Laser Beam and Laser-Arc Hybrid Welding of Aluminium Alloys

Abstract

:1. Introduction

2. Properties of Aluminium Alloys

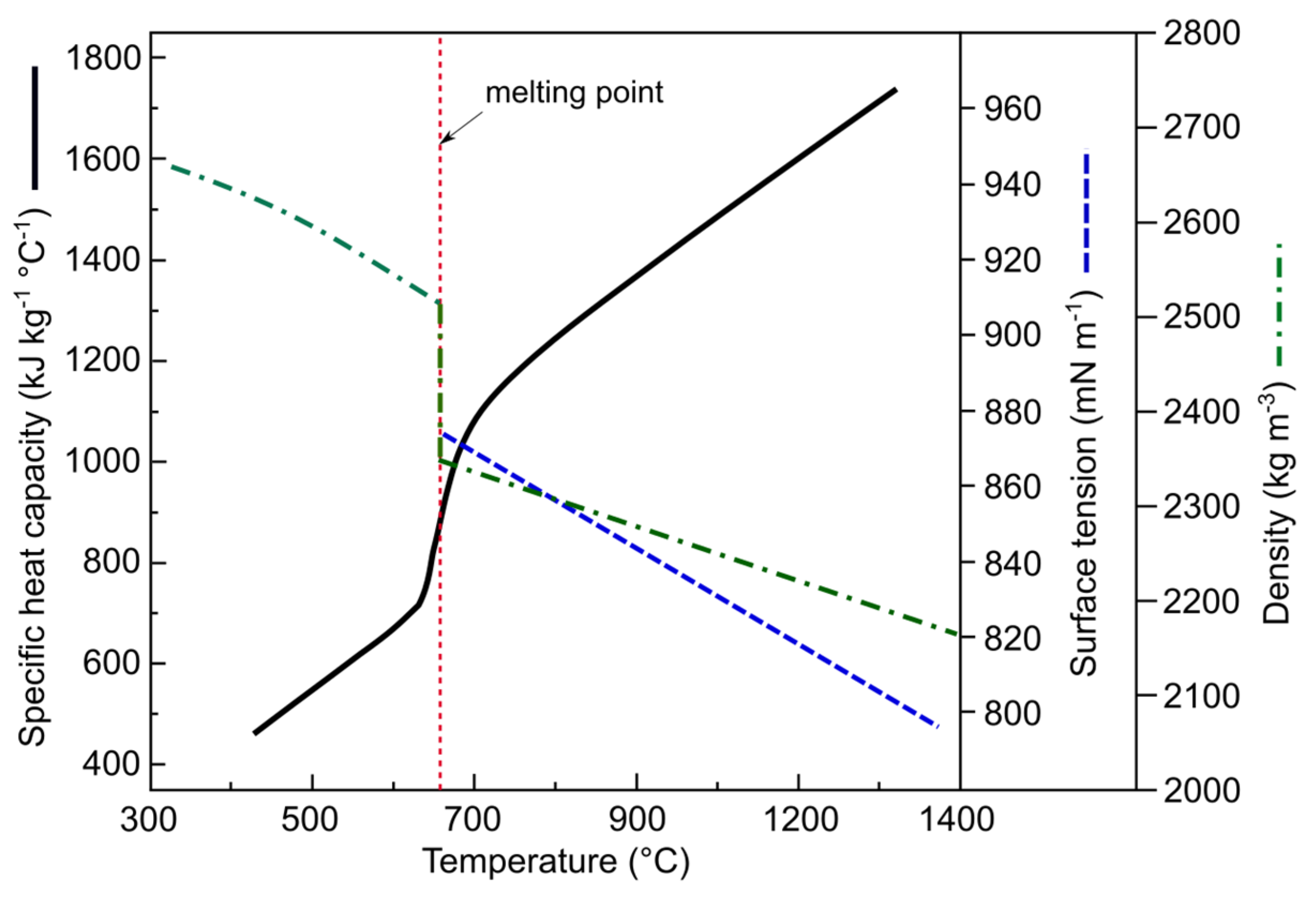

2.1. Thermophysical Properties

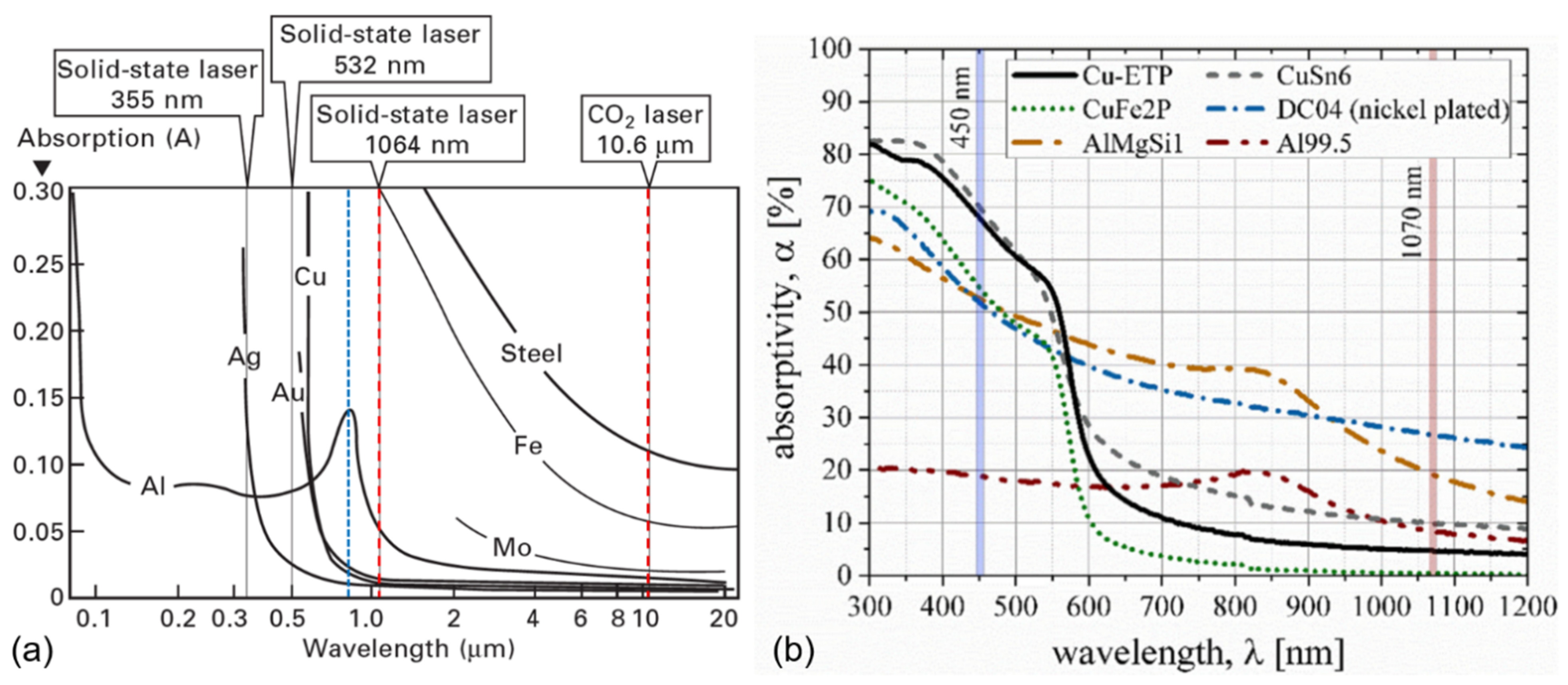

2.2. Absorptivity

- High reflectivity with high thermal conductivity. Therefore, higher power density (as compared to steel) must be supplied to the welding area to melt aluminium, and it may lead to softening in the heat affected zone and weld metal.

- Higher thermal expansion in combination with the low modulus of elasticity may provide excessive distortions and residual stresses.

- Aluminium has surface layer of aluminium oxide, which has a melting point much higher (2050 °C) than Al itself, and thus may contribute to weld defects. Prior to welding, the surface layer of oxide should be removed completely when high-quality requirements must be met.

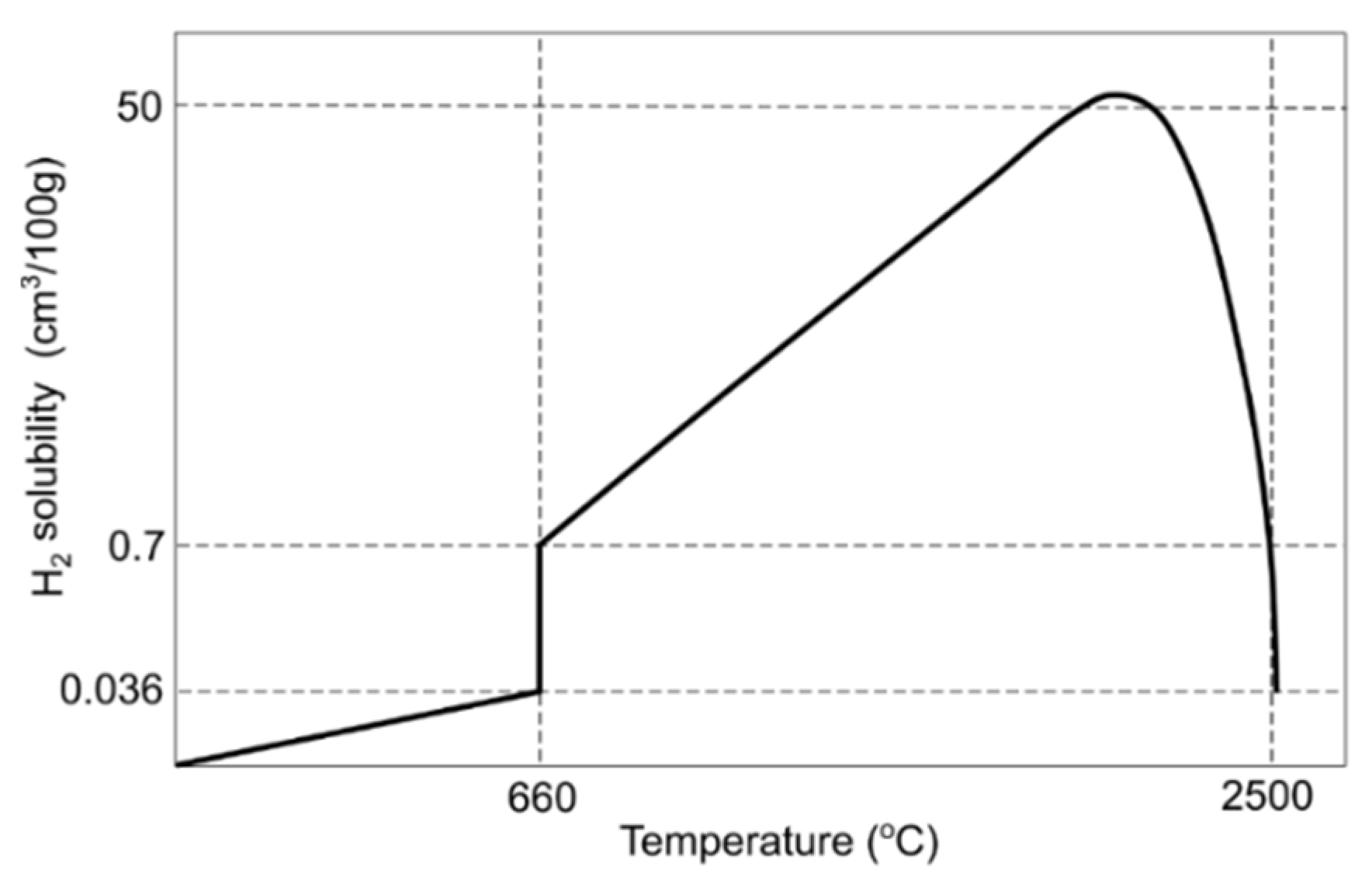

- High susceptibility to porosity due to high hydrogen solubility and unstable keyhole.

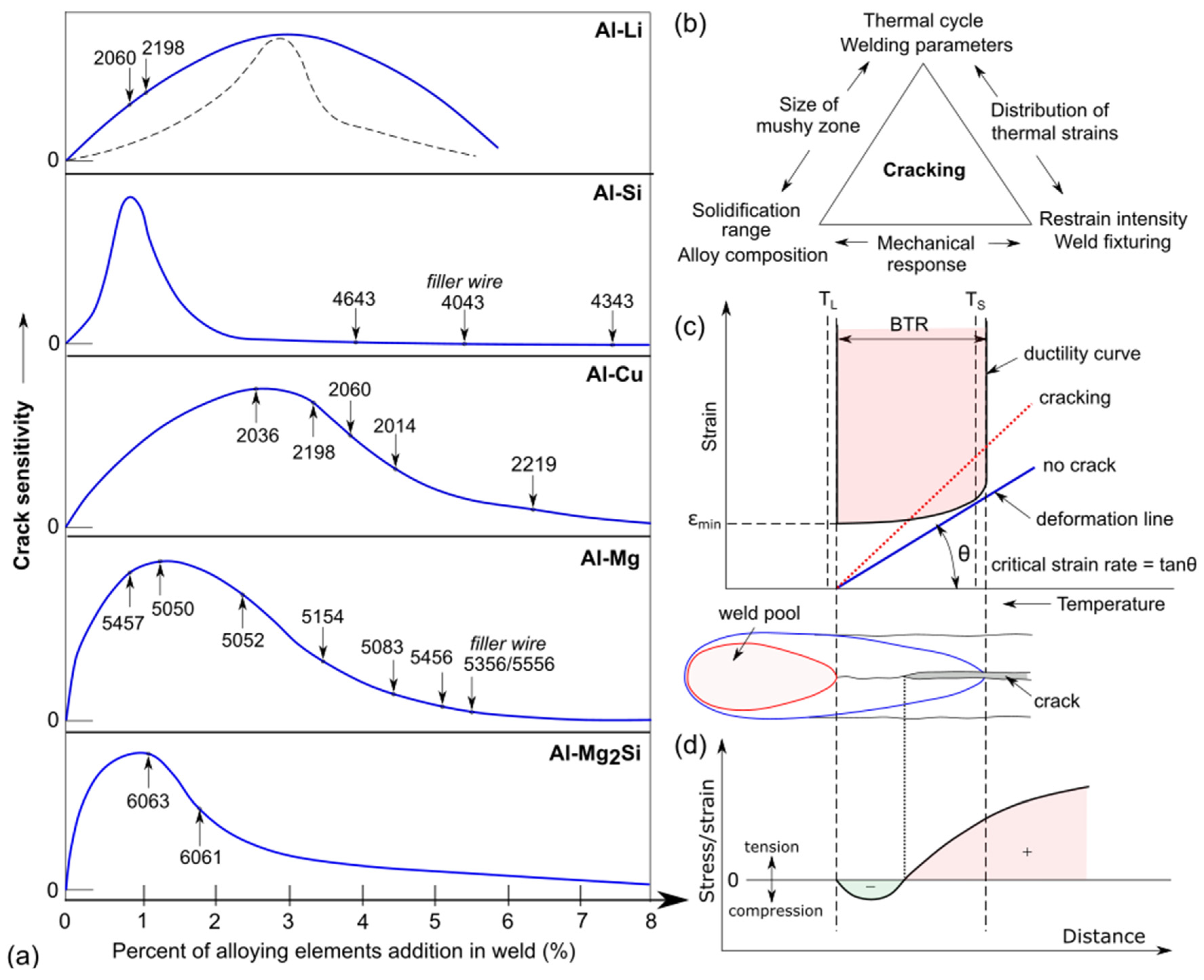

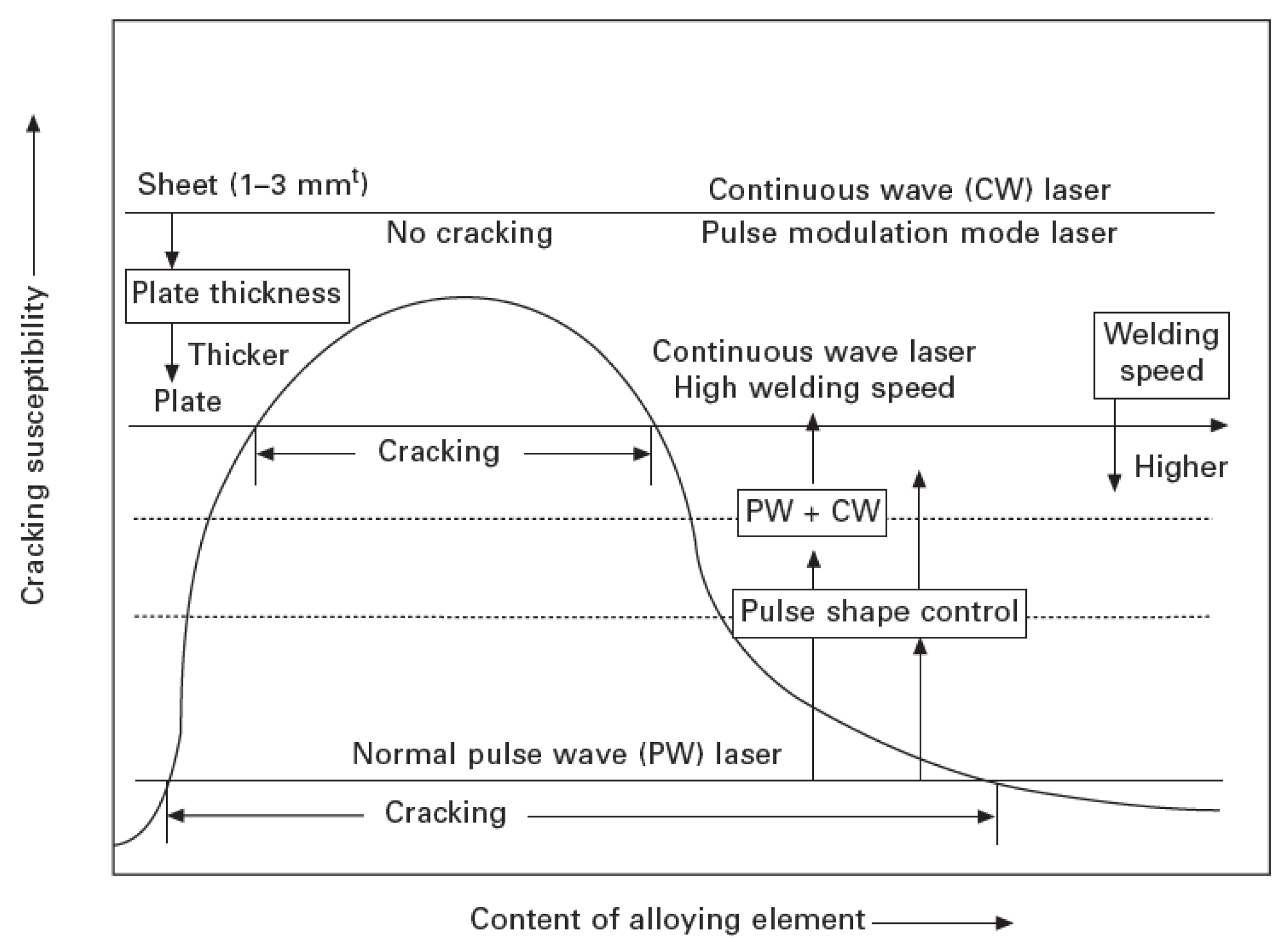

- Some alloys are susceptible to hot cracking due to alloying elements.

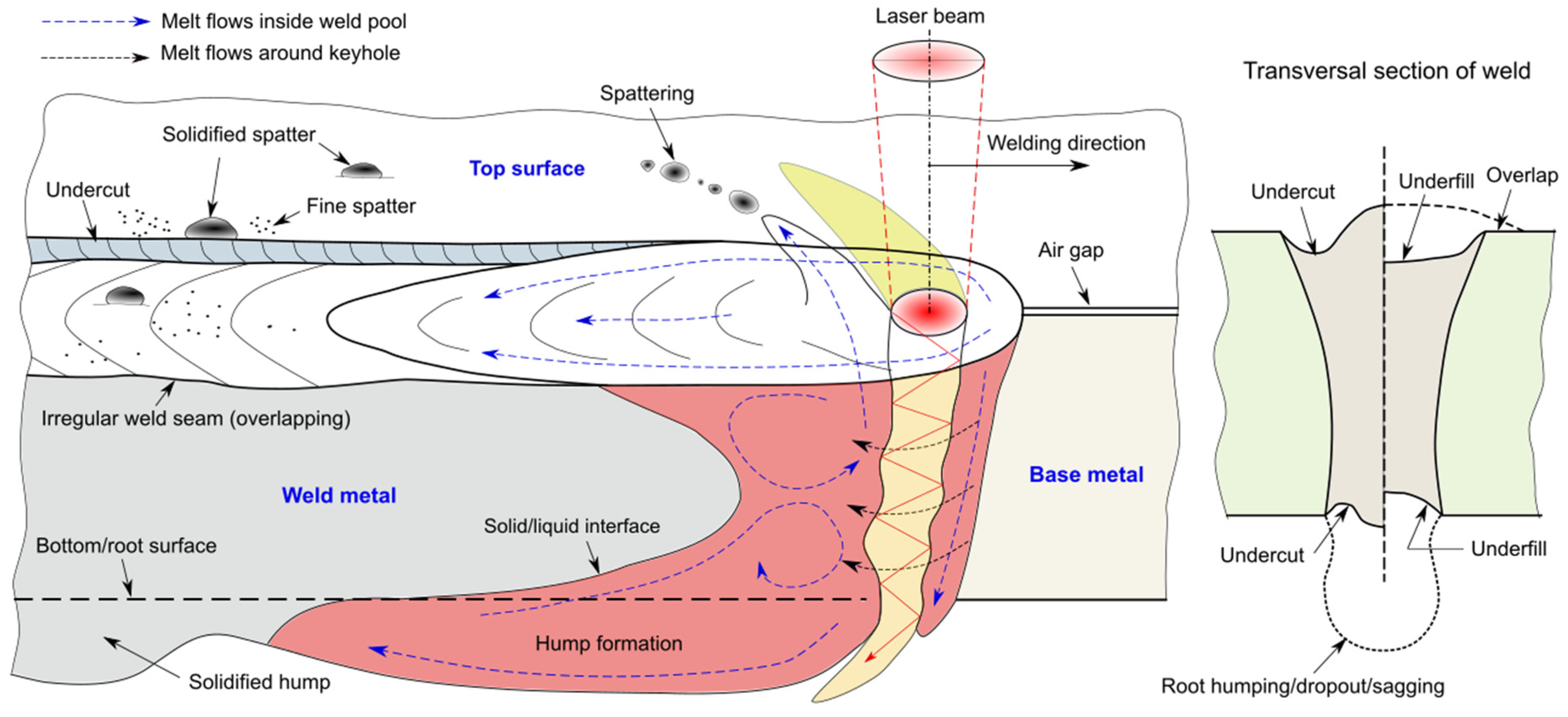

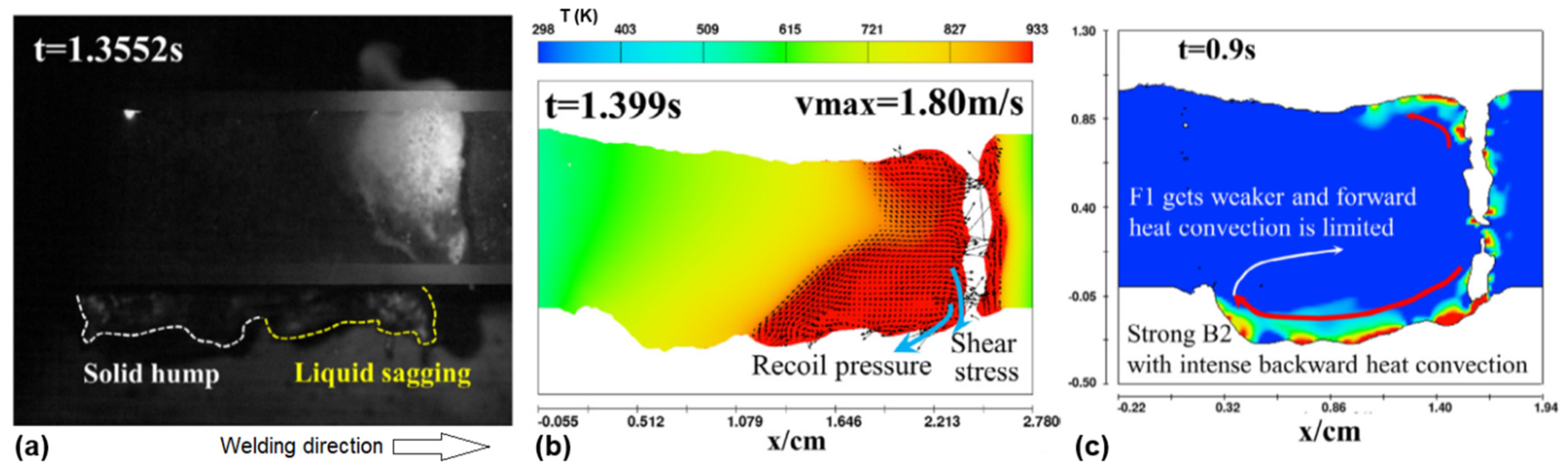

- Al has low surface tension, hence humping/sagging in root is common.

- Volatile alloying elements (Zn, Mg, Li) can evaporate from the keyhole, and the strength may be significantly reduced as well as stability of the process.

2.3. Classification of Aluminium Alloys and Alloying Elements

3. Comparison of Different Welding Methods

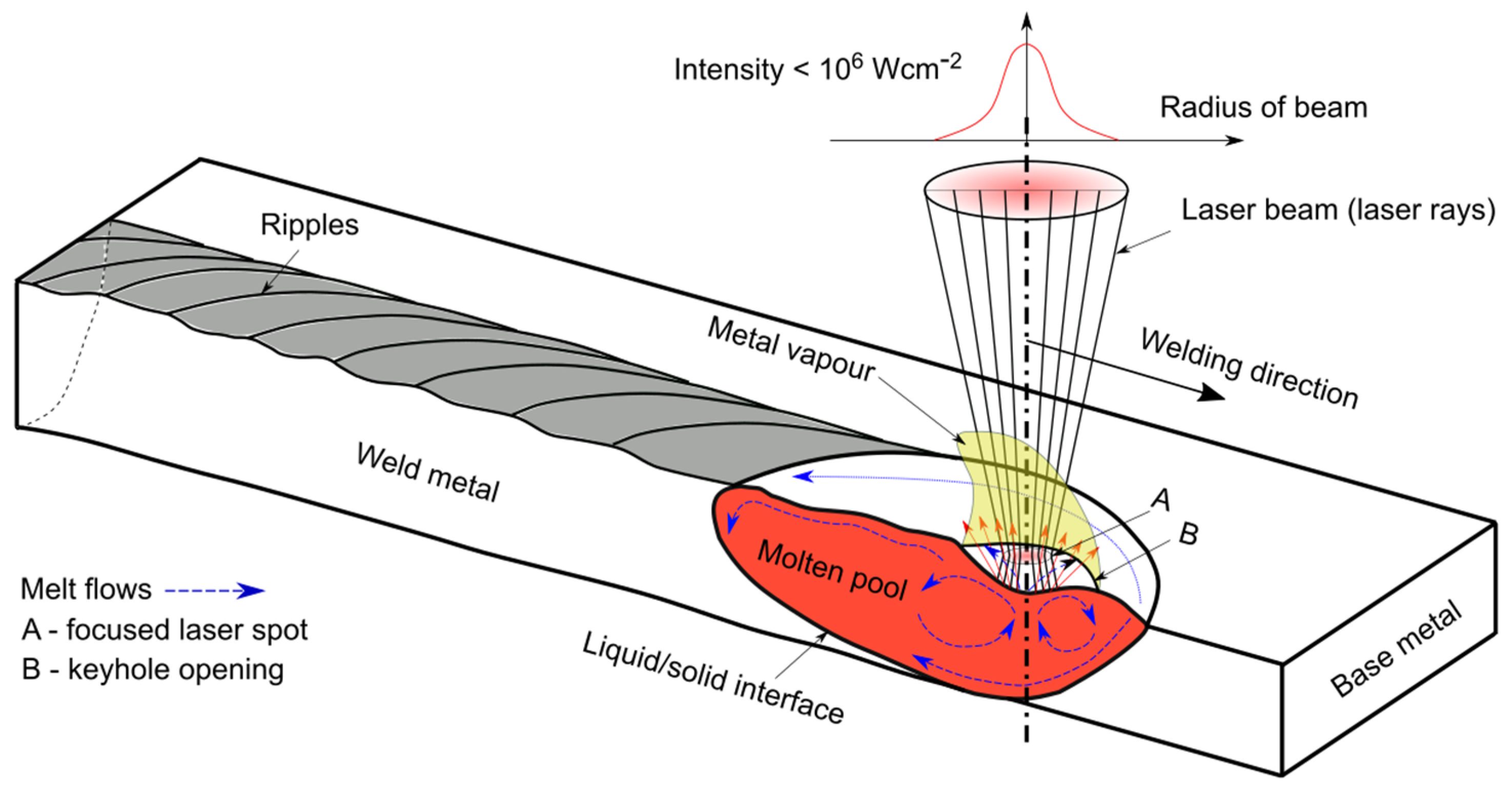

4. Physics of Laser Beam Welding of Aluminium Alloys

4.1. Laser Beam–Matter Interaction

- Fast welding speed due to concentrated energy with deep penetration allowing productivity improvement over conventional arc welding by more than 10–20 times.

- Lower heat input provides lower distortions and residual stresses.

- Reduced HAZ softening due to low heat input.

- Low heat input generates narrower HAZs with reduction of the soft zone width and associated liquation cracking.

- Smaller molten weld pool and faster solidification rates reduce hydrogen pickup from atmosphere; thus, the hydrogen-induced porosity is lower.

- Faster solidification rates prevent columnar dendrites resulting in more equiaxed grains with improved mechanical properties.

- Flexible process and can join various geometries with multi-sheet setups.

- Deep and narrow welds may enhance fatigue properties.

4.2. Physics of Weld Plume and Its Effects on Process

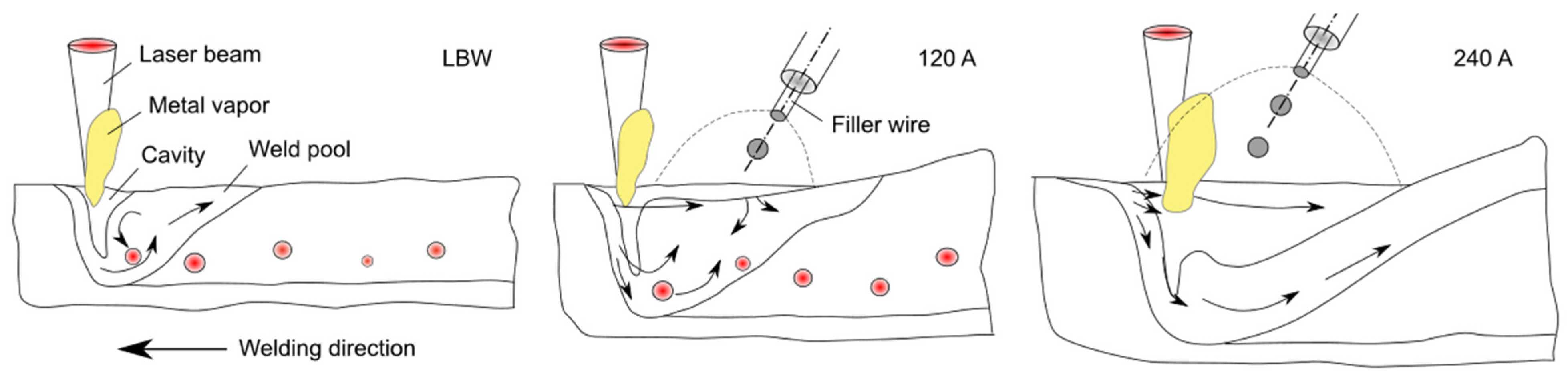

5. Laser-Arc Hybrid Welding

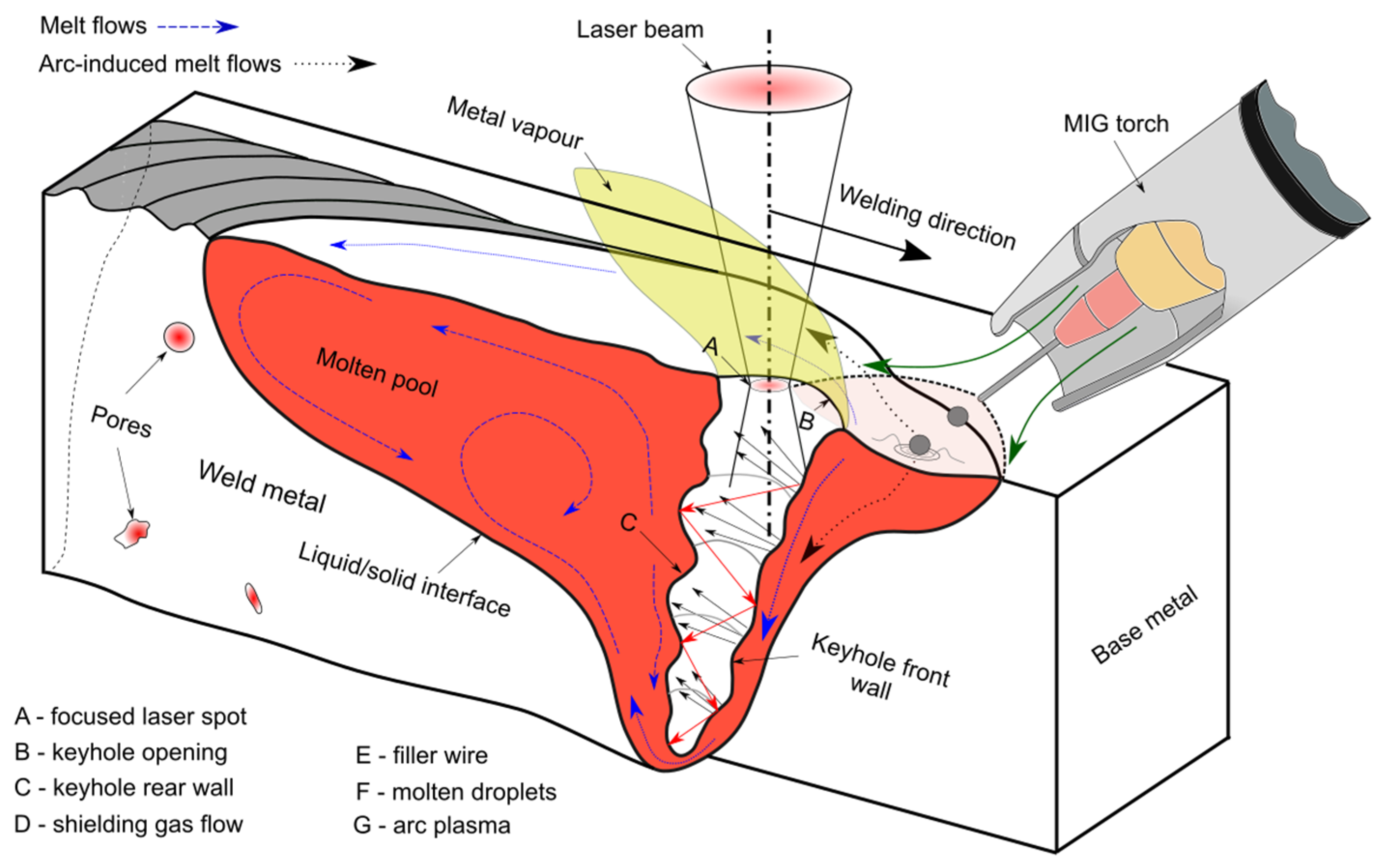

5.1. Fundamentals of LAHW

- The penetration depth is much higher than arc welding and can be improved compared to LBW.

- Fast welding speeds compared to arc welding can be more than 10–15 times faster.

- Laser beam promotes better arc ignition and stabilisation.

- Laser energy can be more efficiently used due to the preheating mechanism of the arc (leading arc setup)

- Lower energy input is obtainable compared to arc welding, providing fewer thermal distortions and residual stresses.

- Arc may prolong cooling time, which reduces susceptibility to cracking.

- Mechanical properties can be also significantly improved by means of filler wire compared to autogenous LBW.

- Lower sensitivity to tolerances for grooves and misalignments, therefore manufacturing time can be reduced dramatically. Moreover, LAHW has superior gap tolerance, especially with MIG.

- Dissimilar thicknesses can be welded with a smoother transition.

- The arc has cleaning effect which contributes to a dissolution of the oxide layer on the aluminium surface which is beneficial to weld quality compared to LBW.

- The high number of parameters, thus requiring much time for determination and implementation into production.

- Sensitivity to welding defects such as cracks and pores in joining thick sections.

- The melt pool is larger than in LBW, hence it becomes more difficult to shield the melt pool. As a result, occurrence of hydrogen-induced porosity is increased.

- Undercut issues in cases of fast welding speeds.

- High investment costs due to laser source considering safety issues due to 1 μm irradiation.

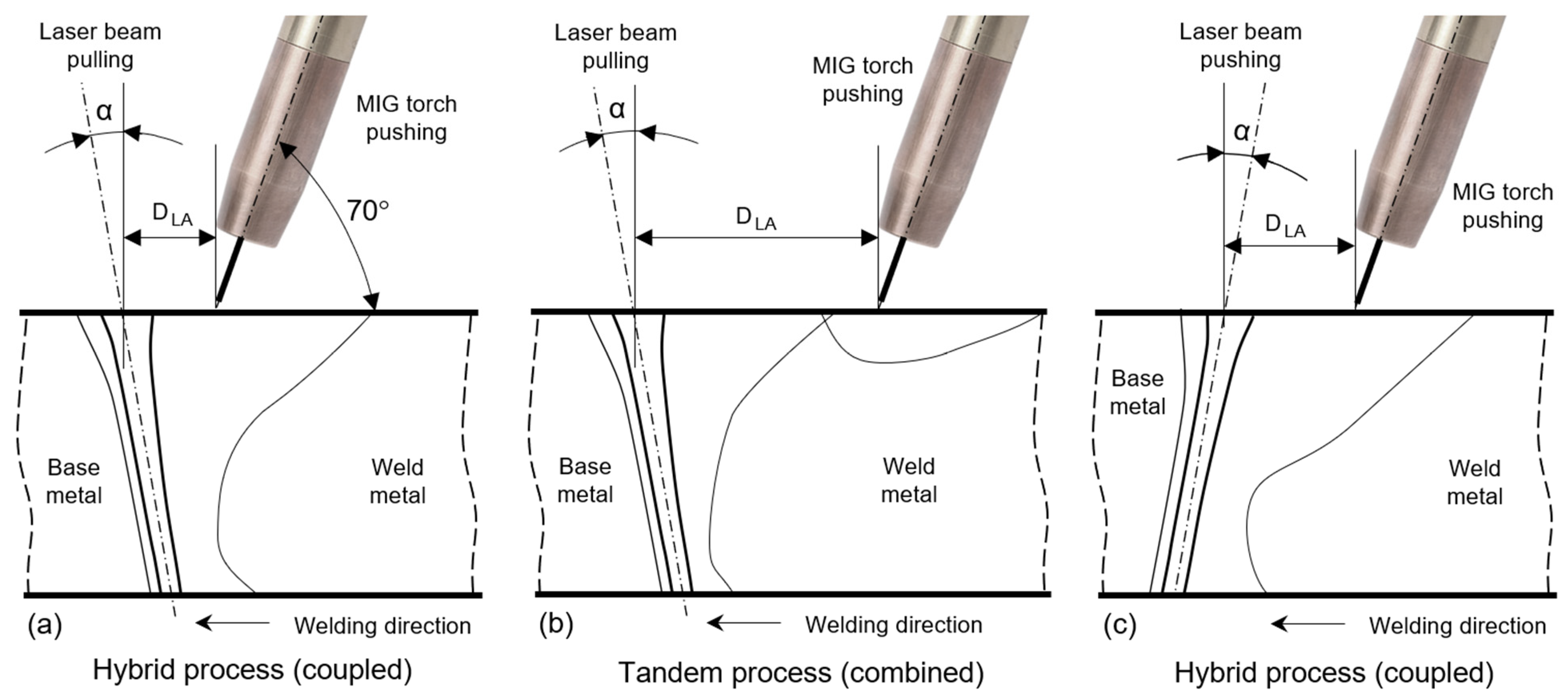

5.2. Variations of LAHW

Innovative LAHW Setups

5.3. Laser Beam and Arc Interaction

- The arc preheats the base metal and enhances the absorption of the laser beam.

- Arc plasma interacts and merges with the laser-induced plasma and may reduce the focal point position.

- The laser beam may stabilize the arc (stabilisation of the voltage and current fluctuations) and arc may stabilize melt pool.

- The temperature of the plasma plume in LAHW is higher than in LBW, which may provide certain advantages. The plasma emission intensity increases with increasing arc current.

- Arc power has a significant effect on the process since it imposes electromagnetic pressure on the weld pool and controls the bead width close to the surface.

- Pulsed arc parameters (pulse duration and pulse frequency) may affect the stability and quality of welds. However, their optimisation is intricate and time consuming.

6. Evaporation of Alloying Elements in LBW/LAHW

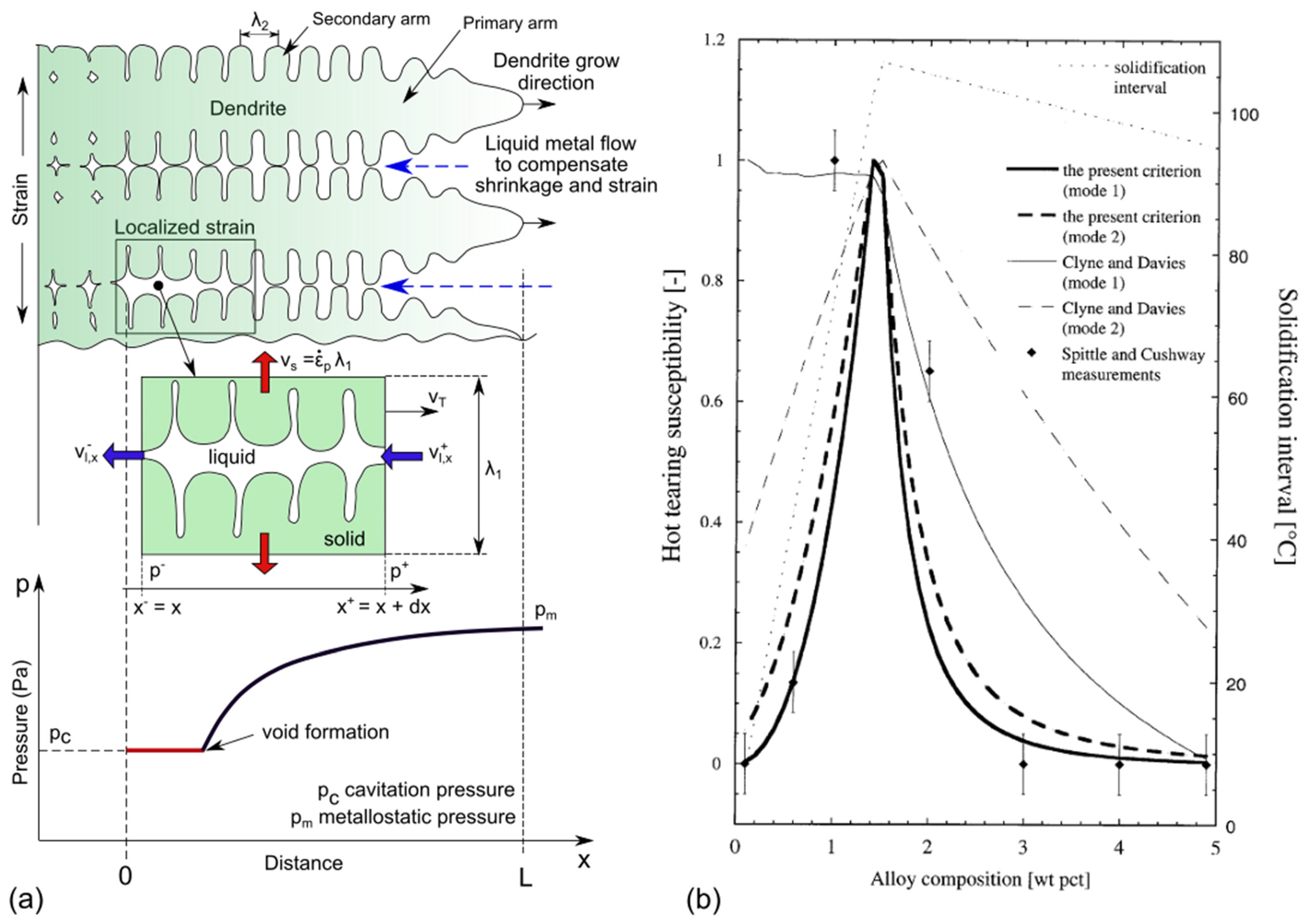

7. Solidification Behaviour and Hot Cracking in Welds

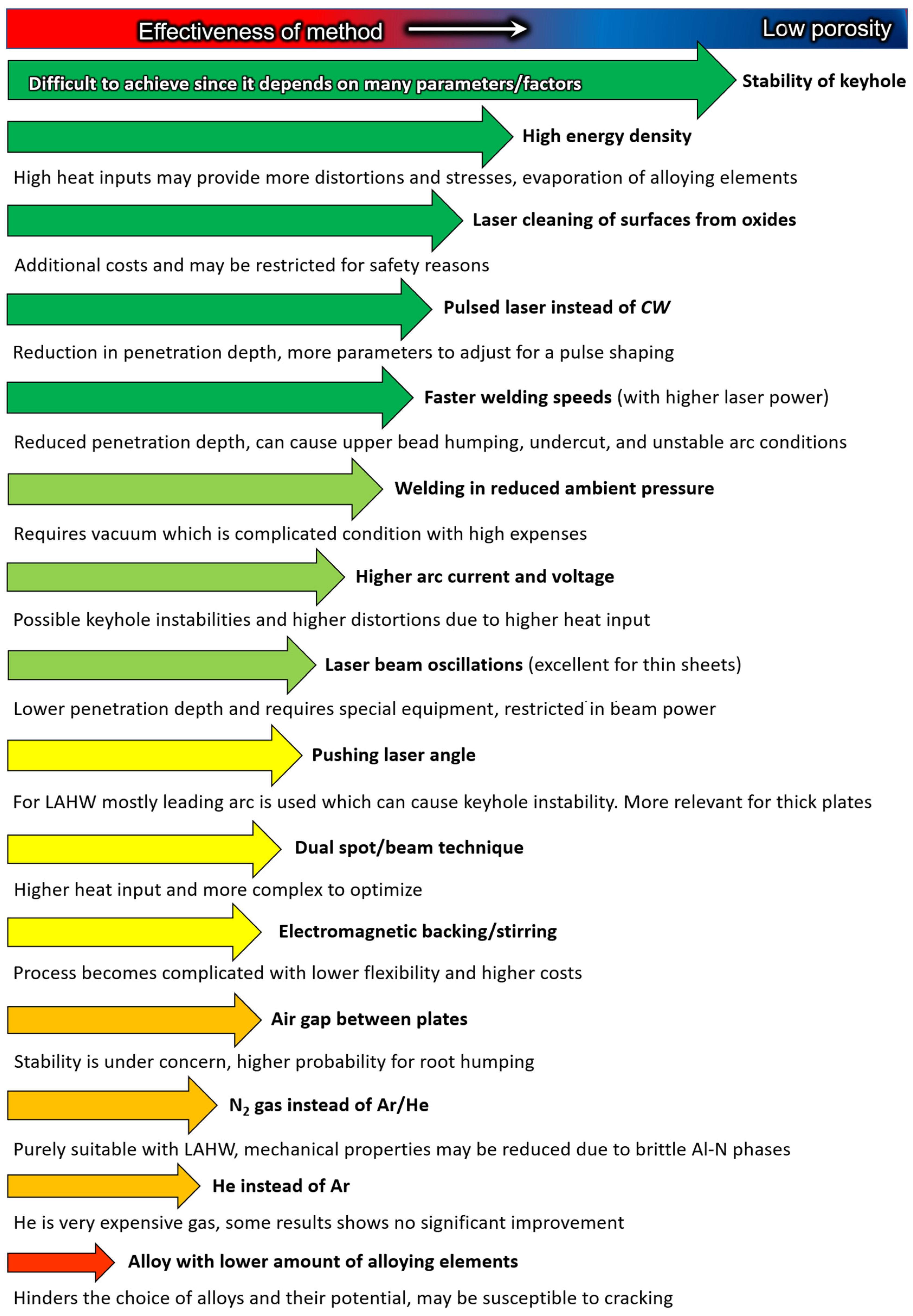

8. Porosity Formation and Strength of Joints

8.1. General Overview

- Inadequate shielding during welding due to low flow rate and positioning.

- Inappropriate shielding gas (with high moisture content).

- Hydrocarbons (oils, grease, and other contaminants) on plates.

- Moisture (water leaks, condensation or hydrated aluminium oxide, gas hoses).

- Contamination through mechanical cutting during preparation of workpieces.

- Filler wire with high hydrogen content.

- Improper cleaning of oxide layer prior to welding.

8.2. Porosity and Strength in Autogenous LBW

8.2.1. Heat Conduction Mode

8.2.2. Autogenous Laser Beam Keyhole Welding

8.2.3. Novel methods to Mitigate Porosity

8.3. Laser-Arc Hybrid Welding

8.3.1. Laser and Arc Power

8.3.2. Shielding Gas

8.3.3. Arc Position

8.3.4. Process Distance

8.3.5. Torch Angle

8.3.6. Welding Speed

8.3.7. Air Gap

8.3.8. Novel Methods to Mitigate Porosity

8.4. Effect of Porosity on Mechanical Properties

8.5. Summary on Porosity

9. Bead formation, Undercut, and Spattering

9.1. Undercut and Underfill

9.2. Spattering and Upper Bead Humping

9.3. Humping and Sagging of Root

10. Microstructure-Mechanical Property Relationship

10.1. Weldability Aspects and Microstructural Features

10.1.1. Al–Cu Alloys (2xxx)

10.1.2. Al–Cu–Li Alloys (2xxx)

10.1.3. Al–Mg Alloys (5xxx)

10.1.4. Al–Mg–Si Alloys (6xxx)

10.1.5. Al–Zn–Mg–Cu Alloys (7xxx)

11. Future Trend in LBW/LAHW of Al Alloys

12. Summary and Conclusions

- Fusion welding inevitably provides reduced mechanical properties due to softening in heat affected zone and weld metal, thus hinders their usage.

- Deep penetration keyhole mode may offer significant increase in productivity >10–20 times compared to conventional arc welding. However, welds are susceptible to imperfections and critical defects such as cracking and porosity, which are detrimental for mechanical properties.

- Porosity can be minimized by optimizing process parameters, which is a challenging, especially for laser-arc hybrid welding with many parameters to be adjusted. The parameters may interact with each other and can be time-consuming process.

- With explicit understanding of the effect of process parameters, it is possible to develop laser welding plan in short time in demanding industries.

- Laser-arc hybrid welding may offer advantages by use of filler wire and wider process window through manipulation of heat inputs. Development of novel filler materials is necessarily to enhance strength and corrosion resistance.

- Application of novel technologies such as laser beam oscillations, electromagnetic backing, shorter wavelength diode laser sources, grain refiners, and nanoparticles in filler wire may further enhance the quality of welds to achieve strength comparable to base metal. With the use of a vacuum, most of processing problems can be solved with significant improvement in productivity, opening new frontiers for manufacturing. However, creating a vacuum is complicated and leads to additional costs, especially for small and medium-size industries.

- The development of aluminium alloys towards higher strength goes much faster than fusion welding technologies. As a result, there is a need to study and analyse the application of laser welding and laser-arc hybrid welding capabilities to be more competitive with friction stir and arc welding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trowell, K.A.; Goroshin, S.; Frost, D.L.; Bergthorson, J.M. Aluminum and its role as a recyclable, sustainable carrier of renewable energy. Appl. Energy 2020, 275, 115112. [Google Scholar] [CrossRef]

- Hong, K.-M.; Shin, Y.C. Prospects of laser welding technology in the automotive industry: A review. J. Mater. Process. Technol. 2017, 245, 46–69. [Google Scholar] [CrossRef]

- Zwicker, M.F.R.; Moghadam, M.; Zhang, W.; Nielsen, C.V. Automotive battery pack manufacturing—A review of battery to tab joining. J. Adv. Join. Process. 2020, 1, 100017. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Huang, L.; Hua, X.; Wu, D.; Jiang, Z.; Li, F.; Wang, H.; Shi, S. Microstructural characterization of 5083 aluminum alloy thick plates welded with GMAW and twin wire GMAW processes. Int. J. Adv. Manuf. Technol. 2017, 93, 1809–1817. [Google Scholar] [CrossRef]

- Kim, C.; Ahn, Y.; Lee, K.-B.; Kim, D. High-deposition-rate position welding of Al 5083 alloy for spherical-type liquefied natural gas tank. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 230, 818–824. [Google Scholar] [CrossRef]

- Hu, B.; Richardson, I.M. Mechanism and possible solution for transverse solidification cracking in laser welding of high strength aluminium alloys. Mater. Sci. Eng. A 2006, 429, 287–294. [Google Scholar] [CrossRef]

- Haboudou, A.; Peyre, P.; Vannes, A.B.; Peix, G. Reduction of porosity content generated during Nd:YAG laser welding of A356 and AA5083 aluminium alloys. Mater. Sci. Eng. A 2003, 363, 40–52. [Google Scholar] [CrossRef]

- Kuo, T.Y.; Lin, H.C. Effects of pulse level of Nd-YAG laser on tensile properties and formability of laser weldments in automotive aluminum alloys. Mater. Sci. Eng. A 2006, 416, 281–289. [Google Scholar] [CrossRef]

- Jandaghi, M.; Parvin, P.; Torkamany, M.J.; Sabbaghzadeh, J. Alloying elemental change of SS-316 and Al-5754 during laser welding using real time laser induced breakdown spectroscopy (LIBS) accompanied by EDX and PIXE microanalysis. Phys. Procedia 2010, 5, 107–114. [Google Scholar] [CrossRef] [Green Version]

- Kawahito, Y.; Matsumoto, N.; Abe, Y.; Katayama, S. Relationship of laser absorption to keyhole behavior in high power fiber laser welding of stainless steel and aluminum alloy. J. Mater. Process. Technol. 2011, 211, 1563–1568. [Google Scholar] [CrossRef]

- Pinto, L.A.; Quintino, L.; Miranda, R.M.; Carr, P. Laser welding of dissimilar aluminium alloys with filler materials. Weld. World 2010, 54, R333–R341. [Google Scholar] [CrossRef]

- Wang, H.; Liu, L.; Liu, F. The characterization investigation of laser-arc-adhesive hybrid welding of Mg to Al joint using Ni interlayer. Mater. Des. 2013, 50, 463–466. [Google Scholar] [CrossRef]

- Easterling, K. Introduction to the Physical Metallurgy of Welding; Butterworth-Heinemann: Oxford, UK, 1983. [Google Scholar]

- European Committee for Standardization. Eurocode 9: Design of Aluminium Structures - Part 1-1: General Structural Rules; European Committee for Standardization: Brussels, Belgium, 1999. [Google Scholar]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Çam, G. Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J. Manuf. Process. 2018, 36, 571–600. [Google Scholar] [CrossRef]

- Mathers, G. The Welding of Aluminium and Its Alloys; Woodhead Publishing: Cambridge, UK, 2002; p. 248. [Google Scholar]

- Sarrafi, R.; Kovacevic, R. Cathodic cleaning of oxides from aluminum surface by variable-polarity arc. Weld. J. 2010, 89. [Google Scholar]

- Leitner, M.; Leitner, T.; Schmon, A.; Aziz, K.; Pottlacher, G. Thermophysical properties of liquid aluminum. Metall. Mater. Trans. A 2017, 48, 3036–3045. [Google Scholar] [CrossRef] [Green Version]

- Ahn, J.; He, E.; Chen, L.; Wimpory, R.C.; Kabra, S.; Dear, J.P.; Davies, C.M. FEM prediction of welding residual stresses in fibre laser-welded AA 2024-T3 and comparison with experimental measurement. Int. J. Adv. Manuf. Technol. 2018, 95, 4243–4263. [Google Scholar] [CrossRef]

- Powell, R.W.; Ho, C.Y.; Liley, P.E. Thermal Conductivity of Selected Materials; National Bureau of Standard: Washington, DC, USA, 1966. [Google Scholar]

- Hummel, M.; Schöler, C.; Häusler, A.; Gillner, A.; Poprawe, R. New approaches on laser micro welding of copper by using a laser beam source with a wavelength of 450 nm. J. Adv. Join. Process. 2020, 1, 100012. [Google Scholar] [CrossRef]

- Pierron, N.; Sallamand, P.; Matteï, S. Study of magnesium and aluminum alloys absorption coefficient during Nd:YAG laser interaction. Appl. Surf. Sci. 2007, 253, 3208–3214. [Google Scholar] [CrossRef]

- Kawahito, Y.; Matsumoto, N.; Abe, Y.; Katayama, S. Laser absorption of aluminium alloy in high brightness and high power fibre laser welding. Weld. Int. 2012, 26, 275–281. [Google Scholar] [CrossRef]

- Miyagi, M.; Wang, H.; Yoshida, R.; Kawahito, Y.; Kawakami, H.; Shoubu, T. Effect of alloy element on weld pool dynamics in laser welding of aluminum alloys. Sci. Rep. 2018, 8, 12944. [Google Scholar] [CrossRef]

- Ning, J.; Zhang, L.-J.; Yin, X.-Q.; Zhang, J.-X.; Na, S.-J. Mechanism study on the effects of power modulation on energy coupling efficiency in infrared laser welding of highly-reflective materials. Mater. Des. 2019, 178, 107871. [Google Scholar] [CrossRef]

- Malekshahi Beiranvand, Z.; Malek Ghaini, F.; Naffakh Moosavy, H.; Sheikhi, M.; Torkamany, M.J.; Moradi, M. The relation between magnesium evaporation and laser absorption and weld penetration in pulsed laser welding of aluminum alloys: Experimental and numerical investigations. Opt. Laser Technol. 2020, 128, 106170. [Google Scholar] [CrossRef]

- Zhao, H.; Debroy, T. Weld metal composition change during conduction mode laser welding of aluminum alloy 5182. Metall. Mater. Trans. B 2001, 32, 163–172. [Google Scholar] [CrossRef]

- Katayama, S. Handbook of Laser Welding Technologies; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Verhaeghe, G.; Hilton, P.; Barnes, S. Achieving low-porosity laser welds in aerospace aluminium alloy. SAE Trans. 2003, 286–294. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Yazdian, N.; Kovacevic, R. Partial penetration laser-based welding of aluminum alloy (AA 5083-H32). Optik 2016, 127, 6782–6804. [Google Scholar] [CrossRef]

- Enz, J.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Laser weldability of high-strength Al-Zn alloys and its improvement by the use of an appropriate filler material. Metall. Mater. Trans. A 2016. [Google Scholar] [CrossRef]

- Weast, R.C. Handbook of Chemistry and Physics, 54th ed.; CRC Press: Boca Raton, FL, USA, 1973. [Google Scholar]

- ASM International. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. In ASM Handbook; ASM International: Almere, The Netherlands, 1990; Volume 2, pp. 17–724. [Google Scholar]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Butterworth-Heinemann: Oxford, UK, 1976. [Google Scholar] [CrossRef]

- ISO 18273. Welding Consumables—Wire Electrodes, Wires and Rods for Welding of Aluminium and Aluminium Alloys—Classification; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Hackius, J.; Naegeler, S.; Brenner, B.; Beyer, E. Innovation in laser hybrid technology for aluminum welding. Int. Congr. Appl. Lasers Electro. Opt. 2000, 2000, B8–B19. [Google Scholar] [CrossRef]

- Ferjutz, K.; Davis, J.R. Welding, Brazing, and Soldering. In ASM Handbook; ASM International: Almere, The Netherlands, 2004; Volume 6. [Google Scholar]

- Olsen, F. Hybrid Laser-Arc Welding; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Steen, W.M.; Mazumder, J. Laser Material Processing; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Cho, W.-I.; Schultz, V.; Woizeschke, P. Numerical study of the effect of the oscillation frequency in buttonhole welding. J. Mater. Process. Technol. 2018, 261, 202–212. [Google Scholar] [CrossRef]

- Schultz, V.; Woizeschke, P. High seam surface quality in keyhole laser welding: Buttonhole welding. J. Manuf. Mater. Process. 2018, 2, 78. [Google Scholar] [CrossRef] [Green Version]

- Behler, K.; Berkmanns, J.; Ehrhardt, A.; Frohn, W. Laser beam welding of low weight materials and structures. Mater. Des. 1997, 18, 261–267. [Google Scholar] [CrossRef]

- Zacharia, T.; David, S.A.; Vitek, J.M.; DebRoy, T. Modeling of interfacial phenomena in welding. Metall. Trans. B 1990, 21B, 600–603. [Google Scholar] [CrossRef]

- Ion, J.C. Laser beam welding of wrought aluminium alloys. Sci. Technol. Weld. Join. 2000, 5, 265–276. [Google Scholar] [CrossRef]

- Haglund, P.; Eriksson, I.; Powell, J.; Kaplan, A. Surface tension stabilized laser welding (donut laser welding)—A new laser welding technique. J. Laser Appl. 2013, 25, 031501. [Google Scholar] [CrossRef]

- Eriksson, I.; Powell, J.; Kaplan, A.F.H. Surface tension generated defects in full penetration laser keyhole welding. J. Laser Appl. 2014, 26, 012006. [Google Scholar] [CrossRef]

- Kawahito, Y.; Wang, H. In-situ observation of gap filling in laser butt welding. Scr. Mater. 2018, 154, 73–77. [Google Scholar] [CrossRef]

- Fellman, A. The Effects of Some Variables on CO2 Laser-MAG Hybrid Welding. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2008. [Google Scholar]

- Kannatey-Asibu, E., Jr. Principles of Laser Materials Processing; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Kaplan, A. A model of deep penetration laser welding based on calculation of the keyhole profile. J. Phys. D Appl. Phys. 1994, 27, 1805–1814. [Google Scholar] [CrossRef]

- Kaplan, A.F.H. Fresnel absorption of 1 μm- and 10 μm-laser beams at the keyhole wall during laser beam welding: Comparison between smooth and wavy surfaces. Appl. Surf. Sci. 2012, 258, 3354–3363. [Google Scholar] [CrossRef]

- Kaplan, A.F.H. Absorption homogenization at wavy melt films by CO2-lasers in contrast to 1 μm-wavelength lasers. Appl. Surf. Sci. 2015, 328, 229–234. [Google Scholar] [CrossRef]

- Cheng, Y.; Jin, X.; Li, S.; Zeng, L. Fresnel absorption and inverse bremsstrahlung absorption in an actual 3D keyhole during deep penetration CO2 laser welding of aluminum 6016. Opt. Laser Technol. 2012, 44, 1426–1436. [Google Scholar] [CrossRef]

- Cho, J.-H.; Na, S.-J. Implementation of real-time multiple reflection and Fresnel absorption of laser beam in keyhole. J. Phys. D Appl. Phys. 2006, 39, 5372–5378. [Google Scholar] [CrossRef]

- Wang, H.; Kawahito, Y.; Yoshida, R.; Nakashima, Y.; Shiokawa, K. A model to calculate the laser absorption property of actual surface. Int. J. Heat Mass Transf. 2018, 118, 562–569. [Google Scholar] [CrossRef]

- Grote, K.-H.; Antonsson, E.K. Springer Handbook of Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Steen, W.M. Arc augmented laser processing of materials. J. Appl. Phys. 1980, 51, 5636–5641. [Google Scholar] [CrossRef]

- Mills, K.C.; Keene, B.J.; Brooks, R.F.; Shirali, A. Marangoni effects in welding. Philos. Trans. Math. Phys. Eng. Sci. 1998, 356, 911–925. [Google Scholar] [CrossRef]

- Arora, A.; Roy, G.G.; DebRoy, T. Unusual wavy weld pool boundary from dimensional analysis. Scr. Mater. 2009, 60, 68–71. [Google Scholar] [CrossRef]

- Pitscheneder, W.; DebRoy, T.; Mundra, K.; Ebner, R. Role of sulfur and processing variables on the temporal evolution of weld pool geometry during multikilowatt laser beam welding of steels. Weld. J. 1996, 75, 71–80. [Google Scholar]

- Kou, S.; Limmaneevichitr, C.; Wei, P.S. Oscillatory marangoni flow: A fundamental study by conduction-mode laser spot welding. Weld. J. 2011, 90, 229–240. [Google Scholar]

- Zhao, H.; White, D.R.; DebRoy, T. Current issues and problems in laser welding of automotive aluminium alloys. Int. Mater. Rev. 1999, 44, 238–266. [Google Scholar] [CrossRef]

- Velde, O.; Gritzki, R.; Grundmann, R. Numerical investigations of Lorentz force influenced Marangoni convection relevant to aluminum surface alloying. Int. J. Heat Mass Transf. 2001, 44, 2751–2762. [Google Scholar] [CrossRef]

- Seto, N.; Katayama, S.; Matsunawa, A. Porosity formation mechanism and suppression procedure in laser welding of aluminium alloys. Weld. Int. 2001, 15, 191–202. [Google Scholar] [CrossRef]

- Kaplan, A.F.H.; Matti, R.S. Absorption peaks depending on topology of the keyhole front and wavelength. J. Laser Appl. 2015, 27, S29012. [Google Scholar] [CrossRef]

- Wu, D.; Hua, X.; Huang, L.; Li, F.; Cai, Y. Observation of the keyhole behavior, spatter, and keyhole-induced bubble formation in laser welding of a steel/glass sandwich. Weld World 2019, 63, 815–823. [Google Scholar] [CrossRef]

- Ki, H.; Mazumder, J.; Mohanty, P.S. Modeling of laser keyhole welding: Part I. mathematical modeling, numerical methodology, role of recoil pressure, multiple reflections, and free surface evolution. Metall. Mater. Trans. A 2002, 33, 1817–1830. [Google Scholar] [CrossRef]

- Ai, Y.; Jiang, P.; Wang, C.; Mi, G.; Geng, S. Experimental and numerical analysis of molten pool and keyhole profile during high-power deep-penetration laser welding. Int. J. Heat Mass Transf. 2018, 126, 779–789. [Google Scholar] [CrossRef]

- Kouraytem, N.; Li, X.; Cunningham, R.; Zhao, C.; Parab, N.; Sun, T.; Rollett, A.D.; Spear, A.D.; Tan, W. Effect of Laser-Matter Interaction on Molten Pool Flow and Keyhole Dynamics. Phys. Rev. Appl. 2019, 11, 064054. [Google Scholar] [CrossRef]

- Luo, M.; Hu, R.; Li, Q.; Huang, A.; Pang, S. Physical understanding of keyhole and weld pool dynamics in laser welding under different water pressures. Int. J. Heat Mass Transf. 2019, 137, 328–336. [Google Scholar] [CrossRef]

- Cho, W.-I.; Na, S.-J.; Thomy, C.; Vollertsen, F. Numerical simulation of molten pool dynamics in high power disk laser welding. J. Mater. Process. Technol. 2012, 212, 262–275. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, M.; Shu, C.; Zhang, Y.; Wu, D.; Ye, Y. Dynamic keyhole behavior and keyhole instability in high power fiber laser welding of stainless steel. Opt. Laser Technol. 2019, 114, 1–9. [Google Scholar] [CrossRef]

- Kawahito, Y.; Nakada, K.; Uemura, Y.; Mizutani, M.; Nishimoto, K.; Kawakami, H.; Katayama, S. Relationship between melt flows based on three-dimensional X-ray transmission in situ observation and spatter reduction by angle of incidence and defocussing distance in high-power laser welding of stainless steel. Weld. Int. 2018, 32, 485–496. [Google Scholar] [CrossRef]

- Li, L.; Xia, H.; Ma, G.; Peng, G. Flow dynamics during single- and dual-spot laser welding with one common keyhole of 321 stainless steel. J. Mater. Process. Technol. 2018, 255, 841–852. [Google Scholar] [CrossRef]

- Chen, G.; Liu, J.; Shu, X.; Gu, H.; Zhang, B. Numerical simulation of keyhole morphology and molten pool flow behavior in aluminum alloy electron-beam welding. Int. J. Heat Mass Transf. 2019, 138, 879–888. [Google Scholar] [CrossRef]

- Wu, D.; Hua, X.; Ye, Y.; Huang, L.; Li, F.; Huang, Y. Experimental and numerical study of spatter formation and composition change in fiber laser welding of aluminum alloy. J. Phys. D Appl. Phys. 2018, 51, 185604. [Google Scholar] [CrossRef]

- Rai, R.; Roy, G.G.; DebRoy, T. A computationally efficient model of convective heat transfer and solidification characteristics during keyhole mode laser welding. J. Appl. Phys. 2007, 101, 054909. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Peng, G.; Wang, J.; Gong, J.; Meng, S. Numerical and experimental study on keyhole and melt flow dynamics during laser welding of aluminium alloys under subatmospheric pressures. Int. J. Heat Mass Transf. 2019, 133, 812–826. [Google Scholar] [CrossRef]

- Wu, D.; Hua, X.; Huang, L.; Zhao, J. Numerical simulation of spatter formation during fiber laser welding of 5083 aluminum alloy at full penetration condition. Opt. Laser Technol. 2018, 100, 157–164. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Hua, X.; Huang, L.; Li, F.; Cai, Y. Elucidation of keyhole induced bubble formation mechanism in fiber laser welding of low carbon steel. Int. J. Heat Mass Transf. 2018, 127, 1077–1086. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; Le Masson, P.; Gaied, S.; Balabane, M. Guidelines in the experimental validation of a 3D heat and fluid flow model of keyhole laser welding. J. Phys. D Appl. Phys. 2016, 49, 155503. [Google Scholar] [CrossRef]

- Schaefer, M.; Kessler, S.; Fetzer, F.; Graf, T. Influence of the focal position on the melt flow during laser welding of steel. J. Laser Appl. 2017, 29, 012010. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.L.; Elmer, J.W.; DebRoy, T. Three-dimensional modeling of grain structure evolution during welding of an aluminum alloy. Acta Mater. 2017, 126, 413–425. [Google Scholar] [CrossRef] [Green Version]

- Panwisawas, C.; Perumal, B.; Ward, R.M.; Turner, N.; Turner, R.P.; Brooks, J.W.; Basoalto, H.C. Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: Experimental and modelling. Acta Mater. 2017, 126, 251–263. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.J.; Zhang, J.X.; Gumenyuk, A.; Rethmeier, M.; Na, S.J. Numerical simulation of full penetration laser welding of thick steel plate with high power high brightness laser. J. Mater. Process. Technol 2014, 214, 1710–1720. [Google Scholar] [CrossRef]

- Zhang, R.; Tang, X.; Xu, L.; Lu, F.; Cui, H. Study of molten pool dynamics and porosity formation mechanism in full penetration fiber laser welding of Al-alloy. Int. J. Heat Mass Transf. 2020, 148, 119089. [Google Scholar] [CrossRef]

- Cho, D.-W.; Cho, W.-I.; Na, S.-J. Modeling and simulation of arc: Laser and hybrid welding process. J. Manuf. Process. 2014, 16, 26–55. [Google Scholar] [CrossRef]

- Katayama, S.; Uchiumi, S.; Mizutani, M.; Wang, J.; Fujii, K. Penetration and porosity prevention mechanism in YAG laser-MIG hybrid welding. Weld. Int. 2007, 21, 25–31. [Google Scholar] [CrossRef]

- Kaplan, A.F.H. Modelling the primary impact of an Yb:Fibre laser beam profile on the keyhole front. Phys. Procedia 2011, 12, 627–637. [Google Scholar] [CrossRef] [Green Version]

- Kaplan, A.F.H. Influence of the beam profile formulation when modeling fiber-guided laser welding. J. Laser Appl. 2011, 23, 042005. [Google Scholar] [CrossRef]

- Volpp, J.; Vollertsen, F. Modeling keyhole oscillations during laser deep penetration welding at different spatial laser intensity distributions. Prod. Eng. 2015, 9, 167–178. [Google Scholar] [CrossRef]

- Volpp, J.; Vollertsen, F. Keyhole stability during laser welding—Part I: Modeling and evaluation. Prod. Eng. 2016, 10, 443–457. [Google Scholar] [CrossRef]

- Volpp, J. Keyhole stability during laser welding—Part II: Process pores and spatters. Prod. Eng. 2017, 11, 9–18. [Google Scholar] [CrossRef]

- Kang, S.; Shin, J. The effect of laser beam intensity distribution on weld characteristics in laser welded aluminum alloy (AA5052). Opt. Laser Technol. 2021, 142, 107239. [Google Scholar] [CrossRef]

- Kang, S.; Shin, J. Laser beam oscillation welding of aluminum alloy using the spatially modulated beam by diffractive optical element (DOE). J. Manuf. Process. 2021, 66, 387–396. [Google Scholar] [CrossRef]

- Volpp, J.; Vollertsen, F. Impact of multi-focus beam shaping on the process stability. Opt. Laser Technol. 2019, 112, 278–283. [Google Scholar] [CrossRef]

- Ono, M.; Shinbo, Y.; Yoshitake, A.; Ohmura, M. Development of laser-arc hybrid welding. NKK Tech. Rev. 2002, 86, 8–12. [Google Scholar]

- Braun, R. Nd:YAG laser butt welding of AA6013 using silicon and magnesium containing filler powders. Mater. Sci. Eng. A 2006, 426, 250–262. [Google Scholar] [CrossRef]

- Finke, B.; Finke, M.; Kapadia, P.; Dowden, J.; Simon, G. Numerical investigation of the Knudsen-layer, appearing in the laser-induced evaporation of metals. Proc. SPIE 1990, 1279. [Google Scholar] [CrossRef]

- Pang, S.; Shao, X.; Li, W.; Chen, X.; Gong, S. Dynamic characteristics and mechanisms of compressible metallic vapor plume behaviors in transient keyhole during deep penetration fiber laser welding. Appl. Phys. A 2016, 122, 702. [Google Scholar] [CrossRef]

- Tenner, F.; Brock, C.; Gürtler, F.-J.; Klämpfl, F.; Schmidt, M. Experimental and numerical analysis of gas dynamics in the keyhole during laser metal welding. Phys. Procedia 2014, 56, 1268–1276. [Google Scholar] [CrossRef] [Green Version]

- Paleocrassas, A.G.; Tu, J.F. Inherent instability investigation for low speed laser welding of aluminum using a single-mode fiber laser. J. Mater. Process. Technol. 2010, 210, 1411–1418. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y.; Mizutani, M. Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys. Procedia 2010, 5, 9–17. [Google Scholar] [CrossRef] [Green Version]

- Ion, J. Laser Processing of Engineering Materials: Principles, Procedure and Industrial Application; Butterworth-Heinemann: Oxford, UK, 2005. [Google Scholar]

- Matsunawa, A.; Kim, J.-D.; Takemoto, T.; Katayama, S. Spectroscopic studies on laser induced plume of aluminum alloys. Int. Congr. Appl. Lasers Electro. Opt. 1995, 1995, 719–728. [Google Scholar] [CrossRef]

- Greses, J.; Hilton, P.A.; Barlow, C.Y.; Steen, W.M. Plume attenuation under high power Nd:YAG laser welding. Int. Congr. Appl. Lasers Electro. Opt. 2002, 2002, 47727. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Hu, M.; Guo, L.; Wang, Z.; Zeng, X. Characteristics of plasma plume in fiber laser welding of aluminum alloy. Appl. Surf. Sci. 2015, 326, 181–186. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, M.; Zeng, X. Influences of synergy effect between laser and arc on laser-arc hybrid welding of aluminum alloys. Opt. Laser Technol. 2019, 120, 105766. [Google Scholar] [CrossRef]

- Zhang, X.; Ashida, E.; Katayama, S.; Mizutani, M. Development of ultra deep penetration welding with 10 kW fiber laser. Int. Congr. Appl. Lasers Electro. Opt. 2008, 2008, 705. [Google Scholar] [CrossRef]

- Wang, J.; Peng, G.; Li, L.; Si, C.; Meng, S.; Gong, J. 30 kW-level laser welding characteristics of 5A06 aluminum alloy thick plate under subatmospheric pressure. Opt. Laser Technol. 2019, 119, 105668. [Google Scholar] [CrossRef]

- Lee, K.-D.; Park, K.-Y. A study on the process robustness of Nd:YAG laser-MIG hybrid welding of aluminum alloy 6061-T6. Int. Congr. Appl. Lasers Electro. Opt. 2003, 2003, 307. [Google Scholar] [CrossRef]

- Bagger, C.; Olsen, F. Review of laser hybrid welding. J. Laser Appl. 2005, 17, 2–14. [Google Scholar] [CrossRef]

- Acherjee, B. Hybrid laser arc welding: State-of-art review. Opt. Laser Technol. 2018, 99, 60–71. [Google Scholar] [CrossRef]

- Vollertsen, F.; Thomy, C. Laser-arc hybrid welding—Recent advances in research and application. Pac. Int. Conf. Appl. Lasers Opt. 2010, 2010, 501. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y.; Mizutani, M. Understanding of laser and hybrid welding phenomena. Mater. Sci. Forum 2008, 580–582, 535–538. [Google Scholar] [CrossRef]

- Mahrle, A.; Beyer, E. Hybrid laser beam welding—Classification, characteristics, and applications. J. Laser Appl. 2006, 18, 169–180. [Google Scholar] [CrossRef]

- Petring, D.; Fuhrmann, C.; Wolf, N.; Poprawe, R. Investigations and applications of laser-arc hybrid welding from thin sheets up to heavy section components. Int. Congr. Appl. Lasers Electro. Opt. 2003, 2003, 301. [Google Scholar] [CrossRef]

- Nielsen, S.E.; Anderson, M.M.; Kristensen, J.K.; Jensen, T.A. Hybrid welding of thick section C/Mn steel and aluminum. In Proceedings of the IIW Commission XII during International Institute of Welding Annual Assembly, Copenhagen, Denmark, 26–28 June 2002. IIW document, XII 1731-02. [Google Scholar]

- Eriksson, I.; Powell, J.; Kaplan, A. Guidelines in the choice of parameters for hybrid laser arc welding with fiber lasers. Phys. Procedia 2013, 41, 119–127. [Google Scholar] [CrossRef] [Green Version]

- Frostevarg, J. The Morphology of Laser Arc Hybrid Welds. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2014. [Google Scholar]

- Moradi, M.; Ghoreishi, M.; Frostevarg, J.; Kaplan, A.F.H. An investigation on stability of laser hybrid arc welding. Opt. Lasers Eng. 2013, 51, 481–487. [Google Scholar] [CrossRef]

- Aalderink, B.J.; Pathiraj, B.; Aarts, R.G.K.M. Seam gap bridging of laser based processes for the welding of aluminium sheets for industrial applications. Int. J. Adv. Manuf. Technol. 2010, 48, 143–154. [Google Scholar] [CrossRef]

- Le Guen, E.; Fabbro, R.; Carin, M.; Coste, F.; Le Masson, P. Analysis of hybrid Nd:Yag laser-MAG arc welding processes. Opt. Laser Technol. 2011, 43, 1155–1166. [Google Scholar] [CrossRef] [Green Version]

- ISO 12932. Welding—Laser-Arc Hybrid Welding of Steels, Nickel and Nickel Alloys—Quality Levels for Imperfections; International Organization for Standardization: Geneva, Switzerland, 2013; Volume 25. [Google Scholar]

- Reisgen, U.; Olschok, S.; Jakobs, S.; Engels, O. Modern hybrid welding process for structural steelwork engineering—Laser submerged arc hybrid welding. J. Laser Appl. 2016, 28, 022011. [Google Scholar] [CrossRef]

- Zou, J.L.; Wu, S.K.; Xiao, R.S.; Li, F. Effects of a paraxial TIG arc on high-power fiber laser welding. Mater. Des. 2015, 86, 321–327. [Google Scholar] [CrossRef]

- Hayashi, T.; Katayama, S.; Abe, N.; Omori, A. High-power CO2 laser-MIG hybrid welding for increased gap tolerance. Hybrid weldability of thick steel plates with a square groove. Weld. Int. 2004, 18, 692–701. [Google Scholar] [CrossRef]

- Cao, X.; Wanjara, P.; Huang, J.; Munro, C.; Nolting, A. Hybrid fiber laser—Arc welding of thick section high strength low alloy steel. Mater. Des. 2011, 32, 3399–3413. [Google Scholar] [CrossRef] [Green Version]

- ISO 15614-14. Specification and Qualification of Welding Procedures for Metallic Materials—Welding Procedure Test—Part 14: Laser-Arc Hybrid Welding of Steels, Nickel and Nickel Alloys; International Organization for Standardization: Geneva, Switzerland, 2013; Volume 24. [Google Scholar]

- Bunaziv, I.; Akselsen, O.M.; Ren, X.; Salminen, A. Hybrid welding possibilities of thick sections for arctic applications. Phys. Procedia 2015, 78, 74–83. [Google Scholar] [CrossRef] [Green Version]

- Kutsuna, M.; Chen, L. Interaction of both plasmas in CO2 laser-MAG hybrid welding of carbon steel. In Proceedings of the LAMP 2002: International Congress on Laser Advanced Materials Processing, Osaka, Japan, 27–31 May 2002; pp. 341–346. [Google Scholar]

- Reutzel, E.W.; Kelly, S.M.; Sullivan, M.J.; Huang, T.D.; Kvidahl, L.; Martukanitz, R.P. Hybrid laser-GMA welding for improved affordability. J. Ship Prod. 2008, 24, 72–81. [Google Scholar] [CrossRef]

- Hu, B.; den Ouden, G. Synergetic effects of hybrid laser/arc welding. Sci. Technol. Weld. Join. 2005, 10, 427–431. [Google Scholar] [CrossRef]

- Thomy, C.; Vollertsen, F. Laser-mig hybrid welding of aluminium to steel—Effect of process parameters on joint properties. Weld. World 2012, 56, 124–132. [Google Scholar] [CrossRef]

- Weman, K. MIG Welding Guide; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Chen, X.; Yu, G.; He, X.; Li, S.; Miao, H. Effect of droplet impact on molten pool dynamics in hybrid laser-MIG welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 96, 209–222. [Google Scholar] [CrossRef] [Green Version]

- Bunaziv, I.; Frostevarg, J.; Akselsen, O.M.; Kaplan, A.F.H. Process stability during fiber laser-arc hybrid welding of thick steel plates. Opt. Lasers Eng. 2018, 102, 34–44. [Google Scholar] [CrossRef]

- Mahrle, A.; Schnick, M.; Rose, S.; Demuth, C.; Beyer, E.; Füssel, U. Process characteristics of fibre-laser-assisted plasma arc welding. J. Phys. D Appl. Phys. 2011, 44. [Google Scholar] [CrossRef]

- Doi, M. Coaxial hybrid process of hollow cathode TIG and YAG laser welding. Weld. Int. 2010, 24, 188–196. [Google Scholar] [CrossRef]

- Gu, X.; Li, H.; Yang, L.; Gao, Y. Coupling mechanism of laser and arcs of laser-twin-arc hybrid welding and its effect on welding process. Opt. Laser Technol. 2013, 48, 246–253. [Google Scholar] [CrossRef]

- Fellman, A.; Salminen, A. Study of the phenomena of fiber laser-MAG hybrid welding. In Proceedings of the 26th International Congress on Applications of Lasers and Electro-Optics (ICALEO), Orlando, FL, USA, 29 October–1 November 2007; pp. 871–880. [Google Scholar]

- Tsukamoto, S.; Sugino, T.; Nakamura, T.; Arakane, G. Fundamental study on welding phenomena in pulsed laser-GMA hybrid welding. In Proceedings of the 24th International Congress on Applications of Lasers and Electro-Optics (ICALEO), Miami, FL, USA, 29 October–1 November 2005; pp. 108–116. [Google Scholar]

- Wang, J.; Wang, C.; Meng, X.; Hu, X.; Yu, Y.; Yu, S. Interaction between laser-induced plasma/vapor and arc plasma during fiber laser-MIG hybrid welding. J. Mech. Sci. Technol. 2011, 25, 1529. [Google Scholar] [CrossRef]

- Pickin, C.G.; Young, K. Evaluation of cold metal transfer (CMT) process for welding aluminium alloy. Sci. Technol. Weld. Join. 2006, 11, 583–585. [Google Scholar] [CrossRef]

- Elrefaey, A. Effectiveness of cold metal transfer process for welding 7075 aluminium alloys. Sci. Technol. Weld. Join. 2015, 20, 280–285. [Google Scholar] [CrossRef]

- Hu, B.; den Ouden, G. Laser induced stabilisation of the welding arc. Sci. Technol. Weld. Join. 2005, 10, 76–81. [Google Scholar] [CrossRef]

- Gatzen, M. Influence of low-frequency magnetic fields during laser beam welding of aluminium with filler wire. Phys. Procedia 2012, 39, 59–66. [Google Scholar] [CrossRef] [Green Version]

- Gatzen, M.; Tang, Z.; Vollertsen, F. Effect of electromagnetic stirring on the element distribution in laser beam welding of aluminium with filler wire. Phys. Procedia 2011, 12, 56–65. [Google Scholar] [CrossRef] [Green Version]

- Otto, A.; Schmidt, M. Towards a universal numerical simulation model for laser material processing. Phys. Procedia 2010, 5, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Pang, S.; Chen, X.; Zhou, J.; Shao, X.; Wang, C. 3D transient multiphase model for keyhole, vapor plume, and weld pool dynamics in laser welding including the ambient pressure effect. Opt. Lasers Eng. 2015, 74, 47–58. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Li, W.; Shao, X.; Gong, S. Efficient multiple time scale method for modeling compressible vapor plume dynamics inside transient keyhole during fiber laser welding. Opt. Laser Technol. 2016, 77, 203–214. [Google Scholar] [CrossRef]

- Otto, A.; Vázquez, R.G.; Hartel, U.; Mosbah, S. Numerical analysis of process dynamics in laser welding of Al and Cu. Procedia CIRP 2018, 74, 691–695. [Google Scholar] [CrossRef]

- Huber, S.; Glasschroeder, J.; Zaeh, M.F. Analysis of the metal vapour during laser beam welding. Phys. Procedia 2011, 12, 712–719. [Google Scholar] [CrossRef] [Green Version]

- Xiangzhong, J.; Licheng, Z.; Yuanyong, C. Direct observation of keyhole plasma characteristics in deep penetration laser welding of aluminum alloy 6016. J. Phys. D Appl. Phys. 2012, 45, 245205. [Google Scholar]

- Cai, C.; He, S.; Chen, H.; Zhang, W. The influences of Ar-He shielding gas mixture on welding characteristics of fiber laser-MIG hybrid welding of aluminum alloy. Opt. Laser Technol. 2019, 113, 37–45. [Google Scholar] [CrossRef]

- Murphy, A.B. Influence of metal vapour on arc temperatures in gas–metal arc welding: Convection versus radiation. J. Phys. D Appl. Phys. 2013, 46, 224004. [Google Scholar] [CrossRef]

- Murphy, A.B. A self-consistent three-dimensional model of the arc, electrode and weld pool in gas–metal arc welding. J. Phys. D Appl. Phys. 2011, 44, 194009. [Google Scholar] [CrossRef]

- Lu, F.; Wang, H.-P.; Murphy, A.B.; Carlson, B.E. Analysis of energy flow in gas metal arc welding processes through self-consistent three-dimensional process simulation. Int. J. Heat Mass Transf. 2014, 68, 215–223. [Google Scholar] [CrossRef]

- Seidgazov, R.D. Thermocapillary mechanism of melt displacement during keyhole formation by the laser beam. J. Phys. D Appl. Phys. 2009, 42, 175501. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, X.; Liu, T.; Kang, Y.; Zhan, X. Investigate on the porosity morphology and formation mechanism in laser-MIG hybrid welded joint for 5A06 aluminum alloy with Y-shaped groove. J. Manuf. Process. 2020, 57, 847–856. [Google Scholar] [CrossRef]

- Kutsuna, M.; Yan, Q. Study on porosity formation in laser welds in aluminium alloys (Report 1): Effects of hydrogen and alloying elements. Weld. Int. 1998, 12, 937–949. [Google Scholar] [CrossRef]

- Enz, J.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Fibre laser welding of high-alloyed Al–Zn–Mg–Cu alloys. J. Mater. Process. Technol. 2016, 237, 155–162. [Google Scholar] [CrossRef]

- Beiranvand, Z.M.; Ghaini, F.M.; Naffakh-moosavy, H.; Sheikhi, M.; Torkamany, M.J. Magnesium loss in Nd:YAG pulsed laser welding of aluminum alloys. Metall. Mater. Trans. B 2018, 49, 2896–2905. [Google Scholar] [CrossRef]

- Yan, S.; Chen, H.; Zhu, Z.; Gou, G. Hybrid laser-metal inert gas welding of Al–Mg–Si alloy joints: Microstructure and mechanical properties. Mater. Des. 2014, 61, 160–167. [Google Scholar] [CrossRef]

- Schempp, P.; Rethmeier, M. Understanding grain refinement in aluminium welding. Weld. World 2015, 59, 767–784. [Google Scholar] [CrossRef]

- Han, R.; Li, Y.; Lu, S. Macro-micro modeling and simulation for the morphological evolution of the solidification structures in the entire weld. Int. J. Heat Mass Transf. 2017, 106, 1345–1355. [Google Scholar] [CrossRef] [Green Version]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley: Hoboken, NJ, USA, 2003; p. 480. [Google Scholar]

- Han, R.; Lu, S.; Dong, W.; Li, D.; Li, Y. The morphological evolution of the axial structure and the curved columnar grain in the weld. J. Cryst. Growth 2015, 431, 49–59. [Google Scholar] [CrossRef]

- Peng, G.; Li, L.; Wang, J.; Xia, H.; Meng, S.; Gong, J. Effect of subatmospheric pressures on weld formation and mechanical properties during disk laser welding of 5A06 aluminium alloy. J. Mater. Process. Technol. 2020, 277, 116457. [Google Scholar] [CrossRef]

- Geng, S.; Jiang, P.; Shao, X.; Guo, L.; Mi, G.; Wu, H.; Wang, C.; Han, C.; Gao, S. Identification of nucleation mechanism in laser welds of aluminum alloy. Appl. Phys. A 2019, 125, 396. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Zhang, C.; Zeng, X. Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy. Mater. Des. 2016, 108, 707–717. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, T.; Yang, W.; Xiao, R.; Liu, Z.; Li, L. Microstructure and mechanical properties of laser beam-welded AA2060 Al-Li alloy. J. Mater. Process. Technol. 2016, 237, 301–308. [Google Scholar] [CrossRef]

- Kostrivas, A.; Lippold, J.C. Weldability of Li-bearing aluminium alloys. Int. Mater. Rev. 1999, 44, 217–237. [Google Scholar] [CrossRef]

- Cui, L.; Li, X.; He, D.; Chen, L.; Gong, S. Effect of Nd:YAG laser welding on microstructure and hardness of an Al–Li based alloy. Mater. Charact. 2012, 71, 95–102. [Google Scholar] [CrossRef]

- Fu, B.; Qin, G.; Meng, X.; Ji, Y.; Zou, Y.; Lei, Z. Microstructure and mechanical properties of newly developed aluminum–lithium alloy 2A97 welded by fiber laser. Mater. Sci. Eng. A 2014, 617, 1–11. [Google Scholar] [CrossRef]

- Jiang, P.; Gao, S.; Geng, S.; Han, C.; Mi, G. Multi-physics multi-scale simulation of the solidification process in the molten pool during laser welding of aluminum alloys. Int. J. Heat Mass Transf. 2020, 161, 120316. [Google Scholar] [CrossRef]

- Yu, F.; Wei, Y.; Liu, X. The evolution of polycrystalline solidification in the entire weld: A phase-field investigation. Int. J. Heat Mass Transf. 2019, 142, 118450. [Google Scholar] [CrossRef]

- Bailey, N.S.; Hong, K.-M.; Shin, Y.C. Comparative assessment of dendrite growth and microstructure predictions during laser welding of Al 6061 via 2D and 3D phase field models. Comput. Mater. Sci. 2020, 172, 109291. [Google Scholar] [CrossRef]

- Geng, S.; Jiang, P.; Shao, X.; Guo, L.; Gao, X. Heat transfer and fluid flow and their effects on the solidification microstructure in full-penetration laser welding of aluminum sheet. J. Mater. Sci. Technol. 2020, 46, 50–63. [Google Scholar] [CrossRef]

- Geng, S.; Jiang, P.; Guo, L.; Gao, X.; Mi, G. Multi-scale simulation of grain/sub-grain structure evolution during solidification in laser welding of aluminum alloys. Int. J. Heat Mass Transf. 2020, 149, 119252. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Liu, L. Research on laser-TIG Hybrid welding of 6061-T6 aluminum alloys joint and post heat treatment. Metals 2020, 10, 130. [Google Scholar] [CrossRef] [Green Version]

- Monteiro, W.A. Mechanical behavior of precipitation hardened aluminum alloys welds. Light Met. Alloys Appl. 2014, 44. [Google Scholar]

- Hagenlocher, C.; Fetzer, F.; Weller, D.; Weber, R.; Graf, T. Explicit analytical expressions for the influence of welding parameters on the grain structure of laser beam welds in aluminium alloys. Mater. Des. 2019, 174, 107791. [Google Scholar] [CrossRef]

- Cruz, K.S.; Meza, E.S.; Fernandes, F.A.P.; Quaresma, J.M.V.; Casteletti, L.C.; Garcia, A. Dendritic arm spacing affecting mechanical properties and wear behavior of Al-Sn and Al-Si alloys directionally solidified under unsteady-state conditions. Metall. Mater. Trans. A 2010, 41, 972–984. [Google Scholar] [CrossRef]

- ISO 13919-2. Welding—Electron and Laser-Beam Welded Joints—Guidance on Quality Levels for Imperfections—Part 2: Aluminium and its Weldable Alloys; International Organization for Standardization: Geneva, Switzerland, 2001. [Google Scholar]

- Hekmatjou, H.; Naffakh-Moosavy, H. Hot cracking in pulsed Nd:YAG laser welding of AA5456. Opt. Laser Technol. 2018, 103, 22–32. [Google Scholar] [CrossRef]

- Stritt, P.; Weber, R.; Graf, T.; Mueller, S.; Weberpals, J.-P. New hot cracking criterion for laser welding in close-edge position. Int. Congr. Appl. Lasers Electro. Opt. 2012, 2012, 357–366. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Hagenlocher, C.; Stritt, P.; Weber, R.; Graf, T. Strain signatures associated to the formation of hot cracks during laser beam welding of aluminum alloys. Opt. Lasers Eng. 2018, 100, 131–140. [Google Scholar] [CrossRef]

- Steenbergen, J.E.; Thornton, H.R. A Quantitative determination of the conditions for hot cracking during welding for aluminum alloys. Weld. J. 1970, 49, 61–68. [Google Scholar]

- Ploshikhin, V.; Prikhodovsky, A.; Makhutin, M.; Zoch, H.-W.; Heimerdinger, C.; Palm, F. Multi-beam welding: Advanced technique for crack-free laser welding. In Proceedings of the Laser Assisted Net Shape Engineering, Erlangen, Germany, 21–24 September 2004; pp. 131–136. [Google Scholar]

- Hagenlocher, C.; Seibold, M.; Weber, R.; Graf, T. Modulation of the local grain structure in laser beam welds to inhibit the propagation of centerline hot cracks. Procedia CIRP 2018, 74, 434–437. [Google Scholar] [CrossRef]

- Ola, O.T.; Doern, F.E. Fusion weldability studies in aerospace AA7075-T651 using high-power continuous wave laser beam techniques. Mater. Des. 2015, 77, 50–58. [Google Scholar] [CrossRef]

- Wang, X.; Lu, F.; Wang, H.-P.; Qu, Z.; Xia, L. Micro-scale model based study of solidification cracking formation mechanism in Al fiber laser welds. J. Mater. Process. Technol. 2016, 231, 18–26. [Google Scholar] [CrossRef]

- Cross, C.E. On the origin of weld solidification cracking. In Hot Cracking Phenomena in Welds; Böllinghaus, T., Herold, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 1, pp. 3–18. [Google Scholar]

- Grong, O. Metallurgical Modelling of Welding; Maney Pub: Cambridge, UK, 1994. [Google Scholar]

- Coniglio, N.; Cross, C.E. Mechanisms for solidification crack initiation and growth in aluminum welding. Metall. Mater. Trans. A 2009, 40, 2718–2728. [Google Scholar] [CrossRef]

- Zhang, Q.; Sun, D.; Pan, S.; Zhu, M. Microporosity formation and dendrite growth during solidification of aluminum alloys: Modeling and experiment. Int. J. Heat Mass Transf. 2020, 146, 118838. [Google Scholar] [CrossRef]

- Kou, S. A criterion for cracking during solidification. Acta Mater. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Liu, J.; Kou, S. Effect of diffusion on susceptibility to cracking during solidification. Acta Mater. 2015, 100, 359–368. [Google Scholar] [CrossRef] [Green Version]

- Geng, S.; Jiang, P.; Shao, X.; Mi, G.; Wu, H.; Ai, Y.; Wang, C.; Han, C.; Chen, R.; Liu, W.; et al. Effects of back-diffusion on solidification cracking susceptibility of Al-Mg alloys during welding: A phase-field study. Acta Mater. 2018, 160, 85–96. [Google Scholar] [CrossRef]

- Geng, S.; Jiang, P.; Shao, X.; Mi, G.; Wu, H.; Ai, Y.; Wang, C.; Han, C.; Chen, R.; Liu, W. Comparison of solidification cracking susceptibility between Al-Mg and Al-Cu alloys during welding: A phase-field study. Scr. Mater. 2018, 150, 120–124. [Google Scholar] [CrossRef]

- Liu, J.; Kou, S. Susceptibility of ternary aluminum alloys to cracking during solidification. Acta Mater. 2017, 125, 513–523. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Duarte, H.P.; Kou, S. Evidence of back diffusion reducing cracking during solidification. Acta Mater. 2017, 122, 47–59. [Google Scholar] [CrossRef] [Green Version]

- Guan, R.-G.; Tie, D. A Review on grain refinement of aluminum alloys: Progresses, challenges and prospects. Acta Metall. Sin. 2017, 30, 409–432. [Google Scholar] [CrossRef]

- Quested, T.E. Understanding mechanisms of grain refinement of aluminium alloys by inoculation. Mater. Sci. Technol. 2004, 20, 1357–1369. [Google Scholar] [CrossRef]

- Easton, M.A.; StJohn, D.H. A model of grain refinement incorporating alloy constitution and potency of heterogeneous nucleant particles. Acta Mater. 2001, 49, 1867–1878. [Google Scholar] [CrossRef]

- Mohanty, P.S.; Gruzleski, J.E. Mechanism of grain refinement in aluminium. Acta Metall. Mater. 1995, 43, 2001–2012. [Google Scholar] [CrossRef]

- Sigworth, G.K.; Kuhn, T.A. Grain refinement of aluminum casting alloys. Int. J. Met. 2007, 1, 31–40. [Google Scholar] [CrossRef]

- Yunjia, H.; Frost, R.H.; Olson, D.L.; Edwards, G.R. Grain refinement of aluminum weld metal. Weld. J. 1989, 68, 280–289. [Google Scholar]

- Carluccio, D.; Bermingham, M.J.; Zhang, Y.; StJohn, D.H.; Yang, K.; Rometsch, P.A.; Wu, X.; Dargusch, M.S. Grain refinement of laser remelted Al-7Si and 6061 aluminium alloys with Tibor® and scandium additions. J. Manuf. Process. 2018, 35, 715–720. [Google Scholar] [CrossRef]

- Völkers, S.; Scharifi, E.; Sajjadifar, S.V.; Böhm, S.; Weidig, U.; Niendorf, T. On the influence of in situ sound wave superposition on the microstructure of laser welded 7000 aluminum alloys. J. Adv. Join. Process. 2020, 1, 100013. [Google Scholar] [CrossRef]

- Eskin, G.I. Broad prospects for commercial application of the ultrasonic (cavitation) melt treatment of light alloys. Ultrason. Sonochemistry 2001, 8, 319–325. [Google Scholar] [CrossRef]

- Dai, W.-L. Effects of high-intensity ultrasonic-wave emission on the weldability of aluminum alloy 7075-T6. Mater. Lett. 2003, 57, 2447–2454. [Google Scholar] [CrossRef]

- Radel, T.; Woizeschke, P. Reduction of hot cracking susceptibility during laser welding of aluminum by vibrations. Weld. World 2019, 63, 599–606. [Google Scholar] [CrossRef]

- Enz, J.; Carrarin, C.; Riekehr, S.; Ventzke, V.; Kashaev, N. Hot cracking behaviour of an autogenously laser welded Al-Cu-Li alloy. Int. J. Adv. Manuf. Technol. 2018, 95, 299–310. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Hao, Z. A pathway to mitigate macrosegregation of laser-arc hybrid Al-Si welds through beam oscillation. Int. J. Heat Mass Transf. 2020, 151, 119467. [Google Scholar] [CrossRef]

- Chen, C.; Xiang, Y.; Gao, M. Weld formation mechanism of fiber laser oscillating welding of dissimilar aluminum alloys. J. Manuf. Process. 2020, 60, 180–187. [Google Scholar] [CrossRef]

- Liu, F.; Tan, C.; Wu, L.; Gong, X.; Chen, B.; Song, X.; Zhao, H.; Wang, G. Influence of waveforms on Laser-MIG hybrid welding characteristics of 5052 aluminum alloy assisted by magnetic field. Opt. Laser Technol. 2020, 132, 106508. [Google Scholar] [CrossRef]

- Xu, L.; Tang, X.; Zhang, R.; Lu, F.; Cui, H. Weld bead characteristics for full-penetration laser welding of aluminum alloy under electromagnetic field support. J. Mater. Process. Technol. 2021, 288, 116896. [Google Scholar] [CrossRef]

- Sheikhi, M.; Malek Ghaini, F.; Assadi, H. Prediction of solidification cracking in pulsed laser welding of 2024 aluminum alloy. Acta Mater. 2015, 82, 491–502. [Google Scholar] [CrossRef]

- Jia, Z.; Zhang, P.; Yu, Z.; Shi, H.; Liu, H.; Wu, D.; Ye, X.; Wang, F.; Tian, Y. Effect of pulse shaping on solidification process and crack in 5083 aluminum alloy by pulsed laser welding. Opt. Laser Technol. 2021, 134, 106608. [Google Scholar] [CrossRef]

- Zhang, J.; Weckman, D.; Zhou, Y. Effects of temporal pulse shaping on cracking susceptibility of 6061-T6 aluminum Nd:YAG laser welds. Weld. J. 2008, 87. [Google Scholar]

- von Witzendorff, P.; Kaierle, S.; Suttmann, O.; Overmeyer, L. Using pulse shaping to control temporal strain development and solidification cracking in pulsed laser welding of 6082 aluminum alloys. J. Mater. Process. Technol 2015, 225, 162–169. [Google Scholar] [CrossRef]

- Le-Quang, T.; Shevchik, S.A.; Meylan, B.; Vakili-Farahani, F.; Olbinado, M.P.; Rack, A.; Wasmer, K. Why is in situ quality control of laser keyhole welding a real challenge? Procedia CIRP 2018, 74, 649–653. [Google Scholar] [CrossRef]

- Bunaziv, I.; Akselsen, O.M.; Salminen, A.; Unt, A. Fiber laser-MIG hybrid welding of 5mm 5083 aluminum alloy. J. Mater. Process. Technol. 2016, 233, 107–114. [Google Scholar] [CrossRef]

- Sánchez-Amaya, J.M.; Delgado, T.; González-Rovira, L.; Botana, F.J. Laser welding of aluminium alloys 5083 and 6082 under conduction regime. Appl. Surf. Sci. 2009, 255, 9512–9521. [Google Scholar] [CrossRef]

- Katayama, S.; Seto, N.; Mizutani, M.; Matsunawa, A. X-ray transmission in-situ observation of keyhole during laser spot welding and pulse-shaping for prevention of porosity. Int. Congr. Appl. Lasers Electro. Opt. 2001, 2001, 1003–1011. [Google Scholar] [CrossRef]

- Tao, W.; Yang, S. Weld zone porosity elimination process in remote laser welding of AA5182-O aluminum alloy lap-joints. J. Mater. Process. Technol. 2020, 286, 116826. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y. Elucidation of phenomena in high power fiber laser welding, and development of prevention procedures of welding defects. In Proceedings of the SPIE—The International Society for Optical Engineering, San Jose, CA, USA, 19 February 2009. 71951R. [Google Scholar] [CrossRef]

- Miyagi, M.; Kawahito, Y.; Kawakami, H.; Shoubu, T. Dynamics of solid-liquid interface and porosity formation determined through x-ray phase-contrast in laser welding of pure Al. J. Mater. Process. Technol. 2017, 250, 9–15. [Google Scholar] [CrossRef]

- Armstrong, R.E. Control of spiking in partial penetration electron beam welds. Weld. J. 1970, 49, 382–388. [Google Scholar]

- Tong, H.; Giedt, W.H. A dynamic interpretation of electron beam welding. Weld. J. 1970, 259–266. [Google Scholar]

- Weber, C.M.; Funk, E.R.; McMaster, R.C. Penetration mechanism of partial penetration electron beam welding. Weld. J. 1972, 51, 90–94. [Google Scholar]

- Wei, P.S.; Chuang, K.C.; DebRoy, T.; Ku, J.S. Scaling of spiking and humping in keyhole welding. J. Phys. D Appl. Phys. 2011, 44, 245501. [Google Scholar] [CrossRef]

- Otto, A.; Vázquez, R.G.; Hartel, U. Insight into the process. Laser Tech. J. 2018, 15, 40–45. [Google Scholar] [CrossRef] [Green Version]

- Fetzer, F.; Hu, H.; Berger, P.; Weber, R.; Eberhard, P.; Graf, T. Fundamental investigations on the spiking mechanism by means of laser beam welding of ice. J. Laser Appl. 2018, 30, 012009. [Google Scholar] [CrossRef] [Green Version]

- Eriksson, I.; Powell, J.; Kaplan, A.F.H. Melt behavior on the keyhole front during high speed laser welding. Opt. Lasers Eng. 2013, 51, 735–740. [Google Scholar] [CrossRef] [Green Version]

- Eriksson, I.; Powell, J.; Kaplan, A.F.H. Measurements of fluid flow on keyhole front during laser welding. Sci. Technol. Weld. Join. 2011, 16, 636–641. [Google Scholar] [CrossRef]

- Matti, R.S.; Kaplan, A.F.H. Analyzing and post-modelling the high speed images of a wavy laser induced boiling front. Phys. Procedia 2015, 78, 192–201. [Google Scholar] [CrossRef] [Green Version]

- Kaplan, A.F.H. Local absorptivity modulation of a 1 μm-laser beam through surface waviness. Appl. Surf. Sci. 2012, 258, 9732–9736. [Google Scholar] [CrossRef]

- Bunaziv, I.; Wenner, S.; Ren, X.; Frostevarg, J.; Kaplan, A.F.H.; Akselsen, O.M. Filler metal distribution and processing stability in laser-arc hybrid welding of thick HSLA steel. J. Manuf. Process. 2020, 54, 228–239. [Google Scholar] [CrossRef]

- Huang, L.; Hua, X.; Wu, D.; Li, F. Numerical study of keyhole instability and porosity formation mechanism in laser welding of aluminum alloy and steel. J. Mater. Process. Technol. 2018, 252, 421–431. [Google Scholar] [CrossRef]

- Bunaziv, I.; Dørum, C.; Nielsen, S.E.; Suikkanen, P.; Ren, X.; Nyhus, B.; Eriksson, M.; Akselsen, O.M. Laser-arc hybrid welding of 12- and 15-mm thick structural steel. Int. J. Adv. Manuf. Technol. 2020, 107, 2649–2669. [Google Scholar] [CrossRef] [Green Version]

- Katayama, S.; Nagayama, H.; Mizutani, M.; Kawahito, Y. Fibre laser welding of aluminium alloy. Weld. Int. 2009, 23, 744–752. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Yang, C.; Gao, M. Study of porosity suppression in oscillating laser-MIG hybrid welding of AA6082 aluminum alloy. J. Mater. Process. Technol. 2021, 292, 117053. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Zhang, M.; Zhou, Y.; Zhang, Y. Dynamic keyhole profile during high-power deep-penetration laser welding. J. Mater. Process. Technol. 2014, 214, 565–570. [Google Scholar] [CrossRef]

- Chen, X.; Pang, S.; Shao, X.; Wang, C.; Zhang, X.; Jiang, P.; Xiao, J. Sub-microsecond vapor plume dynamics under different keyhole penetration regimes in deep penetration laser welding. J. Phys. D Appl. Phys. 2017, 50, 205601. [Google Scholar] [CrossRef]

- Panwisawas, C.; Sovani, Y.; Turner, R.P.; Brooks, J.W.; Basoalto, H.C.; Choquet, I. Modelling of thermal fluid dynamics for fusion welding. J. Mater. Process. Technol. 2018, 252, 176–182. [Google Scholar] [CrossRef]

- Schneider, A.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Laser beam welding of aluminum alloys under the influence of an electromagnetic field. Phys. Procedia 2013, 41, 4–11. [Google Scholar] [CrossRef] [Green Version]

- Bachmann, M.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Experimental and Numerical Investigation of an Electromagnetic Weld Pool Control for Laser Beam Welding. Phys. Procedia 2014, 56, 515–524. [Google Scholar] [CrossRef] [Green Version]

- Deutsch, M.G.; Punkari, A.; Weckman, D.C.; Kerr, H.W. Weldability of 1.6 mm thick aluminium alloy 5182 sheet by single and dual beam Nd: YAG laser welding. Sci. Technol. Weld. Join. 2003, 8, 246–256. [Google Scholar] [CrossRef]

- Fetzer, F.; Sommer, M.; Weber, R.; Weberpals, J.-P.; Graf, T. Reduction of pores by means of laser beam oscillation during remote welding of AlMgSi. Opt. Lasers Eng. 2018, 108, 68–77. [Google Scholar] [CrossRef]

- Li, S.; Mi, G.; Wang, C. A study on laser beam oscillating welding characteristics for the 5083 aluminum alloy: Morphology, microstructure and mechanical properties. J. Manuf. Process. 2020, 53, 12–20. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, Y.; Chen, C.; Zeng, X.; Gao, M. Suppressing porosity of a laser keyhole welded Al-6Mg alloy via beam oscillation. J. Mater. Process. Technol. 2020, 278, 116382. [Google Scholar] [CrossRef]

- Liu, T.; Mu, Z.; Hu, R.; Pang, S. Sinusoidal oscillating laser welding of 7075 aluminum alloy: Hydrodynamics, porosity formation and optimization. Int. J. Heat Mass Transf. 2019, 140, 346–358. [Google Scholar] [CrossRef]

- Li, L.; Gong, J.; Xia, H.; Peng, G.; Hao, Y.; Meng, S.; Wang, J. Influence of scan paths on flow dynamics and weld formations during oscillating laser welding of 5A06 aluminum alloy. J. Mater. Res. Technol. 2021, 11, 19–32. [Google Scholar] [CrossRef]

- Ke, W.; Bu, X.; Oliveira, J.P.; Xu, W.; Wang, Z.; Zeng, Z. Modeling and numerical study of keyhole-induced porosity formation in laser beam oscillating welding of 5A06 aluminum alloy. Opt Laser Technol. 2021, 133, 106540. [Google Scholar] [CrossRef]

- Wu, Q.; Xiao, R.S.; Zou, J.L.; Xu, J.J. Weld formation mechanism during fiber laser welding of aluminum alloys with focus rotation and vertical oscillation. J. Manuf. Process. 2018, 36, 149–154. [Google Scholar] [CrossRef]

- Katayama, S.; Naito, Y.; Uchiumi, S.; Mizutani, S. Physical phenomena and porosity prevention mechanism in laser-arc hybrid welding. Trans. JWRI 2006, 35, 13–18. [Google Scholar]

- Leo, P.; Renna, G.; Casalino, G.; Olabi, A.G. Effect of power distribution on the weld quality during hybrid laser welding of an Al–Mg alloy. Opt. Laser Technol. 2015, 73, 118–126. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Leo, P.; Benyounis, K.Y.; Olabi, A.G. Study on arc and laser powers in the hybrid welding of AA5754 Al-alloy. Mater. Des. 2014, 61, 191–198. [Google Scholar] [CrossRef]

- Ola, O.T.; Doern, F.E. Keyhole-induced porosity in laser-arc hybrid welded aluminum. Int. J. Adv. Manuf. Technol. 2015, 80, 3–10. [Google Scholar] [CrossRef]

- Campana, G.; Ascari, A.; Fortunato, A.; Tani, G. Hybrid laser-MIG welding of aluminum alloys: The influence of shielding gases. Appl. Surf. Sci. 2009, 255, 5588–5590. [Google Scholar] [CrossRef]

- Tani, G.; Campana, G.; Fortunato, A.; Ascari, A. The influence of shielding gas in hybrid LASER–MIG welding. Appl. Surf. Sci. 2007, 253, 8050–8053. [Google Scholar] [CrossRef]

- Tani, G.; Ascari, A.; Campana, G.; Fortunato, A. A study on shielding gas contamination in laser welding of non-ferrous alloys. Appl. Surf. Sci. 2007, 254, 904–907. [Google Scholar] [CrossRef]

- Ancona, A.; Sibillano, T.; Tricarico, L.; Spina, R.; Lugarà, P.M.; Basile, G.; Schiavone, S. Comparison of two different nozzles for laser beam welding of AA5083 aluminium alloy. J. Mater. Process. Technol. 2005, 164–165, 971–977. [Google Scholar] [CrossRef]

- Grevey, D.; Sallamand, P.; Cicala, E.; Ignat, S. Gas protection optimization during Nd:YAG laser welding. Opt. Laser Technol. 2005, 37, 647–651. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Dal Maso, U.; Ludovico, A.D. Arc leading versus laser leading in the hybrid welding of aluminium alloy using a fiber laser. Procedia CIRP 2013, 12, 151–156. [Google Scholar] [CrossRef]

- Huang, L.; Wu, D.; Hua, X.; Liu, S.; Jiang, Z.; Li, F.; Wang, H.; Shi, S. Effect of the welding direction on the microstructural characterization in fiber laser-GMAW hybrid welding of 5083 aluminum alloy. J. Manuf. Process. 2018, 31, 514–522. [Google Scholar] [CrossRef]

- Jiang, Z.; Hua, X.; Huang, L.; Wu, D.; Li, F.; Zhang, Y. Double-sided hybrid laser-MIG welding plus MIG welding of 30-mm-thick aluminium alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 903–913. [Google Scholar] [CrossRef]

- Ascari, A.; Fortunato, A.; Orazi, L.; Campana, G. The influence of process parameters on porosity formation in hybrid LASER-GMA welding of AA6082 aluminum alloy. Opt. Laser Technol. 2012, 44, 1485–1490. [Google Scholar] [CrossRef]

- Schmidt, L.; Schricker, K.; Bergmann, J.P.; Junger, C. Effect of local gas flow in full penetration laser beam welding with high welding speeds. Appl. Sci. 2020, 10, 1867. [Google Scholar] [CrossRef] [Green Version]

- Han, X.; Yang, Z.; Ma, Y.; Shi, C.; Xin, Z. Porosity distribution and mechanical response of laser-MIG hybrid butt welded 6082-T6 aluminum alloy joint. Opt. Laser Technol. 2020, 132, 106511. [Google Scholar] [CrossRef]

- Bunaziv, I.; Frostevarg, J.; Akselsen, O.M.; Kaplan, A.F.H. The penetration efficiency of thick plate laser-arc hybrid welding. Int. J. Adv. Manuf. Technol. 2018, 97, 2907–2919. [Google Scholar] [CrossRef]

- Frostevarg, J. Factors affecting weld root morphology in laser keyhole welding. Opt. Lasers Eng. 2018, 101, 89–98. [Google Scholar] [CrossRef]

- Andersen, M.M.; Jensen, T.A. Hybrid Nd:YAG laser + MIG welding in aluminium. In Proceedings of the 8th Nordic Conference Laser Materials Processing (NOLAMP), Copenhagen, Denmark, 13–15 August 2001; pp. 371–380. [Google Scholar]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The influence of porosity on fatigue crack initiation in additively manufactured titanium components. Sci. Rep. 2017, 7, 7308. [Google Scholar] [CrossRef]

- Yan, S.; Xing, B.; Zhou, H.; Xiao, Y.; Qin, Q.-H.; Chen, H. Effect of filling materials on the microstructure and properties of hybrid laser welded Al-Mg-Si alloys joints. Mater. Charact. 2018, 144, 205–218. [Google Scholar] [CrossRef]

- Yan, S.; Nie, Y.; Zhu, Z.; Chen, H.; Gou, G.; Yu, J.; Wang, G. Characteristics of microstructure and fatigue resistance of hybrid fiber laser-MIG welded Al–Mg alloy joints. Appl. Surf. Sci. 2014, 298, 12–18. [Google Scholar] [CrossRef]

- Wu, S.-C.; Hu, Y.-N.; Song, Z.; Ding, S.-S.; Fu, Y.-N. Fatigue behaviors of laser hybrid welded AA7020 due to defects via synchrotron X-ray microtomography. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2232–2246. [Google Scholar] [CrossRef]

- Oliveira, P.I.; Costa, J.M.; Loureiro, A. Effect of laser beam welding parameters on morphology and strength of dissimilar AA2024/AA7075 T-joints. J. Manuf. Process. 2018, 35, 149–160. [Google Scholar] [CrossRef]

- Ancona, A.; Lugarà, P.M.; Sorgente, D.; Tricarico, L. Mechanical characterization of CO2 laser beam butt welds of AA5083. J. Mater. Process. Technol. 2007, 191, 381–384. [Google Scholar] [CrossRef]

- Wei, P.S. Thermal science of weld bead defects: A review. J. Heat Transf. 2010, 133, 031005. [Google Scholar] [CrossRef]

- Bachmann, M.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Numerical assessment and experimental verification of the influence of the Hartmann effect in laser beam welding processes by steady magnetic fields. Int. J. Therm. Sci. 2016, 101, 24–34. [Google Scholar] [CrossRef]

- Bachmann, M.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. About the influence of a steady magnetic field on weld pool dynamics in partial penetration high power laser beam welding of thick aluminium parts. Int. J. Heat Mass Transf. 2013, 60, 309–321. [Google Scholar] [CrossRef]

- Chen, J.; Wei, Y.; Zhan, X.; Li, Y.; Ou, W.; Zhang, T. Melt flow and thermal transfer during magnetically supported laser beam welding of thick aluminum alloy plates. J. Mater. Process. Technol. 2018, 254, 325–337. [Google Scholar] [CrossRef]

- Zhan, X.; Zhou, J.; Sun, W.; Chen, J.; Wei, Y. Effect of external applied steady magnetic field on the morphology of laser welding joint of 4-mm 2024 aluminum alloy. Appl. Phys. A 2017, 123, 106. [Google Scholar] [CrossRef]

- Chen, J.; Wei, Y.; Zhan, X.; Gao, Q.; Zhang, D.; Gao, X. Influence of magnetic field orientation on molten pool dynamics during magnet-assisted laser butt welding of thick aluminum alloy plates. Opt. Laser Technol. 2018, 104, 148–158. [Google Scholar] [CrossRef]

- Chen, J.; Wei, Y.; Zhan, X.; Pan, P. Weld profile, microstructure, and mechanical property of laser-welded butt joints of 5A06 Al alloy with static magnetic field support. Int. J. Adv. Manuf. Technol. 2017, 92, 1677–1686. [Google Scholar] [CrossRef]

- Kawahito, Y.; Uemura, Y.; Doi, Y.; Mizutani, M.; Nishimoto, K.; Kawakami, H.; Tanaka, M.; Fujii, H.; Nakata, K.; Katayama, S. Elucidation of the effect of welding speed on melt flows in high-brightness and high-power laser welding of stainless steel on basis of three-dimensional X-ray transmission in situ observation. Weld. Int. 2017, 31, 206–213. [Google Scholar] [CrossRef]

- Frostevarg, J.; Kaplan, A. Undercut suppression in laser-arc hybrid welding by melt pool tailoring. J. Laser Appl. 2014, 26. [Google Scholar] [CrossRef]

- Karlsson, J.; Norman, P.; Kaplan, A.F.H.; Rubin, P.; Lamas, J.; Yañez, A. Observation of the mechanisms causing two kinds of undercut during laser hybrid arc welding. Appl. Surf. Sci. 2011, 257, 7501–7506. [Google Scholar] [CrossRef]

- Wang, J.-B.; Nishimura, H.; Katayama, S.; Mizutani, M. Welding of aluminium alloy by using filler-added laser-arc hybrid welding process. Weld. Int. 2013, 27, 98–108. [Google Scholar] [CrossRef]

- Kaplan, A.F.H.; Powell, J. Spatter in laser welding. J. Laser Appl. 2011, 23, 032005. [Google Scholar] [CrossRef]

- Ly, S.; Guss, G.; Rubenchik, A.M.; Keller, W.J.; Shen, N.; Negres, R.A.; Bude, J. Resonance excitation of surface capillary waves to enhance material removal for laser material processing. Sci. Rep. 2019, 9, 8152. [Google Scholar] [CrossRef] [Green Version]

- Bunaziv, I.; Akselsen, O.M.; Frostevarg, J.; Kaplan, A.F.H. Deep penetration fiber laser-arc hybrid welding of thick HSLA steel. J. Mater. Process. Technol. 2018, 256, 216–228. [Google Scholar] [CrossRef]

- Fabbro, R. Melt pool and keyhole behaviour analysis for deep penetration laser welding. J. Phys. D Appl. Phys. 2010, 43, 445501. [Google Scholar] [CrossRef]

- Gao, X.; Wang, Y.; Chen, Z.; Ma, B.; Zhang, Y. Analysis of welding process stability and weld quality by droplet transfer and explosion in MAG-laser hybrid welding process. J. Manuf. Process. 2018, 32, 522–529. [Google Scholar] [CrossRef]

- Kim, C.H.; Ahn, Y.N.; Lee, K.B. Droplet transfer during conventional gas metal arc and plasma-gas metal arc hybrid welding with Al 5183 filler metal. Curr. Appl. Phys. 2012, 12, S178–S183. [Google Scholar] [CrossRef]

- Punkari, A.; Weckman, D.C.; Kerr, H.W. Effects of magnesium content on dual beam Nd: YAG laser welding of Al—Mg alloys. Sci. Technol. Weld. Join. 2003, 8, 269–281. [Google Scholar] [CrossRef]

- Avilov, V.V.; Gumenyuk, A.; Lammers, M.; Rethmeier, M. PA position full penetration high power laser beam welding of up to 30 mm thick AlMg3 plates using electromagnetic weld pool support. Sci. Technol. Weld. Join. 2012, 17, 128–133. [Google Scholar] [CrossRef]

- Bachmann, M.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Numerical simulation of full-penetration laser beam welding of thick aluminium plates with inductive support. J. Phys. D Appl. Phys. 2011, 45, 035201. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Nie, Z.; Huang, H.; Sun, J. Microstructure and mechanical properties of a new Al–Zn–Mg–Cu alloy joints welded by laser beam. Mater. Des. 2015, 83, 451–458. [Google Scholar] [CrossRef]

- Kermanidis, A.T.; Zervaki, A.D.; Haidemenopoulos, G.N.; Pantelakis, S.G. Effects of temper condition and corrosion on the fatigue performance of a laser-welded Al–Cu–Mg–Ag (2139) alloy. Mater. Des. 2010, 31, 42–49. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, W.; Xiao, R. Microstructure and mechanical properties of laser beam welded Al–Li alloy 2060 with Al–Mg filler wire. Mater. Des. 2015, 88, 446–450. [Google Scholar] [CrossRef]

- Faraji, A.H.; Moradi, M.; Goodarzi, M.; Colucci, P.; Maletta, C. An investigation on capability of hybrid Nd:YAG laser-TIG welding technology for AA2198 Al-Li alloy. Opt. Lasers Eng. 2017, 96, 1–6. [Google Scholar] [CrossRef]

- Ning, J.; Zhang, L.-J.; Bai, Q.-L.; Yin, X.-Q.; Niu, J.; Zhang, J.-X. Comparison of the microstructure and mechanical performance of 2A97 Al-Li alloy joints between autogenous and non-autogenous laser welding. Mater. Des. 2017, 120, 144–156. [Google Scholar] [CrossRef]

- Ahn, J.; Chen, L.; He, E.; Davies, C.M.; Dear, J.P. Effect of filler metal feed rate and composition on microstructure and mechanical properties of fibre laser welded AA 2024-T3. J. Manuf. Process. 2017, 25, 26–36. [Google Scholar] [CrossRef]

- Ahn, J.; He, E.; Chen, L.; Dear, J.; Davies, C. The effect of Ar and He shielding gas on fibre laser weld shape and microstructure in AA 2024-T3. J. Manuf. Process. 2017, 29, 62–73. [Google Scholar] [CrossRef] [Green Version]

- Malikov, A.; Orishich, A.; Golyshev, A.; Karpov, E. Manufacturing of high-strength laser welded joints of an industrial aluminum alloy of system Al-Cu-Li by means of post heat treatment. J. Manuf. Process. 2019, 41, 101–110. [Google Scholar] [CrossRef]

- Leo, P.; D’Ostuni, S.; Casalino, G. Hybrid welding of AA5754 annealed alloy: Role of post weld heat treatment on microstructure and mechanical properties. Mater. Des. 2016, 90, 777–786. [Google Scholar] [CrossRef]

- Zhan, X.; Zhao, Y.; Liu, Z.; Gao, Q.; Bu, H. Microstructure and porosity characteristics of 5A06 aluminum alloy joints using laser-MIG hybrid welding. J. Manuf. Process. 2018, 35, 437–445. [Google Scholar] [CrossRef]

- Wang, Z.; Oliveira, J.P.; Zeng, Z.; Bu, X.; Peng, B.; Shao, X. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties. Opt. Laser Technol. 2019, 111, 58–65. [Google Scholar] [CrossRef]

- Hirose, A.; Kurosawa, N.; Kobayashi, K.F.; Todaka, H.; Yamaoka, H. Quantitative evaluation of softened regions in weld heat-affected zones of 6061-T6 aluminum alloy—Characterizing of the laser beam welding process. Metall. Mater. Trans. A 1999, 30, 2115–2120. [Google Scholar] [CrossRef]

- Fabrègue, D.; Deschamps, A.; Suéry, M. Influence of the silicon content on the mechanical properties of AA6xxx laser welds. Mater. Sci. Eng. A 2009, 506, 157–164. [Google Scholar] [CrossRef]

- Pakdil, M.; Çam, G.; Koçak, M.; Erim, S. Microstructural and mechanical characterization of laser beam welded AA6056 Al-alloy. Mater. Sci. Eng. A 2011, 528, 7350–7356. [Google Scholar] [CrossRef]

- Han, X.; Yang, Z.; Ma, Y.; Shi, C.; Xin, Z. Comparative study of laser-arc hybrid welding for AA6082-T6 aluminum alloy with two different arc modes. Metals 2020, 10, 407. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.N.; Wu, S.C.; Song, Z.; Fu, Y.N.; Yuan, Q.X.; Zhang, L.L. Effect of microstructural features on the failure behavior of hybrid laser welded AA7020. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2010–2023. [Google Scholar] [CrossRef]

- Sokoluk, M.; Cao, C.; Pan, S.; Li, X. Nanoparticle-enabled phase control for arc welding of unweldable aluminum alloy 7075. Nat. Commun. 2019, 10, 98. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.G.; Sung, S.H.; Chen, C.S.; Tan, A.H. Study of microstructural and mechanical properties of weld heat affected zones of 2024-T3 aluminium using Gleeble simulation. Mater. Sci. Technol. 2011, 27, 357–365. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, T.-S.; Duan, T.-T.; Li, T.-T.; Qiu, F.; Yang, H.-Y.; Bai, Z.-H.; Liu, Y.-Y.; Jiang, Q.-C. Design of a new Al-Cu alloy manipulated by in-situ nanocrystals with superior high temperature tensile properties and its constitutive equation. Mater. Des. 2019, 181, 107945. [Google Scholar] [CrossRef]

- Prasad, N.E.; Gokhale, A.A.; Wanhill, R.J.H. Aluminum-Lithium Alloys: Processing, Properties, and Applications; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar] [CrossRef]

- Abd El-Aty, A.; Xu, Y.; Guo, X.; Zhang, S.-H.; Ma, Y.; Chen, D. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef] [PubMed]

- Yoshimura, R.; Konno, T.J.; Abe, E.; Hiraga, K. Transmission electron microscopy study of the evolution of precipitates in aged Al–Li–Cu alloys: The θ′ and T1 phases. Acta Mater. 2003, 51, 4251–4266. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Grant, N.J. Aluminium-lithium alloys. J. Mater. Sci. 1987, 22, 1521–1529. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al–Mg–Si alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Li, Z.; Cao, P.; Yuan, T.; Zhu, H. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: Crack-inhibiting and multiple strengthening mechanisms. Acta Mater. 2020, 193, 83–98. [Google Scholar] [CrossRef]

- Yan, J.; Zeng, X.; Gao, M.; Lai, J.; Lin, T. Effect of welding wires on microstructure and mechanical properties of 2A12 aluminum alloy in CO2 laser-MIG hybrid welding. Appl. Surf. Sci. 2009, 255, 7307–7313. [Google Scholar] [CrossRef]

- Ahn, J.; Chen, L.; He, E.; Dear, J.P.; Davies, C.M. Optimisation of process parameters and weld shape of high power Yb-fibre laser welded 2024-T3 aluminium alloy. J. Manuf. Process. 2018, 34, 70–85. [Google Scholar] [CrossRef]