Enhanced Permeability of Fe-Based Amorphous Powder Cores Realized through Selective Incorporation of Carbonyl Iron Powders at Inter-Particle Voids

Abstract

:1. Introduction

2. Experimental Sections

2.1. Materials

2.2. Surface Insulation Coating of AP and CIP

2.3. Fabrication of the SMCs

2.4. Characterization

3. Results and Discussion

4. Conclusions

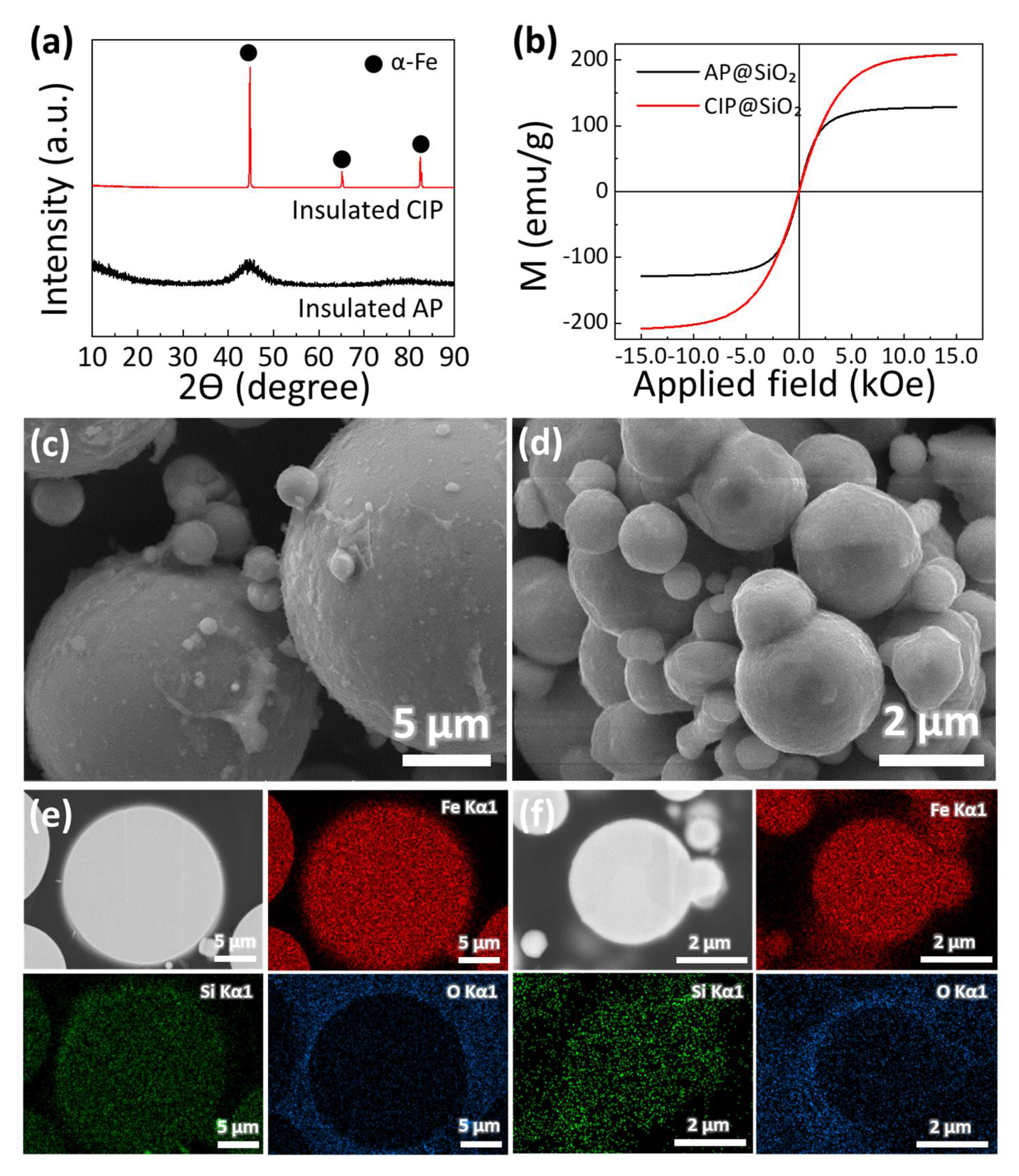

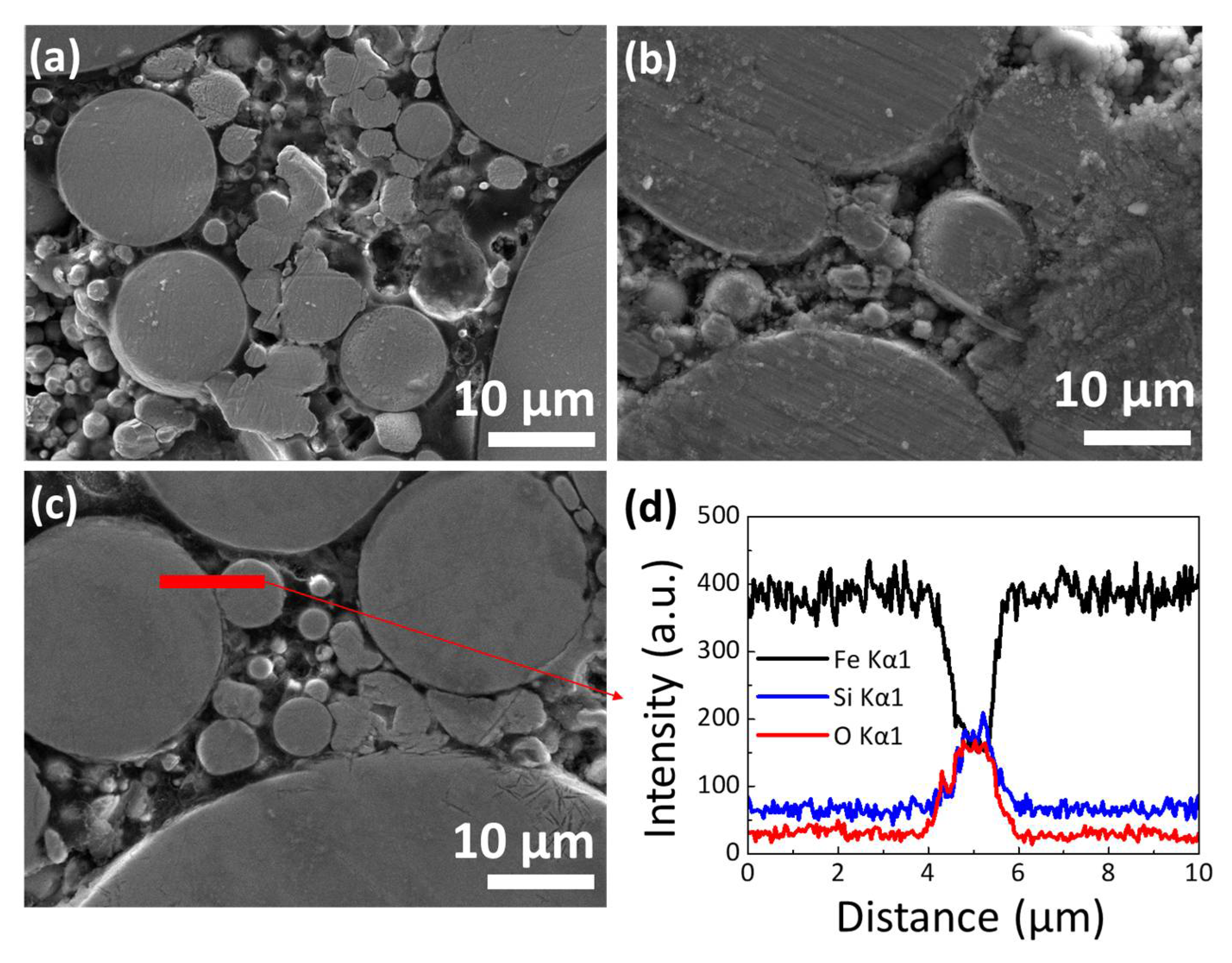

- CIPs are selectively incorporated in voids between APs; they deform during compaction and effectively reduce pores, resulting in the high packing density of cores.

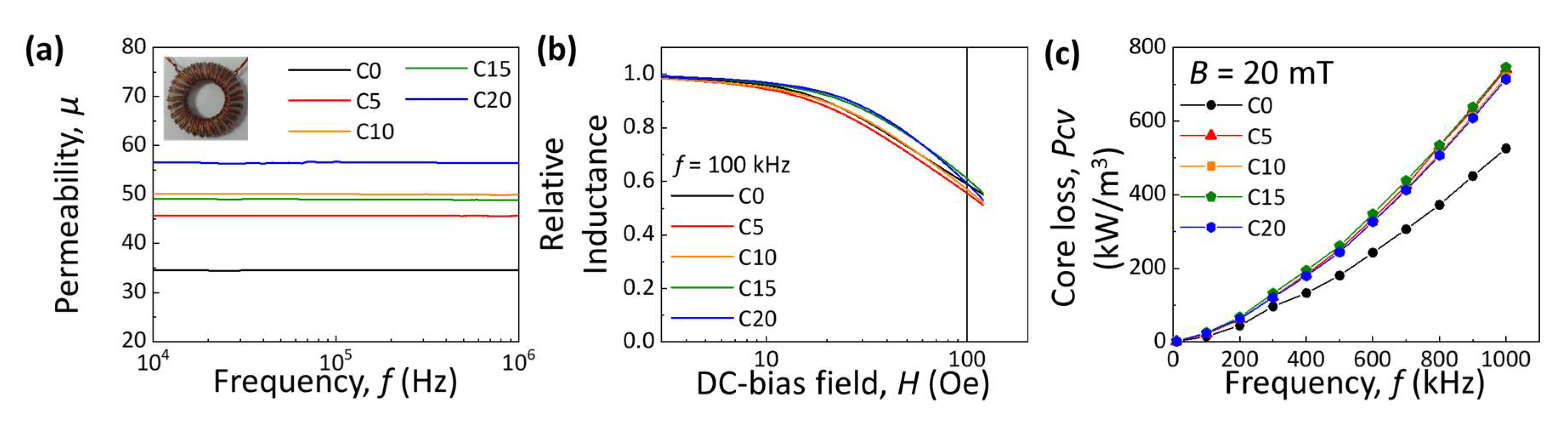

- CIPs magnetically bridge APs and APs rotate their magnetic domains more efficiently than the pure AP cores, resulting in significantly increased permeability of cores. The addition of 20 wt.% CIP in SMC showed constant effective permeability from 57 up to 1 MHz, a remarkable 63% increase compared with the AP core.

- With the help of the high saturation magnetization of CIPs, DC bias superimposing retention level of 61% was secured for the CIP-added hybrid core.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hasegawa, R. Present status of amorphous soft magnetic alloys. J. Magn. Magn. Mater. 2000, 215–216, 240–245. [Google Scholar] [CrossRef]

- Yoshida, S.; Mizushima, T.; Hatanai, T.; Inoue, A. Preparation of new amorphous powder cores using Fe-based glassy alloy. IEEE Trans. Magn. 2000, 36, 3424–3429. [Google Scholar] [CrossRef]

- Hasegawa, R.; Hathaway, R.E.; Chang, C.F. Magnetic properties of consolidated glassy metal powder cores. J. Appl. Phys. 1985, 57, 3566–3568. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Masumoto, T.; Suzuki, K.; Fujimori, H.; Hashimoto, K. Materials Science of Amorphous Metals; Ohm Publication: Tokyo, Japan, 1982; pp. 7–20. [Google Scholar]

- Kikuchi, M.; Fujimori, H.; Obi, Y.; Masumoto, T. New Amorphous Ferromagnets with Low Coercive Force. Jpn. J. Appl. Phys. 1975, 14, 1077–1078. [Google Scholar] [CrossRef]

- Kohmoto, O.; Fujishima, H.; Ojima, T. Magnetic annealing of zero magnetostrictive amorphous alloy with high saturation induction. IEEE Trans. Magn. 1980, 16, 440–443. [Google Scholar] [CrossRef]

- Liu, Y.; Niu, S.; Li, F.; Zhu, Y.; He, Y. Preparation of amorphous Fe-based magnetic powder by water atomization. Powder Technol. 2011, 213, 36–40. [Google Scholar] [CrossRef]

- Kim, Y.B.; Jang, D.H.; Seok, H.K.; Kim, K.Y. Fabrication of Fe–Si–B based amorphous powder cores by cold pressing and their magnetic properties. Mater. Sci. Eng. A 2007, 449–451, 389–393. [Google Scholar] [CrossRef]

- Neamţu, B.V.; Marinca, T.F.; Chicinaş, I.; Isnard, O.; Popa, F.; Păşcuţă, P. Preparation and soft magnetic properties of spark plasma sintered compacts based on Fe–Si–B glassy powder. J. Alloys Compd. 2014, 600, 1–7. [Google Scholar] [CrossRef]

- Chen, H.S. Glassy metals. Rep. Prog. Phys. 1980, 43, 353–432. [Google Scholar] [CrossRef]

- Luborsky, F.E. Magnetic properties of amorphous alloys. J. Magn. Magn. Mater. 1978, 7, 143–149. [Google Scholar] [CrossRef]

- Wun-Fogle, M.; Restorff, J.B.; Cuseo, J.M.; Garshelis, I.J.; Bitar, S. Magnetostriction and magnetization of common high strength steels. IEEE Trans. Magn. 2009, 45, 4112–4115. [Google Scholar] [CrossRef]

- Stearns, M.B. Internal Magnetic Fields, Isomer Shifts, and Relative Abundances of the Various Fe Sites in FeSi Alloys. Phys. Rev. 1963, 129, 1136–1144. [Google Scholar] [CrossRef]

- Ciftci, N.; Ellendt, N.; Coulthard, G.; Barreto, E.S.; Mädler, L.; Uhlenwinkel, V. Novel cooling rate correlations in molten metal gas atomization. Metall. Mater. Trans. B 2019, 50, 666–677. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Y.; Dong, Y.; Li, Q.; He, A.; Chang, C.; Wang, X. Enhanced magnetic properties of Fe-based nanocrystalline composites by addition of carbonyl iron powders. SN Appl. Sci. 2019, 1, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-J.; Nam, S.K.; Kim, K.-S.; Yoon, S.C.; Sohn, K.-Y.; Kim, M.-R.; Song, Y.S.; Park, W.-W. Magnetic properties of amorphous Fe–Si–B powder cores mixed with pure iron powder. Jpn. J. Appl. Phys. 2012, 51, 103001. [Google Scholar] [CrossRef]

- Chang, C.; Guo, J.; Li, Q.; Zhou, S.; Liu, M.; Dong, Y. Improvement of soft magnetic properties of FeSiBPNb amorphous powder cores by addition of FeSi powder. J. Alloys Compd. 2019, 788, 1177–1181. [Google Scholar] [CrossRef]

- Xia, C.; Peng, Y.; Yi, X.; Yao, Z.; Zhu, Y.; Hu, G. Improved magnetic properties of FeSiCr amorphous soft magnetic composites by adding carbonyl iron powder. J. Non-Cryst. Solids 2021, 559, 120673. [Google Scholar] [CrossRef]

- German, R.M. Powder Metallurgy and Particulate Materials Processing: The Processes, Materials, Products, Properties and Applications; Metal Powder Industries Federation Princeton: Princeton, NJ, USA, 2005; pp. 130–132. [Google Scholar]

- Japka, J.E. Microstructure and properties of carbonyl iron powder. JOM 1988, 40, 18–21. [Google Scholar] [CrossRef]

- Zhou, B.; Dong, Y.; Liu, L.; Chang, L.; Bi, F.; Wang, X. Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer. J. Magn. Magn. Mater. 2019, 474, 1–8. [Google Scholar] [CrossRef]

- Wang, C.; Guo, Z.; Wang, J.; Sun, H.; Chen, D.; Chen, W.; Liu, X. Industry-oriented Fe-based amorphous soft magnetic composites with SiO2-coated layer by one-pot high-efficient synthesis method. J. Magn. Magn. Mater. 2020, 509, 166924. [Google Scholar] [CrossRef]

- Xiaolong, L.; Yaqiang, D.; Min, L.; Chuntao, C.; Xin-Min, W. New Fe-based amorphous soft magnetic composites with significant enhancement of magnetic properties by compositing with nano-(NiZn) Fe2O4. J. Alloys Compd. 2017, 696, 1323–1328. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Kan, X.; Wang, Z.; Zhu, R.; Yang, W.; Wu, Q.; Shezad, M. Phosphate coatings evolution study and effects of ultrasonic on soft magnetic properties of FeSiAl by aqueous phosphoric acid solution passivation. J. Alloys Compd. 2019, 783, 434–440. [Google Scholar] [CrossRef]

- Matos, M.C.; Ilharco, L.M.; Almeida, R.M. The evolution of TEOS to silica gel and glass by vibrational spectroscopy. J. Non·Cryst. Solids 1992, 147–148, 232–237. [Google Scholar] [CrossRef]

- Ollendorff, F. Magnetostatik der massekerne. Arch. Elektrotech. 1931, 25, 436–447. [Google Scholar] [CrossRef]

- Xie, D.-Z.; Lin, K.-H.; Lin, S.-T. Effects of processed parameters on the magnetic performance of a powder magnetic core. J. Magn. Magn. Mater. 2014, 353, 34–40. [Google Scholar] [CrossRef]

- Yang, B.; Li, X.; Guo, R.; Yu, R. Oxidation fabrication and enhanced soft magnetic properties for core-shell FeCo/CoFe2O4 micron-nano composites. Mater. Des. 2017, 121, 272–279. [Google Scholar] [CrossRef]

- Takemoto, S.; Saito, T. Effects of crystal grain size and particle size on core loss for Fe-Si compressed cores. Mater. Sci. Forum 2007, 534, 1313–1316. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Guo, P.; Sarangan, A.M.; Agha, I. A review of germanium-antimony-telluride phase change materials for non-volatile memories and optical modulators. Appl. Sci. 2019, 9, 530. [Google Scholar] [CrossRef] [Green Version]

| Samples | Weigh Ratio (%) | Volume Ratio (%) | Core Density | Powder Density * | Relative Density | ||

|---|---|---|---|---|---|---|---|

| AP | CIP | AP | CIP | (g/cm3) | (g/cm3) | (%) | |

| C0 | 100 | 0 | 100 | 0 | 5.429 | 7.087 | 76.61 |

| C5 | 95 | 5 | 95.44 | 4.56 | 5.655 | 7.120 | 79.43 |

| C10 | 90 | 10 | 90.83 | 9.17 | 5.815 | 7.152 | 81.30 |

| C15 | 85 | 15 | 86.18 | 13.82 | 5.957 | 7.186 | 82.90 |

| C20 | 80 | 20 | 81.49 | 18.51 | 6.041 | 7.219 | 83.68 |

| Sample | Hc (kA/m) | Kh | Kdyn (Ke + Ka) |

|---|---|---|---|

| C0 | 0.00326 | 0.2035 | 3.27 × 10−4 |

| C5 | 0.01497 | 0.2636 | 4.86 × 10−4 |

| C10 | 0.01565 | 0.2628 | 4.65 × 10−4 |

| C15 | 0.01706 | 0.3038 | 4.49 × 10−4 |

| C20 | 0.02145 | 0.2664 | 4.54 × 10−4 |

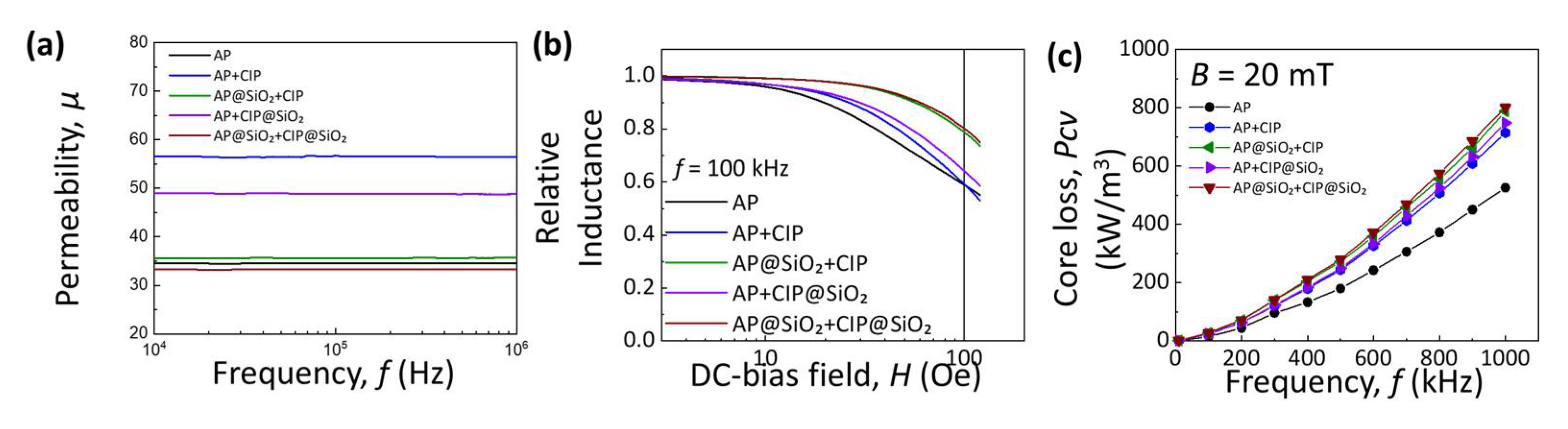

| Sample | Density | Permeability | Core Loss, Pcv (kW/m3) | DC-Bias (%) | |

|---|---|---|---|---|---|

| (g/cm3) | f = 1 MHz | 100 kHz/50 mT | 100 kHz/100 mT | 100 Oe | |

| AP (=C0) | 5.429 | 34.63 | 159.29 | 571.19 | 59.12 |

| AP + CIP (=C20) | 6.041 | 56.45 | 201.03 | 1004.1 | 59.46 |

| AP@SiO2 + CIP | 5.837 | 35.70 | 263.96 | 1195.2 | 79.06 |

| AP + CIP@SiO2 | 5.953 | 48.81 | 231.50 | 1041.7 | 64.50 |

| AP@SiO2 + CIP@SiO2 | 5.769 | 33.34 | 257.66 | 1202.4 | 80.43 |

| Sample | Kh | Kdyn (Ke + Ka) |

|---|---|---|

| AP (=C0) | 0.2035 | 3.27 × 10−4 |

| AP + CIP (=C20) | 0.2664 | 4.54 × 10−4 |

| AP@SiO2 + CIP | 0.3108 | 3.78 × 10−4 |

| AP + CIP@SiO2 | 0.2587 | 4.94 × 10−4 |

| AP@SiO2 + CIP@SiO2 | 0.3244 | 4.84 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-R.; Jang, M.-S.; Nam, Y.-G.; Kim, Y.-S.; Yang, S.-S.; Kim, Y.-J.; Jeong, J.-W. Enhanced Permeability of Fe-Based Amorphous Powder Cores Realized through Selective Incorporation of Carbonyl Iron Powders at Inter-Particle Voids. Metals 2021, 11, 1220. https://doi.org/10.3390/met11081220

Kim H-R, Jang M-S, Nam Y-G, Kim Y-S, Yang S-S, Kim Y-J, Jeong J-W. Enhanced Permeability of Fe-Based Amorphous Powder Cores Realized through Selective Incorporation of Carbonyl Iron Powders at Inter-Particle Voids. Metals. 2021; 11(8):1220. https://doi.org/10.3390/met11081220

Chicago/Turabian StyleKim, Hea-Ran, Min-Sun Jang, Yeong-Gyun Nam, Yun-Seok Kim, Sang-Sun Yang, Yong-Jin Kim, and Jae-Won Jeong. 2021. "Enhanced Permeability of Fe-Based Amorphous Powder Cores Realized through Selective Incorporation of Carbonyl Iron Powders at Inter-Particle Voids" Metals 11, no. 8: 1220. https://doi.org/10.3390/met11081220

APA StyleKim, H.-R., Jang, M.-S., Nam, Y.-G., Kim, Y.-S., Yang, S.-S., Kim, Y.-J., & Jeong, J.-W. (2021). Enhanced Permeability of Fe-Based Amorphous Powder Cores Realized through Selective Incorporation of Carbonyl Iron Powders at Inter-Particle Voids. Metals, 11(8), 1220. https://doi.org/10.3390/met11081220