Correlation between Microstructure and Mechanical Properties of Welded Joint of X70 Submarine Pipeline Steel with Heavy Wall Thickness

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Mechanical Properties

3.2. Microstructure

4. Discussion

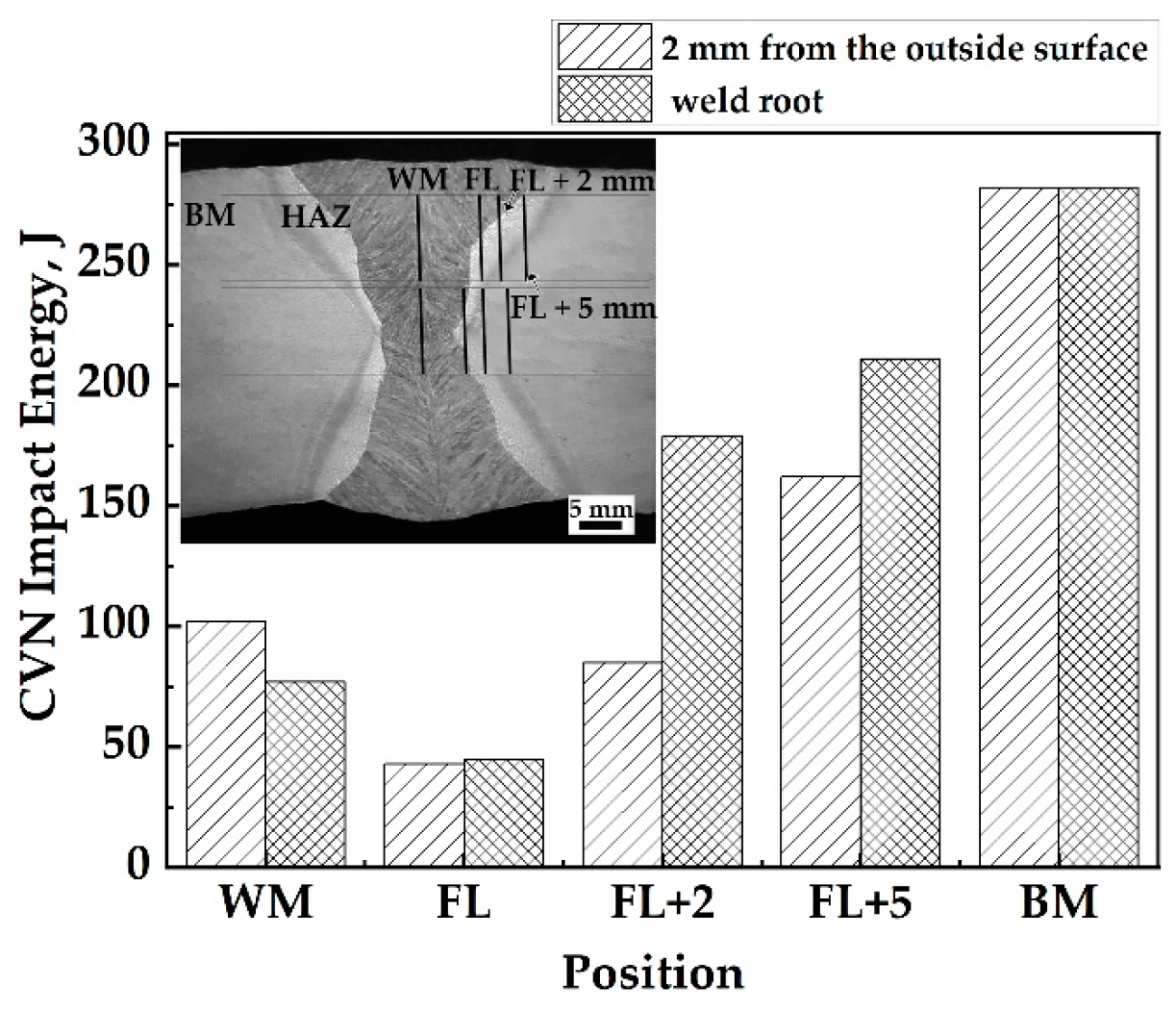

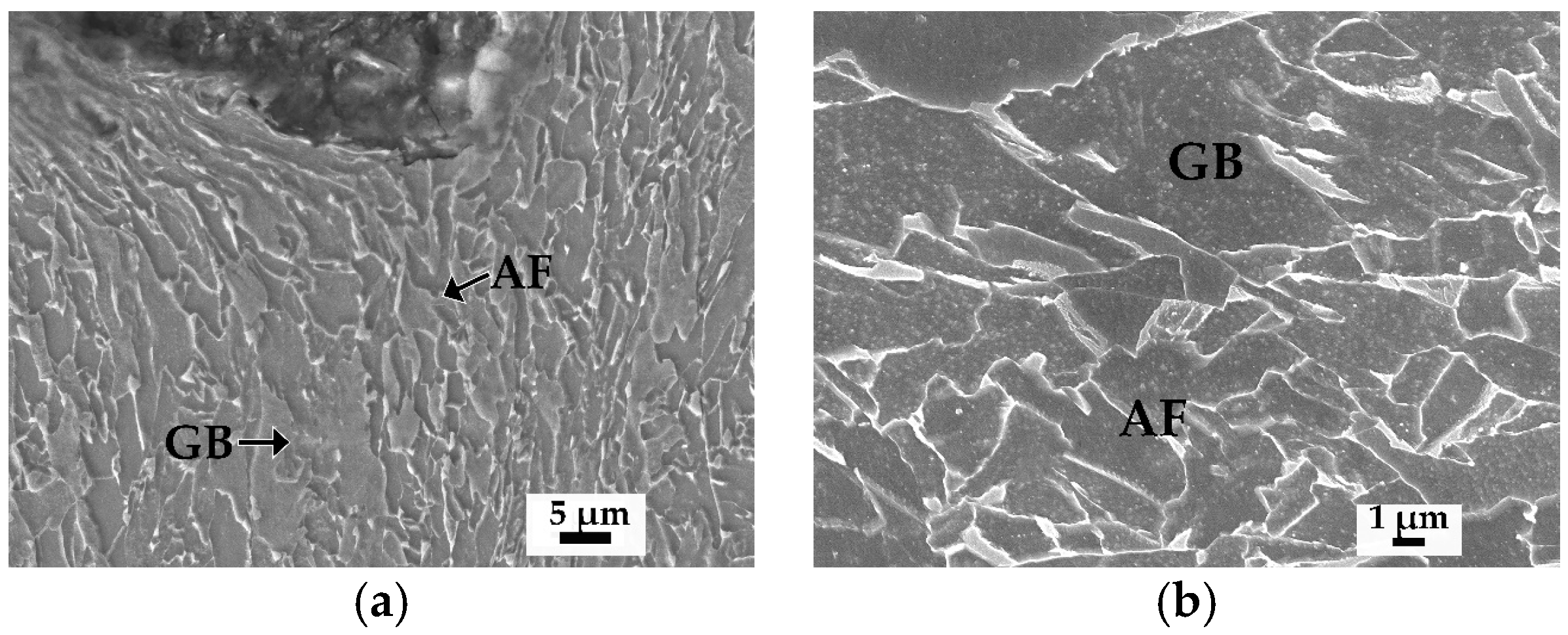

4.1. Influence of Microstructure on Impact Energy

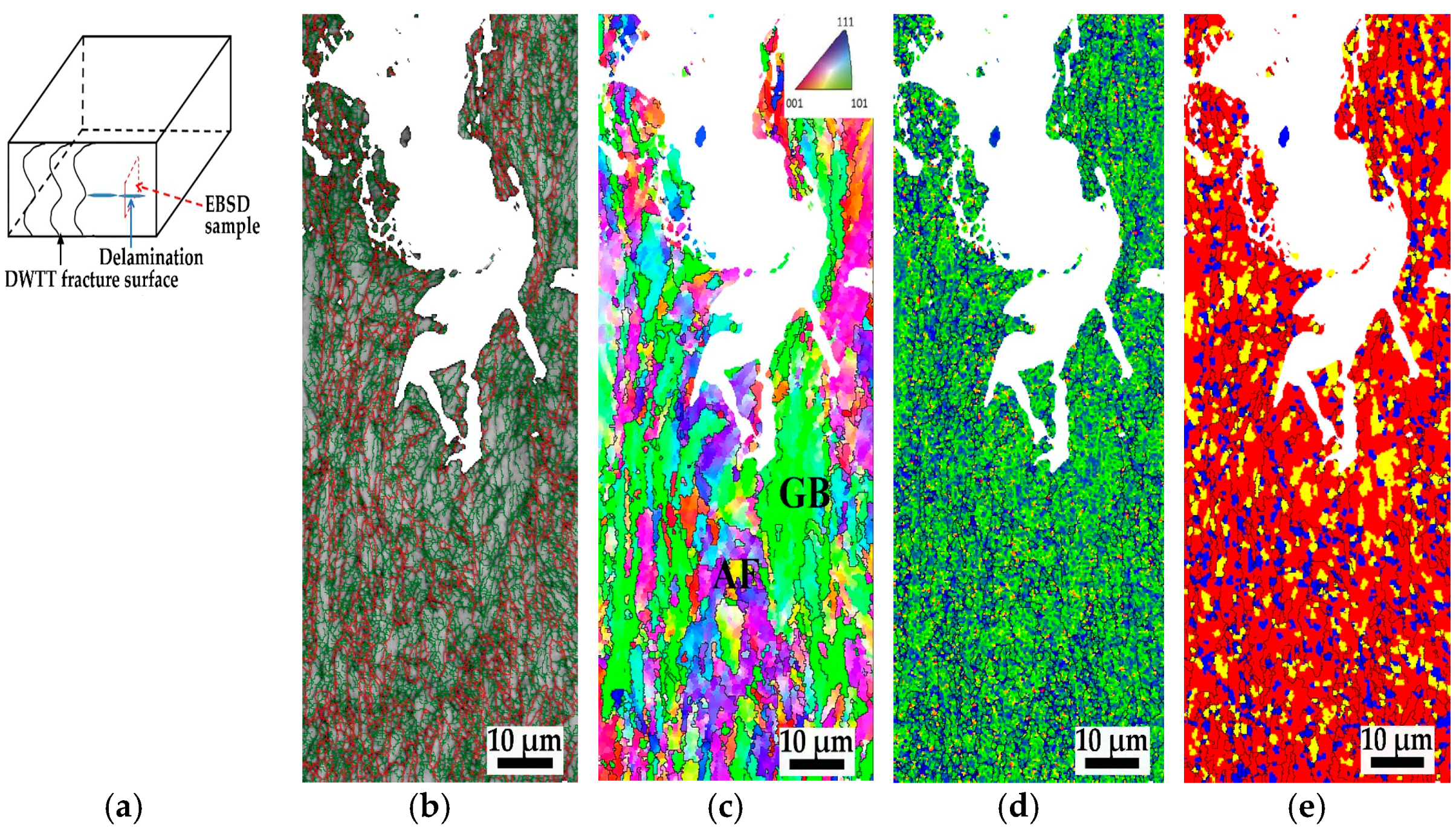

4.2. EBSD Analysis of Delamination Cracks

5. Conclusions

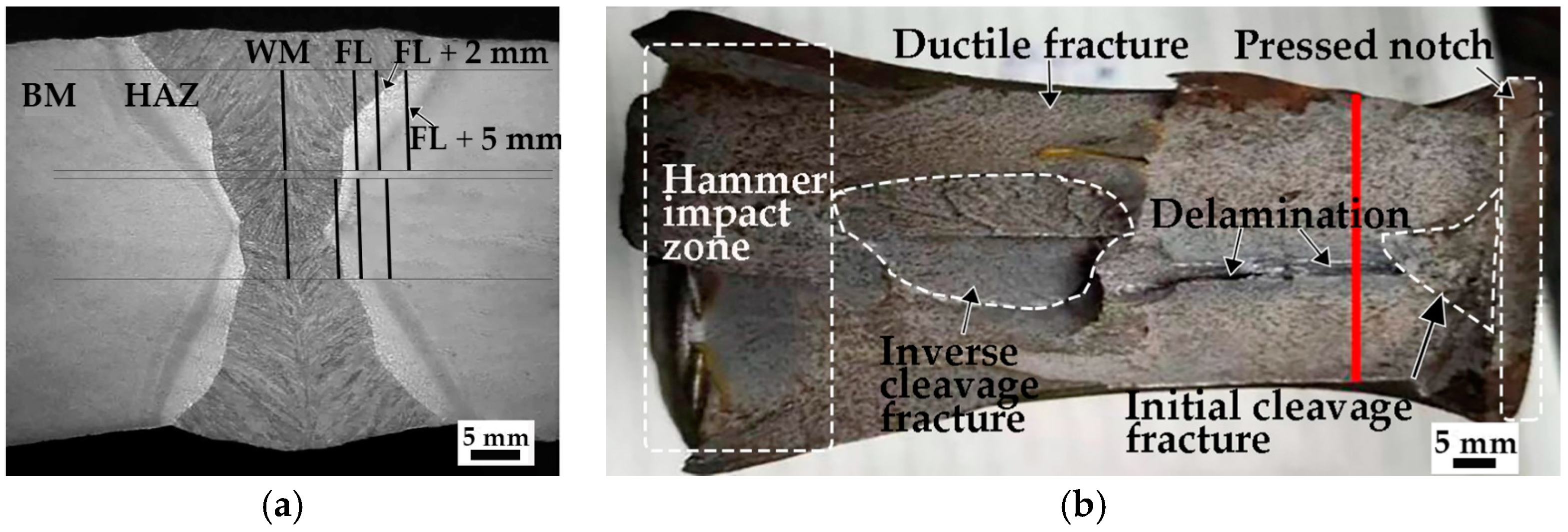

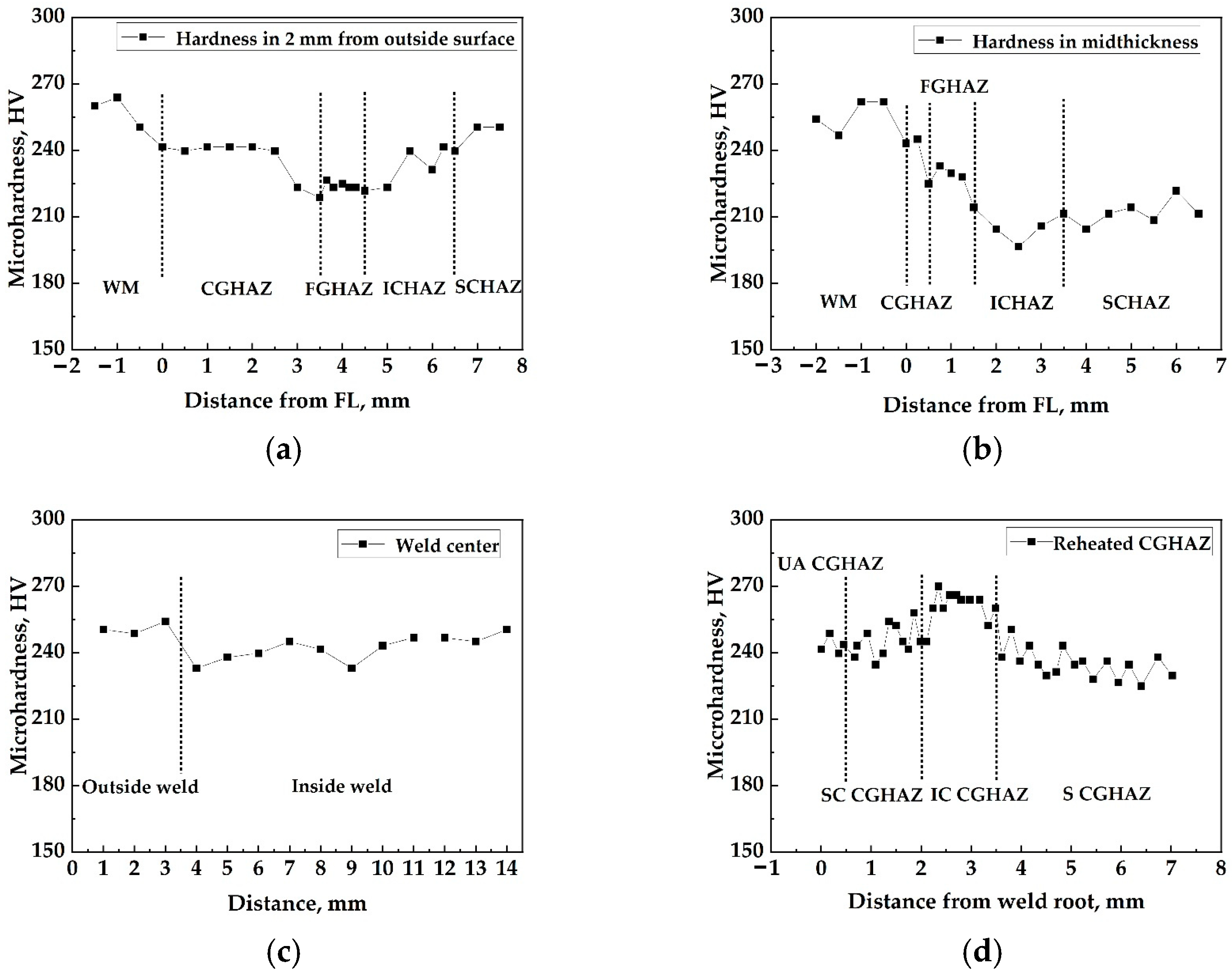

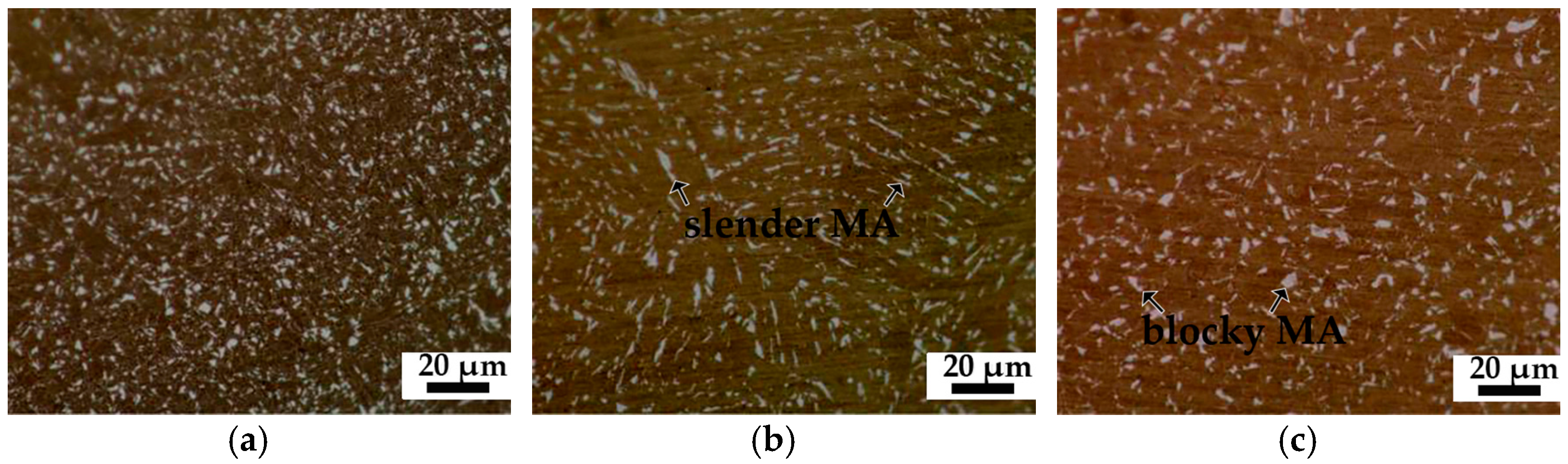

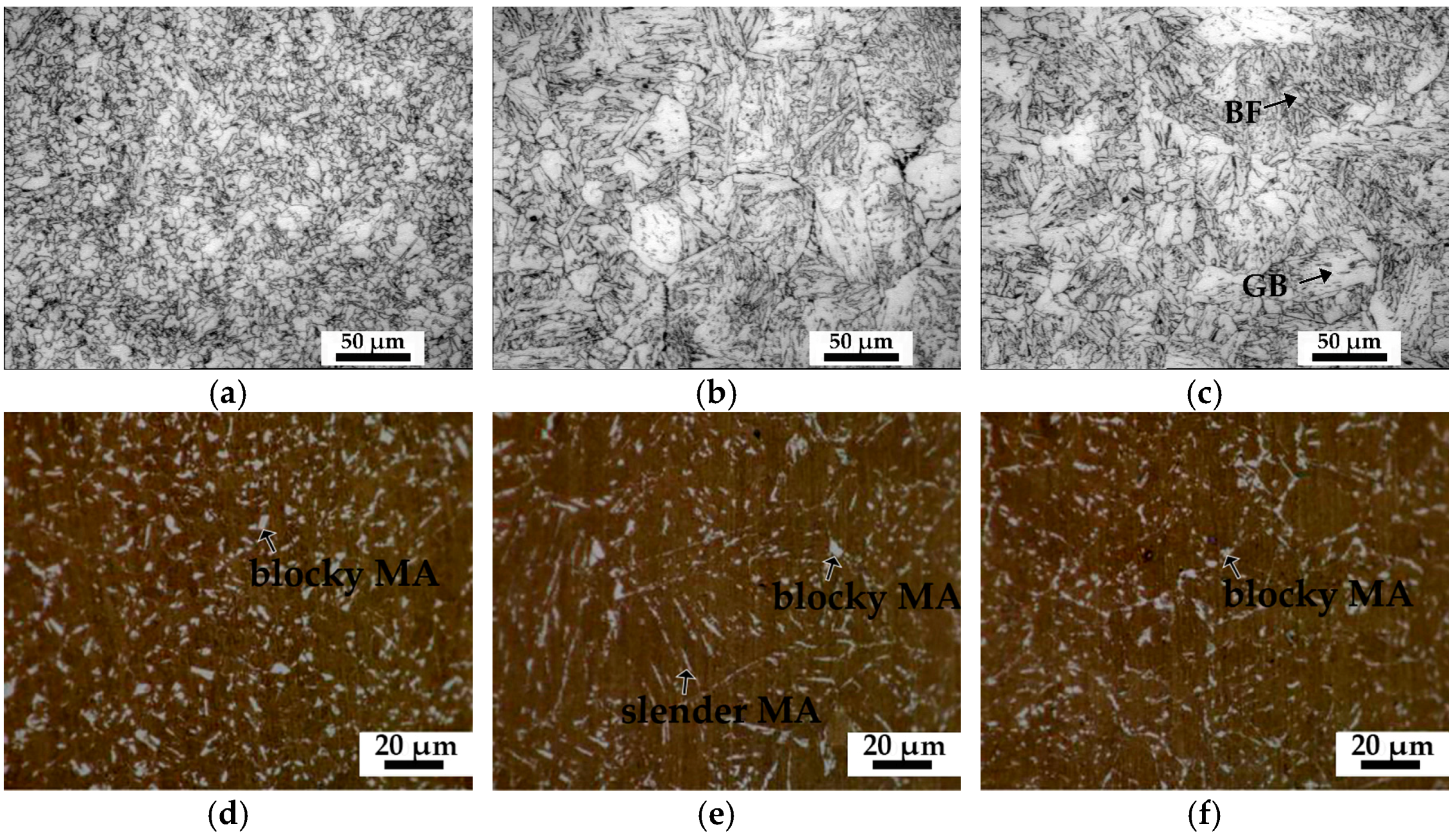

- The BM of the pipe shows a low yield ratio of 0.83 and an excellent elongation of more than 45%. The DWTT shear area of the steel plate reaches 87%, showing excellent low-temperature toughness. IC CGHAZ shows the highest hardness within the reheated CGHAZ, with an average value of up to 262 HV. However, the concentrated blocky/slender MA constituents along the prior austenite grain boundaries of IC CGHAZ show a deteriorated impact toughness.

- Under impact load, microcracks form from MA constituents. The Charpy impact energy increases as the distance away from the FL increases and reaches a maximum at the BM near HAZ due to the small size of MA constituents and grain, while that of the FL zone is the lowest just below 50 J because of two distinct microstructures, namely IAF in WM and coarse BF in CGHAZ, resulting in stress concentration in FL.

- Delamination cracks only occurred in the midthickness of a steel plate with a small opening width, which spread about 2.1 mm perpendicular to the DWTT fracture surface. The delamination cracks were finally arrested at the AF clusters containing a high density of HAGBs. Severe stress concentration appears around the delamination cracks, and there are more substructures and deformed grains around the delamination cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shin, S.Y.; Hwang, B.; Lee, S.; Kim, N.J.; Ahn, S.S. Correlation of microstructure and charpy impact properties in API X70 and X80 line-pipe steels. Mater. Sci. Eng. A 2007, 458, 281–289. [Google Scholar] [CrossRef]

- Hong, S.; Shin, S.Y.; Lee, S.H.; Kim, N.J. Effects of specimen thickness and notch shape on fracture modes in the drop weight tear test of API X70 and X80 linepipe steels. Metall. Mater. Trans. A 2011, 42, 2619–2632. [Google Scholar] [CrossRef] [Green Version]

- Li, C.W.; Wang, Y.; Chen, Y.H. Influence of peak temperature during in-service welding of API X70 pipeline steels on microstructure and fracture energy of the reheated coarse grain heat-affected zones. J. Mater. Sci. 2011, 46, 6424–6431. [Google Scholar] [CrossRef]

- Li, R.T.; Zuo, X.R.; Hu, Y.Y.; Wang, Z.W.; Hu, D.X. Microstructure and properties of pipeline steel with a ferrite/martensite dual-phase microstructure. Mater. Charact. 2011, 62, 801–806. [Google Scholar] [CrossRef]

- Yang, Y.H.; Shi, L.; Xu, Z.; Lu, H.S.; Wang, X. Fracture toughness of the materials in welded joint of X80 pipeline steel. Eng. Fract. Mech. 2015, 148, 337–349. [Google Scholar] [CrossRef]

- Lan, L.Y.; Qiu, C.L.; Zhao, D.W.; Gao, X.H.; Du, L.X. Microstructure characteristics and toughness of the simulated coarse grained heat affected zone of high strength low carbon bainitic steel. Mater. Sci. Eng. A 2011, 529, 192–200. [Google Scholar] [CrossRef]

- Huda, N.; Lazor, R.; Gerlich, A. Study of MA effect on yeild strength and ductility of X80 pipelile steels weld. Metall. Mater. Trans. A 2017, 48, 4166–4179. [Google Scholar] [CrossRef]

- Mohseni, P.; Solbeerg, J.K.; Karlsen, M.; Akselsen, O.M.; Østby, E. Cleavage fracture initiation at M-A constituents in intercritically coarse-grained heat-affected zone of a HSLA Steel. Metall. Mater. Trans. A 2014, 45, 384–394. [Google Scholar] [CrossRef]

- Di, X.J.; Cai, L.; Xing, X.X.; Chen, C.X.; Xue, Z.K. Microstructure and mechanical properties of intercritical heat-affected zone of X80 pipeline steel in simulated in-service welding. Acta Metall. Sin. 2015, 28, 883–891. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.X.; Kuzmikova, L.; Li, H.J.; Barbaro, F. Effect of inter-critically reheating temperature on microstructure and properties of simulated inter-critically reheated coarse grained heat affected zone in X70 steel. Mater. Sci. Eng. A 2014, 605, 8–13. [Google Scholar] [CrossRef]

- Moeinifar, S.; Kokabi, A.H.; Madaah Hosseini, H.R. Role of tandem submerged arc welding thermal cycles on properties of the heat affected zone in X80 microalloyed pipe line steel. J. Mater. Process. Technol. 2011, 211, 368–375. [Google Scholar] [CrossRef]

- DNV-OS-F101; Offshore Standard Submarine Pipeline Systems. Det Norske Veritas: Bærum, Norway, 2013; pp. 140–187.

- Zhao, J.; Hu, W.; Wang, X.; Kang, J.; Yuan, J.; Di, H.; Misra, R.D.K. Effect of microstructure on the crack propagation behavior of microalloyed 560 MPa (X80) strip during ultra-fast cooling. Mater. Sci. Eng. A 2016, 666, 214–224. [Google Scholar] [CrossRef]

- Yuan, G.; Hu, W.; Wang, X.; Kang, J.; Zhao, J.; Di, H.; Misra, R.D.K.; Wang, G. The relationship between microstructure, crystallographic orientation, and fracture behavior in a high strength ferrous alloy. J. Alloys Comp. 2017, 695, 526–539. [Google Scholar] [CrossRef]

- Shukla, R.; Ghosh, S.K.; Chakrabarti, D.; Chatterjee, S. Microstructure, texture, property relationship in thermo-mechanically processed ultra-low carbon microalloyed steel for pipeline application. Mater. Sci. Eng. A 2013, 587, 201–208. [Google Scholar] [CrossRef]

- Andrews, K. Empirical formulae for the calculation of some transformation temperatures. J. Iron Steel Inst. 1965, 203, 721–727. [Google Scholar]

- Xiong, Z.H.; Liu, S.L.; Wang, X.M.; Shang, C.J.; Li, X.C.; Misra, R.D.K. The contribution of intragranular acicular ferrite microstructural constituent on impact toughness and impeding crack initiation and propagation in the heat-affected zone (HAZ) of low-carbon steels. Mater. Sci. Eng. A 2015, 636, 117–123. [Google Scholar] [CrossRef]

- Xiao, F.R.; Liao, B.; Shan, Y.Y.; Qiao, G.Y.; Zhong, Y.; Zhang, C.L.; Yang, K. Challenge of mechanical properties of an acicular ferrite pipeline steel. Mater. Sci. Eng. A 2006, 431, 41–52. [Google Scholar] [CrossRef]

- Zhao, M.C.; Yang, K. Effects of nano-sized microalloyed carbonitrides and high-density pinned dislocations on sulfide stress cracking resistance of pipeline steels. J. Mater. Res. 2005, 20, 2248–2251. [Google Scholar] [CrossRef]

- Bataev, I.A.; Bataev, A.A.; Burov, V.G.; Lizunkova, Y.S.; Zakharevich, E.E. Structure of widmanstatten crystals of ferrite and cementite. Steel Transl. 2008, 38, 684–687. [Google Scholar] [CrossRef]

- Sun, X.J.; Yuan, S.F.; Xie, Z.J.; Dong, L.L.; Shang, C.J.; Misra, R.D.K. Microstructure-property relationship in a high strength-high toughness combination ultra-heavy gauge offshore plate steel: The significance of multiphase microstructure. Mater. Sci. Eng. A 2017, 689, 212–219. [Google Scholar] [CrossRef]

- Huda, N.; Midawi, A.R.H.; Gianetto, J.; Lazor, R.; Gerlich, A.P. Influence of martensite-austenite (MA) on impact toughness of X80 line pipe steels. Mater. Sci. Eng. A 2016, 662, 481–491. [Google Scholar] [CrossRef]

- Moeinifar, S.; Kokabi, A.H.; Madaah, H.H.R. Influence of peak temperature during simulation and real thermal cycles on microstructure and fracture properties of the reheated zones. Mater. Des. 2010, 31, 2948–2955. [Google Scholar] [CrossRef]

- Yakubtsov, I.A.; Poruks, P.; Boyd, J.D. Microstructure and mechanical properties of bainitic low carbon high strength plate steels. Mater. Sci. Eng. A 2008, 480, 109–116. [Google Scholar] [CrossRef]

- Gervasyev, A.; Pyshmintsev, I.; Petrov, R.; Huo, C.Y.; Barbaro, F. Splitting susceptibility in modern X80 pipeline steels. Mater. Sci. Eng. A 2020, 772, 138746. [Google Scholar] [CrossRef]

- Li, X.D.; Ma, X.P.; Subramanian, S.V.; Shang, C.J. EBSD characterization of secondary microcracks in the heat affected zone of a X100 pipeline steel weld joint. Int. J. Fract. 2015, 193, 131–139. [Google Scholar] [CrossRef]

- Yang, X.L.; Xu, Y.B.; Tan, X.D.; Wu, D. Relationships among crystallographic texture, fracture behavior and Charpy impact toughness in API X100 pipeline steel. Mater. Sci. Eng. A 2015, 641, 96–106. [Google Scholar] [CrossRef]

- Sha, Q.Y.; Li, D.H. Microstructure, mechanical properties and hydrogen induced cracking susceptibility of X80 pipeline steel with reduced Mn content. Mater. Sci. Eng. A 2013, 585, 214–221. [Google Scholar] [CrossRef]

| Specimen | Parameter | Single Value | Mean Values | Standard Deviation | ||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| Base metal (T) | Yield strength (MPa) | 535 | 557 | 534 | 542 | 13.0 |

| Tensile strength (MPa) | 650 | 660 | 641 | 650 | 9.5 | |

| Yield ratio | 0.82 | 0.84 | 0.83 | 0.83 | 0.010 | |

| Elongation (%) | 47 | 48 | 42 | 46 | 3.21 | |

| Base metal (L) | Yield strength (MPa) | 536 | 529 | 525 | 530 | 5.6 |

| Tensile strength (MPa) | 646 | 633 | 640 | 640 | 6.5 | |

| Yield ratio | 0.83 | 0.84 | 0.82 | 0.83 | 0.010 | |

| Elongation (%) | 46 | 43 | 45 | 45 | 1.53 | |

| Weld metal (L) | Yield strength (MPa) | 650 | 641 | 630 | 640 | 10.0 |

| Tensile strength (MPa) | 730 | 718 | 713 | 720 | 8.7 | |

| Yield ratio | 0.89 | 0.89 | 0.88 | 0.89 | 0.006 | |

| Elongation (%) | 40 | 35 | 47 | 41 | 6.03 | |

| Region | WM | CGHAZ | FGHAZ | ICHAZ |

|---|---|---|---|---|

| Average size (μm) | 1.28 | 1.84 | 1.74 | 1.70 |

| Volume fraction (%) | 4.36 | 5.46 | 5.26 | 4.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Liu, D.; Hong, L.; Liu, J.; Zuo, X. Correlation between Microstructure and Mechanical Properties of Welded Joint of X70 Submarine Pipeline Steel with Heavy Wall Thickness. Metals 2022, 12, 716. https://doi.org/10.3390/met12050716

Dong Y, Liu D, Hong L, Liu J, Zuo X. Correlation between Microstructure and Mechanical Properties of Welded Joint of X70 Submarine Pipeline Steel with Heavy Wall Thickness. Metals. 2022; 12(5):716. https://doi.org/10.3390/met12050716

Chicago/Turabian StyleDong, Yifan, Denghui Liu, Liang Hong, Jingjing Liu, and Xiurong Zuo. 2022. "Correlation between Microstructure and Mechanical Properties of Welded Joint of X70 Submarine Pipeline Steel with Heavy Wall Thickness" Metals 12, no. 5: 716. https://doi.org/10.3390/met12050716

APA StyleDong, Y., Liu, D., Hong, L., Liu, J., & Zuo, X. (2022). Correlation between Microstructure and Mechanical Properties of Welded Joint of X70 Submarine Pipeline Steel with Heavy Wall Thickness. Metals, 12(5), 716. https://doi.org/10.3390/met12050716