Predicted Torque Model in Low-Frequency-Assisted Boring (LFAB) Operations

Abstract

:1. Introduction

2. Materials and Methods

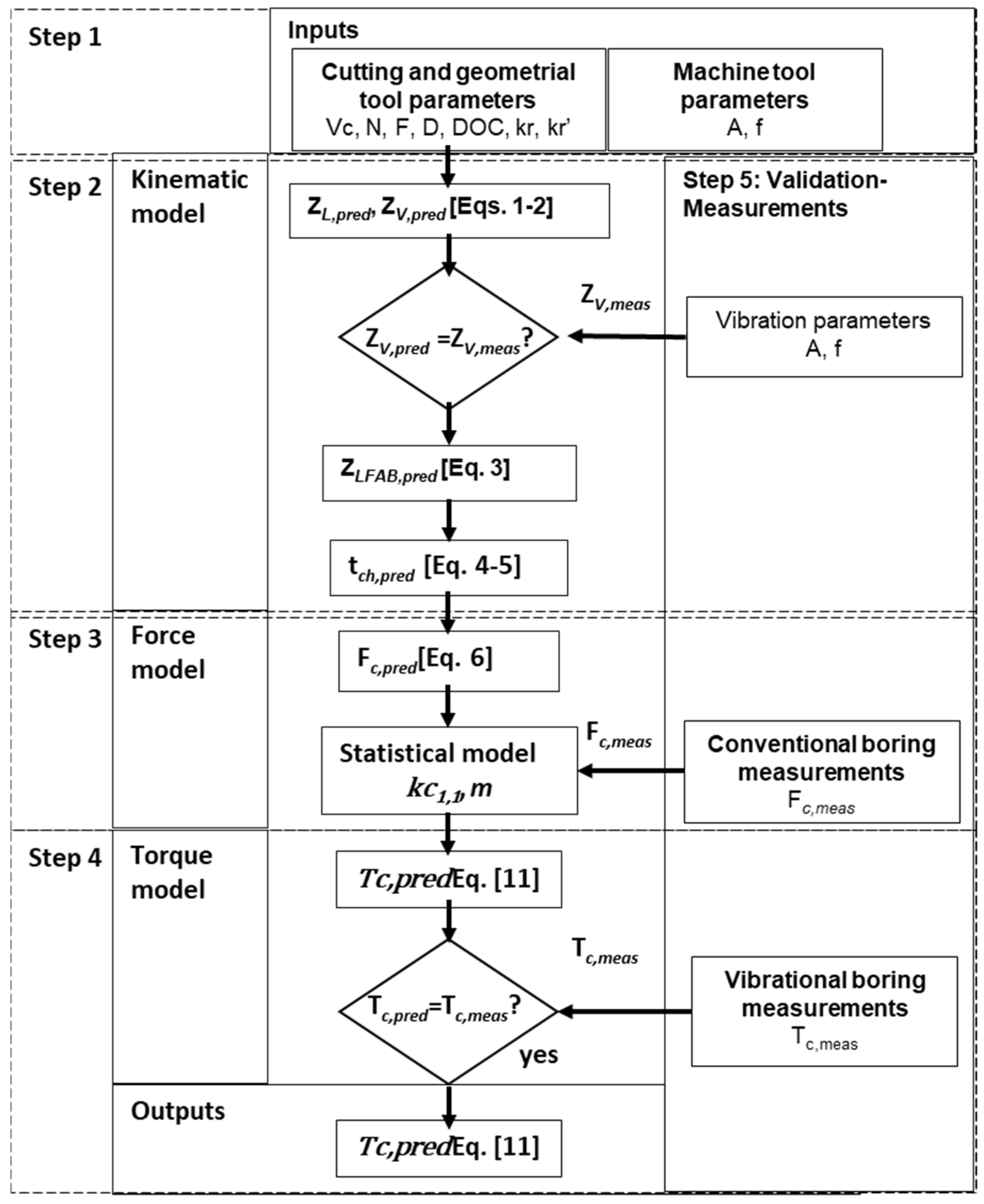

2.1. Kinematic and Torque Modeling for LFAB

2.1.1. Input Parameters for the LFAB Model (Step 1)

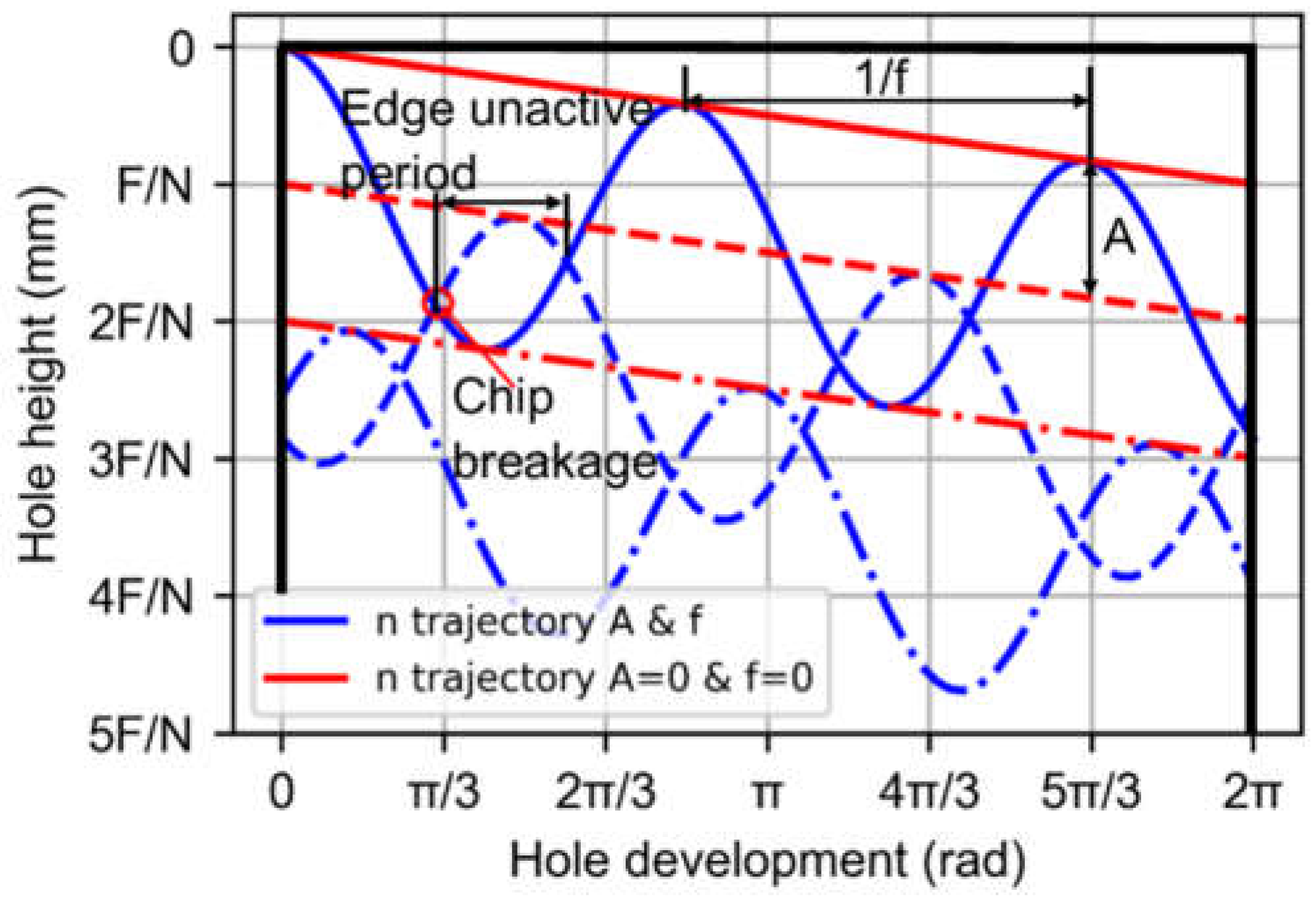

2.1.2. Uncut Chip Thickness Model (Step 2)

2.1.3. Force and Torque Model (Steps 3 and 4)

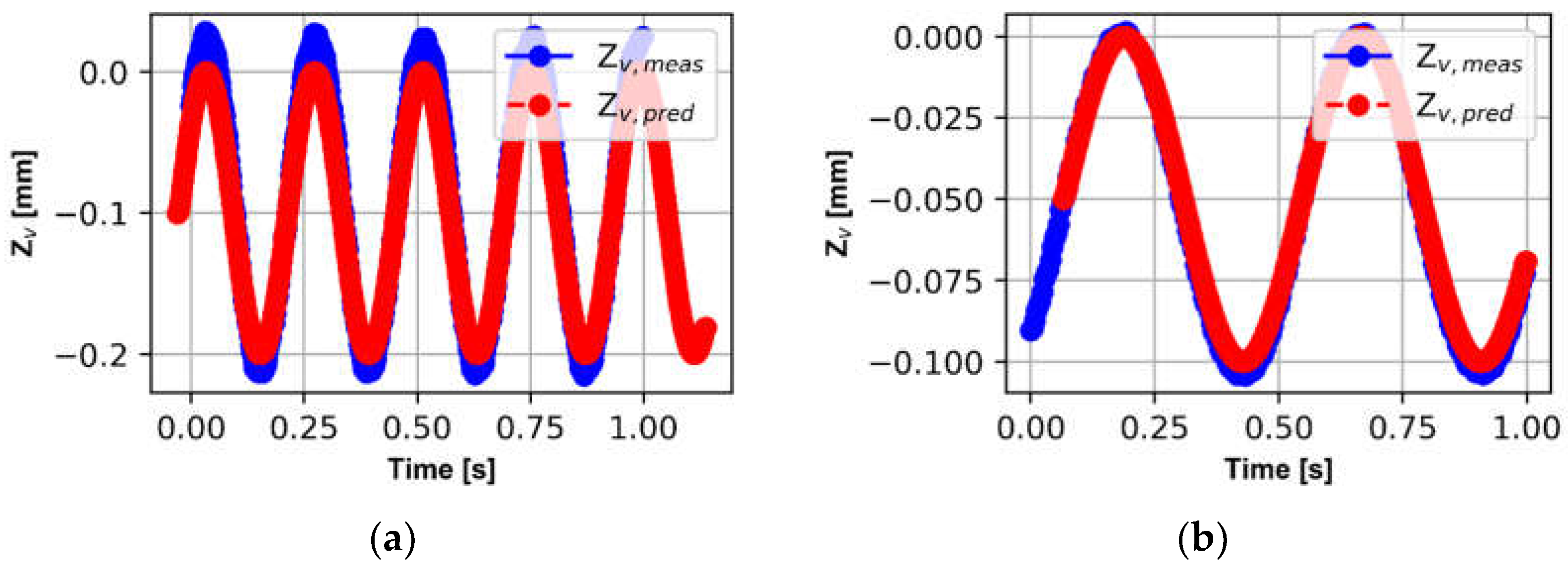

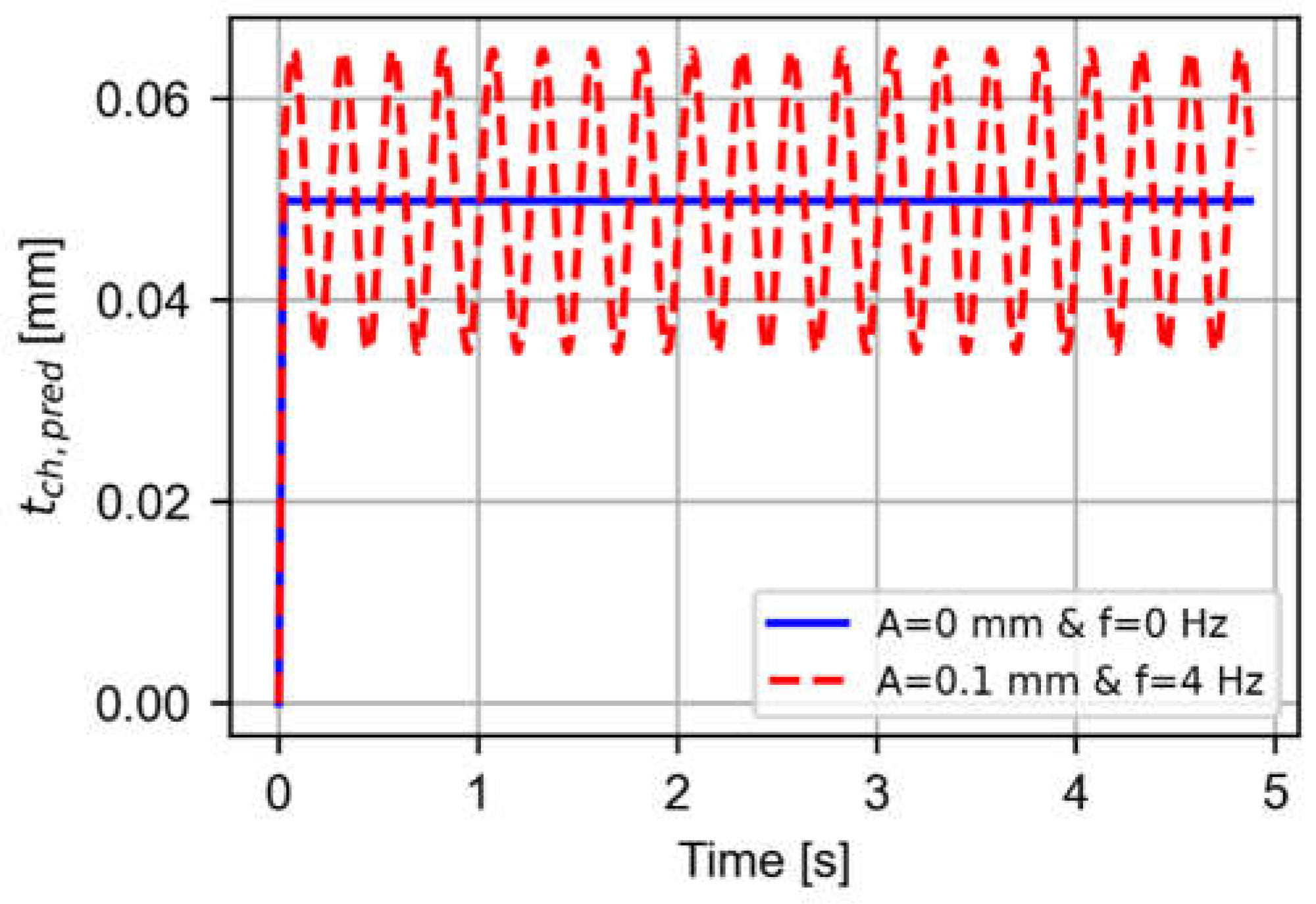

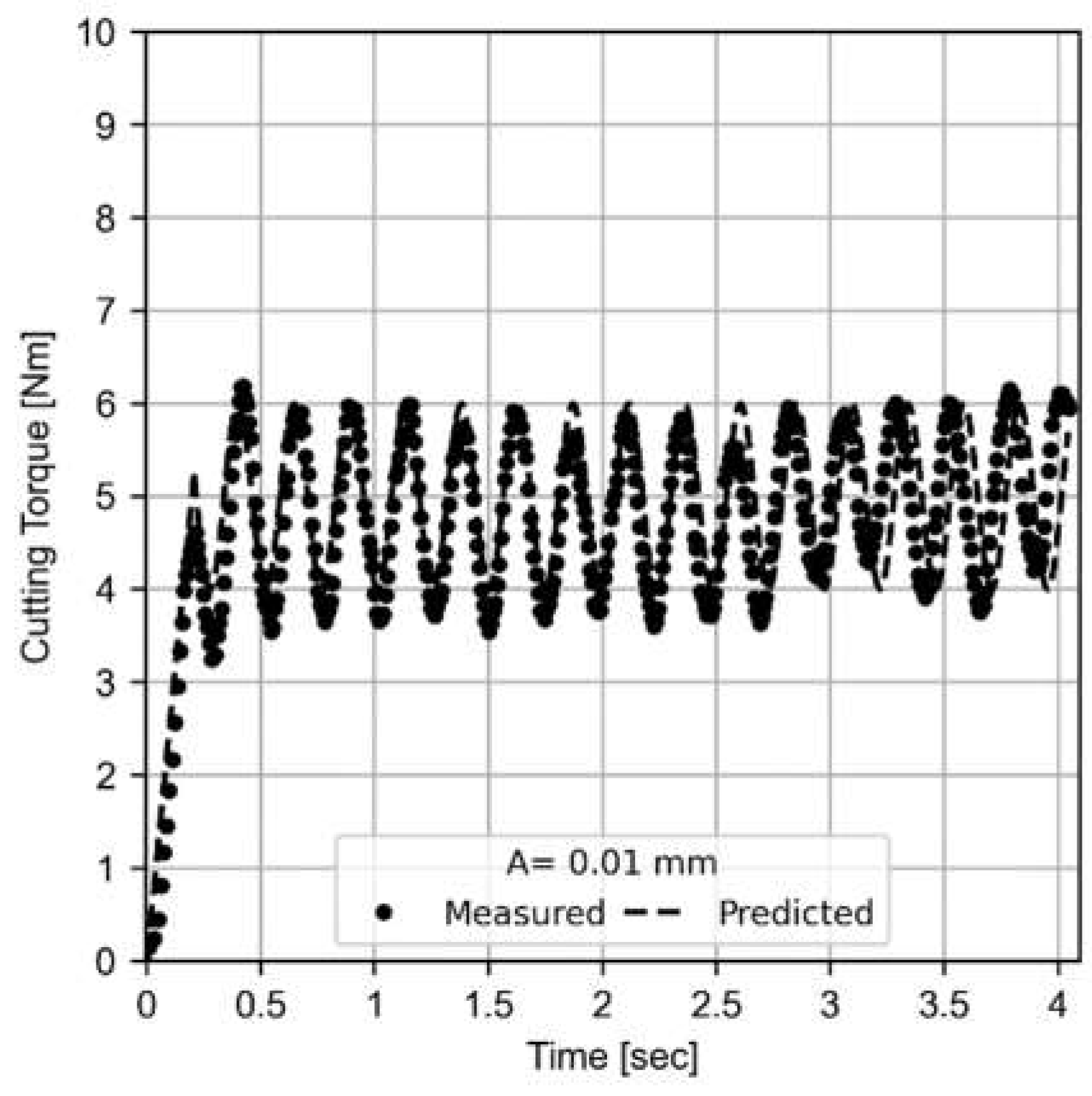

2.1.4. Validation Results and Discussion (Step 5)

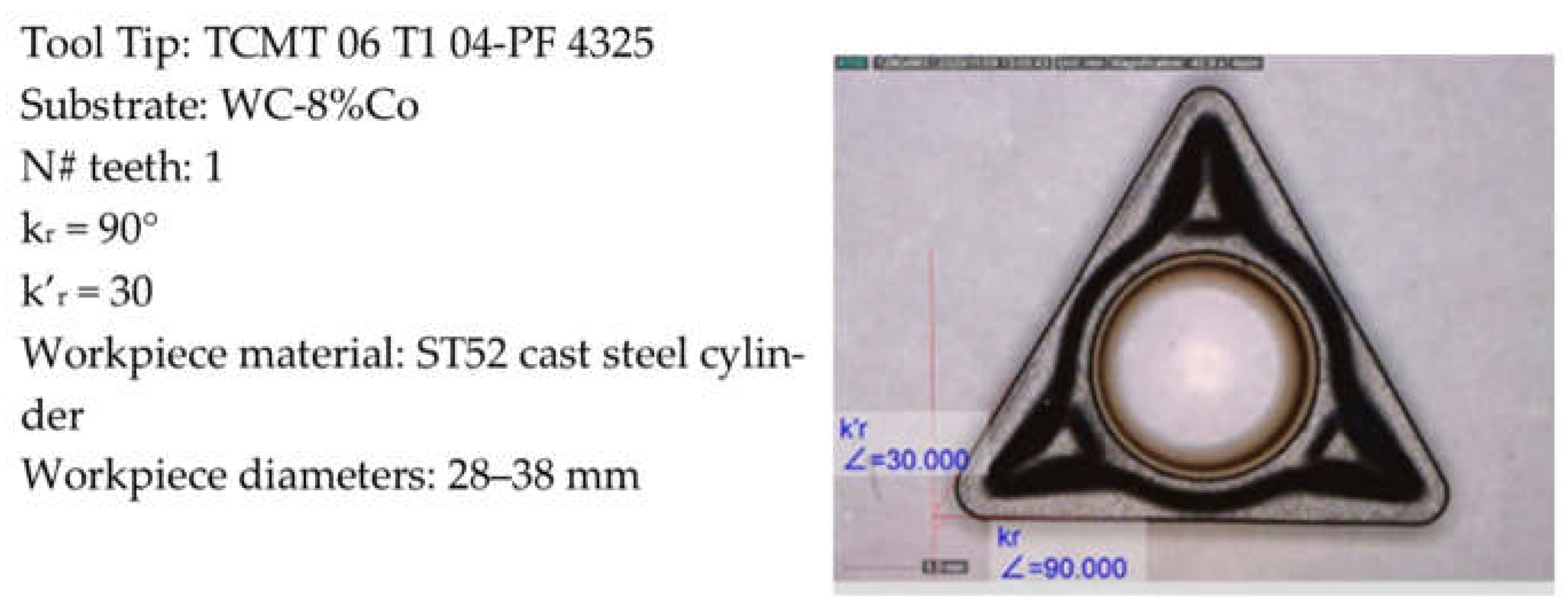

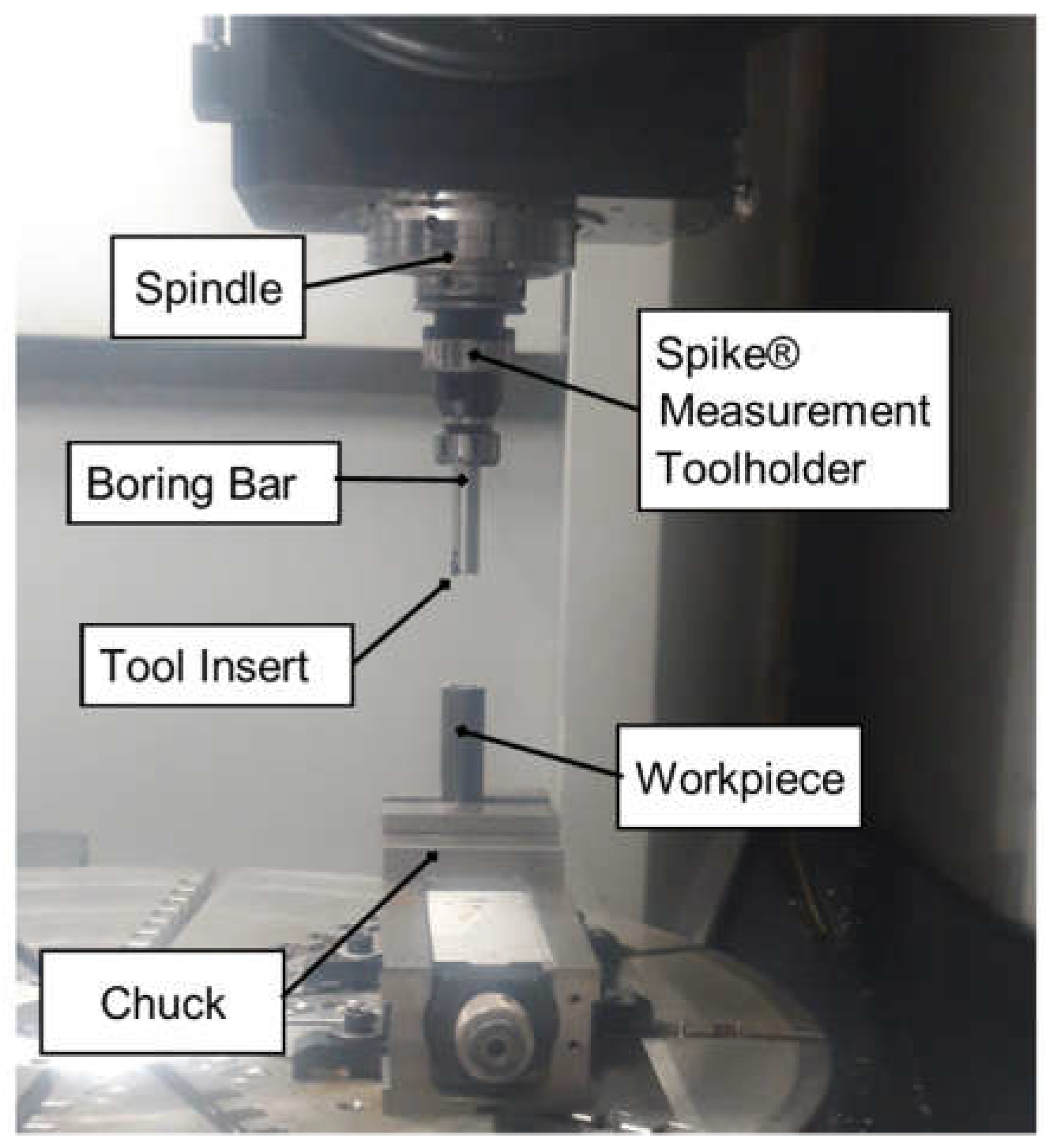

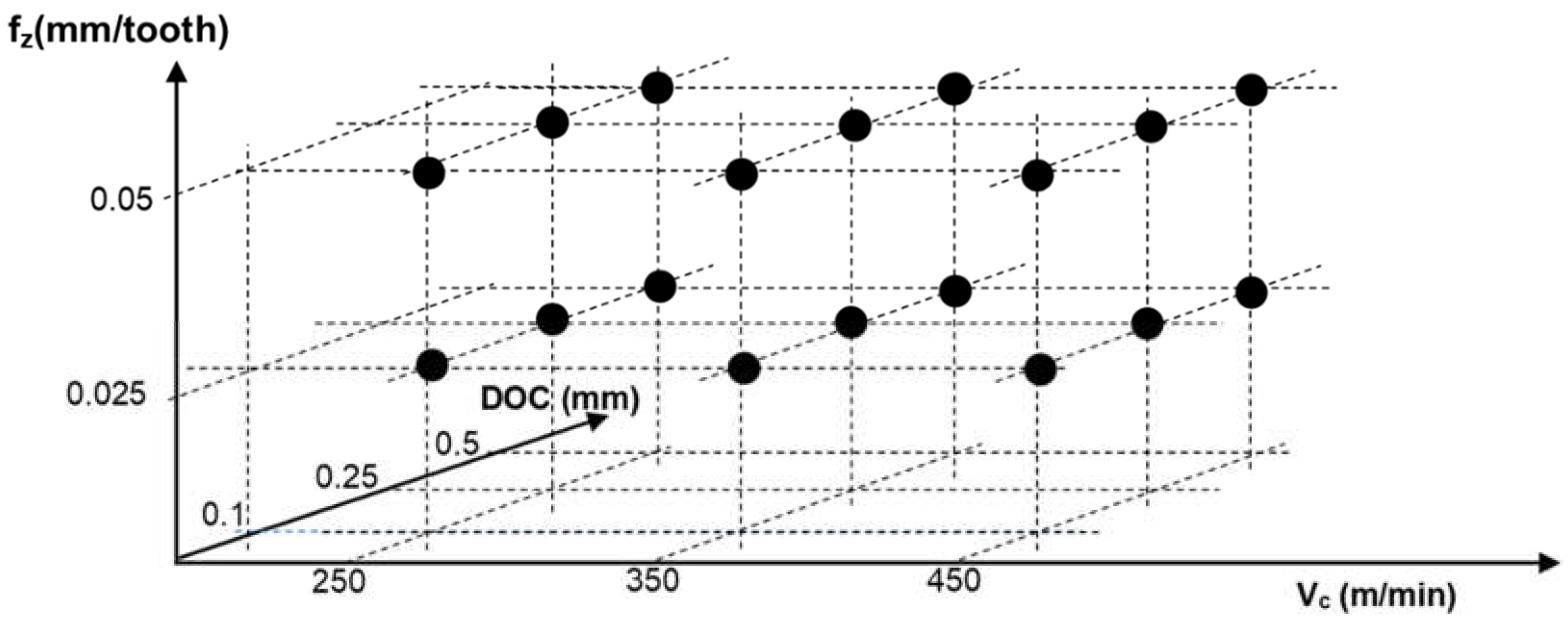

2.2. LFAB Tests Set-Up

3. Results and Discussion

3.1. Uncut Chip Thickness Model Results

3.2. Fitting of Force Model Results

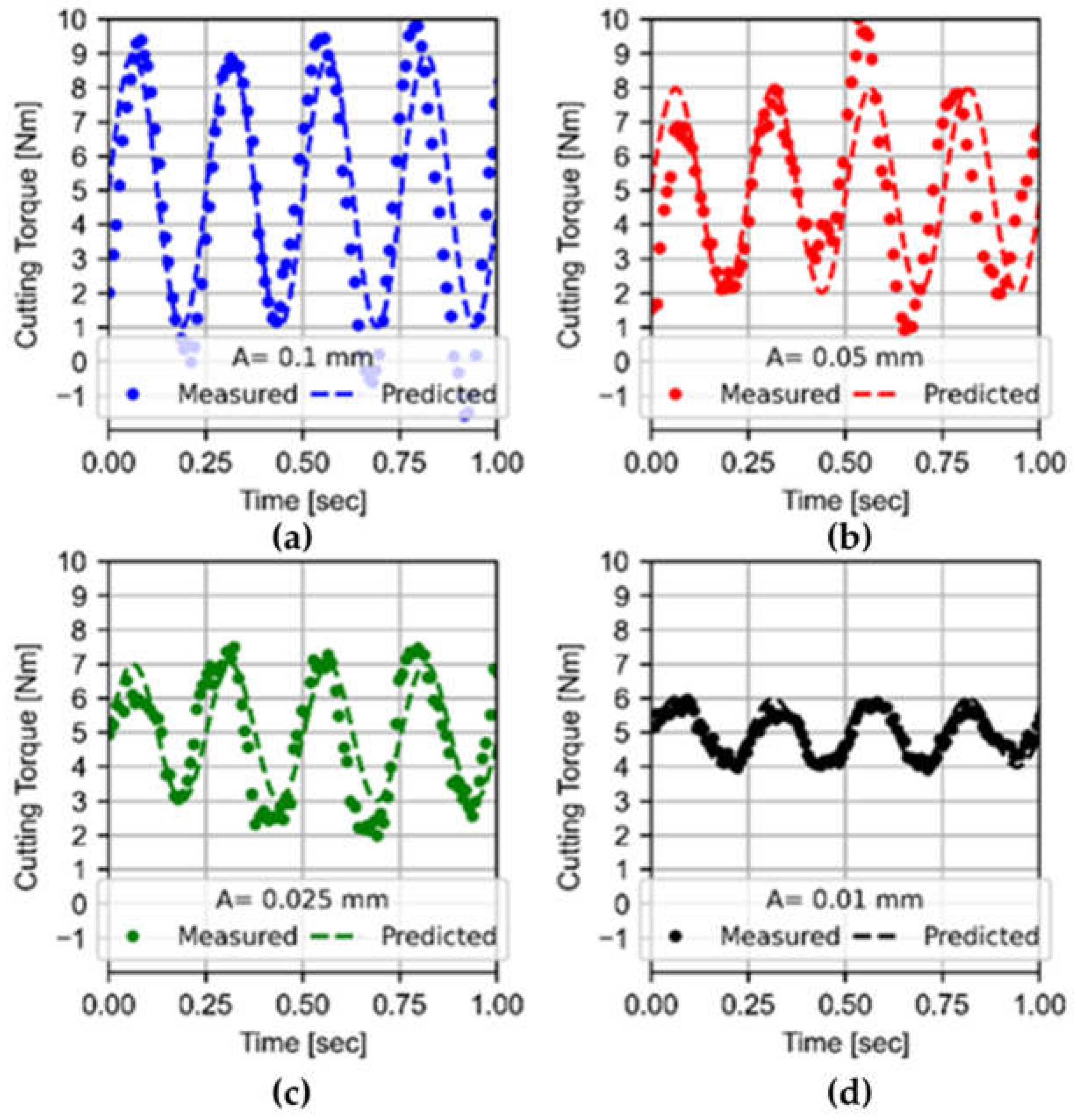

3.3. Torque Model Results

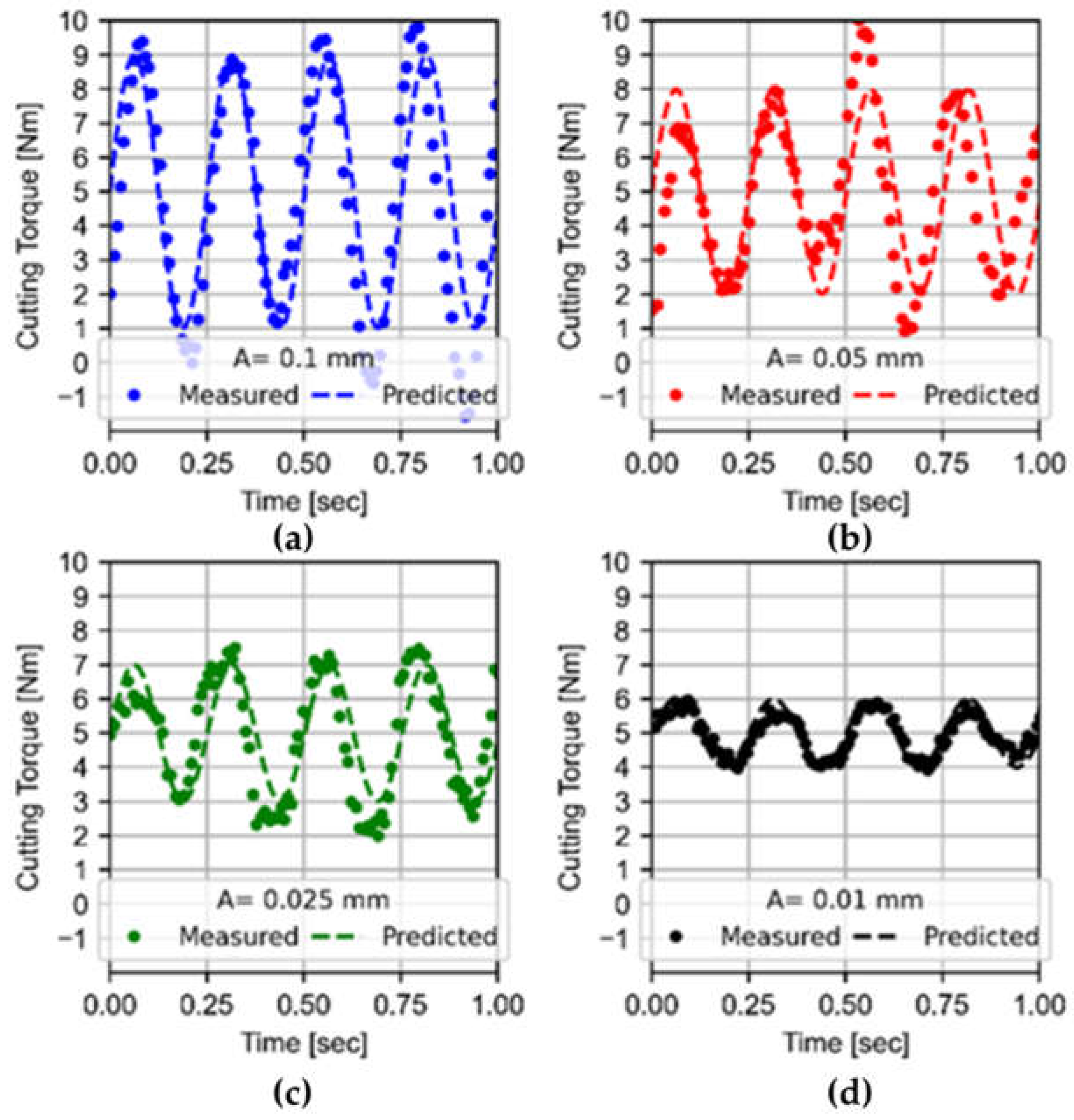

3.4. Observation of Chip Formation

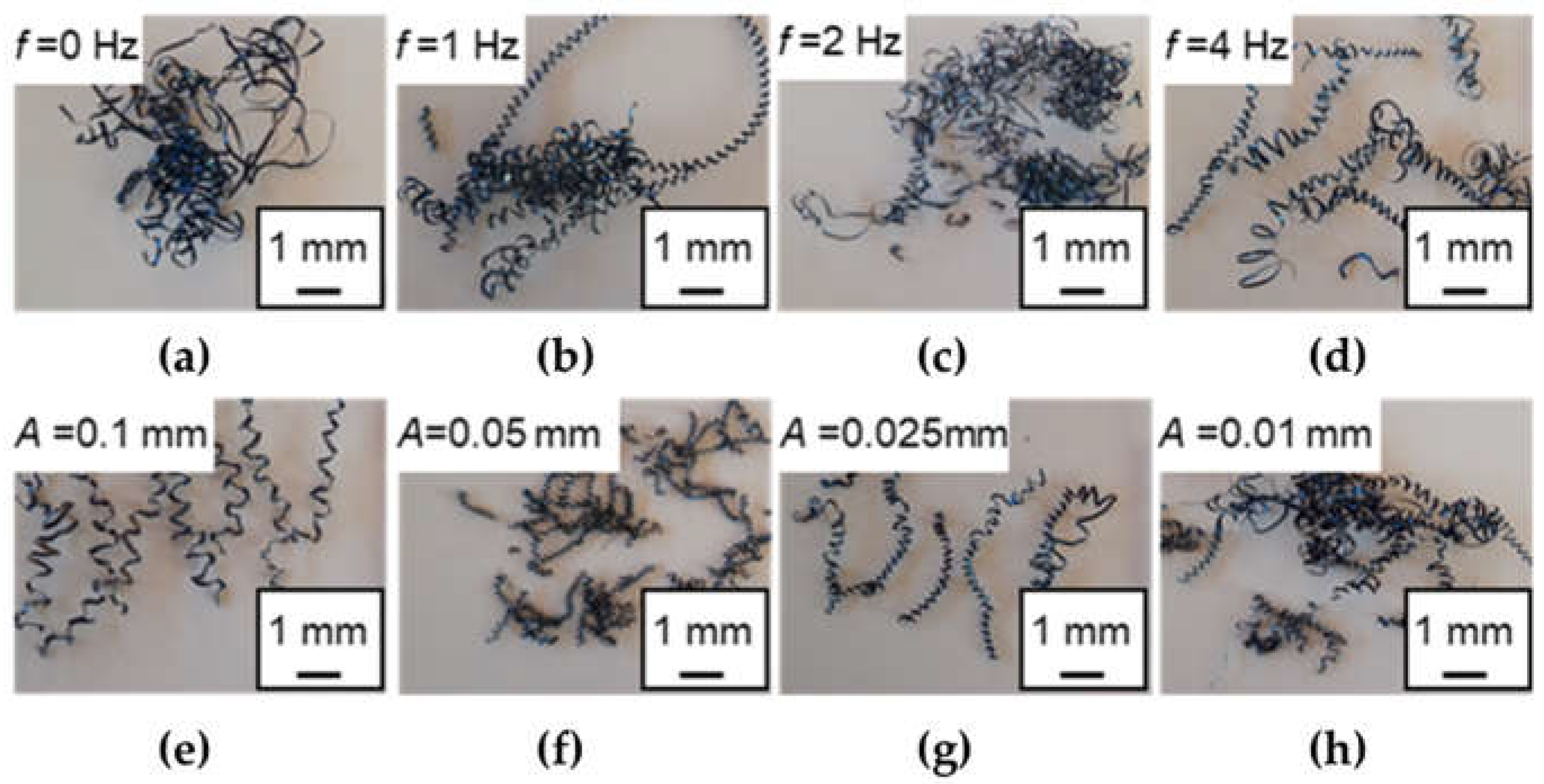

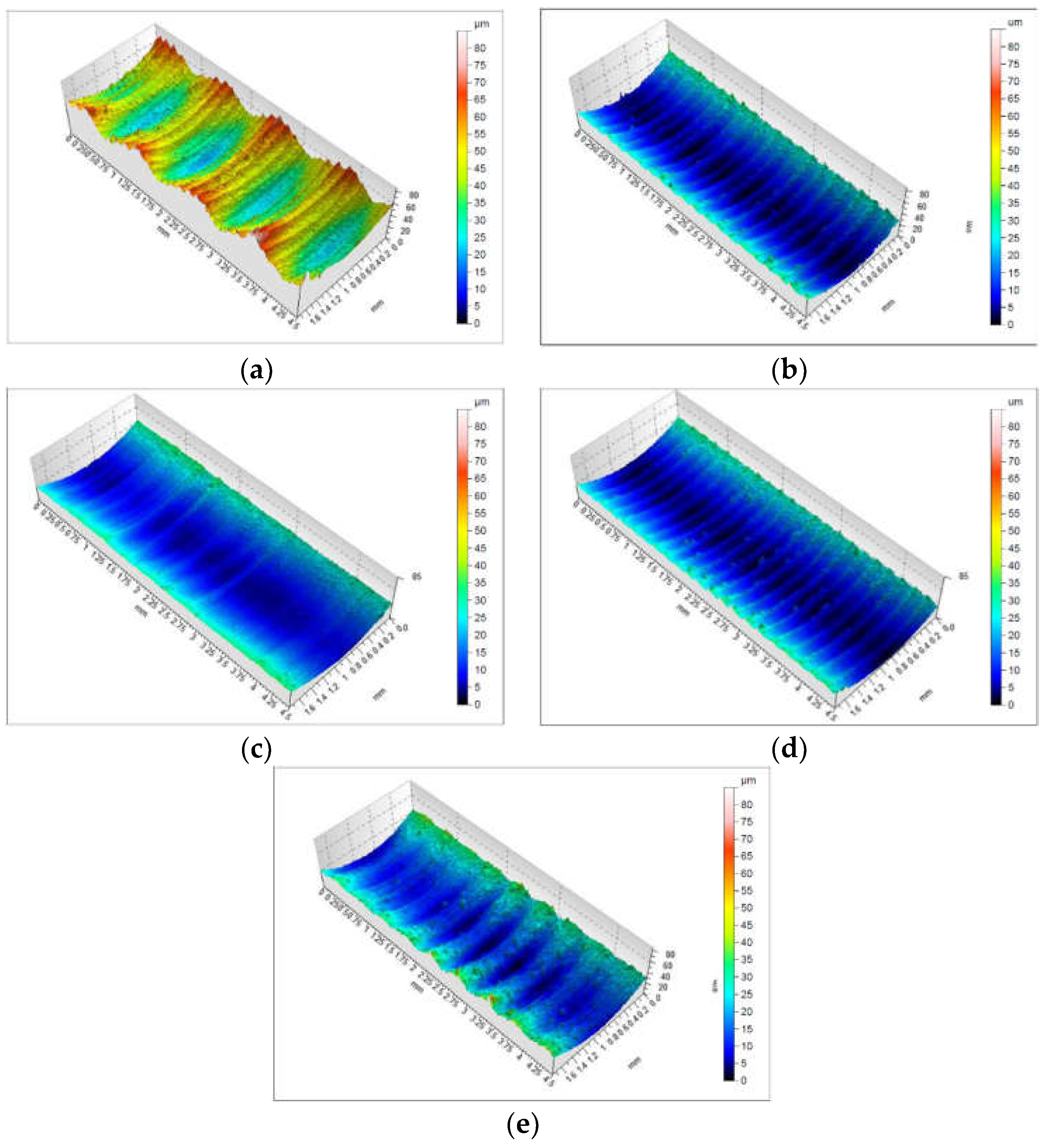

3.5. Surface Roughness

4. Conclusions

- The CNC function is more attractive for the industry because there is no need for intrusive vibration sensors.

- The LFAB operations permit chip breakage and easy removal from bored holes.

- The LFAB model is validated for different low frequencies and high amplitudes. The model estimates the cutting torques with a predicted error of 9% in the case of amplitude variable testing and 13 in the frequency evaluation testing.

- The model is for general purposes and could be applied to different cutting materials and conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Vc | Cutting velocity (m/min) |

| N | Rotatory velocity (rpm) |

| F | Feed rate (mm/min) |

| fz | Feed per tooth (mm/tooth) |

| DOC | Depth of cut (mm) |

| D | Boring tool diameter (m) |

| kr | Main edge angle (°) |

| kr’ | Second edge angle (°) |

| A | Amplitude of LFAB process (mm) |

| F | Frequency of predicted model (Hz) |

| Freq | Frequency of LFAB process (Hz) |

| ZL,pred | Vertical position of boring tool (mm) |

| Zv,pred | Vibration vertical position of boring tool (mm) |

| Zv,meas | Vibration vertical position of commercial function (mm) |

| Θ | Matrix of the angular position of tool when developing a cylinder (°) |

| ZLFAB, pred | Vertical position of LFAB process (mm) |

| tch, pred | Uncut thickness of LFAB process (mm) |

| t | Time (s) |

| kc1 | Specific cutting force (N/mm2) in the main edge |

| kc2 | Specific cutting force (N/mm2) in the second edge |

| A1,pred | Cutting area in the main edge (mm2) |

| A2,pred | Cutting area in the second edge (mm2) |

| b1 | Width of cut in the main edge (mm) |

| b2 | Width of cut in the second edge (mm) |

| kc1,1 | Predicted value of specific force (N/mm2) |

| m | Material constant (-) |

| Fc,pred | Predicted cutting force of LFAB process (N) |

| Tc,pred | Predicted cutting torque of LFAB process (N·m) |

References

- Yang, S.; Tong, X.; Ma, X.; Ji, W.; Liu, X.; Zhang, Y. The guide block structure design of boring and trepanning association (BTA) deep hole drilling. Int. J. Adv. Manuf. Technol. 2018, 99, 911–918. [Google Scholar] [CrossRef]

- Biermann, D.; Bleicher, F.; Heisel, U.; Klocke, F.; Möhring, H.-C.; Shih, A. Deep hole drilling. CIRP Ann. 2018, 67, 673–694. [Google Scholar] [CrossRef]

- Li, X.; Zheng, J.; Li, Y.; Xiao, J.; Guo, B.; Liu, C. Modeling and experimental investigation of drilling force for low-frequency axial vibration-assisted BTA deep hole drilling. Int. J. Adv. Manuf. Technol. 2020, 111, 1721–1733. [Google Scholar] [CrossRef]

- Zheng, L.; Chen, W.; Huo, D. Review of vibration devices for vibration-assisted machining. Int. J. Adv. Manuf. Technol. 2020, 108, 1631–1651. [Google Scholar] [CrossRef]

- Paulsen, T.; Guba, N.; Sölter, J.; Karpuschewski, B. Influence of the workpiece material on the cutting performance in low frequency vibration assisted drilling. CIRP J. Manuf. Sci. Technol. 2020, 31, 140–152. [Google Scholar] [CrossRef]

- Yang, H.; Ding, W.; Chen, Y.; Laporte, S.; Xu, J.; Fu, Y. Drilling force model for forced low frequency vibration assisted drilling of Ti-6Al-4V titanium alloy. Int. J. Mach. Tools Manuf. 2019, 146, 103438. [Google Scholar] [CrossRef]

- Gorostidi, J.M.; Beudaert, X.; Astarloa, A.; Ealo, J.A.; Soraluce, J.A.; Fernandes, M.H. Chip breaking system for turning applications using machine drive oscillations. DYNA Ing. E Ind. 2020, 95, 100–106. [Google Scholar] [CrossRef]

- Chen, W.; Huo, D.; Shi, Y.; Hale, J.M. State-of-the-art review on vibration-assisted milling: Principle, system design, and application. Int. J. Adv. Manuf. Technol. 2018, 97, 2033–2049. [Google Scholar] [CrossRef] [Green Version]

- Suárez, A.; Veiga, F.; Polvorosa, R.; Artaza, T.; Holmberg, J.; de Lacalle, L.L.; Wretland, A. Surface integrity and fatigue of non-conventional machined Alloy 718. J. Manuf. Process. 2019, 48, 44–50. [Google Scholar] [CrossRef]

- Yarar, E.; Karabay, S. Investigation of the effects of ultrasonic assisted drilling on tool wear and optimization of drilling parameters. CIRP J. Manuf. Sci. Technol. 2020, 31, 265–280. [Google Scholar] [CrossRef]

- Dong, G.; Wang, L.; Li, C.; Yu, Y. Investigation on ultrasonic elliptical vibration boring of deep holes with large depth–diameter ratio for high-strength steel 18Cr2Ni4WA. Int. J. Adv. Manuf. Technol. 2020, 108, 1527–1539. [Google Scholar] [CrossRef]

- Ngo, Q.H.; Chu, N.H.; Nguyen, V.D. A Study on Design of Vibratory Apparatus and Experimental Validation on Hard Boring with Ultrasonic-Assisted Cutting. Int. J. Adv. Eng. Res. Appl. 2018, 3, 383–396. [Google Scholar]

- Moraru, G.F. Nonlinear Dynamics in Drilling and Boring Operations Assisted by Low Frequency Vibration. In ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Proceedings of the 6th International Conference on Multibody Systems, Nonlinear Dynamics, and Control, Parts A, B, and C, Las Vegas, NV, USA, 4–7 September 2007; The American Society of Mechanical Engineers: New York, NY, USA, 2007; Volume 5, pp. 951–960. [Google Scholar]

- Mikołajczyk, T.; Latos, H.; Pimenov, D.Y.; Paczkowski, T.; Gupta, M.K.; Krolczyk, G. Influence of the main cutting edge angle value on minimum uncut chip thickness during turning of C45 steel. J. Manuf. Process. 2020, 57, 354–362. [Google Scholar] [CrossRef]

- Zou, F.; Dang, J.; An, Q.; Chen, M. Mechanism and feasibility study of low frequency vibration assisted drilling of a newly developed CFRP/Al co-cured material. J. Manuf. Process. 2021, 68, 115–127. [Google Scholar] [CrossRef]

- Li, C.; Xu, J.; Chen, M.; An, Q.; El Mansori, M.; Ren, F. Tool wear processes in low frequency vibration assisted drilling of CFRP/Ti6Al4V stacks with forced air-cooling. Wear 2019, 426-427, 1616–1623. [Google Scholar] [CrossRef]

- Veiga, F.; Suárez, A.; Val, A.G.D.; Penalva, M.; Lacalle, L.N.L.D. Evaluation on advantages of low frequency assisted drilling (LFAD) aluminium alloy Al7075. Int. J. Mechatron. Manuf. Syst. 2020, 13, 230–246. [Google Scholar]

- Jallageas, J.; K’Nevez, J.-Y.; Chérif, M.; Cahuc, O. Modeling and optimization of vibration-assisted drilling on positive feed drilling unit. Int. J. Adv. Manuf. Technol. 2013, 67, 1205–1216. [Google Scholar] [CrossRef]

- Bleicher, F.; Reiter, M.; Brier, J. Increase of chip removal rate in single-lip deep hole drilling at small diameters by low-frequency vibration support. CIRP Ann. 2019, 68, 93–96. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Giasin, K.; Mikolajczyk, T.; Sharma, S. Modeling of Cutting Parameters and Tool Geometry for Multi-Criteria Optimization of Surface Roughness and Vibration via Response Surface Methodology in Turning of AISI 5140 Steel. Materials 2020, 13, 4242. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Sağlam, H.; Pimenov, D.Y.; Giasin, K.; Mikolajczyk, T. Optimization and Analysis of Surface Roughness, Flank Wear and 5 Different Sensorial Data via Tool Condition Monitoring System in Turning of AISI 5140. Sensors 2020, 20, 4377. [Google Scholar] [CrossRef]

- Steel, R.G.D.; Torrie, J.H. Principles and Procedures of Statistics: With Special Reference to the Biological Sciences, Volume 1; McGraw Hill: New York, NY, USA, 1960; pp. 187–287. [Google Scholar]

- Coromant, S. Training Handbook; Sandvik Coromant: Sandviken, Sweden, 2020; pp. 1–391. [Google Scholar]

- Ivester, R.W.; Kennedy, M.; Davies, M.; Stevenson, R.; Thiele, J.; Furness, R.; Athavale, S. Assessment of machining models: Progress report. Mach. Sci. Technol. 2000, 4, 511–538. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 3685. Tool-Life Testing with Single-Point Turning Tools; ISO: Geneva, Switzerland, 1993. [Google Scholar]

| Material Alloy | Chemical Composition (wt %) | ||||

|---|---|---|---|---|---|

| C | Si | Mn | P | S | |

| Steel ST 52 | 0.20 | 0.55 | 1.60 | 0.040 | 0.040 |

| Group | Test # | Vc (m/min) | fz (mm/tooth) | N (rpm) | F (mm/min) | DOC (mm) | Amplitude (mm) | f = 2freq (Hz) | Coolant |

|---|---|---|---|---|---|---|---|---|---|

| a | 01 | 250 | 0.025 | 2487 | 62 | 0.10 | - | - | DRY |

| 02 | 250 | 0.025 | 2487 | 62 | 0.25 | - | - | DRY | |

| 03 | 250 | 0.025 | 2487 | 62 | 0.50 | - | - | DRY | |

| 04 | 250 | 0.050 | 2487 | 124 | 0.10 | - | - | DRY | |

| 05 | 250 | 0.050 | 2487 | 124 | 0.25 | - | - | DRY | |

| 06 | 250 | 0.050 | 2487 | 124 | 0.50 | - | - | DRY | |

| 07 | 350 | 0.025 | 3482 | 87 | 0.10 | - | - | DRY | |

| 08 | 350 | 0.025 | 3482 | 87 | 0.25 | - | - | DRY | |

| 09 | 350 | 0.025 | 3482 | 87 | 0.50 | - | - | DRY | |

| 10 | 350 | 0.050 | 3482 | 174 | 0.10 | - | - | DRY | |

| 11 | 350 | 0.050 | 3482 | 174 | 0.25 | - | - | DRY | |

| 12 | 350 | 0.050 | 3382 | 174 | 0.50 | - | - | DRY | |

| 13 | 450 | 0.025 | 4476 | 112 | 0.10 | - | - | DRY | |

| 14 | 450 | 0.025 | 4476 | 112 | 0.25 | - | - | DRY | |

| 15 | 450 | 0.025 | 4476 | 112 | 0.50 | - | - | DRY | |

| 16 | 450 | 0.050 | 4476 | 224 | 0.10 | - | - | DRY | |

| 17 | 450 | 0.050 | 4476 | 224 | 0.25 | - | - | DRY | |

| 18 | 450 | 0.050 | 4476 | 224 | 0.50 | - | - | DRY | |

| b | 19 | 250 | 0.050 | 2487 | 124 | 0.5 | 0.100 | 4 | DRY |

| 20 | 250 | 0.050 | 2487 | 124 | 0.5 | 0.050 | 4 | DRY | |

| 21 | 250 | 0.050 | 2487 | 124 | 0.5 | 0.025 | 4 | DRY | |

| 22 | 250 | 0.050 | 2487 | 124 | 0.5 | 0.010 | 4 | DRY | |

| 23 | 250 | 0.050 | 2487 | 124 | 0.5 | 0 | 0 | DRY | |

| 24 | 250 | 0.050 | 2487 | 124 | 0.5 | 0.100 | 1 | DRY | |

| 25 | 250 | 0.050 | 2487 | 124 | 0.5 | 0.100 | 2 | DRY | |

| 26 | 250 | 0.050 | 2487 | 124 | 0.5 | 0.100 | 4 | DRY |

| Vc (m/min) | fz (mm/tooth) | N (rpm) | F (mm/min) | DOC (mm) | Amplitude (mm) | f = 2freq (Hz) | Coolant |

|---|---|---|---|---|---|---|---|

| 250 | 0.050 | 2487 | 124 | 0.5 | 0.100 | 4 | DRY |

| 250 | 0.050 | 2487 | 124 | 0.5 | 0.050 | 2 | DRY |

| Vc (m/min) | fz (mm/tooth) | N (rpm) | F (mm/min) | DOC (mm) | Amplitude (mm) | f (Hz) | Coolant |

|---|---|---|---|---|---|---|---|

| 250 | 0.050 | 2487 | 124 | 0.5 | 0.100 | 4 | DRY |

| 250 | 0.050 | 2487 | 124 | 0.5 | 0.000 | 0 | DRY |

| Amplitude | Ra (µm) | Rz (µm) | Sa (µm) | Sz (µm) |

|---|---|---|---|---|

| A = 0 mm | 2.95 | 13.93 | 3.11 | 57.00 |

| A = 0.1 mm | 2.16 | 10.80 | 2.31 | 32.80 |

| A = 0.05 mm | 1.42 | 7.56 | 1.50 | 16.10 |

| A = 0.025 mm | 1.53 | 9.92 | 1.41 | 19.40 |

| A = 0 01 mm | 1.85 | 7.17 | 1.92 | 18.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Veiga, F.; Gil Del Val, A.; Penalva, M.L.; Pereira, O.; Suárez, A.; López de Lacalle Marcaide, L.N. Predicted Torque Model in Low-Frequency-Assisted Boring (LFAB) Operations. Metals 2021, 11, 1009. https://doi.org/10.3390/met11071009

Veiga F, Gil Del Val A, Penalva ML, Pereira O, Suárez A, López de Lacalle Marcaide LN. Predicted Torque Model in Low-Frequency-Assisted Boring (LFAB) Operations. Metals. 2021; 11(7):1009. https://doi.org/10.3390/met11071009

Chicago/Turabian StyleVeiga, Fernando, Alain Gil Del Val, Mari Luz Penalva, Octavio Pereira, Alfredo Suárez, and Luis Norberto López de Lacalle Marcaide. 2021. "Predicted Torque Model in Low-Frequency-Assisted Boring (LFAB) Operations" Metals 11, no. 7: 1009. https://doi.org/10.3390/met11071009

APA StyleVeiga, F., Gil Del Val, A., Penalva, M. L., Pereira, O., Suárez, A., & López de Lacalle Marcaide, L. N. (2021). Predicted Torque Model in Low-Frequency-Assisted Boring (LFAB) Operations. Metals, 11(7), 1009. https://doi.org/10.3390/met11071009