Study on the Influence of the Gurson–Tvergaard–Needleman Damage Model on the Fatigue Crack Growth Rate

Abstract

:1. Introduction

2. Numerical Model

2.1. Elasto-Plastic Material Behaviour

2.2. Boundary Conditions, Geometry, and Specimen Descritization

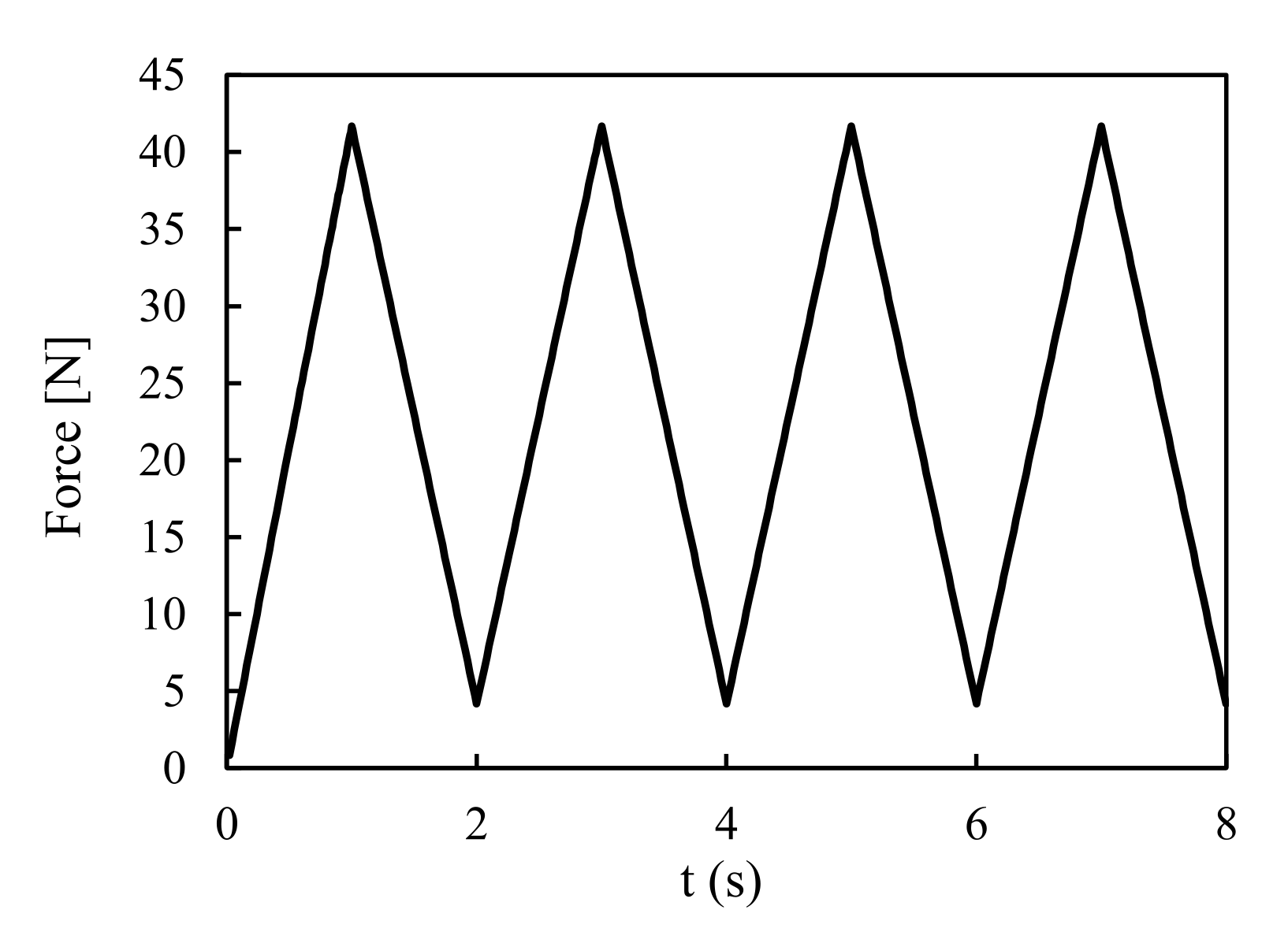

2.3. Loading Case and Propagation Criterion

2.4. GTN Model

2.4.1. Gurson’s Damage Model

2.4.2. Tvergaard and Needleman Contributions

3. Results and Discussion

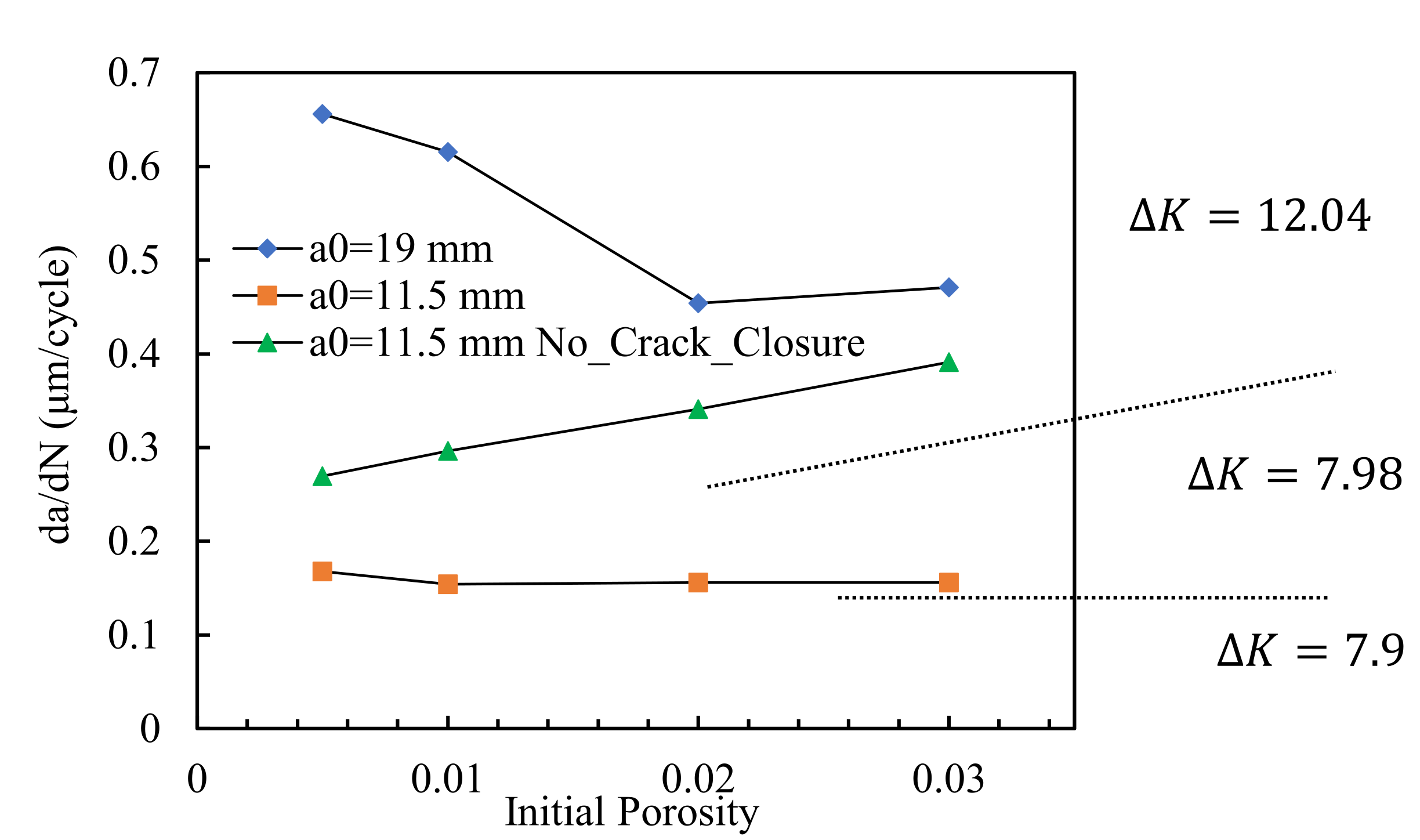

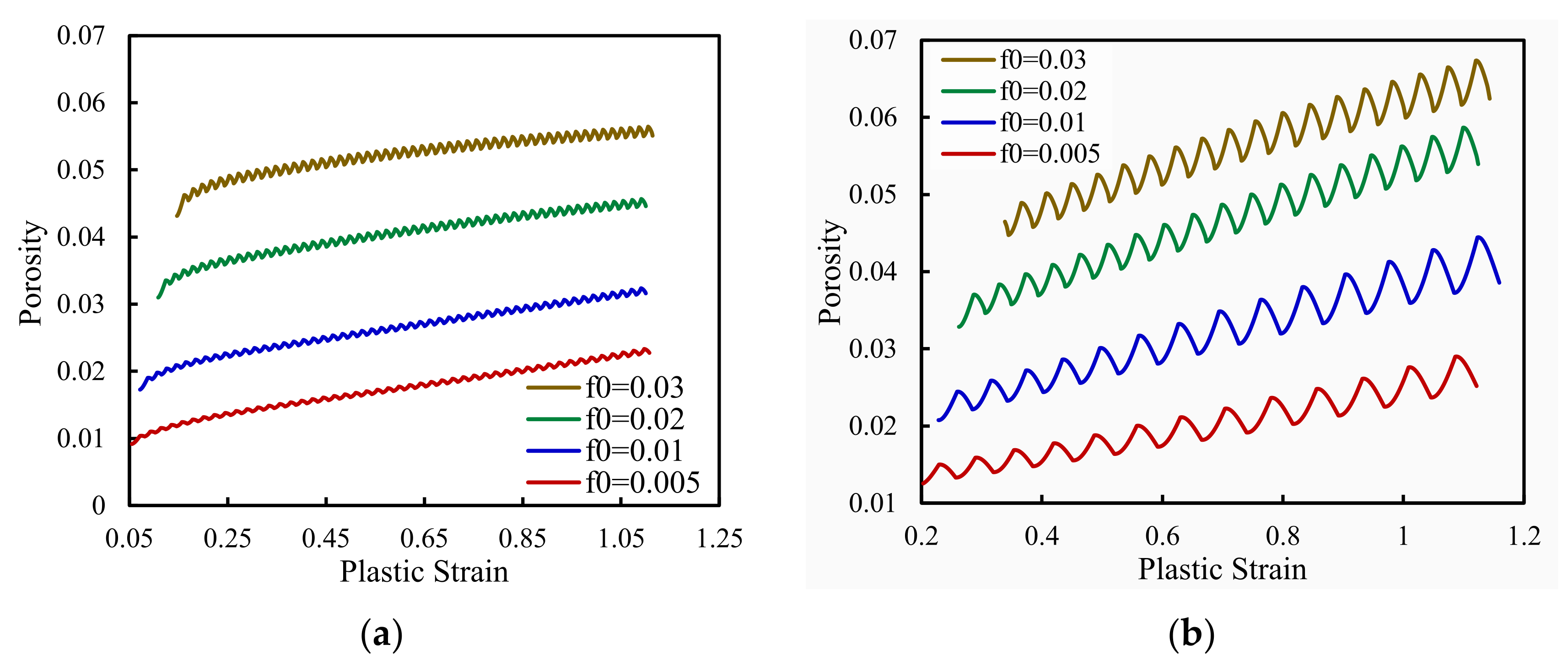

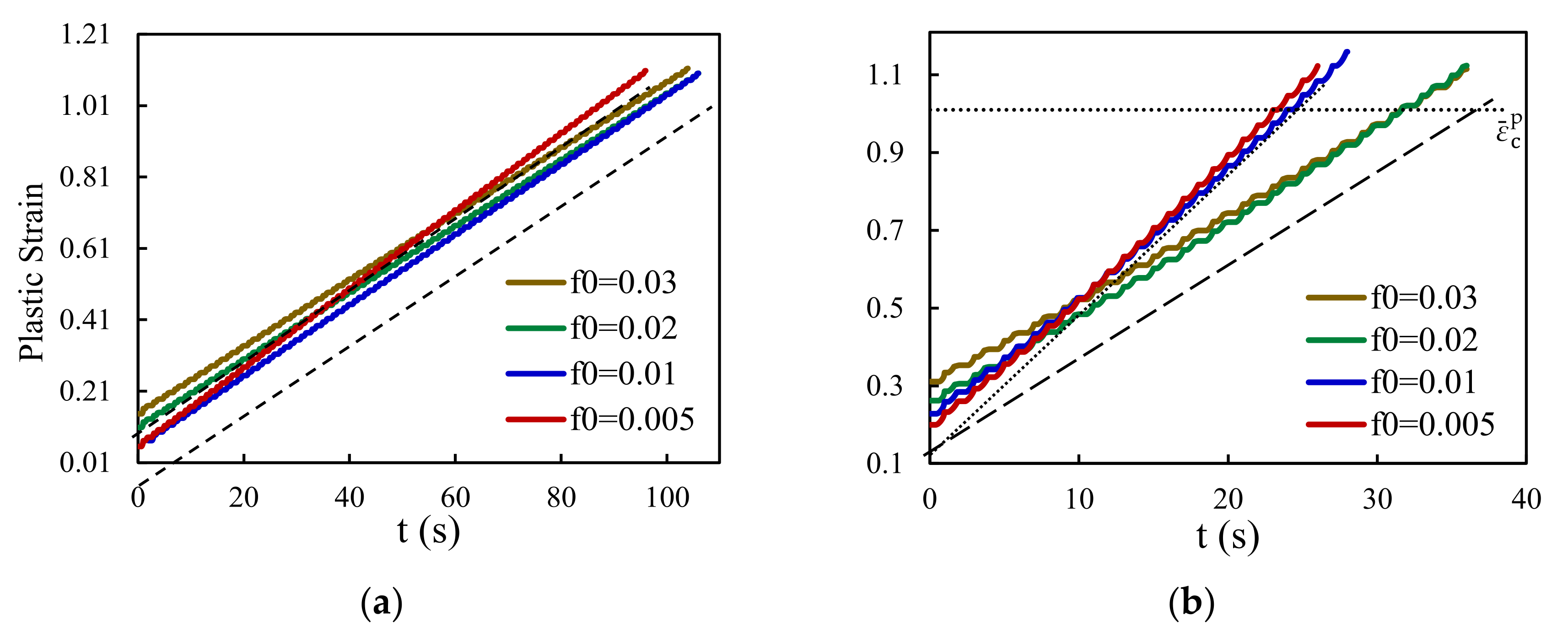

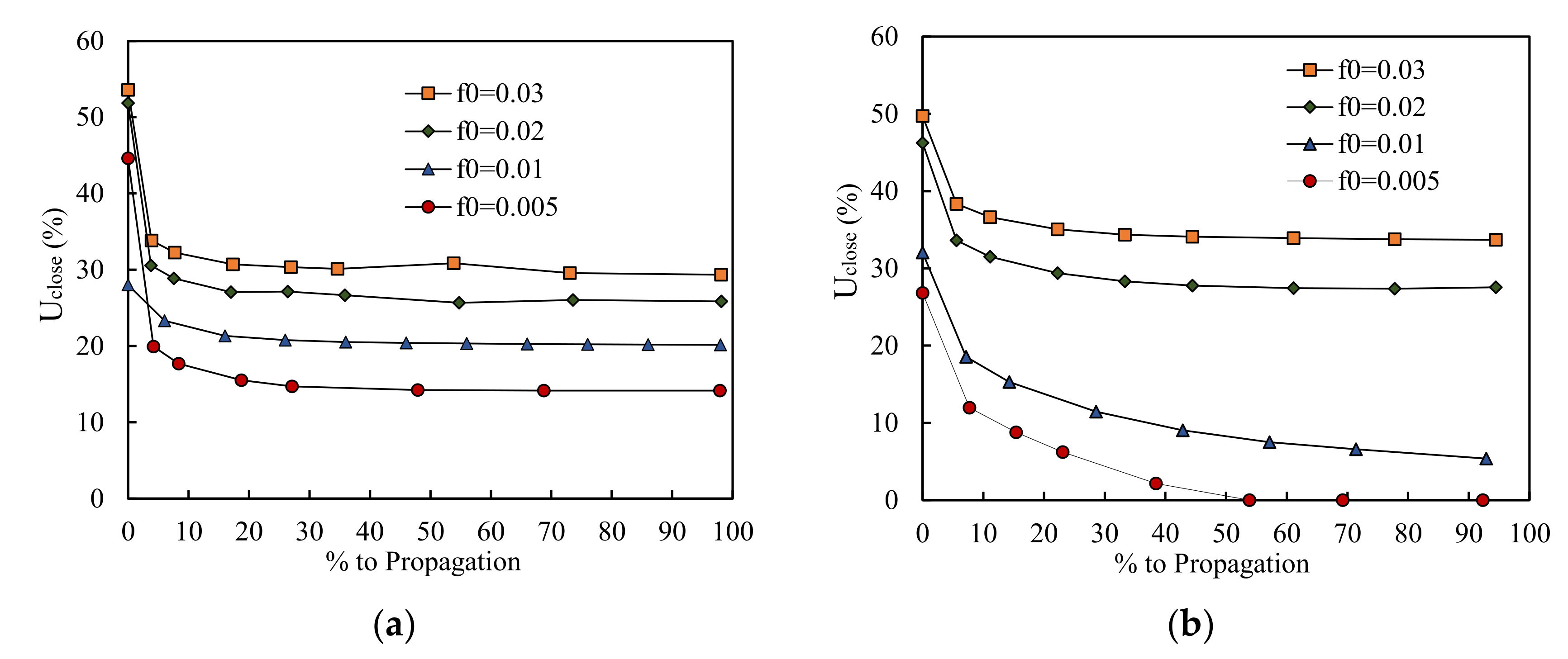

3.1. Effect of Initial Void Volume Fraction, f0

3.2. Effect of the Tvergaard Parameters, q1, q2, and q3

3.2.1. Analysis of q1

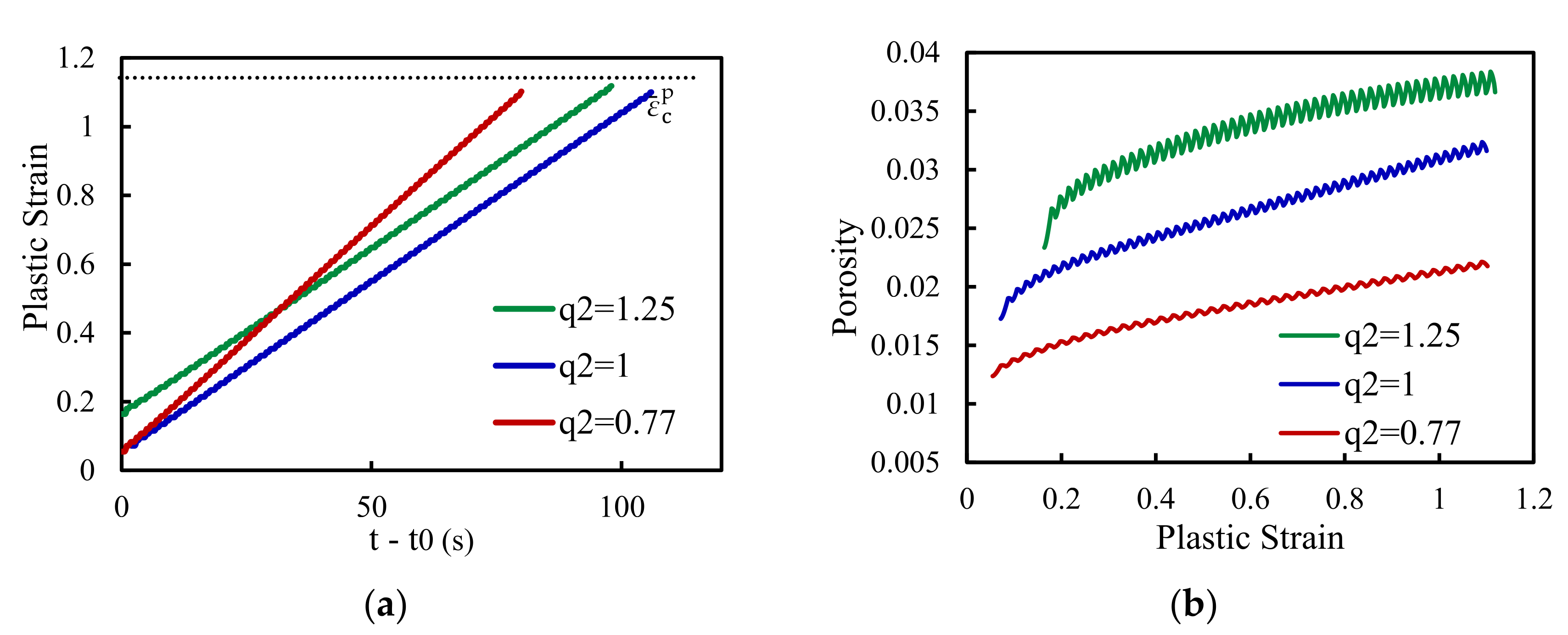

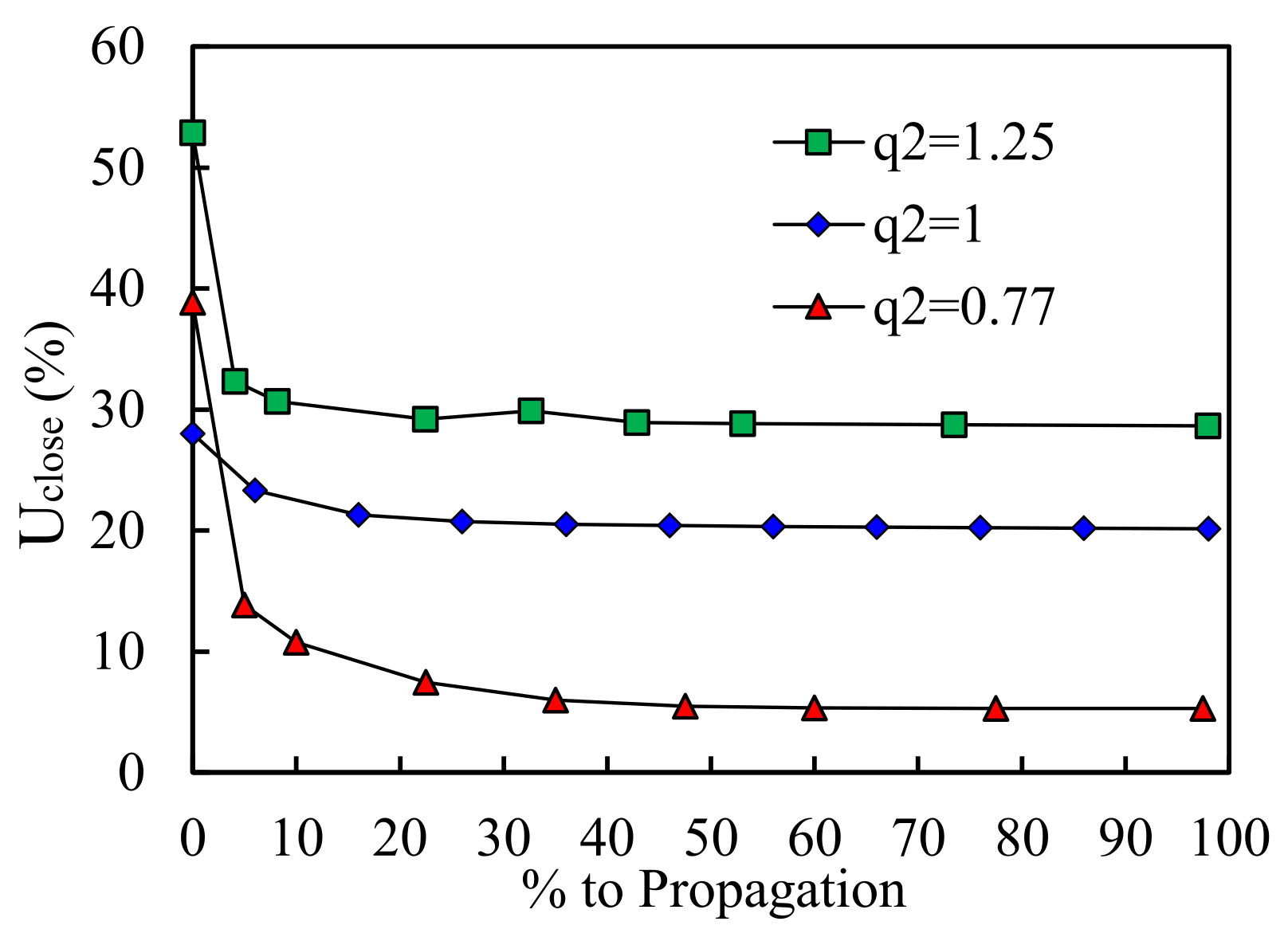

3.2.2. Analysis of q2

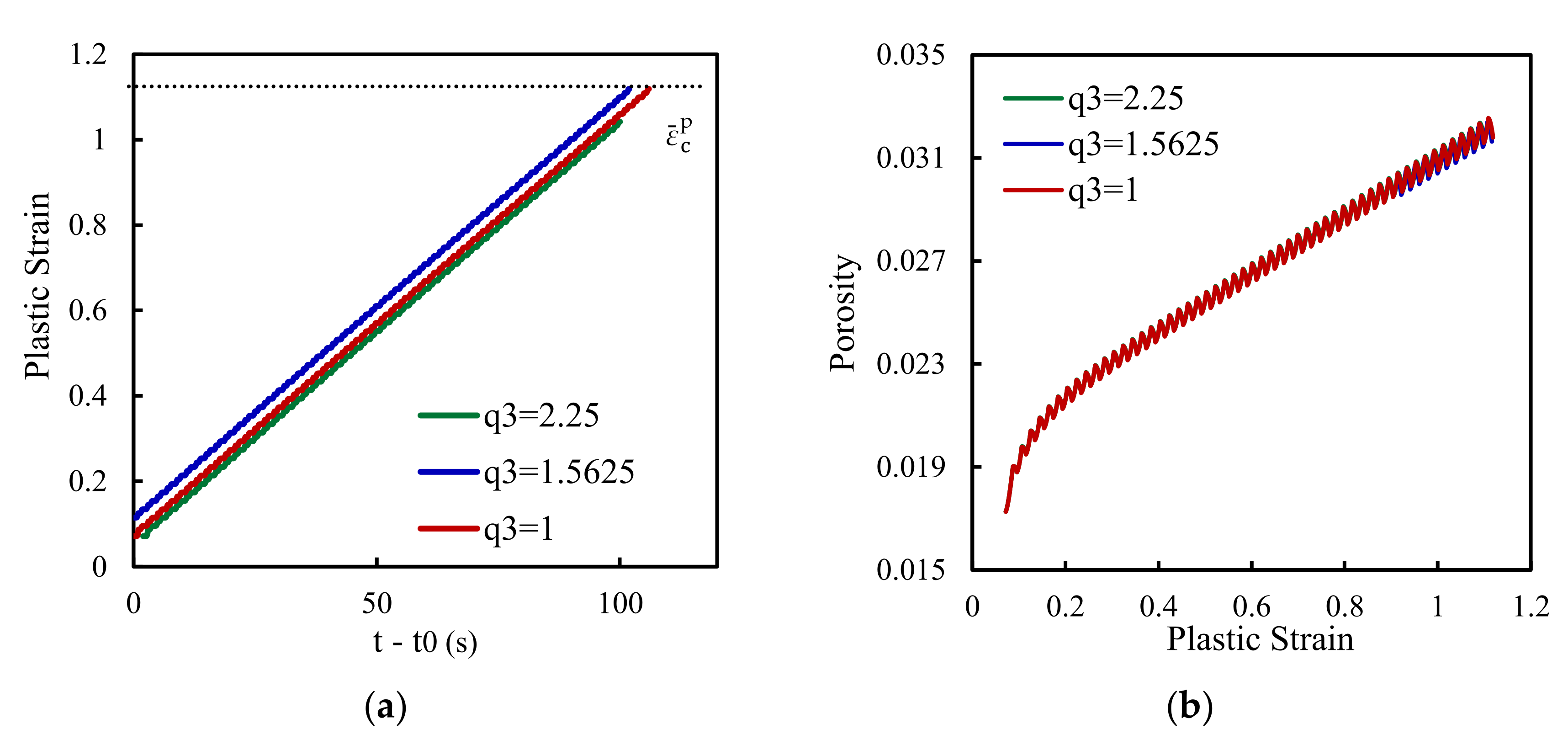

3.2.3. Analysis of q3

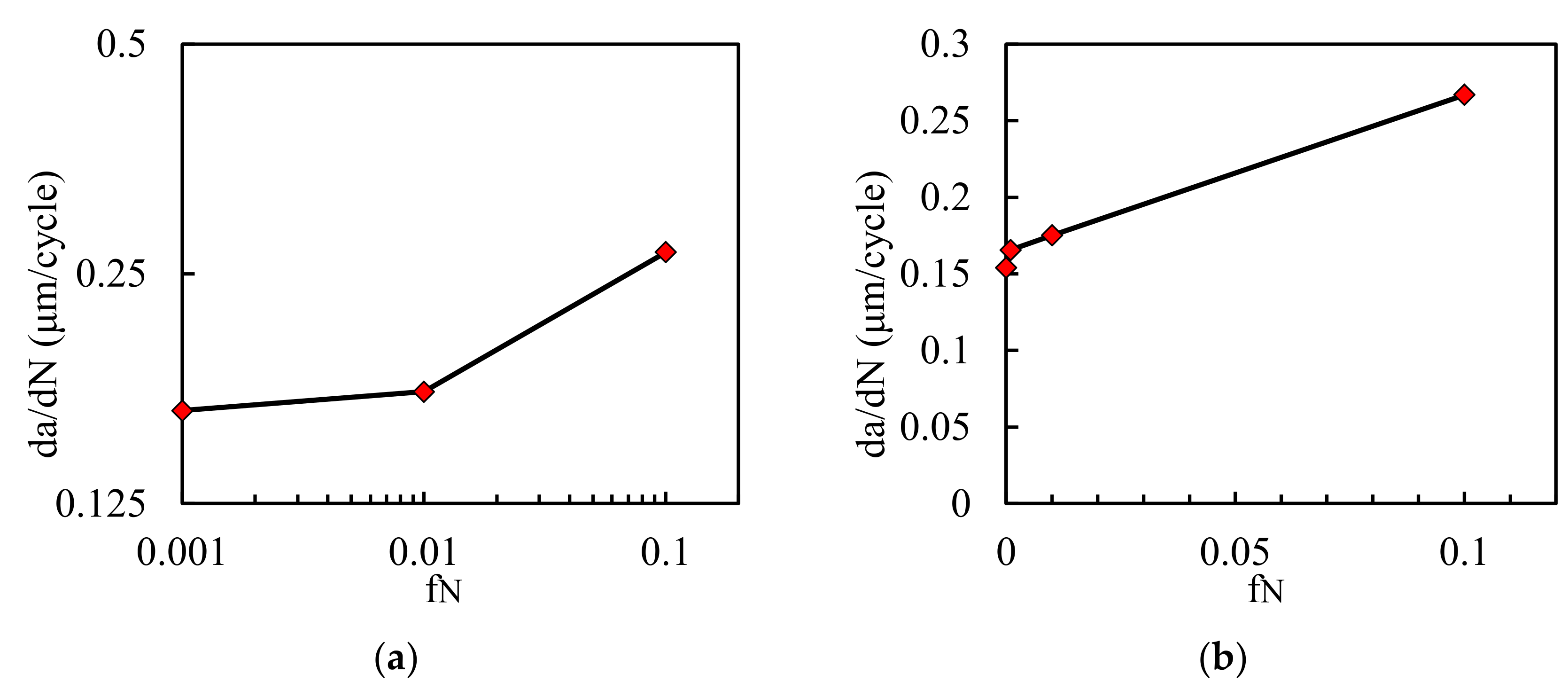

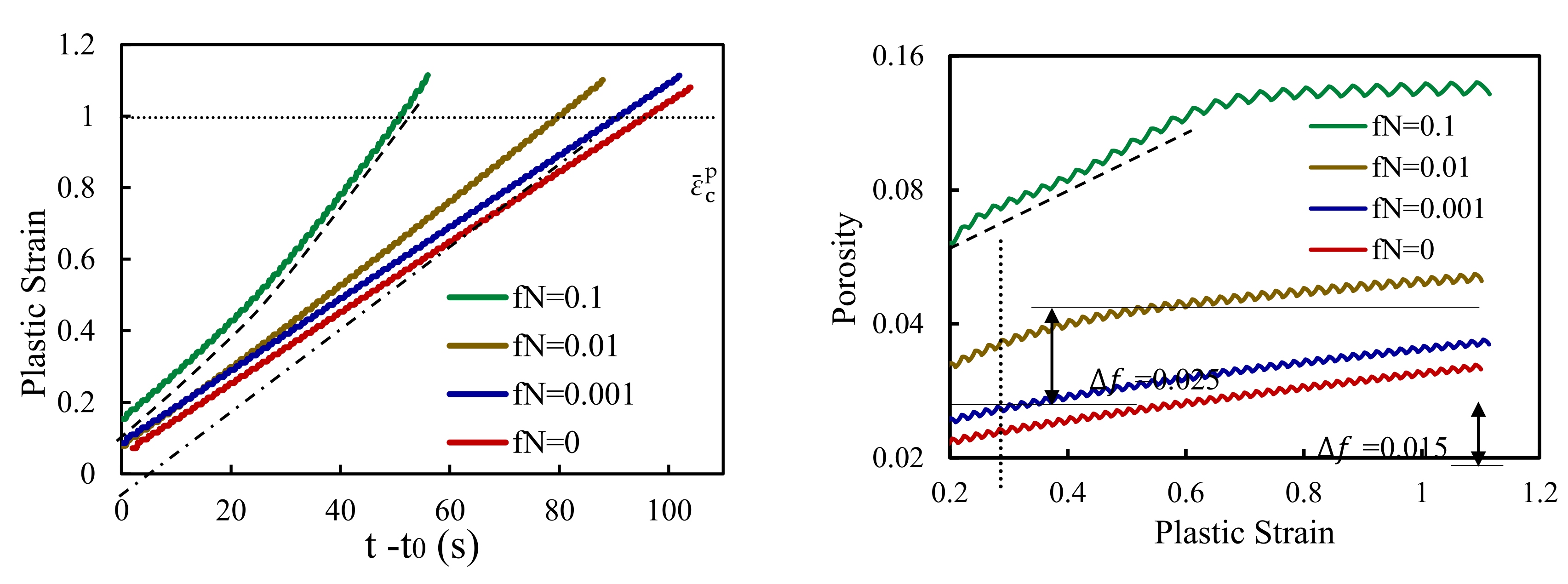

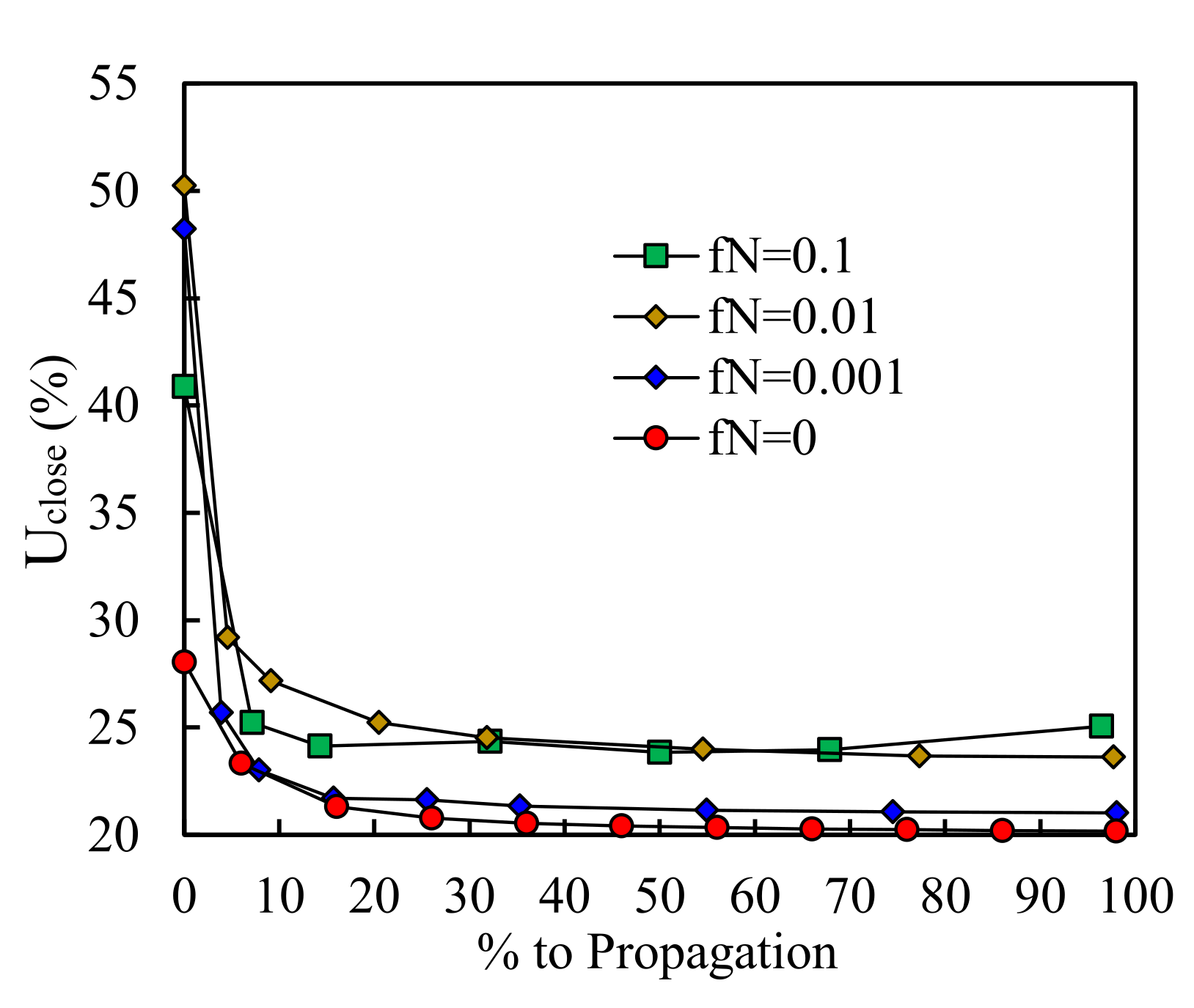

3.3. Effect of the Void Fraction to Be Nucleated,

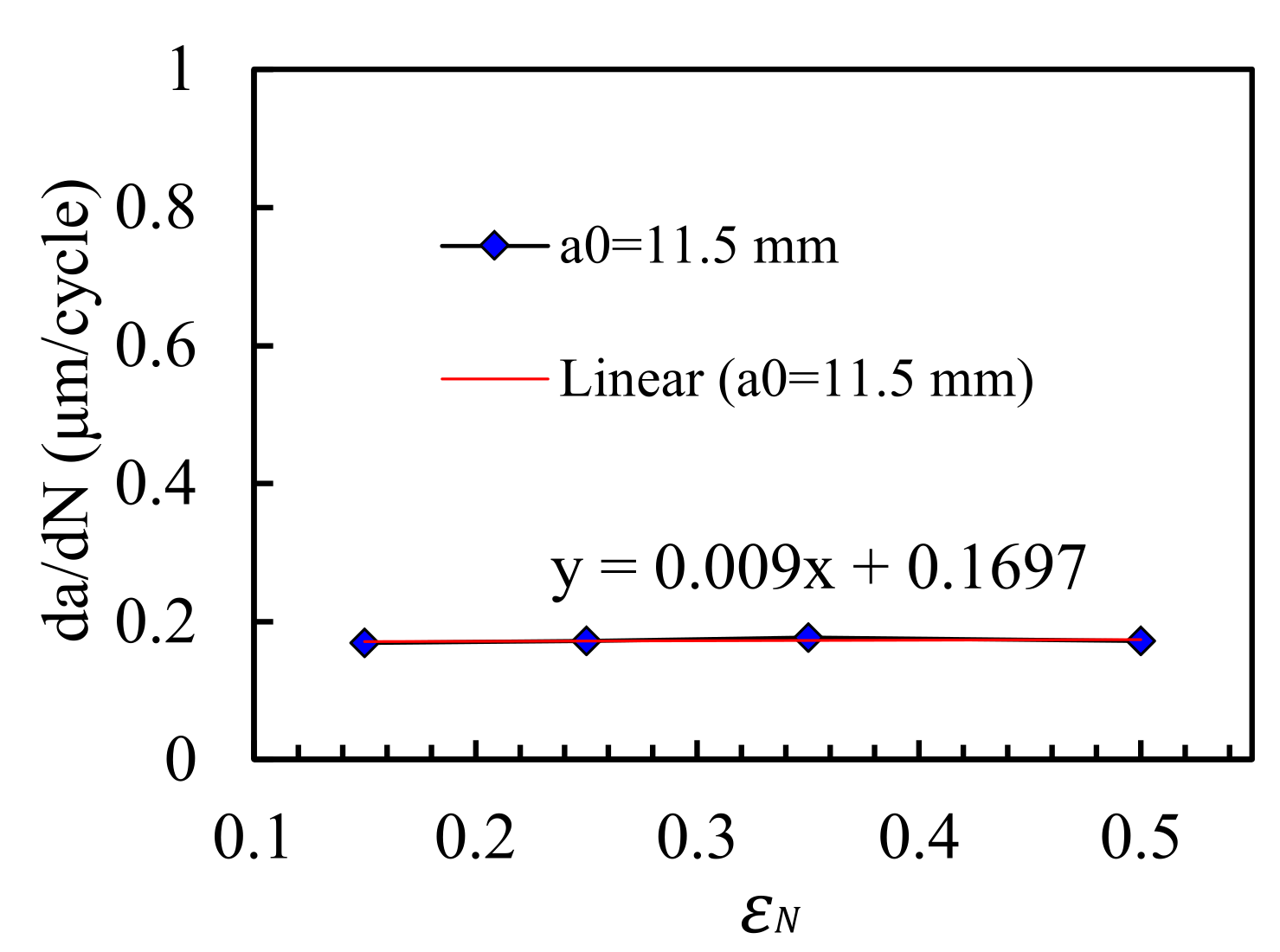

3.4. Effect of the Mean Nucleation Strain,

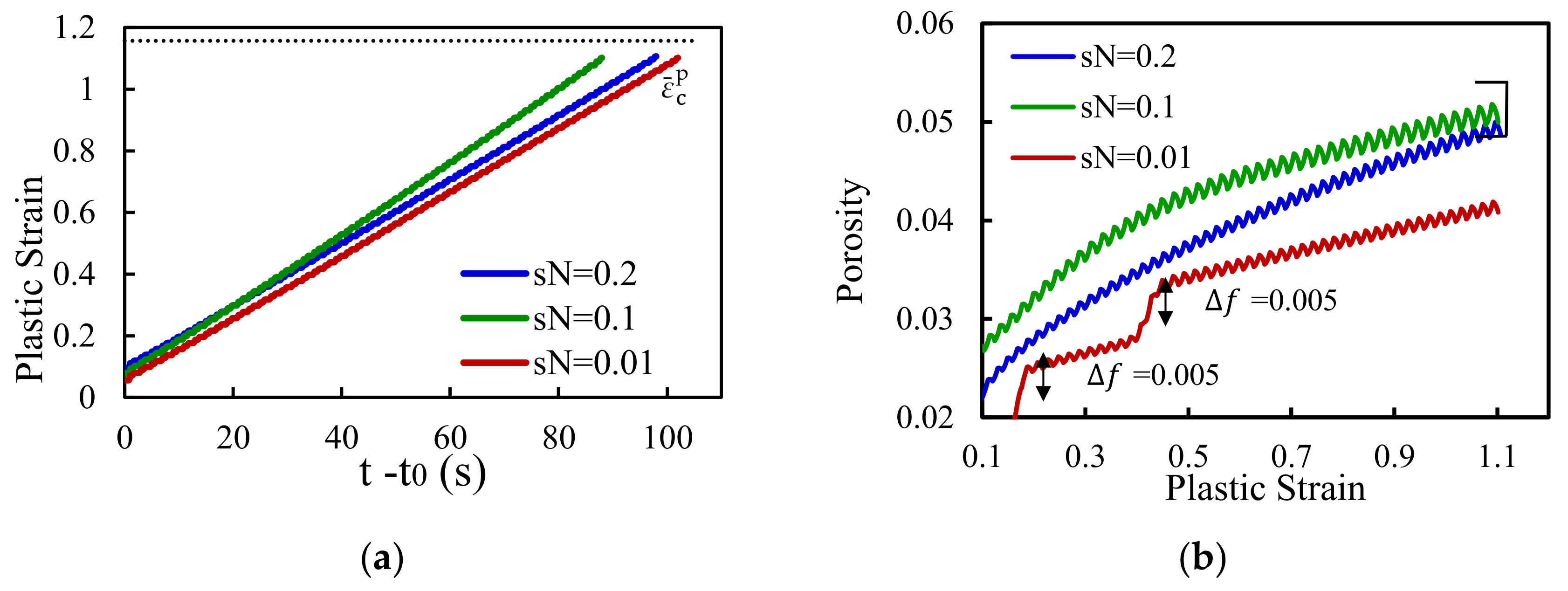

3.5. Influence of the Standard Deviation on Void Nucleation,

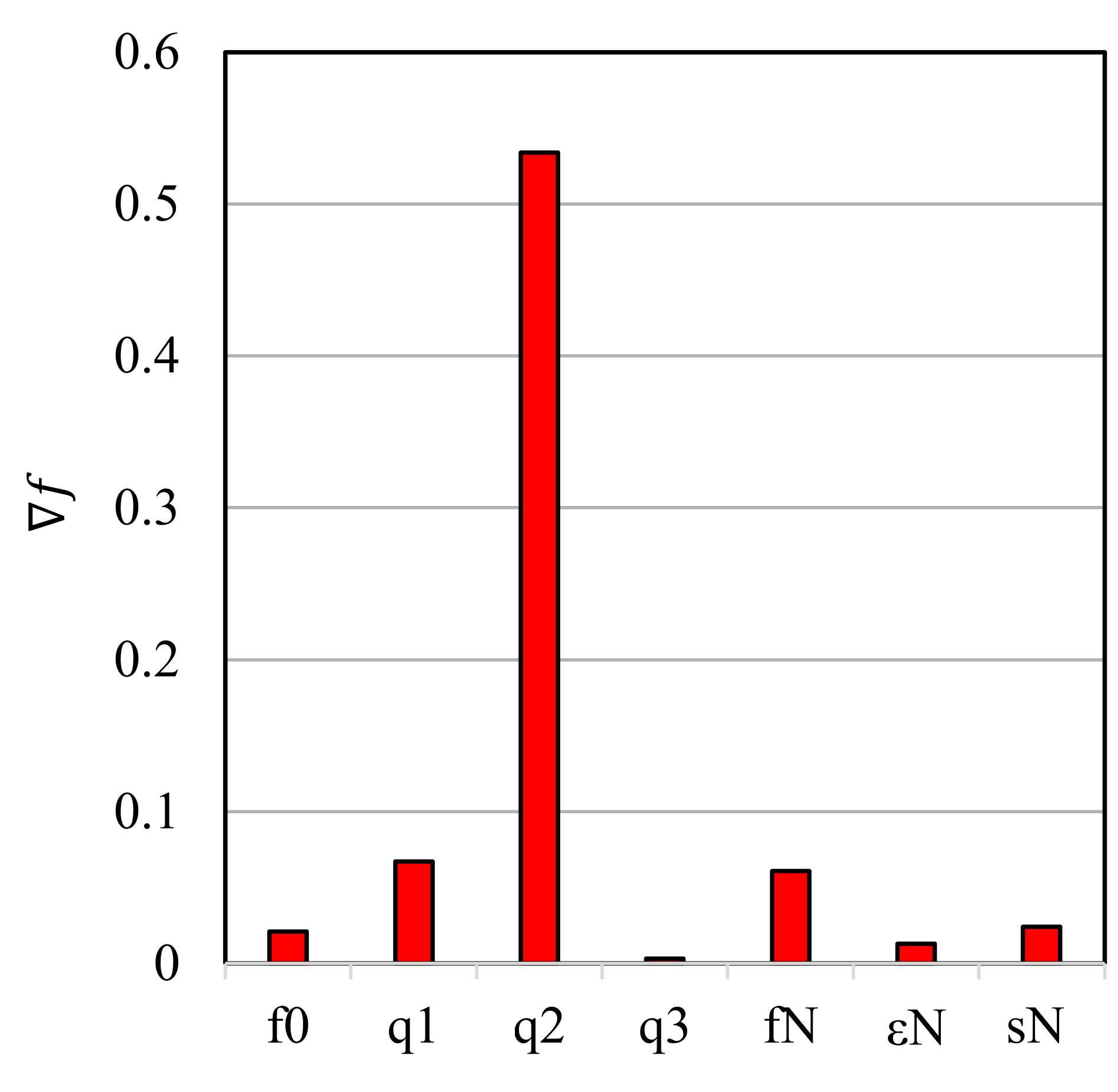

4. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Irwin, G.R. Analysis of Stresses and Strains Near the End of a Crack Traversing a Plate. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar] [CrossRef]

- Newman, J.; Raju, I. An empirical stress-intensity factor equation for the surface crack. Eng. Fract. Mech. 1981, 15, 185–192. [Google Scholar] [CrossRef]

- Borges, M.; Neto, D.; Antunes, F. Numerical simulation of fatigue crack growth based on accumulated plastic strain. Theor. Appl. Fract. Mech. 2020, 108, 102676. [Google Scholar] [CrossRef]

- Borrego, L.; Ferreira, J.; Pinho-Da-Cruz, J.; Costa, J. Evaluation of overload effects on fatigue crack growth and closure. Eng. Fract. Mech. 2003, 70, 1379–1397. [Google Scholar] [CrossRef] [Green Version]

- Rao, K.; Yu, W.; Ritchie, R. On the behavior of small fatigue cracks in commercial aluminum-lithium alloys. Eng. Fract. Mech. 1988, 31, 623–635. [Google Scholar] [CrossRef] [Green Version]

- Borrego, L.F.; Ferreira, J.; Costa, J. Fatigue crack growth and crack closure in an AlMgSi alloy. Fatigue Fract. Eng. Mater. Struct. 2001, 24, 255–265. [Google Scholar] [CrossRef]

- Antunes, F.; Branco, R.; Correia, L.; Ramalho, A. A numerical study of non-linear crack tip parameters. Frattura ed Integrità Strutturale 2015, 9, 199–208. [Google Scholar] [CrossRef] [Green Version]

- Antunes, F.; Serrano, S.; Branco, R.; Prates, P. Fatigue crack growth in the 2050-T8 aluminium alloy. Int. J. Fatigue 2018, 115, 79–88. [Google Scholar] [CrossRef]

- Chen, H.; Chen, W.; Li, T.; Ure, J. Effect of circular holes on the ratchet limit and crack tip plastic strain range in a centre cracked plate. Eng. Fract. Mech. 2011, 78, 2310–2324. [Google Scholar] [CrossRef] [Green Version]

- Park, H.-B.; Kim, K.-M.; Lee, B.-W. Plastic zone size in fatigue cracking. Int. J. Press. Vessel. Pip. 1996, 68, 279–285. [Google Scholar] [CrossRef]

- Liaw, P.K.; Kwun, S.I.; Fine, M.E. Plastic work of fatigue crack propagation in steels and aluminum alloys. Met. Mater. Trans. A 1981, 12, 49–55. [Google Scholar] [CrossRef]

- Tvergaard, V. On fatigue crack growth in ductile materials by crack–tip blunting. J. Mech. Phys. Solids 2004, 52, 2149–2166. [Google Scholar] [CrossRef]

- Pippan, R.; Grosinger, W. Fatigue crack closure: From LCF to small scale yielding. Int. J. Fatigue 2013, 46, 41–48. [Google Scholar] [CrossRef] [Green Version]

- Antunes, F.V.; Branco, R.; Prates, P.; Borrego, L.F. Fatigue crack growth modelling based on CTOD for the 7050-T6 alloy. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1309–1320. [Google Scholar] [CrossRef]

- Vasco-Olmo, J.; Díaz, F.; Antunes, F.; James, M. Characterisation of fatigue crack growth using digital image correlation measurements of plastic CTOD. Theor. Appl. Fract. Mech. 2019, 101, 332–341. [Google Scholar] [CrossRef]

- Hamam, R.; Pommier, S.; Bumbieler, F. Mode I fatigue crack growth under biaxial loading. Int. J. Fatigue 2005, 27, 1342–1346. [Google Scholar] [CrossRef]

- Jiang, Y.; Feng, M. Modeling of Fatigue Crack Propagation. J. Eng. Mater. Technol. 2004, 126, 77–86. [Google Scholar] [CrossRef]

- Hosseini, Z.; Dadfarnia, M.; Somerday, B.P.; Sofronis, P.; Ritchie, R.O. On the theoretical modeling of fatigue crack growth. J. Mech. Phys. Solids 2018, 121, 341–362. [Google Scholar] [CrossRef]

- Kuwamura, H.; Akiyama, H. Brittle fracture under repeated high stresses. J. Constr. Steel Res. 1994, 29, 5–19. [Google Scholar] [CrossRef]

- Kiran, R.; Khandelwal, K. Gurson model parameters for ductile fracture simulation in ASTM A992 steels. Fatigue Fract. Eng. Mater. Struct. 2013, 37, 171–183. [Google Scholar] [CrossRef]

- Rousselier, G. Ductile fracture models and their potential in local approach of fracture. Nucl. Eng. Des. 1987, 105, 97–111. [Google Scholar] [CrossRef]

- Wilsdorf, H.G.F. Void initiation, growth, and coalescence in ductile fracture of metals. J. Electron. Mater. 1975, 4, 791–809. [Google Scholar] [CrossRef]

- Garrison, W.; Moody, N. Ductile fracture. J. Phys. Chem. Solids 1987, 48, 1035–1074. [Google Scholar] [CrossRef]

- Rice, J.R.; Tracey, D.M. On the ductile enlargement of voids in triaxial stress fields*. J. Mech. Phys. Solids 1969, 17, 201–217. [Google Scholar] [CrossRef] [Green Version]

- Bao, Y. Prediction of Ductile Crack Formation in Uncracked Bodies. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications. 2005, pp. 73–74. Available online: http://site.ebrary.com/id/11166314 (accessed on 20 June 2021).

- Besson, J. Continuum Models of Ductile Fracture: A Review. Int. J. Damage Mech. 2010, 19, 3–52. [Google Scholar] [CrossRef] [Green Version]

- Tipper, C.F. Metallurgia, 1948–1949. Volume 39, 133–137.

- Puttick, K.E. Ductile fracture in metals. Philos. Mag. 1959, 4, 964–969. [Google Scholar] [CrossRef]

- Schmitt, J.-H.; Jalinier, J.M.; Baudelet, B. Analysis of damage and its influence on the plastic properties of copper. J. Mater. Sci. 1981, 16, 95–101. [Google Scholar] [CrossRef]

- Brünig, M.; Gerke, S.; Hagenbrock, V. Micro-mechanical studies on the effect of the stress triaxiality and the Lode parameter on ductile damage. Int. J. Plast. 2013, 50, 49–65. [Google Scholar] [CrossRef]

- Menezes, L.F.; Teodosiu, C. Three-dimensional numerical simulation of the deep-drawing process using solid finite elements. J. Mater. Process. Technol. 2000, 97, 100–106. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, M.C.; Alves, J.L.C.M.; Menezes, L.F. Algorithms and Strategies for Treatment of Large Deformation Frictional Contact in the Numerical Simulation of Deep Drawing Process. Arch. Comput. Methods Eng. 2008, 15, 113–162. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, F.F.; Neto, D.M.; Jesus, J.S.; Prates, P.A.; Antunes, F.V. Numerical Prediction of the Fatigue Crack Growth Rate in SLM Ti-6Al-4V Based on Crack Tip Plastic Strain. Metals 2020, 10, 1133. [Google Scholar] [CrossRef]

- Neto, D.; Borges, M.; Antunes, F.; Jesus, J. Mechanisms of fatigue crack growth in Ti-6Al-4V alloy subjected to single overloads. Theor. Appl. Fract. Mech. 2021, 114, 103024. [Google Scholar] [CrossRef]

- Borges, M.F.; Antunes, F.V.; Moreno, B.; Prates, P.; Camas, D.; Neto, D.M. Fatigue crack propagation analysis in 2024-T351 aluminium alloy using nonlinear parameters. Int. J. Fatigue 2021. submitted. [Google Scholar]

- Antunes, F.; Camas, D.; Correia, L.; Branco, R. Finite element meshes for optimal modelling of plasticity induced crack closure. Eng. Fract. Mech. 2015, 142, 184–200. [Google Scholar] [CrossRef] [Green Version]

- Gurson, A.L. Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I—Yield Criteria and Flow Rules for Porous Ductile Media. J. Eng. Mater. Technol. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Chaboche, J.L.; Boudifa, M.; Saanouni, K. A CDM Approach of Ductile Damage with Plastic Compressibility. Int. J. Fract. 2006, 137, 51–75. [Google Scholar] [CrossRef]

- Malcher, L.; Pires, F.; de Sa, J.C. An extended GTN model for ductile fracture under high and low stress triaxiality. Int. J. Plast. 2014, 54, 193–228. [Google Scholar] [CrossRef]

- Xue, L. Ductile Fracture Modeling: Theory, Experimental Investigation and Numerical Verification. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2009. [Google Scholar]

- Tvergaard, V. Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 1981, 17, 389–407. [Google Scholar] [CrossRef]

- Tvergaard, V. On localization in ductile materials containing spherical voids. Int. J. Fract. 1982, 18, 237–252. [Google Scholar] [CrossRef]

- Nielsen, K. Predicting failure response of spot welded joints using recent extensions to the Gurson model. Comput. Mater. Sci. 2010, 48, 71–82. [Google Scholar] [CrossRef]

- Malcher, L. Continuum Modelling and Numerical Simulation of Damage for Ductile Materials. Ph.D. Thesis, Universidade do Porto, Porto, Portugal, 2012. [Google Scholar] [CrossRef]

- Chu, C.C.; Needleman, A. Void Nucleation Effects in Biaxially Stretched Sheets. J. Eng. Mater. Technol. 1980, 102, 249–256. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. Analysis of the cup-cone fracture in a round tensile bar. Acta Met. 1984, 32, 157–169. [Google Scholar] [CrossRef]

- Goods, S.; Brown, L. Overview No. 1. Acta Met. 1979, 27, 1–15. [Google Scholar] [CrossRef]

- Chen, D.; Li, Y.; Yang, X.; Jiang, W.; Guan, L. Efficient parameters identification of a modified GTN model of ductile fracture using machine learning. Eng. Fract. Mech. 2021, 245, 107535. [Google Scholar] [CrossRef]

| Material | E (GPa) | ||||||

|---|---|---|---|---|---|---|---|

| AA 2024-T351 | 72.26 | 0.29 | 288.96 | 389.00 | 0.056 | 111.84 | 138.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sérgio, E.R.; Antunes, F.V.; Neto, D.M.; Borges, M.F. Study on the Influence of the Gurson–Tvergaard–Needleman Damage Model on the Fatigue Crack Growth Rate. Metals 2021, 11, 1183. https://doi.org/10.3390/met11081183

Sérgio ER, Antunes FV, Neto DM, Borges MF. Study on the Influence of the Gurson–Tvergaard–Needleman Damage Model on the Fatigue Crack Growth Rate. Metals. 2021; 11(8):1183. https://doi.org/10.3390/met11081183

Chicago/Turabian StyleSérgio, Edmundo R., Fernando V. Antunes, Diogo M. Neto, and Micael F. Borges. 2021. "Study on the Influence of the Gurson–Tvergaard–Needleman Damage Model on the Fatigue Crack Growth Rate" Metals 11, no. 8: 1183. https://doi.org/10.3390/met11081183

APA StyleSérgio, E. R., Antunes, F. V., Neto, D. M., & Borges, M. F. (2021). Study on the Influence of the Gurson–Tvergaard–Needleman Damage Model on the Fatigue Crack Growth Rate. Metals, 11(8), 1183. https://doi.org/10.3390/met11081183