituted a working platform, a powder feeding system, and a laser scanning system. For L-PBF, the experimental platform could be vacuumed or filled with a protective gas according to the material and processing requirements to prevent the oxidation or burning of metal powders during melting and solidification.

Figure 2.

L-PBF equipment.

2.2. Experimental Platform and Calculation Method of Boiling Heat Transfer

Boiling heat transfer is convective heat transfer process in which heat is transferred from the wall to the liquid to make the liquid boil and vaporize. When the heating surface temperature Tw exceeds the saturation temperature TS of the liquid and reaches a certain value, the liquid forms vapor bubbles at certain points on the heating surface. The vapor bubbles absorb a large amount of latent heat of vaporization during the formation and growth process, and the vapor bubbles depart and rise. The movement produces severe disturbances, so the boiling heat transfer is stronger than the convective heat transfer of a single-phase fluid. If the liquid has reached the saturation temperature, the vapor bubble will continue to absorb heat and grow until it escapes the liquid surface. At this time, it is called saturated boiling or nucleate boiling. With the increase of the heat flux density q passing through the heating surface, the vaporization core increases until the generated vapor bubbles are too late to escape and connect to form a vapor film. The heat transfer coefficient is greatly reduced, and the wall temperature rises sharply, so the heat flux density at the time of nucleate boiling begins to form Called the critical heat flux (CHF) [17].

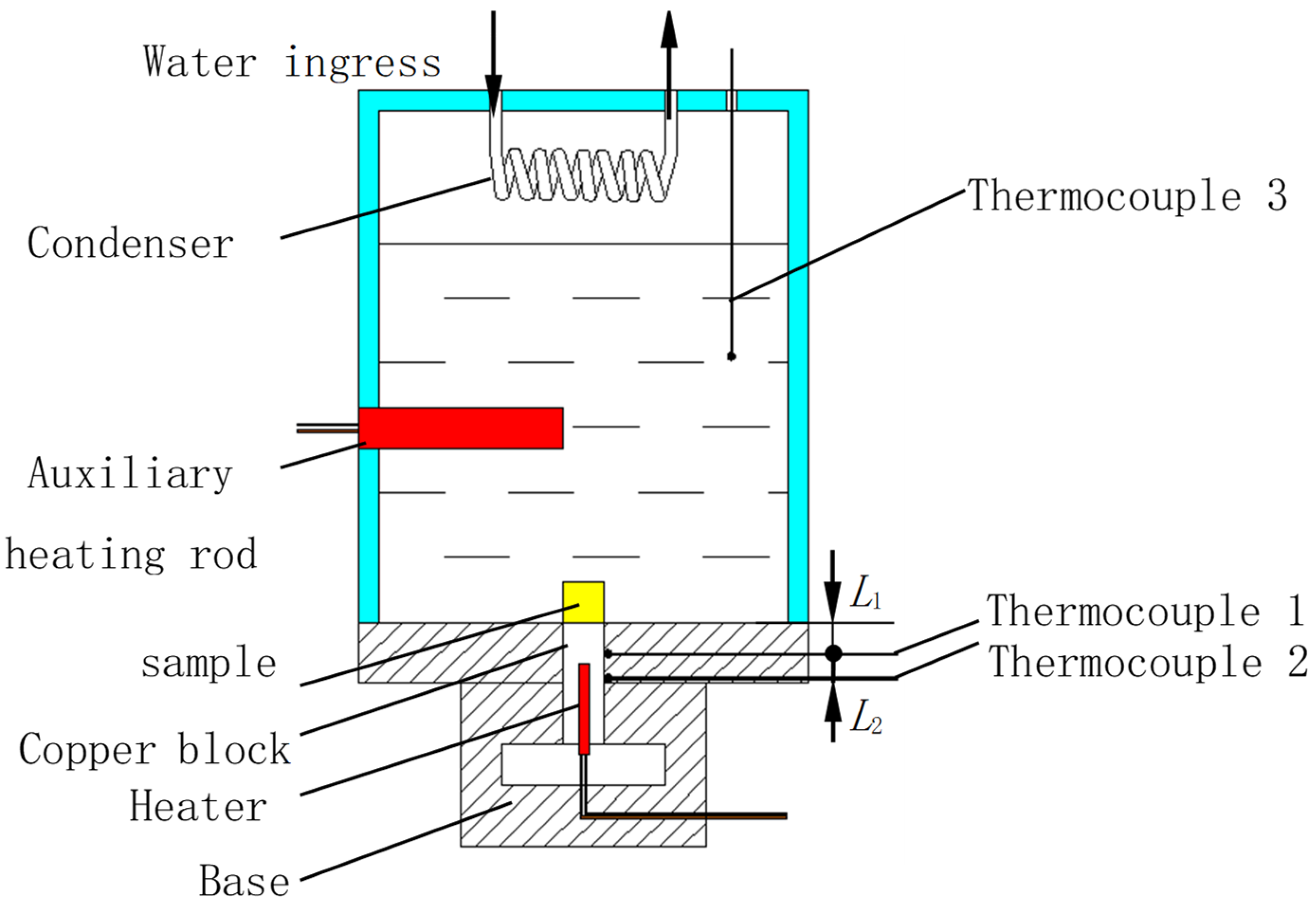

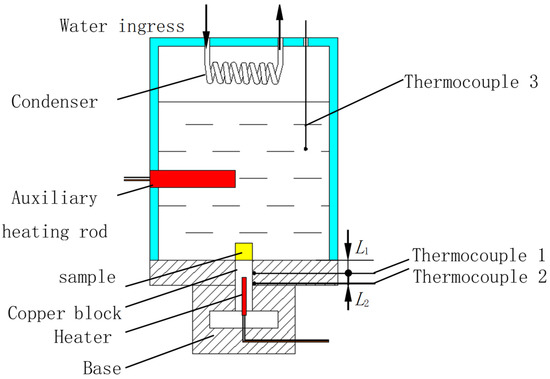

The experimental platform of boiling heat transfer included a boiling heat transfer test device, an auxiliary heating control device, a main heating control device, and a data acquisition device (Figure 3). The auxiliary heating control device used an alternating-current (AC) transformer to control its rod power to maintain the boiling working medium in the saturated boiling state. The main heating control device provided different heat fluxes to the sample by adjusting the power of the main heating rod. A K-type thermocouple was connected to the data acquisition device for temperature acquisition. The experimental setup of boiling heat transfer comprised a main container, a condensing tube, thermocouples, an insulating base, and heating rods. The main container was made of transparent materials and comprised a glass container and upper and lower cover plates. The upper cover plate had opening holes to allow the steam to escape. The main heater, comprising a heating rod and a copper block, was placed on the base. The heating rod was inserted into the copper block to heat it, and heat insulation materials were filled between the copper block and base. The sample was placed on the copper block, fastened with steel wires, and was completely immersed in the liquid. Two thermocouples, T1 and T2, were successively placed on the copper block to calculate the heat flux and upper wall temperature of the copper block. Thermocouple T3 was used to measure water temperature. An auxiliary heating rod and a condensing tube were installed for preheating and condensing, respectively. The following steps were used in the boiling heat transfer experiment: Add the boiling working medium into the container, adjust the power of the auxiliary heating rod, and heat the liquid in the container to the saturated boiling point for approximately 30 min to eliminate non-condensable gases and the gases present in sample pores. Turn on the main heater to a specific power and record the temperature data collected by the thermocouples when the system reaches the quasi-steady state. Gradually increase the heating power of the main heating rod, monitor whether the data of the thermocouples attains the stable state, and record the collected data.

Figure 3.

Experimental setup for boiling heat transfer.

The heat flux q/W∙cm−2 is calculated as:

The wall temperature Tw/°C of the copper block is calculated as [26]:

The temperature measurement error of the K-type thermocouple was ±0.2 °C, and the length measurement error of the vernier caliper was ±0.01 mm.

2.3. Experimental Material

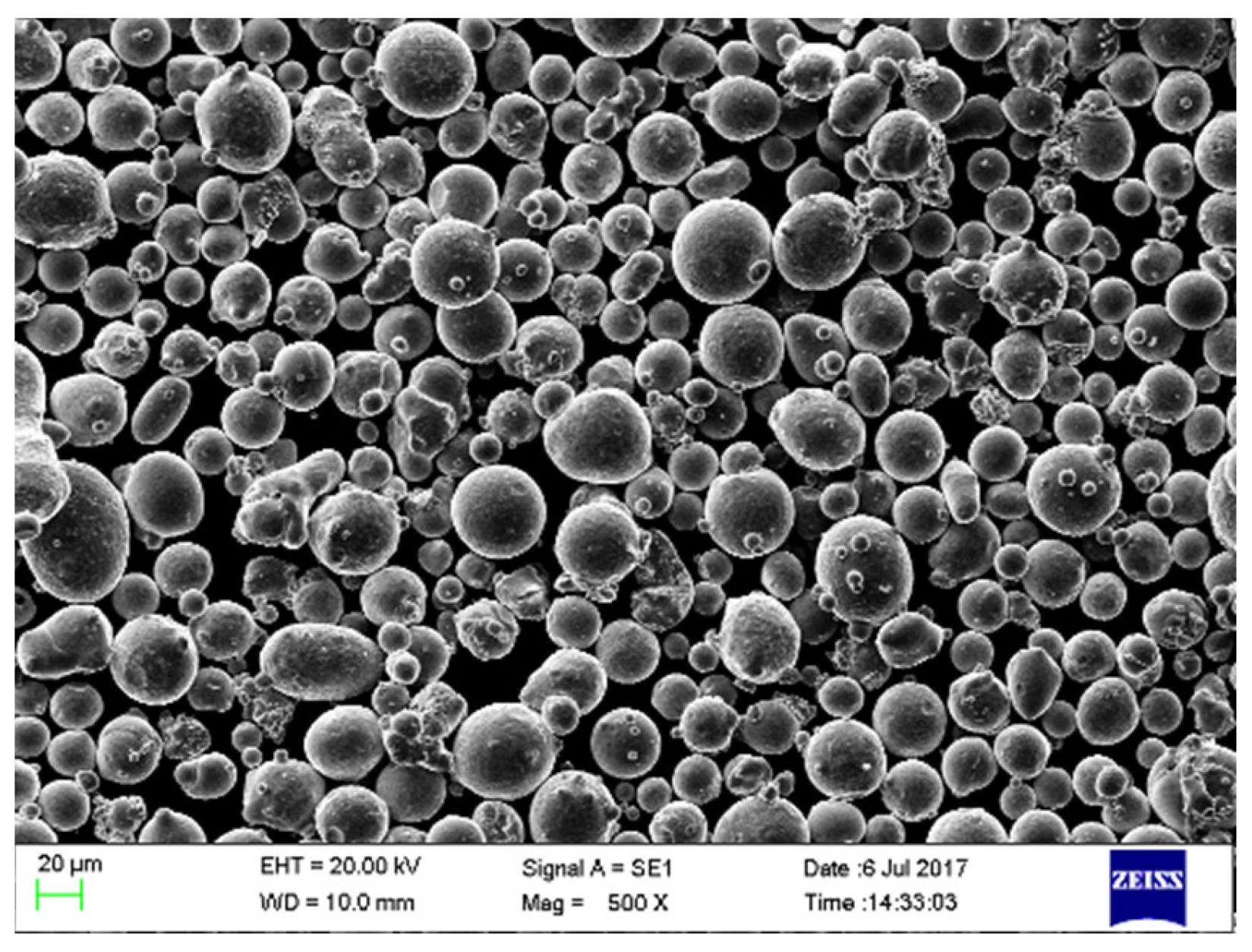

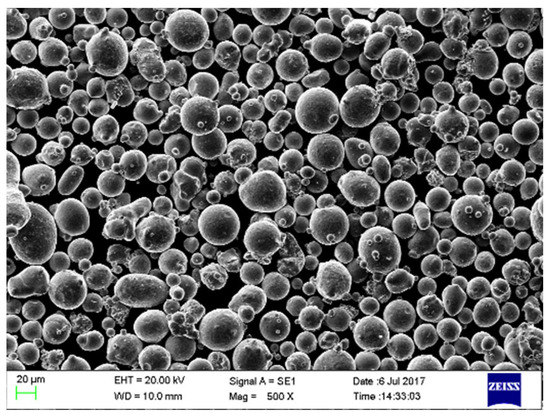

The experimental material used was a 316L stainless steel powder. Its micromorphology is shown in Figure 4, and its chemical composition and particle size composition are presented in Table 2.

Figure 4.

Scanning electron microscope (SEM) image of the 316L stainless steel powder.

Table 2.

Chemical composition and particle size distribution of the 316L stainless steel powder.

3. Microchannel Design and Process Parameter Selection

3.1. Self-Supporting Pass Design and Process Parameter Selection

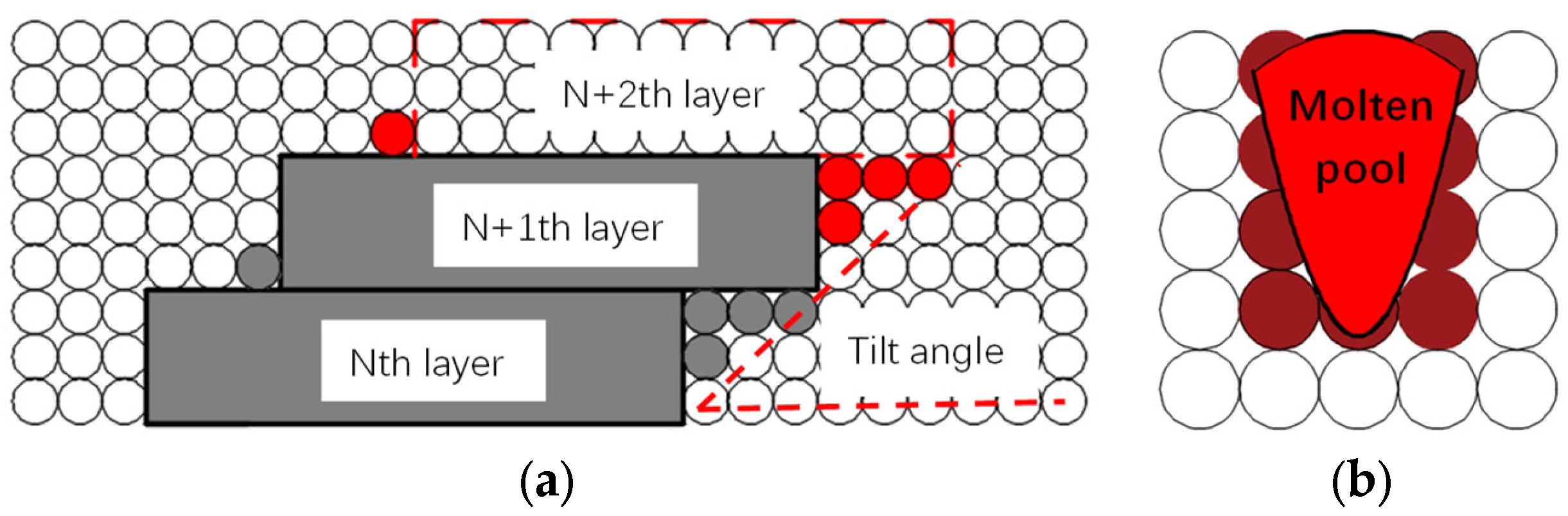

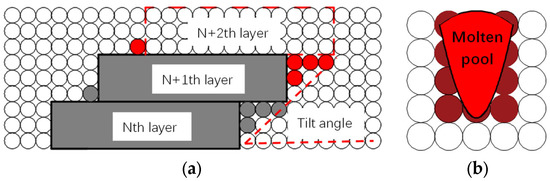

L-PBF provides parts in a layered process. For the inclined planes, the manufacturing accuracy is influenced by the step effect, as shown in Figure 5a. A decrease in the layer thickness can increase the printing accuracy however, the printing time also increases. As shown in Figure 5b, when printing a suspended surface, the laser directly irradiates and penetrates the powders. Due to the poor heat dissipation of the powders, the energy accumulates, and slags are formed. Therefore, support must be added to the surface with a small inclination angle and suspended surfaces for facilitating the effective combination of layers in the case of inclined surfaces and providing heat conduction paths for suspended surfaces. The use of support circumvents the warping of components due to thermal deformation [24,27] and enables L-PBF technology to provide parts with arbitrary geometries. However, when the disassembly of supports is restricted, their use may compromise the functions of the parts and result in rough surfaces after support removal. The pore size of the microchannel structure for boiling heat transfer is generally small; thus, support removal may be difficult, which makes support-free manufacturing necessary.

Figure 5.

Formation of surfaces with no support. (a) Inclined surface with no support, (b) horizontal surface with no support.

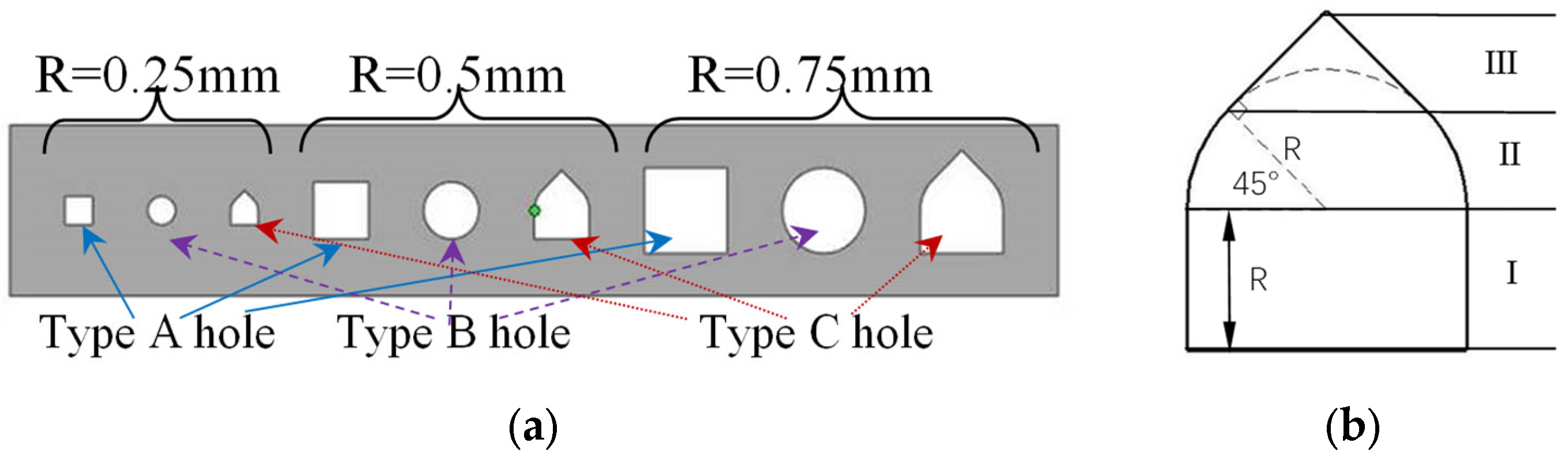

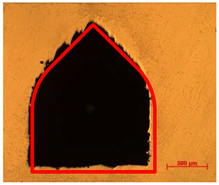

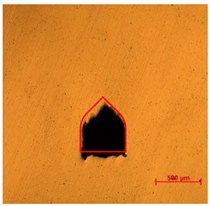

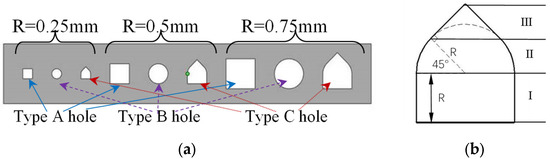

To study the L-PBF manufacturability of microchannels and feasibility of self-supporting holes, a single-channel model with a dimension of 19 mm × 5 mm × 3 mm was designed, as shown in Figure 6. As illustrated in Figure 6a, three hole types, A, B, and C, were designed, with R values of 0.25, 0.5, 0.75 mm, respectively. Type A was a square hole with a side length of 2R. Type B was a circular hole with a diameter of 2R. Type C had three parts: Part I was an R × 2R rectangle, Part II was an arc with radius R, and Part III was an inclined plane with an inclination angle of 45°, as shown in Figure 6b. When the inclination angle was ≥45°, the inclined surface exhibited good self-supporting characteristics, making additional support unnecessary.

Figure 6.

Types and sizes of single-channel models. (a) Single-channel test model, (b) Self-supporting holes.

To realise the efficient heat transfer and high-strength bearing of the liquid-cooled plate, the 316L stainless steel powder was used as the experimental material. The formation experiments with six groups of process parameters were conducted on the aforementioned L-PBF equipment. The formation process parameters are listed in Table 3.

Table 3.

L-PBF process parameters of the single-channel samples.

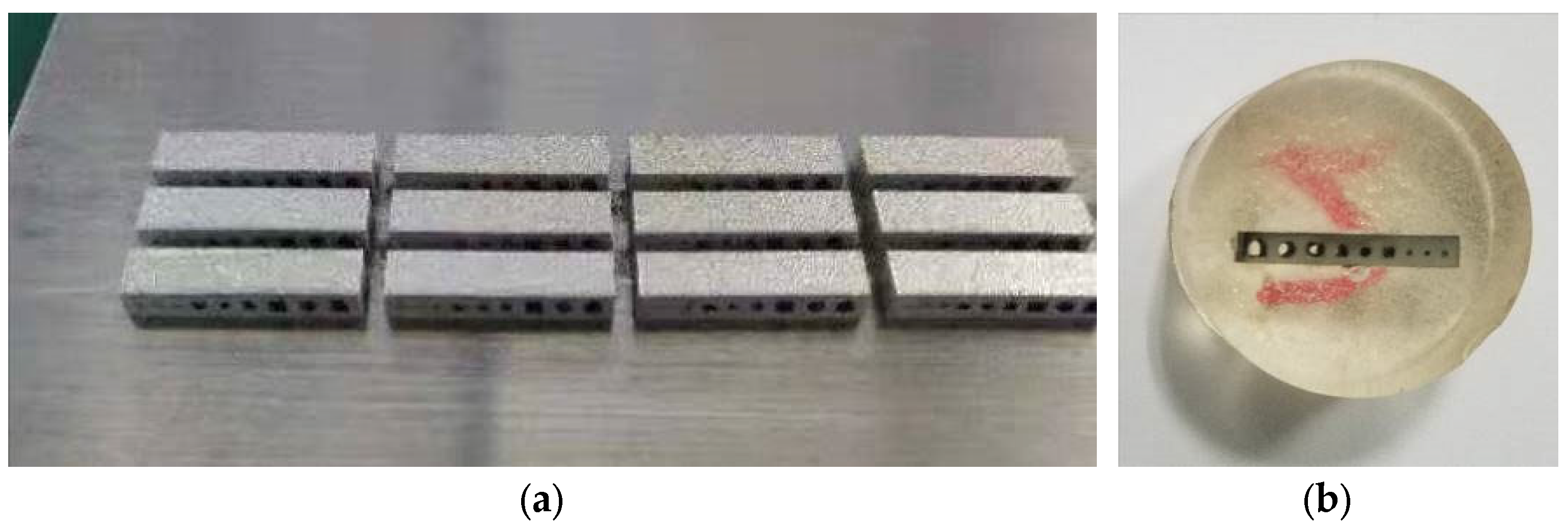

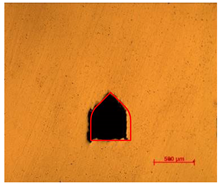

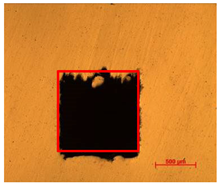

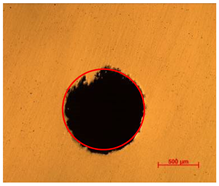

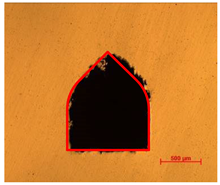

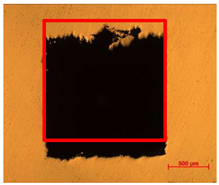

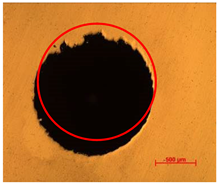

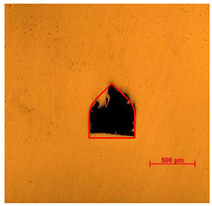

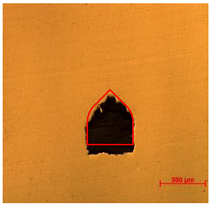

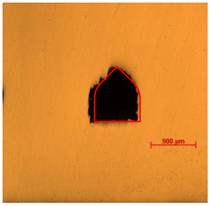

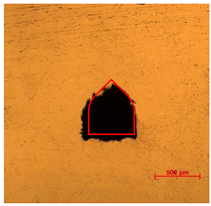

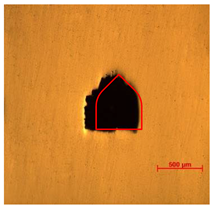

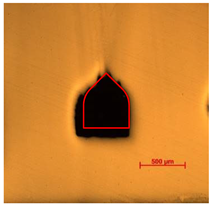

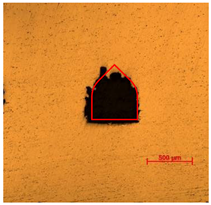

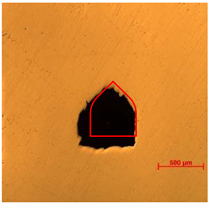

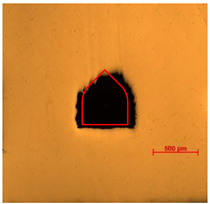

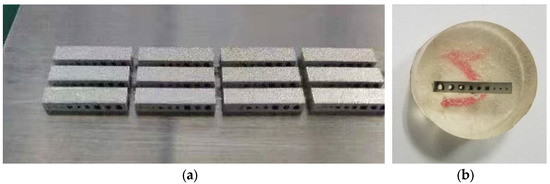

3.2. Selection of Microchannel Parameters and Single-Channel Size

To determine the optimal hole parameters, this study selected nine self-supporting hole structures for comparative experiments. The formation tests were performed on the same liquid-cooled plate. The formed single-channel samples are shown in Figure 7a. The samples were then cold mounted with resin and curing agent and were polished, as shown in Figure 7b. An optical microscope was used to observe the samples. The nine holes of Sample 1 are presented in Table 4, indicating obvious slags on the top of Type A and B holes. Type C holes, however, maintained their shapes and showed good self-supporting characteristics.

Figure 7.

Single-channel samples with various pass types and sizes. (a) Samples on a substrate, (b) Sample after cold mounting.

Table 4.

Self-supporting micropores of sample 1 with different R-value parameters and types.

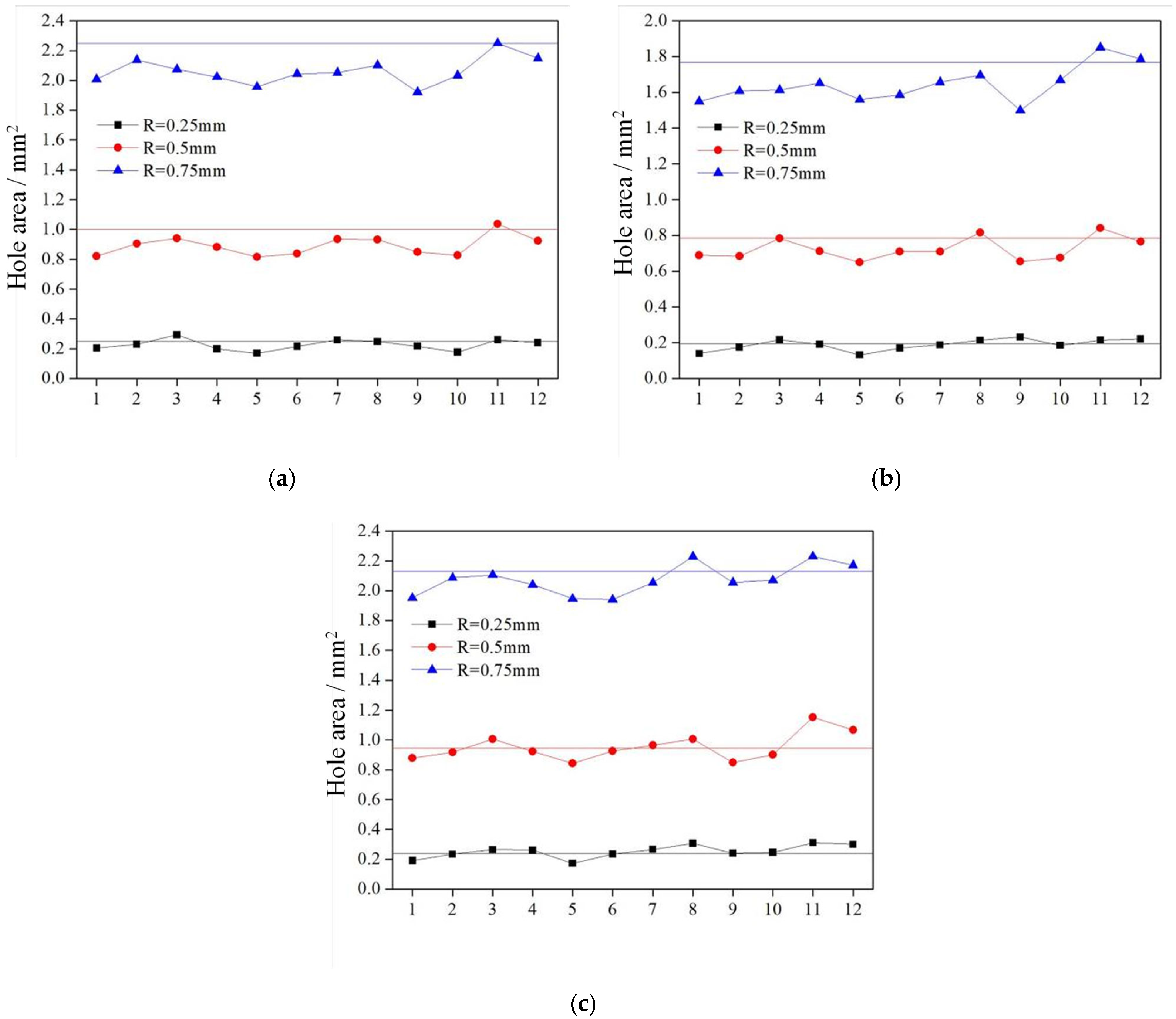

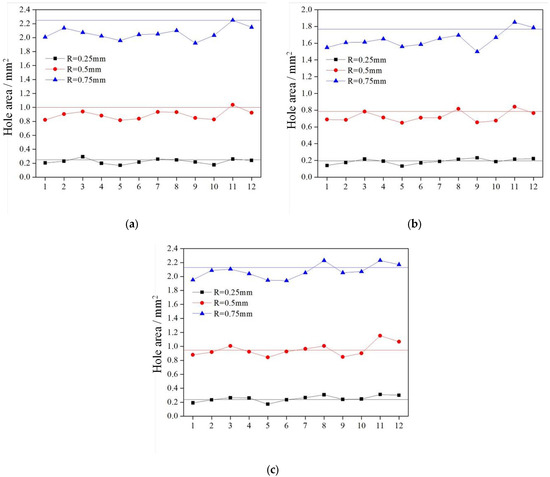

To analyse the formability of holes with different sizes, the dimensional accuracy and surface roughness of the formed microchannels were characterised. Image-Pro Plus software was used to investigate the SEM image of each hole and obtain the area, as shown in Figure 8. The horizontal lines in Figure 8 represent the design areas of the holes. When R = 0.75 mm, the difference between the area of Type C hole and the design value was the smallest. When R = 0.5 mm, the areas of Type A and B holes were smaller than the design values, and the area of Type C hole fluctuated and deviated less from the design value. When R = 0.25 mm, the areas of Type A, B, and C holes were almost the same as the design values. Considering these results and the pore morphology presented in Table 4, Type C hole was selected to construct the microchannel structure. From Figure 8, when R = 0.75 mm, the hole areas were typically smaller than the design values, with the largest deviation; when R = 0.25 mm, the difference between the practical hole area and the design value was small, and the designed shape could be maintained. A smaller pore size corresponds to a stronger capillary force, which benefits the filling of liquid and thus strengthens boiling heat transfer. Therefore, Type C hole with a size of R = 0.25 mm was selected for the microchannel structure.

Figure 8.

Comparison of practical and theoretical areas for the single channel. (a) Type A hole, (b) Type B hole, (c) Type C hole.

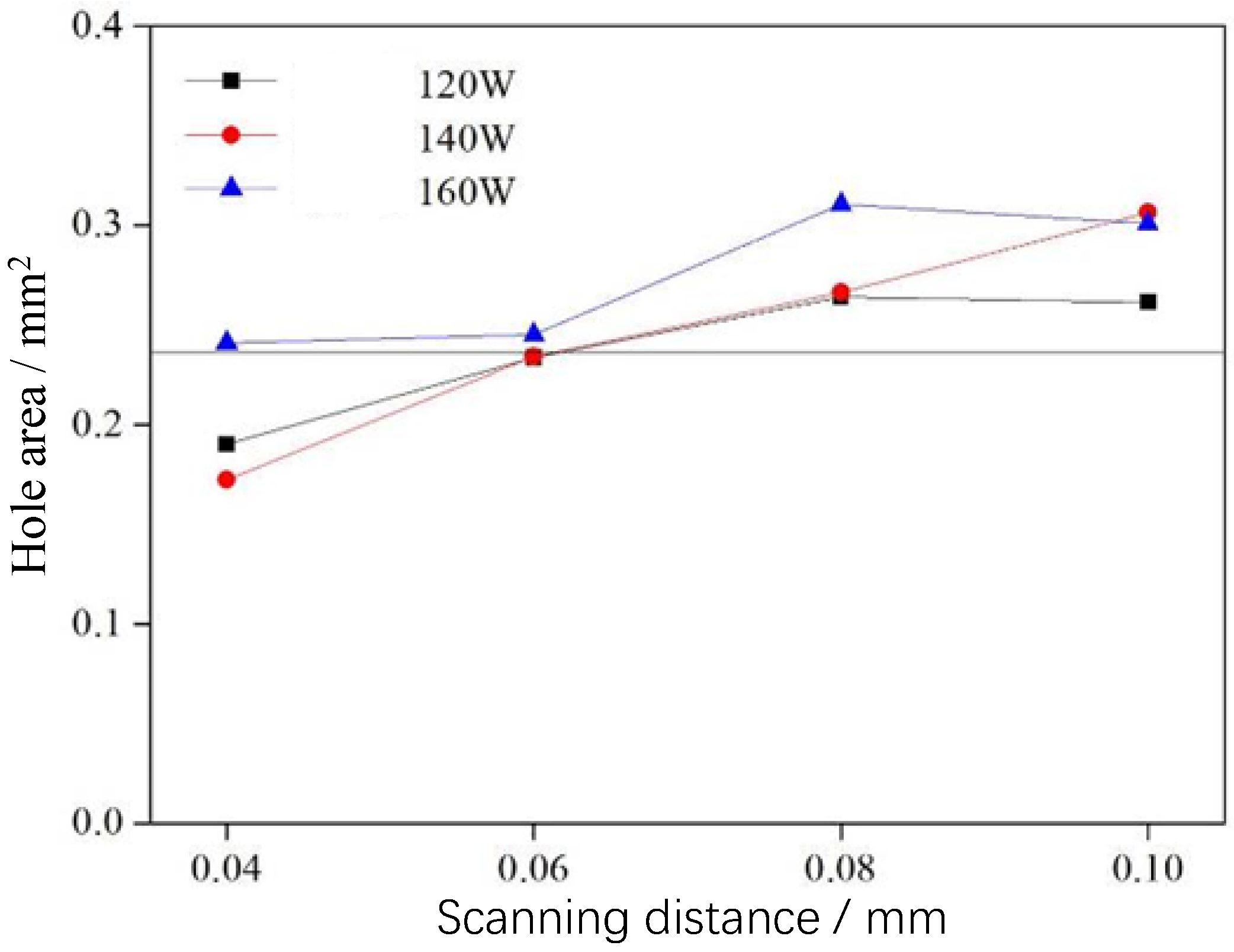

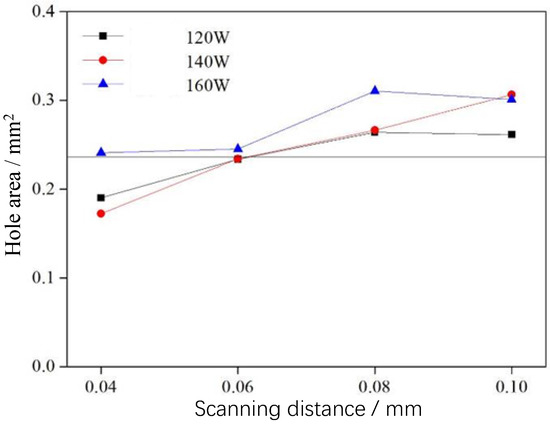

To understand the influences of process parameters on the microchannel formation accuracy and surface roughness, 12 formation process parameters with varying laser powers and spot compensation values were compared for the selected Type C hole. The microscopic images of Type C holes with R = 0.25 mm under different process parameters are presented in Table 5. The influences of process parameters on the area of Type C holes were also analysed, as shown in Figure 9. When spot compensation increased from 0.04 to 0.10 mm, the hole area exhibited an increasing trend and gradually exceeded the design value. When spot compensation was 0.06 mm, the hole area was closest to the design value; hence, the spot compensation of 0.06 mm was selected to form the microchannel structure. Furthermore, the area of the hole formed with a laser power of 160 W was large and fluctuated considerably with the spot diameter change. As displayed in Table 5, the holes appearing at the laser power of 160 W exhibited an irregular shape mainly because the high power caused vaporisation of some powders and severe fluctuation of the molten pool, which led to poor formation. In the remaining cases of 120 and 140 W, the areas of the formed holes were slightly different. However, at 140 W, the hole area increased steadily with the increase in spot compensation. Considering this and the pore morphology presented in Table 5, the laser power of 140 W was selected as a formation process parameter.

Table 5.

Self-supporting channels with different process parameters (R = 0.25 mm).

Figure 9.

Relationship between the area of the Type C hole and process parameters.

Based on the aforementioned analysis, the microchannel structure adopted the design of the Type C hole with a size of R = 0.25 mm. Its formation process parameters are summarised in Table 6.

Table 6.

L-PBF formation process parameters for the microchannel structure.

4. Design and Formation of the Liquid-Cooled Plate Structure

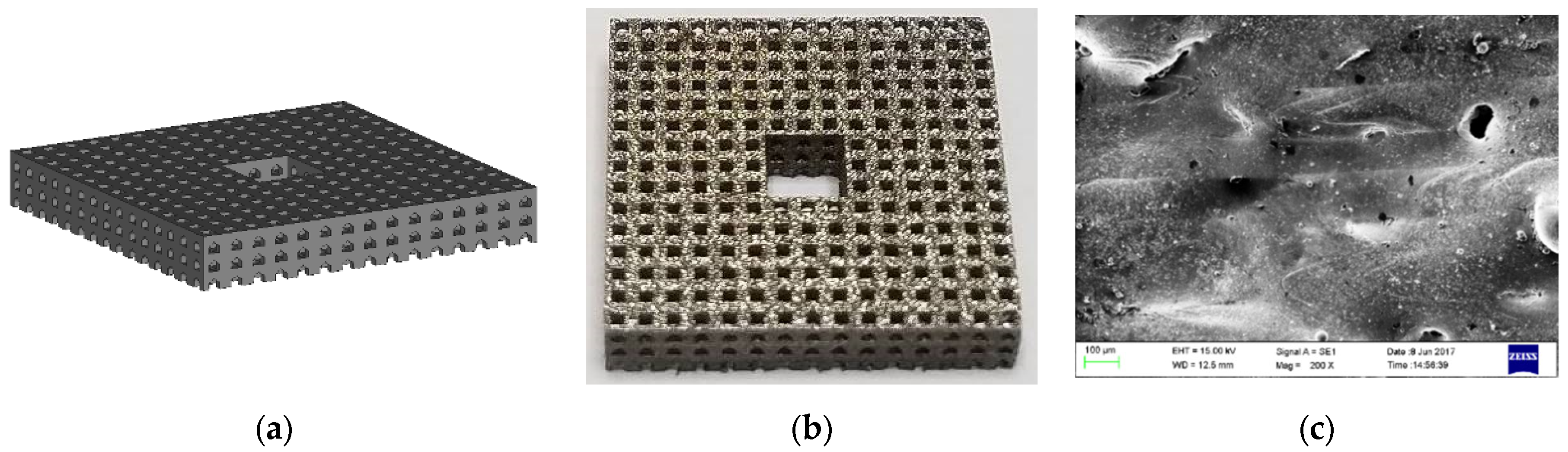

In transverse single-direction microchannels, the narrow path provides a strong capillary force, which is conducive to liquid replenishment. However, this also offers a small channel for the bubbles to escape. Therefore, vertical holes in the middle of the model are necessary to increase the upward escape speed of bubbles. To compare the influence of vertical hole sizes on the heat flux, three vertical hole sizes were designed: 1 mm × 1 mm, 3 mm × 3 mm, and 5 mm × 5 mm. The spacing for the vertical hole arrays was 2 mm. The designed microchannel structure model is presented in Figure 10a. A substrate with a height of 0.2 mm was added.

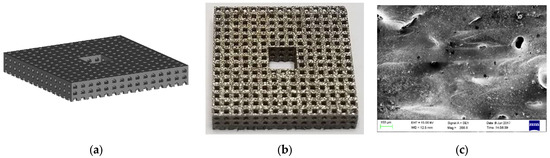

Figure 10.

Microchannel structure. (a) Model, (b) Sample, (c) Surface micromorphology after the formation using L-PBF.

According to the selected process parameters, the L-PBF formation experiment of the liquid-cooled plate was conducted with the 316L stainless steel powder. The sample size was 15 mm × 15 mm × 1.7 mm, the scanning mode was inclined zoning, and the thickness of powder layer was 0.03 mm. Other process parameters are summarised in Table 7.

Table 7.

Formation process parameters of the plate sample.

The formed part was separated from the substrate through wire cutting and was ground at its bottom. The obtained microchannel structure sample is shown in Figure 10b. The formed plate sample, exhibiting pores, using L-PBF is shown in Figure 10c. Therefore, the sample was further polished and then used for the boiling heat transfer test.

To evaluate the dimensional accuracy and surface roughness of the liquid-cooled plate samples, the size, volume, and surface area of the model were characterised using the Magics software of Materialise Company. These parameters were then used to calculate the porosity and surface-to-volume ratio of the model. The porosity of the sample was measured by drying and weighing. The results presented in Table 8 indicated that the practical sample porosity was slightly higher than the design value.

Table 8.

Designed and practical parameters of the microchannel structure.

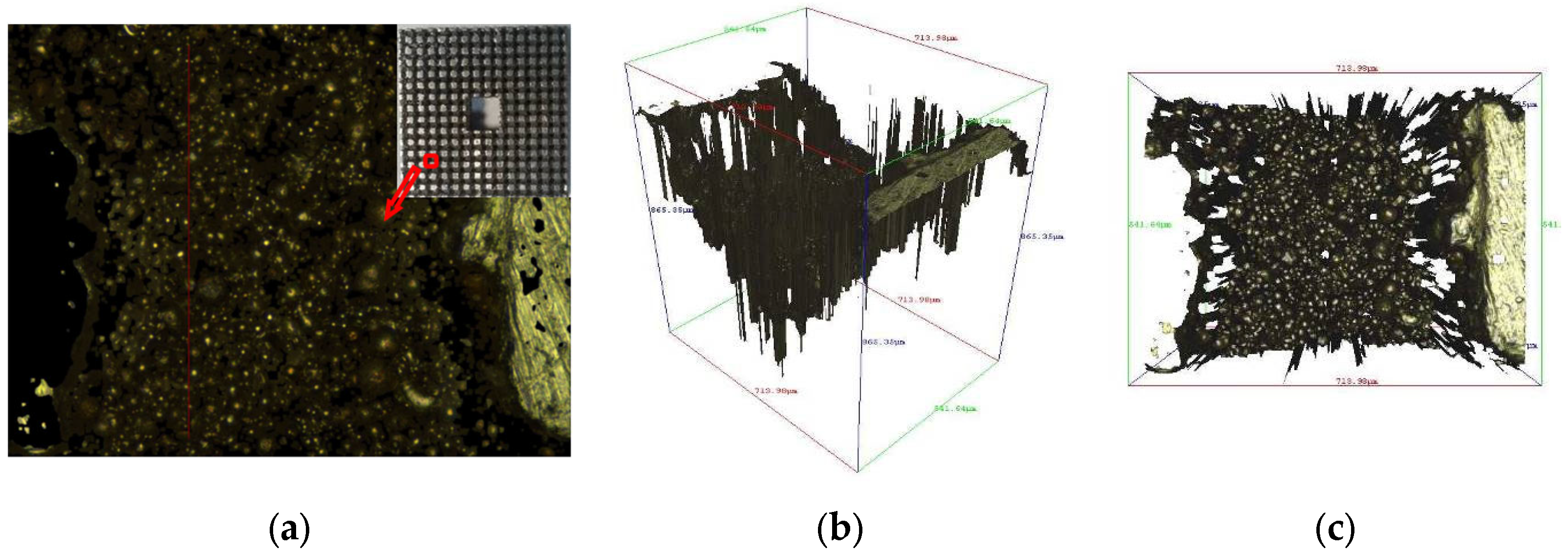

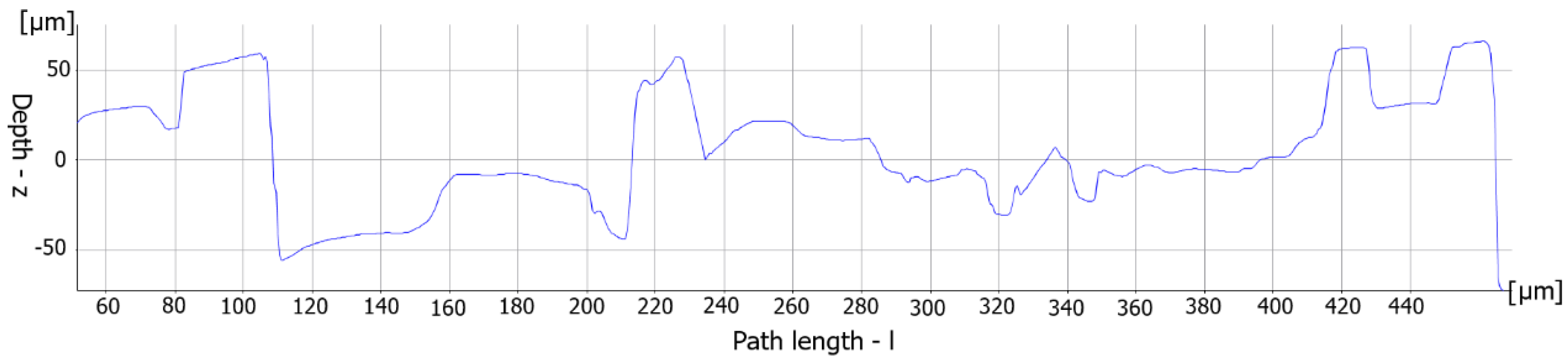

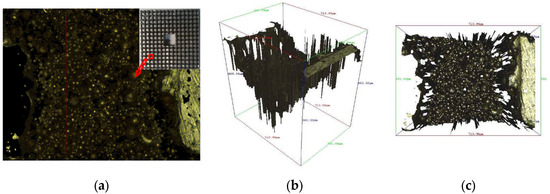

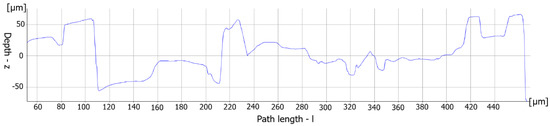

To analyse the influence of surface morphology on overall heat dissipation, the sample surface morphology was characterised using a roughness-measuring instrument. The three-dimensional morphology of the upper surface for the microchannel structure of Sample 2 is presented in Figure 11. The roughness on the red line, as marked in Figure 11a, was measured. The results are shown in Figure 12. The calculated average roughnesses (Ra) of Samples 1, 2, and 3 were 19.34, 24.87, and 43.60 μm, respectively. The difference was observed because the escape holes in Sample 1 had a small size and maintained the shape well during formation through L-PBF. For Sample 3, the size of the escape holes was large; when printed to a certain height, the grid between the escape holes formed a thin-walled structure with a large aspect ratio. After L-PBF laser scanning, the thin-walled structure became prone to tilt in the height direction and gradually bent in the plane direction, thus leading to a rough surface.

Figure 11.

Three-dimensional morphology of the microchannel structure for Sample 2. (a) SEM image of the upper microchannel surface, (b) oblique view, (c) top view.

Figure 12.

Upper surface roughness of channels in Sample 2.

5. Analysis of the Boiling Heat Transfer Characteristics of the Microchannel Structure

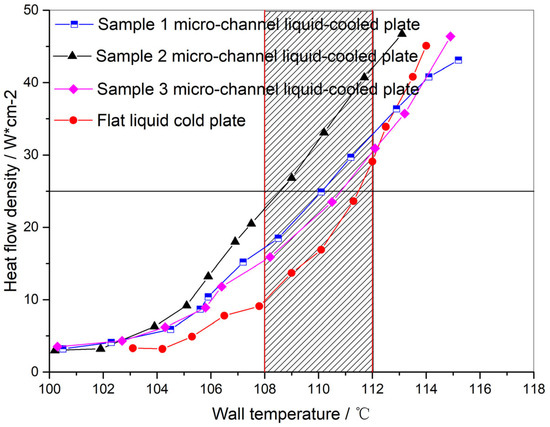

For all the three liquid-cooled plate structures with different escape hole sizes and the traditional copper-tube liquid-cooled plate structure, the boiling heat transfer experiments were conducted with deionised water as the boiling working medium. The obtained saturated boiling heat transfer curves are displayed in Figure 13; the abscissa is the wall temperature in °C, and the ordinate is the heat flow density (heat flux per unit area) with a unit of W∙cm−2. Under the same heat flow density (horizontal line of 25 W∙cm−2 in Figure 13), the wall temperature of the three microchannel structure samples was lower than that of the traditional copper-tube liquid-cooled plate. In particular, the temperature of Sample 2 was 4% lower than that of the traditional plate, microchannel structure samples is 108.2 °C, traditional copper-tube liquid-cooled plate is 111.9 °C. Within the same optimal boiling temperature (108–112 °C) [17], the average heat flow densities of all the three samples increased by over 60% compared with those of the traditional liquid-cooled plate from minimum 16 W∙cm−2 of traditional liquid-cooled plate to maximum 34 W∙cm−2. At initial boiling temperature, the heat flow density of Sample 2 (escape hole size of 3 mm × 3 mm) increased to more than double than that of the traditional liquid-cooled plate. The results indicated a strong strengthening effect of the microchannel structure on pool boiling heat transfer because of the balance between the strengthening effect of dense nucleation sites and weakening effect of the increased thermal resistance due to steam blockage and obstructed liquid replenishment.

Figure 13.

Saturated boiling heat transfer curves.

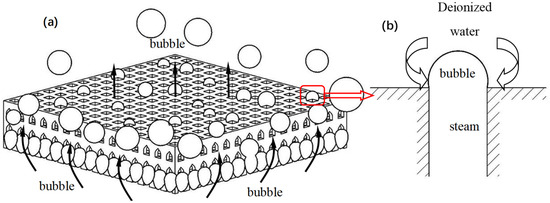

To understand the physics of liquid cooling by microchannels, the boiling heat transfer process was investigated from the perspective of microchannel shape characteristics. The interior of the microchannel structure is shown in Figure 14, which illustrates numerous potential nucleation sites. The roughness (Ra) was 24.87 μm. When a large amount of liquid flowed into the microchannel and the buoyancy was greater than the surface tension, the bubbles left the channel with a considerably decreased radius. The surface tension pulled the remaining gas back into the vertical channels, preventing the gases in the microchannel structure from escaping, as shown in Figure 14b. Moreover, the pore size of the microchannel structure was large and the pore density was small, resulting in a large radius of escaping bubbles and low escape frequency. Eventually, the bubbles, some of which were trapped, nucleated, and grew inside the microchannels. Given the thermal conductivity of the gas was substantially lower than that of deionised water and 316L stainless steel, the equivalent thermal resistance of the upper layer of the microchannel structure increased abruptly. Therefore, upper surface temperature became considerably lower than lower layer temperature. Furthermore, the upper surface, on which the bubbles were difficult to nucleate, had a low roughness (Ra < 5 μm). Therefore, as shown in Figure 14a, many bubbles escaped from the side at the lower layer of the microchannel structure, whereas on the upper surface, bubbles only escaped from the vertical channels with a low separation frequency. Gas flow inside the microchannel structure not only minimised the thermal resistance but also increased the negative pressure, which was conducive to the replenishment of the surrounding liquid, and thus strengthened the process of boiling heat transfer. Therefore, the self-supporting microchannel structure could realise satisfactory liquid-cooled heat transfer when maintaining its own strength structure, Figure 14b Bubble escape process.

Figure 14.

Principle of boiling heat transfer in the microchannel structure. (a) Boiling heat transfer in the microchannel structure, (b) Bubble escape process.

6. Conclusions

This study focused on efficient heat dissipation of the liquid-cooled plate in T/R modules. Its main contributions are as follows.

- The self-supporting pass design was developed. By analysing the hole area and pore morphology under different pass types, hole sizes, and process parameters, the hole formation accuracy under various parameters was obtained. The appropriate pass type, hole size, and process parameters were selected to design and form the microchannel structure.

- The microchannel structure model was designed, and the experiment of formation using L-PBF was conducted with the 316L stainless steel powder. The porosity and dimension of the sample were calculated and compared with the designed parameters, which provided a high formation accuracy. The three-dimensional morphology and roughness of the microchannel structure were characterised.

- Taking deionised water as the working medium, the boiling heat transfer experiments of microchannel structures were performed. According to the saturated boiling heat transfer curves and the bubble escape conditions, the boiling heat transfer characteristics were analysed and compared with those of the traditional copper-tube liquid-cooled plate. Under the same heat flow density, the average wall temperature of the prepared samples was 4% lower than that of the traditional liquid-cooled plate. Within the same optimal boiling temperature range, the average heat flow density of the prepared samples was 60% higher than that of the traditional liquid-cooled plate. The results demonstrated that the self-supporting microchannel structure can improve the heat dissipation of T/R modules and solve the local overheating problem.

Author Contributions

Conceptualization, B.Q. and P.L.; methodology, J.Z.; software, B.Q.; validation, B.Q., H.F. and G.L.; formal analysis, H.F.; investigation, P.L.; resources, B.Q.; data curation, H.F.; writing—original draft preparation, P.L.; writing—review and editing, B.Q.; visualization, H.F., G.L. and J.Z.; project administration, G.L.; funding acquisition, B.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Key Project of Chinese National Programs for Fundamental Research and Development- Model Processing and Process Planning Software Project for Additive Manufacturing (2018YFB1105300)- Universal Full-dimension Digital Model Project (2018YFB1105301) and National Natural Science Foundation of China (51705307), Open Project Program of the State Key Lab of CAD&CG (Grant No. A2015).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Qu, Y.; Wang, S.; Tian, Y. A review of thermal performance in multiple evaporators loop heat pipe. Appl. Therm. Eng. 2018, 143, 209–224. [Google Scholar] [CrossRef]

- Vasiliev, L.L. Micro and miniature heat pipes—Electronic component coolers. Appl. Therm. Eng. 2008, 28, 266–273. [Google Scholar] [CrossRef]

- Zhou, S.Z. Sintering Mechanism and Boiling Heat Transfer Performance of Porous Structure; South China University of Technology: Guangzhou, China, 2014. [Google Scholar]

- Jafari, D.; Wits, W.W. The utilization of selective laser melting technology on heat transfer devices for thermal energy conversion applications: A review. Renew. Sustain. Energy Rev. 2018, 91, 420–442. [Google Scholar] [CrossRef]

- Gu, D.D.; Shi, X.Y.; Poprawe, R.; Bourell, D.L. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, 1–15. [Google Scholar] [CrossRef]

- Yampolskiy, M.; King, W.E.; Gatlin, J.; Song, B.; Wei, Q.S.; Bourell, D. Security of additive manufacturing: Attack taxonomy and survey. Addit. Manuf. 2018, 21, 431–457. [Google Scholar] [CrossRef]

- Yeh, C.C. Trend analysis for the market and application development of 3D printing. Int. J. Autom. Smart Technol. 2014, 4, 1–3. [Google Scholar] [CrossRef] [Green Version]

- Deckers, J.; Vleugels, J.; Kruthl, J.P. Additive manufacturing of ceramics: A review. J. Ceram. Sci. Technol. 2014, 5, 245–260. [Google Scholar]

- Zhang, J.L.; Song, B.; Wei, Q.S.; Bourell, D.; Shi, Y.S. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, K.Y.; Wu, D.B.; Pan, T.; Zhang, X.C. Analysis and optimization of the machining fixture system stiffness for near-net-shaped aero-engine blade. Int. J. Adv. Manuf. Technol. 2021, 113, 3509–3523. [Google Scholar] [CrossRef]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Kotthoff, S.; Gorenflo, D.; Doff, J. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Parry, L.; Ashcroft, I.A.; Wildman, R.D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Bourell, D.L.; Rosen, D.W.; Leu, M.C. The roadmap for additive manufacturing and its impact. 3D Print Addit. Manuf. 2014, 1, 6–9. [Google Scholar] [CrossRef]

- Li, L.; Pan, T.; Zhang, X.C.; Chen, Y.T. Deformations and stresses prediction of cantilever structures fabricated by selective laser melting process. Rapid Prototyp. J. 2021. [Google Scholar] [CrossRef]

- Ding, L.P.; Tan, S.J.; Chen, W.L.; Wong, K.K.; Leong, K.C. Manufacturability analysis of extremely fine porous structures for selective laser melting process of Ti6Al4V alloy. Rapid Prototyp. J. 2021, 27, 1523–1537. [Google Scholar] [CrossRef]

- Poniewski, M.E.; Thome, J.R. Nucleate Boiling on Micro-Structured Surfaces; Heat Transfer Research Inc.: College Station, TX, USA, 2008. [Google Scholar]

- Kotthoff, S.; Gorenflo, D.; Danger, E.; Vleugels, J.; Kruthl, J.P. Heat transfer and bubble formation in pool boiling: Effect of basic surface modifications for heat transfer enhancement. Int. J. Therm. Sci. 2006, 45, 217–236. [Google Scholar] [CrossRef]

- Chi, Z.; Li, Z.; Hong, X.; Pei, L.; Bo, Q. Performance of pool boiling with 3D grid structure manufactured by selective laser melting technique. Int. J. Heat Mass Transf. 2019, 128, 570–580. [Google Scholar]

- Ameli, M.; Agnew, B.; Leung, P.S.; Zhang, J.L.; Song, B.; Wei, Q.S. A novel method for manufacturing sintered aluminium heat pipes (SAHP). Appl. Therm. Eng. 2013, 52, 498–504. [Google Scholar] [CrossRef]

- Ho, J.Y.; Wong, K.K.; Leong, K.C. Saturated pool boiling of FC-72 from enhanced surfaces produced by Selective Laser Melting. Int. J. Heat Mass Transf. 2016, 99, 107–121. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Leary, M.; McMillan, M. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2021. [Google Scholar] [CrossRef]

- Bagheri, Z.S.; Melancon, D.; Liu, L.; Tian, Y.; Mostafavi, M. Compensation strategy to reduce geometry and mechanics mismatches in porous biomaterials built with Selective Laser Melting. J. Mech. Behav. Biomed. Mater. 2016, 70, 17–27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alredha, S.; Shterenlikht, A.; Mostafavi, M.; Ashcroft, I.A.; Wildman, R.D. Effect of build orientation on fracture behaviour of AlSi10Mg produced by selective laser melting. Rapid Prototyp. J. 2020, 27, 112–119. [Google Scholar] [CrossRef]

- Duan, W.P.; Han, J.T.; Xia, Q.N.; Zhang, X.C.; Chen, Y.T. Investigation on the relationship between bending angle of the overhanging surface and overhanging surface quality printed using selective laser melting. Rapid Prototyp. J. 2021, 27, 1573–1579. [Google Scholar] [CrossRef]

- Gazzerro, A.; Polini, W.; Sorrentino, L. Investigation on selective laser sintering of PA12: Dimensional accuracy and mechanical performance. Rapid Prototyp. J. 2021, 27, 1010–1019. [Google Scholar] [CrossRef]

- Xu, Z.G.; Qu, Z.G.; Zhao, C.Y.; Song, B.; Wei, Q.S. Experimental correlation for pool boiling heat transfer on metallic foam surface and bubble cluster growth behavior on grooved array foam surface. Int. J. Heat Mass Transf. 2014, 77, 1169–1182. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; McMillan, M.; Yampolskiy, M.; King, W.E. SLM additive manufacture of H13 tool steel with conformal cooling and structural lattices. Rapid Prototyp. J. 2016, 22, 504–518. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).