Experimental and Computational Approach to Fatigue Behavior of Polycrystalline Tantalum

Abstract

1. Introduction

2. Experimental Approach

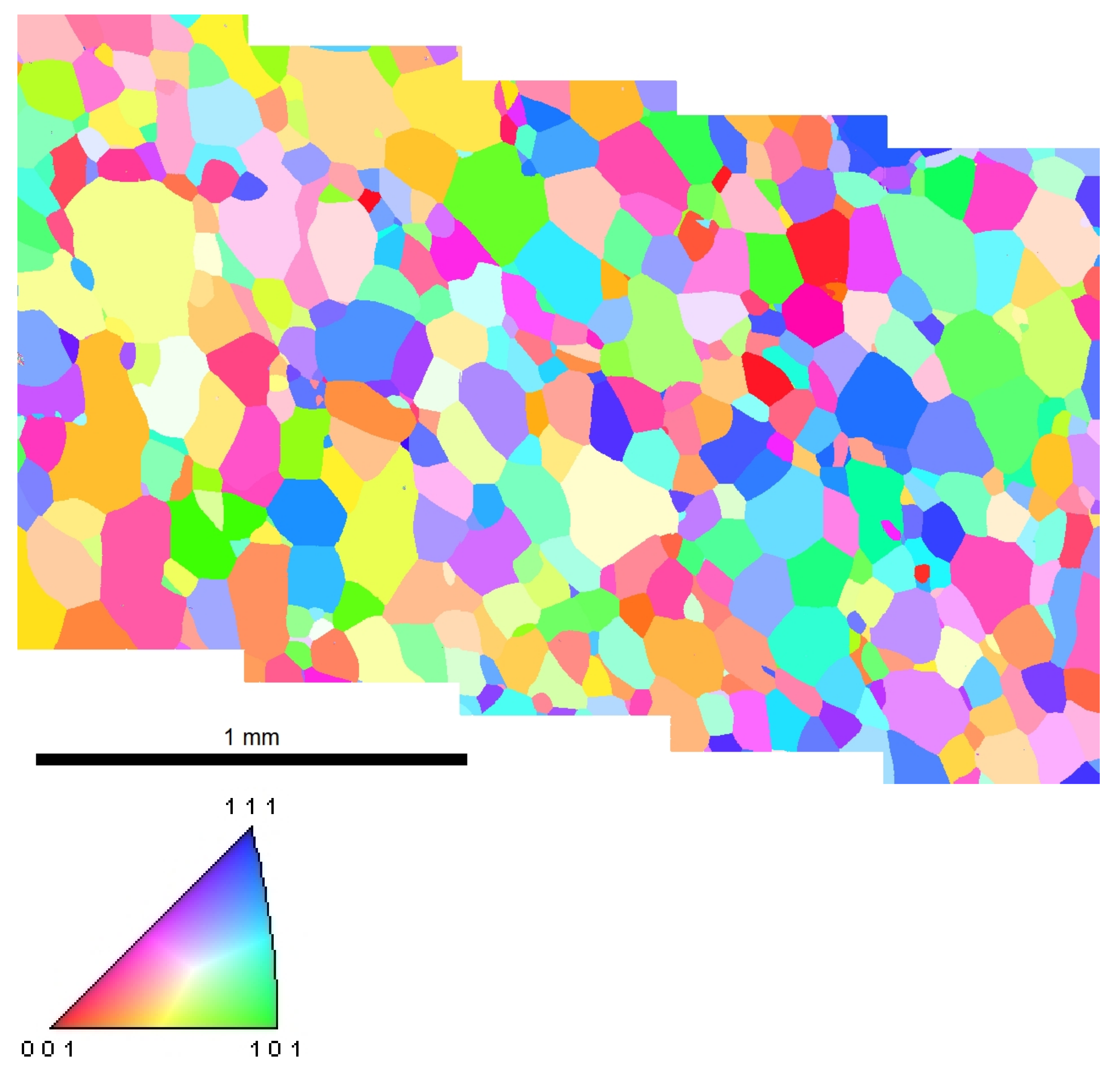

2.1. Material and Experimental Methods

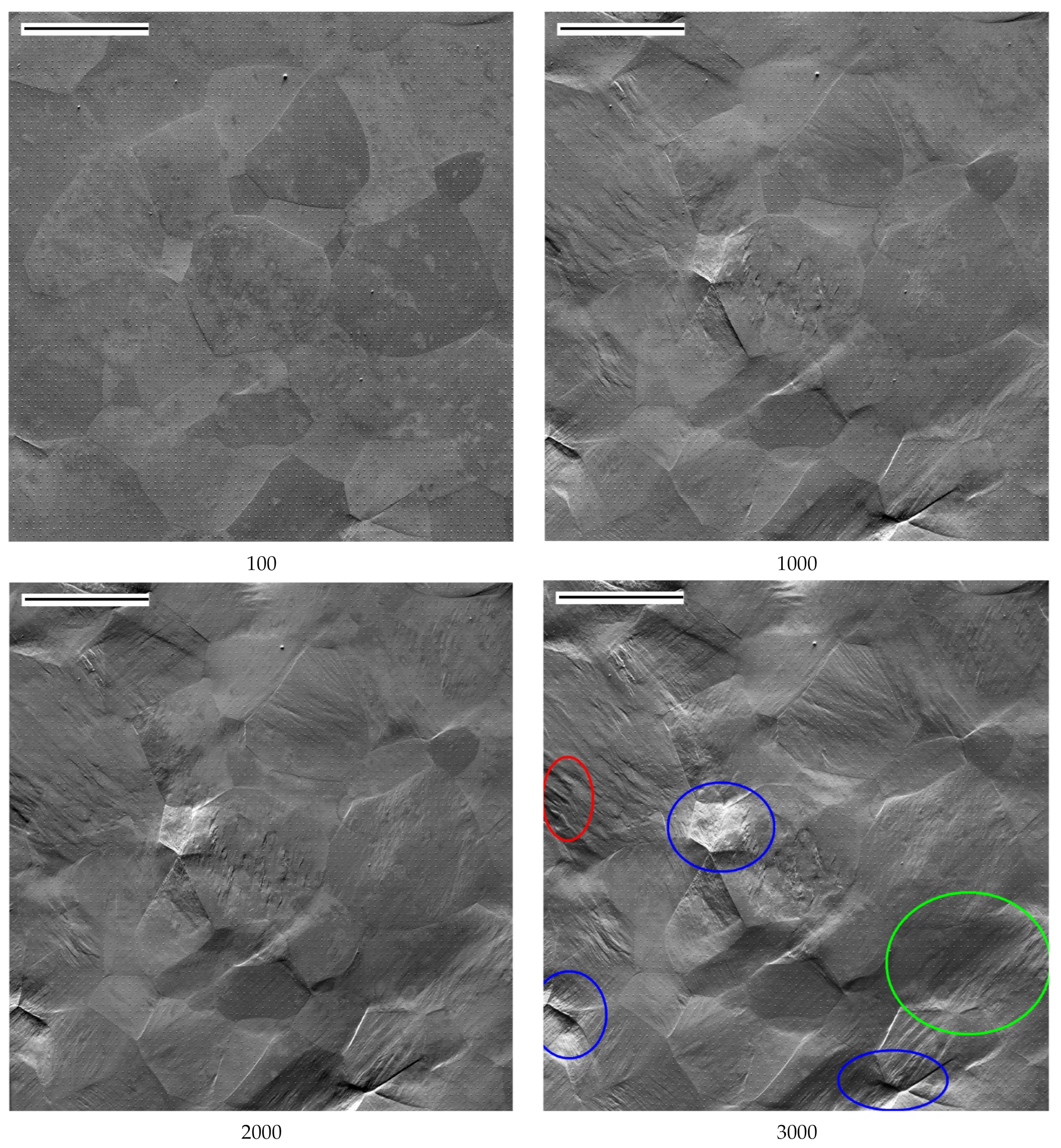

2.2. Local Evolution of the Surface during Cycling

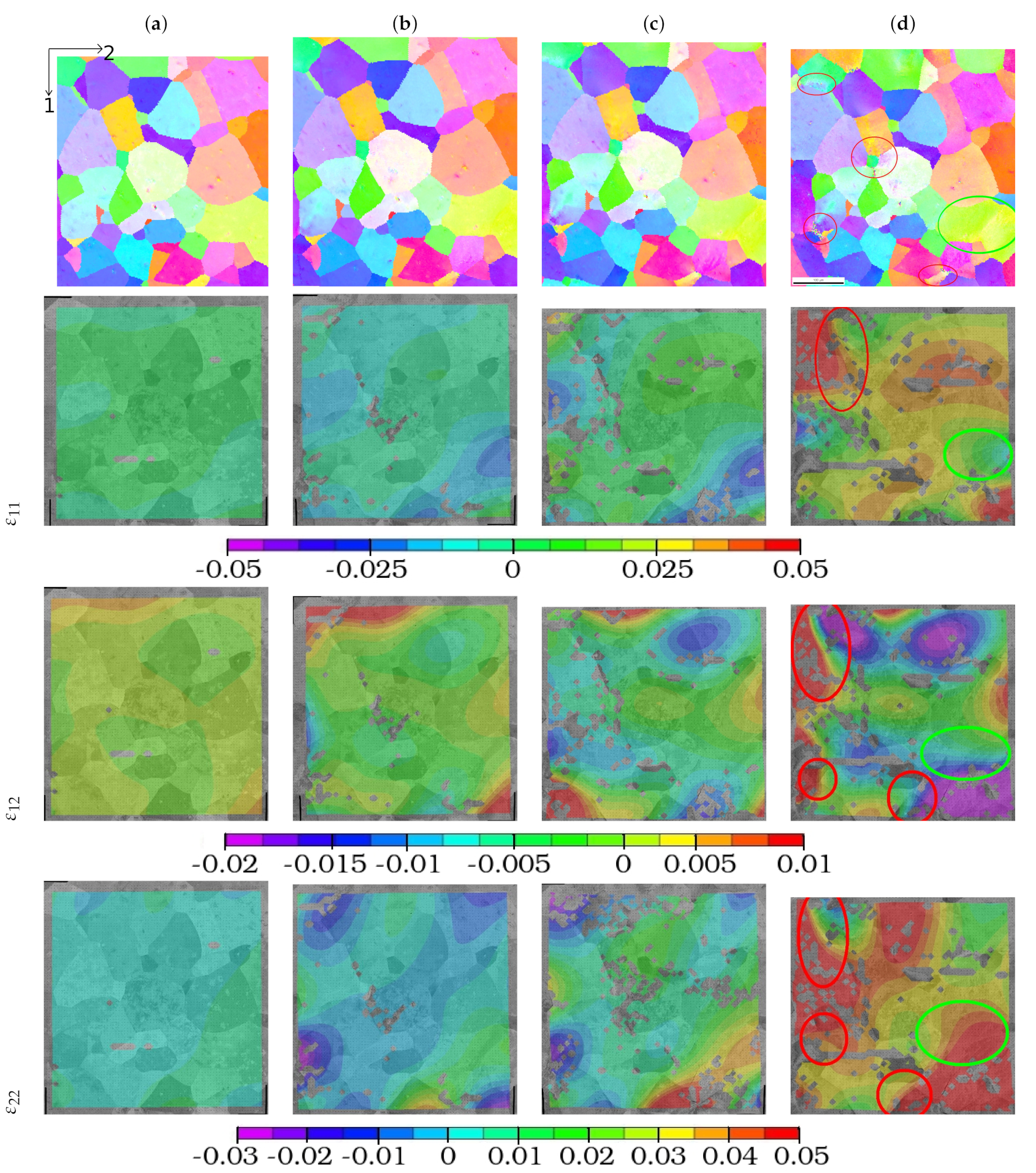

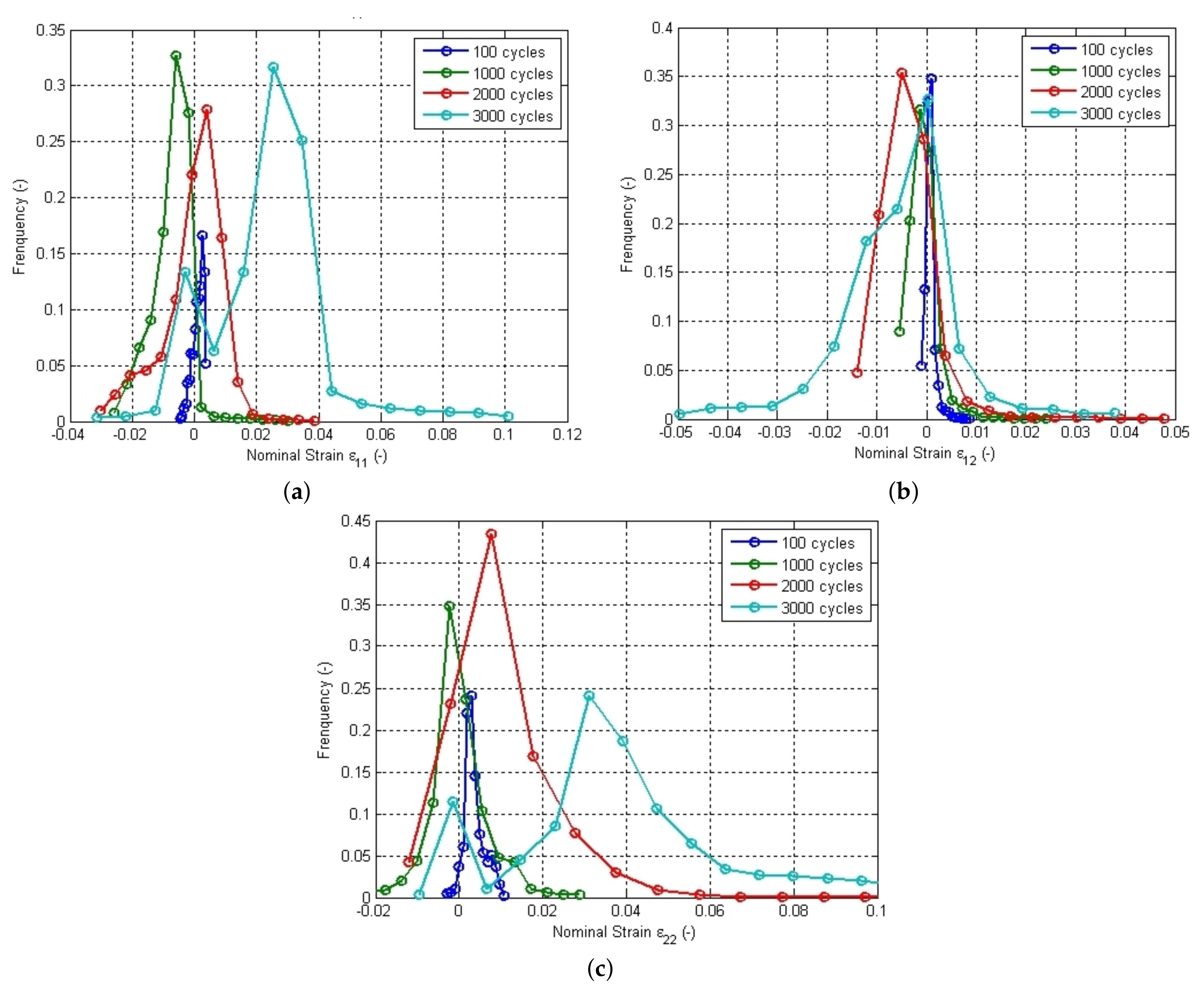

2.3. Strain Field Measurements

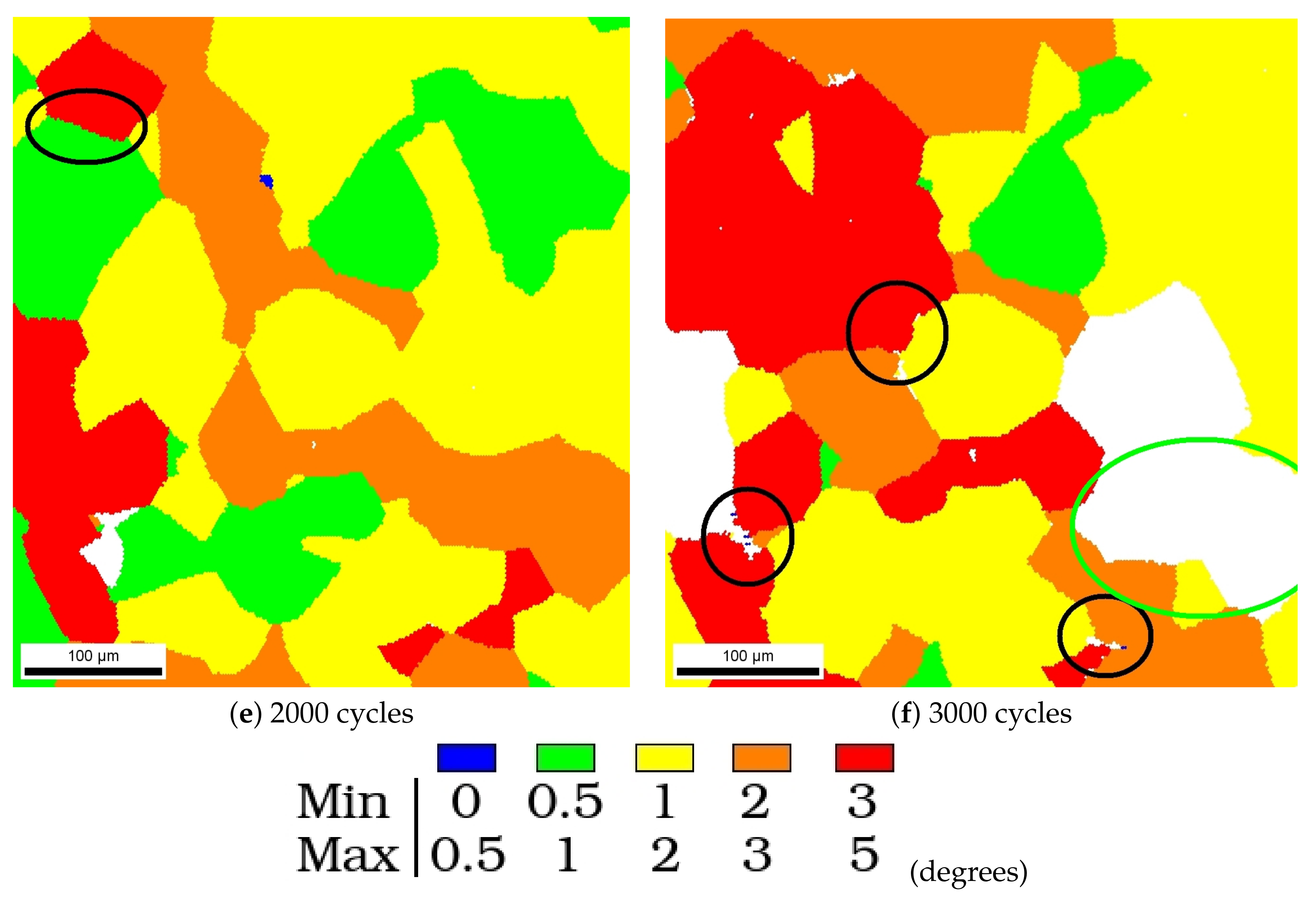

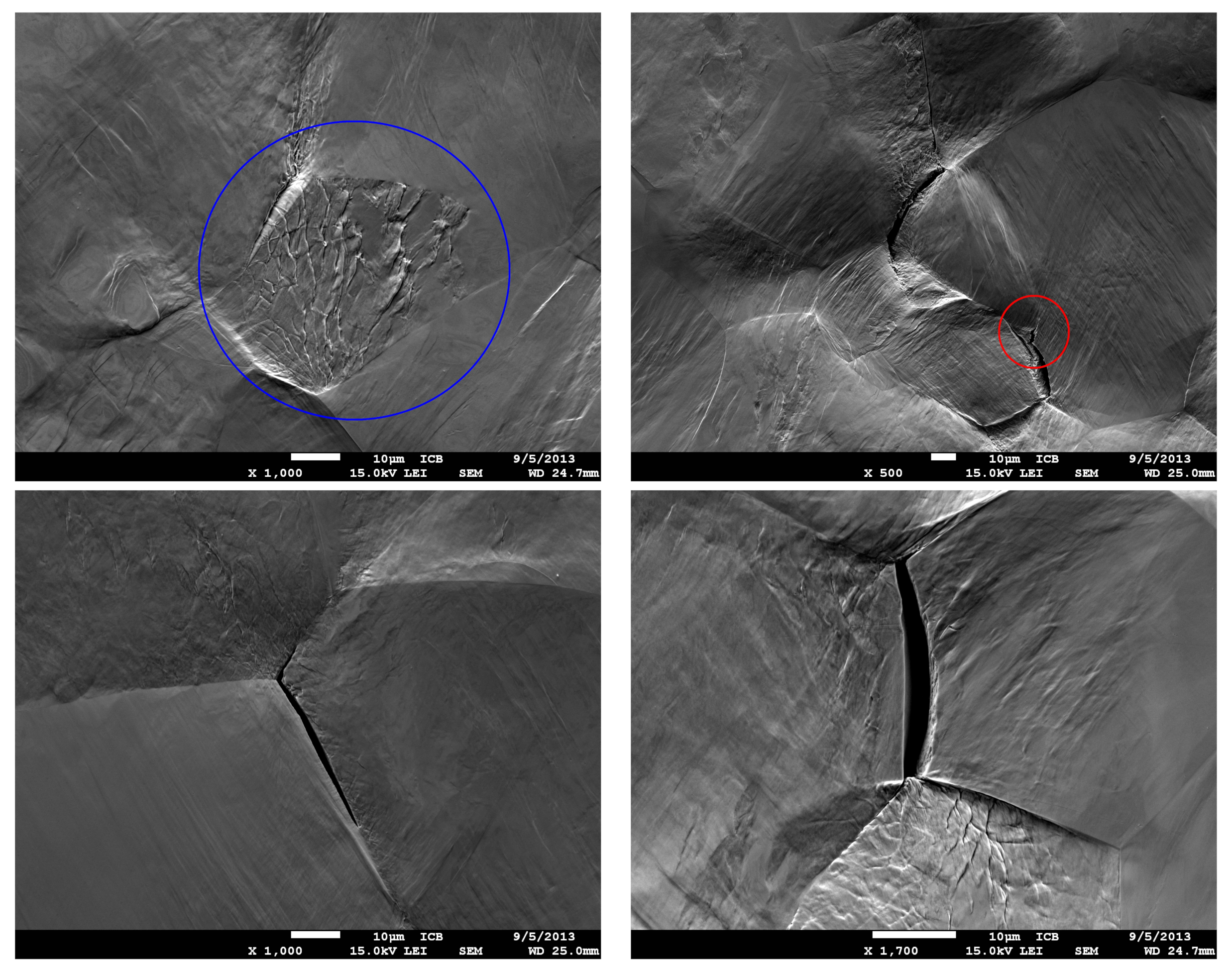

2.4. Fatigue Crack Initiation

3. Finite Element Simulation

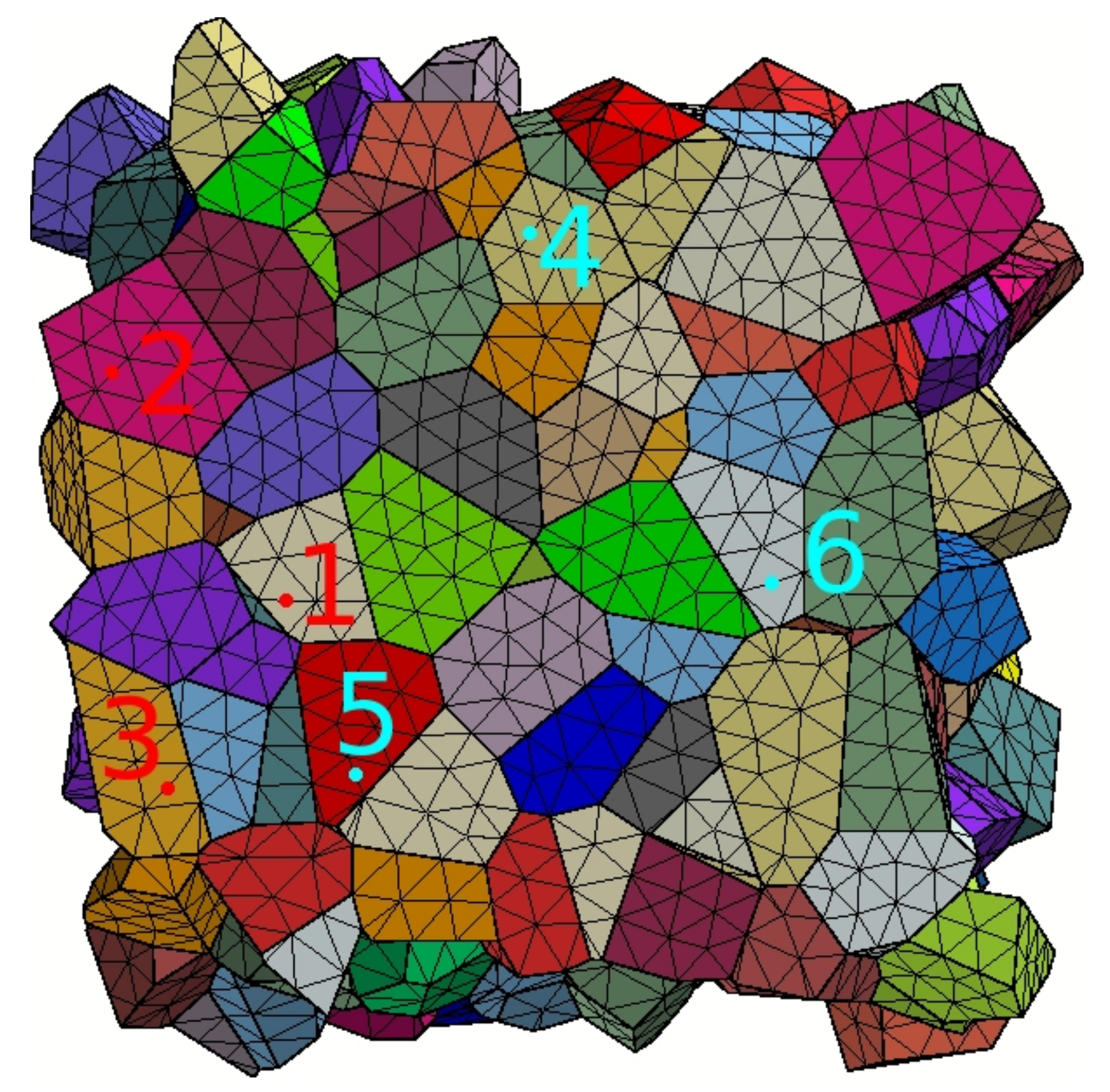

3.1. Description of Semi-Periodic Polycrystalline Aggregates

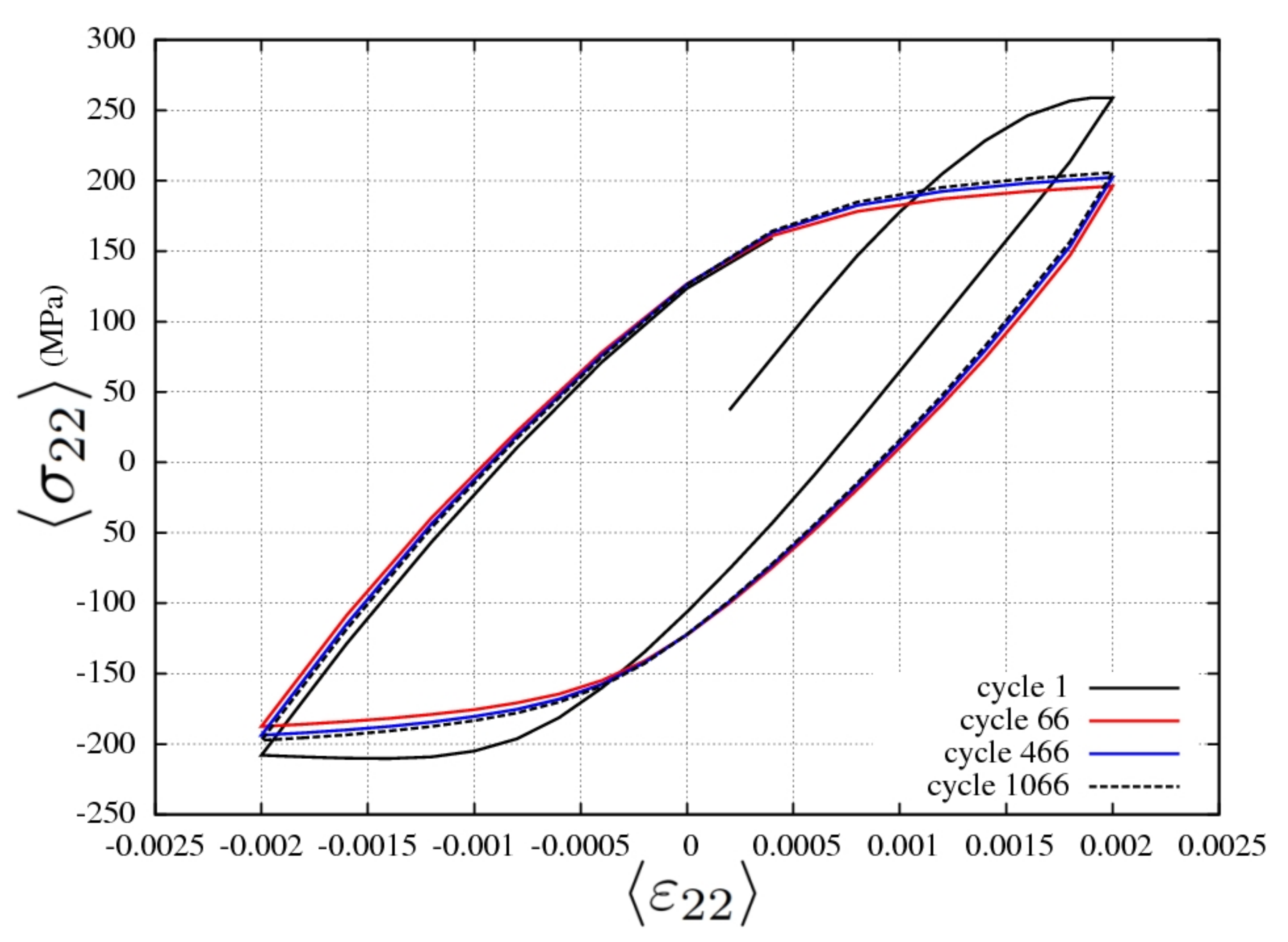

3.2. Crystal Plasticity Model and Identification of Material Parameters

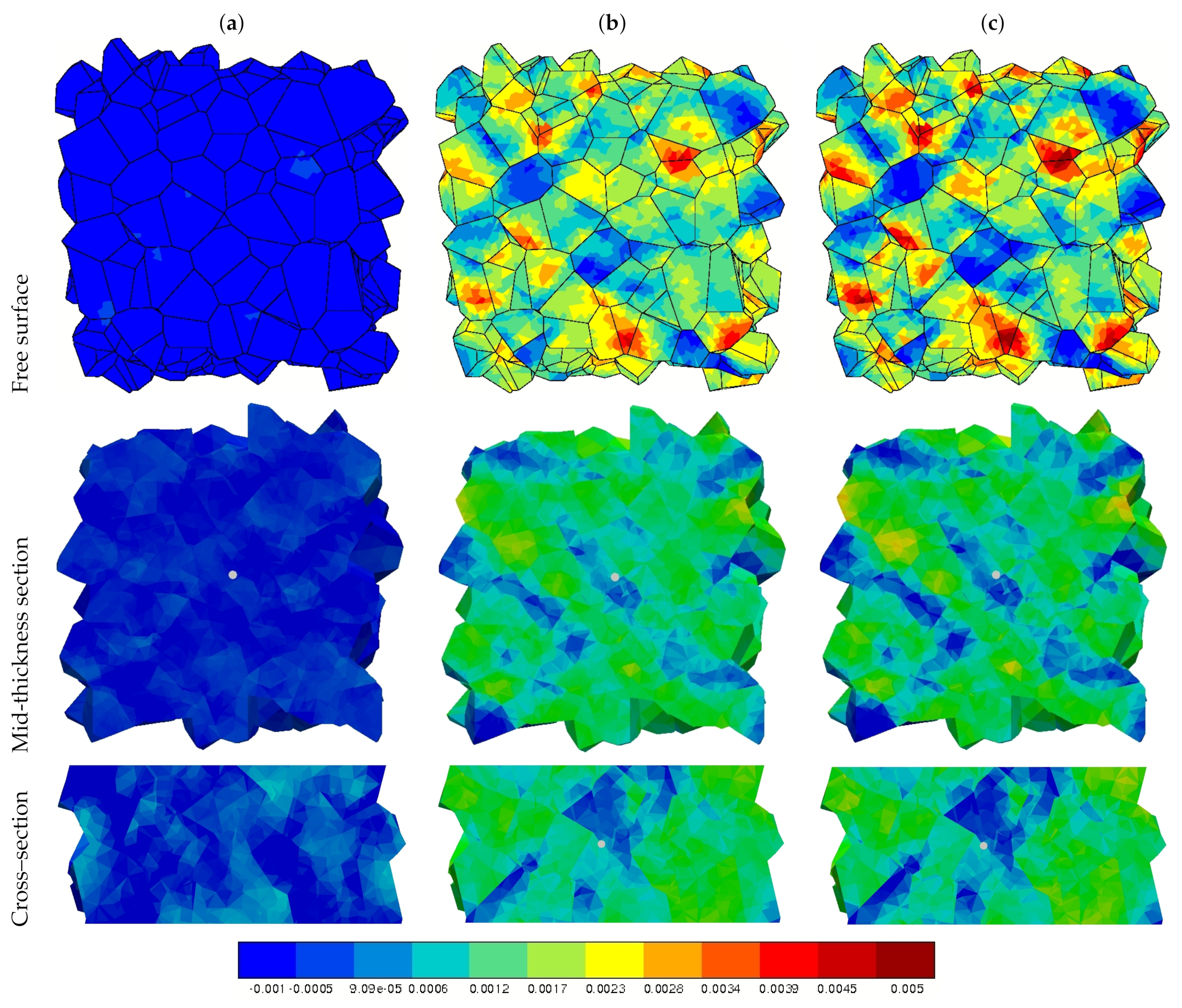

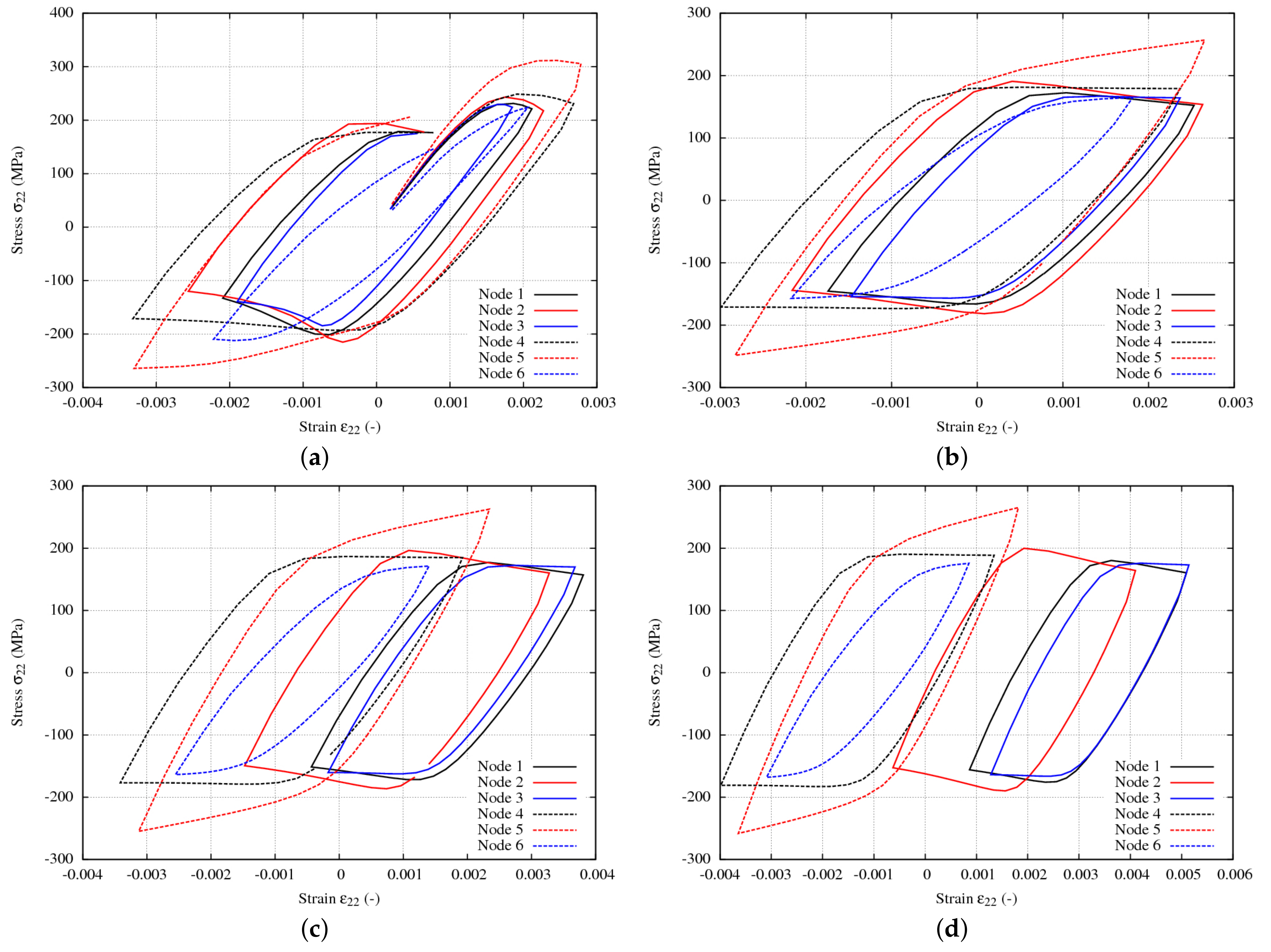

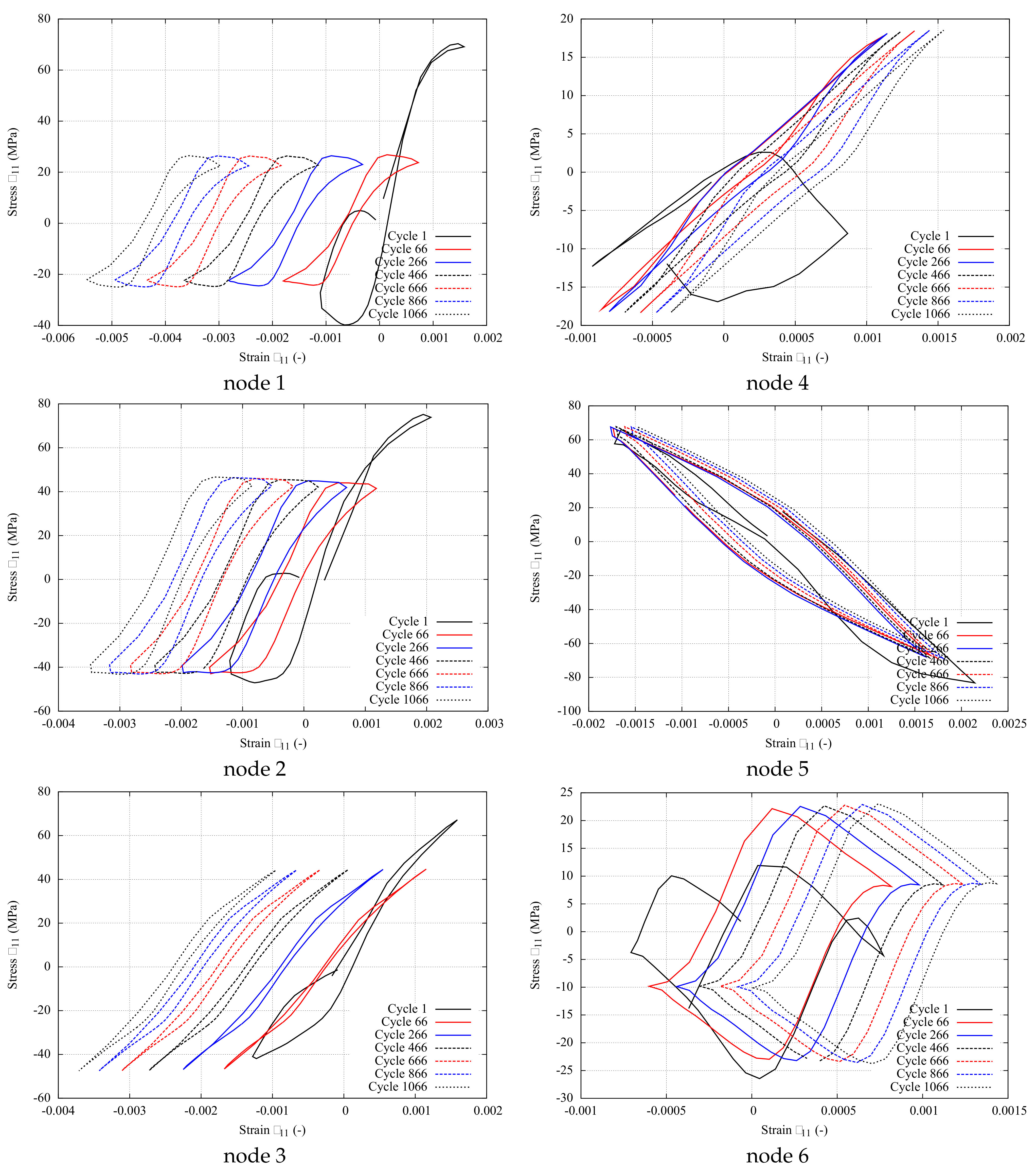

3.3. Simulation of the Mechanical Fields at the Free Surface

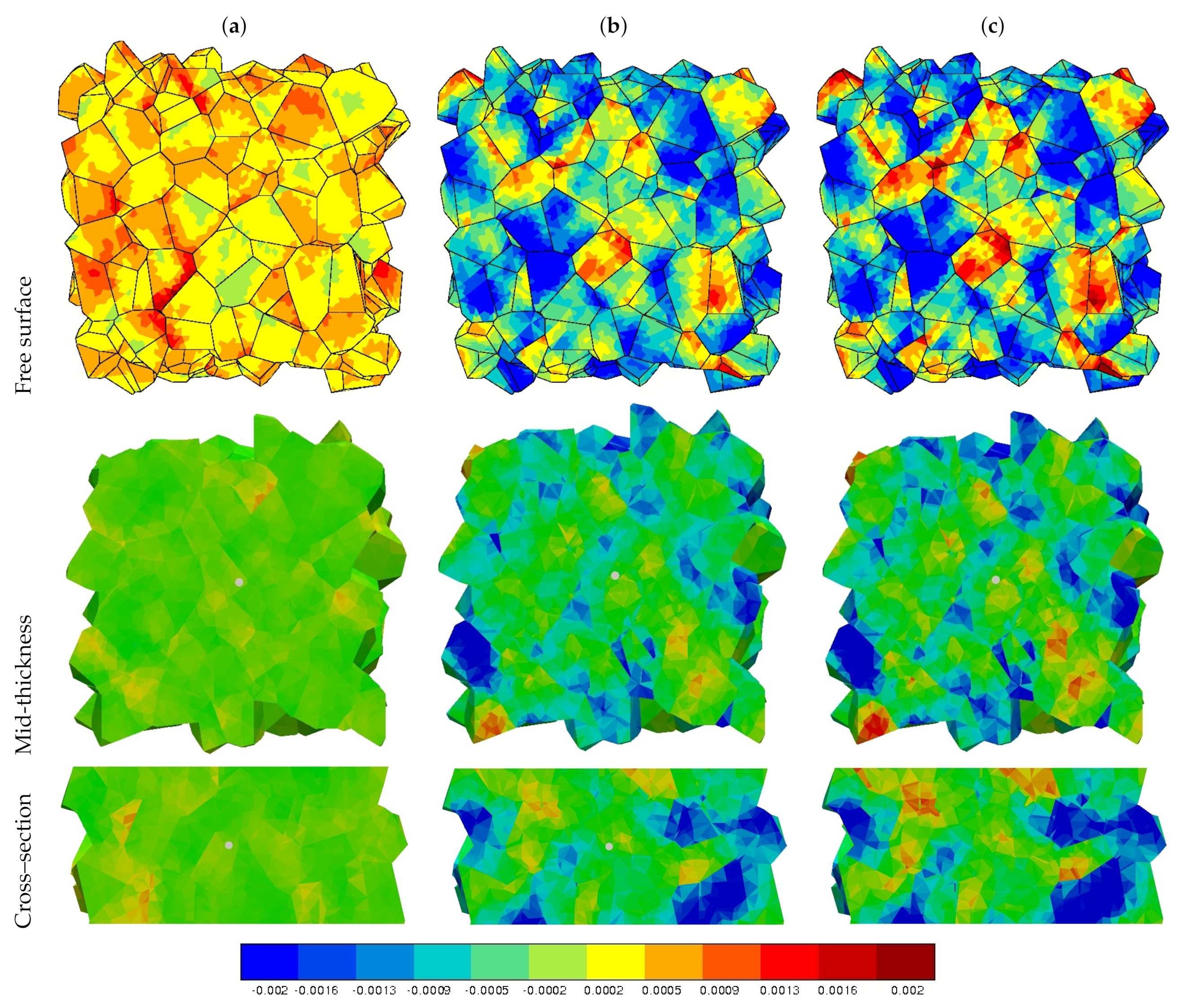

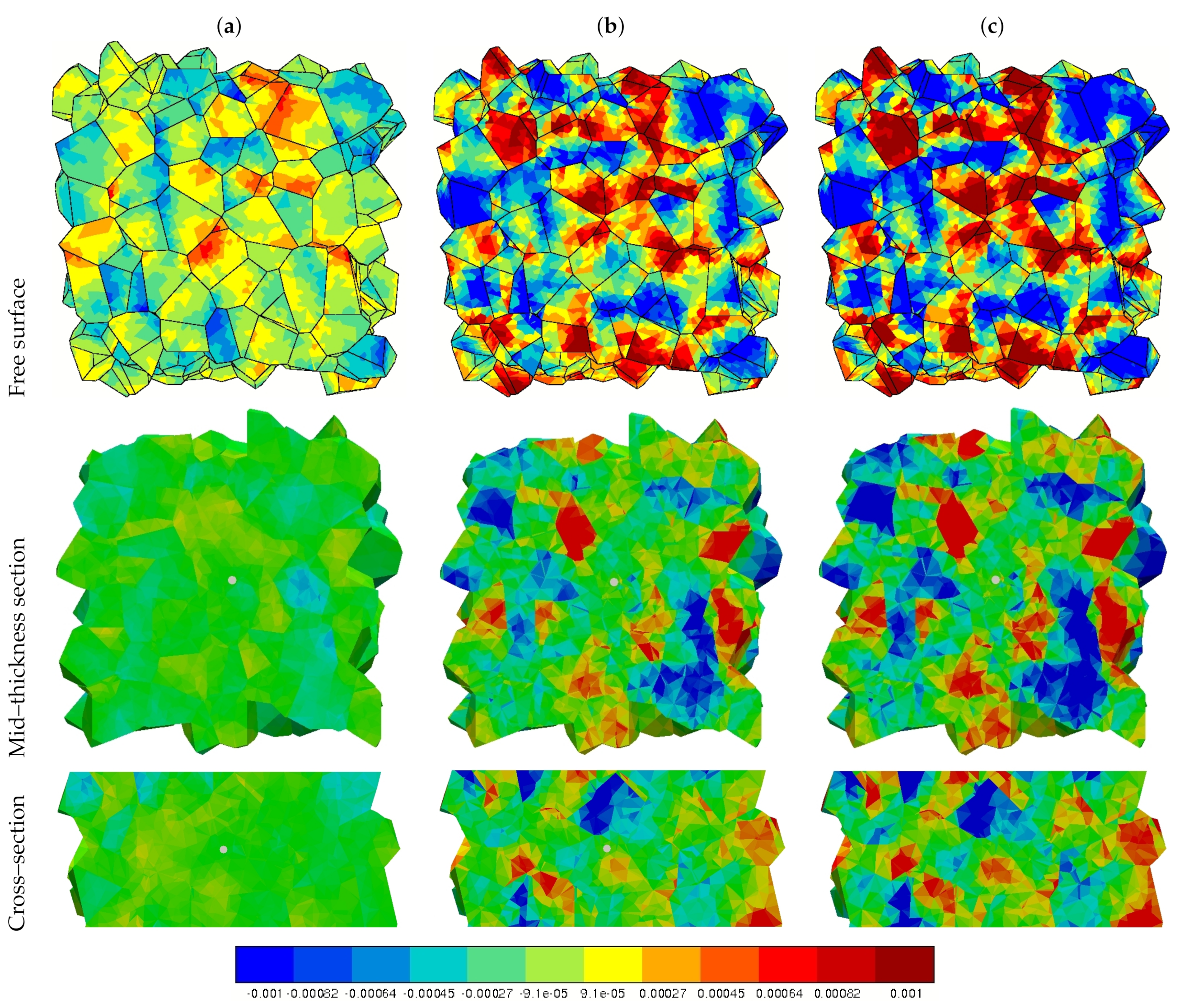

3.3.1. Surface Strain Field

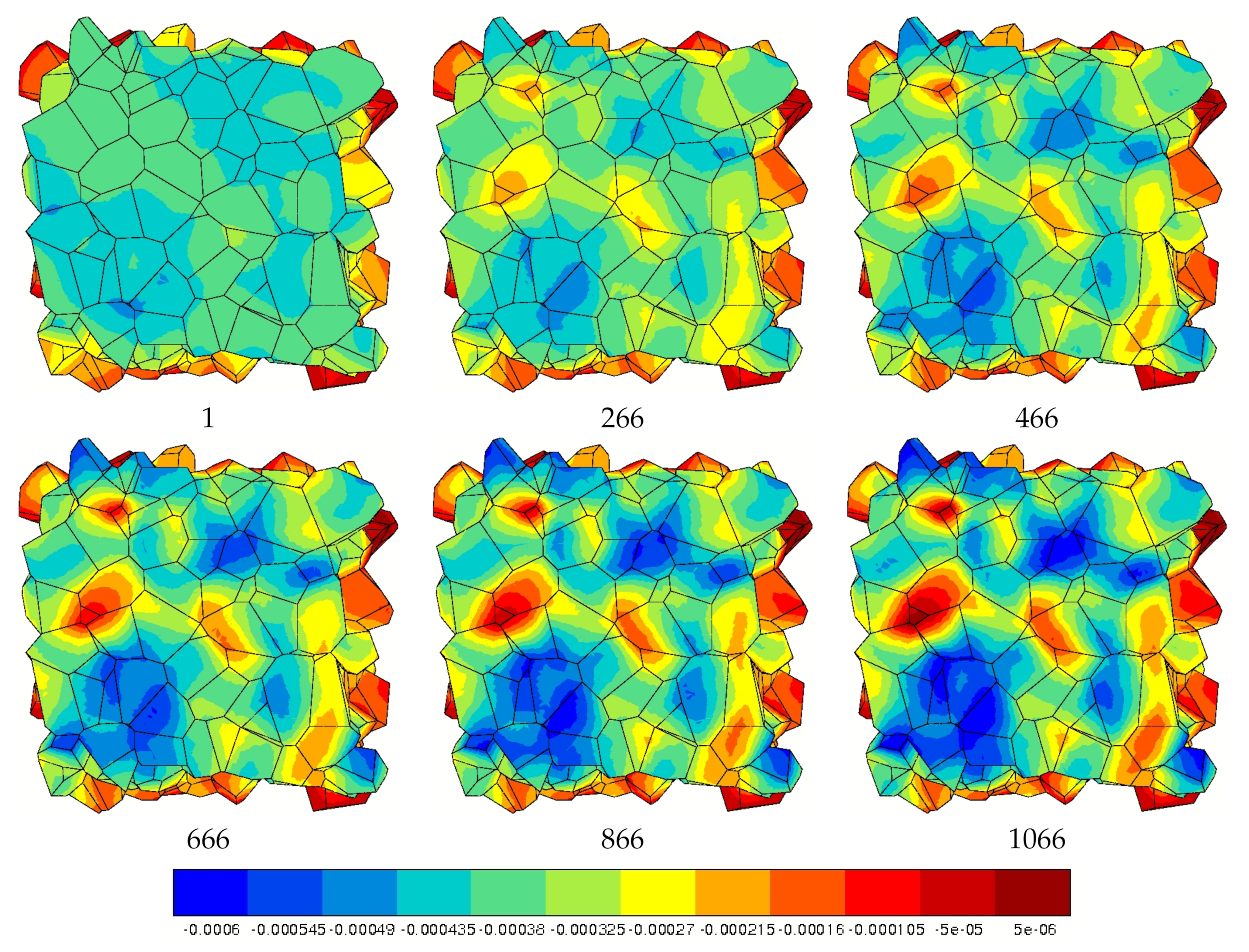

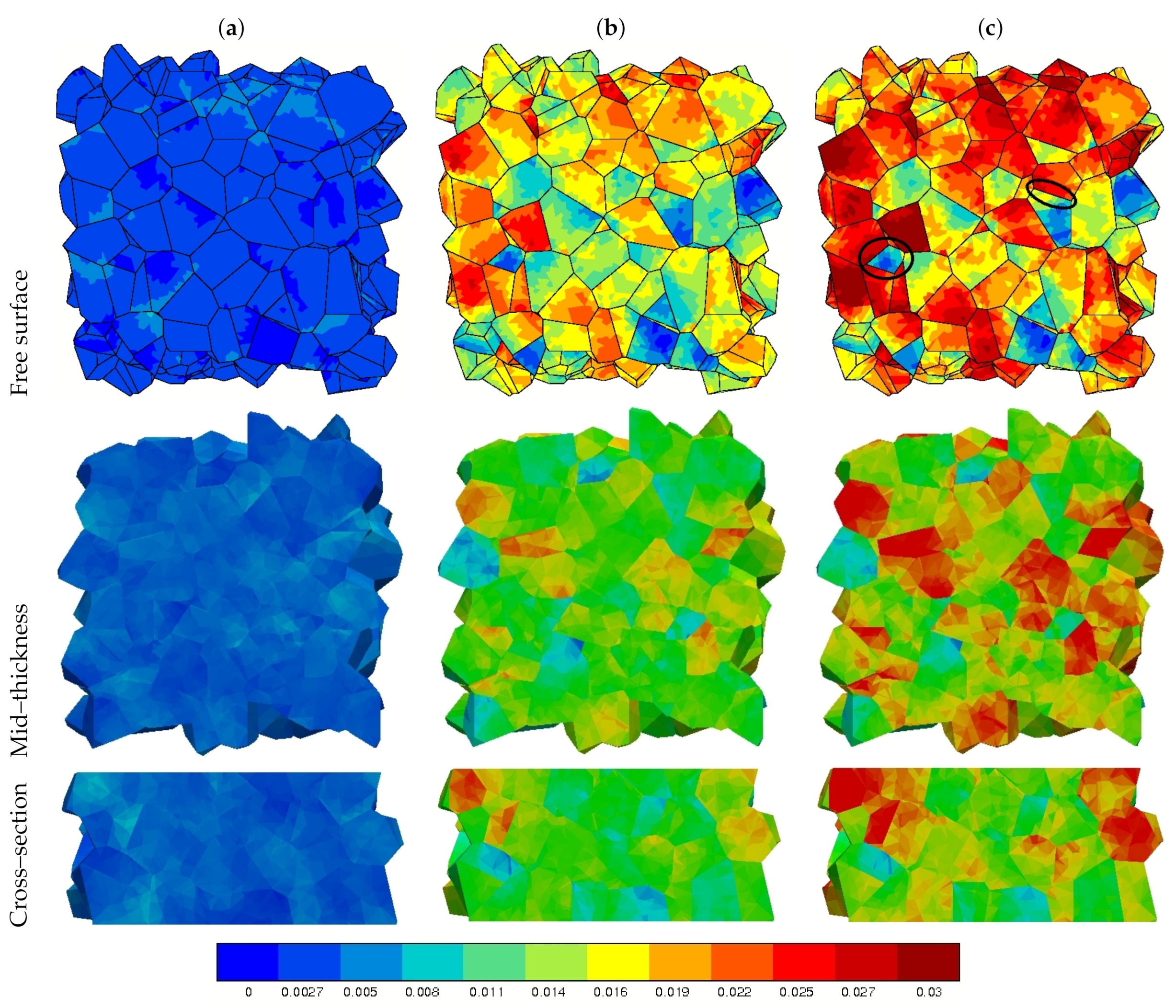

3.3.2. Plastic Slip Evolution

4. Discussion

4.1. The FE Model Underestimates Strain Heterogeneities and Roughness in Fatigue

4.2. Local Ratcheting Behavior

Ratcheting Indicator

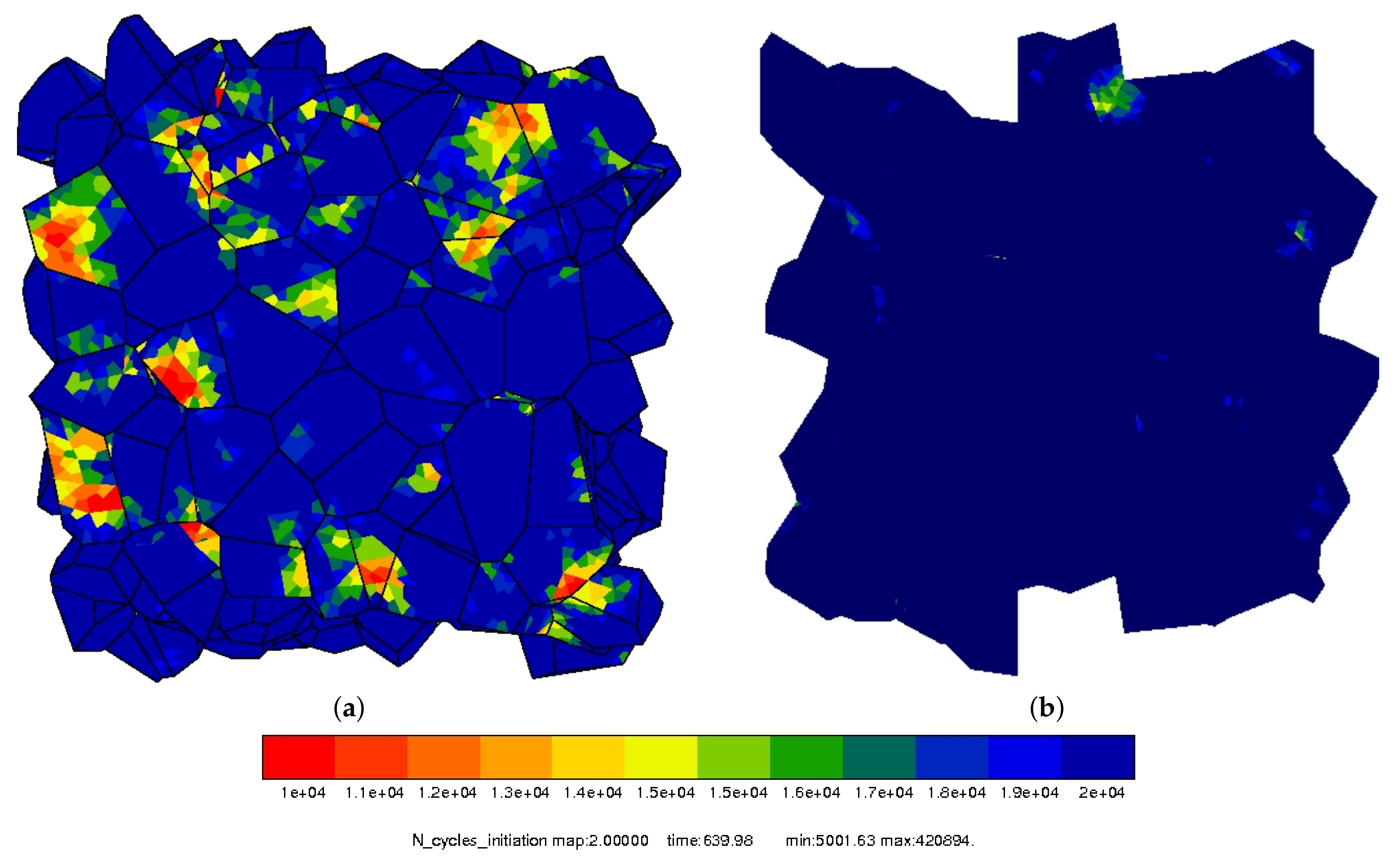

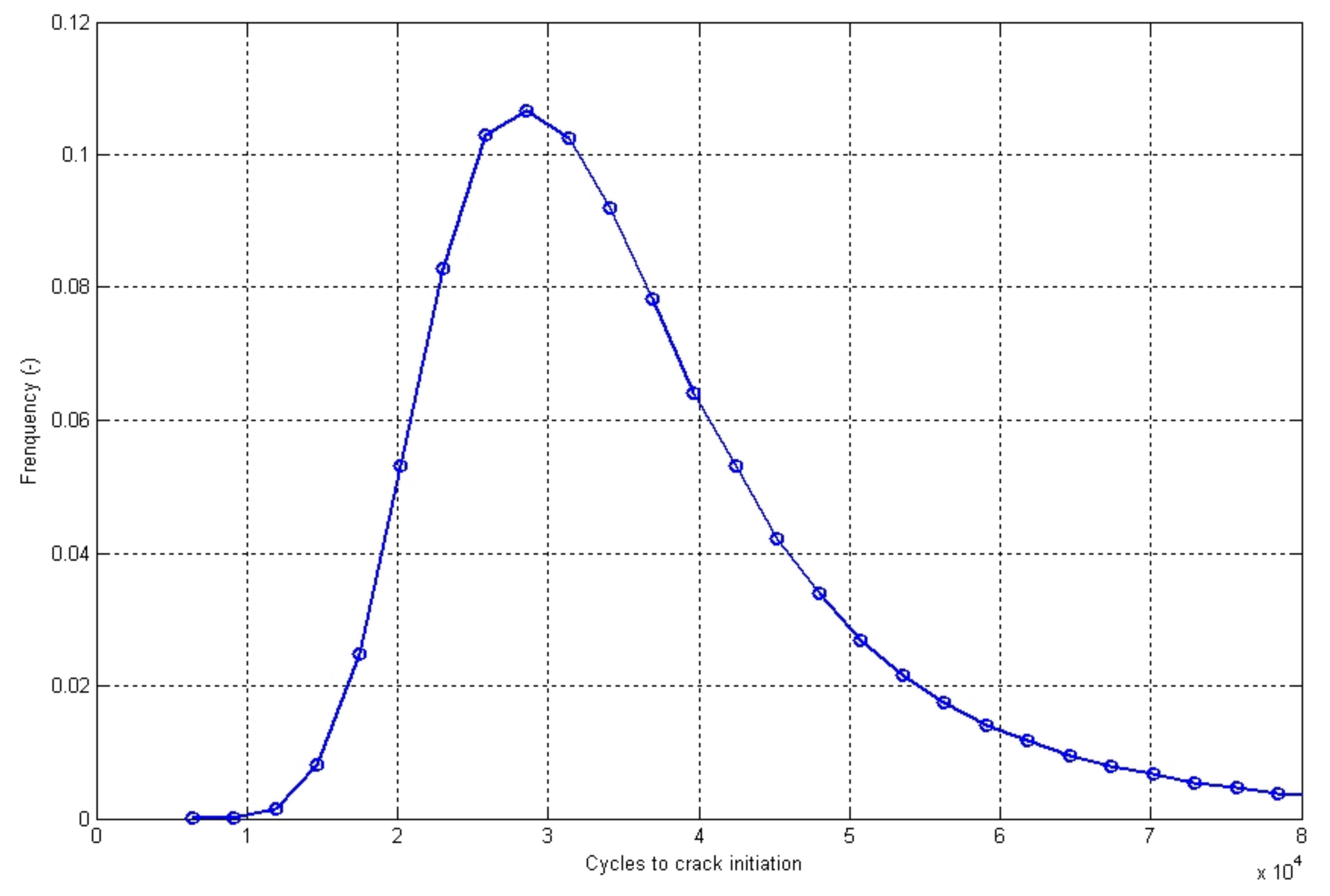

4.3. Fatigue Criterion

5. Conclusions

- Unique experimental results from an interrupted cyclic tension–compression test have been provided. They show the development of plastic activity in the form of sinuous slip lines and intense slip bands. The development of lattice curvature resulting from inhomogeneous plastic slip inside the grains was illustrated after 100, 1000, 2000, and 3000 cycles.

- Strain field measurements reveal local strain values of a few percents even though the overall loading was ±0.2%. These values are compatible with observed local amounts of lattice rotation. This results in significant roughening of the free surface during cycling.

- Fatigue cracks were shown to initiate between 3000 and 5000 cycles mainly in the form of intergranular cracks.

- Unique FE simulation results of crystal plasticity in a semi-periodic polycrystalline aggregate were provided for more than 1000 cycles. They confirm but underestimate the strain heterogeneity that develops at the free surface.

- An original fatigue criterion was proposed for stage I crack initiation at the grain level. It is based on the local determination of a multiaxial ratcheting indicator to be compared with a critical plastic equivalent strain value. The criterion indirectly incorporates the effects of resolved shear stresses and mean stress through the induced multiaxial plastic slip.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nemat-Nasser, S.; Isaacs, J.; Liu, M. Microstructure of high-strain, high-strain-rate deformed tantalum. Acta Mater. 1998, 46, 1307–1325. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Okinaka, T.; Ni, L. A physically-based constitutive model for BCC crystals with application to polycrystalline tantalum. J. Mech. Phys. Solids 1998, 46, 1009–1038. [Google Scholar] [CrossRef]

- Chen, Y.; Meyers, M.; Nesterenko, V. Spontaneous and forced shear localization in high-strain-rate deformation of tantalum. Mater. Sci. Eng. A 1999, 268, 70–82. [Google Scholar] [CrossRef]

- Diehl, M.; Niehuesbernd, J.; Bruder, E. On the PLC Effect in a Particle Reinforced AA2017 Alloy. Metals 2019, 9, 1252. [Google Scholar] [CrossRef]

- Bornert, M.; Brémand, F.; Doumalin, P.; Dupré, J.C.; Fazzini, M.; Grédiac, M.; Hild, F.; Mistou, S.; Molimard, J.; Orteu, J.J.; et al. Assessment of Digital Image Correlation Measurement Errors: Methodology and Results. Exp. Mech. 2009, 49, 353–370. [Google Scholar] [CrossRef]

- Cho, H.; Bronkhorst, C.A.; Mourad, H.M.; Mayeur, J.R.; Luscher, D.J. Anomalous plasticity of body-centered-cubic crystals with non-Schmid effect. Int. J. Solids Struct. 2018, 139–140, 138–149. [Google Scholar] [CrossRef]

- Alleman, C.; Ghosh, S.; Luscher, D.J.; Bronkhorst, C.A. Evaluating the effects of loading parameters on single-crystal slip in tantalum using molecular mechanics. Philos. Mag. 2014, 94, 92–116. [Google Scholar] [CrossRef]

- Lim, H.; Carroll, J.D.; Battaile, C.C.; Boyce, B.L.; Weinberger, C.R. Quantitative comparison between experimental measurements and CP-FEM predictions of plastic deformation in a tantalum oligocrystal. Int. J. Mech. Sci. 2015, 92, 98–108. [Google Scholar] [CrossRef]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. Statistical analysis of dislocations and dislocation boundaries from EBSD data. Ultramicroscopy 2017, 179, 63–72. [Google Scholar] [CrossRef]

- Lim, H.; Carroll, J.D.; Michael, J.R.; Battaile, C.C.; Chen, S.R.; Lane, J.M.D. Investigating active slip planes in tantalum under compressive load: Crystal plasticity and slip trace analyses of single crystals. Acta Mater. 2020, 185, 1–12. [Google Scholar] [CrossRef]

- Hansen, L.T.; Fullwood, D.T.; Homer, E.R.; Wagoner, R.H.; Lim, H.; Carroll, J.D.; Zhou, G.; Bong, H.J. An investigation of geometrically necessary dislocations and back stress in large grained tantalum via EBSD and CPFEM. Mater. Sci. Eng. A 2020, 772, 138704. [Google Scholar] [CrossRef]

- Chen, J.; Hahn, E.N.; Dongare, A.M.; Fensin, S.J. Understanding and predicting damage and failure at grain boundaries in BCC Ta. J. Appl. Phys. 2019, 126, 165902. [Google Scholar] [CrossRef]

- Wauthle, R.; van der Stok, J.; Yavari, S.A.; Van Humbeeck, J.; Kruth, J.P.; Zadpoor, A.A.; Weinans, H.; Mulier, M.; Schrooten, J. Additively manufactured porous tantalum implants. Acta Biomater. 2015, 14, 217–225. [Google Scholar] [CrossRef] [PubMed]

- Marechal, D.; Saintier, N.; Palin-Luc, T.; Nadal, F. High-Cycle Fatigue Behaviour of Pure Tantalum under Multiaxial and Variable Amplitude Loadings. Adv. Mater. Res. 2014, 891–892, 1341–1346. [Google Scholar] [CrossRef]

- Colas, D.; Finot, E.; Forest, S.; Flouriot, S.; Mazière, M.; Paris, T. Investigation and modelling of the anomalous yield point phenomenon in pure Tantalum. Mater. Sci. Eng. 2014, A615, 283–295. [Google Scholar] [CrossRef]

- Taleb, L.; Keller, C. Experimental contribution for better understanding of ratcheting in 304LSS. Int. J. Mech. Sci. 2018, 105, 527–535. [Google Scholar] [CrossRef]

- Colas, D.; Finot, E.; Flouriot, S.; Forest, S.; Mazière, M.; Paris, T. Local Ratcheting Phenomena in the Cyclic Behavior of Polycrystalline Tantalum. JOM J. Miner. Met. Mater. Soc. 2019, 71, 2586–2599. [Google Scholar] [CrossRef]

- Zhou, G.; Jeong, W.; Homer, E.R.; Fullwood, D.T.; Lee, M.G.; Kim, J.H.; Lim, H.; Zbib, H.; Wagoner, R.H. A predictive strain-gradient model with no undetermined constants or length scales. J. Mech. Phys. Solids 2020, 145, 104178. [Google Scholar] [CrossRef]

- McDowell, D. Simulation-based strategies for microstructure-sensitive fatigue modeling. Mater. Sci. Eng. 2007, A468, 4–14. [Google Scholar] [CrossRef]

- Li, Y.; Aubin, V.; Rey, C.; Bompard, P. Polycrystalline numerical simulation of variable amplitude loading effects on cyclic plasticity and microcrack initiation in austenitic steel 304L. Int. J. Fatigue 2012, 42, 71–81. [Google Scholar] [CrossRef]

- Dunne, F. Fatigue crack nucleation: Mechanistic modelling across the length scales. Curr. Opin. Solid State Mater. Sci. 2014, 18, 170–179. [Google Scholar] [CrossRef]

- Lu, J.; Sun, W.; Becker, A. Material characterisation and finite element modelling of cyclic plasticity behaviour for 304 stainless steel using a crystal plasticity model. Int. J. Mech. Sci. 2016, 105, 315–329. [Google Scholar] [CrossRef]

- Proudhon, H.; Li, J.; Ludwig, W.; Roos, A.; Forest, S. Simulation of short fatigue crack propagation in a 3D experimental microstructure. Adv. Eng. Mater. 2017. [Google Scholar] [CrossRef]

- Hor, A.; Saintier, N.; Robert, C.; Palin-Luc, T.; Morel, F. Statistical assessment of multiaxial HCF criteria at the grain scale. Int. J. Fatigue 2014, 67, 151–158. [Google Scholar] [CrossRef][Green Version]

- Le, V.; Morel, F.; Bellett, D.; Saintier, N.; Osmond, P. Multiaxial high cycle fatigue damage mechanisms associated with the different microstructural heterogeneities of cast aluminium alloys. Mater. Sci. Eng. A 2016, 649, 426–440. [Google Scholar] [CrossRef]

- Ghosh, S.; Chakraborty, P. Microstructure and load sensitive fatigue crack nucleation in Ti-6242 using accelerated crystal plastificty FEM simulations. Int. J. Fatigue 2013, 48, 231–246. [Google Scholar] [CrossRef]

- Zeghadi, A.; Nguyen, F.; Forest, S.; Gourgues, A.F.; Bouaziz, O. Ensemble averaging stress–strain fields in polycrystalline aggregates with a constrained surface microstructure—Part 1: Anisotropic elastic behaviour. Philos. Mag. 2007, 87, 1401–1424. [Google Scholar] [CrossRef]

- Zeghadi, A.; Forest, S.; Gourgues, A.F.; Bouaziz, O. Ensemble averaging stress–strain fields in polycrystalline aggregates with a constrained surface microstructure—Part 2: Crystal plasticity. Philos. Mag. 2007, 87, 1425–1446. [Google Scholar] [CrossRef]

- Wasserbach, W. Work-Hardening and Dislocation Behaviour of Tantalum and Tantalum Alloys; The Minerals, Metals and Materials Society: Pittsburgh, PA, USA, 1996. [Google Scholar]

- Hosseini, E.; Kazeminezhad, M. Dislocation structure and strength evolution of heavily deformed tantalum. Int. J. Refract. Met. Hard Mater. 2009, 27, 605–610. [Google Scholar] [CrossRef]

- Frenois, S.; Munier, E.; Feaugas, X.; Pilvin, P. A polycrystalline model for stress-strain behaviour of tantalum at 300cK. J. De Phys. IV 2001, 11, 301–308. [Google Scholar]

- Norlain, M. Comportement Mécanique du Tantale, Texture et Recristallisation. Ph.D. Thesis, Mines ParisTech, Paris, France, 1999. [Google Scholar]

- Kerisit, C.; Logé, R.E.; Jacomet, S.; Llorca, V.; Bozzolo, N. EBSD coupled to SEM in situ annealing for assessing recrystallization and grain growth mechanisms in pure tantalum. J. Microsc. 2013, 250, 189–199. [Google Scholar] [CrossRef] [PubMed]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. About quantitative EBSD analysis of deformation and recovery substructures in pure Tantalum. IOP Conf. Ser. Mater. Sci. Eng. 2015, 89, 012038. [Google Scholar] [CrossRef]

- Priester, L. Grain Boundaries: From Theory to Engineering, 1st ed.; Springer Series in Materials Science 172; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Magnin, T.; Driver, J.; Lepinoux, J.; Kubin, L. Aspects microstructuraux de la deformation cyclique dans les metaux et alliages C.C. et C.F.C. - I. Consolidation cyclique. Rev. Phys. Appl. 1984, 19, 467–482. [Google Scholar] [CrossRef][Green Version]

- Le, L.T.; Ammar, K.; Forest, S. Efficient simulation of single and poly–crystal plasticity based on the pencil glide mechanism. C. R. Méc. 2020. [Google Scholar] [CrossRef]

- Guillaumain, J. Etude du Comportement du Tantale en Fatigue à Grand Nombre de Cycles, Document Interne CEA. 2009.

- VIC-3D. Correlated Solutions. 2010. Available online: www.correlatedsolutions.com (accessed on 3 March 2021).

- Allais, L.; Bornert, M.; Bretheau, T.; Caldemaison, D. Experimental characterization of the local strain field in a heterogeneous elastoplastic material. Acta Metall. Mater. 1994, 42, 3865–3880. [Google Scholar] [CrossRef]

- Doumalin, P. Microextensométrie Locale par Corrélation d’Images Numériques: Application Aux études Micromécaniques par Microscopie Électronique à Balayage. Ph.D. Thesis, Ecole Polytechnique, Palaiseau, France, 2000. [Google Scholar]

- Racine, A.; Bornert, M.; Sainte Catherine, C.; Caldemaison, D. Étude expérimentale des micro-mécanismes d’endommagement et de rupture des zircaloy hydrurés. J. Phys. IV Fr. 2003, 106, 109–118. [Google Scholar] [CrossRef]

- Bodelot, L.; Charkaluk, E.; Sabatier, L.; Dufrénoy, P. Experimental study of heterogeneities in strain and temperature fields at the microstructural level of polycrytalline metals through fully-coupled full-field measurements by Digital Image Correlation and Infrared Thermography. Mech. Mater. 2011, 43, 654–670. [Google Scholar] [CrossRef]

- Sutton, M.; Yan, J.; Tiwari, V.; Schreier, H.; Orteu, J. The effect of out-of-plane motion on 2D and 3D digital image correlation measurements. Opt. Lasers Eng. 2008, 46, 746–757. [Google Scholar] [CrossRef]

- Clair, A. Caractérisation Expérimentale des Propriétés Micromécaniques et Micromorphologiques des Alliages Base Nickel Contraints par la Croissance d’une Couche d’oxydes formée Dans le Milieu Primaire d’une Centrale Nucléaire. Ph.D. Thesis, Université de Bourgogne, Dijon, France, 2011. [Google Scholar]

- Vignal, V.; Finot, E.; Oltra, R.; Lacroute, Y.; Bourillot, E.; Dereux, A. Mappring the 3D-surface strain field of patterned tensile stainless steels using atomic force microscopy. Ultramicroscopy 2005, 103, 183–189. [Google Scholar] [CrossRef]

- Shi, Q.; Roux, S.; Latourte, F.; Hild, F.; Loisnard, D.; Brynaert, N. On the use of SEM correlative tools for in situ mechanical tests. Ultramicroscopy 2018, 184, 71–87. [Google Scholar] [CrossRef] [PubMed]

- Proudhon, H.; Guéninchault, N.; Forest, S.; Ludwig, W. Incipient Bulk Polycrystal Plasticity Observed by Synchrotron In-Situ Topotomography. Materials 2018, 11, 2018. [Google Scholar] [CrossRef]

- Pineau, A.; McDowell, D.L.; Busso, E.P.; Antolovich, S.D. Failure of metals II: Fatigue. Acta Mater. 2016, 107, 484–507. [Google Scholar] [CrossRef]

- François, F.; Pineau, A.; Zaoui, A. Mechanical Behaviour of Materials. Volume 2: Fracture Mechanics and Damage; Solid Mechanics and its Applications; Springer: Berlin/Heidelberg, Germany, 2013; Volume 191. [Google Scholar]

- El Bartali, A.; Aubin, V.; Degallaix, S. Surface observation and measurement techniques to study the fatigue damage micromechanisms in a duplex stainless steel. Int. J. Fatigue 2009, 31, 2049–2055. [Google Scholar] [CrossRef]

- Kuo, J.C.; Chen, D.; Tung, S.H.; Shih, M.H. Prediction of the orientation spread in an aluminum bicrystal during plane strain compression using a DIC-based Taylor model. Comput. Mater. Sci. 2008, 42, 564–569. [Google Scholar] [CrossRef]

- Clair, A.; Foucault, M.; Calonne, O. Strain mapping near a triple junction in strained Ni-based alloy using EBSD and biaxial nanogauges. Acta Mater. 2011, 59, 3116–3123. [Google Scholar] [CrossRef]

- Helstroffer, A. Etude en Fatigue du Tantale. Rapport de Stage Document Interne CEA. 2010. [Google Scholar]

- Forsyth, P. Fatigue Behaviour and Its Dependence on Microstructure; Colloque de Métallurgie de Saclay: Saclay, France, 1972. [Google Scholar]

- Guilhem, Y.; Basseville, S.; Curtit, F.; Stephan, J.; Cailletaud, G. Numerical investigations of the free surface effect in three-dimensional polycrystalline aggregates. Comput. Mater. Sci. 2013, 70, 150–162. [Google Scholar] [CrossRef]

- Barbe, F.; Quey, R.; Musienko, A.; Cailletaud, G. Three-dimensional characterization of strain localization bands in high-resolution elastoplastic polycrystals. Mech. Res. Commun. 2009, 36, 762–768. [Google Scholar] [CrossRef]

- Bouchedjra, M.; Kanit, T.; Boulemia, C.; Amrouche, A.; Belouchrani, M.E.A. Determination of the RVE size for polycrystal metals to predict monotonic and cyclic elastoplastic behavior: Statistical and numerical approach with new criteria. Eur. J. Mech. A Solids 2018, 72, 1–15. [Google Scholar] [CrossRef]

- Barbe, F.; Forest, S.; Cailletaud, G. Intergranular and intragranular behavior of polycrystalline aggregates. Part 2: Results. Int. J. Plast. 2001, 17, 537–563. [Google Scholar] [CrossRef]

- Zhang, K.S.; Ju, J.W.; Bai, Y.L.; Brocks, W. Micromechanics based fatigue life prediction of a polycrystalline metal applying crystal plasticity. Mech. Mater. 2015, 85, 16–37. [Google Scholar] [CrossRef]

- Kanit, T.; Forest, S.; Galliet, I.; Mounoury, V.; Jeulin, D. Determination of the size of the Representative Volume Element for random composites: Statistical and numerical approach. Int. J. Solids Struct. 2003, 40, 3647–3679. [Google Scholar] [CrossRef]

- Gérard, C.; Bacroix, B.; Bornert, M.; Cailletaud, G.; Crépin, J.; Leclercq, S. Hardening description for FCC materials under complex loading paths. Comput. Mater. Sci. 2009, 45, 751–755. [Google Scholar] [CrossRef][Green Version]

- Guilhem, Y.; Basseville, S.; Curtit, F.; Stephan, J.; Cailletaud, G. Investigations of the effect of grain clusters on fatigue crack initiation in plycrystals. Int. J. Fatigue 2010, 32, 1748–1763. [Google Scholar] [CrossRef]

- Méric, L.; Cailletaud, G. Single crystal modeling for structural calculations. Part. 2: Finite element implementation. J. Eng. Mater. Technol. 1991, 113, 171–182. [Google Scholar] [CrossRef]

- Eyraud, V.; Nadal, M.H.; Gondard, C. Texture measurement of shaped material by impulse acoustic microscopy. Ultrasonics 2000, 38, 438–442. [Google Scholar] [CrossRef]

- Hoc, T.; Crépin, J.; Gélébart, L.; Zaoui, A. A procedure for identifying the plastic behavior of single crystals from the local response of polycrystals. Acta Mater. 2003, 51, 5477–5488. [Google Scholar] [CrossRef]

- Lim, H.; Carroll, J.D.; Battaile, C.C.; Buchheit, T.E.; Boyce, B.L.; Weinberger, C.R. Grain-scale experimental validation of crystal plasticity finite element simulations of tantalum oligocrystals. Int. J. Plast. 2015, 60, 1–18. [Google Scholar] [CrossRef]

- Z–Set Package. Non-Linear Material & Structure Analysis Suite. 2013. Available online: www.zset-software.com (accessed on 3 March 2021).

- Besson, J.; Cailletaud, G.; Chaboche, J.L.; Forest, S.; Blétry, M. Non–Linear Mechanics of Materials; Solid Mechanics and Its Applications 167; Springer-Verlag: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Šiška, F.; Forest, S.; Gumbsch, P.; Weygand, D. Finite element simulations of the cyclic elastoplastic behavior of copper thin films. Model. Simul. Mater. Sci. Eng. 2007, 15, S217–S238. [Google Scholar] [CrossRef]

- Linne, M.A.; Venkataraman, A.; Sangid, M.D.; Daly, S. Grain Boundary Sliding and Slip Transmission in High Purity Aluminum. Exp. Mech. 2019, 59, 643–658. [Google Scholar] [CrossRef]

- Déprés, C.; Robertson, C.F.; Fivel, M.C. Low-strain fatigue in AISI 316L steel surface grains: A three-dimensional discrete dislocation dynamics modelling of the early cycles I. Dislocation microstructures and mechanical behaviour. Philos. Mag. 2004, 84, 2257–2275. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L. Mechanics of Solid Materials; University Press: Cambridge, UK, 1994. [Google Scholar]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Bower, A.; Johnson, K. The influence of strain hardening on cumulative plastic deformation in rolling and sliding contact. J. Mech. Phys. Solids 1989, 37, 471–493. [Google Scholar] [CrossRef]

- McDowell, D. Stress state dependence of cyclic ratchetting behavior of two rail steels. Int. J. Plast. 1995, 11, 397–421. [Google Scholar] [CrossRef]

- Zhang, M.; Neu, R.; McDowell, D. Microstructure-sensitive modelling: Application to fretting contacts. Int. J. Fatigue 2009, 31, 1397–1406. [Google Scholar] [CrossRef]

- Agbessi, K. Approches Expérimentales et Multi-Échelles des Processus d’amorçage des Fissures de Fatigue sous Chargements Complexes. Ph.D. Thesis, Ecole Nationale Supérieure d’Arts et Métiers, Bordeaux, France, 2013. [Google Scholar]

- Li, J.; Proudhon, H.; Roos, A.; Chiaruttini, V.; Forest, S. Crystal plasticity finite element simulation of crack growth in single crystals. Comput. Mater. Sci. 2014, 90, 191–197. [Google Scholar] [CrossRef]

- Proudhon, H.; Li, J.; Wang, F.; Roos, A.; Chiaruttini, V.; Forest, S. 3D simulation of short fatigue crack propagation by finite element crystal plasticity and remeshing. Int. J. Fatigue 2016, 82, 238–246. [Google Scholar] [CrossRef]

- Nadal, F. Résistance en Fatigue du Tantale. Document Interne CEA. 2011. [Google Scholar]

- Fleury, E.; Rémy, L. Low cycle fatigue damage in nickel-base superalloy single crystals at elevated temperature. Mater. Sci. Eng. A 1993, 167, 23–30. [Google Scholar] [CrossRef]

- Bathias, C.; Pineau, A. La Fatigue des Matériaux et des Structures, 1st ed.; Hermès Science: Paris, France, 2008. [Google Scholar]

- Lebensohn, R.A.; Brenner, R.; Castelnau, O.; Rollett, A.D. Orientation image-based micromechanical modelling of subgrain texture evolution in polycrystalline copper. Acta Mater. 2008, 56, 3914–3926. [Google Scholar] [CrossRef]

- Ren, X.; Yang, S.; Wen, G.; Zhao, W. A Crystal-Plasticity Cyclic Constitutive Model for the Ratchetting of Polycrystalline Material Considering Dislocation Substructures. Acta Mech. Sin. 2020, 33, 268–280. [Google Scholar] [CrossRef]

- Aslan, O.; Quilici, S.; Forest, S. Numerical modeling of fatigue crack growth in single crystals based on microdamage theory. Int. J. Damage Mech. 2011, 20, 681–705. [Google Scholar] [CrossRef]

- Lindroos, M.; Laukkanen, A.; Andersson, T.; Vaara, J.; Mäntylä, A.; Frondelius, T. Micromechanical modeling of short crack nucleation and growth in high cycle fatigue of martensitic microstructures. Comput. Mater. Sci. 2019, 170, 109185. [Google Scholar] [CrossRef]

- Mareau, C. A non-local damage model for the fatigue behaviour of metallic polycrystals. Philos. Mag. 2020, 100, 955–981. [Google Scholar] [CrossRef]

| s | MPa | ||

| 5 MPa | 8000 | ||

| 0 MPa | 250 MPa | ||

| Q | 1 MPa | ||

| b | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colas, D.; Finot, E.; Flouriot, S.; Forest, S.; Mazière, M.; Paris, T. Experimental and Computational Approach to Fatigue Behavior of Polycrystalline Tantalum. Metals 2021, 11, 416. https://doi.org/10.3390/met11030416

Colas D, Finot E, Flouriot S, Forest S, Mazière M, Paris T. Experimental and Computational Approach to Fatigue Behavior of Polycrystalline Tantalum. Metals. 2021; 11(3):416. https://doi.org/10.3390/met11030416

Chicago/Turabian StyleColas, Damien, Eric Finot, Sylvain Flouriot, Samuel Forest, Matthieu Mazière, and Thomas Paris. 2021. "Experimental and Computational Approach to Fatigue Behavior of Polycrystalline Tantalum" Metals 11, no. 3: 416. https://doi.org/10.3390/met11030416

APA StyleColas, D., Finot, E., Flouriot, S., Forest, S., Mazière, M., & Paris, T. (2021). Experimental and Computational Approach to Fatigue Behavior of Polycrystalline Tantalum. Metals, 11(3), 416. https://doi.org/10.3390/met11030416