Microstructure, Plasticity and Ductility of a TNM+ Alloy Densified by Spark Plasma Sintering

Abstract

1. Introduction

2. Materials and Methods

- -

- Yield strength: stress at which plastic deformation starts and defined as the stress at 10−3% plastic elongation;

- -

- R0.2: the tensile stress at 0.2% plastic elongation;

- -

- UTS: ultimate tensile stress; and

- -

- A: plastic elongation at rupture.

3. Results

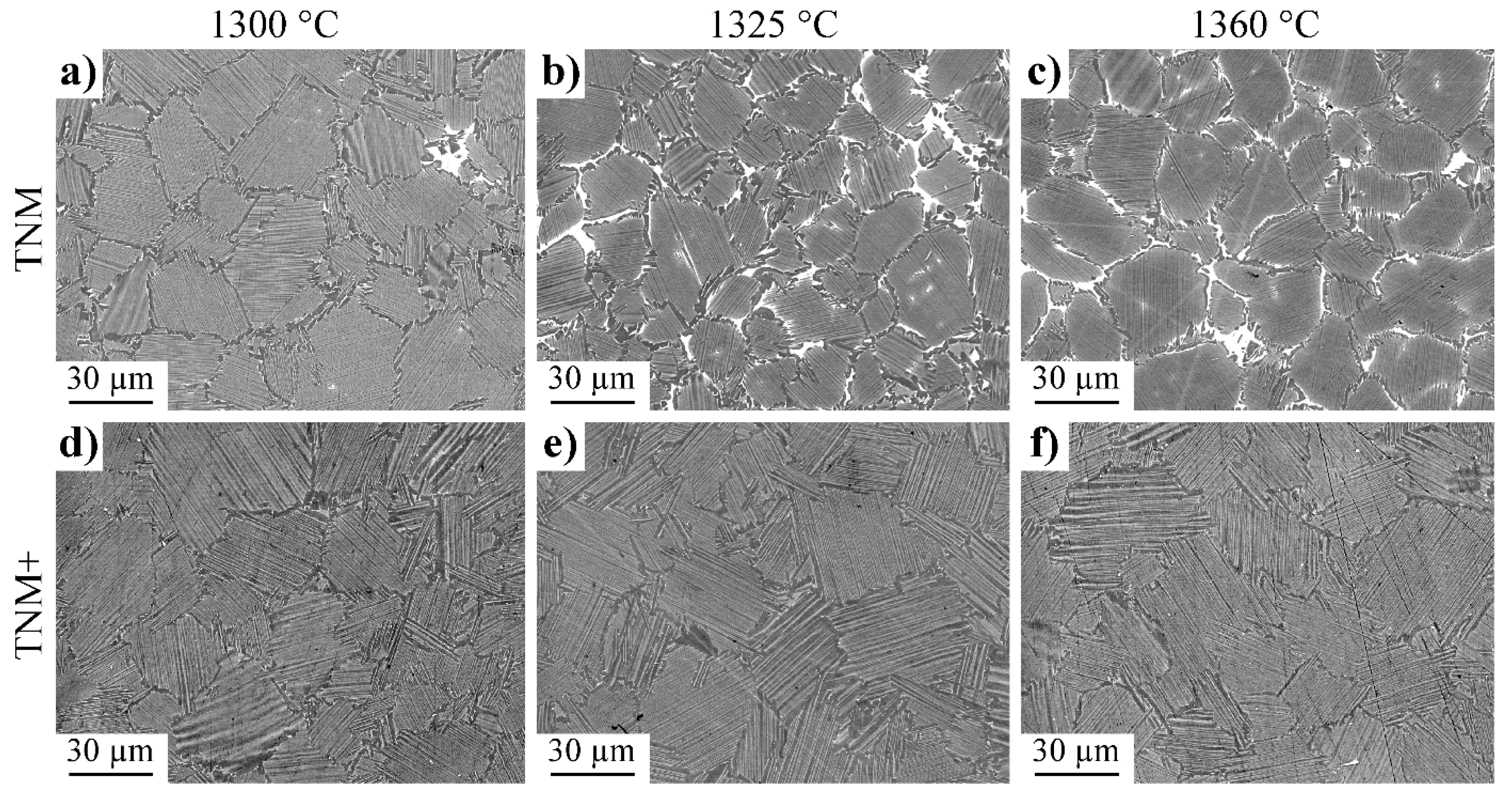

3.1. Microstructure after SPS

3.2. Microstructure after Heat Treatments

3.3. Mechanical Tests and Fractography

3.4. Plasticity of the Phase

4. Discussion

4.1. Microstructural Evolution during SPS

4.2. Plasticity and Brittleness of the as-SPSed TNM+ Alloy

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Kainuma, R.; Fujita, Y.; Mitsui, H.; Ohnuma, I.; Ishida, K. Phase equilibria among α (hcp), β (bcc) and γ (L10) phases in Ti–Al base ternary alloys. Intermetallics 2000, 8, 855–867. [Google Scholar] [CrossRef]

- Clemens, H.; Wallgram, W.; Kremmer, S.; Güther, V.; Otto, A.; Bartels, A. Design of Novel β-Solidifying TiAl Alloys with Adjustable β/B2-Phase Fraction and Excellent Hot-Workability. Adv. Eng. Mater. 2008, 10, 707–713. [Google Scholar] [CrossRef]

- Küstner, V.; Oehring, M.; Chatterjee, A.; Clemens, H.; Appel, F. Analysis of the solidification microstructure of multi-component gamma titanium aluminide alloys. In Solidification and Crystallization; Herlach, D.M., Ed.; WILEY-VCH: Weinheim, Germany, 2004; pp. 250–258. [Google Scholar]

- Schwaighofer, E.; Clemens, H.; Mayer, S.; Lindemann, J.; Klose, J.; Smarsly, W.; Güther, V. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy. Intermetallics 2014, 44, 128–140. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Rashkova, B.; Clemens, H.; Mayer, S. Enhancement of creep properties and microstructural stability of intermetallic β-solidifying γ-TiAl based alloys. Intermetallics 2015, 63, 19–26. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys: Science and Technology; WILEY-VCH: Weinheim, Germany, 2011. [Google Scholar]

- Kestler, H.; Clemens, H. Production, processing and application of γ(TiAl)-based alloys. In Titanium and Titanium Alloys; Leyens, C., Peters, M., Eds.; WILEY-VCH: Weinheim, Germany, 2003; pp. 351–392. [Google Scholar]

- Paul, J.D.H.; Appel, F.; Wagner, R. The compression behaviour of niobium alloyed γ-titanium alumindies. Acta Mater. 1998, 46, 1075–1085. [Google Scholar] [CrossRef]

- Wallgram, W.; Schmölzer, T.; Cha, L.; Das, G.; Güther, V.; Clemens, H. Technology and mechanical properties of advanced γ-TiAl based alloys. Int. J. Mat. Res. 2009, 100, 1021–1030. [Google Scholar] [CrossRef]

- Kim, Y.-W. Strength and ductility in TiAl alloys. Intermetallics 1998, 6, 623–628. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Hantcherli, M.; Mayer, S.; Clemens, H.; Couret, A. Microstructures and mechanical properties of a multi-phase β-solidifying TiAl alloy densified by spark plasma sintering. Acta Mater. 2014, 73, 107–115. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Perrut, M.; Couret, A. Obtaining of a fine near-lamellar microstructure in TiAl alloys by Spark Plasma Sintering. Intermetallics 2016, 71, 88–97. [Google Scholar] [CrossRef]

- Voisin, T.; Durand, L.; Karnatak, N.; le Gallet, S.; Thomas, M.; le Berre, Y.; Castagné, J.-F.; Couret, A. Temperature control during Spark Plasma Sintering and application to up-scaling and complex shaping. J. Mater. Process. Technol. 2013, 213, 269–278. [Google Scholar] [CrossRef]

- Imayev, R.M.; Imayev, V.M.; Oehring, M.; Appel, F. Alloy design concepts for refined gamma titanium aluminide based alloys. Intermetallics 2007, 15, 451–460. [Google Scholar] [CrossRef]

- Kim, S.W.; Wang, P.; Oh, M.H.; Wee, D.M.; Kumar, K.S. Mechanical properties of Si- and C-doped directionally solidified TiAl–Nb alloys. Intermetallics 2004, 12, 499–509. [Google Scholar] [CrossRef]

- Appel, F.; Lorenz, U.; Oehring, M.; Sparka, U.; Wagner, R. Thermally activated deformation mechanisms in micro-alloyed two-phase titanium amminide alloys. Mater. Sci. Eng. A 1997, 233, 1–14. [Google Scholar] [CrossRef]

- Scheu, C.; Stergar, E.; Schober, M.; Cha, L.; Clemens, H.; Bartels, A.; Schimansky, F.-P.; Cerezo, A. High carbon solubility in a γ-TiAl-based Ti–45Al–5Nb–0.5C alloy and its effect on hardening. Acta Mater. 2009, 57, 1504–1511. [Google Scholar] [CrossRef]

- Klein, T.; Schachermayer, M.; Mendez-Martin, F.; Schöberl, T.; Rashkova, B.; Clemens, H.; Mayer, S. Carbon distribution in multi-phase γ-TiAl based alloys and its influence on mechanical properties and phase formation. Acta Mater. 2015, 94, 205–213. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Staron, P.; Rashkova, B.; Stark, A.; Schell, N.; Clemens, H.; Mayer, S. In situ small-angle X-ray scattering study of the perovskite-type carbide precipitation behavior in a carbon-containing intermetallic TiAl alloy using synchrotron radiation. Acta Mater. 2014, 77, 360–369. [Google Scholar] [CrossRef]

- Noda, T.; Okabe, M.; Isobe, S.; Sayashi, M. Silicide precipitation strengthened TiAl. Mater. Sci. Eng. A 1995, 192, 774–779. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Kim, S.-L. Effects of microstructure and C and Si additions on elevated temperature creep and fatigue of gamma TiAl alloys. Intermetallics 2014, 53, 92–101. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Rashkova, B.; Clemens, H.; Stark, A.; Mayer, S. Effect of carbon addition on solidification behavior, phase evolution and creep properties of an intermetallic β-stabilized γ-TiAl based alloy. Intermetallics 2014, 46, 173–184. [Google Scholar] [CrossRef]

- Musi, M.; Galy, B.; Stark, A.; Schell, N.; Hantcherli, M.; Monchoux, J.-P.; Couret, A.; Clemens, H.; Spoerk-Erdely, P. How Si affects the microstructural evolution and phase transformations of intermetallic γ-TiAl based alloys. Materialia 2022, 24, 101475. [Google Scholar] [CrossRef]

- Lutterotti, L. Total pattern fitting for the combined size–strain–stress–texture determination in thin film diffraction. Nucl. Instrum. Methods B 2010, 268, 334–340. [Google Scholar] [CrossRef]

- Zghal, S.; Naka, S.; Couret, A. A quantitative TEM analysis of the lamellar microstructure in TiAl based alloys. Acta Mater. 1997, 45, 3005–3015. [Google Scholar] [CrossRef]

- Zghal, S.; Thomas, M.; Naka, S.; Finel, A.; Couret, A. Phase transformations in TiAl based alloys. Acta Mater. 2005, 53, 2653–2664. [Google Scholar] [CrossRef]

- Klein, T.; Rashkova, B.; Holec, D.; Clemens, H.; Mayer, S. Silicon distribution and silicide precipitation during annealing in an advanced multi-phase γ-TiAl based alloy. Acta Mater. 2016, 110, 236–245. [Google Scholar] [CrossRef]

- Hu, D. Effect of boron addition on tensile ductility in lamellar TiAl alloys. Intermetallics 2002, 10, 851–858. [Google Scholar] [CrossRef]

- Liss, K.-D.; Bartels, A.; Clemens, H.; Bystrzanowski, S.; Stark, A.; Buslaps, T.; Schimansky, F.-P.; Gerling, R.; Scheu, C.; Schreyer, A. Recrystallization and phase transitions in a γ-TiAl-based alloy as observed by ex situ and in situ high-energy X-ray diffraction. Acta Mater. 2006, 54, 3721–3735. [Google Scholar] [CrossRef]

- Saada, G.; Couret, A. Relaxation of coherency stresses by dislocation networks in lamellar γ-TiAl. Philos. Mag. A 2001, 81, 2109–2120. [Google Scholar] [CrossRef]

- Farenc, S.; Coujou, A.; Couret, A. An in situ study of twin propagation in TiAl. Philos. Mag. A 1993, 67, 127–142. [Google Scholar] [CrossRef]

- Couret, A.; Farenc, S.; Caillard, D.; Coujou, A. Twinning in Advanced Materials. In TMS Symposium Proceedings; Yoo, M.H., Wuttig, M., Eds.; TMS: Warrendale, PA, USA, 1994; pp. 316–374. [Google Scholar]

- Inui, H.; Oh, M.H.; Nakamura, A.; Yamaguchi, M. Room-temperature tensile deformation of polysynthetically twinned (PST) crystals of TiAl. Acta Metall. Mater. 1992, 40, 3095–3104. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Klein, T.; Rashkova, B.; Weißensteiner, I.; Clemens, H.; Mayer, S. Phase transformations in a β-solidifying γ-TiAl based alloy during rapid solidification. Intermetallics 2017, 91, 100–109. [Google Scholar] [CrossRef]

- Jabbar, H.; Couret, A.; Durand, L.; Monchoux, J.-P. Identification of microstructural mechanisms during densification of a TiAl alloy by spark plasma sintering. J. Alloys Compd. 2011, 509, 9826–9835. [Google Scholar] [CrossRef]

- Mishin, Y.; Herzig, C. Diffusion in the Ti–Al system. Acta Mater. 2000, 48, 589–623. [Google Scholar] [CrossRef]

- Jabbar, H.; Monchoux, J.-P.; Houdellier, F.; Dollé, M.; Schimansky, F.-P.; Pyczak, F.; Thomas, M.; Couret, A. Microstructure and mechanical properties of high niobium containing TiAl alloys elaborated by spark plasma sintering. Intermetallics 2010, 18, 2312–2321. [Google Scholar] [CrossRef]

- Couret, A.; Allen, M.; Rackel, M.W.; Galy, B.; Monchoux, J.-P.; Güther, V.; Pyczak, F.; Sallot, P.; Thomas, M. Chemical heterogeneities in tungsten containing TiAl alloys processed by powder metallurgy. Materialia 2021, 18, 101147. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Thomas, M.; Deshayes, C.; Couret, A. Mechanical Properties of the TiAl IRIS Alloy. Metall. Mater. Trans. A 2016, 47, 6097–6108. [Google Scholar] [CrossRef]

- Couret, A. An in-situ study of ordinary dislocation glide in γ-TiAl alloys. Philos. Mag. A 1999, 79, 1977–1994. [Google Scholar] [CrossRef]

- Molénat, G.; Galy, B.; Musi, M.; Toualbi, L.; Thomas, M.; Clemens, H.; Monchoux, J.-P.; Couret, A. Plasticity and brittleness of the ordered βo phase in a TNM-TiAl alloy. Intermetallics 2022, 151, 107653. [Google Scholar] [CrossRef]

- Couret, A.; Monchoux, J.-P.; Caillard, D. On the high creep strength of the W containing IRIS-TiAl alloy at 850 °C. Acta Mater. 2019, 181, 331–341. [Google Scholar] [CrossRef]

| Alloy | Ti | Al | Nb | Mo | B | C | Si |

|---|---|---|---|---|---|---|---|

| TNM | 51.1 | 43.9 | 4.0 | 0.95 | 0.1 | - | - |

| TNM+ | 51.0 | 43.1 | 3.35 | 0.95 | 0.1 | 0.3 | 0.3 |

| Alloys | TNM+ | TNM | |||||

|---|---|---|---|---|---|---|---|

| SPS Temperature (°C) | 1300 | 1325 | 1360 | 1300 | 1325 | 1360 | |

| SEM | α2/γ colony size (μm) | 27 | 26 | 31 | 21 | 20 | 20 |

| Fraction γ borders (%) | 11 | 9 | 6 | 16 | 16 | 14 | |

| Fraction βo (%) | 0 | 0 | 0 | 3 | 6 | 7 | |

| Fraction lamellar colonies (%) | 89 | 91 | 94 | 81 | 78 | 79 | |

| XRD | Volume fraction γ (vol.%) | 78 | 78 | 78 | 71 | 70 | 72 |

| Volume fraction α2 (vol.%) | 21 | 22 | 21 | 23 | 22 | 20 | |

| Volume fraction βo (vol.%) | <1 | <1 | <1 | 6 | 8 | 8 | |

| Microstructural Feature | Alloy | Ti | Al | Nb | Mo | Si |

|---|---|---|---|---|---|---|

| Lamellar colonies | TNM | 50.6 | 43.2 | 4.3 | 1 | - |

| TNM+ | 50.9 | 43.6 | 4.2 | 1.1 | 0.3 | |

| γ border | TNM | 48.4 | 46.5 | 4.4 | 0.8 | - |

| TNM+ | 48.5 | 46.1 | 4.2 | 0.9 | 0.3 | |

| βo phase | TNM | 54.7 | 35.6 | 5.8 | 3.9 | - |

| TNM+ | Phase not present | |||||

| Elements | Ti | Al | Nb | Mo | Si |

|---|---|---|---|---|---|

| Zone 1 | 43.9 | 50.6 | 3.9 | 1.1 | 0.5 |

| Zone 2 | 51.7 | 42.2 | 4.2 | 1.3 | 0.6 |

| Zone 3 | 50.6 | 21.5 | 7.0 | 1.9 | 19.0 |

| ξ-silicide [31] | 50.9 | 13.3 | 9.5 | 0.7 | 21.4 |

| Dwell Temperature | YS (MPa) | R0.2 (MPa) | UTS (MPa) | A (%) | ||

|---|---|---|---|---|---|---|

| TNM+ | 1300 °C | Spec 1 | 545 | 669 | 0.09 | |

| 1325 °C | Spec 1 | 553 | 675 | 0.10 | ||

| Spec 2 | 487 | 618 | 0.04 | |||

| Spec 3 | 477 | 590 | 0.04 | |||

| Spec 4 | 505 | 565 | 0.02 | |||

| 1360 °C | Spec 1 | 545 | 611 | 0.06 | ||

| TNM | 1300 °C | Spec 1 | 559 | 771 | 923 | 0.73 |

| Spec 2 | 554 | 759 | 910 | 0.75 | ||

| 1325 °C | Spec 1 | 591 | 814 | 995 | 0.92 | |

| Spec 2 | 583 | 792 | 961 | 0.81 | ||

| Spec 3 | 559 | 755 | 914 | 0.93 | ||

| Spec 4 | 545 | 748 | 905 | 1 | ||

| 1360 °C | Spec 1 | 538 | 770 | 901 | 0.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musi, M.; Deshayes, C.; Molénat, G.; Toualbi, L.; Galy, B.; Spoerk-Erdely, P.; Hantcherli, M.; Monchoux, J.-P.; Thomas, M.; Clemens, H.; et al. Microstructure, Plasticity and Ductility of a TNM+ Alloy Densified by Spark Plasma Sintering. Metals 2022, 12, 1915. https://doi.org/10.3390/met12111915

Musi M, Deshayes C, Molénat G, Toualbi L, Galy B, Spoerk-Erdely P, Hantcherli M, Monchoux J-P, Thomas M, Clemens H, et al. Microstructure, Plasticity and Ductility of a TNM+ Alloy Densified by Spark Plasma Sintering. Metals. 2022; 12(11):1915. https://doi.org/10.3390/met12111915

Chicago/Turabian StyleMusi, Michael, Christophe Deshayes, Guy Molénat, Louise Toualbi, Benjamin Galy, Petra Spoerk-Erdely, Muriel Hantcherli, Jean-Philippe Monchoux, Marc Thomas, Helmut Clemens, and et al. 2022. "Microstructure, Plasticity and Ductility of a TNM+ Alloy Densified by Spark Plasma Sintering" Metals 12, no. 11: 1915. https://doi.org/10.3390/met12111915

APA StyleMusi, M., Deshayes, C., Molénat, G., Toualbi, L., Galy, B., Spoerk-Erdely, P., Hantcherli, M., Monchoux, J.-P., Thomas, M., Clemens, H., & Couret, A. (2022). Microstructure, Plasticity and Ductility of a TNM+ Alloy Densified by Spark Plasma Sintering. Metals, 12(11), 1915. https://doi.org/10.3390/met12111915