Hardness Evolution of Solution-Annealed LPBFed Inconel 625 Alloy under Prolonged Thermal Exposure

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure of the Initial Conditions

3.2. Microstructure Evolution under Thermal Exposure

3.2.1. Evolution of δ Phases under Thermal Exposures

3.2.2. Evolution of γ″ Phase under Thermal Exposure

3.3. Hardness and γ Lattice Parameter Evolution

4. Conclusions

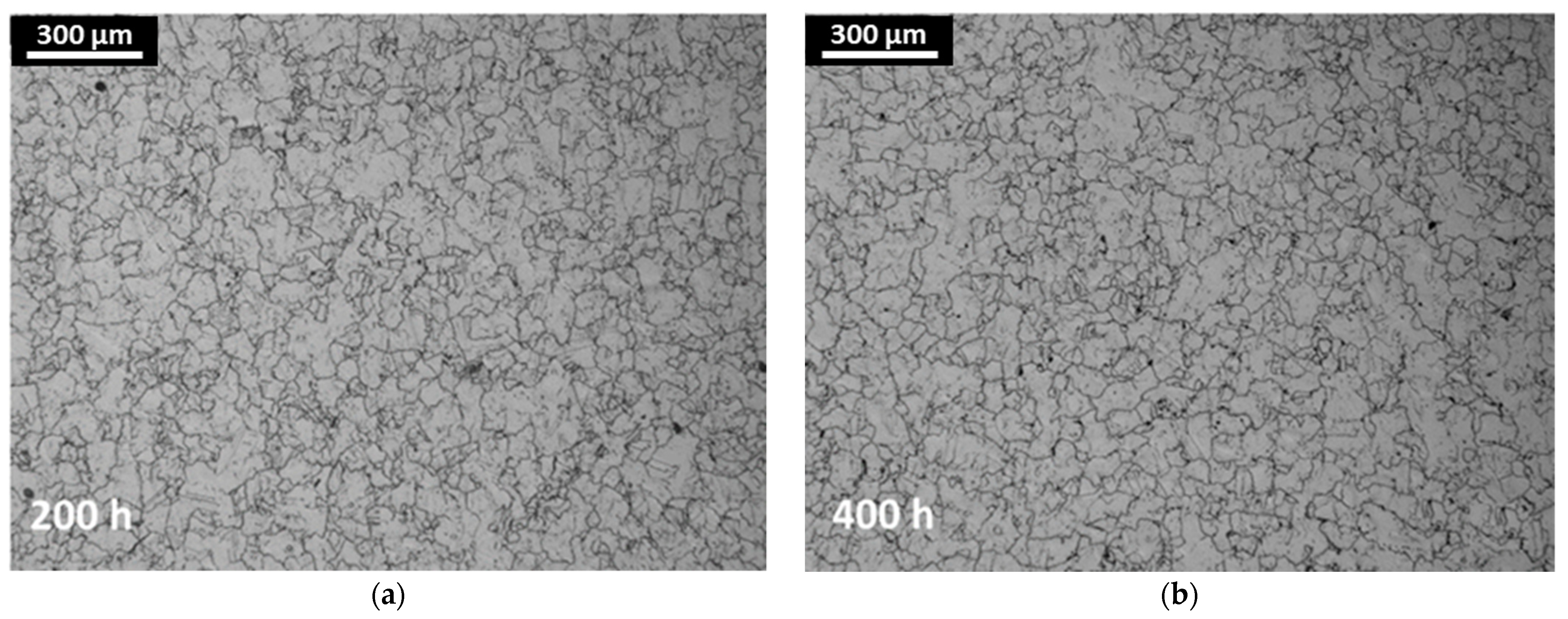

- The thermal exposure did not activate the grain size growth in the material. For this reason, all the microstructure and hardness modifications were ascribed to newly formed phases.

- The formation of γ″ phases drastically increased the hardness, reducing the lattice parameters of the γ matrix after only 200 h. Afterward, the hardness slowly increased with time up to 2000 h. This is mainly attributed to the γ″ phase transformation into intergranular and intragranular δ phases, which have less of a strengthening effect than the γ″ particles.

- The formation of δ phases appeared along the grain boundaries after 200 h of thermal exposure. Moreover, intragranular δ phases could be observed after 1000 and 2000 h of thermal exposure. This is mainly caused by the transformation of γ″ phases into δ phases. The δ phases presented larger dimensions along the grain boundaries than inside the grains due to the faster Nb diffusion in these areas.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Floreen, S.; Fuchs, G.E.; Yang, W.J. The Metallurgy of Alloy 625. In Superalloys 718, 625, 706 and Various Derivatives; Loria, E.A., Ed.; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1994; pp. 13–37. [Google Scholar]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Paul, C.P.; Ganesh, P.; Mishra, S.K.; Bhargava, P.; Negi, J.; Nath, A.K. Investigating Laser Rapid Manufacturing for Inconel-625 Components. Opt. Laser Technol. 2007, 39, 800–805. [Google Scholar] [CrossRef]

- Shankar, V.; Bhanu Sankara Rao, K.; Mannan, S.L. Microstructure and Mechanical Properties of Inconel 625 Superalloy. J. Nucl. Mater. 2001, 288, 222–232. [Google Scholar] [CrossRef]

- Suave, L.M.; Bertheau, D.; Cormier, J.; Villechaise, P.; Soula, A.; Hervier, Z.; Laigo, J. Impact of Microstructural Evolutions during Thermal Aging of Alloy 625 on Its Monotonic Mechanical Properties. MATEC Web Conf. 2014, 14, 21001. [Google Scholar] [CrossRef] [Green Version]

- Suave, L.M.; Cormier, J.; Villechaise, P.; Soula, A.; Hervier, Z.; Bertheau, D.; Laigo, J. Microstructural Evolutions during Thermal Aging of Alloy 625: Impact of Temperature and Forming Process. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 2963–2982. [Google Scholar] [CrossRef]

- Ezugwu, E.O. Key Improvements in the Machining of Difficult-to-Cut Aerospace Superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Attallah, M.M.; Jennings, R.; Wang, X.; Carter, L.N. Additive Manufacturing of Ni-Based Superalloys: The Outstanding Issues. MRS Bull. 2016, 41, 758–764. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Inaekyan, K.; Kreitcberg, A.; Turenne, S.; Brailovski, V. Microstructure and Mechanical Properties of Laser Powder Bed-Fused IN625 Alloy. Mater. Sci. Eng. A 2019, 768, 138481. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Elevated Temperature Mechanical Behavior of IN625 Alloy Processed by Laser Powder-Bed Fusion. Mater. Sci. Eng. A 2017, 700, 540–553. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Effect of Heat Treatment and Hot Isostatic Pressing on the Microstructure and Mechanical Properties of Inconel 625 Alloy Processed by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- Carter, L.N.; Wang, X.; Read, N.; Khan, R.; Aristizabal, M.; Essa, K.; Attallah, M.M. Process Optimisation of Selective Laser Melting Using Energy Density Model for Nickel Based Superalloys. Mater. Sci. Technol. 2016, 32, 657–661. [Google Scholar] [CrossRef]

- Fang, X.Y.; Li, H.Q.; Wang, M.; Li, C.; Guo, Y.B. Characterization of Texture and Grain Boundary Character Distributions of Selective Laser Melted Inconel 625 Alloy. Mater. Charact. 2018. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.Y.; Weaver, M.; Guo, Y.B. Microstructure Evolution Characteristics of Inconel 625 Alloy from Selective Laser Melting to Heat Treatment. Mater. Sci. Eng. A 2017, 705, 20–31. [Google Scholar] [CrossRef]

- Lass, E.A.; Stoudt, M.R.; Katz, M.B.; Williams, M.E. Precipitation and Dissolution of δ and Γ″ during Heat Treatment of a Laser Powder-Bed Fusion Produced Ni-Based Superalloy. Scr. Mater. 2018, 154, 83–86. [Google Scholar] [CrossRef]

- Lindwall, G.; Campbell, C.E.; Lass, E.A.; Zhang, F.; Stoudt, M.R.; Allen, A.J.; Levine, L.E. Simulation of TTT Curves for Additively Manufactured Inconel 625. Metall. Mater. Trans. A 2019, 50, 457–467. [Google Scholar] [CrossRef] [Green Version]

- Stoudt, M.R.; Lass, E.A.; Ng, D.S.; Williams, M.E.; Zhang, F.; Campbell, C.E.; Lindwall, G.; Levine, L.E. The Influence of Annealing Temperature and Time on the Formation of δ-Phase in Additively-Manufactured Inconel 625. Metall. Mater. Trans. A 2018, 49A, 3028–3037. [Google Scholar] [CrossRef] [Green Version]

- Malej, S.; Medved, J.; Tehovnik, F.; Godec, M. Microstructural Evolution of Inconel 625 During Thermal Aging. Metabk 2017, 56, 319–322. [Google Scholar]

- Kohler, M. Effect of the Elevated-Temperature-Precpitation in Alloy 625 on Properties and Microstructure. In Superalloys 718, 625, 706 and Various Derivatives; Loria, E.A., Ed.; TMS (The Minerals, Metals & Materials Society): Pittsburgh, PA, USA, 1991; pp. 363–374. [Google Scholar]

- Marchese, G.; Bassini, E.; Parizia, S.; Manfredi, D.; Ugues, D.; Lombardi, M.; Fino, P.; Biamino, S. Role of the Chemical Homogenization on the Microstructural and Mechanical Evolution of Prolonged Heat-Treated Laser Powder Bed Fused Inconel 625. Mater. Sci. Eng. A 2020, 796, 140007. [Google Scholar] [CrossRef]

- Gola, K.; Dubiel, B.; Kalemba-Rec, I. Microstructural Changes in Inconel 625 Alloy Fabricated by Laser-Based Powder Bed Fusion Process and Subjected to High-Temperature Annealing. J. Mater. Eng. Perform. 2020, 29, 1528–1534. [Google Scholar] [CrossRef] [Green Version]

- Marchese, G.; Parizia, S.; Rashidi, M.; Saboori, A.; Manfredi, D.; Ugues, D.; Lombardi, M.; Hryha, E.; Biamino, S. The Role of Texturing and Microstructure Evolution on the Tensile Behavior of Heat-Treated Inconel 625 Produced via Laser Powder Bed Fusion. Mater. Sci. Eng. A 2020, 769, 138500. [Google Scholar] [CrossRef]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2002; ISBN 0871707497. [Google Scholar]

- Suave, L.M.; Cormier, J.; Bertheau, D.; Villechaise, P.; Soula, A.; Hervier, Z.; Hamon, F. High Temperature Low Cycle Fatigue Properties of Alloy 625. Mater. Sci. Eng. A 2016, 650, 161–170. [Google Scholar] [CrossRef]

- Shoemaker, L.E. Alloys 625 and 725: Trends in Properties and Applications. In Superalloys 718, 625, 706 and Derivatives 2005; Loria, E.A., Ed.; TMS (The Minerals, Metals & Materials Society): Pittsburgh, PA, USA, 2005; pp. 409–418. [Google Scholar]

- Rai, S.K.; Kumar, A.; Shankar, V.; Jayakumar, T.; Rao, K.B.S.; Raj, B. Characterization of Microstructures in Inconel 625 Using X-Ray Diffraction Peak Broadening and Lattice Parameter Measurements. Scr. Mater. 2004, 51, 59–63. [Google Scholar] [CrossRef]

| Element (%) | Cr | Mo | Nb | Fe | Ti and Al | Co | C | Ta | Si and Mn | P and S |

|---|---|---|---|---|---|---|---|---|---|---|

| Amount (w%) | 20–23 | 8–10 | 3.15–4.15 | <5 | <0.4 | <1 | <0.1 | <0.05 | <0.5 | <0.015 |

| Exposure Time (h) | Average Grain Size (µm) |

|---|---|

| 200 | 81 ± 24 |

| 2000 | 83 ± 26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marinucci, F.; Marchese, G.; Bassini, E.; Aversa, A.; Fino, P.; Ugues, D.; Biamino, S. Hardness Evolution of Solution-Annealed LPBFed Inconel 625 Alloy under Prolonged Thermal Exposure. Metals 2022, 12, 1916. https://doi.org/10.3390/met12111916

Marinucci F, Marchese G, Bassini E, Aversa A, Fino P, Ugues D, Biamino S. Hardness Evolution of Solution-Annealed LPBFed Inconel 625 Alloy under Prolonged Thermal Exposure. Metals. 2022; 12(11):1916. https://doi.org/10.3390/met12111916

Chicago/Turabian StyleMarinucci, Fabrizio, Giulio Marchese, Emilio Bassini, Alberta Aversa, Paolo Fino, Daniele Ugues, and Sara Biamino. 2022. "Hardness Evolution of Solution-Annealed LPBFed Inconel 625 Alloy under Prolonged Thermal Exposure" Metals 12, no. 11: 1916. https://doi.org/10.3390/met12111916

APA StyleMarinucci, F., Marchese, G., Bassini, E., Aversa, A., Fino, P., Ugues, D., & Biamino, S. (2022). Hardness Evolution of Solution-Annealed LPBFed Inconel 625 Alloy under Prolonged Thermal Exposure. Metals, 12(11), 1916. https://doi.org/10.3390/met12111916