Multiphysics Numerical Simulation of the Transient Forming Mechanism of Magnetic Pulse Welding

Abstract

:1. Introduction

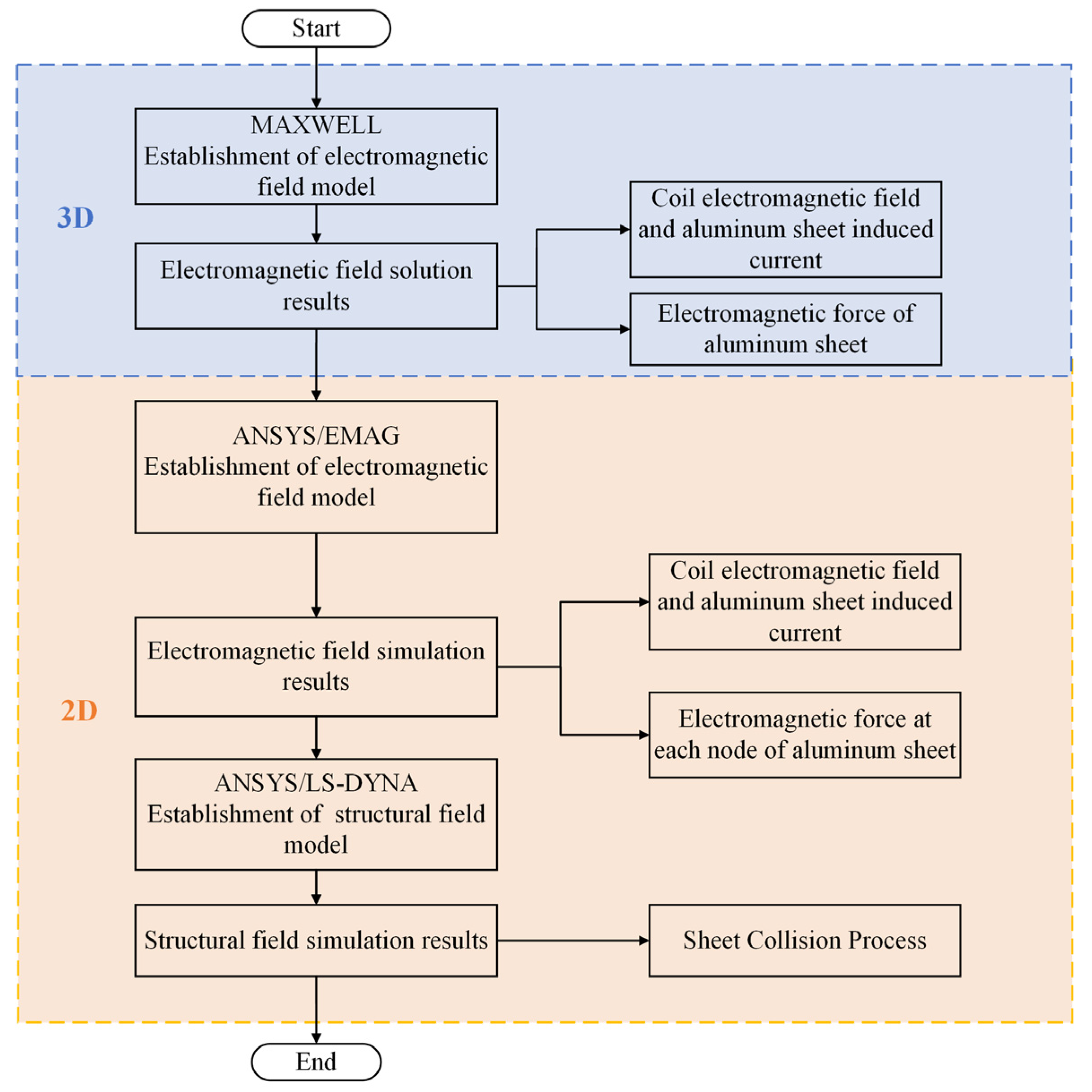

2. Simulation Scheme

3. Ansoft Maxwell 3D Numerical Simulation of Electromagnetic Field

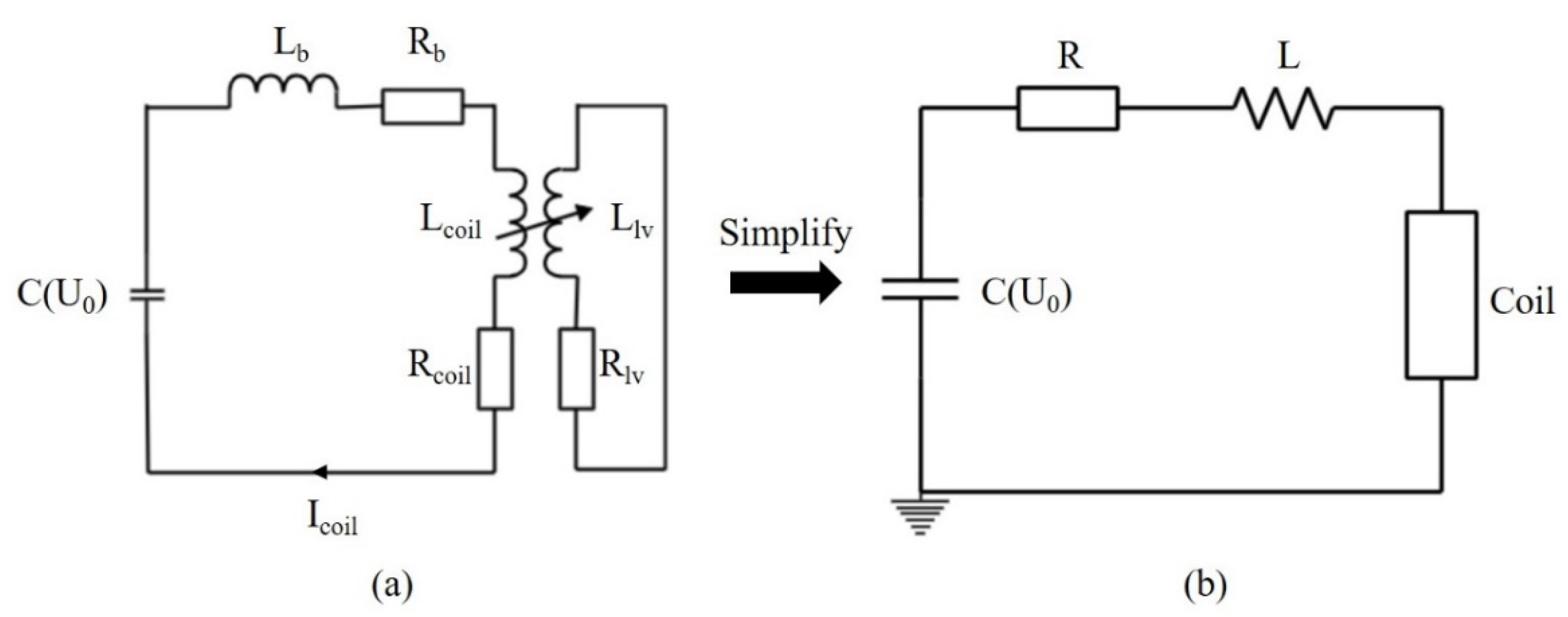

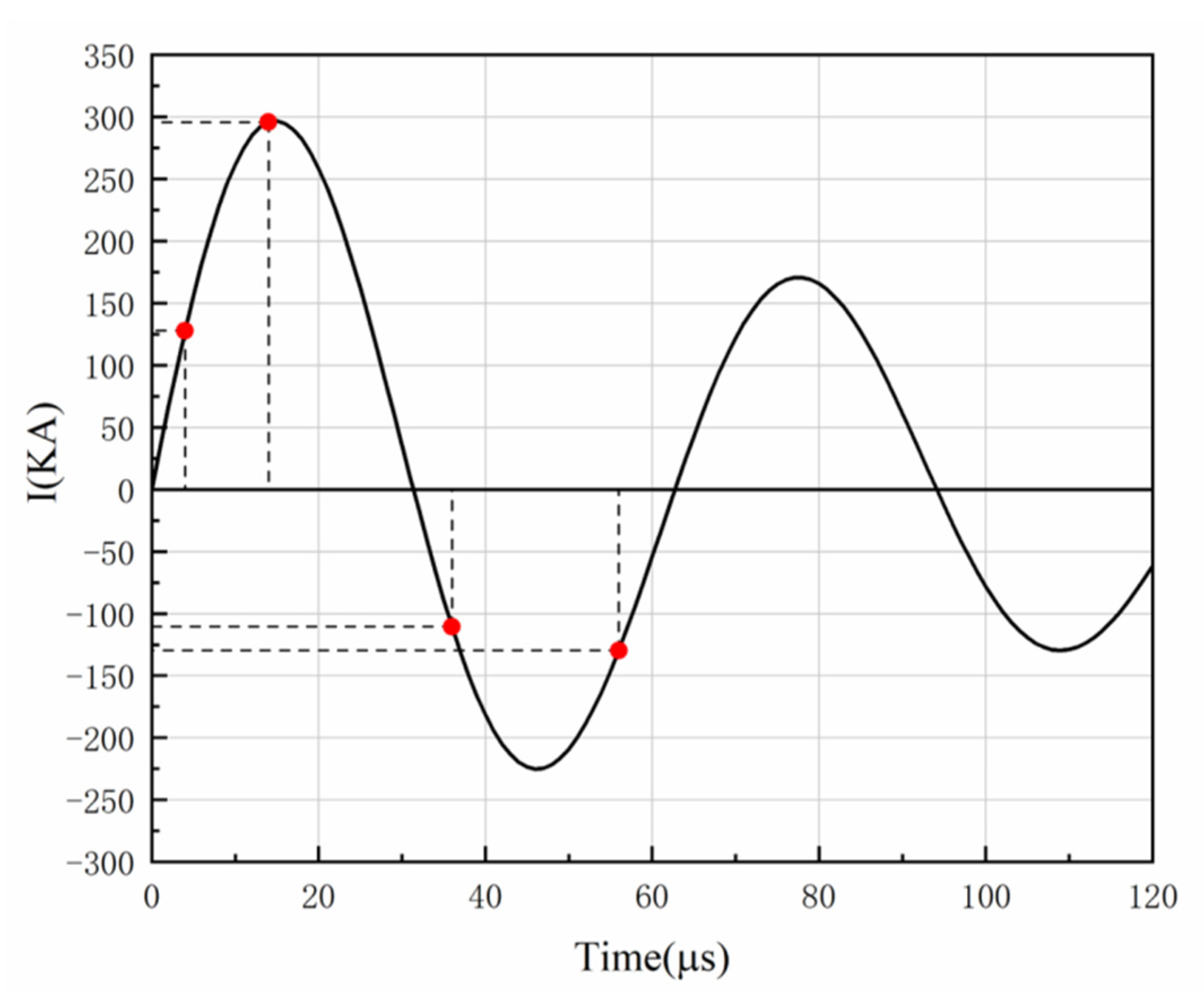

3.1. Establishment of External Circuit and Solution of Electrical Parameters

3.2. Three-Dimensional Electromagnetic Field Modeling and Analysis

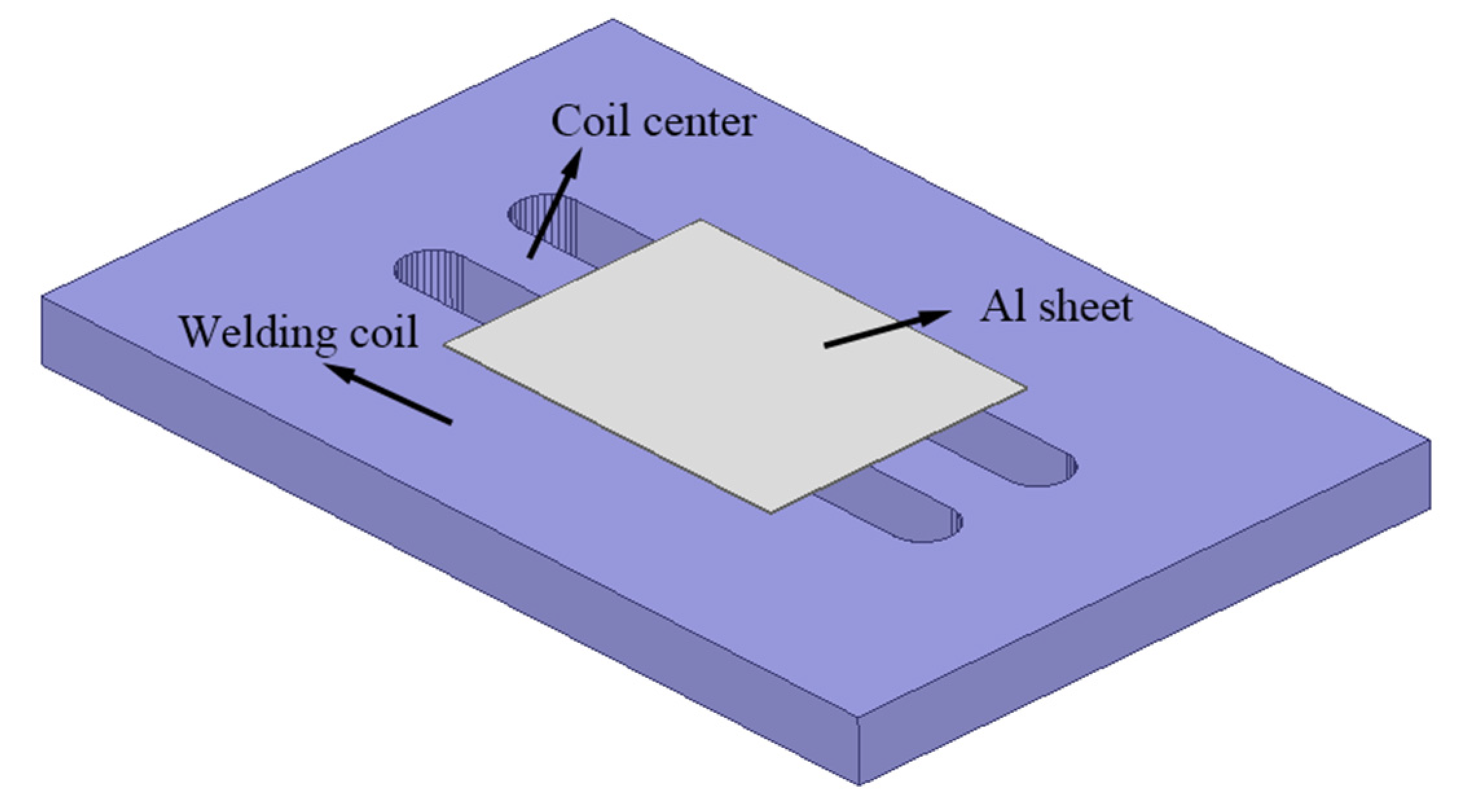

3.2.1. Electromagnetic Field Simulation Modeling

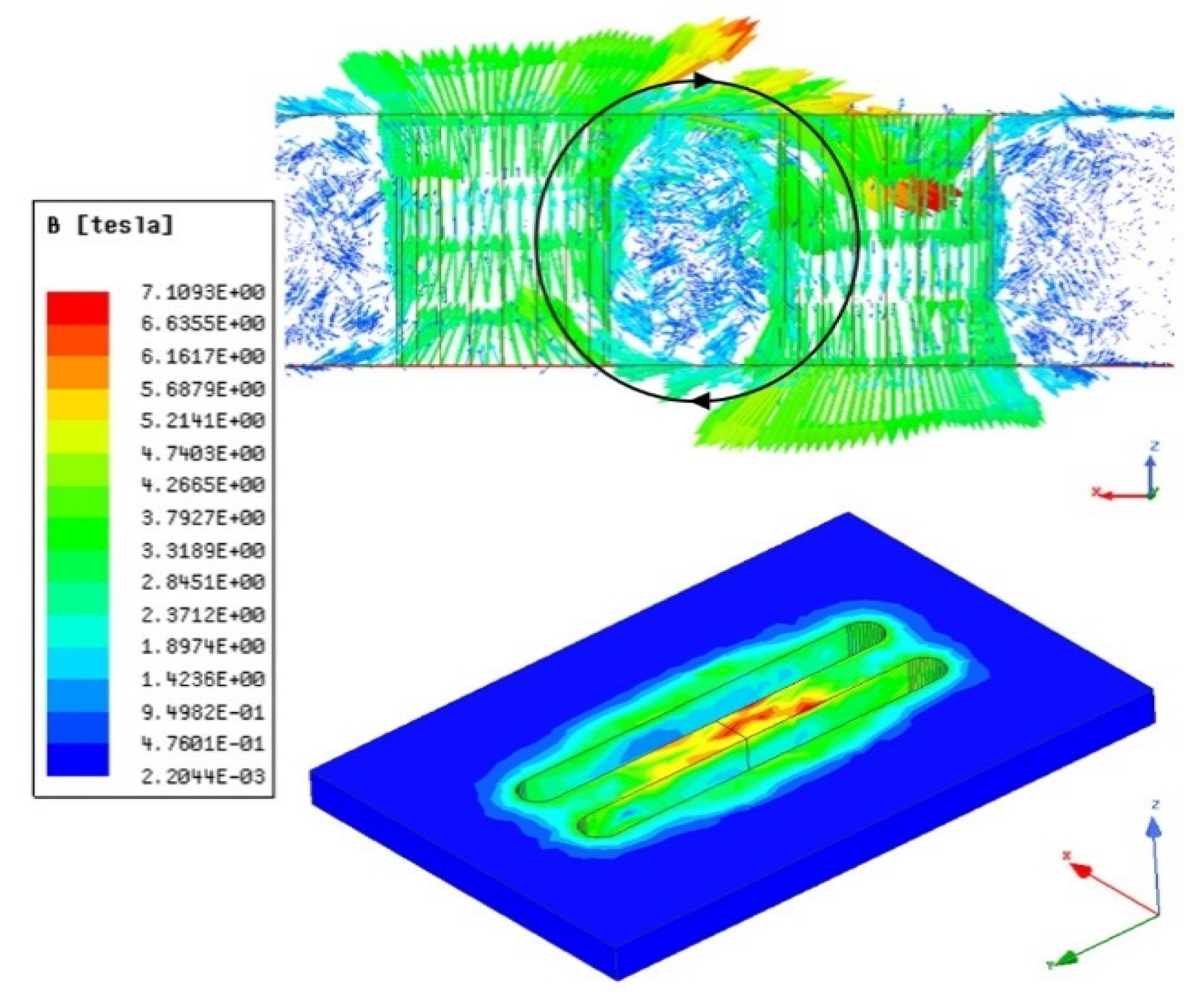

3.2.2. Analysis of Electromagnetic Field and Induced Current in Al Sheet

4. ANSYS/EMAG 2D Numerical Simulation of Electromagnetic Field

4.1. Model Building

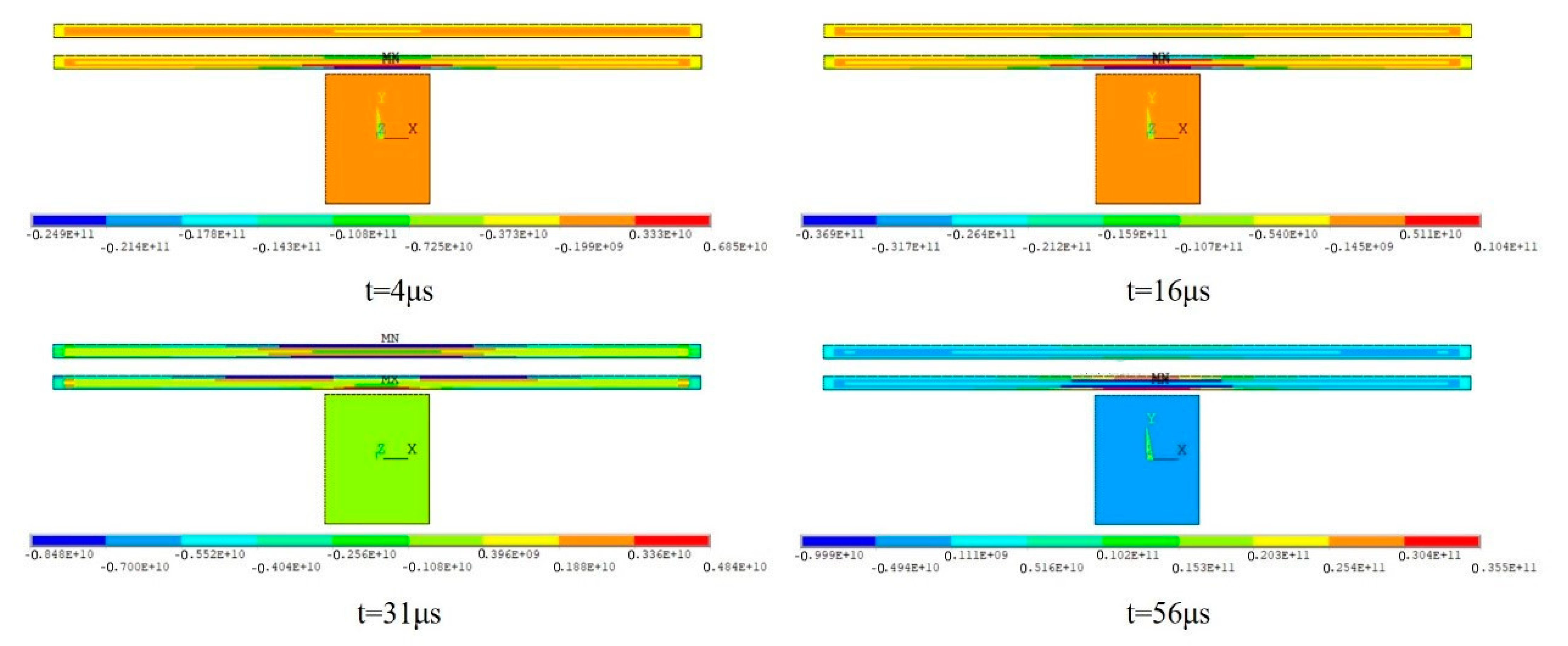

4.2. Regional Magnetic Field Analysis of Al Sheet and Mg Sheet

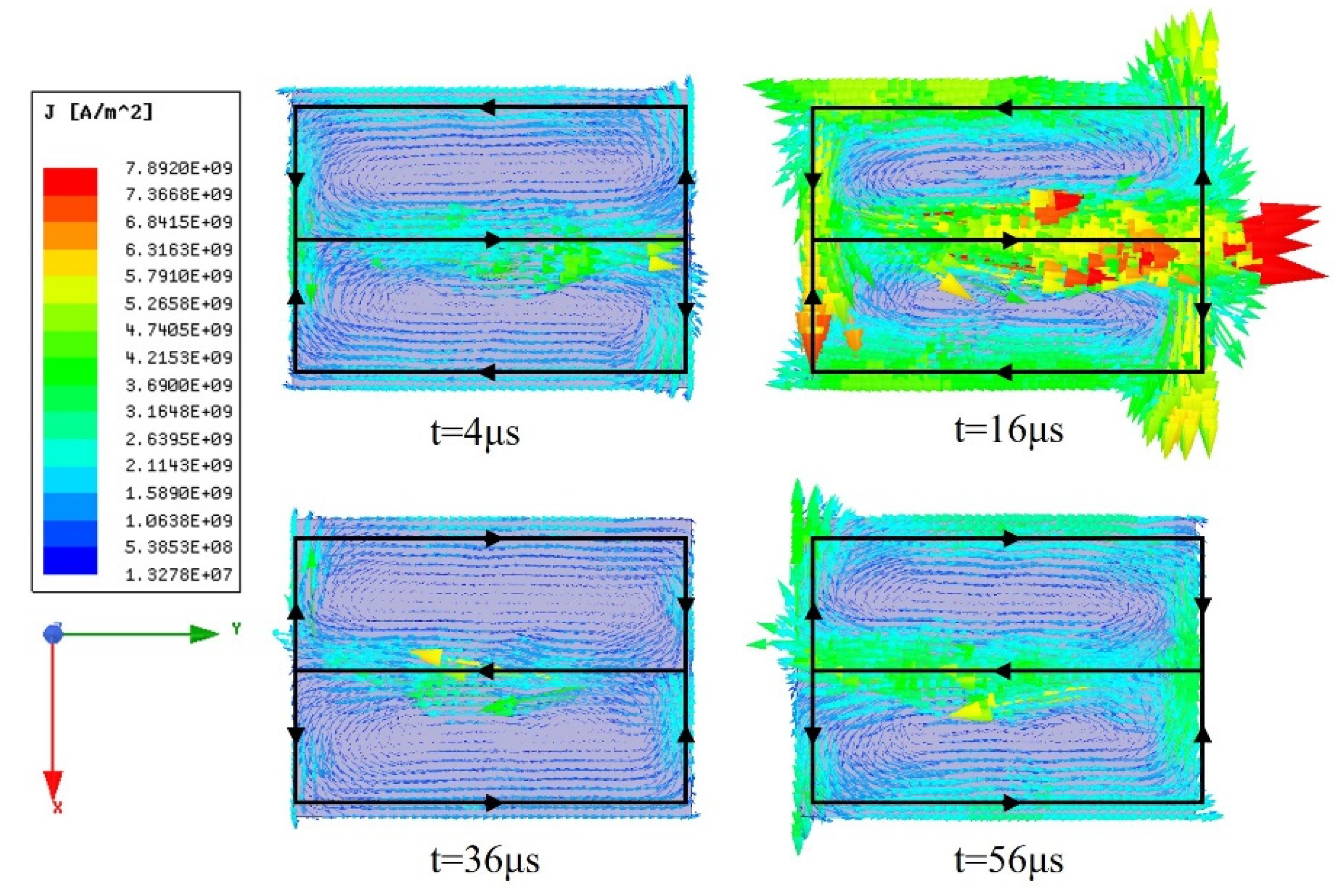

4.3. Analysis of Induced Current of the Al Sheet

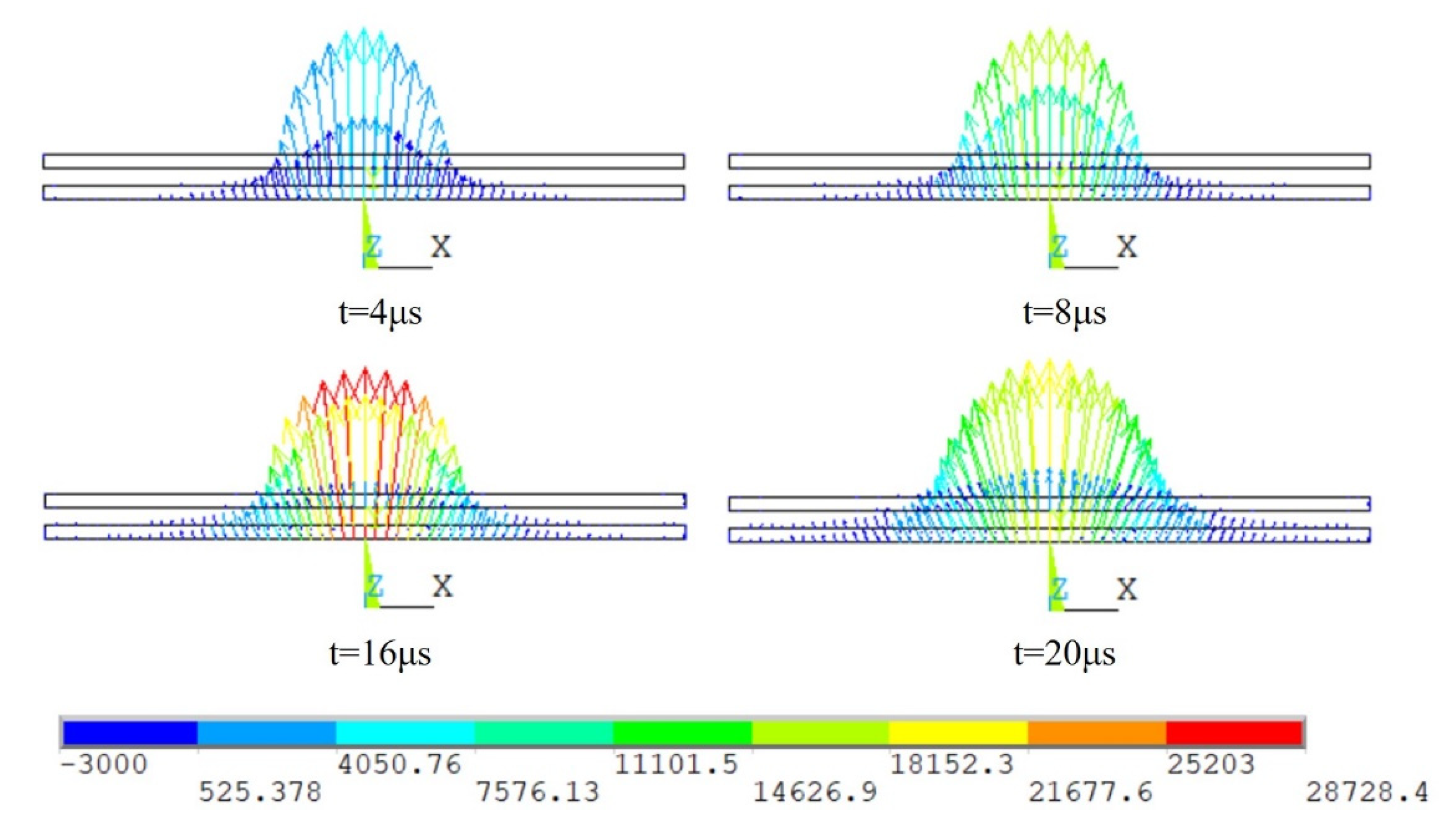

4.4. Analysis of Electromagnetic Force on Al Sheet

5. ANSYS/LS-DYNA 2D Structural Field Numerical Simulation

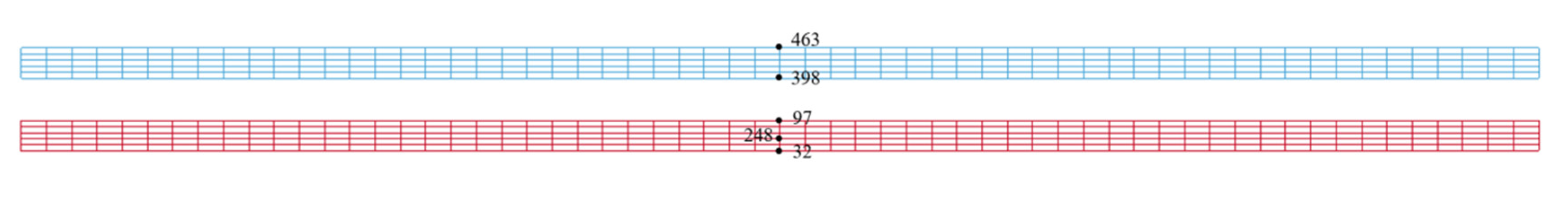

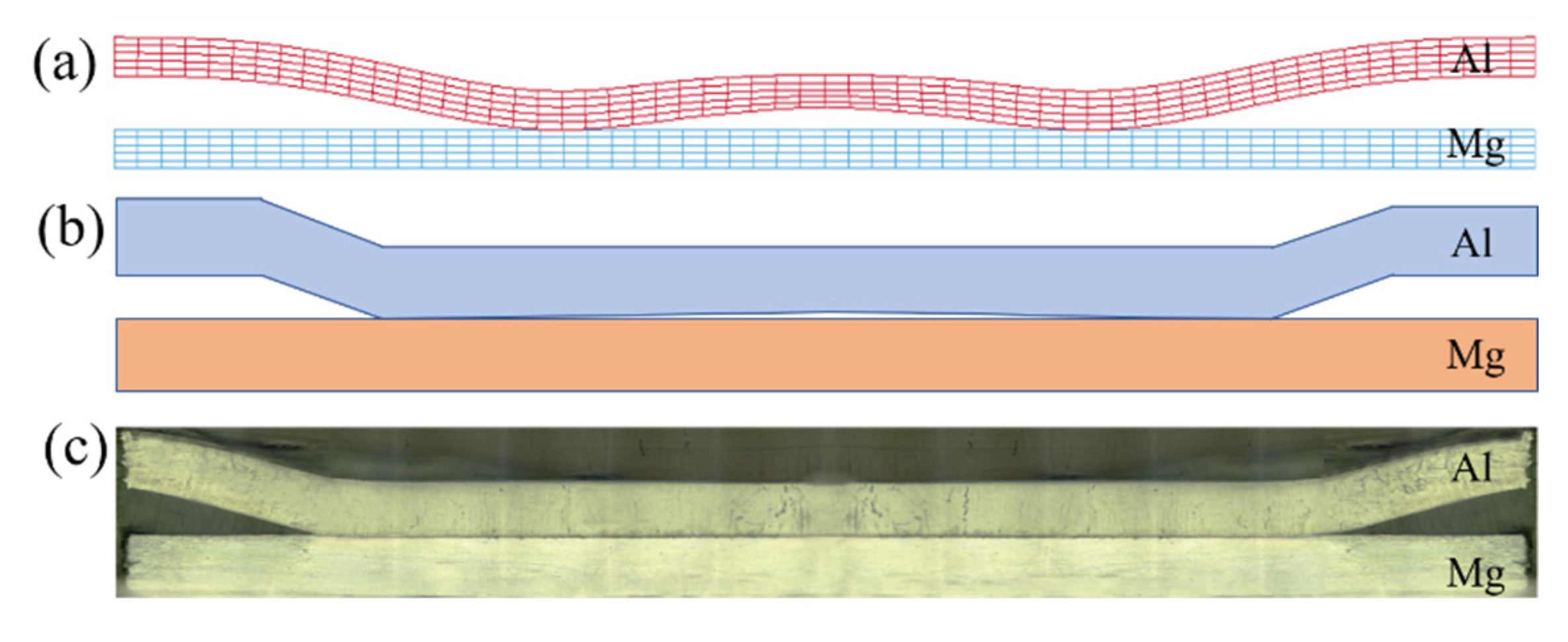

5.1. Model Establishment

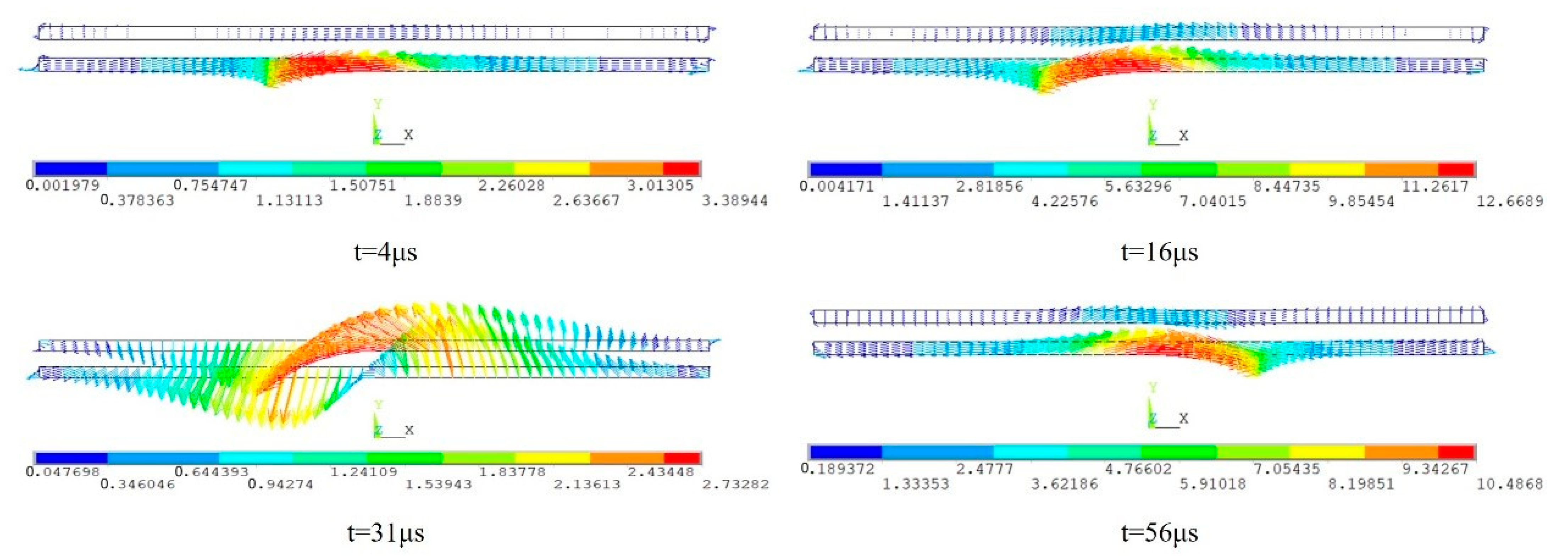

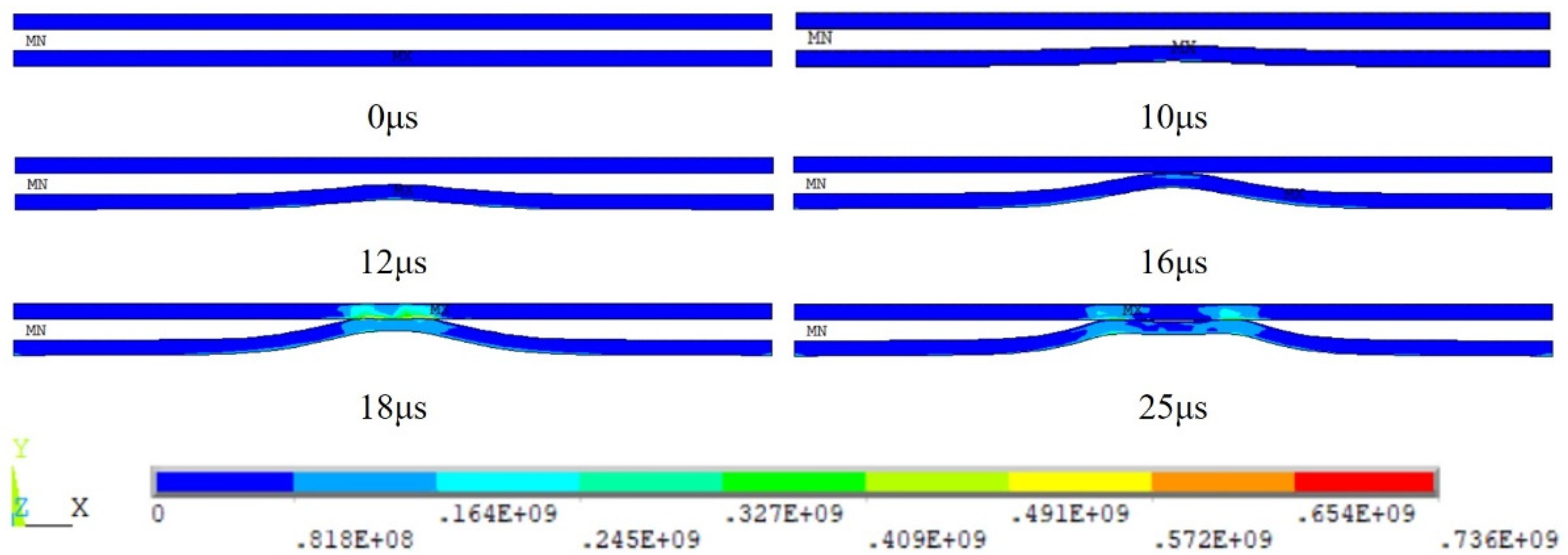

5.2. Structural Field Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khorasani, M.; Ghasemi, A.M.H.; Rolfe, B.F.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2021, 28, 87–100. [Google Scholar] [CrossRef]

- Ben-Artzy, A.; Munitz, A.; Kohn, G.; Bronfin, B.; Shtechman, A. Joining of light hybrid constructions made of magnesium and aluminum alloys. Magnes. Technol. 2002, 302. [Google Scholar]

- Chen, S.; Jiang, X. Microstructure evolution during magnetic pulse welding of dissimilar aluminium and magnesium alloys. J. Manuf. Processes 2015, 19, 14–21. [Google Scholar] [CrossRef]

- Stern, A.; Shribman, V.; Ben-Artzy, A.; Aizenshtein, M. Interface Phenomena and Bonding Mechanism in Magnetic Pulse Welding. J. of Materi Eng and Perform 2014, 23, 3449–3458. [Google Scholar] [CrossRef]

- Casalino, G.; Ludovico, A.D. Finite element simulation of high speed pulse welding of high specific strength metal alloys. J. Mater. Processing Technol. 2008, 197, 301–305. [Google Scholar] [CrossRef]

- Shim, J.Y.; Kang, B.Y.; Kim, I.S.; Kang, M.J.; Kim, I.J. A Study on Distributions of Electromagnetic Force of the Dissimilar Metal Joining in MPW Using a FEM. Adv. Mater. Res. 2009, 83, 214–221. [Google Scholar] [CrossRef]

- Shim, J.Y.; Kang, B.Y. Distribution of Electromagnetic Force of Square Working Coil for High-Speed Magnetic Pulse Welding Using FEM. Mater. Sci. Appl. 2013, 04, 856–862. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Cui, J.; Yu, H.; Li, C. Research on the impact velocity of magnetic impulse welding of pipe fitting. Mater. Des. 2013, 49, 736–745. [Google Scholar] [CrossRef]

- Mishra, S.; Sharma, S.K.; Kumar, S.; Sagar, K.; Shyam, A. 40 kJ magnetic pulse welding system for expansion welding of aluminium 6061 tube. J. Mater. Processing Technol. 2017, 240, 168–175. [Google Scholar] [CrossRef]

- Serizawa, H.; Shibahara, I.; Rashed, S.; Murakawa, H. Numerical Study of Joining Process in Magnetic Pressure Seam Welding. Trans. JWRI 2009, 38, 63–68. [Google Scholar]

- Li, C.X.; Du, J.; Zhou, Y.; Shen, T.; Yao, C.G. Development of Electromagnetic Pulse Welding Equipment for Plates and Experimental Research on Magnesium/Aluminum Alloy Welding. Trans. China Electrotech. Soc. 2021, 36, 2018–2027. [Google Scholar]

- Zhu, C.C.; Sun, L.Q.; Gao, W.L.; Li, G.Y.; Cui, J.J. The effect of temperature on microstructure and mechanical properties of Al/Mg lap joints manufactured by magnetic pulse welding-ScienceDirect. J. Mater. Res. Technol. 2019, 8, 3270–3280. [Google Scholar] [CrossRef]

- Chen, S.J.; Yu, Y.; Xia, Y.; Liu, K.L.; Lu, Z.Y. Heat Production Mechanism at Al-Mg Magnetic Pulse Welding Interface. Rare Met. Mater. Eng. 2013, 42, 5. [Google Scholar]

- Zhou, Y.; Li, C.X.; Du, J.; Wang, X.M.; Yao, C.G. Investigation on the Effect of Discharge Voltage on Metal Jet and Bonded Interface in Mg-Al Magnetic Pulse Welding. Trans. China Electrotech. Soc. 2022, 37, 11. [Google Scholar]

- Chen, S.J.; Xia, Y.; Yu, Y.; Lu, Z.Y. Morphology Study of Al-Mg Alloy Magnetic Pulse Welding Interface. Rare Met. Mater. Eng. 2012, 41, 352–355. [Google Scholar]

- Sapanathan, T.; Chernikov, D.; Yang, K. Thermal Effect during Electromagnetic Pulse Welding Process. Mater. Sci. Forum 2017, 879, 1662–1667. [Google Scholar] [CrossRef]

- Watanabe, M.; Kumai, S. High-Speed Deformation and Collision Behavior of Pure Aluminum Plates in Magnetic Pulse Welding. Mater. Trans. 2009, 59, 2035–2042. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Wu, Z. Microstructural Characteristics and Mechanical Properties of 2205/AZ31B Laminates Fabricated by Explosive Welding. Met.-Open Access Metall. J. 2017, 7, 125. [Google Scholar] [CrossRef]

- Zhu, C.C.; Meng, Y.F.; Liu, Q.X.X.; Li, G.Y.; Cui, J.J. Study on Process and Mechanical Properties of Al/Mg Dissimilar Metal Sheet Joints by Magnetic Pulse Welding. J. Netshape Form. Eng. 2021, 13, 7. [Google Scholar]

| Parameter | Li/nH | Ci/μF | Ri/mΩ | β | T/μs |

|---|---|---|---|---|---|

| Value | 354.49 | 240 | 6.22 | 7690.92 | 63 |

| Name | Material | Resistivity/(Ω·m) | Relative Permeability | Unit Type |

|---|---|---|---|---|

| Coil | Copper alloy | 1.75 × 10−8 | 1 | PLAN 13 |

| Al sheet | Al 1060 | 2.83 × 10−8 | 1 | PLAN 13 |

| Mg sheet | AZ31B | 4.45 × 10−8 | 1 | PLAN 13 |

| The near air element region | --- | +∞ | 1 | PLAN 13 |

| The far air element region | --- | +∞ | 1 | INFIN 110 |

| Name | Material | Density/(kg·m3) | Elastic Modulus (GPa) | Poisson Ratio | Unit Type |

|---|---|---|---|---|---|

| Al sheet | 1060 | 2.71 × 103 | 69 | 0.33 | PLANE 162 |

| Mg sheet | AZ31B | 1.78 × 103 | 45 | 0.35 | PLANE 162 |

| Material | A (MPa) | B (MPa) | C | n | m |

|---|---|---|---|---|---|

| 1060 Al | 35.5 | 68.7 | 0.015 | 0.14 | 0.018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Yang, D.; Yang, W.; Wu, Z.; Liu, C. Multiphysics Numerical Simulation of the Transient Forming Mechanism of Magnetic Pulse Welding. Metals 2022, 12, 1149. https://doi.org/10.3390/met12071149

Li Y, Yang D, Yang W, Wu Z, Liu C. Multiphysics Numerical Simulation of the Transient Forming Mechanism of Magnetic Pulse Welding. Metals. 2022; 12(7):1149. https://doi.org/10.3390/met12071149

Chicago/Turabian StyleLi, Yan, Dezhi Yang, Wenyu Yang, Zhisheng Wu, and Cuirong Liu. 2022. "Multiphysics Numerical Simulation of the Transient Forming Mechanism of Magnetic Pulse Welding" Metals 12, no. 7: 1149. https://doi.org/10.3390/met12071149

APA StyleLi, Y., Yang, D., Yang, W., Wu, Z., & Liu, C. (2022). Multiphysics Numerical Simulation of the Transient Forming Mechanism of Magnetic Pulse Welding. Metals, 12(7), 1149. https://doi.org/10.3390/met12071149