Shape Memory Alloys and Polymers for MEMS/NEMS Applications: Review on Recent Findings and Challenges in Design, Preparation, and Characterization

Abstract

:1. Introduction

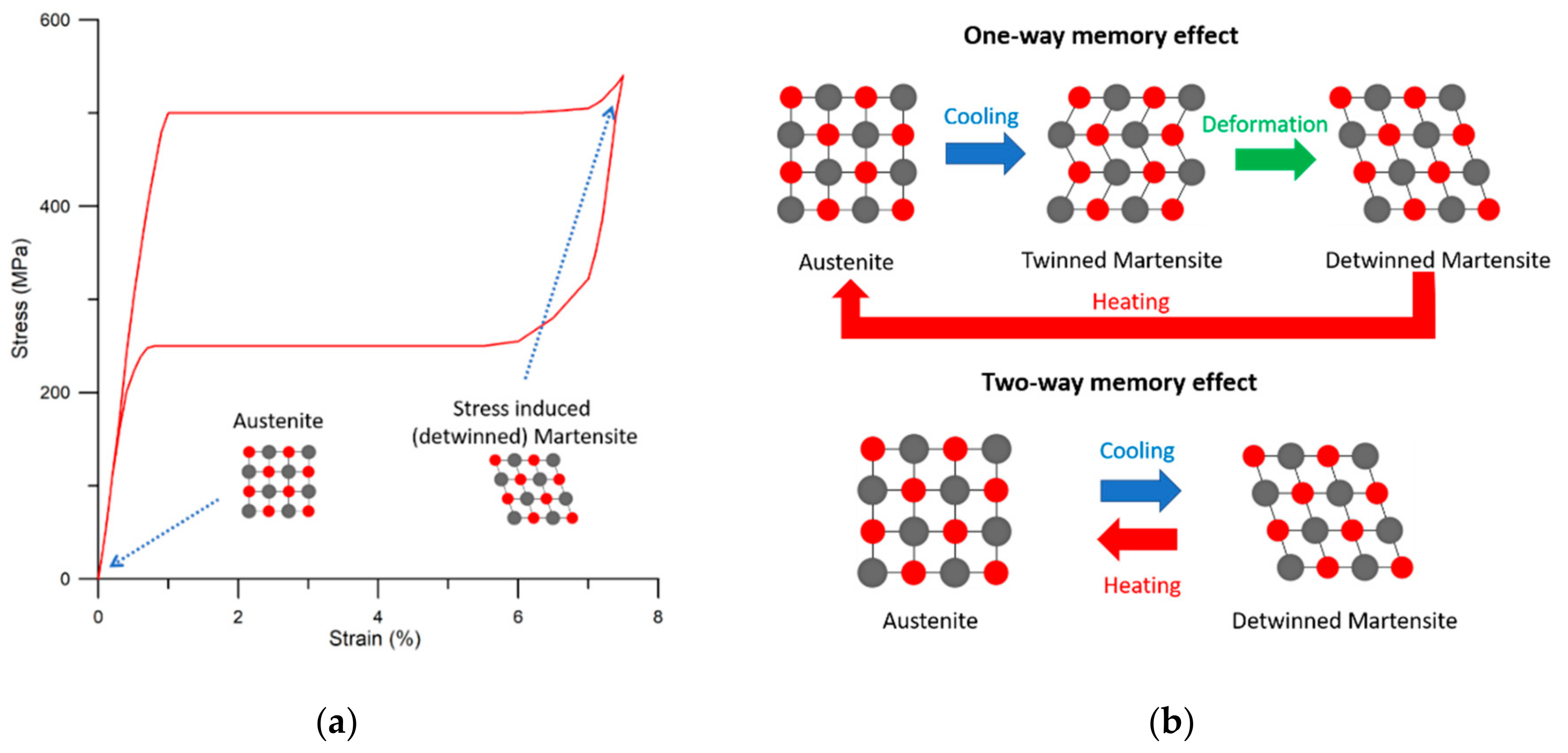

2. Fundamental Properties of Shape Memory Materials

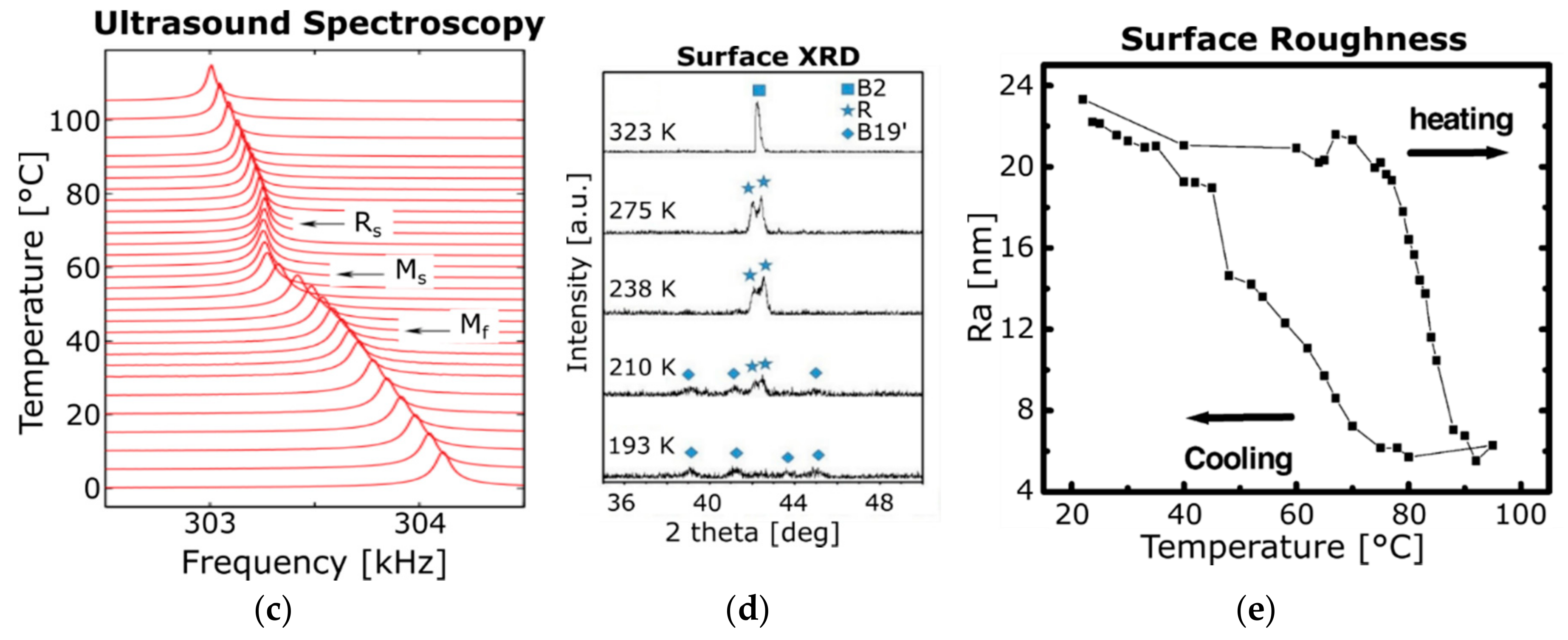

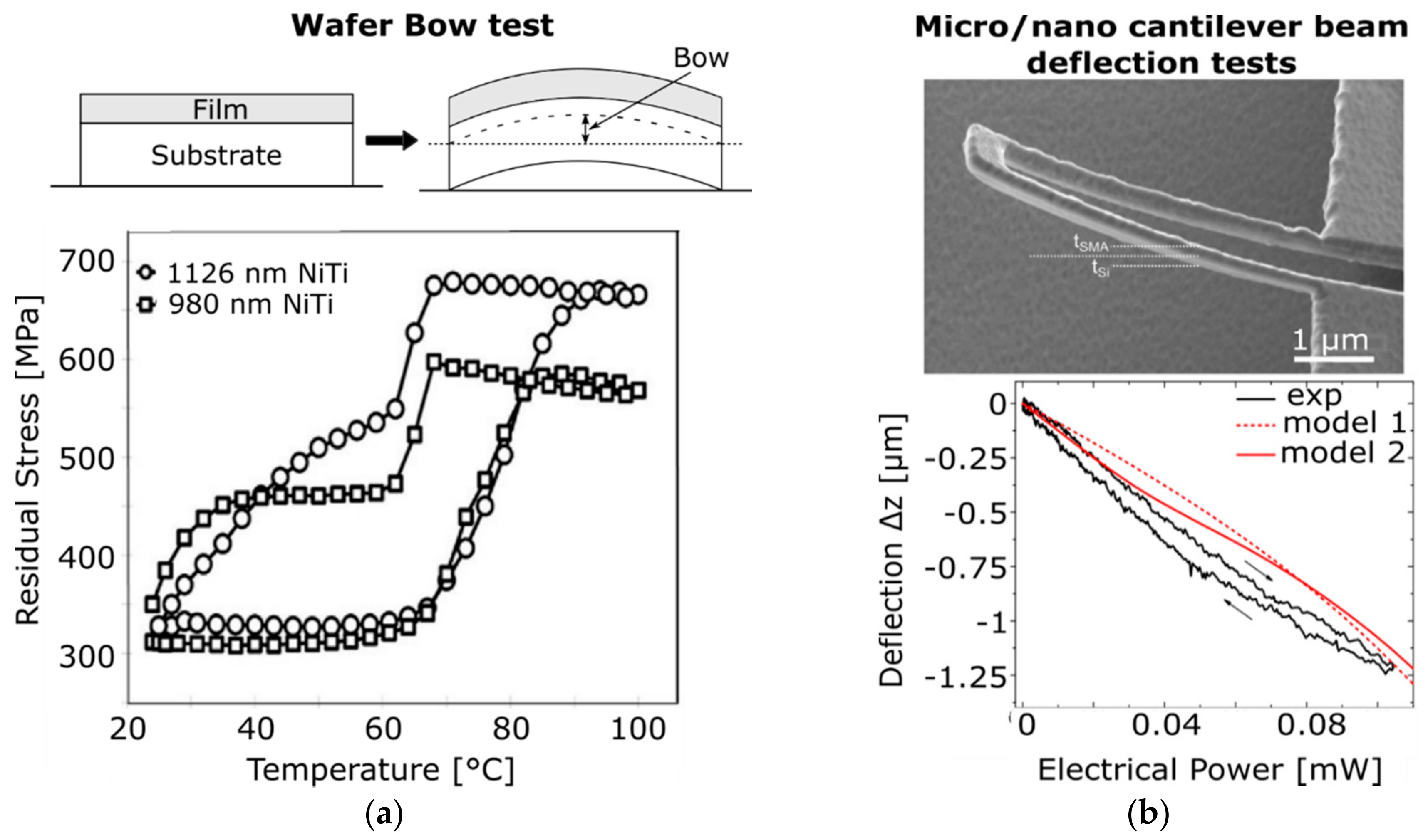

2.1. Shape Memory Alloys

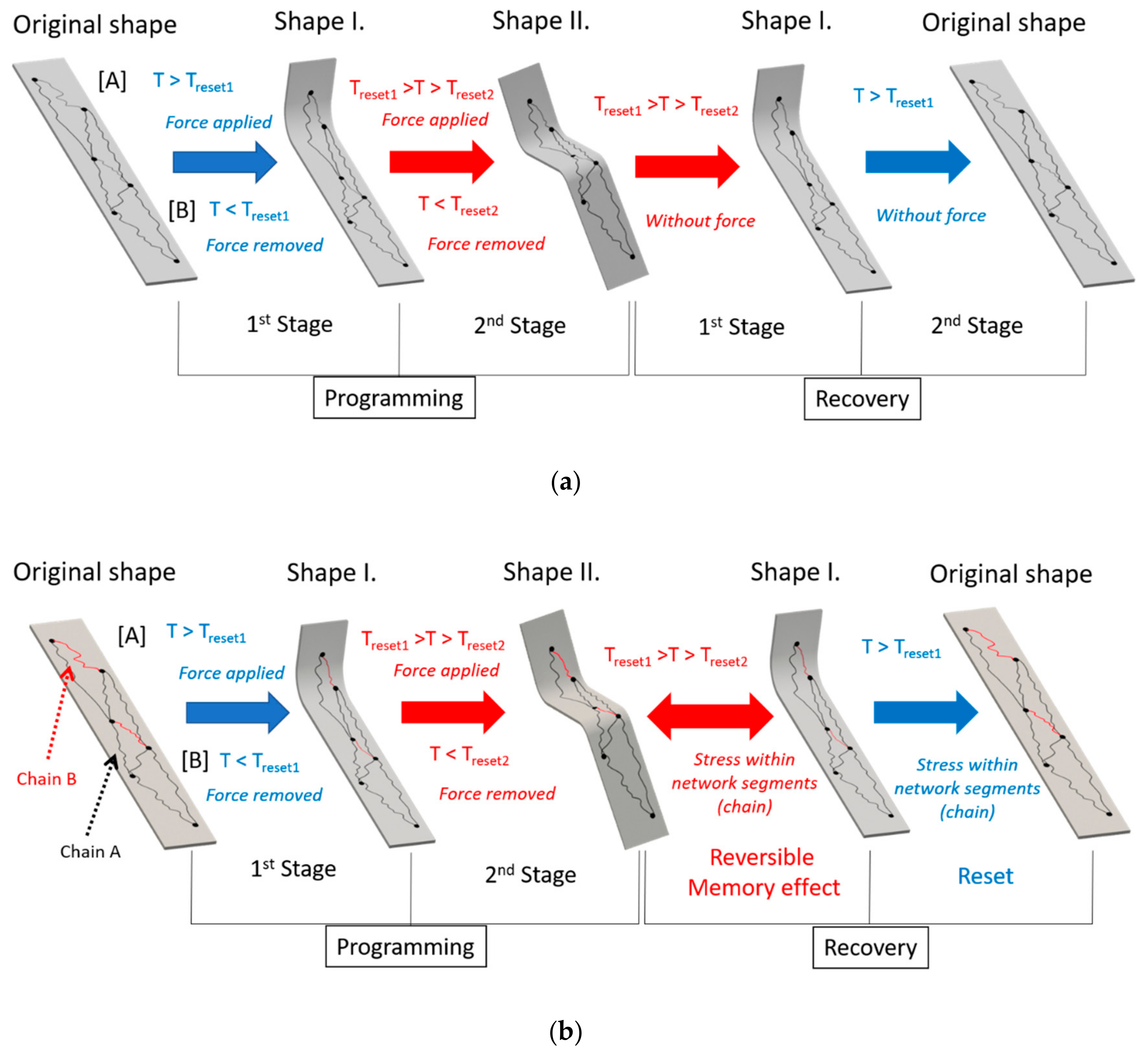

2.2. Shape Memory Polymers

| Property of SMP | Units | Usual Value(s) |

|---|---|---|

| Density | g/cm3 | 0.9–1.1 |

| Young‘s modulus of temporary shape (T < Treset) | GPa | 0.01–3 |

| Young‘s modulus of original shape (T > Treset) | GPa | 10−4–10−2 |

| Stress (for deformation / from recovery) | MPa | 1–3 |

| Thermal conductivity | W/(m·K) | 0.15–0.3 |

| Recovery speed | sec | 1–600 |

| Recovery deformation | % | <800 |

3. Preparation of SMAs and SMPs Thin Films and Heterostructures

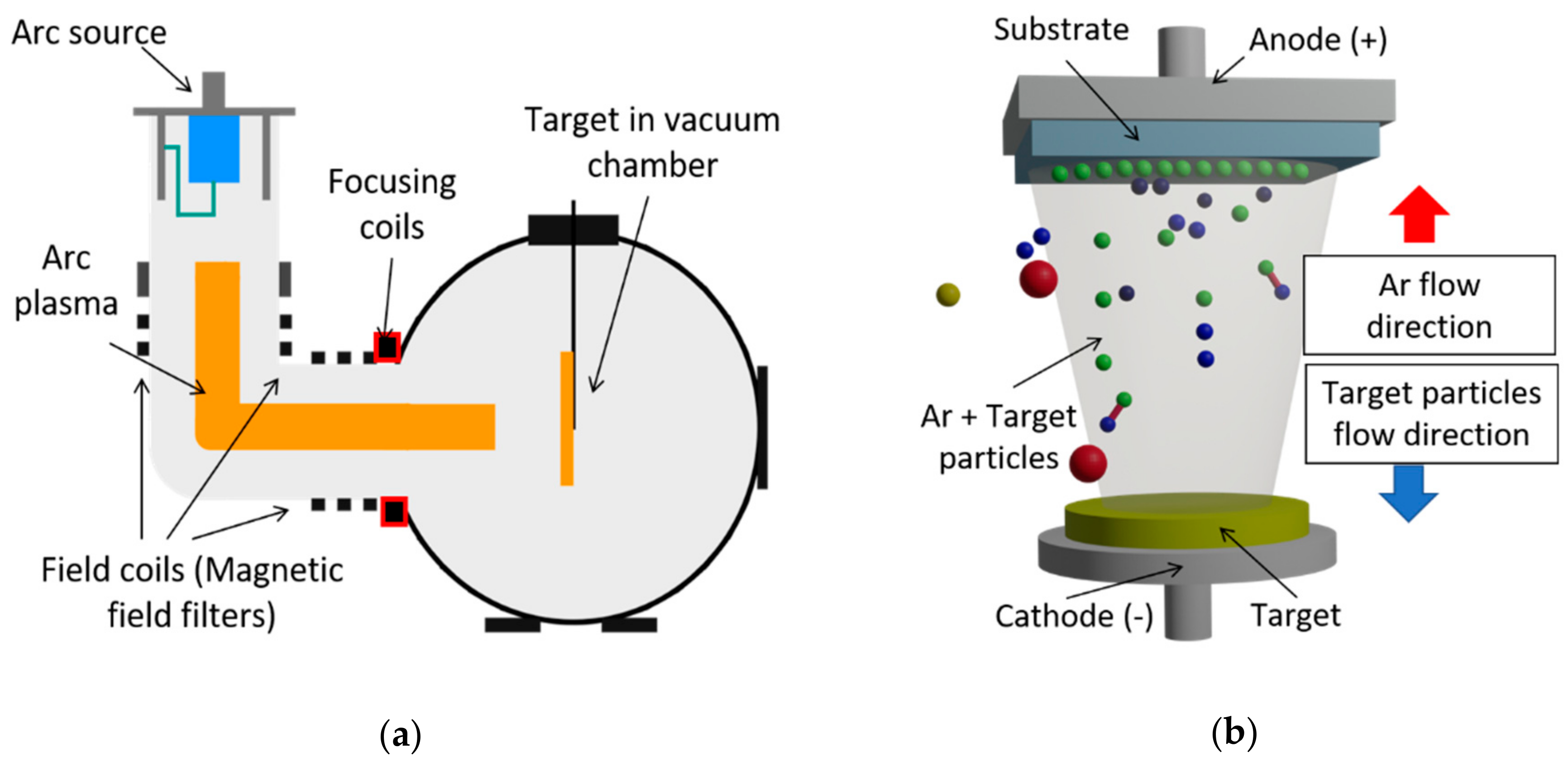

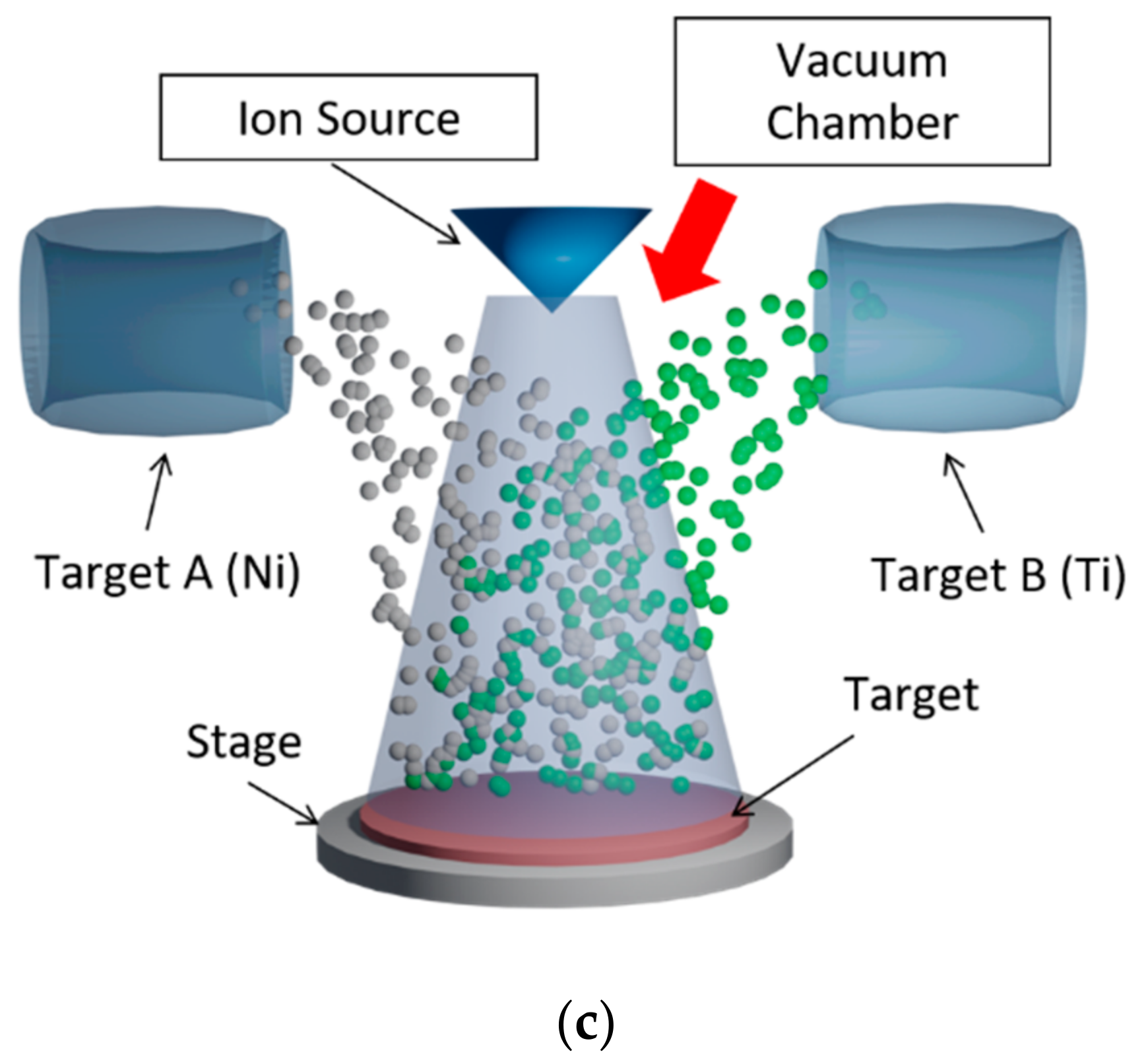

3.1. Shape Memory Alloys

3.2. Shape Memory Polymers

4. Characterization of SMAs and SMPs Thin Films and Heterostructures

5. Modelling of SMAs and SMPs Thin Films and Heterostructures

6. Existing Nanotechnology Applications of SMAs and SMPs, and Future Outlook

7. Conclusions Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stachiv, I. On the Nanoparticle or Macromolecule Mass Detection in Fluid Utilizing Vibrating Micro-/Nanoresonators Including Carbon Nanotubes. Sens. Lett. 2013, 11, 613–616. [Google Scholar] [CrossRef]

- Stachiv, I.; Fang, T.-H.; Jeng, Y.-R. Mass Detection in Viscous Fluid Utilizing Vibrating Micro– and Nanomechanical Mass Sensors under Applied Axial Tensile Force. Sensors 2015, 15, 19351–19368. [Google Scholar] [CrossRef]

- Fedorchenko, A.I.; Stachiv, I.; Wang, W.-C. Method of the viscosity measurement by means of the vibrating micro–/nano-mechanical resonators. Flow Meas. Instrum. 2013, 32, 84–89. [Google Scholar] [CrossRef]

- Zhang, X.C.; Myers, E.B.; Sader, J.E.; Roukes, M.L. Nanomechanical Torsional Resonators for Frequency-Shift Infrared Thermal Sensing. Nano Lett. 2013, 13, 1528–1534. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stachiv, I.; Kuo, C.-Y.; Fang, T.-H.; Mortet, V. Simultaneous determination of the residual stress, elastic modulus, density and thickness of ultrathin film utilizing vibrating doubly clamped micro-/nanobeams. AIP Adv. 2016, 6, 045005. [Google Scholar] [CrossRef] [Green Version]

- Stachiv, I.; Vokoun, D.; Jeng, Y.-R. Measurement of Young’s modulus and volumetric mass density/thickness of ultrathin films utilizing resonant based mass sensors. Appl. Phys. Lett. 2014, 104, 083102. [Google Scholar] [CrossRef]

- Lee, J.; Wang, Z.; He, K.; Yang, R.; Shan, J.; Feng, P.X.-L. Electrically tunable single- and few–layer MoS2nanoelectromechanical systems with broad dynamic range. Sci. Adv. 2018, 4, eaao6653. [Google Scholar] [CrossRef] [Green Version]

- Cerdán-Pasarán, A.; López-Luke, T.; Esparza, D.; Zarazúa, I.; De La Rosa, E.; Fuentes-Ramírez, R.; Alatorre-Ordaz, A.; Sánchez-Solís, A.; Torres-Castro, A.; Zhang, J.Z. Photovoltaic properties of multilayered quantum dot/quantum rod-sensitized TiO2 solar cells fabricated by SILAR and electrophoresis. Phys. Chem. Chem. Phys. 2015, 17, 18590–18599. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.-W.; Lin, L. A comprehensive review on piezoelectric energy harvesting technology: Materials, mechanisms, and applications. Appl. Phys. Rev. 2018, 5, 041306. [Google Scholar] [CrossRef]

- Matheny, M.H.; Emenheiser, J.; Fon, W.; Chapman, A.; Salova, A.; Rohden, M.; Li, J.; De Badyn, M.H.; Pósfai, M.; Duenas-Osorio, L.; et al. Exotic states in a simple network of nanoelectromechanical oscillators. Science 2019, 363, eaav7932. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jensen, K.H.; Kim, K.; Zettl, A. An atomic–resolution nanomechanical mass sensor. Nat. Nanotechnol. 2008, 3, 533–537. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, W. Recent advances in graphene-based nanomaterials for fabricating electrochemical hydrogen peroxide sensors. Biosens. Bioelectron. 2017, 89, 249–268. [Google Scholar] [CrossRef]

- Kumar, R.; Goel, N.; Kumar, M. UV–Activated MoS2 Based Fast and Reversible NO2 Sensor at Room Temperature. ACS Sens. 2017, 2, 1744–1752. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, M.; Roscow, J.; Bao, Y.; Zhou, K.; Zhang, D.; Bowen, C.R. Enhanced pyroelectric and piezoelectric properties of PZT with aligned porosity for energy harvesting applications. J. Mater. Chem. A 2017, 5, 6569–6580. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elhajjar, R.; Law, C.-T.; Pegoretti, A. Magnetostrictive polymer composites: Recent advances in materials, structures and properties. Prog. Mater. Sci. 2018, 97, 204–229. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Kim, D.-R.; Ahn, S.-H. Curved shape memory alloy-based soft actuators and application to soft gripper. Compos. Struct. 2017, 176, 398–406. [Google Scholar] [CrossRef]

- Karabalin, R.B.; Matheny, M.H.; Feng, X.L.; Defaÿ, E.; Le Rhun, G.; Marcoux, C.; Hentz, S.; Andreucci, P.; Roukes, M.L. Piezoelectric nanoelectromechanical resonators based on aluminum nitride thin films. Appl. Phys. Lett. 2009, 95, 103111. [Google Scholar] [CrossRef] [Green Version]

- Greve, H.; Woltermann, E.; Quenzer, H.-J.; Wagner, B.; Quandt, E. Giant magnetoelectric coefficients in (Fe90Co10)78Si12B10–AlN thin film composites. Appl. Phys. Lett. 2010, 96, 182501. [Google Scholar] [CrossRef]

- Xie, X.; Mao, C.; Liu, X.; Tan, L.; Cui, Z.; Yang, X.; Zhu, S.; Li, Z.; Yuan, X.; Zheng, Y.; et al. Tuning the Bandgap of Photo-Sensitive Polydopamine/Ag3PO4/Graphene Oxide Coating for Rapid, Noninvasive Disinfection of Implants. ACS Central Sci. 2018, 4, 724–738. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Wei, Y.; Li, Y. 3D printing of shape memory polymer for functional part fabrication. Int. J. Adv. Manuf. Technol. 2016, 84, 2079–2095. [Google Scholar] [CrossRef]

- Tyc, O.; Heller, L.; Vronka, M.; Šittner, P. Effect of temperature on fatigue of superelastic NiTi wires. Int. J. Fatigue 2020, 134, 105470. [Google Scholar] [CrossRef]

- Crăciunescu, C.; Ercuta, A. Shape memory microactuation design by substrate’s reinforcement layers. Mater. Des. 2016, 96, 364–369. [Google Scholar] [CrossRef]

- SoltanRezaee, M.; Bodaghi, M. Nonlinear dynamic stability of piezoelectric thermoelastic electromechanical resonators. Sci. Rep. 2020, 10, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Singh, J.; Kumar, A.; Chelvane, J.A. Stress compensated MEMS magnetic actuator based on magnetostrictive Fe65Co35 thin films. Sens. Actuators A Phys. 2019, 294, 54–60. [Google Scholar] [CrossRef]

- Rivadeneyra, A.; Soto-Rueda, J.M.; O’Keeffe, R.; Banqueri, J.; Jackson, N.; Mathewson, A.; López-Villanueva, J.A. Tunable MEMS piezoelectric energy harvesting device. Microsyst. Technol. 2015, 22, 823–830. [Google Scholar] [CrossRef]

- Karaman, I.; Basaran, B.; Karaca, H.E.; Karsilayan, A.I.; Chumlyakov, Y.I. Energy harvesting using martensite variant reorientation mechanism in a NiMnGa magnetic shape memory alloy. Appl. Phys. Lett. 2007, 90, 172505. [Google Scholar] [CrossRef]

- Lindquist, P.; Hobza, T.; Patrick, C.; Müllner, P. Efficiency of Energy Harvesting in Ni–Mn–Ga Shape Memory Alloys. Shape Mem. Superelasticity 2018, 4, 93–101. [Google Scholar] [CrossRef]

- Morán, M.; Condó, A.; Suarez, S.; Soldera, F.; Haberkorn, N. Ion implantation inducing two-way shape memory effect in Cu–Al–Ni thin films. Mater. Lett. 2019, 255, 126569. [Google Scholar] [CrossRef]

- Karim, A.; Guan, C.; Chen, B.; Li, Y.; Zhang, J.; Zhu, L.; Deng, X.; Hu, Y.; Bi, K.; Li, H.; et al. Dynamic observation of Joule heating-induced structural and domain transformation in smart shape-memory alloy. Acta Mater. 2020, 186, 223–228. [Google Scholar] [CrossRef]

- Gong, X.; Tan, K.; Deng, Q.; Shen, S. Athermal Shape Memory Effect in Magnetoactive Elastomers. ACS Appl. Mater. Interfaces 2020, 12, 16930–16936. [Google Scholar] [CrossRef]

- Sedmák, P.; Pilch, J.; Heller, L.; Kopeček, J.; Wright, J.; Sedlák, P.; Frost, M.; Šittner, P. Grain–resolved analysis of localized deformation in nickel-titanium wire under tensile load. Science 2016, 353, 559–562. [Google Scholar] [CrossRef] [PubMed]

- Vallejos, J.M.; Giordana, M.F.; Sobrero, C.E.; Malarria, J.A. Excellent pseudoelasticity of Al–rich Fe–33Mn–17Al–6Ni–0.15C (at %) shape memory single crystals obtained without an aging conditioning stage. Scr. Mater. 2020, 179, 25–29. [Google Scholar] [CrossRef]

- De Sousa, V.C.; Junior, C.D.M. Effect of pseudoelastic hysteresis of shape memory alloy springs on the aeroelastic behavior of a typical airfoil section. J. Intell. Mater. Syst. Struct. 2014, 27, 117–133. [Google Scholar] [CrossRef]

- La Roca, P.; Isola, L.; Vermaut, P.; Malarría, J. Relationship between grain size and thermal hysteresis of martensitic transformations in Cu-based shape memory alloys. Scr. Mater. 2017, 135, 5–9. [Google Scholar] [CrossRef]

- Heczko, O.; Sozinov, A.; Ullakko, K. Giant field–induced reversible strain in magnetic shape memory NiMnGa alloy. IEEE Trans. Magn. 2000, 36, 3266–3268. [Google Scholar] [CrossRef]

- Izadi, M.; Ghafoori, E.; Shahverdi, M.; Motavalli, M.; Maalek, S. Development of an iron-based shape memory alloy (Fe–SMA) strengthening system for steel plates. Eng. Struct. 2018, 174, 433–446. [Google Scholar] [CrossRef]

- Šittner, P.; Heller, L.; Pilch, J.; Curfs, C.; Alonso, T.; Favier, D. Young’s Modulus of Austenite and Martensite Phases in Superelastic NiTi Wires. J. Mater. Eng. Perform. 2014, 23, 2303–2314. [Google Scholar] [CrossRef]

- Kohl, M. Shape Memory Microactuators; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Fu, Y.; Du, H.; Huang, W.; Zhang, S.; Hu, M. TiNi-based thin films in MEMS applications: A review. Sens. Actuators A Phys. 2004, 112, 395–408. [Google Scholar] [CrossRef]

- Schauer, S.; Worgull, M.; Hölscher, H. Bio–inspired hierarchical micro– and nano–wrinkles obtained via mechanically directed self–assembly on shape–memory polymers. Soft Matter 2017, 13, 4328–4334. [Google Scholar] [CrossRef]

- Kirillova, A.; Ionov, L. Shape-changing polymers for biomedical applications. J. Mater. Chem. B 2019, 7, 1597–1624. [Google Scholar] [CrossRef]

- Tang, L.; Wen, L.; Xu, S.; Pi, P.-H.; Wen, X. Ca2+, redox, and thermoresponsive supramolecular hydrogel with programmed quadruple shape memory effect. Chem. Commun. 2018, 54, 8084–8087. [Google Scholar] [CrossRef]

- Lendlein, A.; Gould, O.E.C. Reprogrammable recovery and actuation behaviour of shape–memory polymers. Nat. Rev. Mater. 2019, 4, 116–133. [Google Scholar] [CrossRef]

- Hou, H.; Tang, Y.; Hamilton, R.F.; Horn, M.W. Functional fatigue of submicrometer NiTi shape memory alloy thin films. J. Vac. Sci. Technol. A 2017, 35, 040601. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Q.; Hu, S.; Zhang, W.; Du, C. On thermomechanical behaviors of the functional graded shape memory alloy composite for jet engine chevron. J. Intell. Mater. Syst. Struct. 2018, 29, 2986–3005. [Google Scholar] [CrossRef]

- Pengzhen, L.; Xiaoli, Z.; Feng, T.; Hua, S. Fundamentals of Shape Memory Alloy–Rubber Bearing Seismic Design and Assessment. J. Mater. Civ. Eng. 2017, 29, 04017081. [Google Scholar] [CrossRef]

- Braga, M.T.; Alves, M.T.S.; Cavalini, A.A.; Steffen, V. Influence of temperature on the passive control of a rotating machine using wires of shape memory alloy in the suspension. Smart Mater. Struct. 2020, 29, 035040. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Miyazaki, S.; Fu, Y.Q.; Huang, W.M. Thin Film Shape Memory Alloys: Fundamentals and Device Applications; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Kan, Q.; Yu, C.; Kang, G.; Li, J.; Yan, W. Experimental observations on rate-dependent cyclic deformation of super-elastic NiTi shape memory alloy. Mech. Mater. 2016, 97, 48–58. [Google Scholar] [CrossRef]

- Shariat, B.S.; Bakhtiari, S.; Yang, H.; Liu, Y. Controlled initiation and propagation of stress–induced martensitic transformation in functionally graded NiTi. J. Alloys Compd. 2021, 851, 156103. [Google Scholar] [CrossRef]

- Atli, K.; Karaman, I.; Noebe, R.D.; Bigelow, G.; Gaydosh, D. Work production using the two-way shape memory effect in NiTi and a Ni-rich NiTiHf high-temperature shape memory alloy. Smart Mater. Struct. 2015, 24, 125023. [Google Scholar] [CrossRef]

- Leu, C.-C.; Vokoun, D.; Hu, C.-T. Two-way shape memory effect of TiNi alloys induced by hydrogenation. Met. Mater. Trans. A 2002, 33, 17–23. [Google Scholar] [CrossRef]

- Vokoun, D.; Hu, C. Two-way shape memory effect in Fe–28.8 at. % Pd melt-spun ribbons. Scr. Mater. 2002, 47, 453–457. [Google Scholar] [CrossRef]

- Stachiv, I.; Gan, L. Gan Hybrid Shape Memory Alloy-Based Nanomechanical Resonators for Ultrathin Film Elastic Properties Determination and Heavy Mass Spectrometry. Materials 2019, 12, 3593. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Galvin, S. Criteria for pseudoelasticity in near–equiatomic NiTi shape memory alloys. Acta Mater. 1997, 45, 4431–4439. [Google Scholar] [CrossRef]

- Tanzi, M.C.; Farè, S.; Candiani, G. Foundations of Biomaterials Engineering; Elsevier BV: Oxford, UK, 2019. [Google Scholar]

- Shamimi, A.; Amin-Ahmadi, B.; Stebner, A.; Duerig, T. The Effect of Low Temperature Aging and the Evolution of R–Phase in Ni–Rich NiTi. Shape Mem. Superelasticity 2018, 4, 417–427. [Google Scholar] [CrossRef]

- Prokoshkin, S.; Dubinskiy, S.; Brailovski, V.; Korotitskiy, A.; Konopatsky, A.; Sheremetyev, V.; Blinova, E. Nanostructures and stress–induced phase transformation mechanism in titanium nickelide annealed after moderate cold deformation. Mater. Lett. 2017, 192, 111–114. [Google Scholar] [CrossRef]

- Ainslie, K.; Knick, C.; Smith, G.; Li, J.; Troxel, C.; Mehta, A.; Kukreja, R. Controlling shape memory effects in NiTi thin films grown on Ru seed layer. Sens. Actuators A Phys. 2019, 294, 133–139. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, X.; Qian, M.; Imran, M. Elastocaloric effects related to B2↔R and B2↔B19′ martensite transformations in nanocrystalline Ni50.5Ti49.5 microwires. J. Alloys Compd. 2019, 792, 780–788. [Google Scholar] [CrossRef]

- Ha, J.-H.; Kim, S.K.; Cohenca, N.; Kim, H.-C. Effect of R–phase Heat Treatment on Torsional Resistance and Cyclic Fatigue Fracture. J. Endod. 2013, 39, 389–393. [Google Scholar] [CrossRef]

- Tyc, O.; Pilch, J.; Šittner, P.; Hausild, P. Investigation of the Precipitation Processes in NiTi Filaments. In Proceedings of the International Conference on Martensitic Transformations: Chicago; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2018; pp. 173–177. [Google Scholar] [CrossRef]

- Wang, X.; Kustov, S.; Verlinden, B.E.; Van Humbeeck, J. Fundamental Development on Utilizing the R–phase Transformation in NiTi Shape Memory Alloys. Shape Mem. Superelasticity 2015, 1, 231–239. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 79–120. [Google Scholar] [CrossRef] [Green Version]

- Mazurek-Budzinska, M.; Razzaq, M.Y.; Behl, M.; Lendlein, A. Shape-memory polymers. In Functional Polymers; Polymers and Polymeric Composites: A Reference Series; Jafar Mazumder, M.A., Sheardown, H., Al-Ahmed, A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 605–663. [Google Scholar]

- Amir, F.; Liles, K.P.; Delawder, A.O.; Colley, N.D.; Palmquist, M.S.; Linder, H.R.; Sell, S.A.; Barnes, J.C. Reversible Hydrogel Photopatterning: Spatial and Temporal Control over Gel Mechanical Properties Using Visible Light Photoredox Catalysis. ACS Appl. Mater. Interfaces 2019, 11, 24627–24638. [Google Scholar] [CrossRef]

- Bhargava, A.; Peng, K.; Stieg, J.; Mirzaeifar, R.; Shahab, S. Focused ultrasound actuation of shape memory polymers; acoustic-thermoelastic modeling and testing. RSC Adv. 2017, 7, 45452–45469. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhou, S.; Chong, K.C.; Wang, S.; Liu, B. Near-infrared light-induced shape memory, self-healable and anti-bacterial elastomers prepared by incorporation of a diketopyrrolopyrrole-based conjugated polymer. Mater. Chem. Front. 2019, 3, 836–841. [Google Scholar] [CrossRef]

- Zare, M.; Prabhakaran, M.P.; Parvin, N.; Ramakrishna, S. Thermally–induced two-way shape memory polymers: Mechanisms, structures, and applications. Chem. Eng. J. 2019, 374, 706–720. [Google Scholar] [CrossRef]

- Zhang, C.; Gou, X.; Xiao, R. Controllable shape-memory recovery regions in polymers through mechanical programming. J. Appl. Polym. Sci. 2017, 135, 45909. [Google Scholar] [CrossRef]

- Xie, T. Tunable polymer multi-shape memory effect. Nat. Cell Biol. 2010, 464, 267–270. [Google Scholar] [CrossRef]

- Wu, Y.; Hu, J.; Han, J.; Zhu, Y.; Huang, H.; Li, J.; Tang, B. Two–way shape memory polymer with “switch–spring” composition by interpenetrating polymer network. J. Mater. Chem. A 2014, 2, 18816–18822. [Google Scholar] [CrossRef]

- Song, H.; Fang, Z.; Jin, B.; Pan, P.; Zhao, Q.; Xie, T. Synergetic Chemical and Physical Programming for Reversible Shape Memory Effect in a Dynamic Covalent Network with Two Crystalline Phases. ACS Macro Lett. 2019, 8, 682–686. [Google Scholar] [CrossRef]

- Wang, K.; Jia, Y.-G.; Zhu, X.X. Two-Way Reversible Shape Memory Polymers Made of Cross-Linked Cocrystallizable Random Copolymers with Tunable Actuation Temperatures. Macromolecules 2017, 50, 8570–8579. [Google Scholar] [CrossRef]

- Hui, J.; Xia, H.; Chen, H.; Qiu, Y.; Fu, Y.; Ni, Q.-Q. Two–way reversible shape memory polymer: Synthesis and characterization of benzoyl peroxide–crosslinked poly (ethylene-co-vinyl acetate). Mater. Lett. 2020, 258, 126762. [Google Scholar] [CrossRef]

- Wen, Z.; McBride, M.K.; Zhang, X.; Han, X.; Martinez, A.M.; Shao, R.; Zhu, C.; Visvanathan, R.; Clark, N.A.; Wang, Y.; et al. Reconfigurable LC Elastomers: Using a Thermally Programmable Monodomain To Access Two–Way Free–Standing Multiple Shape Memory Polymers. Macromolecules 2018, 51, 5812–5819. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of progress in shape-memory polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Busch, J.D.; Johnson, A.D.; Lee, C.H.; Stevenson, D.A. Shape-memory properties in Ni-Ti sputter-deposited film. J. Appl. Phys. 1990, 68, 6224–6228. [Google Scholar] [CrossRef]

- Zuberek, R.; Chumak, O.; Nabiałek, A.; Chojnacki, M.; Radelytskyi, I.; Szymczak, H. Magnetocaloric effect and magnetoelastic properties of NiMnGa and NiMnSn Heusler alloy thin films. J. Alloys Compd. 2018, 748, 1–5. [Google Scholar] [CrossRef]

- Pandey, H.; Rout, P.K.; Anupam Joshi, P.C.; Hossain, Z.; Budhani, R.C. Magnetoelastic coupling induced magnetic anisotropy in Co2 (Fe/Mn)Si thin films. Appl. Phys. Lett. 2014, 104, 022402. [Google Scholar] [CrossRef] [Green Version]

- Domenichini, P.; Condó, A.; Soldera, F.; Sirena, M.; Haberkorn, N. Influence of the microstructure on the resulting 18R martensitic transformation of polycrystalline Cu Al Zn thin films obtained by sputtering and reactive annealing. Mater. Charact. 2016, 114, 289–295. [Google Scholar] [CrossRef]

- Yang, L.; Tieu, A.; Dunne, D.; Huang, S.; Li, H.; Wexler, D.; Jiang, Z. Cavitation erosion resistance of NiTi thin films produced by Filtered Arc Deposition. Wear 2009, 267, 233–243. [Google Scholar] [CrossRef] [Green Version]

- Kauffmann-Weiss, S.; Hahn, S.; Weigelt, C.; Schultz, L.; Wagner, M.-X.; Fähler, S. Growth, microstructure and thermal transformation behaviour of epitaxial Ni–Ti films. Acta Mater. 2017, 132, 255–263. [Google Scholar] [CrossRef] [Green Version]

- Hou, H.; Hamilton, R.F.; Horn, M.W.; Jin, Y. NiTi thin films prepared by biased target ion beam deposition co-sputtering from elemental Ni and Ti targets. Thin Solid Films 2014, 570, 1–6. [Google Scholar] [CrossRef]

- Musiienko, D.; Straka, L.; Klimša, L.; Saren, A.; Sozinov, A.; Heczko, O.; Ullakko, K. Giant magnetic–field–induced strain in Ni–Mn–Ga micropillars. Scr. Mater. 2018, 150, 173–176. [Google Scholar] [CrossRef]

- Li, H.F.; Qiu, K.J.; Zhou, F.Y.; Li, L.; Zheng, Y.F. Design and development of novel antibacterial Ti–Ni–Cu shape memory alloys for biomedical application. Sci. Rep. 2016, 6, 37475. [Google Scholar] [CrossRef]

- Bergdahl, G.E.; Andersson, T.; Allhorn, M.; Yngman, S.; Timm, R.; Lood, R. In VivoDetection and Absolute Quantification of a Secreted Bacterial Factor from Skin Using Molecularly Imprinted Polymers in a Surface Plasmon Resonance Biosensor for Improved Diagnostic Abilities. ACS Sensors 2019, 4, 717–725. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Schryvers, D.; Liu, D.; Jiang, Q.; Van Humbeeck, J. Stability of Ni in nitinol oxide surfaces. Acta Biomater. 2011, 7, 892–899. [Google Scholar] [CrossRef] [PubMed]

- McNamara, K.; Beloshapkin, S.; Hossain, K.; Dhoubhadel, M.; Tofail, S. Tantalum coating inhibits Ni–migration from titanium out–diffusion in NiTi shape memory biomedical alloy. Appl. Surf. Sci. 2021, 535, 147621. [Google Scholar] [CrossRef]

- Jamesh, M.I.; Li, P.; Bilek, M.M.; Boxman, R.; McKenzie, D.R.; Chu, P.K. Evaluation of corrosion resistance and cytocompatibility of graded metal carbon film on Ti and NiTi prepared by hybrid cathodic arc/glow discharge plasma-assisted chemical vapor deposition. Corros. Sci. 2015, 97, 126–138. [Google Scholar] [CrossRef]

- Stanford, N.; Huang, S.; Dunne, D. Characterisation of Ni–Ti thin films produced by filtered arc deposition. Mater. Sci. Eng. A 2008, 473, 172–179. [Google Scholar] [CrossRef]

- Boxman, R.L.; Zhitomirsky, V.N. Vacuum arc deposition devices. Rev. Sci. Instruments 2006, 77, 021101. [Google Scholar] [CrossRef]

- Wibowo, E.; Kwok, C.Y. Fabrication and characterization of sputtered NiTi shape memory thin films. J. Micromech. Microeng. 2005, 16, 101–108. [Google Scholar] [CrossRef]

- Sharma, A.; Mohan, S.; Suwas, S. Development of bi–axial preferred orientation in epitaxial NiMnGa thin films and its consequence on magnetic properties. Acta Mater. 2016, 113, 259–271. [Google Scholar] [CrossRef]

- Li, J.; Yi, X.; Meng, X.; Qiao, S.; Cai, W.; Zhao, L. Deposition and phase transformation behaviors of Ti–Ni–Hf–Cu quaternary shape memory alloy thin films. J. Alloys Compd. 2019, 806, 33–39. [Google Scholar] [CrossRef]

- Karki, V.; Debnath, A.; Kumar, S.; Bhattacharya, D. Synthesis of co-sputter deposited Ni–Ti thin alloy films and their compositional characterization using depth sensitive techniques. Thin Solid Films 2020, 697, 137800. [Google Scholar] [CrossRef]

- Stachiv, I.; Sittner, P.; Olejnicek, J.; Landa, M.; Heller, L. Exploiting NiTi shape memory alloy films in design of tunable high frequency microcantilever resonators. Appl. Phys. Lett. 2017, 111, 213105. [Google Scholar] [CrossRef]

- Momeni, S.; Biskupek, J.; Tillmann, W. Tailoring microstructure, mechanical and tribological properties of NiTi thin films by controlling in-situ annealing temperature. Thin Solid Films 2017, 628, 13–21. [Google Scholar] [CrossRef]

- Fu, Y.; Du, H.; Zhang, S. Sputtering deposited TiNi films: Relationship among processing, stress evolution and phase transformation behaviors. Surf. Coat. Technol. 2003, 167, 120–128. [Google Scholar] [CrossRef]

- Abadias, G.; Chason, E.; Keckes, J.; Sebastiani, M.; Thompson, G.B.; Barthel, E.; Doll, G.; Murray, C.; Stoessel, C.H.; Martinu, L. Review Article: Stress in thin films and coatings: Current status, challenges, and prospects. J. Vac. Sci. Technol. A 2018, 36, 020801. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Vlassak, J.J. Thickness and film stress effects on the martensitic transformation temperature in equi–atomic NiTi thin films. Mech. Mater. 2015, 88, 50–60. [Google Scholar] [CrossRef] [Green Version]

- Juan, J.S.; Nó, M.L.; Schuh, C.A. Superelasticity and Shape Memory in Micro– and Nanometer-scale Pillars. Adv. Mater. 2008, 20, 272–278. [Google Scholar] [CrossRef]

- Hou, H.; Horn, M.W.; Hamilton, R.F. Biased Target Ion Beam Deposition and Nanoskiving for Fabricating NiTi Alloy Nanowires. Shape Mem. Superelasticity 2016, 2, 330–336. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Wang, S.; Tian, J.; Chen, K.; Xue, P.; Wu, Y.; Chou, W. Effect of PEW and CS on the Thermal, Mechanical, and Shape Memory Properties of UHMWPE. Polymers 2020, 12, 483. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, X.-J.; Xue, C.-H.; Sathasivam, S.; Page, K.; He, G.; Guo, J.; Promdet, P.; Heale, F.L.; Carmalt, C.J.; Parkin, I.P. Fabrication of robust superhydrophobic surfaces via aerosol–assisted CVD and thermo–triggered healing of superhydrophobicity by recovery of roughness structures. J. Mater. Chem. A 2019, 7, 17604–17612. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, L.; Song, H.; Ni, C.; Wu, J.; Zhao, Q.; Xie, T. 4D Printing of a Digital Shape Memory Polymer with Tunable High Performance. ACS Appl. Mater. Interfaces 2019, 11, 32408–32413. [Google Scholar] [CrossRef] [PubMed]

- Parameswaranpillai, J.; Siengchin, S.; George, J.J.; Jose, S. Shape Memory Polymers, Blends and Composites; Springer: Singapore, 2020. [Google Scholar]

- Kramer, N.J.; Sachteleben, E.; Ozaydin-Ince, G.; Van De Sanden, R.; Gleason, K.K. Shape Memory Polymer Thin Films Deposited by Initiated Chemical Vapor Deposition. Macromolecules 2010, 43, 8344–8347. [Google Scholar] [CrossRef]

- Schröder, S.; Strunskus, T.; Rehders, S.; Gleason, K.K.; Faupel, F. Tunable polytetrafluoroethylene electret films with extraordinary charge stability synthesized by initiated chemical vapor deposition for organic electronics applications. Sci. Rep. 2019, 9, 2237. [Google Scholar] [CrossRef] [Green Version]

- Alf, M.E.; Asatekin, A.; Barr, M.C.; Baxamusa, S.H.; Chelawat, H.; Ozaydin-Ince, G.; Petruczok, C.D.; Sreenivasan, R.; Tenhaeff, W.E.; Trujillo, N.J.; et al. Chemical Vapor Deposition of Conformal, Functional, and Responsive Polymer Films. Adv. Mater. 2009, 22, 1993–2027. [Google Scholar] [CrossRef] [PubMed]

- Gleason, K.K. Nanoscale control by chemically vapour-deposited polymers. Nat. Rev. Phys. 2020, 2, 347–364. [Google Scholar] [CrossRef]

- Mao, Y.; Yu, K.; Isakov, M.S.; Wu, J.; Dunn, M.L.; Qi, H.J. Sequential Self–Folding Structures by 3D Printed Digital Shape Memory Polymers. Sci. Rep. 2015, 5, 13616. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, Q.; Feng, J. 3D printing of tunable shape memory polymer blends. J. Mater. Chem. C 2017, 5, 8361–8365. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, L.; Guo, Y.; Zhang, H.; Zhang, Z. Multi-responsive shape memory polymer printed by fused deposition modeling technique. Express Polym. Lett. 2020, 14, 348–357. [Google Scholar] [CrossRef]

- Kuang, X.; Wu, J.; Chen, K.; Zhao, Z.; Ding, Z.; Hu, F.; Fang, D.; Qi, H.J. Grayscale digital light processing 3D printing for highly functionally graded materials. Sci. Adv. 2019, 5, eaav5790. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Yu, S.; Wei, J.; Su, P.-C. High speed 4D printing of shape memory polymers with nanosilica. Appl. Mater. Today 2020, 18, 100515. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, H.; Zhang, Q.; Yao, Y.; Liu, L.; Liu, Y.; Leng, J. Direct-Write Fabrication of 4D Active Shape-Changing Structures Based on a Shape Memory Polymer and Its Nanocomposite. ACS Appl. Mater. Interfaces 2017, 9, 876–883. [Google Scholar] [CrossRef]

- Bodkhe, S.; Ermanni, P. 3D printing of multifunctional materials for sensing and actuation: Merging piezoelectricity with shape memory. Eur. Polym. J. 2020, 132, 109738. [Google Scholar] [CrossRef]

- Bártová, B.; Schryvers, D.; Yang, Z.; Ignacova, S.; Šittner, P.; Sedlakova, S. Microstructure and precipitates in as–cast Co38Ni33Al29 shape memory alloy. Scr. Mater. 2007, 57, 37–40. [Google Scholar] [CrossRef]

- Bae, J.; Lee, H.; Seo, D.; Yun, S.; Yang, J.; Huh, S.; Jeong, H.; Noh, J. Grain Size and Phase Transformation Behavior of TiNi Shape–Memory–Alloy Thin Film under Different Deposition Conditions. Materials 2020, 13, 3229. [Google Scholar] [CrossRef] [PubMed]

- Choudhary, N.; Kharat, D.; Kaur, D. Structural, electrical and mechanical properties of magnetron sputtered NiTi/PZT/TiOx thin film heterostructures. Surf. Coat. Technol. 2011, 205, 3387–3396. [Google Scholar] [CrossRef]

- Costanza, G.; Paoloni, S.; Tata, M.E. IR Thermography and Resistivity Investigations on Ni-Ti Shape Memory Alloy. Key Eng. Mater. 2014, 605, 23–26. [Google Scholar] [CrossRef]

- Thomasová, M.; Sedlák, P.; Seiner, H.; Janovská, M.; Kabla, M.; Shilo, D.; Landa, M. Young’s moduli of sputter-deposited NiTi films determined by resonant ultrasound spectroscopy: Austenite, R–phase, and martensite. Scr. Mater. 2015, 101, 24–27. [Google Scholar] [CrossRef]

- Konig, D.; Ehmann, M.; Thienhaus, S.; Ludwig, A. Micro– to Nanostructured Devices for the Characterization of Scaling Effects in Shape-Memory Thin Films. J. Microelectromech. Syst. 2010, 19, 1264–1269. [Google Scholar] [CrossRef]

- Sedlák, P.; Seiner, H.; Zidek, J.; Janovska, M.; Landa, M. Determination of All 21 Independent Elastic Coefficients of Generally Anisotropic Solids by Resonant Ultrasound Spectroscopy: Benchmark Examples. Exp. Mech. 2014, 54, 1073–1085. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, B.; Vlassak, J.J.; Schick, C. Nanocalorimetry: Door opened for in situ material characterization under extreme non-equilibrium conditions. Prog. Mater. Sci. 2019, 104, 53–137. [Google Scholar] [CrossRef]

- Motemani, Y.; McCluskey, P.J.; Zhao, C.; Tan, M. –J.; Vlassak, J.J. Analysis of Ti–Ni–Hf shape memory alloys by combinatorial nanocalorimetry. Acta Mater. 2011, 59, 7602–7614. [Google Scholar] [CrossRef]

- McCluskey, P.J.; Xiao, K.; Gregoire, J.M.; Dale, D.; Vlassak, J.J. Application of in-situ nano-scanning calorimetry and X–ray diffraction to characterize Ni–Ti–Hf high-temperature shape memory alloys. Thermochim. Acta 2015, 603, 53–62. [Google Scholar] [CrossRef]

- McCluskey, P.J.; Zhao, C.; Kfir, O.; Vlassak, J.J. Precipitation and thermal fatigue in Ni–Ti–Zr shape memory alloy thin films by combinatorial nanocalorimetry. Acta Mater. 2011, 59, 5116–5124. [Google Scholar] [CrossRef]

- Meng, X.L.; Sun, B.; Sun, J.Y.; Gao, Z.Y.; Cai, W.; Zhao, L.C. Microstructure and Shape Memory Behavior of Ti–Nb Shape Memory Alloy Thin Film. Shape Mem. Superelasticity 2017, 3, 230–237. [Google Scholar] [CrossRef]

- Ossmer, H.; Lambrecht, F.; Gültig, M.; Chluba, C.; Quandt, E.; Kohl, M. Evolution of temperature profiles in TiNi films for elastocaloric cooling. Acta Mater. 2014, 81, 9–20. [Google Scholar] [CrossRef]

- Namazu, T.; Hashizume, A.; Inoue, S. Thermomechanical tensile characterization of Ti–Ni shape memory alloy films for design of MEMS actuator. Sens. Actuators A Phys. 2007, 139, 178–186. [Google Scholar] [CrossRef]

- Chen, C.-H.; Lu, N.-H. Improved functional stability of Ti–rich TiNi shape memory ribbon prepared by melt–spinning. J. Alloys Compd. 2020, 819, 152988. [Google Scholar] [CrossRef]

- Janssen, G.; Abdalla, M.; van Keulen, F.; Pujada, B.; van Venrooy, B. Celebrating the 100th anniversary of the Stoney equation for film stress: Developments from polycrystalline steel strips to single crystal silicon wafers. Thin Solid Films 2009, 517, 1858–1867. [Google Scholar] [CrossRef]

- Knick, C.R.; Smith, G.L.; Morris, C.J.; Bruck, H.A. Rapid and low power laser actuation of sputter–deposited NiTi shape memory alloy (SMA) MEMS thermal bimorph actuators. Sens. Actuators A Phys. 2019, 291, 48–57. [Google Scholar] [CrossRef]

- Hou, H.; Hamilton, R.F.; Horn, M.W. Narrow thermal hysteresis of NiTi shape memory alloy thin films with submicrometer thickness. J. Vac. Sci. Technol. A 2016, 34, 050602. [Google Scholar] [CrossRef]

- Stachiv, I.; Šittner, P. Nanocantilevers with Adjustable Static Deflection and Significantly Tunable Spectrum Resonant Frequencies for Applications in Nanomechanical Mass Sensors. Nanomaterials 2018, 8, 116. [Google Scholar] [CrossRef] [Green Version]

- Fu, Y.; Huang, W.; Du, H.; Huang, X.; Tan, J.; Gao, X. Characterization of TiNi shape–memory alloy thin films for MEMS applications. Surf. Coat. Technol. 2001, 145, 107–112. [Google Scholar] [CrossRef]

- Lambrecht, F.; Lay, C.; Aseguinolaza, I.R.; Chernenko, V.; Kohl, M. NiMnGa/Si Shape Memory Bimorph Nanoactuation. Shape Mem. Superelasticity 2016, 2, 347–359. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Kumar, I.A.; Marandi, L.; Sen, I. Assessment of small–scale deformation characteristics and stress–strain behavior of NiTi based shape memory alloy using nanoindentation. Acta Mater. 2020, 201, 303–315. [Google Scholar] [CrossRef]

- Anuja, J.; Narasimhan, R.; Ramamurty, U.; Jaganathan, A.; Upadrasta, R. Effects of superelasticity and plasticity on the spherical indentation response of shape memory alloys: A finite element analysis. Smart Mater. Struct. 2019, 28, 035028. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Bubach, B.; Dietrich, R.; Rasouli, V. Nano-dynamic mechanical analysis (nano-DMA) of creep behavior of shales: Bakken case study. J. Mater. Sci. 2018, 53, 4417–4432. [Google Scholar] [CrossRef]

- Nakamura, N.; Ueno, T.; Ogi, H. Precise control of hydrogen response of semicontinuous palladium film using piezoelectric resonance method. Appl. Phys. Lett. 2019, 114, 201901. [Google Scholar] [CrossRef]

- Stachiv, I.; Zapoměl, J.; Chen, Y.-L. Simultaneous determination of the elastic modulus and density/thickness of ultrathin films utilizing micro–/nanoresonators under applied axial force. J. Appl. Phys. 2014, 115, 124304. [Google Scholar] [CrossRef]

- Ma, S.; Huang, H.; Lu, M.; Veidt, M. A simple resonant method that can simultaneously measure elastic modulus and density of thin films. Surf. Coat. Technol. 2012, 209, 208–211. [Google Scholar] [CrossRef]

- Wang, Q.; Li, X.; Zhao, W.-M.; Jin, S. Lossy mode resonance–based fiber optic sensor using layer–by–layer SnO2 thin film and SnO2 nanoparticles. Appl. Surf. Sci. 2019, 492, 374–381. [Google Scholar] [CrossRef]

- Stachiv, I.; Gan, L. Simple Non–Destructive Method of Ultrathin Film Material Properties and Generated Internal Stress Determination Using Microcantilevers Immersed in Air. Coatings 2019, 9, 486. [Google Scholar] [CrossRef] [Green Version]

- Segiet, D.; Neuendorf, L.M.; Tiller, J.C.; Katzenberg, F. Realizing a shape–memory effect for synthetic rubber (IR). Polymer 2020, 203, 122788. [Google Scholar] [CrossRef]

- Yao, R.; Dong, P.; Liaw, P.K.; Zhou, J.; Wang, W. Microstructure and shape memory effect of laser welded Nitinol wires. Mater. Lett. 2019, 238, 1–5. [Google Scholar] [CrossRef]

- Liu, Y.; Gould, O.E.; Rudolph, T.; Fang, L.; Kratz, K.; Lendlein, A. Polymeric Microcuboids Programmable for Temperature-Memory. Macromol. Mater. Eng. 2020, 305, 2000333. [Google Scholar] [CrossRef]

- Fang, L.; Gould, O.E.C.; Lysyakova, L.; Jiang, Y.; Sauter, T.; Frank, O.; Becker, T.; Schossig, M.; Kratz, K.; Lendlein, A. Implementing and Quantifying the Shape-Memory Effect of Single Polymeric Micro/Nanowires with an Atomic Force Microscope. ChemPhysChem 2018, 19, 2078–2084. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Jiang, L.; Wardini, J.L.; Macdonald, B.E.; Wen, H.; Xiong, W.; Zhang, D.; Zhou, Y.; Rupert, T.J.; Chen, W.; et al. A high-entropy alloy with hierarchical nanoprecipitates and ultrahigh strength. Sci. Adv. 2018, 4, eaat8712. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.; Zeng, H.; Xu, K.; Zhao, K.; Liu, Z.F.; Yao, J.; You, Y.; Wang, D. AFM–IR probing the influence of polarization on the expression of protein within single macrophages. J. Mater. Chem. B 2021. [Google Scholar] [CrossRef]

- Stachiv, I.; Gan, L.; Kuo, C.-Y.; Sittner, P.; Sevecek, O. Mass spectrometry of heavy analytes and large biological aggregates by monitoring changes in quality factor of nanomechanical resonator in air. ACS Sens. 2020, 7, 2128–2135. [Google Scholar] [CrossRef]

- Lagoudas, D.C.; Entchev, P.B.; Popov, P.; Patoor, E.; Brinson, L.C.; Gao, X. Shape memory alloys, Part II: Modeling of polycrystals. Mech. Mater. 2006, 38, 430–462. [Google Scholar] [CrossRef]

- Arghavani, J.; Auricchio, F.; Naghdabadi, R.; Reali, A.; Sohrabpour, S. A 3–D phenomenological constitutive model for shape memory alloys under multiaxial loadings. Int. J. Plast. 2010, 26, 976–991. [Google Scholar] [CrossRef]

- Luig, P.; Bruhns, O. On the modeling of shape memory alloys using tensorial internal variables. Mater. Sci. Eng. A 2008, 481, 379–383. [Google Scholar] [CrossRef]

- Lexcellent, C.; Leclercq, S.; Gabry, B.; Bourbon, G. The two way shape memory effect of shape memory alloys: An experimental study and a phenomenological model. Int. J. Plast. 2000, 16, 1155–1168. [Google Scholar] [CrossRef]

- Peng, X.; Chen, B.; Chen, X.; Wang, J.; Wang, H. A constitutive model for transformation, reorientation and plastic deformation of shape memory alloys. Acta Mech. Solida Sin. 2012, 25, 285–298. [Google Scholar] [CrossRef]

- Chemisky, Y.; Chatzigeorgiou, G.; Kumar, P.; Lagoudas, D.C. A constitutive model for cyclic actuation of high-temperature shape memory alloys. Mech. Mater. 2014, 68, 120–136. [Google Scholar] [CrossRef] [Green Version]

- Hartl, D.J.; Chatzigeorgiou, G.; Lagoudas, D.C. Three–dimensional modeling and numerical analysis of rate-dependent irrecoverable deformation in shape memory alloys. Int. J. Plast. 2010, 26, 1485–1507. [Google Scholar] [CrossRef]

- Auricchio, F.; Reali, A.; Stefanelli, U. A three–dimensional model describing stress-induced solid phase transformation with permanent inelasticity. Int. J. Plast. 2007, 23, 207–226. [Google Scholar] [CrossRef]

- Sedlák, P.; Frost, M.; Benešová, B.; Ben Zineb, T.; Šittner, P. Thermomechanical model for NiTi–based shape memory alloys including R–phase and material anisotropy under multi–axial loadings. Int. J. Plast. 2012, 39, 132–151. [Google Scholar] [CrossRef]

- Tobushi, H.; Hashimoto, T.; Hayashi, S.; Yamada, E. Thermomechanical Constitutive Modeling in Shape Memory Polymer of Polyurethane Series. J. Intell. Mater. Syst. Struct. 1997, 8, 711–718. [Google Scholar] [CrossRef]

- Liu, Y.; Gall, K.; Dunn, M.L.; Greenberg, A.R.; Diani, J. Thermomechanics of shape memory polymers: Uniaxial experiments and constitutive modeling. Int. J. Plast. 2006, 22, 279–313. [Google Scholar] [CrossRef]

- Li, Y.; Hu, J.; Liu, Z. A constitutive model of shape memory polymers based on glass transition and the concept of frozen strain release rate. Int. J. Solids Struct. 2017, 124, 252–263. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z. A novel constitutive model of shape memory polymers combining phase transition and viscoelasticity. Polymer 2018, 143, 298–308. [Google Scholar] [CrossRef]

- Yarali, E.; Baniasadi, M.; Bodaghi, M.; Baghani, M. 3D constitutive modeling of electro–magneto–visco–hyperelastic elastomers: A semi–analytical solution for cylinders under large torsion–extension deformation. Smart Mater. Struct. 2020, 29, 085031. [Google Scholar] [CrossRef]

- Bonner, M.; De Oca, H.M.; Brown, M.; Ward, I. A novel approach to predict the recovery time of shape memory polymers. Polymer 2010, 51, 1432–1436. [Google Scholar] [CrossRef]

- Baghani, M.; Naghdabadi, R.; Arghavani, J.; Sohrabpour, S. A thermodynamically–consistent 3D constitutive model for shape memory polymers. Int. J. Plast. 2012, 35, 13–30. [Google Scholar] [CrossRef]

- Diani, J.; Gilormini, P.; Frédy, C.; A Rousseau, I. Predicting thermal shape memory of crosslinked polymer networks from linear viscoelasticity. Int. J. Solids Struct. 2012, 49, 793–799. [Google Scholar] [CrossRef] [Green Version]

- Baniasadi, M.; Foyouzat, A.; Baghani, M. Multiple Shape Memory Effect for Smart Helical Springs with Variable Stiffness over Time and Temperature. Int. J. Mech. Sci. 2020, 182, 105742. [Google Scholar] [CrossRef]

- Patriarca, L.; Sehitoglu, H.; Panchenko, E.Y.; Chumlyakov, Y. High-temperature functional behavior of single crystal Ni51.2Ti23.4Hf25.4 shape memory alloy. Acta Mater. 2016, 106, 333–343. [Google Scholar] [CrossRef] [Green Version]

- Alarcon, E.; Heller, L. Deformation infrared calorimetry for materials characterization applied to study cyclic superelasticity in NiTi wires. Mater. Des. 2021, 199, 109406. [Google Scholar] [CrossRef]

- Yu, H.; Young, M.L. Effect of temperature on high strain rate deformation of austenitic shape memory alloys by phenomenological modeling. J. Alloys Compd. 2019, 797, 194–204. [Google Scholar] [CrossRef]

- Zhuo, M. Timescale competition dictates thermo–mechanical responses of NiTi shape memory alloy bars. Int. J. Solids Struct. 2020, 193–194, 601–617. [Google Scholar] [CrossRef]

- Shaw, J.A. Simulations of localized thermo-mechanical behavior in a NiTi shape memory alloy. Int. J. Plast. 2000, 16, 541–562. [Google Scholar] [CrossRef]

- Wendler, F.; Ossmer, H.; Chluba, C.; Quandt, E.; Kohl, M. Mesoscale simulation of elastocaloric cooling in SMA films. Acta Mater. 2017, 136, 105–117. [Google Scholar] [CrossRef]

- Duval, A.; Haboussi, M.; Ben Zineb, T. Modelling of localization and propagation of phase transformation in superelastic SMA by a gradient nonlocal approach. Int. J. Solids Struct. 2011, 48, 1879–1893. [Google Scholar] [CrossRef]

- Frost, M.; Benešová, B.; Seiner, H.; Kružík, M.; Šittner, P.; Sedlák, P. Thermomechanical model for NiTi-based shape memory alloys covering macroscopic localization of martensitic transformation. Int. J. Solids Struct. 2020, in press. [Google Scholar] [CrossRef]

- Jiang, D.; Kyriakides, S.; Bechle, N.J.; Landis, C.M. Bending of pseudoelastic NiTi tubes. Int. J. Solids Struct. 2017, 124, 192–214. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Lee, C.-H.; Kim, J.-H.; Lim, J.H. Numerical modeling of shape memory alloy plates considering tension/compression asymmetry and its verification under pure bending. Int. J. Solids Struct. 2018, 77–88. [Google Scholar] [CrossRef]

- Zaki, W.; Moumni, Z.; Morin, C. Modeling Tensile–Compressive Asymmetry for Superelastic Shape Memory Alloys. Mech. Adv. Mater. Struct. 2011, 18, 559–564. [Google Scholar] [CrossRef]

- Bechle, N.J.; Kyriakides, S. Evolution of phase transformation fronts and associated thermal effects in a NiTi tube under a biaxial stress state. Extreme Mech. Lett. 2016, 8, 55–63. [Google Scholar] [CrossRef] [Green Version]

- Damanpack, A.; Bodaghi, M.; Liao, W. A finite-strain constitutive model for anisotropic shape memory alloys. Mech. Mater. 2017, 112, 129–142. [Google Scholar] [CrossRef]

- Šittner, P.; Sedlák, P.; Seiner, H.; Sedmák, P.; Pilch, J.; Delville, R.; Heller, L.; Kadeřávek, L. On the coupling between martensitic transformation and plasticity in NiTi: Experiments and continuum based modelling. Prog. Mater. Sci. 2018, 98, 249–298. [Google Scholar] [CrossRef]

- Oliveira, S.D.A.; Dornelas, V.M.; Savi, M.A.; Pacheco, P.M.C.L.; Paiva, A. A phenomenological description of shape memory alloy transformation induced plasticity. Meccanica 2018, 53, 2503–2523. [Google Scholar] [CrossRef]

- Merzouki, T.; Duval, A.; Ben Zineb, T. Finite Element analysis of a shape memory alloy actuator for a micropump. Simul. Model. Pr. Theory 2012, 27, 112–126. [Google Scholar] [CrossRef]

- Pan, Q.; Cho, C. The Investigation of a Shape Memory Alloy Micro–Damper for MEMS Applications. Sensors 2007, 7, 1887–1900. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, H.-T.; Kim, M.-S.; Lee, G.-Y.; Kim, C.-S.; Ahn, S.-H. Shape Memory Alloy (SMA)–Based Microscale Actuators with 60% Deformation Rate and 1.6 kHz Actuation Speed. Small 2018, 14, e1801023. [Google Scholar] [CrossRef] [PubMed]

- AbuZaiter, A.; Nafea, M.; Ali, M.S.S.M. Development of a shape-memory-alloy micromanipulator based on integrated bimorph microactuators. Mechatronics 2016, 38, 16–28. [Google Scholar] [CrossRef]

- Jiang, D.; Xiao, Y. Modelling on grain size dependent thermomechanical response of superelastic NiTi shape memory alloy. Int. J. Solids Struct. 2021, 210–211, 170–182. [Google Scholar] [CrossRef]

- Yu, C.; Kang, G.; Xie, X.; Rao, W. A micromechanical model for the grain size dependent super–elasticity degeneration of NiTi shape memory alloys. Mech. Mater. 2018, 125, 35–51. [Google Scholar] [CrossRef]

- Li, M.; Sun, Q. Nanoscale phase transition behavior of shape memory alloys–closed form solution of 1D effective modelling. J. Mech. Phys. Solids 2018, 110, 21–37. [Google Scholar] [CrossRef]

- Heller, L.; Karafítov, I.; Petrich, L.; Pawlas, Z.; Shayanfard, P.; Benes, V.; Schmidt, V.; Sittner, P.; Karafiatova, I. Numerical microstructure model of NiTi wire reconstructed from 3D–XRD data. Model. Simul. Mater. Sci. Eng. 2020, 28, 055007. [Google Scholar] [CrossRef]

- Kafka, V. Shape memory polymers: A mesoscale model of the internal mechanism leading to the SM phenomena. Int. J. Plast. 2008, 24, 1533–1548. [Google Scholar] [CrossRef]

- Maurel, G.; Schnell, B.; Goujon, F.; Couty, M.; Malfreyt, P. Multiscale Modeling Approach toward the Prediction of Viscoelastic Properties of Polymers. J. Chem. Theory Comput. 2012, 8, 4570–4579. [Google Scholar] [CrossRef]

- Uddin, S.; Ju, J. Enhanced Coarse-Graining of Thermoplastic Polyurethane Elastomer for Multiscale Modeling. J. Eng. Mater. Technol. 2016, 139, 011001. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Moon, J.; Kim, B.; Cho, M. Multi–scale coarse–grained molecular dynamics simulation to investigate the thermo–mechanical behavior of shape–memory polyurethane copolymers. Polymer 2021, 213, 123228. [Google Scholar] [CrossRef]

- Zhong, Y.; Gall, K.; Zhu, T. Atomistic characterization of pseudoelasticity and shape memory in NiTi nanopillars. Acta Mater. 2012, 60, 6301–6311. [Google Scholar] [CrossRef]

- Ko, W.-S.; Grabowski, B.; Neugebauer, J. Development and application of a Ni–Ti interatomic potential with high predictive accuracy of the martensitic phase transition. Phys. Rev. B 2015, 92, 134107. [Google Scholar] [CrossRef] [Green Version]

- Diani, J.; Gall, K. Molecular dynamics simulations of the shape-memory behaviour of polyisoprene. Smart Mater. Struct. 2007, 16, 1575–1583. [Google Scholar] [CrossRef]

- Wang, M.; Jiang, S.; Zhang, Y. Phase Transformation, Twinning, and Detwinning of NiTi Shape–Memory Alloy Subject to a Shock Wave Based on Molecular–Dynamics Simulation. Materials 2018, 11, 2334. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lv, C.; Zhang, X.P.; Wang, G.J.; Zhao, F.; Luo, N.; Bland, S.N.; Tan, F.L.; Zhao, J.H.; Liu, C.L.; Sun, C.W. Twinning and rotational deformation of nanocrystalline NiTi under shock loading. Phys. Rev. Mater. 2020, 4, 093607. [Google Scholar] [CrossRef]

- Wang, B.; Kang, G.; Kan, Q.; Zhou, K.; Yu, C. Molecular dynamics simulations to the pseudo-elasticity of NiTi shape memory alloy nano–pillar subjected to cyclic compression. Comput. Mater. Sci. 2017, 131, 132–138. [Google Scholar] [CrossRef]

- Chen, X.; Chen, W.; Ma, Y.; Zhao, Y.; Deng, C.; Peng, X.; Fu, T. Tension-Compression asymmetry of single–crystalline and nanocrystalline NiTi shape memory alloy: An atomic scale study. Mech. Mater. 2020, 145, 103402. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, J.; Zhu, J. Phase field study of the microstructure evolution and thermomechanical properties of polycrystalline shape memory alloys: Grain size effect and rate effect. Comput. Mater. Sci. 2018, 145, 252–262. [Google Scholar] [CrossRef]

- Ko, W.-S.; Choi, W.S.; Xu, G.; Choi, P.-P.; Ikeda, Y.; Grabowski, B. Dissecting functional degradation in NiTi shape memory alloys containing amorphous regions via atomistic simulations. Acta Mater. 2021, 202, 331–349. [Google Scholar] [CrossRef]

- Wang, B.; Kang, G.; Wu, W.; Zhou, K.; Kan, Q.; Yu, C. Molecular dynamics simulations on nanocrystalline super–elastic NiTi shape memory alloy by addressing transformation ratchetting and its atomic mechanism. Int. J. Plast. 2020, 125, 374–394. [Google Scholar] [CrossRef]

- Gur, S.; Frantziskonis, G.N.; Muralidharan, K. Atomistic simulation of shape memory effect (SME) and superelasticity (SE) in nano–porous NiTi shape memory alloy (SMA). Comput. Mater. Sci. 2018, 152, 28–37. [Google Scholar] [CrossRef]

- Wick, C.D.; Peters, A.J.; Li, G. Quantifying the contributions of energy storage in a thermoset shape memory polymer with high stress recovery: A molecular dynamics study. Polymer 2021, 213, 123319. [Google Scholar] [CrossRef]

- Zhang, X.-J.; Yang, Q.-S.; Liu, X.; Shang, J.-J.; Leng, J.-S. Atomistic investigation of the shape–memory effect of amorphous poly(L–lactide) with different molecular weights. Smart Mater. Struct. 2019, 29, 015040. [Google Scholar] [CrossRef]

- Shu, Y.-C. Shape–Memory Micropumps. Mater. Trans. 2002, 43, 1037–1044. [Google Scholar] [CrossRef] [Green Version]

- Knick, C.R.; Sharar, D.J.; A Wilson, A.; Smith, G.L.; Morris, C.J.; A Bruck, H. High frequency, low power, electrically actuated shape memory alloy MEMS bimorph thermal actuators. J. Micromech. Microeng. 2019, 29, 075005. [Google Scholar] [CrossRef]

- Singh, S.; Subramaniam, K.; Chittora, N.; Brolin, A.; Palani, I. Studies on development of NiTi–integrated optical fiber sensor and its life cycle behavior. J. Intell. Mater. Syst. Struct. 2020, 31, 869–881. [Google Scholar] [CrossRef]

- Askari-Naeini, F.G.; Taghizadeh, M.; Mohri, M.; Nili-Ahmadabadi, M. On the microstructure and mechanical properties of a two–way shape memory NiTi/NiTiCu bi–layer diaphragm. Mater. Des. 2020, 188, 108464. [Google Scholar] [CrossRef]

- Robertson, J.M.; Rodriguez, R.X.; Holmes, L.R.; Mather, P.T.; Wetzel, E.D. Thermally driven microfluidic pumping via reversible shape memory polymers. Smart Mater. Struct. 2016, 25, 085043. [Google Scholar] [CrossRef]

- Kabla, M.; Ben-David, E.; Shilo, D. A novel shape memory alloy microactuator for large in–plane strokes and forces. Smart Mater. Struct. 2016, 25, 75020. [Google Scholar] [CrossRef] [Green Version]

- AbuZaiter, A.; Nafea, M.; Faudzi, A.A.M.; Kazi, S.; Ali, M.S.M. Thermomechanical behavior of bulk NiTi shape-memory–alloy microactuators based on bimorph actuation. Microsyst. Technol. 2015, 22, 2125–2131. [Google Scholar] [CrossRef]

- Shelyakov, A.; Sitnikov, N.; Borodako, K.; Koledov, V.; Khabibullina, I.; Von Gratowski, S. Design of microgrippers based on amorphous–crystalline TiNiCu alloy with two-way shape memory. J. Micro-Bio Robot. 2020, 16, 43–51. [Google Scholar] [CrossRef]

- Xiong, F.; Yang, H.; Liu, K.; Man, J.; Chen, H. Forming and two-way shape memory effect of NiTi alloy induced by laser shock imprinting. Opt. Laser Technol. 2019, 120, 105762. [Google Scholar] [CrossRef]

- Song, S.-H.; Lee, J.-Y.; Rodrigue, H.; Choi, I.-S.; Kang, Y.J.; Ahn, S.-H. 35 Hz shape memory alloy actuator with bending–twisting mode. Sci. Rep. 2016, 6, 21118. [Google Scholar] [CrossRef]

- Stachiv, I.; Sittner, P.; Jeng, Y.R.; Vokoun, D. Active frequency tuning of the cantilever nanoresonator utilizing a phase transformation of NiTi thin film. J. Vibroeng. 2017, 19, 5161–5169. [Google Scholar] [CrossRef]

- Kohl, M.; Gueltig, M.; Pinneker, V.; Yin, R.; Wendler, F.; Krevet, B. Magnetic Shape Memory Microactuators. Micromachines 2014, 5, 1135–1160. [Google Scholar] [CrossRef]

- Qingxin, Z.; Qihang, F.; Luping, W.; Yunhong, G. Research and Experimental Analysis of Damping Characteristics of Magnetic Shape Memory Alloy. Trans. Electr. Electron. Mater. 2018, 19, 272–278. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, C.; Zhou, M. NARMAX Model–Based Hysteresis Modeling of Magnetic Shape Memory Alloy Actuators. IEEE Trans. Nanotechnol. 2020, 19, 1–4. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, Y.; Wang, Y.; Zhou, M. Takagi–Sugeno Fuzzy Neural Network Hysteresis Modeling for Magnetic Shape Memory Alloy Actuator Based on Modified Bacteria Foraging Algorithm. Int. J. Fuzzy Syst. 2020, 22, 1314–1329. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, L.; Zhang, F.; Leng, J.; Liu, Y. Shape memory polymers and their composites in biomedical applications. Mater. Sci. Eng. C 2019, 97, 864–883. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Pan, X.; Debije, M.G.; Heuts, J.P.A.; Mulder, D.-J.; Schenning, A.P.H.J. Programmable liquid crystal elastomer microactuators prepared via thiol–ene dispersion polymerization. Soft Matter 2020, 16, 4908–4911. [Google Scholar] [CrossRef] [PubMed]

- Zainal, M.A.; Ahmad, A.; Ali, M.S.M. Frequency-controlled wireless shape memory polymer microactuator for drug delivery application. Biomed. Microdevices. 2017, 19, 8. [Google Scholar] [CrossRef]

- De Marco, C.; Alcântara, C.C.J.; Kim, S.; Briatico, F.; Kadioglu, A.; De Bernardis, G.; Chen, X.; Marano, C.; Nelson, B.J.; Pané, S. Indirect 3D and 4D Printing of Soft Robotic Microstructures. Adv. Mater. Technol. 2019, 4. [Google Scholar] [CrossRef] [Green Version]

- Georgopoulou, A.; Michel, S.; VanderBorght, B.; Clemens, F. Piezoresistive sensor fiber composites based on silicone elastomers for the monitoring of the position of a robot arm. Sens. Actuators A Phys. 2021, 318, 112433. [Google Scholar] [CrossRef]

- Farhan, M.; Rudolph, T.; Nöchel, U.; Yan, W.; Kratz, K.; Lendlein, A. Noncontinuously Responding Polymeric Actuators. ACS Appl. Mater. Interfaces 2017, 9, 33559–33564. [Google Scholar] [CrossRef]

- Alian, A.; Meguid, S. Multiscale modeling of the coupled electromechanical behavior of multifunctional nanocomposites. Compos. Struct. 2019, 208, 826–835. [Google Scholar] [CrossRef]

| Property of NiTi | Units | Martensite | Austenite |

|---|---|---|---|

| Density | g/cm3 | ~6.45 | |

| Poisson‘s ratio | – | ~0.33 | |

| Ultimate tensile strength | MPa | up to 1900 | |

| Young‘s modulus | GPa | 25–40 | 60–83 |

| Yield strength | MPa | 70–140 | 195–690 |

| Thermal conductivity | W/(m·K) | 8.6 | 18 |

| Coefficient of thermal expansion | K−1 | 6.6 | 11 |

| Magnetic susceptibility | emu/g | 2.4 | 3.8 |

| Electric resistivity | Ω·cm | 76 | 82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stachiv, I.; Alarcon, E.; Lamac, M. Shape Memory Alloys and Polymers for MEMS/NEMS Applications: Review on Recent Findings and Challenges in Design, Preparation, and Characterization. Metals 2021, 11, 415. https://doi.org/10.3390/met11030415

Stachiv I, Alarcon E, Lamac M. Shape Memory Alloys and Polymers for MEMS/NEMS Applications: Review on Recent Findings and Challenges in Design, Preparation, and Characterization. Metals. 2021; 11(3):415. https://doi.org/10.3390/met11030415

Chicago/Turabian StyleStachiv, Ivo, Eduardo Alarcon, and Miroslav Lamac. 2021. "Shape Memory Alloys and Polymers for MEMS/NEMS Applications: Review on Recent Findings and Challenges in Design, Preparation, and Characterization" Metals 11, no. 3: 415. https://doi.org/10.3390/met11030415

APA StyleStachiv, I., Alarcon, E., & Lamac, M. (2021). Shape Memory Alloys and Polymers for MEMS/NEMS Applications: Review on Recent Findings and Challenges in Design, Preparation, and Characterization. Metals, 11(3), 415. https://doi.org/10.3390/met11030415