The Effect of Annealing on the Microstructure and Properties of Ultralow-Temperature Rolled Mg–2Y–0.6Nd–0.6Zr Alloy

Abstract

:1. Introduction

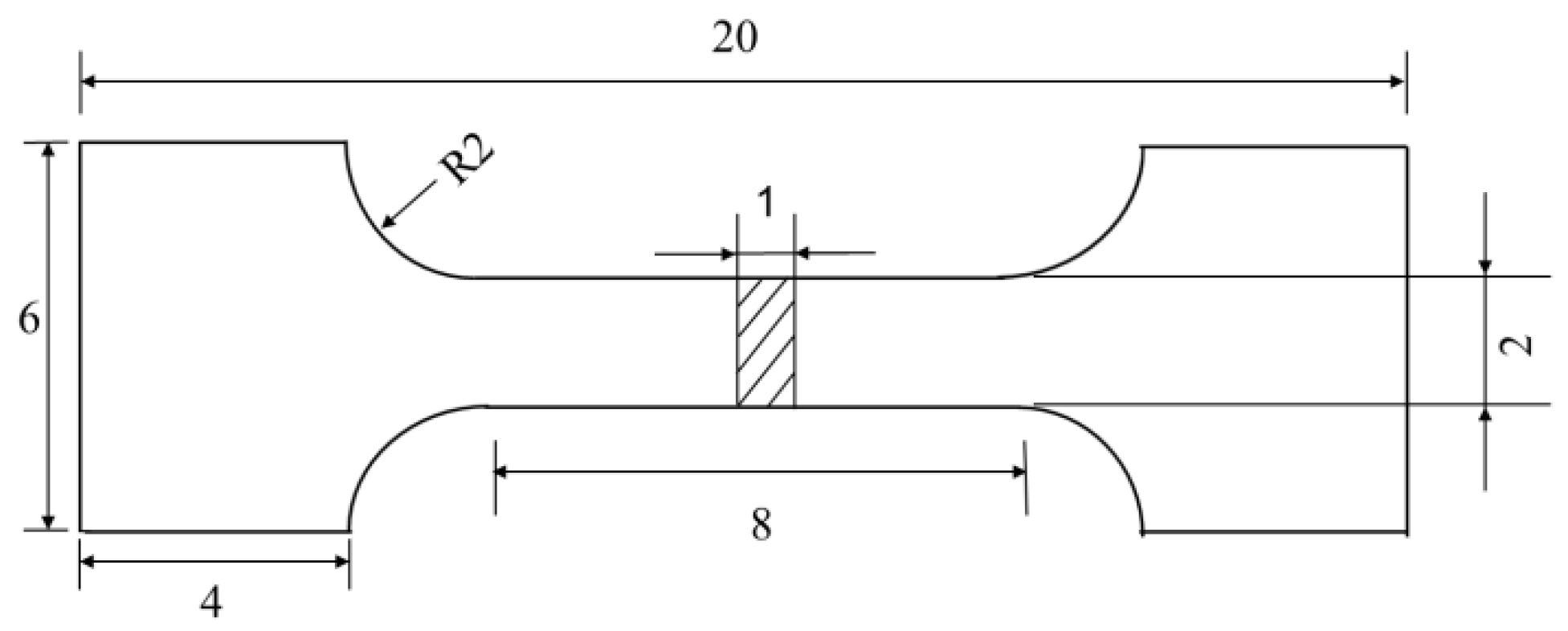

2. Material and Methods

3. Results and Discussion

3.1. Microstructure Analysis

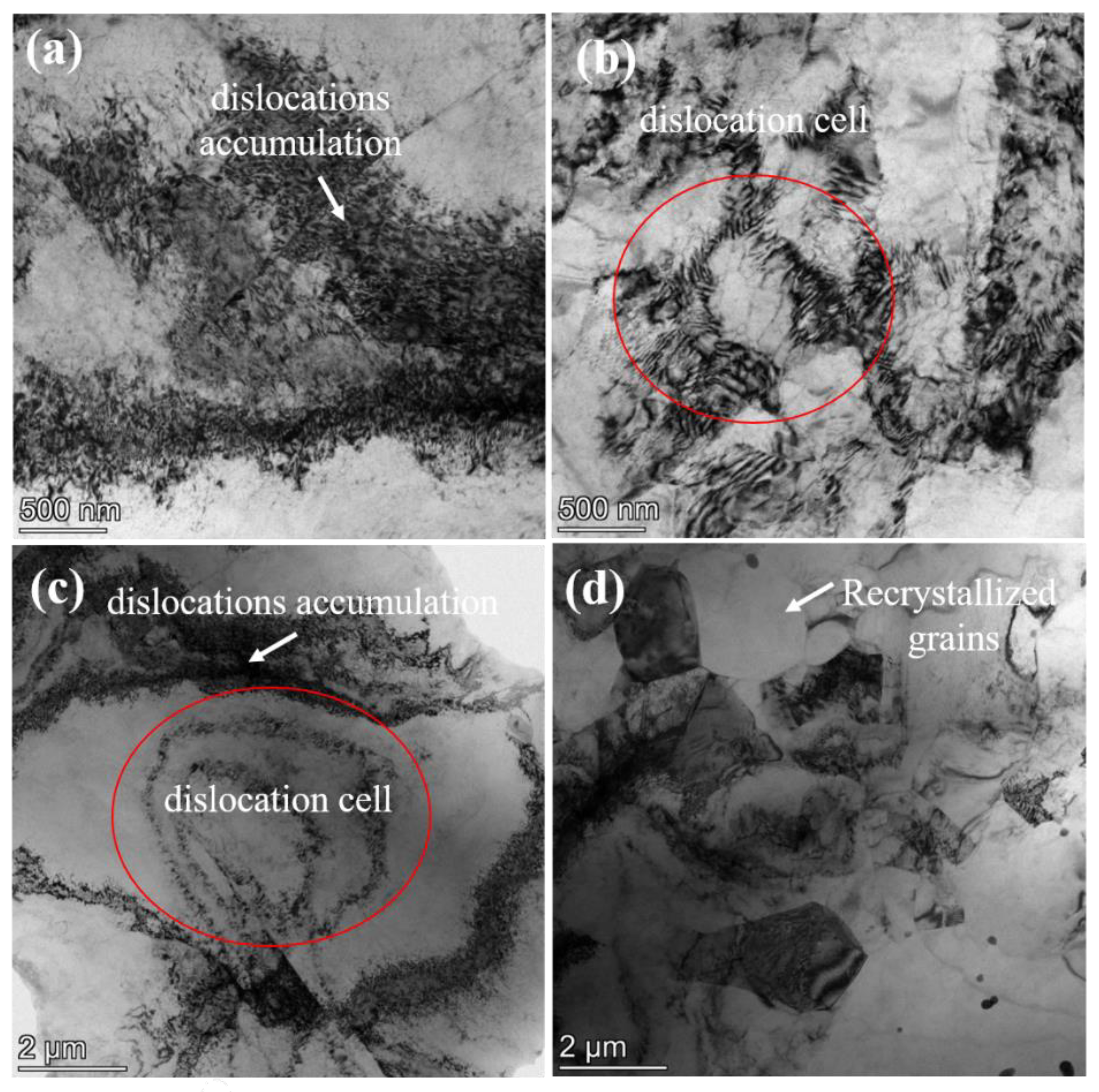

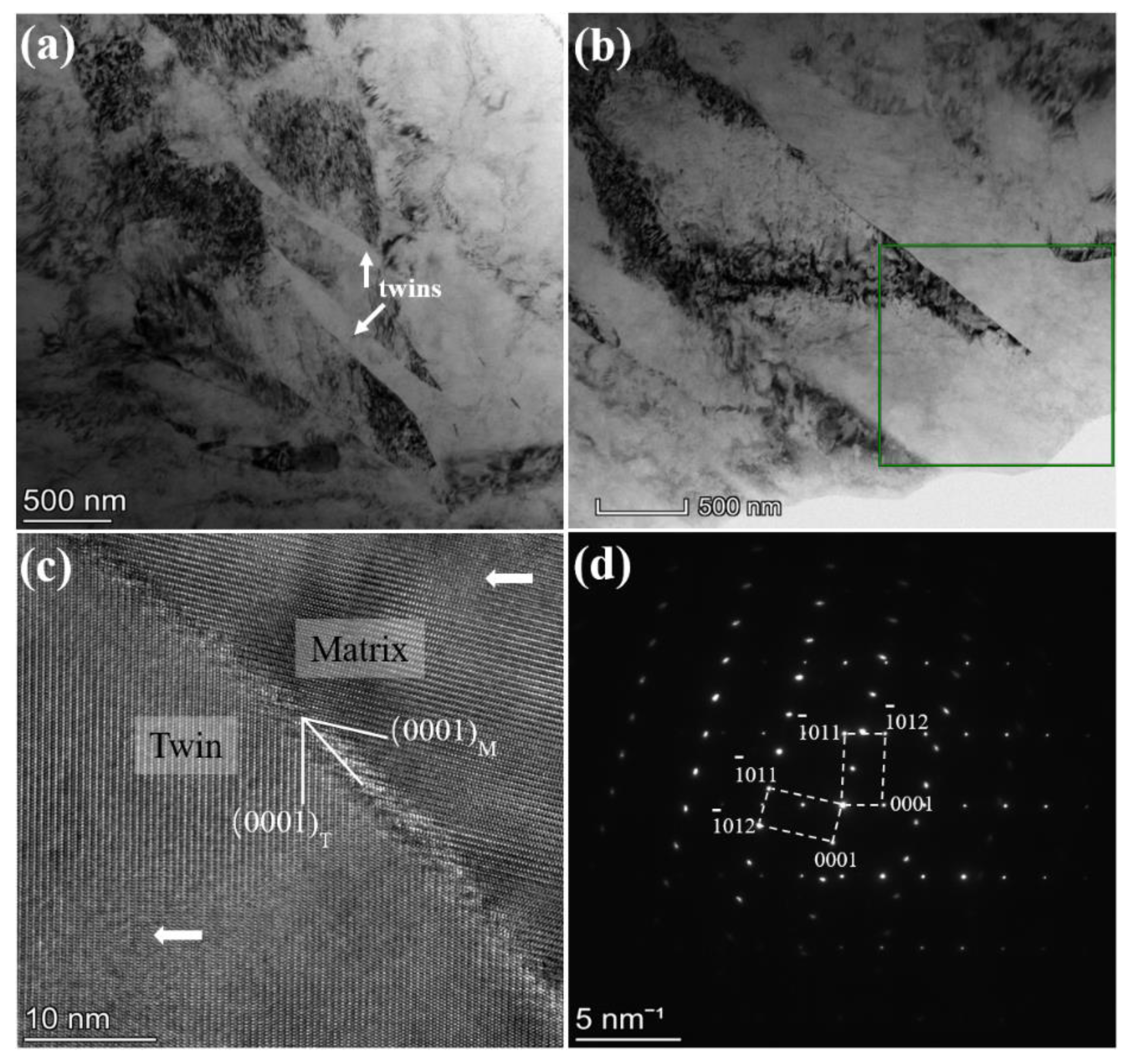

3.2. TEM Analysis

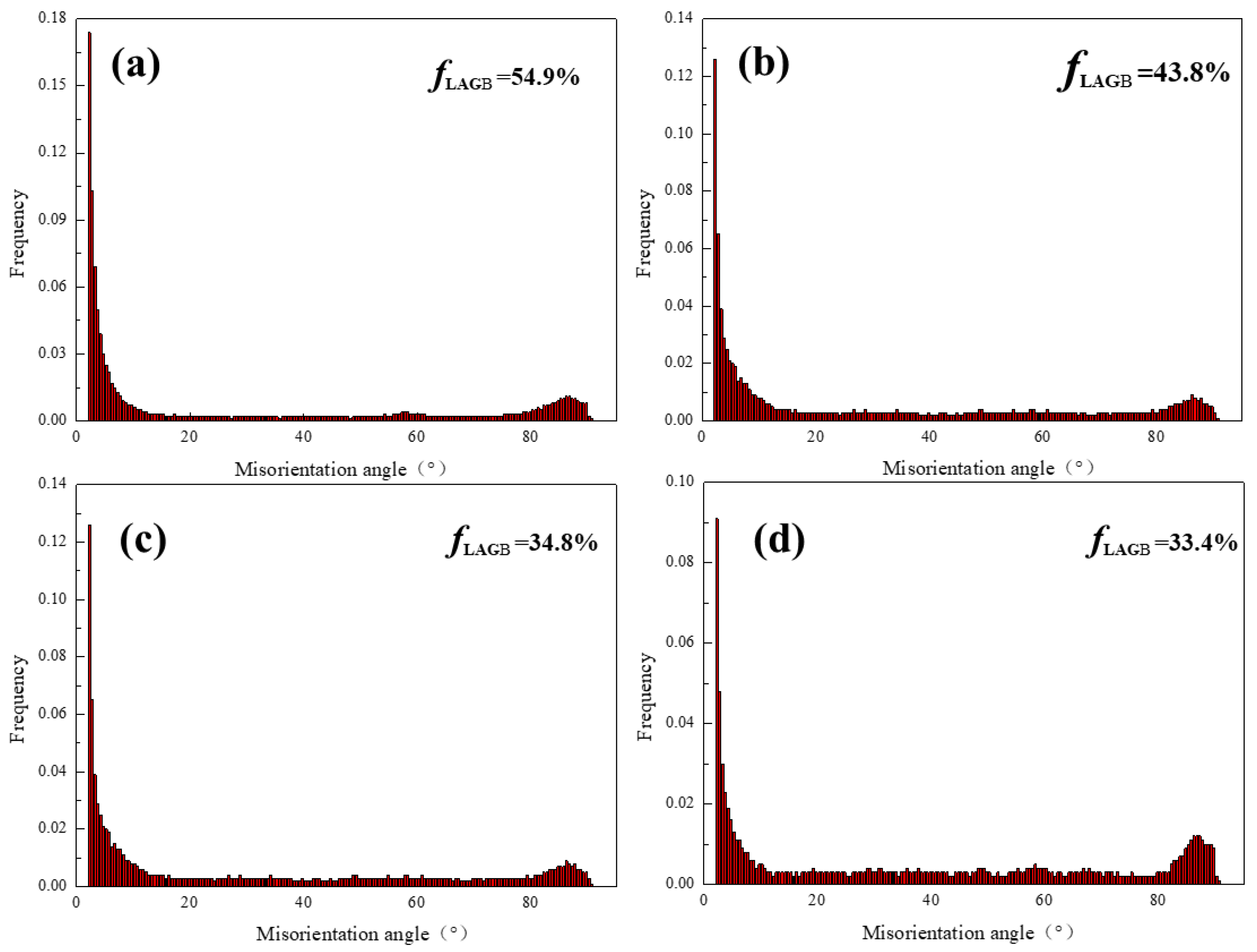

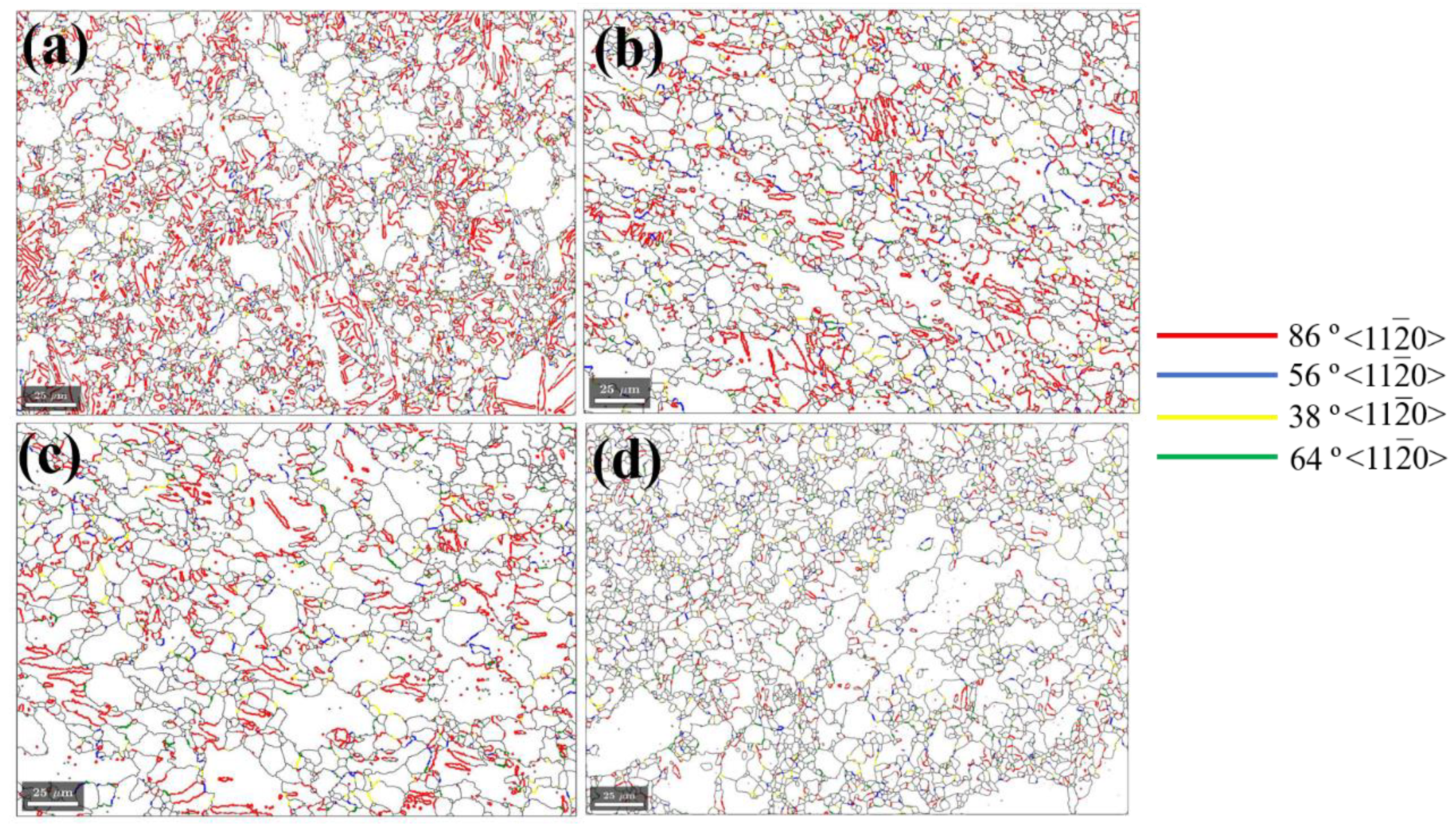

3.3. EBSD Analysis

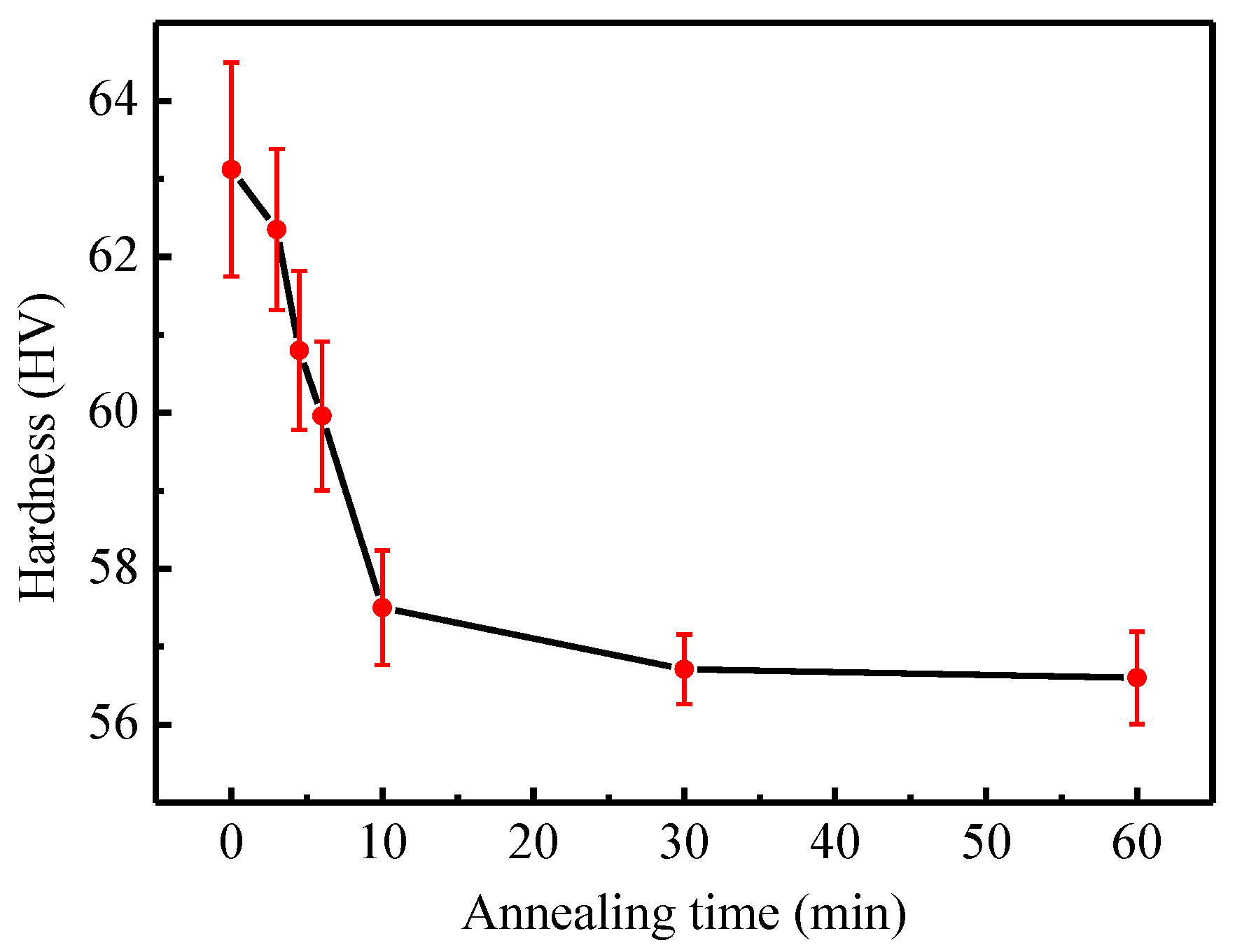

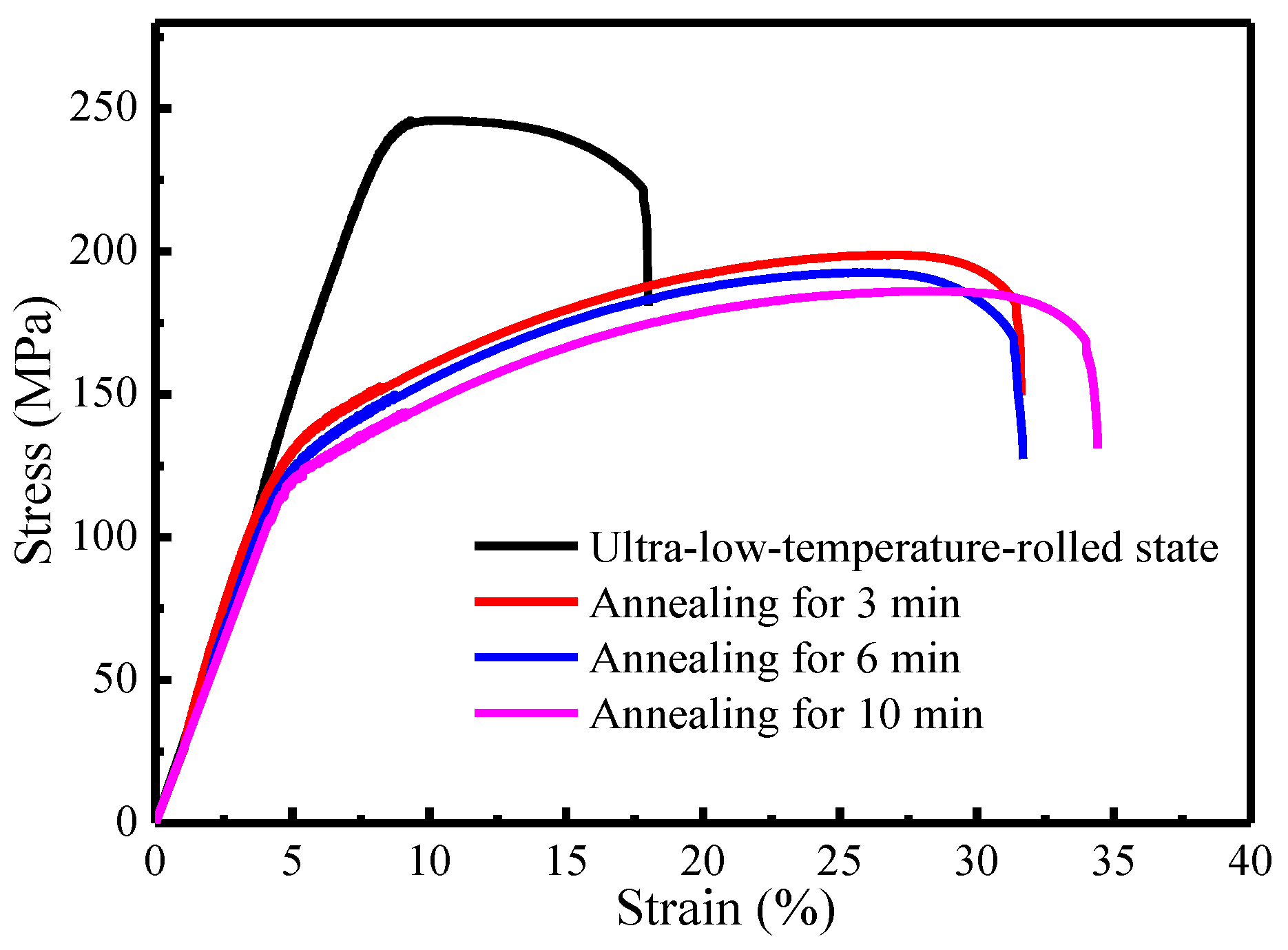

3.4. Mechanical Properties

4. Conclusions

- The alloy was treated with ECAP to obtain fine grains. Ultralow-temperature rolling introduced a large number of high-energy defects, such as grain boundaries and dislocations, which served as preferential nucleation sites during subsequent annealing for recrystallized grain formation. The twins formed by tension exerted along the c-axis during rolling under ultralow temperatures were mainly {} <> tensile twins.

- Increasing the annealing time at 350 °C resulted in the gradual completion of the static recrystallization process. The walls of the cells formed by dislocation entanglement flattened and formed subcrystalline grains during annealing, thereby gradually decreasing the twin content and the proportion of small-angle grain boundaries.

- By increasing the annealing time at 350 °C, the hardness decreased by 10.32% from 63.12 to 56.6 HV, the tensile strength of the alloy was reduced from 245.89 to 186.15 MP, and the plasticity of the alloy significantly increased by 34.48% from 11% to 29%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ECAP | equal channel angular pressing |

| OM | optical microscopy |

| EBSD | electron backscatter diffraction technology |

| TEM | transmission electron microscopy |

| CYS | compress yield strength |

| UTS | ultimate tensile strength |

| EL | elongation |

| HCP | hexagonal close packed |

| SPD | severe plastic deformation |

| UFG | ultrafine grain |

| HPT | high-pressure torsion |

| MAF | multiaxial forging |

| ARB | accumulative roll-bonding |

| YS | yield strength |

| ND | normal direction |

| ED | extrusion direction |

| RD | rolling direction |

| TD | transverse direction |

| θ | the phase difference between adjacent grains |

| LAGB | low-angle grain boundaries (2° < θ < 10°) |

| HAGB | high-angle grain boundaries (θ > 10°) |

| fLAGB | the proportion of low-angle grain boundary to total grain boundary |

References

- Adel, A.; Danil, P.; Ivan, E.; Mohamed, T.; Mahmoud, S.; Magdy, E.R. ANN Surface Roughness Optimization of AZ61 Magnesium Alloy Finish Turning: Minimum Machining Times at Prime Machining Costs. Materials 2018, 11, 808. [Google Scholar]

- Jing, T.W.; Yin, D.L.; Jin, Q.L.; Tao, J.; Yan, L.S.; Xiang, Z. Effect of grain size on mechanical property of Mg–3Al–1Zn alloy. Scr. Mater. 2008, 59, 63–66. [Google Scholar]

- Liu, Q.; Zhou, X.; Zhou, H.; Fan, X.; Liu, K. The effect of extrusion conditions on the properties and textures of AZ31B alloy. J. Magn. Alloy 2017, 5, 202–209. [Google Scholar] [CrossRef]

- Reed-Hill, R.E.; Robertson, W.D. Additional modes of deformation twinning in magnesium. Acta Metall. 1957, 5, 717–727. [Google Scholar] [CrossRef]

- Atik, K.; Efe, M. Twinning-induced shear banding and its control in rolling of magnesium. Mater. Sci. Eng. A 2018, 725, 267–273. [Google Scholar] [CrossRef]

- Edalati, K.; Yamamoto, A.; Horita, Z.; Ishihara, T. High-pressure torsion of pure magnesium: Evolution of mechanical properties, microstructures and hydrogen storage capacity with equivalent strain. Scr. Mater. 2011, 64, 880–883. [Google Scholar] [CrossRef]

- Schafler, E.; Pippan, R. Effect of thermal treatment on microstructure in high pressure torsion (HPT) deformed nickel. Mater. Sci. Eng. A 2004, 387, 799–804. [Google Scholar] [CrossRef]

- Bhowmik, A.; Biswas, S.; Dhinwal, S.S.; Sarkar, A.; Ray, R.K.; Bhattacharjee, D.; Suwas, S. Microstructure and Texture Evolution in Interstitial-Free (IF) Steel Processed by Multi-Axial Forging. Mater. Sci. Forum 2012, 702–703, 774–777. [Google Scholar] [CrossRef]

- Shamsolhodaei, A.; Zarei-Hanzaki, A.; Moghaddam, M. Structural and functional properties of a semi equiatomic NiTi shape memory alloy processed by multi-axial forging. Mater. Sci. Eng. A 2017, 700, 1–9. [Google Scholar] [CrossRef]

- Duan, J.Q.; Quadir, M.Z.; Xu, W.; Kong, C.; Ferry, M. Texture balancing in a fcc/bcc multilayered composite produced by accumulative roll bonding. Acta Mater. 2017, 123, 11–23. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—Development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Matsubara, K.; Miyahara, Y.; Horita, Z.; Langdon, T.G. Developing superplasticity in a magnesium alloy through a combination of extrusion and ECAP. Acta Mater. 2003, 51, 3073–3084. [Google Scholar] [CrossRef]

- Tham, Y.W.; Fu, M.W.; Hng, H.H.; Pei, Q.X.; Lim, K.B. Microstructure and Properties of Al-6061 Alloy by Equal Channel Angular Extrusion for 16 Passes. Adv. Manuf. Processes 2007, 22, 819–824. [Google Scholar] [CrossRef]

- Beyerlein, L.J.; Tóthb, L.S. Texture evolution in equal-channel angular extrusion. Prog. Mater. Sci. 2009, 54, 427–510. [Google Scholar] [CrossRef]

- Jahadi, R.; Sedighi, M.; Jahed, H. ECAP effect on the micro-structure and mechanical properties of AM30 magnesium alloy. Mater. Sci. Eng. A 2014, 593, 178–184. [Google Scholar] [CrossRef]

- Garces, G.; Muñoz-Morris, M.A.; Morris, D.G.; Adeva, P.; Perez, P. Optimization of strength by microstructural refinement of MgY_2Zn_1 alloy during extrusion and ECAP processing. Mater. Sci. Eng. A 2014, 614, 96–105. [Google Scholar] [CrossRef] [Green Version]

- Sarker, D.; Friedman, J.; Chen, D.L. De-twinning and Texture Change in an Extruded AM30 Magnesium Alloy during Compression along Normal Direction. J. Mater. Sci. Technol. 2015, 31, 264–268. [Google Scholar] [CrossRef]

- Sarker, D.; Friedman, J.; Chen, D.L. Twin Growth and Texture Evolution in an Extruded AM30 Magnesium Alloy During Compression. J. Mater. Sci. Technol. 2014, 30, 884–887. [Google Scholar] [CrossRef]

- Sarker, D.; Chen, D.L. Detwinning and strain hardening of an extruded magnesium alloy during compression. Scr. Mater. 2012, 67, 165–168. [Google Scholar] [CrossRef]

- Sarker, D.; Chen, D.L. Dependence of compressive deformation on pre-strain and loading direction in an extruded magnesium alloy: Texture, twinning and de-twinning. Mater. Sci. Eng. A 2014, 596, 134–144. [Google Scholar] [CrossRef]

- Sarker, D.; Friedman, J.; Chen, D.L. Influence of pre-strain on de-twinning activity in an extruded AM30 magnesium alloy. Mater. Sci. Eng. A 2014, 605, 73–79. [Google Scholar] [CrossRef]

- Sarker, D.; Chen, D.L. Texture transformation in an extruded magnesium alloy under pressure. Mater. Sci. Eng. A 2013, 582, 63–67. [Google Scholar] [CrossRef]

- Lei, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh Strength and High Electrical Conductivity in Copper. Science 2004, 304, 422–426. [Google Scholar]

- Zhang, D.D.; Yang, Q.; Guan, K.; Li, B.S.; Wang, N.; Qin, P.F.; Jiang, B.; Sun, C.; Qin, X.; Tian, Z.; et al. A high-strength low-rare-earth-alloyed magnesium alloy via traditional hot-extrusion. J. Alloy Compd. 2019, 810, 151967. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.M.; Molina-Aldareguia, J.M.; Pérez-Prado, M.T. Origin of the twinning to slip transition with grain size refinement, with decreasing strain rate and with increasing temperature in magnesium. Acta Mater. 2015, 88, 232–244. [Google Scholar] [CrossRef]

- Drouven, C.; Basu, I.; Al-Samman, T.; Korte-Kerzel, S. Twinning effects in deformed and annealed magnesium–neodymium alloys. Mater. Sci. Eng. A 2015, 647, 91–104. [Google Scholar] [CrossRef]

- Sarker, D.; Friedman, J.; Chen, D.L. Influence of pre-deformation and subsequent annealing on strain hardening and anisotropy of AM30 magnesium alloy. J. Alloy Compd. 2014, 611, 341–350. [Google Scholar] [CrossRef]

- Kim, Y.J.; Lee, J.U.; Kim, S.H.; Kim, Y.M.; Park, S.H. Grain size effect on twinning and annealing behaviors of rolled magnesium alloy with bimodal structure. Mater. Sci. Eng. A 2019, 754, 38–45. [Google Scholar] [CrossRef]

- Song, D.; Li, C.; Liang, N.N.; Yang, F.L.; Jiang, J.H.; Sun, J.P.; Wu, G.S.; Ma, A.B.; Ma, X.L. Simultaneously improving corrosion resistance and mechanical properties of a magnesium alloy via equal-channel angular pressing and post water annealing. Mater. Des. 2019, 166, 107621. [Google Scholar] [CrossRef]

- Chen, W.Z.; Ma, L.M.; Chen, X.M.; Cui, G.R.; Zhang, W.C.; Wang, E.D. Microstructure evolution and mechanical performance improvement of thin ZK61 magnesium alloy sheets subjected to cumulative cold rolling and intermediate annealing. Mater. Sci. Eng. A 2018, 733, 350–360. [Google Scholar] [CrossRef]

- Guo, F.; Pei, R.S.; Jiang, L.Y.; Zhang, D.F.; Korte-Kerzel, S.; Al-Samman, T. The role of recrystallization and grain growth in optimizing the sheet texture of magnesium alloys with calcium addition during annealing. J. Magn. Alloy 2020, 8, 252–268. [Google Scholar] [CrossRef]

- Matsuda, M.; Ii, S.; Kawamura, Y.; Ikuhara, Y.; Nishida, M. Interaction between long period stacking order phase and deformation twin in rapidly solidified Mg97Zn1Y2 alloy. Mater. Sci. Eng. A 2004, 386, 447–452. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

| Sample | Ultimate Tensile Strength (UTS/MPa) | Elongation (EL/%) |

|---|---|---|

| Ultralow-temperature rolled state | 245.89 | 11 |

| Annealing for 3 min | 198.8 | 26 |

| Annealing for 6 min | 192.64 | 25 |

| Annealing for 10 min | 186.15 | 29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Li, W.; Tan, Y.; Tan, Y. The Effect of Annealing on the Microstructure and Properties of Ultralow-Temperature Rolled Mg–2Y–0.6Nd–0.6Zr Alloy. Metals 2021, 11, 315. https://doi.org/10.3390/met11020315

Yu H, Li W, Tan Y, Tan Y. The Effect of Annealing on the Microstructure and Properties of Ultralow-Temperature Rolled Mg–2Y–0.6Nd–0.6Zr Alloy. Metals. 2021; 11(2):315. https://doi.org/10.3390/met11020315

Chicago/Turabian StyleYu, Hongmin, Wei Li, Yun Tan, and Yuanbiao Tan. 2021. "The Effect of Annealing on the Microstructure and Properties of Ultralow-Temperature Rolled Mg–2Y–0.6Nd–0.6Zr Alloy" Metals 11, no. 2: 315. https://doi.org/10.3390/met11020315