A Numerical Simulation of Machining 6061 Syntactic Foams Reinforced with Hollow Al2O3 Shells

Abstract

:1. Introduction

2. Materials and Methods

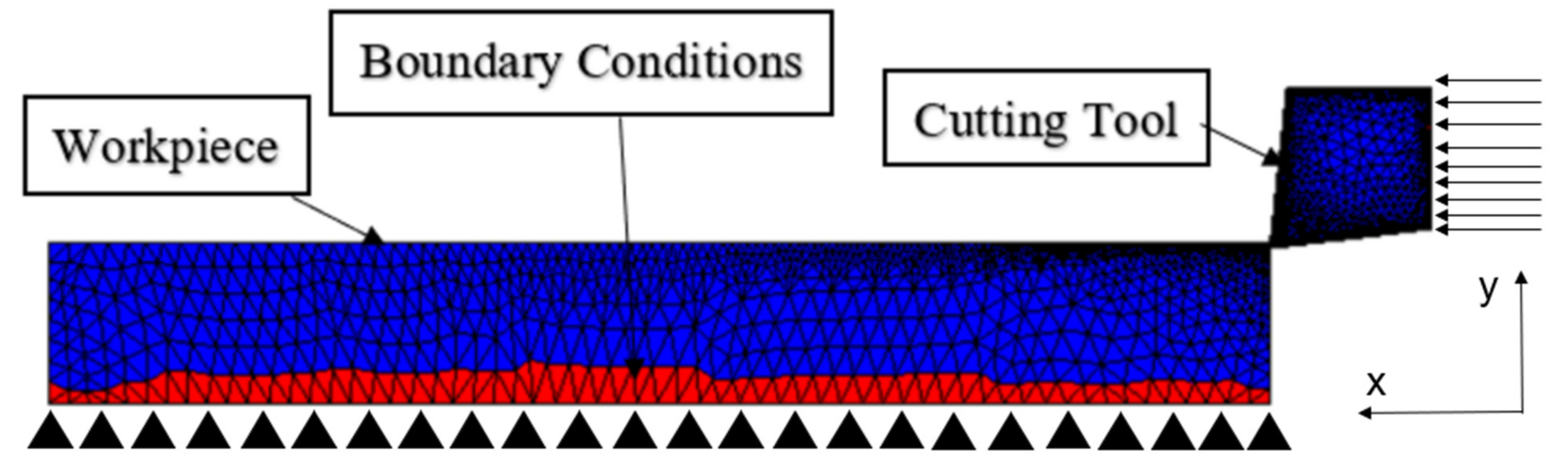

2.1. Numerical Model of the Machining of Aluminum Closed Cell Syntactic Foams

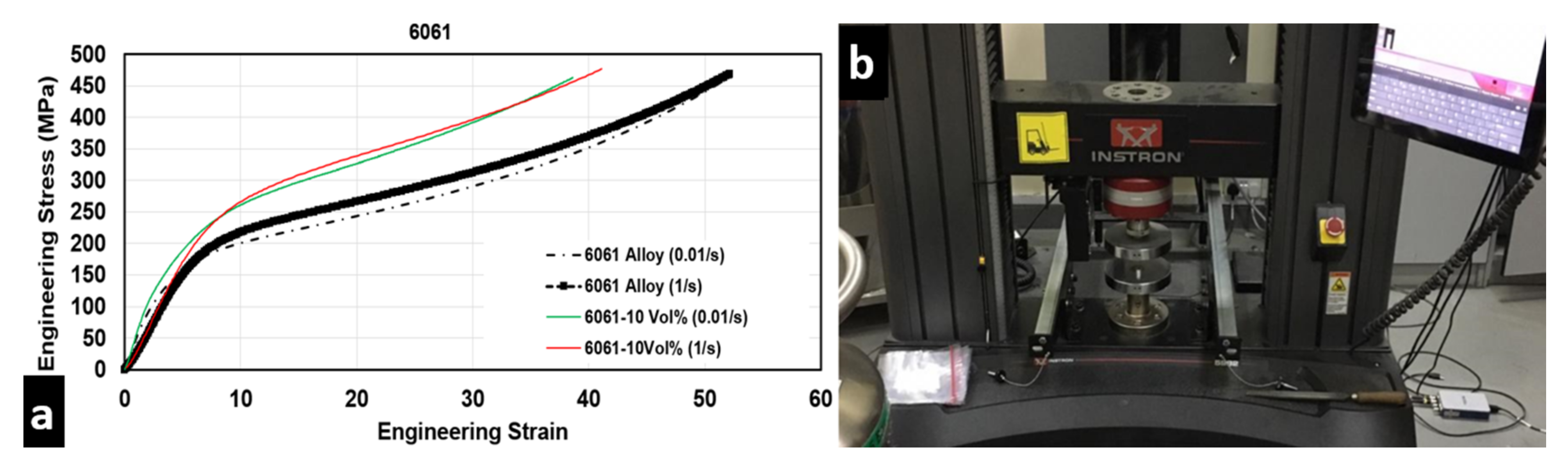

2.2. Material Model

2.3. Chip Separation Criterion

2.4. Chip–Tool Interaction

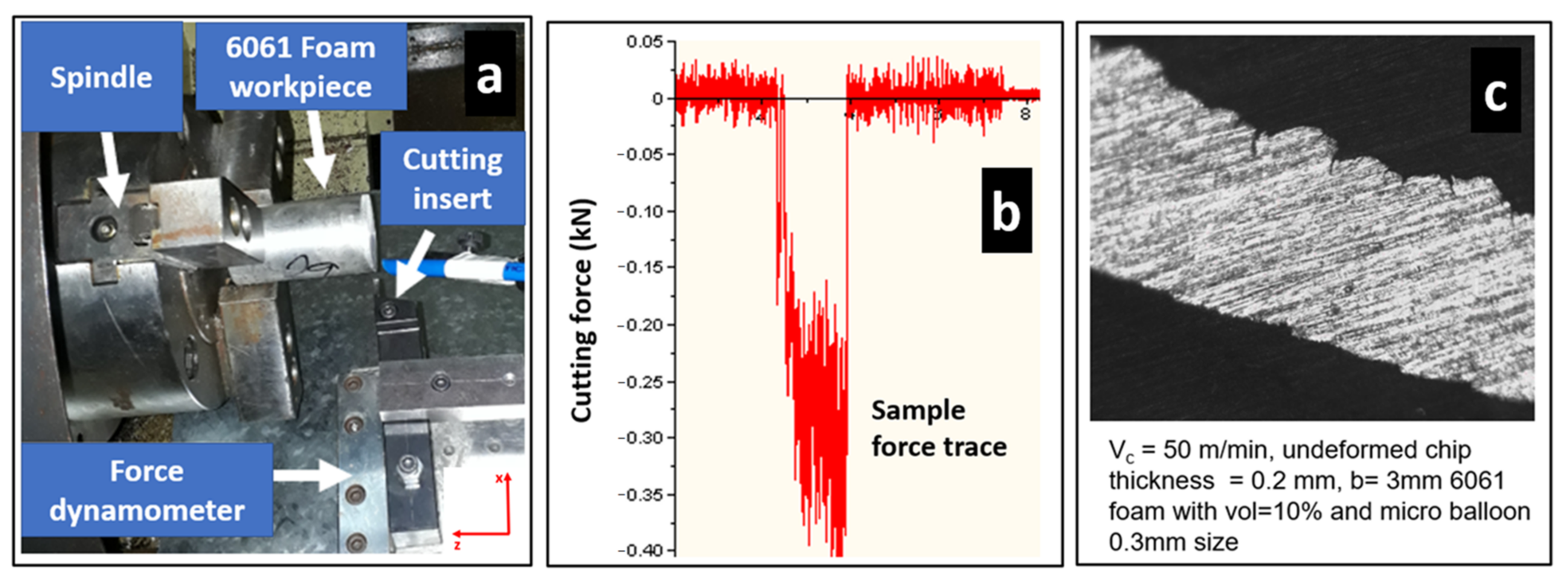

2.5. Experimental Validation

3. Results and Discussion

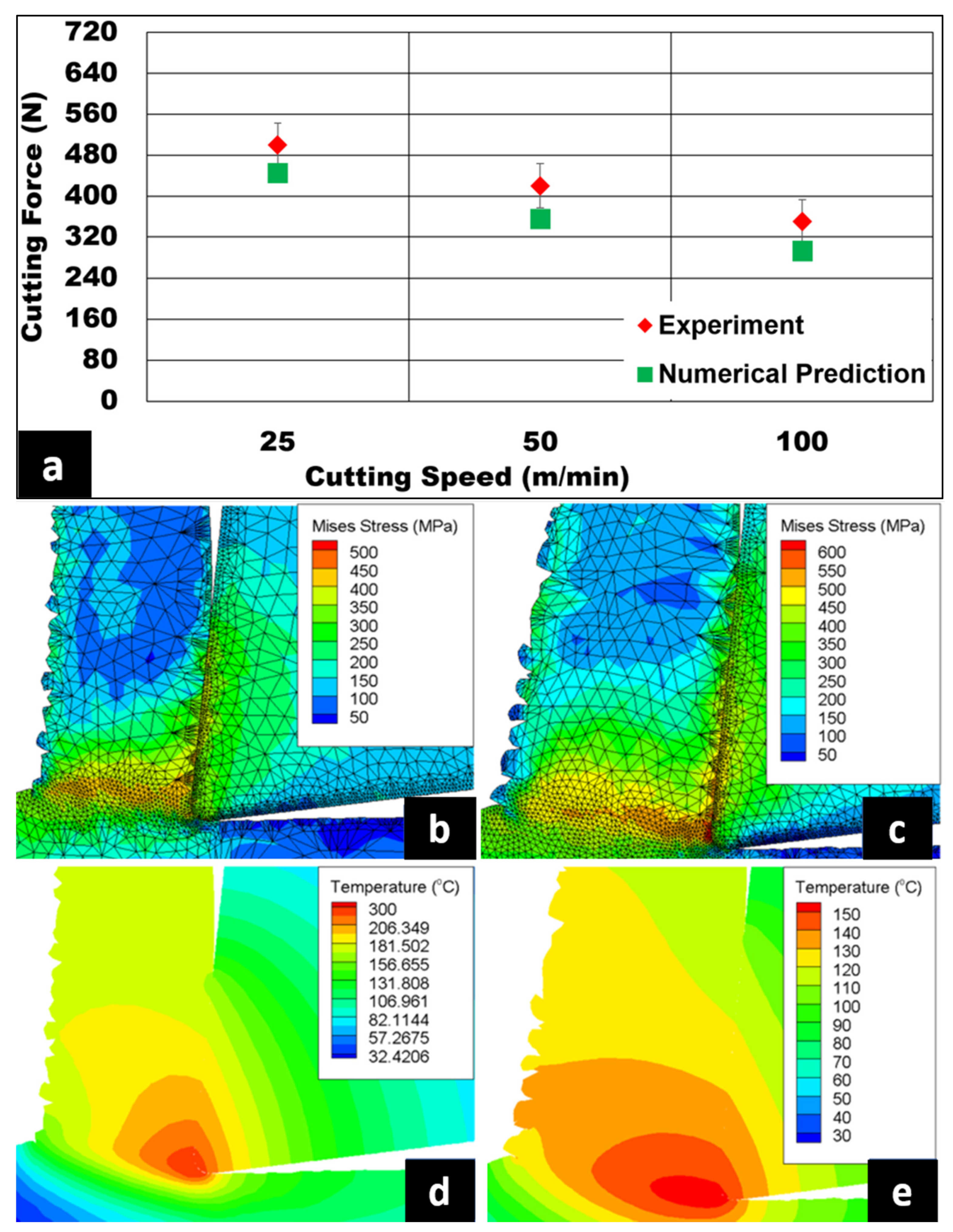

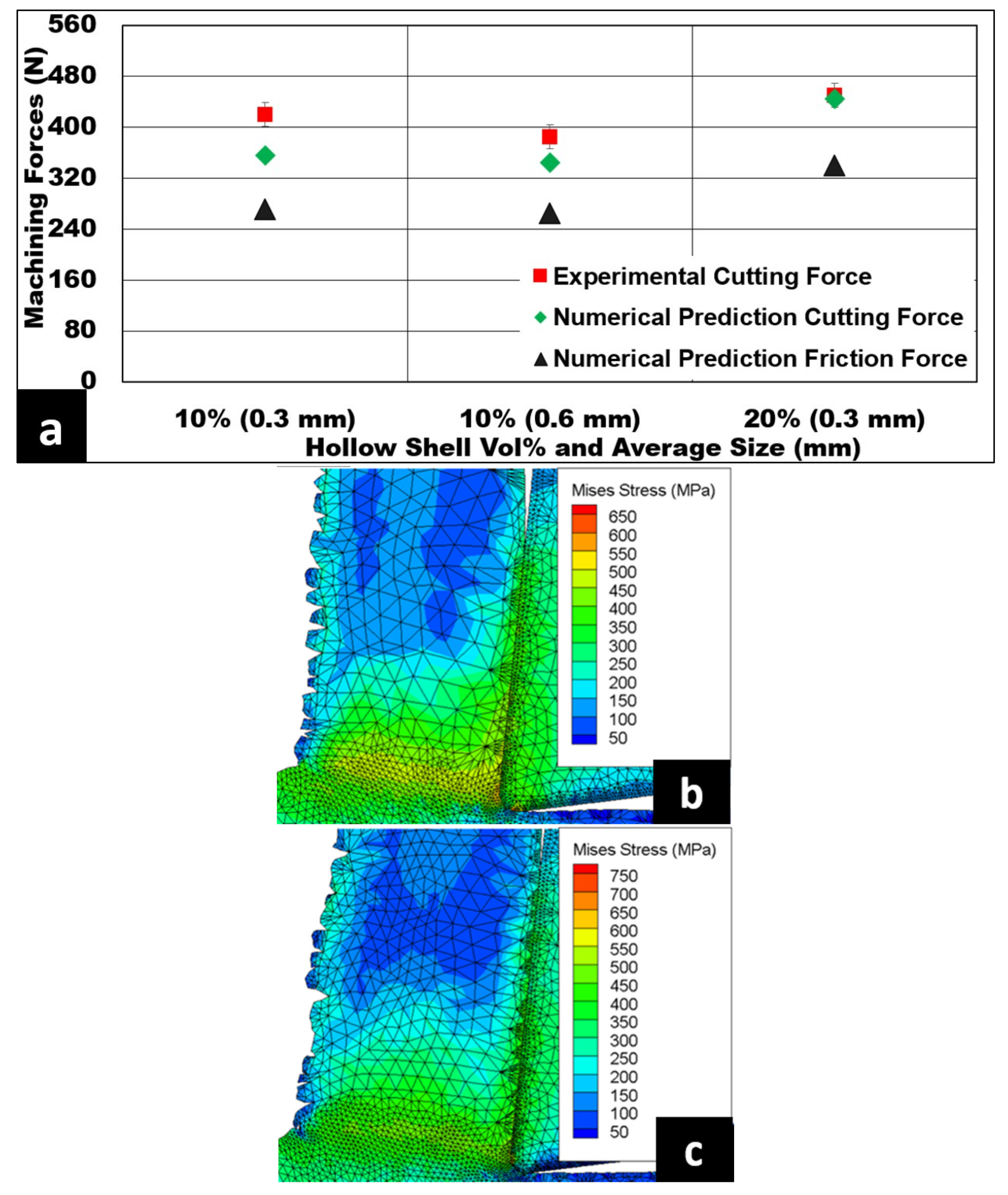

3.1. Machining Forces and Temperature Distribution

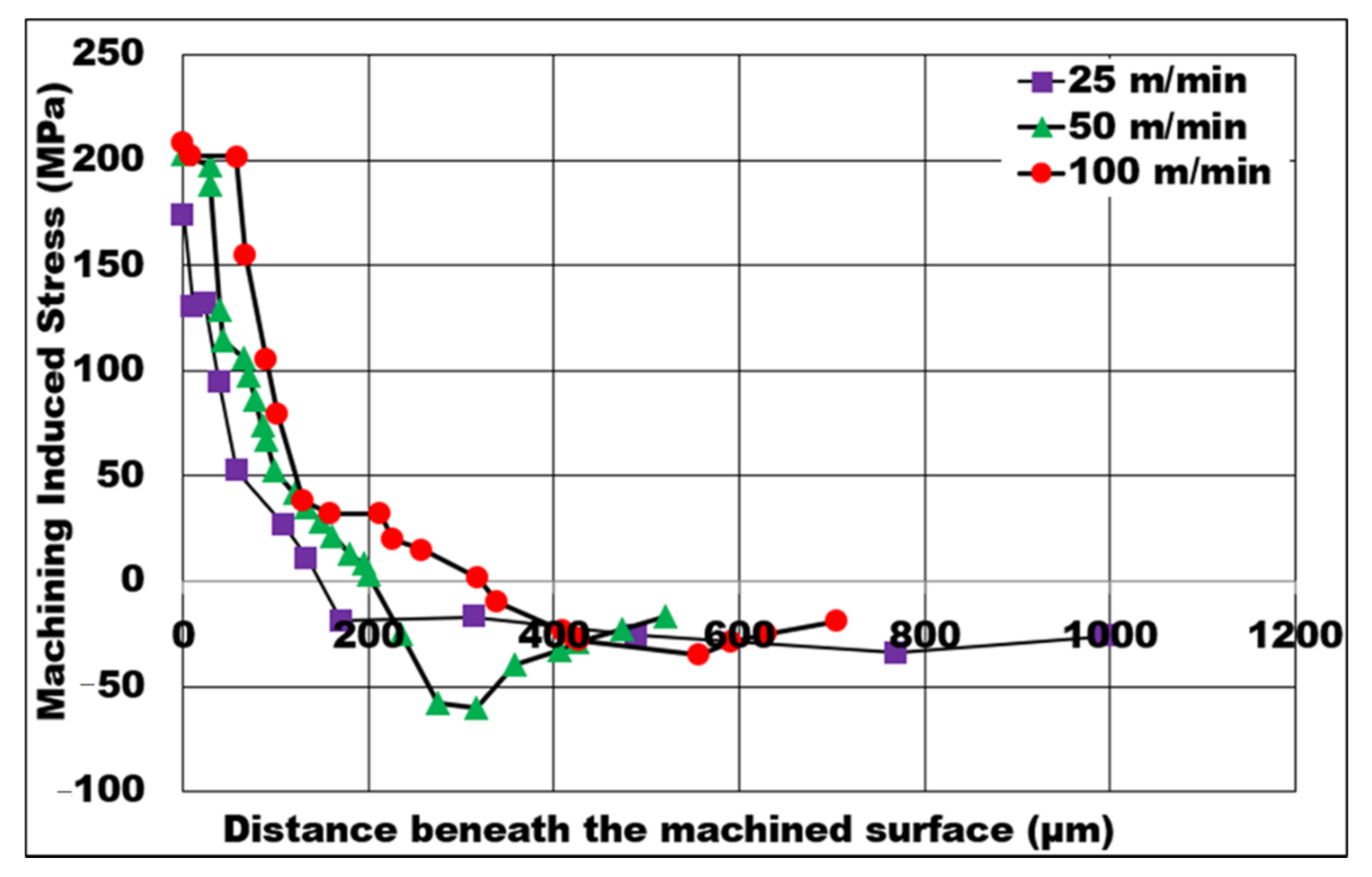

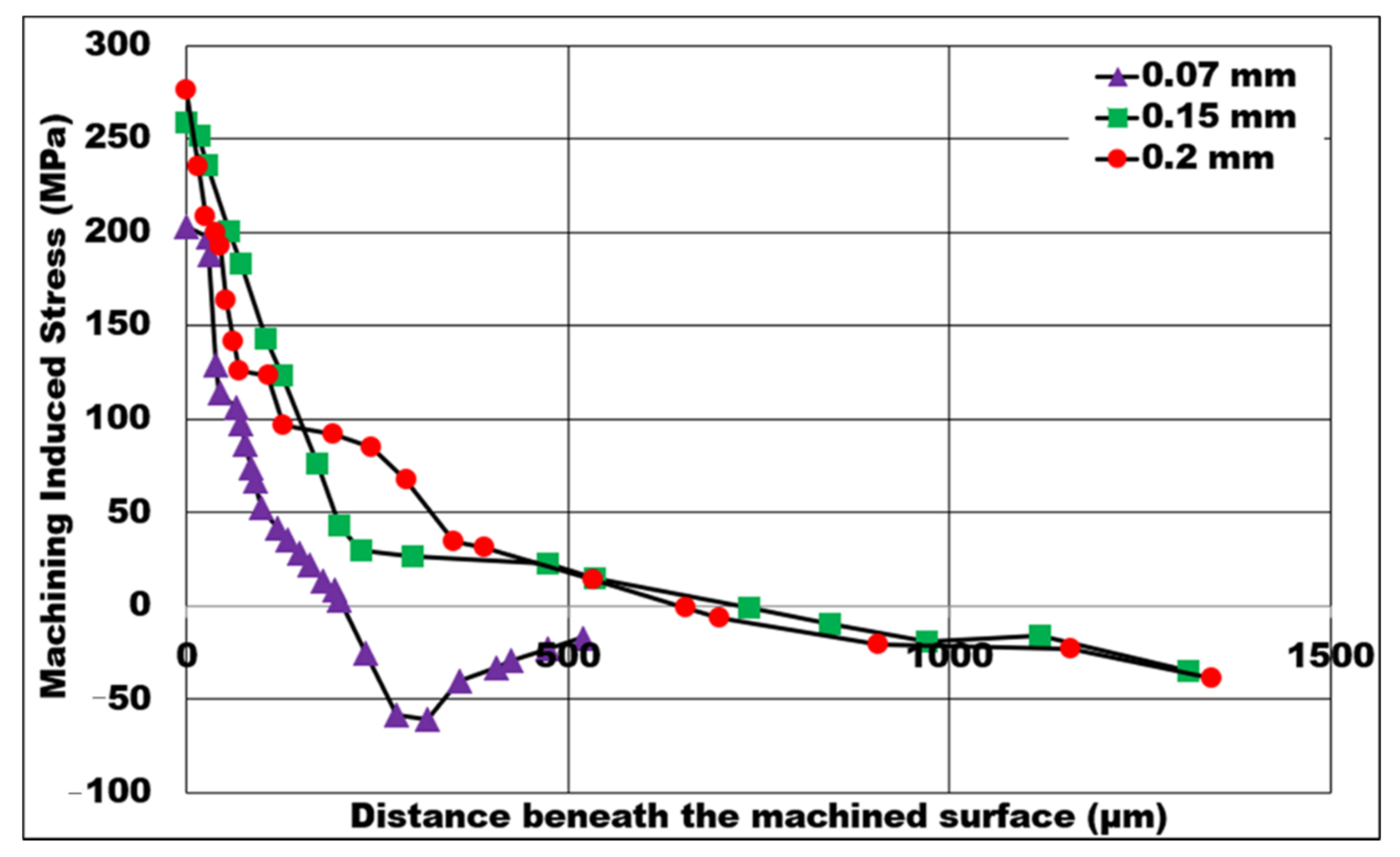

3.2. Effect of the Process Parameters on the Simulated Machining-Induced Stress

4. Conclusions

- An increase in the cutting speed resulted in a reduction of the cutting forces by at least 33%, primarily due to thermal softening of the matrix as indicated by the temperature distribution contours. Therefore, the magnitude of machining-induced tensile stresses on the cutting layer increased by 20%.

- Machining at higher uncut chip thickness resulted in an increase of the machining force by almost 140%, leading to an increase in machining-induced stress values by 35%.

- The higher the volume fraction of hollow alumina shells and the finer the shell diameter, the higher the magnitude of the cutting forces. A higher machining-induced stress depth was recorded for syntactic foams with coarser alumina shells.

- A favorable compressive stress distribution in the machined layer was obtained while machining at lower cutting speed and uncut chip thickness values for a volume fraction of 10% hollow alumina shell reinforcements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Movahedi, N.; Murch, G.E.; Belova, I.V.; Fiedler, T. Manufacturing and compressive properties of tube-filled metal syntactic foams. J. Alloys Compd. 2020, 822, 153465. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Szlancsik, A.; Kemény, A.; Kincses, D. Compressive mechanical properties of low-cost, aluminium matrix syntactic foams. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105923. [Google Scholar] [CrossRef]

- Fragoso-Medina, O.; Velázquez-Villegas, F. Aluminum foam to improve crash safety performance: A numerical simulation approach for the automotive industry. Mech. Based Des. Struct. Mach. 2021. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Kemény, A.; Filep, Á.; Gácsi, Z. Compressive characteristics of bimodal aluminium matrix syntactic foams. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105479. [Google Scholar] [CrossRef] [Green Version]

- Thiyagarajan, R.; Kumar, M.S. A Review on Closed Cell Metal Matrix Syntactic Foams: A Green Initiative towards Eco-Sustainability. Mater. Manuf. Process. 2021, 36, 1333–1351. [Google Scholar] [CrossRef]

- Samvatsar, K.; Dave, H. A comprehensive study on using fly ash as reinforcement material in aluminium and magnesium based syntactic foams. Mater. Today Proc. 2021, 47, 2384–2390. [Google Scholar] [CrossRef]

- Shukla, A.K.; Mondal, D.P.; Dutta Majumdar, J. Metallurgical Characteristics, Compressive Strength, and Chemical Degradation Behavior of Aluminum-Cenosphere Composite Foam Developed by Spray Forming Route. J. Mater. Eng. Perform. 2021, 30, 5750–5762. [Google Scholar] [CrossRef]

- Bolat, Ç.; Akgün, İ.C.; Göksenli, A. On the Way to Real Applications: Aluminum Matrix Syntactic Foams. Eur. Mech. Sci. 2020, 4, 131–141. [Google Scholar] [CrossRef]

- Su, M.; Wang, H.; Hao, H.; Fiedler, T. Compressive properties of expanded glass and alumina hollow spheres hybrid reinforced aluminum matrix syntactic foams. J. Alloys Compd. 2020, 821, 153233. [Google Scholar] [CrossRef]

- Bolat, Ç.; Ergene, B.; Karakılınç, U.; Gökşenli, A. Investigating on the machinability assessment of precision machining pumice reinforced AA7075 syntactic foam. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021. [Google Scholar] [CrossRef]

- Kannan, S.; Kishawy, H.A.; Pervaiz, S.; Thomas, K.; Karthikeyan, R.; Arunachalam, R. Machining of novel AA7075 foams containing thin-walled ceramic bubbles. Mater. Manuf. Process. 2020, 35, 1812–1821. [Google Scholar] [CrossRef]

- Kannan, S.; Pervaiz, S.; Klassen, R.J.; Huo, D.; Haghshenas, M. An energy-based analysis for machining novel AZ91 magnesium composite foam dispersed with ceramic microspheres. J. Manuf. Sci. Eng. Trans. ASME 2021, 143, 031007. [Google Scholar] [CrossRef]

- Kannan, S.; Pervaiz, S.; Alhourani, A.; Klassen, R.J.; Selvam, R.; Haghshenas, M. On the role of hollow aluminium oxide microballoons during machining of AZ31 magnesium syntactic foam. Materials 2020, 13, 3534. [Google Scholar] [CrossRef] [PubMed]

- Ullen, N.B. Characterization of machinability of sintered steel foams having different porosities during drilling operations. Mach. Sci. Technol. 2020, 25, 527–557. [Google Scholar] [CrossRef]

- Guerra-Silva, R.; Teicher, U.; Ihlenfeldt, S.; González-Zamora, A. Finite element analysis of orthogonal cutting of cellular metals: Influence of cutting conditions on chip formation and surface damage. Int. J. Adv. Manuf. Technol. 2021, 113, 1267–1280. [Google Scholar] [CrossRef]

- Rajendran, A.M.; Grove, D.J. Modeling of shock and impact behaviors of aluminum oxide. Trans. Built Environ. 1998, 32, 447–460. [Google Scholar]

- Ghandehariun, A.; Nazzal, M.; Kishawy, H.A.; Umer, U. On modeling the deformations and tool-workpiece interactions during machining metal matrix composites. Int. J. Adv. Manuf. Technol. 2017, 91, 1507–1516. [Google Scholar] [CrossRef]

- Aluminum 6061-T6; 6061-T651. Available online: http://www.matweb.com/search/datasheet_print.aspx?matguid=1b8c06d0ca7c456694c7777d9e10be5b (accessed on 18 April 2021).

- Blau, P.J. Wear of Materials; Elsevier: Amsterdam, The Netherlands, 2003; ISBN 978-0-08-044301-0. [Google Scholar]

- Kurlov, A.S.; Gusev, A.I. Tungsten Carbides: Structure, Properties and Application in Hardmetals; Springer: Berlin/Heidelberg, Germany, 2013; Volume 184. [Google Scholar] [CrossRef]

- Koklu, U. The Drilling Machinability of 5083 Aluminum Under Shallow and Deep Cryogenic Treatment. Emerg. Mater. Res. 2020, 9, 323–330. [Google Scholar] [CrossRef]

- Koklu, U.; Kayhanlar, H. An Experimental Investigation on Machinability of AZ31B Magnesium Alloy under Dry and Dipped Cryogenic Approaches. J. Mater. Eng. Perform. 2022, 31, 1285–1296. [Google Scholar] [CrossRef]

- Köklü, U.; Koçar, O.; Morkavuk, S.; Giasin, K.; Ayer, Ö. Influence of extrusion parameters on drilling machinability of AZ31 magnesium alloy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022. [Google Scholar] [CrossRef]

| Chemical Composition of 6061 Aluminum in Weight (%) | |||||||

| Al | Cr | Cu | Fe | Si | Mg | Mn | Zn |

| 95.8–98.6 | 0.04–0.35 | 0.15–0.4 | 0.7 | 0.4 | 1.5 | 0.1 | 0.25 |

| Chemical Composition of the Hollow Alumina Shell in Weight (%) | |||||||

| Al2O3 | Fe2O3 | CaO | SiO2 | Na2O | |||

| 99.7 | 0.003 | 0.01 | 0.025 | 0.26 | |||

| Hollow Alumina Shell | |||||

| Physical Properties | |||||

| Bulk Density (g/cm3) | Average Porosity (%) | Average Wall Thickness (μm) | Average Bubble Size (mm) | Bubble vol% | Thermal Conductivity (W m−1K−1) |

| 1.8 | 83 | 0.04–0.08 | 0.3–0.6 | 10%, 20% | 1.5 |

| Mechanical Properties | |||||

| Crush Strength (MPa) | Poisson’s Ratio | ||||

| 10 | 0.231 | ||||

| 6061 Matrix | |||||

| Physical Properties | |||||

| Density (g/cm3) | Thermal Conductivity (W m−1K−1) | Specific Heat (J kg−1K−1) | |||

| 2.7 | 165 | 896 | |||

| Mechanical Properties | |||||

| Poisson Ratio | Compressive Strength (MPa) | Yield Strength (MPa) | Young’s Modulus (GPa) | ||

| 0.33 | 250 | 150 | 68 | ||

| Thermal Conductivity (W m−1K−1) | Coefficient of Thermal Expansion (1/K) | Young’s Modulus (GPa) | Poisson’s Ratio | Density (g/cm3) | Specific Heat (J kg−1K−1) |

|---|---|---|---|---|---|

| 110 | 5.5 × 10−6 | 700 | 0.31 | 15.6 | 39.8 |

| Matrix | 6061 aluminum |

| Reinforcement | Hollow alumina thin-walled shell |

| Tool | Carbide-coated insert from SandvikTM |

| Rake angle and clearance angle | 6° and 7° |

| Cutting speed (m/min) | 25, 50, 100 |

| Undeformed Chip Thickness (mm) | 0.02, 0.07, 0.15, 0.2 |

| Volume fraction of hollow microsphere | 10%, 20% |

| Average size of hollow microsphere (mm) | 0.1–0.5 mm, 0.5–1 mm |

| Width of cut (mm) | 3 |

| Lubrication | Dry |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thomas, K.; Kannan, S.; Nazzal, M.; Pervaiz, S.; Karthikeyan, R. A Numerical Simulation of Machining 6061 Syntactic Foams Reinforced with Hollow Al2O3 Shells. Metals 2022, 12, 596. https://doi.org/10.3390/met12040596

Thomas K, Kannan S, Nazzal M, Pervaiz S, Karthikeyan R. A Numerical Simulation of Machining 6061 Syntactic Foams Reinforced with Hollow Al2O3 Shells. Metals. 2022; 12(4):596. https://doi.org/10.3390/met12040596

Chicago/Turabian StyleThomas, Kevin, Sathish Kannan, Mohammad Nazzal, Salman Pervaiz, and Ramanujam Karthikeyan. 2022. "A Numerical Simulation of Machining 6061 Syntactic Foams Reinforced with Hollow Al2O3 Shells" Metals 12, no. 4: 596. https://doi.org/10.3390/met12040596