Welding of Large Thickness Super Duplex Stainless Steel: Microstructure and Properties

Abstract

:1. Introduction

2. Materials and Testing

2.1. Materials and Welding Experiments

2.2. Microstructural Inspection

2.3. Chemical Analysis

2.4. Mechanical Testing

2.5. Corrosion Testing

3. Results

3.1. Microstructure and Phase Balance

3.1.1. SA-R Weldment

3.1.2. SA-H Weldment

3.1.3. GM-R Weldment

3.1.4. Phase Balance

3.2. Chemical Analysis

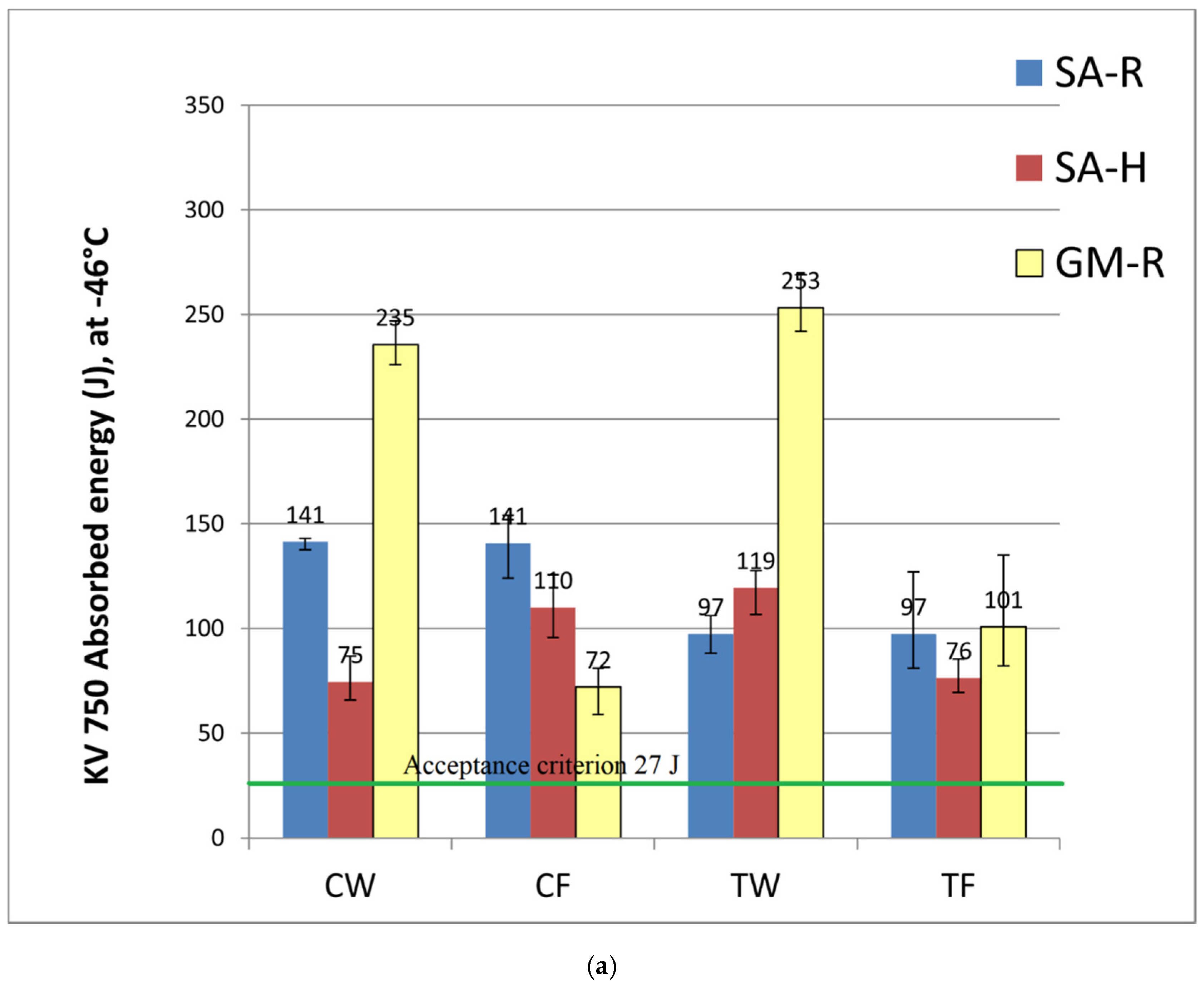

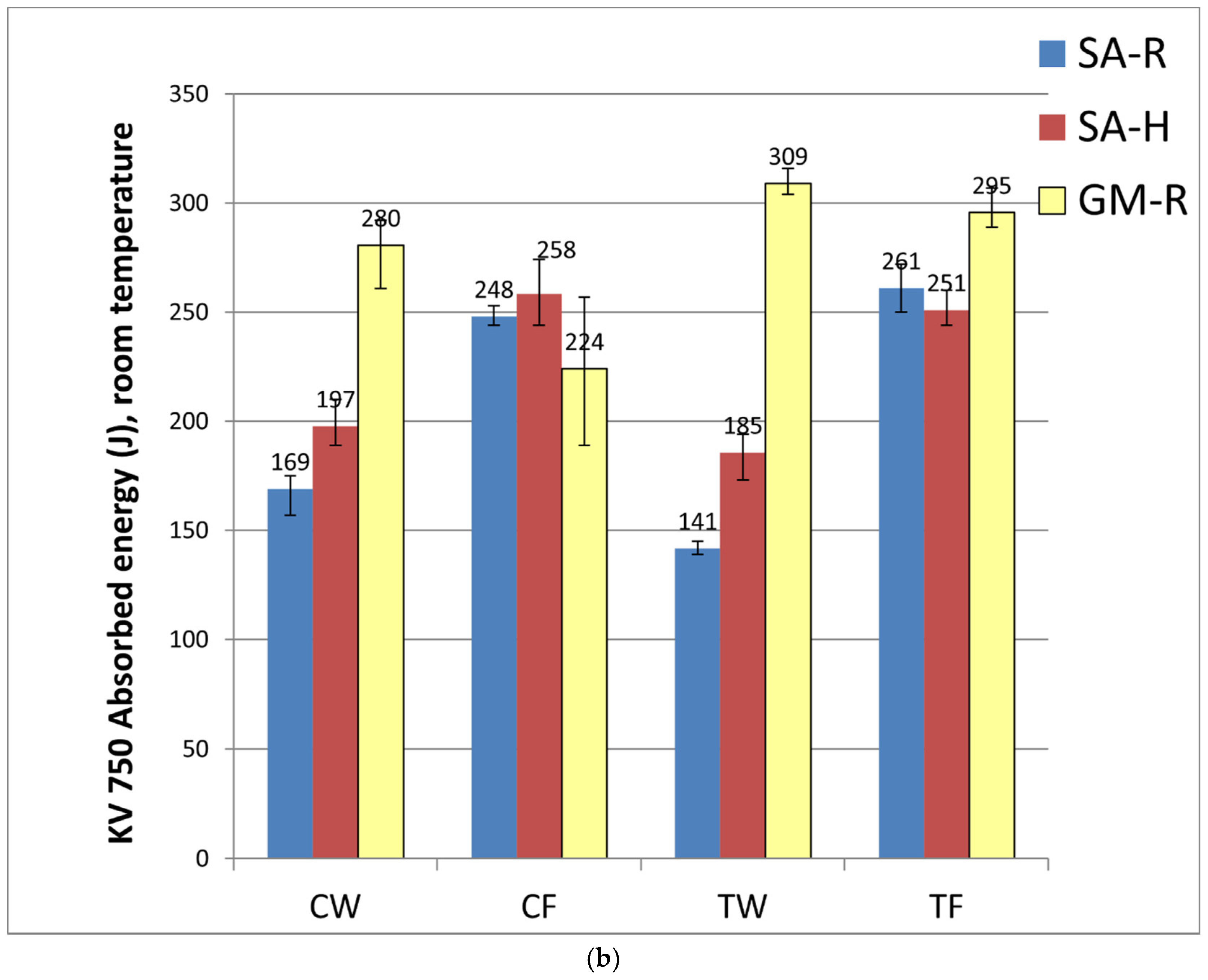

3.3. Impact Toughness

3.4. Tensile Testing

3.5. Corrosion Testing Results

3.6. Productivity: Welding Time

4. Discussion

4.1. Chemical Composition

4.2. Microstructure

4.3. Mechanical Properties

4.4. Corrosion Resistance

4.5. Productivity Aspects

5. Conclusions

- Both GMAW and SAW processes were proved to produce large thickness (33 mm) weldments of super duplex 2507 plates, meeting the microstructural, mechanical, and corrosion resistance requirements.

- With SAW it was possible to exceed the recommended arc energy up to 2.3 kJ/mm and the recommended interpass temperature up to 180 °C, while meeting the microstructural, mechanical, and corrosion resistance requirements.

- By using higher than recommended arc energy and interpass temperatures, it was possible to reduce the number of welding passes by half, compared to the use of recommended settings.

- When using recommended arc energy and interpass temperature, the SAW process needed half of the welding time for the GMAW process to produce a weldment with the same number of weld passes.

- Based on the results of this investigation, the current practical recommendations for welding large thickness duplex and super duplex should be revised and updated.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Charles, J. Duplex Stainless Steels, a Review after DSS’07 Held in Grado. In Proceedings of the Duplex Stainless Steel Conference, Maastricht, The Netherlands, 21–23 October 2009; pp. 1–22. [Google Scholar]

- Van der Mee, V.; Neessen, F.; Chadha, V. Welding Duplex Stainless Steel- Industry Guide. In Proceedings of the Duplex Stainless Steel Conference, Beaune, France, 13–15 October 2010; pp. 619–632. [Google Scholar]

- Wåle, J.; Utterström, P. Environmentally Induced Cracking of Duplex Stainless Steels in the Pulp & Paper Industry. In Proceedings of the Duplex Stainless Steel Conference, Beaune, France, 13–15 October 2010; pp. 203–208. [Google Scholar]

- Wensley, A. Duplex in the Pulp and Paper Industry—the Good, the Bad, and the Ugly. In Proceedings of the Duplex Stainless Steel Conference, Beaune, France, 13–15 October 2010; pp. 775–786. [Google Scholar]

- Thierry, D.; Larché, N.; Eidhagen, J.; Kivisäkk, U.; Cassagne, T.; Mehus, L. Service Performance of Super Duplex Umbilical Tubing within the Umbilical Design. In Proceedings of the Duplex Stainless Steel Conference, Beaune, France, 13–15 October 2010; pp. 517–528. [Google Scholar]

- Turbeville, E.; Busschaert, F.; Benum, S.; Madsen, B. A Summary of Recent Experience on Designing and Fabricating Subsea Oil and Gas Production Systems with 22Cr and 25Cr Piping Materials. In Proceedings of the Duplex Stainless Steel Conference, Beaune, France, 13–15 October 2010; pp. 545–560. [Google Scholar]

- Karlsson, L. Intermetallic Phase Precipitation in Duplex Stainless Steels and Weld Metals: Metallurgy, Influence on Properties, Welding and Testing Aspects; Welding Research Council Bulletin; Welding Research Council: New York, NY, USA, 1999; Volume 438. [Google Scholar]

- Karlsson, L.; Rigdal, S.; Pak, S. Effects of Elemental Distribution on Precipitation Behaviour and Properties of Duplex Stainless Steel Weldments. In Proceedings of the Duplex Stainless Steel Conference, Venice, Italy, 17–20 October 2000. [Google Scholar]

- Hosseini, V.; Karlsson, L.; Engelberg, D.; Wessman, S. Time-Temperature-Precipitation and Property Diagrams for Super Duplex Stainless Steel Weld Metals. Weld. World 2018, 62, 517–533. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, V.; Karlsson, L.; Wessman, S.; Fuertes, N. Effect of Sigma Phase Morphology on the Degradation of Properties in a Super Duplex Stainless Steel. Materials 2018, 11, 933. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hosseini, V.; Hurtig, K.; Karlsson, L. Bead by Bead Study of a Multipass Shielded Metal Arc-Welded Super-Duplex Stainless Steel. Weld. World 2020, 64, 283–299. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, V. Influence of Multiple Welding Cycles on Microstructure and Corrosion Resistance of a Super Duplex Stainless Steel. Licentiate Thesis, University West, Trollhättan, Sweden, 2016. [Google Scholar]

- Valiente Bermejo, M.A.; Hurtig, K.; Eyzop, D.; Karlsson, L. A New Approach to the Study of Multi-Pass Welds–Microstructure and Properties of Welded 20-Mm-Thick Superduplex Stainless Steel. Appl. Sci. 2019, 9, 1050. [Google Scholar] [CrossRef] [Green Version]

- Avesta Welding AB. How to Weld Duplex Stainless Steels. In Technical Document 10601EN-GB; Avesta Welding AB: Avesta, Sweden, 2006. [Google Scholar]

- Metrode Products Ltd. Welding Guidelines for Duplex & Superduplex Stainless Steels; Metrode Products Ltd.: Chertsey, UK, 2005. [Google Scholar]

- Pettersson, C.-O.; Fager, S.-Å. Welding Practice for the Sandvik Duplex Stainless Steels SAF 2304, SAF 2205 and SAF 2507; Technical Document S-91-57; AB Sandvik Steel: Sandviken, Sweden, 1995. [Google Scholar]

- Karlsson, L. Welding Duplex Stainless Steels—A Review Of Current Recommendations. Weld. World 2012, 56, 65–76. [Google Scholar] [CrossRef]

- Swedish Standards Institute. Destructive Tests on Welds in Metallic Materials-Impact Test-Test Specimen Location, Notch Orientation and Examination; Swedish Standards Institute: Stockholm, Sweden, 2012. [Google Scholar]

- Swedish Standards Institute. Destructive Tests on Welds in Metallic Materials-Transverse Tensile Test; Swedish Standards Institute: Stockholm, Sweden, 2012. [Google Scholar]

- Swedish Standards Institute. Destructive Tests on Welds in Metallic Materials-Longitudinal Tensile Test on Weld Metal in Fusion Welded Joints; Swedish Standards Institute: Stockholm, Sweden, 2011. [Google Scholar]

- ASTM International. Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Standard, Norsok. NORSOK Standard M-601: Welding and Inspection of Piping; Standards Norway: Lysaker, Norway, 2004. [Google Scholar]

- ASTM International. Standard Test Method for Electrochemical Critical Pitting Temperature Testing of Stainless Steels; ASTM International: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Sales, A.M.; Westin, E.M.; Jarvis, B.L. Effect of Nitrogen in Shielding Gas of Keyhole GTAW on Properties of Duplex and Superduplex Welds. Weld. World 2017, 61, 1133–1140. [Google Scholar] [CrossRef]

- Hosseini, V.; Karlsson, L. Physical and Kinetic Simulation of Nitrogen Loss in High Temperature Heat Affected Zone of Duplex Stainless Steels. Materialia 2019, 6, 100325. [Google Scholar] [CrossRef]

- Nilsson, J.-O.; Chai, G. The Physical Metallurgy of Duplex Stainless Steels. In Proceedings of the Duplex Stainless Steel Conference, Beaune, France, 13–15 October 2010; pp. 369–390. [Google Scholar]

- Ramirez, A.J.; Brandi, S.D.; Lippold, J.C. Secondary Austenite and Chromium Nitride Precipitation in Simulated Heat Affected Zones of Duplex Stainless Steels. Sci. Technol. Weld. Join. 2004, 9, 301–313. [Google Scholar] [CrossRef]

- Nilsson, J.-O.; Karlsson, L.; Andersson, J.-O. Secondary Austenite Formation and Its Relation to Pitting Corrosion in Duplex Stainless Steel Weld Metal. Mater. Sci. Technol. 1995, 11, 276–283. [Google Scholar] [CrossRef]

- Hosseini, V.; Hurtig, K.; Karlsson, L. Effect of Multipass TIG Welding on the Corrosion Resistance and Microstructure of a Super Duplex Stainless Steel: Multipass Welding of a Super Duplex Stainless Steel. Mater. Corros. 2017, 68, 405–415. [Google Scholar] [CrossRef]

- Yousefieh, M.; Shamanian, M.; Saatchi, A. Influence of Step Annealing Temperature on the Microstructure and Pitting Corrosion Resistance of SDSS UNS S32760 Welds. J. Mater. Eng. Perform. 2011, 20, 1678–1683. [Google Scholar] [CrossRef]

- Kobayashi, D.Y.; Wolynec, S. Evaluation of the Low Corrosion Resistant Phase Formed during the Sigma Phase Precipitation in Duplex Stainless Steels. Mat. Res. 1999, 2, 239–247. [Google Scholar] [CrossRef] [Green Version]

- American Welding Society. Welding Science and Technology, 9th ed.; American Welding Society: Miami, FL, USA, 2001; Volume 1. [Google Scholar]

| Product and Designation | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | W |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SDX 2507 33 mm thickness plate | 0.015 | 0.34 | 0.74 | 0.021 | 0.001 | 24.97 | 6.89 | 3.80 | 0.200 | 0.275 | 0.046 |

| GMAW: AWS SFA5.9 ER2594 ø 1.2 mm | 0.015 | 0.40 | 0.61 | 0.014 | 0.001 | 25.23 | 9.22 | 4.04 | 0.09 | 0.260 | 0.04 |

| SAW wire: AWS SFA5.9 ER2594 ø 2.4 mm | 0.012 | 0.44 | 0.60 | 0.015 | 0.001 | 24.94 | 9.21 | 3.88 | 0.09 | 0.260 | 0.008 |

| SAW All-weld metal. Flux: EN ISO 14174: S A AF 2 DC. | 0.01 | 0.45 | 0.6 | NR | NR | 22.5 | 9.2 | 4.0 | NR | 0.26 | NR |

| Ref. | Welding Layout | Pass | Current (A) | Voltage (V) | Welding Speed (mm/s) | Arc Energy (kJ/mm) | Average Interpass T (°C) |

|---|---|---|---|---|---|---|---|

| GM-R |  | 1 | 209 | 31.7 | 4.2 | 1.58 | 25 |

| 2–18 | 207–246 | 31.9–28.9 | 5.5 | 1.18–1.29 | Side 1: 65 Side 2: 76 | ||

| SA-R |  | 1/side 1 | 450 | 28 | 8.3 | 1.5 | 20 |

| 2–17 | 450 | 30 | 10.8 | 1.2 | Side 1: 74 Side 2: 81 | ||

| SA-H |  | 1/side 1 | 450 | 28 | 8.3 | 1.5 | 24 |

| 2–4/side 1 | 450–550 | 30 | 6.7–8.3 | 2.0 | 140 | ||

| 5–8/side 2 | 500 | 30 | 6.7 | 2.3 | 180 |

| Weldment | % Ferrite (Average Values) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| WM Top | Std | WM Center | Std | WM Root | Std | WM Overall | StD | HAZ | Std | |

| SA-R | 52 | 5 | 51 | 3 | 59 | 2 | 53 | 5 | 64 | 4 |

| SA-H | 51 | 4 | 49 | 3 | 51 | 3 | 51 | 4 | 61 | 7 |

| GM-R | 59 | 3 | 52 | 5 | 56 | 4 | 56 | 5 | 65 | 4 |

| Weldment | wt. (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Ni | Mo | C | Si | Mn | P | S | Cu | N | O | |

| SA-R | 24.5 +/− 0.1 | 8.2 +/− 0.5 | 4.0 +/− 0.0 | 0.04 +/− 0.01 | 0.5 +/− 0.0 | <0.8 | 0.02 +/− 0.00 | 0.005 +/− 0.000 | 0.1 +/− 0.0 | 0.248 +/− 0.004 | 0.045 +/− 0.005 |

| SA-H | 24.5 +/− 0.2 | 7.9 +/− 0.4 | 4.0 +/− 0.1 | 0.04 +/− 0.01 | 0.4 +/− 0.0 | <0.8 | 0.02 +/− 0.00 | 0.004 +/− 0.000 | 0.2 +/− 0.0 | 0.256 +/− 0.011 | 0.051 +/− 0.013 |

| GM-R | 24.9 +/− 0.1 | 8.6 +/− 0.3 | 4.1 +/− 0.1 | 0.04 +/− 0.00 | 0.4 +/− 0.0 | <0.8 | 0.02 +/− 0.00 | 0.004 +/− 0.001 | 0.1 +/− 0.0 | 0.228 +/− 0.005 | 0.013 +/− 0.004 |

| Weldment | ASTM G48E | ASTM G150 | ||

|---|---|---|---|---|

| CPT (°C) | Section Investigated and Microstructural Features Observed | CPT * (°C) | Location of Pitting Initiation | |

| GM-R | 60 | - | - | - |

| SA-R | 45 | Section investigated includes weld pass 2 (showing nitrides), weld pass 3 (showing ɣ2), weld pass 4 (showing nitrides +σ-phase), and HAZ (showing nitrides). | 64.7 | In the weld metal |

| SA-H | 55 | Section investigated includes weld pass 7 (showing ɣ2), weld pass 8 (free from secondary phases), and HAZ (showing nitrides and ɣ2). | 70.9 | In the HAZ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valiente Bermejo, M.A.; Eyzop, D.; Hurtig, K.; Karlsson, L. Welding of Large Thickness Super Duplex Stainless Steel: Microstructure and Properties. Metals 2021, 11, 1184. https://doi.org/10.3390/met11081184

Valiente Bermejo MA, Eyzop D, Hurtig K, Karlsson L. Welding of Large Thickness Super Duplex Stainless Steel: Microstructure and Properties. Metals. 2021; 11(8):1184. https://doi.org/10.3390/met11081184

Chicago/Turabian StyleValiente Bermejo, Maria Asuncion, Daniel Eyzop, Kjell Hurtig, and Leif Karlsson. 2021. "Welding of Large Thickness Super Duplex Stainless Steel: Microstructure and Properties" Metals 11, no. 8: 1184. https://doi.org/10.3390/met11081184

APA StyleValiente Bermejo, M. A., Eyzop, D., Hurtig, K., & Karlsson, L. (2021). Welding of Large Thickness Super Duplex Stainless Steel: Microstructure and Properties. Metals, 11(8), 1184. https://doi.org/10.3390/met11081184