Influence of Welding Parameters and Filler Material on the Mechanical Properties of HSLA Steel S960MC Welded Joints

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

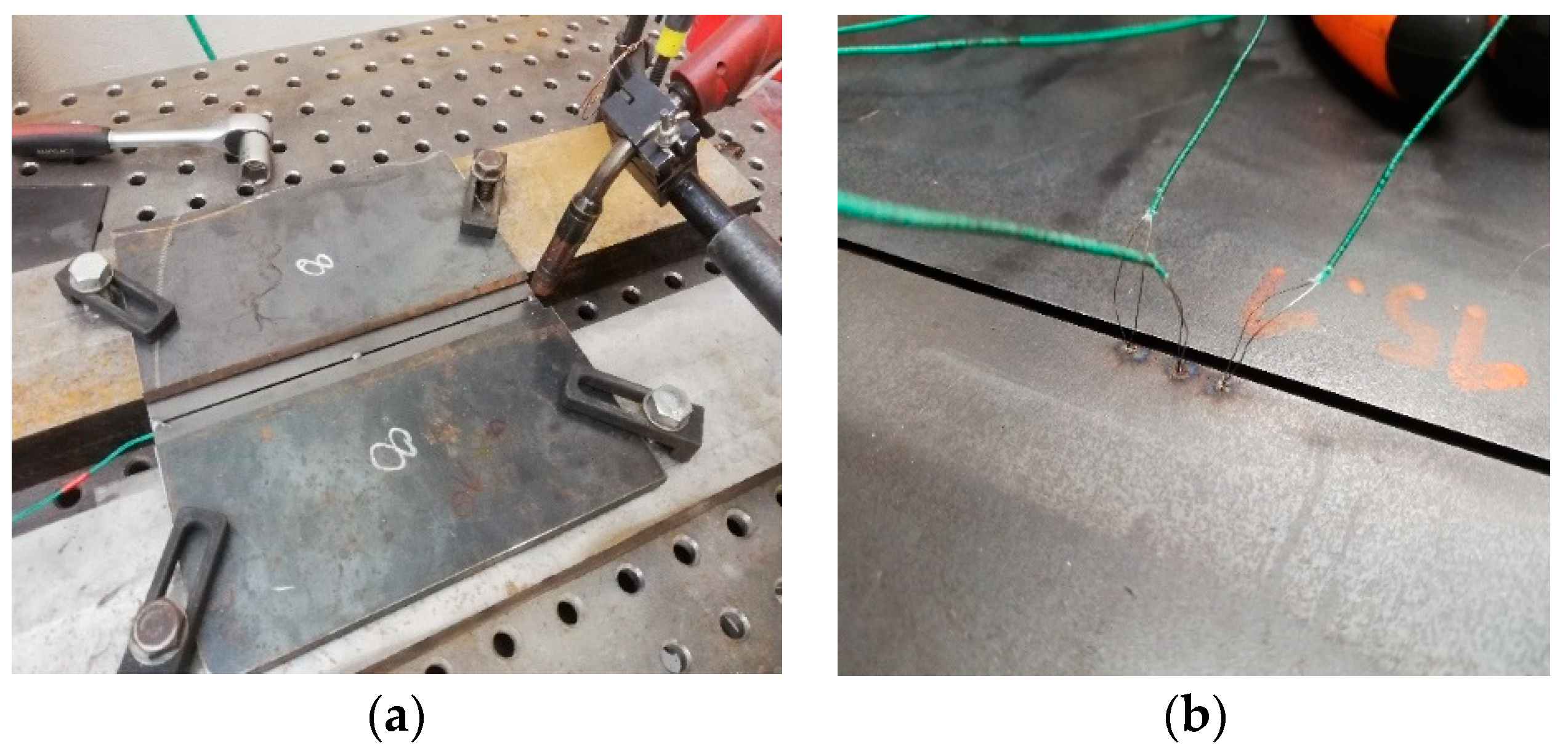

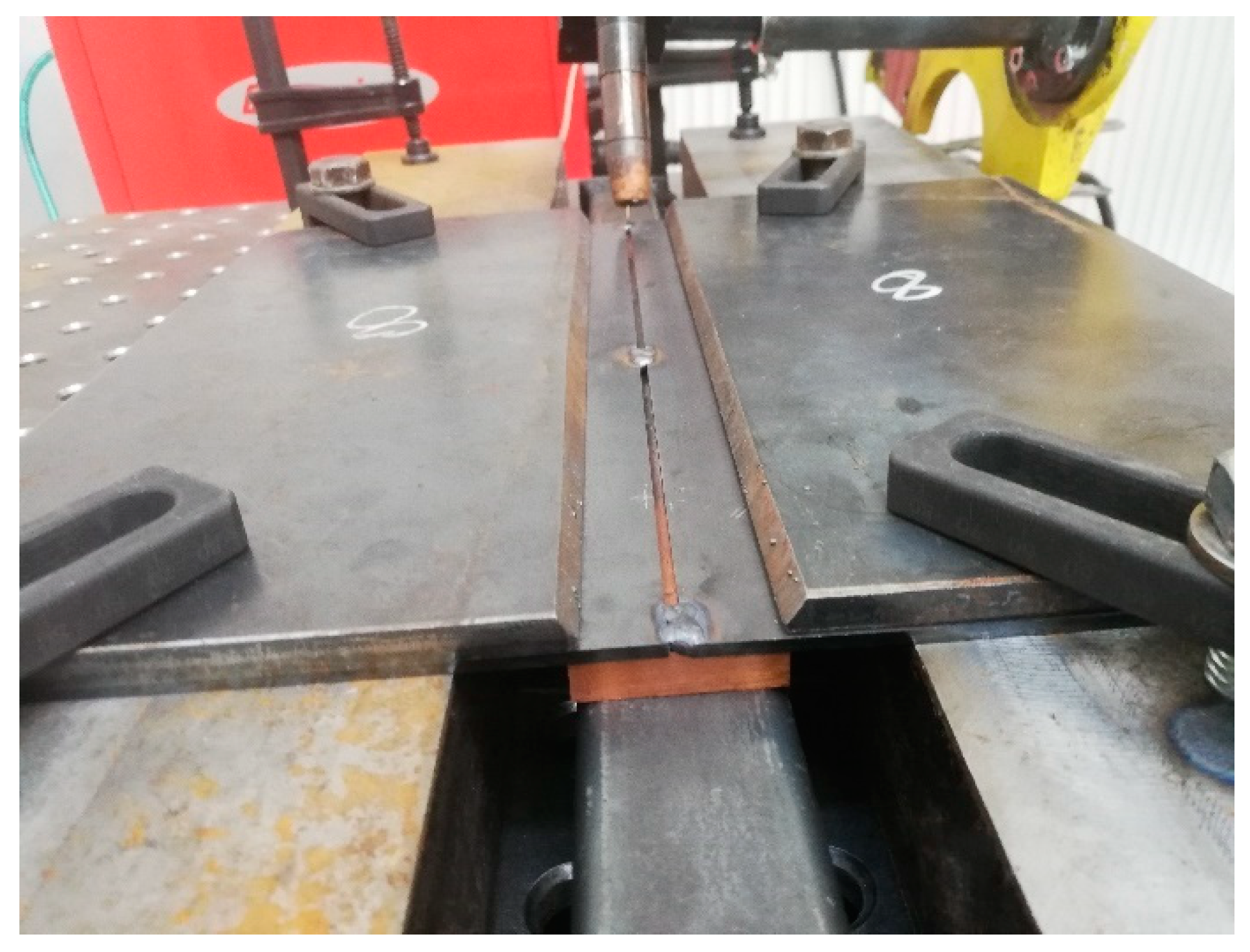

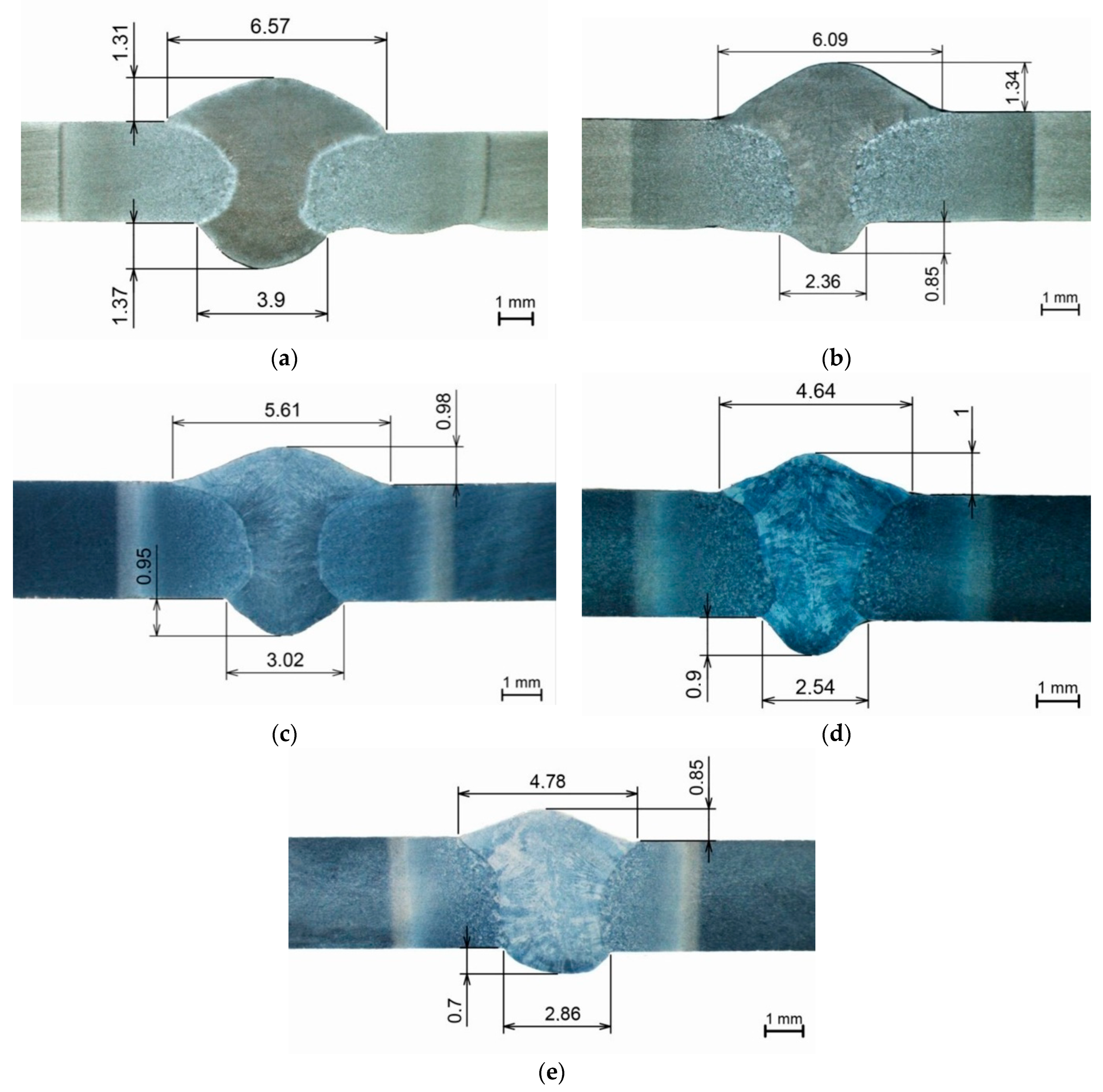

2.2. Welding Procedure

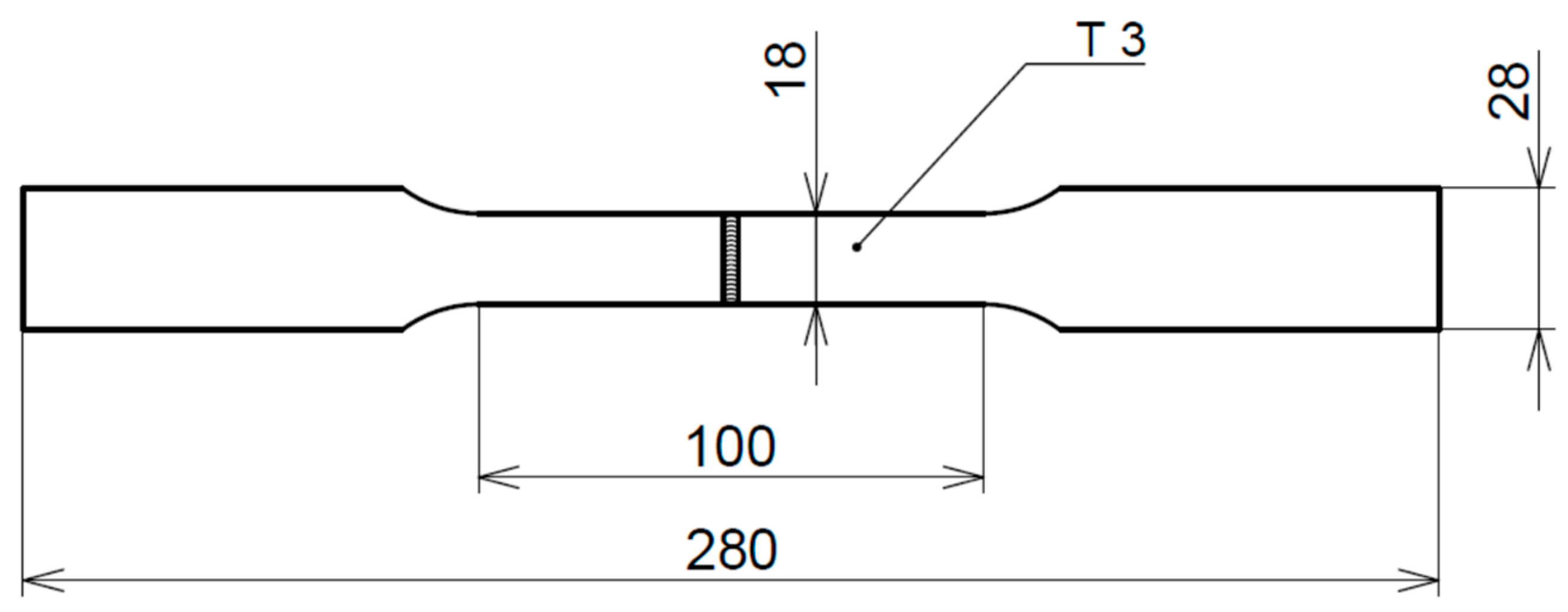

2.3. Mechanical Testing and Microstructural Analysis

3. Results and Discussion

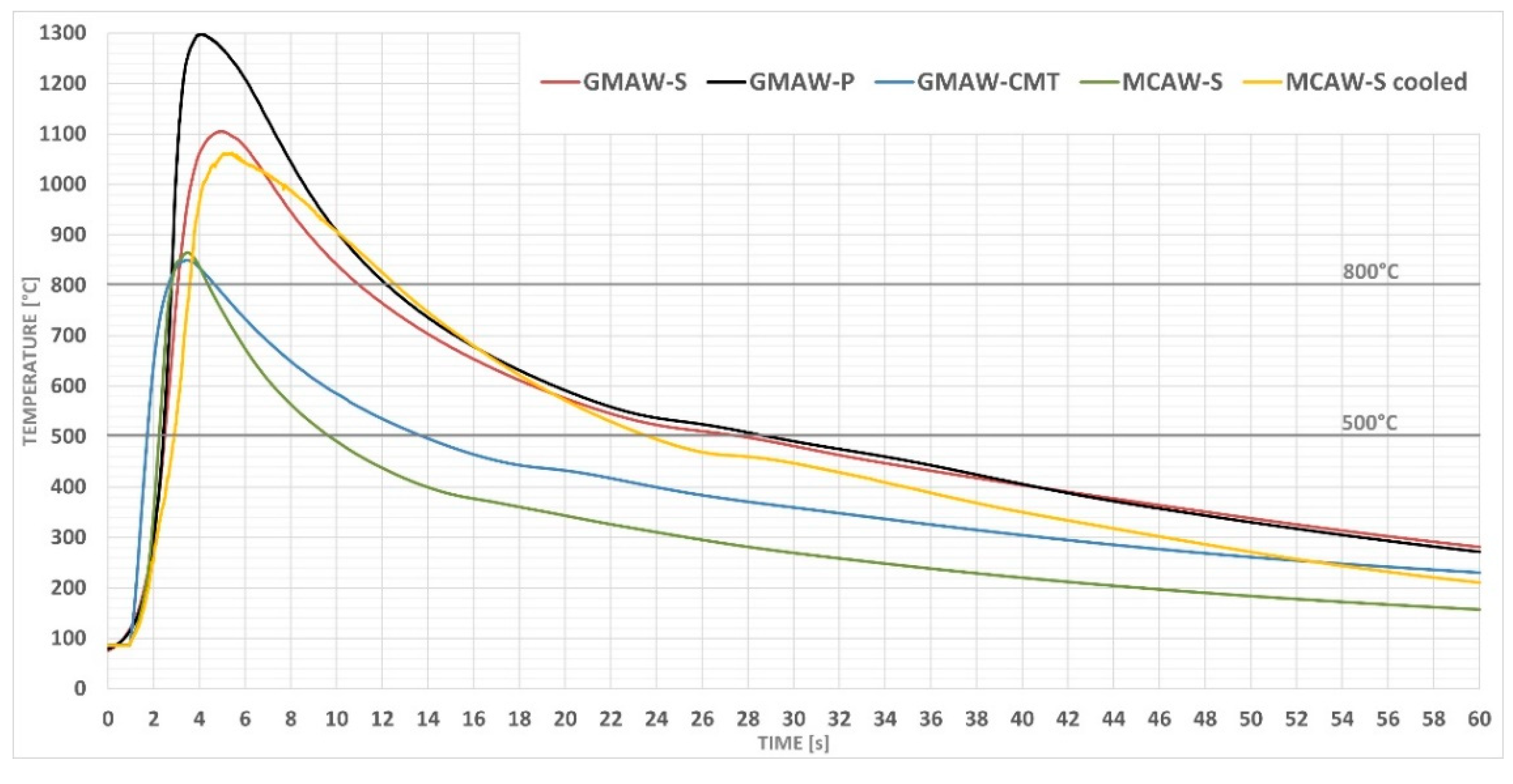

3.1. Thermal Cycle Analysis

3.2. Tensile Test

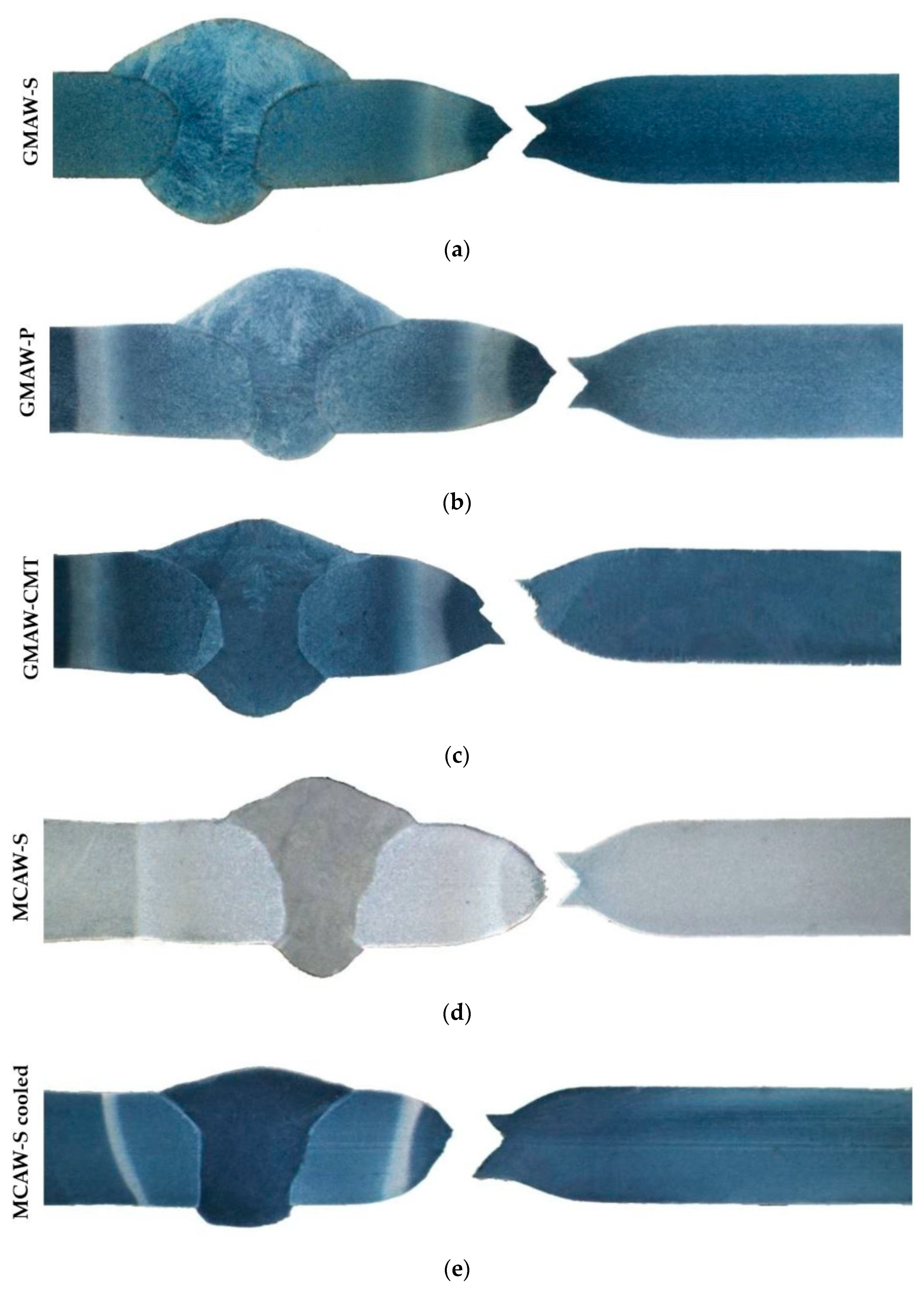

3.3. Bend Test

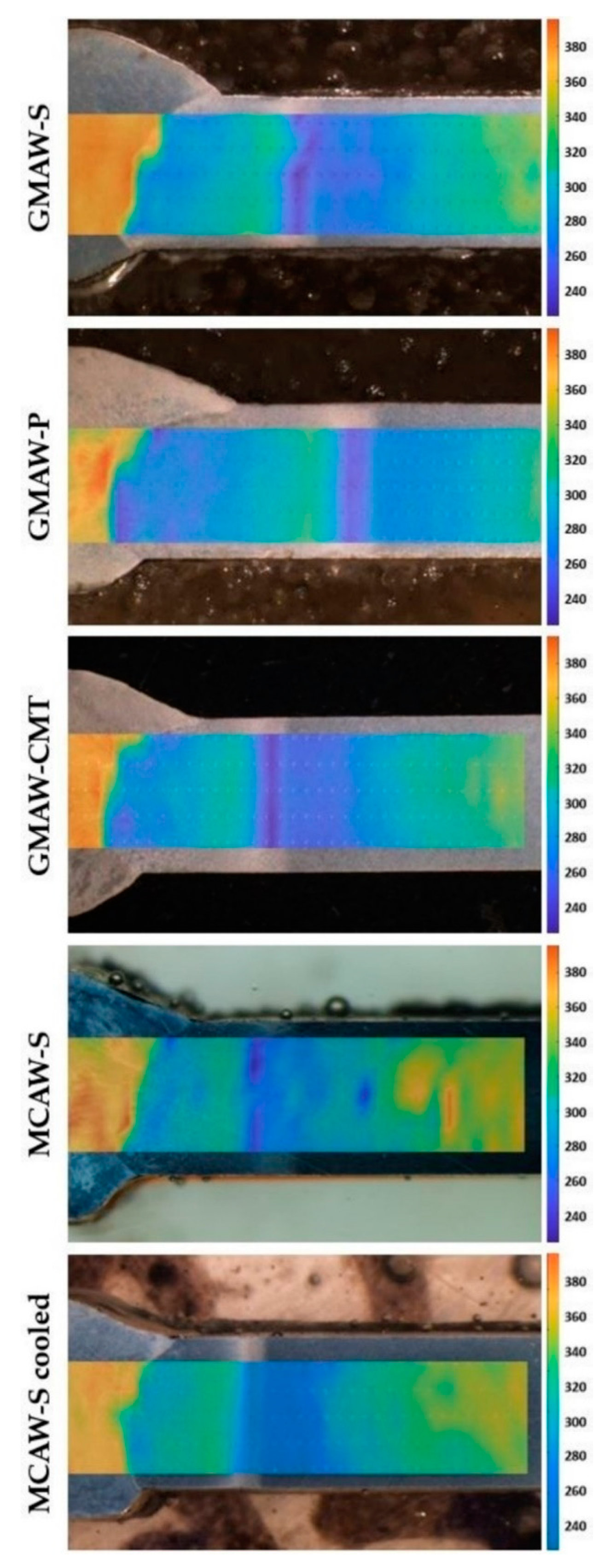

3.4. Hardness Mapping

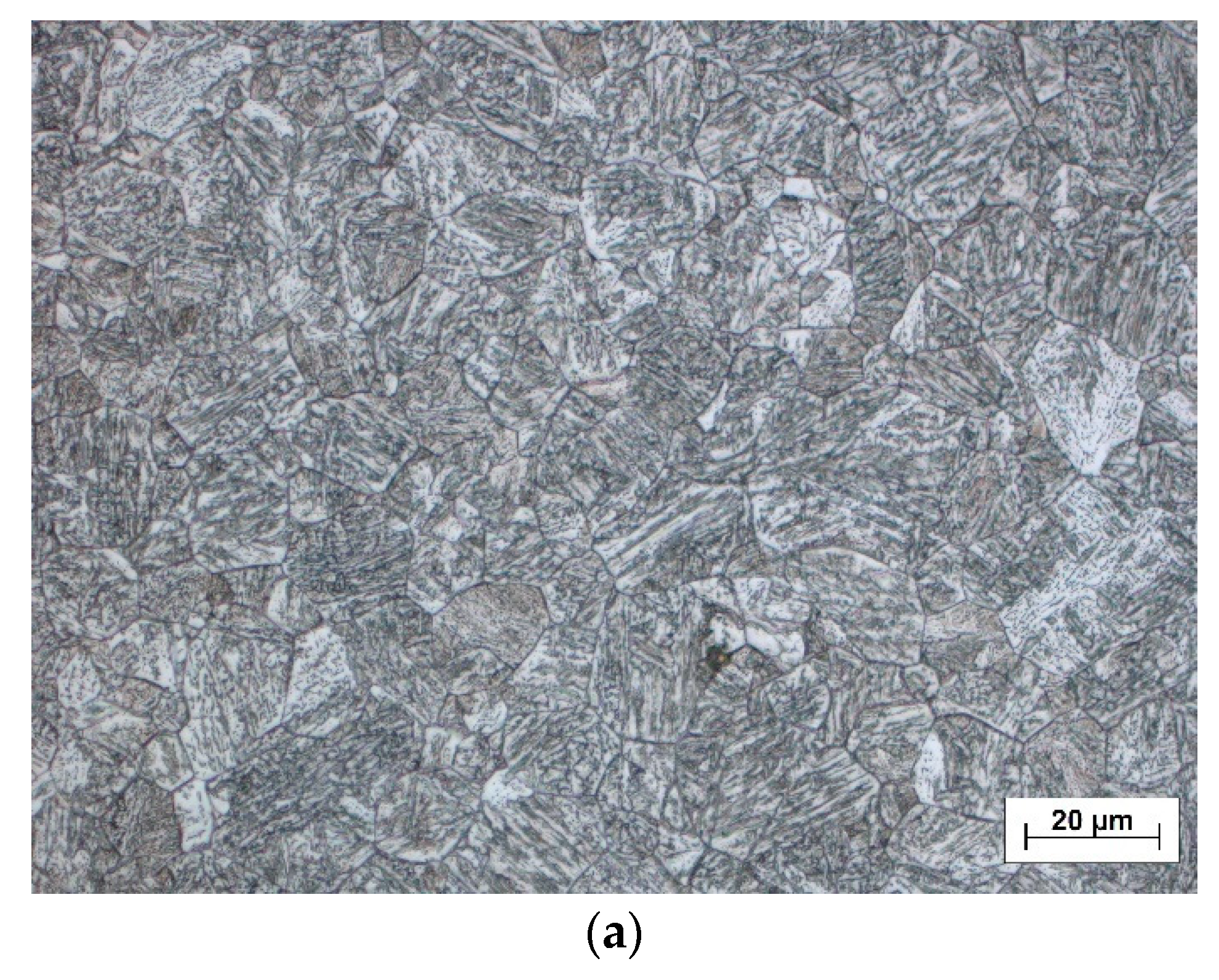

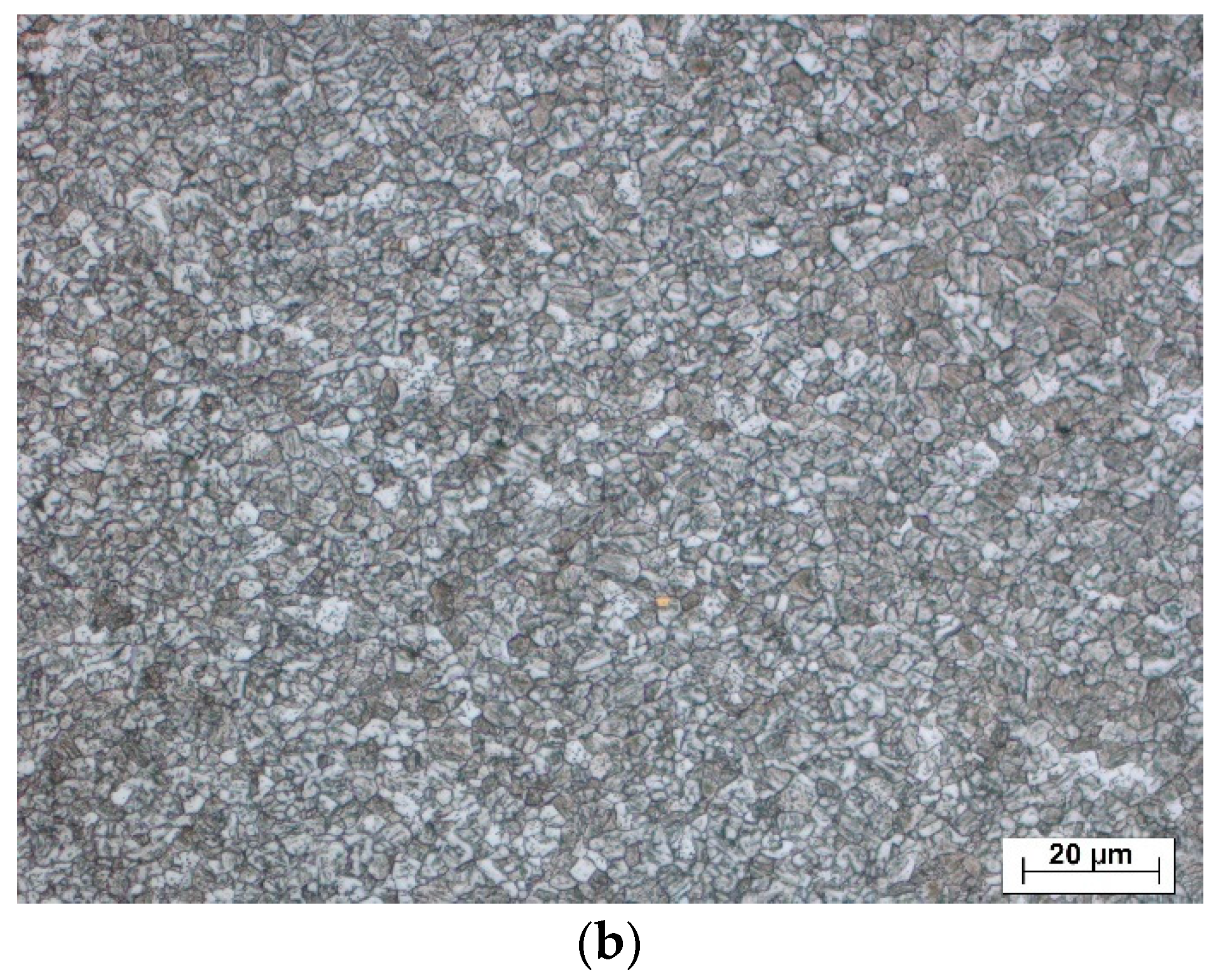

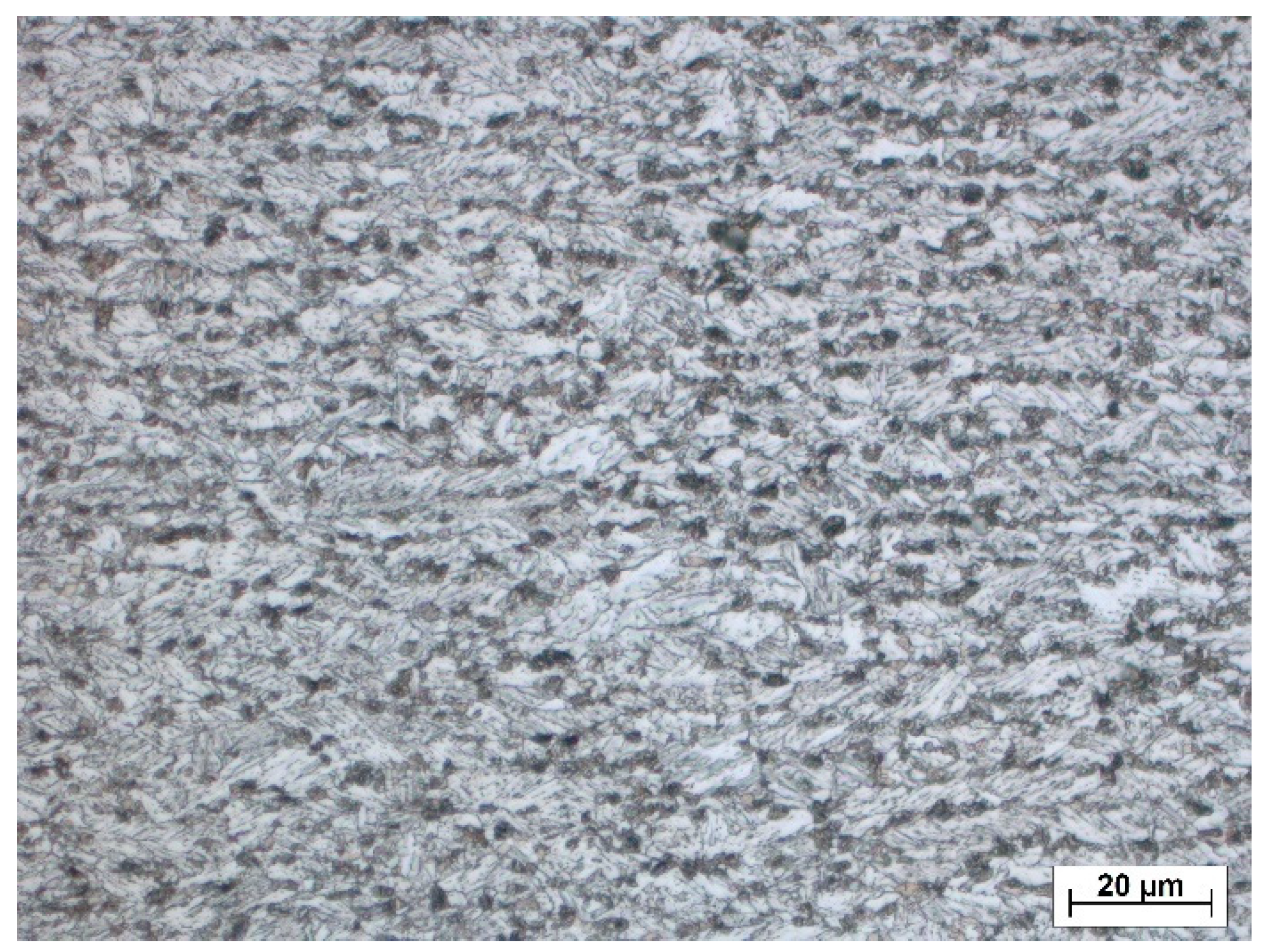

3.5. Microstructural and Macrostructural Analysis

3.6. Soft Zone Properties

3.7. Effect of the Soft Zone on the Mechanical Properties

4. Conclusions

- Compared to the standard mode, the use of the pulsed and CMT arc modes was able to achieve a greater strength of the welded joints, as they allowed a significant decrease in heat input.

- The use of a metal-cored wire enabled a significant reduction in heat input compared to using a solid wire, which was also accompanied by an increase in the deposition rate.

- With a decreased heat input, the cooling rate increased, which resulted in a decrease in the width of the soft zone in the HAZ and the relative thickness of the soft zone (XSZ).

- The decrease in XSZ was reflected in the increase in the strength of the welded joints, which still did not reach the strength of the base material. Nevertheless, there was a significant increase in the YS/TS compared to using the GMAW technology in standard mode.

- The results showed the effect of the shape of the weld bead on the overall heat distribution in the weld. This resulted in greater overheating of the material, even in the case of a lower heat input, and an associated increase in the width of the soft zone.

Author Contributions

Funding

Conflicts of Interest

References

- Endo, S.; Nakata, N. Development of Thermo-Mechanical Control Process (TMCP) and High Performance Steel in JFE Steel. JFE Tech. Rep. 2015, 20, 1–7. [Google Scholar]

- Suzuki, H. Weldability of Modern Structural Steels in Japan. Trans. ISIJ 1983, 23, 189–204. [Google Scholar] [CrossRef]

- Strenx. Welding of Strenx; SSAB AB: Stockholm, Sweden, 2017. [Google Scholar]

- Moravec, J.; Sobotka, J.; Solfronk, P.; Thakral, R. Heat Input Influence on the Fatigue Life of Welds from Steel S460MC. Metals 2020, 10, 1288. [Google Scholar] [CrossRef]

- Webel, J.; Herges, A.; Britz, D.; Detemple, E.; Flaxa, V.; Mohrbacher, H.; Mücklich, F. Tracing Microalloy Precipitation in Nb-Ti HSLA Steel during Austenite Conditioning. Metals 2020, 10, 243. [Google Scholar] [CrossRef]

- Wang, B.; Lian, J. Effect of microstructure on low-temperature toughness of a low carbon Nb-V-Ti microalloyed pipeline steel. Mater. Sci. Eng. A 2014, 592, 50–56. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.-X.; Xie, H.; Gao, X.-H.; Misra, R.D.K. Microstructure and mechanical properties of TMCP heavy plate microalloyed steel. Mater. Sci. Eng. A 2014, 607, 122–131. [Google Scholar] [CrossRef]

- De Meester, B. The weldability of Modern Structural TMCP Steels. ISIJ Int. 1997, 37, 537–551. [Google Scholar] [CrossRef]

- Pisarski, H.G.; Dolby, R.E. The Significance of Softened HAZs in High Strength Structural Steels. Weld. World 2012, 47, 32–34. [Google Scholar] [CrossRef]

- Węglowski, M.S.; Zeman, M. Prevention of cold cracking in ultra-high strength steel Weldox 1300. Arch. Civ. Mech. Eng. 2014, 14, 417–424. [Google Scholar] [CrossRef]

- Senuma, T. Physical Metallurgy of Modern High Strength Steel Sheets. ISIJ Int. 2001, 41, 520–532. [Google Scholar] [CrossRef]

- Kim, J.H.; Seo, J.S.; Kim, H.J.; Ryoo, H.S.; Kim, K.H.; Huh, M.Y. Effect of Weld Metal Microstructures on Cold Crack Susceptibility of FCAW Weld Metal. Met. Mater. Int. 2008, 14, 239–245. [Google Scholar] [CrossRef]

- Fydrych, D.; Łabanowski, J.; Rogalski, G.; Haras, J.; Tomków, J.; Świerczyńska, A.; Jakóbczak, P.; Kostro, Ł. Weldability of S500MC Steel in Underwater Conditions. Adv. Mater. Sci. 2014, 14, 37–45. [Google Scholar] [CrossRef]

- Hochhauser, F.; Ernst, W.; Rauch, R.; Vallant, R.; Enzinger, N. Influence of the Soft Zone on the Strength of Welded modern HSLA Steels. Weld. World 2012, 56, 77–85. [Google Scholar] [CrossRef]

- Schneider, C.; Ernst, W.; Schnitzer, R.; Staufer, H.; Vallant, R.; Enzinger, N. Welding of S960MC with undermatching filler material. Weld. World 2018, 62, 801–809. [Google Scholar] [CrossRef]

- Jambor, M.; Nový, F.; Mičian, M.; Trško, L.; Bokůvka, O.; Pastorek, F.; Harmaniak, D. Gas metal arc welding of thermo-mechanically controlled processed S960MC steel thin sheets with different welding parameters. Communications 2018, 20, 29–35. [Google Scholar] [CrossRef]

- Guo, W.; Crowther, D.; Francis, J.A.; Thompson, A.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser welded S960 high strength steel. Mater. Des. 2015, 85, 534–548. [Google Scholar] [CrossRef]

- Mičian, M.; Harmaniak, D.; Nový, F.; Winczek, J.; Moravec, J.; Trško, L. Effect of the t8/5 Cooling Time on the Properties of S960MC Steel in the HAZ of Welded Joints Evaluated by Thermal Physical Simulation. Metals 2020, 10, 229. [Google Scholar] [CrossRef]

- Maurer, W.; Ernst, W.; Rauch, R.; Vallant, R.; Enzinger, N. Evaluation of the factors influencing the strength of HSLA steel weld joint with softened HAZ. Weld. World 2015, 59, 809–822. [Google Scholar] [CrossRef]

- Bang, K.S.; Kim, W.Y. Estimation and Prediction of HAZ Softening in Thermomechanically Controlled-Rolled and Accelerated-Cooled Steel. Weld. J. 2002, 81, 174–179. [Google Scholar]

- Gáspár, M. Effect of Welding Heat Input on Simulated HAZ Areas in S960QL High Strength Steel. Metals 2019, 9, 1226. [Google Scholar] [CrossRef]

- Njock Bayock, F.; Kah, P.; Mvola, B.; Layus, P. Effect of heat input and undermatched filler wire on the microstructure and mechanical properties of dissimilar S700MC/S960QC high-strength steels. Metals 2019, 9, 883. [Google Scholar] [CrossRef]

- Komizo, Y. Performance of welded joints in TMCP steel plates. Weld. Int. 1991, 5, 598–601. [Google Scholar] [CrossRef]

- Rodrigues, D.M.; Menezes, L.F.; Loureiro, A.; Fernandes, J.V. Numerical study of the plastic behavior in tension of welds in high strength steels. Int. J. Plast. 2004, 20, 1–18. [Google Scholar] [CrossRef]

- An, G.B.; Nam, S.K.; Jang, T.W. Effect of weld HAZ softening on tensile strength of welded joint with weld HAZ softening. Mater. Sci. Forum 2008, 580–582, 589–592. [Google Scholar] [CrossRef]

- Mai, R.; Jiang, Z.; Ma, J.; Zhang, Y. Analytical Study on Microstructure and Mechanical Property in HAZ-Softened Weld Joint with High Heat Input of Low Carbon TMCP Steel. Appl. Mech. Mater. 2017, 872, 99–106. [Google Scholar] [CrossRef]

- Mochizuki, M.; Shintomi, T.; Hashimoto, Y.; Toyoda, M. Analytical Study on Deformation and Strength in HAZ-Softened Welded Joints of Fine-Grained Steel. Weld. World 2004, 48, 2–12. [Google Scholar] [CrossRef]

- Lahtinen, T.; Vilaça, P.; Peura, P.; Mehtonen, S. MAG Welding Tests of Modern High Strength Steels with Minimum Yield Strength of 700 MPa. Appl. Sci. 2019, 9, 1031. [Google Scholar] [CrossRef]

- Silva, A.; Szczucka-Lasota, B.; Węgrzyn, T.; Jurek, A. MAG welding of S700MC steel used in transport means with the operation of low arc welding method. Weld. Technol. Rev. 2019, 91, 23–28. [Google Scholar] [CrossRef][Green Version]

- Golyakevich, A.A.; Orlov, L.N.; Maksimov, S.Y. Mechanized Welding with Metal Cored Wire. Adv. Mater. Res. 2020, 1157, 113–122. [Google Scholar] [CrossRef]

- Prajapati, P.; Badheka, V.J. Investigation on Various Welding Consumables on Properties of Carbon Steel Material in Gas Metal Arc Welding under Constant Voltage Mode. Sadhana 2017, 42, 1751–1761. [Google Scholar] [CrossRef]

- Górka, J. Assessment of the Effect of Laser Welding on the Properties and Structure of TMCP Steel Butt Joints. Metals 2020, 13, 1312. [Google Scholar] [CrossRef] [PubMed]

- Górka, J. Assessment of the Weldability of T-Welded Joints in 10 mm Thick TMCP Steel Using Laser Beam. Materials 2018, 11, 1192. [Google Scholar] [CrossRef]

- Zubar, T.; Fedosyuk, V.; Tishkevich, D.; Konafyev, O.; Astapovich, K.; Kozlovskiy, A.; Zdorovets, M.; Vinnik, D.; Gudkova, S.; Kaniukov, E.; et al. The Effect of Heat Treatment on the Microstructure and Mechanical Properties of 2D Nanostructured Au/NiFe System. Nanomaterials 2020, 10, 1077. [Google Scholar] [CrossRef]

- Li, Y.; Bushby, A.J.; Dunstan, D.J. The Hall–Petch effect as a manifestation of the general size effect. Proc. R. Soc. A 2016, 472, 20150890. [Google Scholar] [CrossRef]

- Kik, T.; Moravec, J.; Švec, M. Experiments and Numerical Simulations of the Annealing Temperature Influence on the Residual Stresses Level in S700MC Steel Welded Elements. Materials 2020, 13, 5289. [Google Scholar] [CrossRef] [PubMed]

- Nowotnik, A.; Siwecki, T. The effect of TMCP parameters on the microstructure and mechanical properties of Ti-Nb microalloyed steel. J. Microsc. 2010, 237, 258–262. [Google Scholar] [CrossRef] [PubMed]

- Wald, F.; Jandera, M. Stability and Ductility of Steel Structures 2019, 1st ed.; CRC Press/Balkema: Leiden, The Netherlands, 2019; p. 127. [Google Scholar]

| Rp0.2 (MPa) | Rm (MPa) | A50mm (%) | CET (CEV) | KV −20 °C (J) |

|---|---|---|---|---|

| 1018 | 1108 | 10 | 0.26 (0.50) | 32 |

| C | Si | Mn | P | S | Al | Nb | V |

|---|---|---|---|---|---|---|---|

| 0.085 | 0.18 | 1.06 | 0.01 | 0.003 | 0.036 | 0.002 | 0.007 |

| Ti | Cu | Cr | Ni | Mo | N | B | Fe |

| 0.026 | 0.01 | 1.08 | 0.07 | 0.109 | 0.005 | 0.0015 | bal. |

| Filler Material | Type | Fe | C | Si | Mn | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| Union X96 | Solid wire | bal. | 0.12 | 0.80 | 1.90 | 0.45 | 2.35 | 0.55 |

| Böhler X96 L-MC | Metal-cored wire | bal. | 0.06 | 0.70 | 1.90 | 0.60 | 2.20 | 0.50 |

| Method | Filler Material | Effective Arc Voltage Uef (V) | Effective Current Ief(A) | Welding Speed vs. (cm·min–1) | Wire Feed Speed vd (m·min–1) | Heat Input Qp (kJ·cm–1) | Weld Gap b (mm) |

|---|---|---|---|---|---|---|---|

| GMAW-S | Union X96 | 16.6 | 102 | 22.2 | 3.8 | 3.69 | 1.5 |

| GMAW-P | Union X96 | 19.7 | 61 | 22.2 | 3.2 | 2.62 | 2.0 |

| GMAW-CMT | Union X96 | 13.1 | 131 | 49.8 | 5.3 | 1.65 | 2.3 |

| MCAW-S | Böhler X96 L-MC | 14.7 | 86 | 24.0 | 3.0 | 2.53 | 2.3 |

| MCAW-S cooled | Böhler X96 L-MC | 14.7 | 86 | 24.0 | 3.0 | 2.53 | 2.3 |

| Method | Qp (kJ·mm–1) | Tmax (°C) | t8/5 (s) |

|---|---|---|---|

| GMAW-S | 0.369 | 1104 | 17.5 |

| GMAW-P | 0.262 | 1292 | 11.6 |

| GMAW-CMT | 0.165 | 838 | 5.0 |

| MCAW-S | 0.253 | 853 | 5.3 |

| MCAW-S cooled | 0.253 | 1054 | 6.0 |

| Sample No. | YS (MPa) | Average Value of YS (MPa) | TS (MPa) | Average Value of TS (MPa) | A50mm (%) | Average Value of A50mm (%) |

|---|---|---|---|---|---|---|

| GMAW-S-01 | 890 | 883 | 916 | 921 | 3.20 | 3.30 |

| GMAW-S-02 | 876 | 926 | 3.30 | |||

| GMAW-P-01 | 913 | 915 | 941 | 940 | 2.20 | 2.20 |

| GMAW-P-02 | 917 | 938 | 2.10 | |||

| GMAW-CMT-01 | 930 | 927 | 941 | 945 | 2.23 | 2.20 |

| GMAW-CMT-02 | 924 | 949 | 2.20 | |||

| MCAW-S-01 | 949 | 951 | 968 | 969 | 2.17 | 2.20 |

| MCAW-S-02 | 953 | 970 | 2.17 | |||

| MCAW-S cooled-01 | 947 | 955 | 965 | 972 | 1.65 | 1.70 |

| MCAW-S cooled-02 | 959 | 975 | 1.78 |

| Method | Soft Zone (mm) | XSZ (-) | |

|---|---|---|---|

| Left Side of the HAZ | Right Side of the HAZ | ||

| GMAW-S | 3.05 | 3.25 * | 1.08 |

| GMAW-P | 3.10 * | 2.50 | 1.03 |

| GMAW-CMT | 3.00 * | 2.40 | 1.00 |

| MCAW-S | 2.75 * | 2.60 | 0.92 |

| MCAW-S cooled | 2.20 * | 1.50 | 0.73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mičian, M.; Frátrik, M.; Kajánek, D. Influence of Welding Parameters and Filler Material on the Mechanical Properties of HSLA Steel S960MC Welded Joints. Metals 2021, 11, 305. https://doi.org/10.3390/met11020305

Mičian M, Frátrik M, Kajánek D. Influence of Welding Parameters and Filler Material on the Mechanical Properties of HSLA Steel S960MC Welded Joints. Metals. 2021; 11(2):305. https://doi.org/10.3390/met11020305

Chicago/Turabian StyleMičian, Miloš, Martin Frátrik, and Daniel Kajánek. 2021. "Influence of Welding Parameters and Filler Material on the Mechanical Properties of HSLA Steel S960MC Welded Joints" Metals 11, no. 2: 305. https://doi.org/10.3390/met11020305

APA StyleMičian, M., Frátrik, M., & Kajánek, D. (2021). Influence of Welding Parameters and Filler Material on the Mechanical Properties of HSLA Steel S960MC Welded Joints. Metals, 11(2), 305. https://doi.org/10.3390/met11020305