Abstract

Herein, the stress corrosion cracking (SCC) susceptibility of duplex (UNS S32205) and austenitic (UNS S31653) stainless steel (SS) reinforcements was evaluated using integrity assessment criteria. Mechanical properties were analyzed and compared by different SCC susceptibility factors. The integrity assessment was conducted applying Cosenza, Creazza, and Ortega ductility criteria, following three different standards (ACI 318-19, ASTM A615, and FIB). A conventional carbon steel (UNS G10080) reinforcement was also evaluated for comparative purposes, whose high residual stress value (>280 MPa) promoted a high corrosion growth rate. Duplex UNS S32205 SS grade showed a significant decrease in elongation, leading to failure after ductility assessment at high chloride concentrations. Fractographic analysis of both SS grades, duplex and austenitic, revealed less than 40% brittle areas at 8 wt.% Cl−, while UNS G10080 had over 85% at 4 wt.% Cl−.

1. Introduction

Onshore and offshore reinforced concrete structures (RCSs), as well as RCSs exposed to de-icing salts, can suffer stress corrosion cracking (SCC) when simultaneously subjected to tensile stresses [1]. The SCC phenomenon is often inconspicuous and not visibly apparent and considered one of the most critical factors on RCSs compromising structural integrity and leading to catastrophic failure [2]. SCC severely impacts the integrity, reliability, durability, and sustainability of the RCS, which are some of the key parameters for the design and construction of RCSs. Corrosion and materials degradation have a deleterious effect on the resilience of the RCS, and even further when SCC develops, as they reduce the service lifetime and its capability to withstand external damage [3]. The corrosion damage on RCSs presents direct consequences on the sustainability, where the shorter lifespans caused by premature failure require demolition and rebuilding [4,5].

In the United States, 600 million tons of construction and demolition debris were generated in 2018 [6]. The construction and building industry was responsible for 38% of global energy consumption worldwide, also accounting for 15% of direct CO2 emission [7]. The United States spent $276 billion in 2016 (3.1% of GDP) to repair corrosion damage, 12 times more than in climate/weather disasters (USD 24.4 billion), where $8.3 billion were allocated to address corrosion issues of reinforced concrete [8,9]. This cost increased to $450 billion in 2021, an over 60% increase in just 5 years [10]. These threats also impact civil engineering and transportation sectors, where 7.6% of the highway bridges in the US were identified as deficient in a survey conducted in 2019, due to corrosion of the reinforcement [11].

To increase the durability of the RCS, CS reinforcements are swapped for more corrosion-resistant stainless steel (SS) grades, to prolong service lifetime, as well as to prevent sudden failures. The superior corrosion performance of SS is further enhanced at a high-alkaline pH due to the formation of a stable Cr-rich passive film, providing a barrier layer against chloride attack [12,13]. The SS grades combine a good corrosion protection together with improved mechanical properties and a more resistant microstructure than the CS, which imparts to the RCS an enhanced performance against SCC.

Some examples of RCSs where SS has been used are: The Progresso Pier in Mexico built in 1940 out of UNS S30400 austenitic SS, which over its 70 years of service has not suffer any major repairs; the New Champlain Bridge in Canada, made out of UNS S32304 duplex SS in 2016; the Sheik Zayed Bridge in Abu Dhabi built in 2010, using grade UNS S32205 duplex SS [14]; the Hong Kong–Zhuhai–Macau Bridge (55 km long), recently constructed in 2018, that has been designed for a 120-year lifespan using both carbon steel and stainless steel (SS) reinforcements of UNS S32304 [15]. Nevertheless, it is the Second Gateway Bridge (1.6 km long) built in 2010 in Brisbane (Australia) that has almost triple the service lifetime of the Hong Kong–Zhuhai–Macau Bridge with its 300 years of design life [16]. The Second Gateway Bridge combines vanguard civil engineering technology with careful material selection for each of its components, such as the UNS S32205 and UNS S32101 SS reinforcements and fly-ash addition in the concrete for the splash zone.

The use of SS reinforcements requires a higher investment, with the cost of SS being 3 to 8 times the cost of conventional carbon steel reinforcements, mainly due to the price of nickel. To decrease this high initial cost, SS reinforcements should be used in critical places, such as in the splash zone, reducing the overall cost. There are several RCSs already using SS, such as the Schaffhausen Bridge in Switzerland, which showed a 14% maintenance cost reduction for the SS compared to carbon steel [17]. In the case of marine structures or bridges, it has been shown that SS can reduce the overall maintenance costs up to 50% [18]. That is why careful material selection depending on the environment is needed to have the best performance/cost-effective solution.

The main causes of RCS failure are attributed to corrosion mechanisms of reinforcements, and the exerted pressure the oxide scale originates in the steel/concrete interface leading to spallation: (i) First, they promote the loss of bonding and (ii) second, a recrystallization pressure develops, putting the concrete under tension. This extra pressure nucleates the first cracks, leading to spallation of the concrete cover [19,20,21,22]. Engineering failure analysis of RCSs has concluded that reinforcement corrosion is a key factor in the loss of concrete sections. Most of the literature studies focus on corrosion of rebars, volume expansion of the oxides, concrete cover cracking, and its modeling [23,24,25,26].

However, a few studies are found on the SCC mechanisms of the steel reinforcement [27,28,29,30]. While it is less studied, SCC of the steel reinforcement causes a sudden brittle fracture, leading to a catastrophic failure without any previous sign of damage. A study on SCC of AISI 316 stainless steel rebar in seawater sand concrete found that SCC did not develop at 60 °C regardless of the addition of the seawater sand to the concrete (NaCl 35 g/L at 13.4 pH) [31]. In a different study, after analysis of elongation to failure, no evidence of SCC was found on 2001 LDSS and 2205 DSS under the combined action of chlorides and load [32]. This study also revealed no significant toughness change in the 2205 DSS and minor reduction in the modulus of resilience of 2001 LDSS.

The present work studies the SCC susceptibility and structural integrity of duplex UNS S32205 and austenitic UNS S31653 SS, as well as UNS G10080 CS reinforcements in simulated concrete pore solution (SCPS) contaminated with chlorides. Mechanical and corrosion properties of the SS, duplex and austenitic, as well as CS were evaluated and correlated with microstructure. The SCC of SS reinforcements exposed to high chloride concentrations is assessed by the loss in mechanical properties as well as the ratio of ductile to brittle fracture areas.

2. Materials and Methods

2.1. Materials

The reinforcing bars used for this study were all 10 mm in diameter (size #3). The elemental compositions of the SS and CS reinforcing steels are shown in Table 1. The specimens were machined with a circular 60° V-notch in the center of the sample to accelerate the crack initiation process during slow strain rate testing (SSRT). Before the testing, samples were rinsed with deionized (DI) water, degreased with acetone, and blow-dried with air. The samples were epoxy-mounted and polished to mirror finishing by SiC paper and diamond powder (1 μm) for microstructural characterization. The etchant solutions used to reveal the microstructure were: (a) UNS S32205 in 40 wt.% NaOH, (b) UNS S31653 in aqua regia; and (c) UNS G10080 in 3% nital. Metallographic study was performed using scanning electron microscopy (SEM) in a Tescan Lyra 3 XMU. To obtain the residual stress (σR), the voltage was set to 40 kV and the current to 44 mA in a Rigaku SmartLab-3 kW. The selected free residual stress peak for the X-ray diffraction (XRD) analysis was the austenite diffracted plane orientation (211) found at 2θ = 156° [33].

Table 1.

Elemental composition of reinforcing bar (wt.%), Fe balance.

2.2. Testing Method and Environment

The reinforcements were tested under SCC conditions via a uniaxial tensile test by SSRT while being immersed in corrosive media following ASTM-G129 [34]. The SSRT experiments were conducted with a strain rate of 1 × 10−6 s−1 to increase the number of environmental interactions. Three different chloride concentrations, 0, 4, and 8 wt.% Cl−, were tested for both SSs (UNS S32205 and UNS S31653) and 0, 0.4, and 4 wt.% Cl− for UNS G10080 by means of CaCl2 additions. These chloride concentrations were selected based on the chloride threshold of SS and CS in reinforced concrete, 4.9 and 0.4 wt.% Cl−, respectively [35,36]. The simulated concrete pore solution (SCPS) was made out of saturated Ca(OH)2 aqueous solution (pH 12.6), whose pH remained unchanged throughout the straining of the sample, regardless of the chloride content. The solution was kept at 25 °C. All tests were performed in triplicate to ensure reproducibility.

2.3. Characterization Techniques

The surface morphology of specimens was studied via scanning electron microscopy (SEM). The SEM analysis was performed in secondary electron mode (SE) at an accelerating voltage of 15 kV and at a working distance of 10 mm. The analysis of the ductile/brittle area ratios was carried out with ImageJ 1.8.0 software.

3. Results

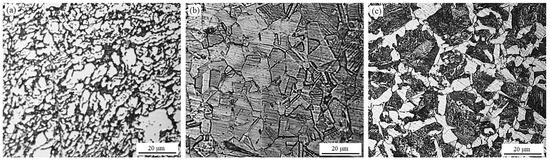

3.1. Microstructure Characterization

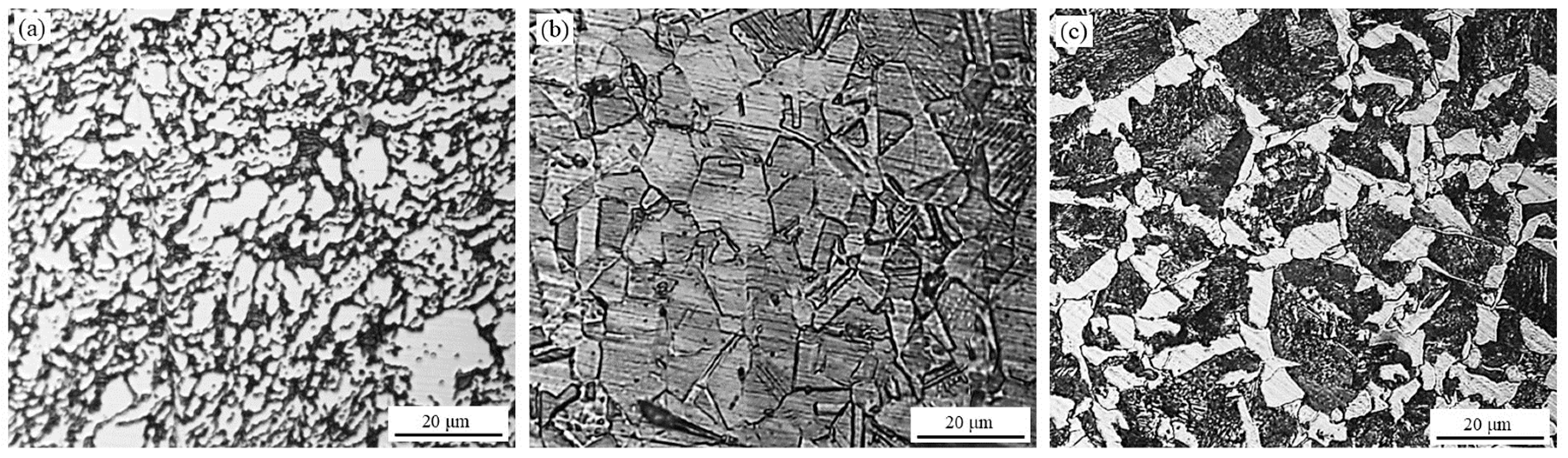

The microstructure of the as-received alloys in the transversal direction of each reinforcement can be seen in Figure 1, where UNS S32205 presents austenite (γ) phase grains (black) embedded in the ferrite (α) phase matrix (white) (see Figure 1a) [37]; UNS S31653 presents a polygonal shape of γ-phase matrix with some minor dislocation twins and slip bands (see Figure 1b) [38]; and UNS G10080 presented a structure comprising pearlitic colonies (dark areas, with α (white) and cementite lamellae (black)) and α-phase (white) (see Figure 1c) [39].

Figure 1.

Microstructure characterization of the as-received reinforcements at ×100: (a) UNS S32205, (b) UNS S31653, and (c) UNS G10080.

The grain size of the γ-phase matrix of UNS S31653 was 13 µm, while the grain size of the cementite of UNS G10080 was 22 µm, and the α-phase 11 µm. The smaller the grain size, the larger the grain boundary surface, which favors intergranular corrosion due to inclusions and precipitates. In this case, the three selected alloys presented no sign of inclusions or precipitates in the grain boundaries. However, the finer the grains, the harder the initiation of a crack, as seen by both fatigue and SCC testing [40]. In this regard and from a grain size perspective, UNS S31653 would have a better SCC resistance against corrosion compared to UNS G10080.

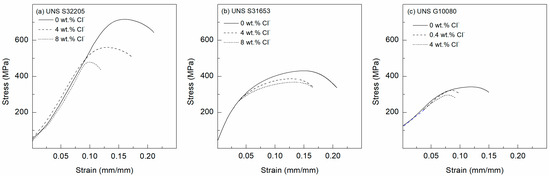

3.2. Slow Strain Rate Testing (SSRT)

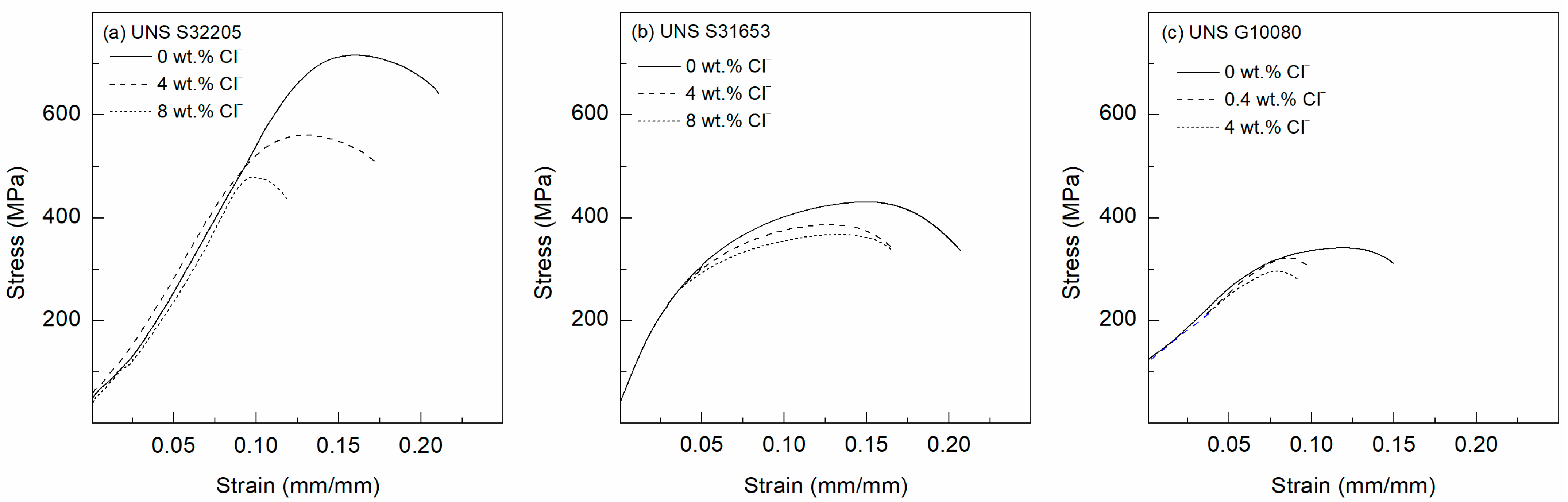

The stress–strain curves of the SS reinforcements (UNS S32205, UNS S31653, and UNS G10080) immersed in SCPS as a function of the Cl− content can be seen in Figure 2 [41]. The mechanical behavior was influenced by Cl− additions, with a severe impact on the ultimate tensile stress (σUTS) and both elongation to σUTS (εUTS) and the final elongation to failure (εf); while a similar yield stress (σy) was found (see Table 2) [31].

Figure 2.

Stress–strain curves of reinforcements as a function of the chloride content in simulated concrete pore solution (pH 12.6): (a) UNS S32205, (b) UNS S31653, and (c) UNS G10080.

Table 2.

Mechanical properties of the reinforcements after SSRT in SCPS (pH 12.6) at different chloride concentrations.

The best-performing alloy was UNS S32205, having the highest stresses. However, at high chloride concentrations, UNS S31653 was able to elongate more compared to UNS S32205. In addition, the changes seen for UNS S31653 as a function of the chloride additions were not as severe as the ones seen for UNS S32205.

Carbon steel UNS G10080 reinforcements revealed the lowest σUTS values, regardless of the chloride content. The increased chloride content of the SCPS promoted pitting corrosion and decreased the εf by 33%, thus indicating a high SCC susceptibility.

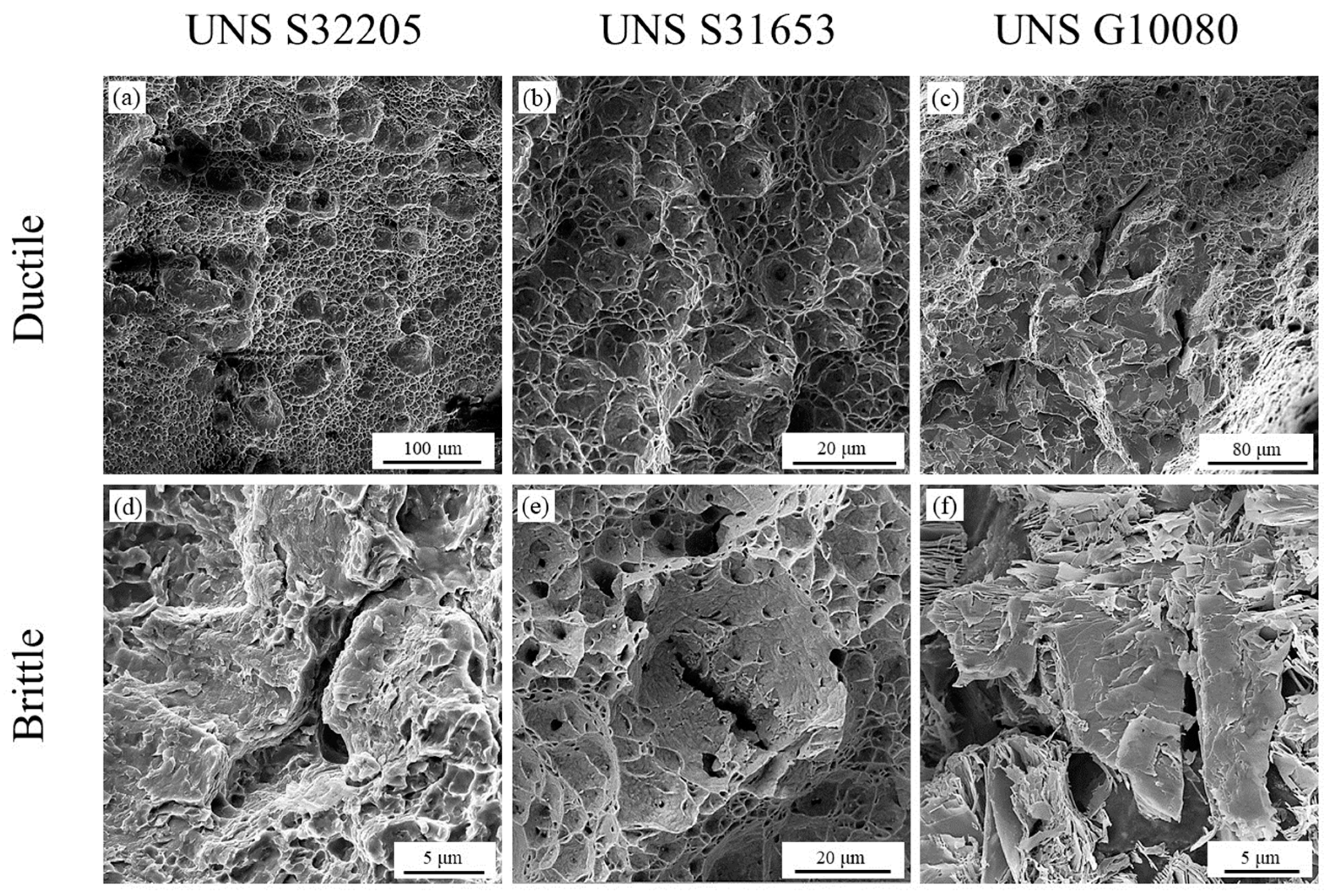

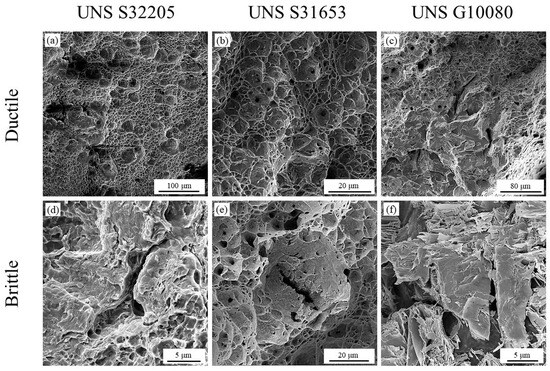

3.3. Fractographic Study

After the straining by SSRT in the different environments, an analysis of the fracture area was carried out for all reinforcements to identify the main fracture features. Figure 3 depicts the most predominant ductile and brittle features of each reinforcement [42]. UNS S32205 showed major areas of ductile areas, with microvoids and coalescence of dimples attributed to the ductile behavior of the γ-phase (see Figure 3a) [43]. However, when UNS S32205 developed brittle fracture, cracks on the ferrite facets were seen, thus showing that the α-phase is the more SCC-susceptible phase (see Figure 3d) [28,44]. UNS S31653 also developed microvoids and coalescence of dimples for the ductile fracture (see Figure 3b), nevertheless, for the brittle fracture, cracks inside the dimples were the predominant feature, besides the development of cleavage planes (see Figure 3e) [45]. Finally, UNS G10080 developed major areas of ductile overload areas, despite the absence of chlorides, where not only dimples were present but also cleavage facets (see Figure 3c) [30]. After the 0.4 wt.% Cl− addition, the SCC severely increased, promoting delamination and rupture of the cementite.

Figure 3.

Micrographs of reinforcements after slow strain rate test (SSRT) immersed in SCPS: Ductile fracture features of (a) UNS S32205 microvoids and coalescence of dimples ×700, (b) UNS S31653 microvoids and coalescence of dimples ×3500, (c) UNS G10080 ductile overload areas with cleavage facets ×900; brittle fracture features, (d) UNS S32205 cracks on the ferrite facets ×10,500, (e) UNS S31653 cracks inside the dimples ×3200, and (f) UNS G10080 cementite delamination and rupture ×9300.

4. Discussion

4.1. Residual Stress

The differences in the SCC susceptibility are dependent not only on the microstructure but also on the residual stress, as this will later make that lower applied stresses reach the stress intensity factor sooner to develop SCC (KISCC) and thus the first crack [40,46]. Table 3 gathers all the tested reinforcements and their respective σR from the as-received condition, where all SSs were hot-rolled and UNS G10080 was cold-rolled [47].

Table 3.

Residual stress (σR) value of steel reinforcements from the as-received condition.

While both stainless steels had a σR around 30 MPa, UNS G10080 experienced high σR values of 280 MPa. The reason was the cold work processing, which deformed the grains without thermal treatment, avoiding the recrystallization and relaxation of the microstructure [48,49]. Combining both σR and the microstructure effect in terms of developing the pit growth, the most important factor is the alloy composition, providing most of the corrosion protection, while the σR acts as a detrimental factor, lowering the required stress [50]. As seen from the degradation of the mechanical properties, the SSs performed best, with their superior microstructure and lower σR, compared to the UNS G10080 whose microstructure does not supply good corrosion performance.

4.2. Mechanical Properties Degradation and Ductility Assessment

In order to quantitatively measure the SCC susceptibility as a function of the chloride content, several criteria based on mechanical properties were calculated according to ASTM G129-21 (see Table 2) [34,51]. In addition, SCC susceptibility index (ISCC) was also used, as this ratio is widely used to assess how harsh the environment is (see Equation (1)) [52]:

where εUTS,SCC is the elongation to σUTS of the samples tested under SCC and εUTS,b is the elongation to σUTS of the blank sample tested without chlorides, σUTS,SCC is the ultimate tensile strength of the samples tested under SCC, and σUTS,b is the ultimate tensile strength of the blank sample tested without chlorides. The plasticity lost (Iδ) is obtained using Equation (2) [34]:

where εf,SCC is the elongation to failure of the sample tested under SCC and εf,b is the elongation to failure of the blank sample tested without chlorides. Additionally, the ratio of elasticity loss (REL) is obtained (see Equation (3)) [34,51]:

where σy,SCC is the yield strength of the sample tested under SCC and σy,b is the yield strength of the blank sample tested without chlorides.

Table 4 gathers all the obtained parameters for each reinforcement and environment. Despite the better mechanical properties of UNS S32205, it showed the highest ISCC and REL, due to the highest reduction in εf. The integrity assessment revealed that the best performing rebar grade tested under 8 wt. Cl− was UNS S31653, as it showed lower ISCC values, and its ductility properties did not get depleted as fast as the UNS S32205.

Table 4.

Integrity assessment parameters of the reinforcements after SSRT in SCPS (pH 12.6) at different chloride concentrations.

To further compare the mechanical properties of SS and CS, the classification of steel ductility based on the work from Cosenza (see Equation (4)), Creazza (see Equation (5)), and Ortega was applied (see Equation (6)) [53]:

A few examples from the literature are presented in Table 5, where the mechanical properties were used to calculate the three criteria [17].

The criteria (p, Anom, and Id) for considering the SS or CS highly ductile are found in Table 6 based on different standards (FIB, ASTM A615, and ACI 318-19) [53,54,55].

Table 6.

Ductility values according to the criteria of equivalent steel for high-ductility steel [56].

Table 5.

Experimental parameters of reinforcements ductility based on the criteria from Cosenza, Creazza, and Ortega [53,56].

Table 5.

Experimental parameters of reinforcements ductility based on the criteria from Cosenza, Creazza, and Ortega [53,56].

| Standard | High Ductility | εUTS,k % | p | Anom MPa | Id | |

|---|---|---|---|---|---|---|

| MC 2010 | D | ≥1.25 < 1.45 | ≥8.0 | 1.37 | 388 | 70 |

| EC-2 | C | ≥1.15 < 1.35 | ≥7.5 | 0.82 | 363 | 62 |

| ASTM A615 | Grade 60 | ≥1.25 | ≥7.0 | 1.24 | 338 | 61 |

| ≥1.13 | ≥9.0 | 0.83 | 438 | 75 | ||

| FIB | S | ≥1.15 | ≥6.0 | 0.70 | 288 | 49 |

| ≥1.17 | ≥5.0 | 0.68 | 238 | 41 |

HR: hot-rolled, CR: cold-rolled.

Comparing the different standards, the least restrictive is the FIB, as it has the lowest minimums to categorize samples as highly ductile. Even with the lowest requirements, some of the CR rebars do not meet standards, due to loss of ductility.

For the EC2 being more restrictive, all HR SSs meet requirements to a greater extent than CS, which stays in the 1.2 range compared to the 1.4 range of most HR SSs. Furthermore, when compared with the most restrictive standard (MC 2010), it is found that when applying Id criteria not even the HR CS would pass it, showing the ductility advantages of the SSs over the CS. Overall, the mechanical properties of SS rebar are very similar, all being designed for normal working conditions [57]. That is why, in the absence of an aggressive environment, carbon steel is the most cost-effective material. Nevertheless, de-icing salts and the proximity to the sea influence degradation of the rebar and impact mechanical properties. Now, analyzing the ductility values obtained at the different chloride concentrations, it can be seen from Table 7 that the obtained values are much smaller.

Table 7.

Ductility assessment values of the reinforcements after SSRT in SCPS (pH 12.6) at different chloride concentrations.

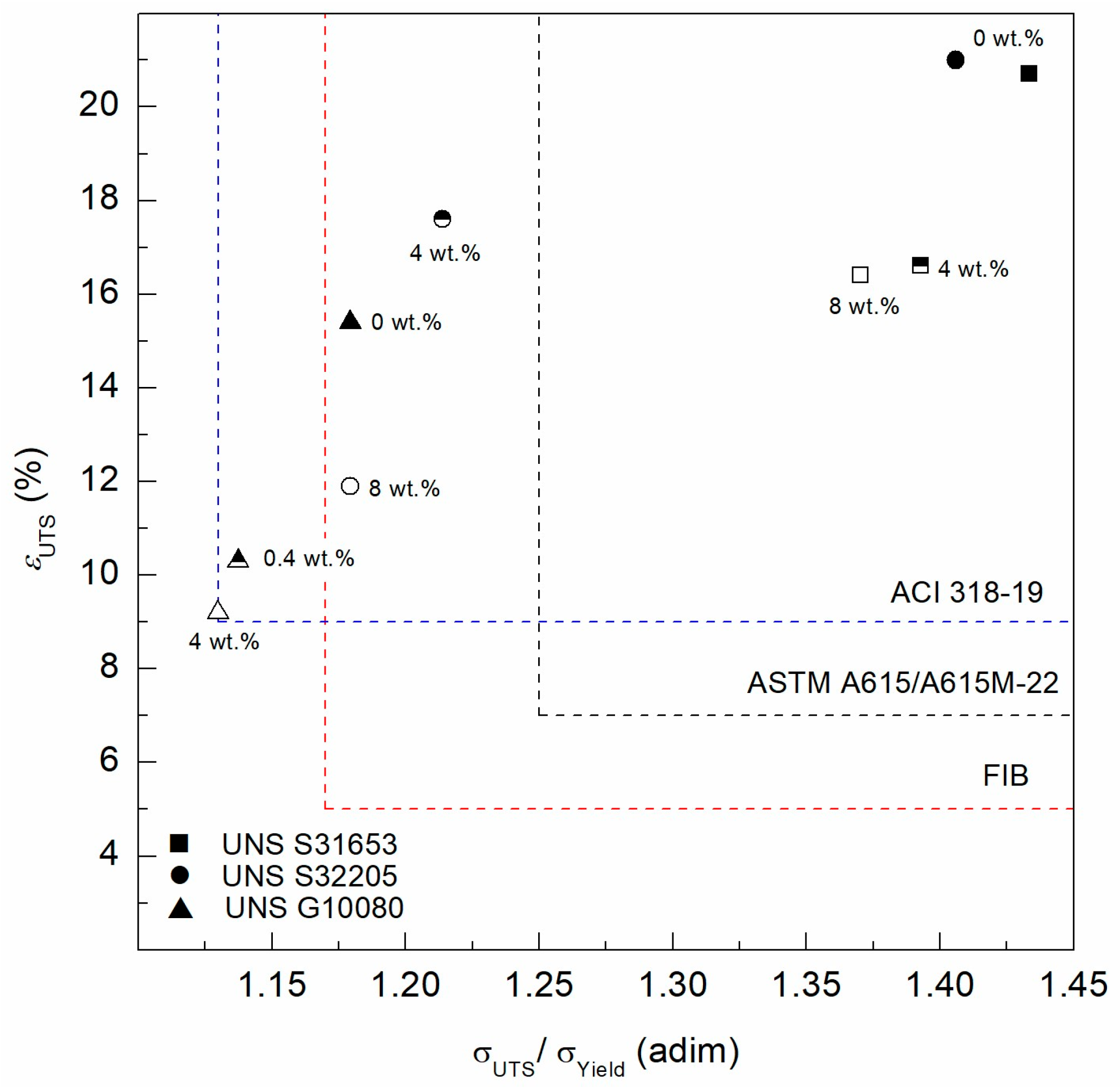

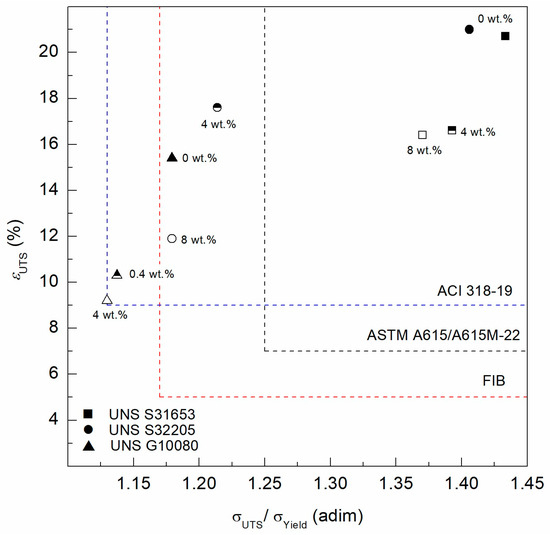

In order to see the chlorides effect on the SCC using ductility criteria, Figure 4 presents the obtained values of all reinforcements using the three main standards.

Figure 4.

Ductility classification based on different standards for UNS S32205, UNS S31653, and UNS G10080 reinforcements under SCC conditions.

Based on ACI 318-19, all reinforcements would pass, where only UNS G10080 at its highest chloride concentration would be at the limit for being considered ductile. The FIB shows that none of the UNS G10080 reinforcements under chloride environments would pass. Finally, ASTM A615, being the most restrictive, shows that even UNS S32205 at 4 wt.% Cl− fails, and only UNS S31653 passes up to 8 wt.% Cl−. Despite the lower stress values obtained during the straining, UNS S31653 was able to keep good elongation and maintain the lowest mechanical property degradation. Figure 4 shows how detrimental SCC is for the ductility assessment, as it will make even SS fail under such aggressive conditions. Material selection needs to be carefully carried out for each specific environment, pairing the needed material with the most suitable material.

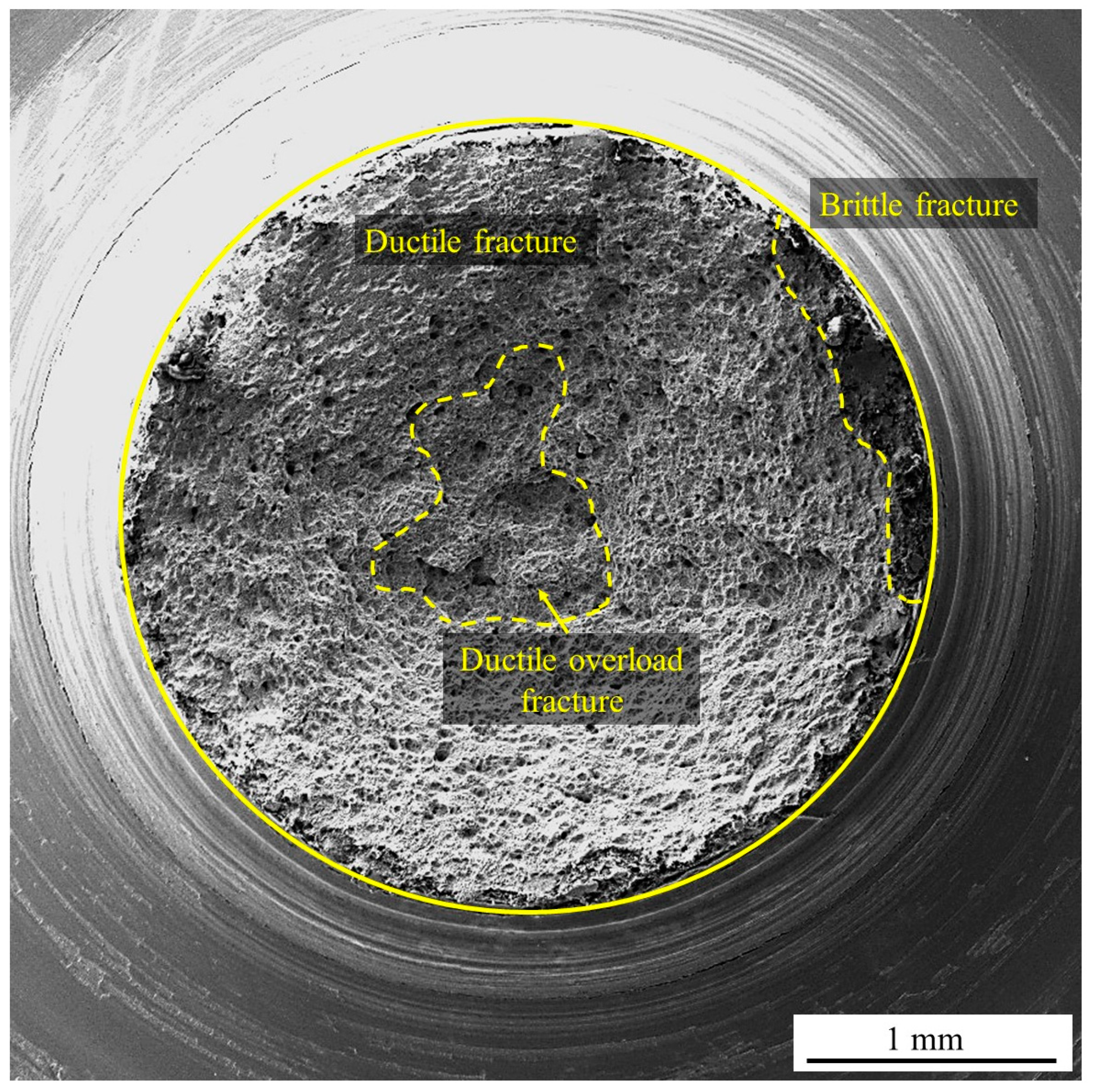

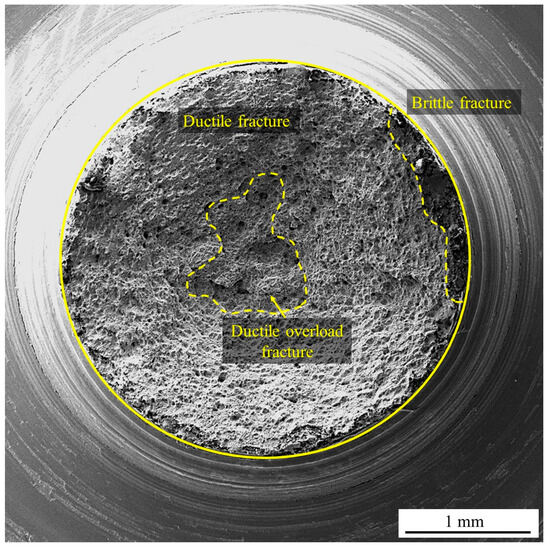

4.3. Change in Ductile/Brittle Area Ratio

Besides the depletion of the mechanical properties due to the aggressive environments, the fracture mode also changes, as seen from the development of brittle fracture [58]. The change from ductile, to ductile overload, to brittle can be quantified by measuring the fracture area ratio. Figure 5 shows an example of the fractographic analysis, which was carried out with ImageJ 1.8.0 software. First, the area of the fracture surface was measured, then each individual zone was delimited, and by the difference in area, the percentage of each category was calculated (ductile, ductile overload, brittle).

Figure 5.

Fractographic analysis and fracture area ratio measurement of UNS S32205 in SCPS with no chlorides ×50.

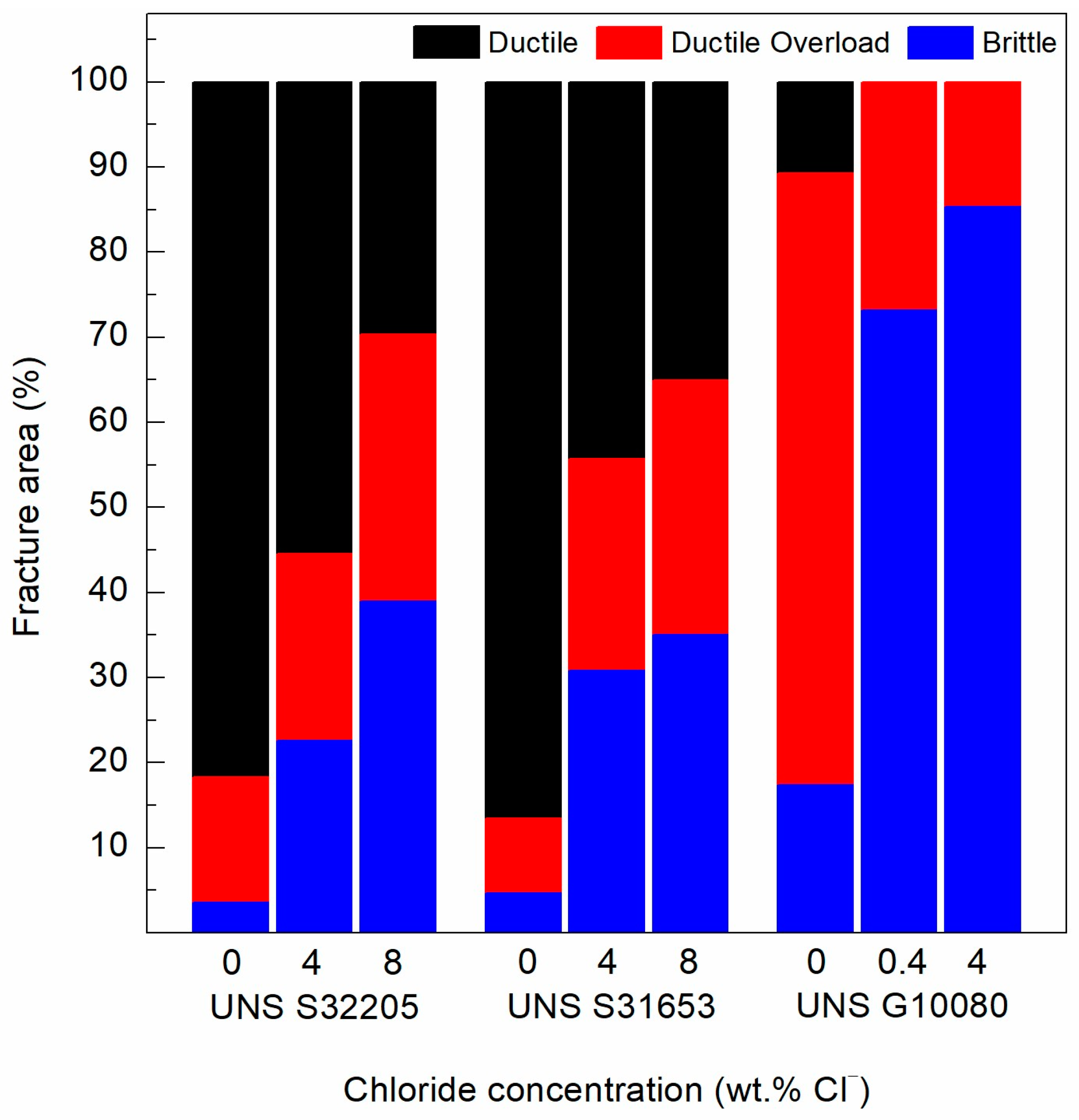

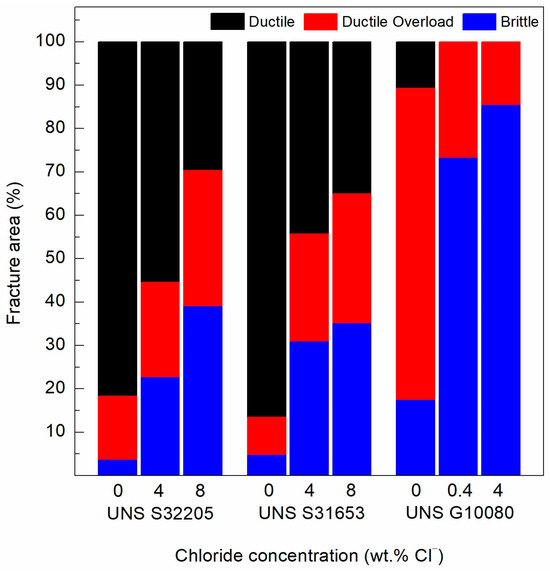

By repeating the process for every reinforcement in each environment, Figure 6 is obtained, showing the fracture mode change as a consequence of the chloride addition. Both SSs showed a similar trend, where the majority of the fractured area was ductile, and with every chloride addition, the ductile overload and brittle areas increased. Despite 8 wt.% Cl−, both alloys had more than 60% ductile and ductile overload areas combined. Meanwhile, UNS G10080 dramatically increased the brittle surface from over 10% to 70 and 85% for 0.4 and 4 wt.% Cl−, respectively.

Figure 6.

Fracture area ratio analysis of the reinforcements after exposure to SCC conditions for different chloride concentrations.

The higher SCC resistance and materials performance of UNS S32205 and UNS S31653 SS alloys are shown in Figure 6, in addition to the ductility results presented in Figure 4. Nevertheless, a detrimental SCC susceptibility of CS is revealed. Thus, the material selection plays a crucial role on the integrity and resilience of the RCS. More careful attention to offshore structures is recommended, where chlorides are present, or bridges where de-icing salts are used, as carbon steel reinforcements are prone to chloride attack. In this regard, SSs are a valuable option for integrity management as they can provide improved corrosion resistance, increasing the safety and service lifetime of the RCS.

5. Conclusions

In this work, an integrity assessment was conducted by analyzing the degradation of the mechanical properties of CS and SS reinforcements under an SCC environment as a function of the chloride concentration. The main conclusions can be drawn as follows:

The mechanical properties revealed a more severe depletion for UNS G10080, due to the higher corrosion susceptibility and higher residual stresses (>280 MPa) compared to the SS. UNS S31653 showed signs of SCC susceptibility by the different parameters; however, it did not severely increase with the chloride addition. Meanwhile, UNS S32205 had a substantial increase in the ISCC with increasing chloride concentration. Nevertheless, its mechanical properties overperformed compared to UNS G10080.

The ductility assessment showed that only UNS S31653 was able to meet all the standards (ACI 318-19, ASTM A615, and FIB), even at 8 wt.% Cl−, making it the most ductile alloy under SCC. Meanwhile, UNS S32205 failed at 8 wt.% Cl− under the most restrictive standard ASTM A615 due to the loss of elongation. From this study, it could be seen that where higher toughness requirements are needed, UNS S32205 would be the selected alloy, while where ductility is needed, UNS S31653 would be the best choice.

After the failure of all the selected rebars, the fractographic analysis showed that both SSs presented less than 40% brittle fracture surface coverage at 8 wt.% Cl−, while UNS G10080 had over 85% at 4 wt.% Cl−.

Author Contributions

Conceptualization, U.M. and D.M.B.; Methodology, U.M. and D.M.B.; Experimental design, U.M. and D.M.B.; Data analysis, U.M. and D.M.B.; Resources, D.M.B.; Writing—original draft preparation, U.M. and D.M.B.; Writing—review and editing, U.M. and D.M.B.; Visualization, D.M.B.; Supervision, D.M.B.; Project administration, D.M.B.; Funding acquisition, D.M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Firestone Research Grant 639430 and the University of Akron Fellowships FRC-207160 and FRC-207865.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available as the data also forms part of an ongoing study.

Acknowledgments

The authors acknowledge the technical support and facilities of the National Center for Education and Research on Corrosion and Materials Performance (NCERCAMP-UA).

Conflicts of Interest

David M. Bastidas was employed by the company ROSEN USA. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Andrade, C. 17—Future trends in research on reinforcement corrosion. In Woodhead Publishing Series in Civil and Structural Engineering, 2nd ed.; Harries, K.A., Sharma, B., Eds.; Woodhead Publishing: Sawston, UK, 2023; pp. 353–374. ISBN 978-0-12-821840-2. [Google Scholar]

- Ghosh, P.; Recinos, A. Computation of corrosion initiation time with HPC mixtures and high-quality rebars. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Qian, J.; Zheng, Y.; Dong, Y.; Wu, H.; Guo, H.; Zhang, J. Sustainability and resilience of steel—Shape memory alloy reinforced concrete bridge under compound earthquakes and functional deterioration within entire life-cycle. Eng. Struct. 2022, 271, 114937. [Google Scholar] [CrossRef]

- Horáková, A.; Broukalová, I.; Kohoutková, A.; Vašková, J. Sustainability and durability analysis of reinforced concrete structures. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246, 012038. [Google Scholar] [CrossRef]

- Almasabha, G.; Murad, Y.; Alghossoon, A.; Saleh, E.; Tarawneh, A. Sustainability of using steel fibers in reinforced concrete deep beams without stirrups. Sustainability 2023, 15, 4721. [Google Scholar] [CrossRef]

- EPA. Construction and Demolition Debris Management in the United States; U.S. Environmental Protection Agency: Washington, DC, USA, 2020.

- Ahmed, G.H. A review of “3D concrete printing”: Materials and process characterization, economic considerations and environmental sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Kalina, R.D.; Lean, S.M.; Breen, J.E. Comparative Study of Mechanical and Corrosion Resistance Properties of Bridge Post-Tensioning Strands; Technical Report FHWA/TX-11/0-4562-3; Texas Department of Transportation: Austin, TX, USA, 2011.

- Zhou, Y.; Mahmood, S.; Engelberg, D.L. Bipolar electrochemistry for high throughput screening of localised corrosion in stainless steel rebars. Constr. Build. Mater. 2023, 366, 130174. [Google Scholar] [CrossRef]

- Tri-Council Development Fund. The High Cost of Corrosion. 2021. Available online: https://tcdfillinois.org/news/the-high-cost-of-corrosion (accessed on 15 November 2023).

- ARTBA. Bridge Report; American Road & Transportation Builders Association: Washington, DC, USA, 2019. [Google Scholar]

- ASTM A941-22a; Standard Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Pokhmurs’kyi, V.I.; Balyts’kyi, O.I.; Krokhmal’nyi, O.O. General and pitting corrosion of chromium-manganese steels in halogen solutions. Mater. Sci. 2000, 36, 313–324. [Google Scholar] [CrossRef]

- EN 1990:2019; Eurocode—Basis of Structural Design. European Standard: Brussels, Belgium, 2019.

- Li, K.; Wang, P.; Li, Q.; Fan, Z. Durability assessment of concrete structures in HZM sea link project for service life of 120 years. Mater. Struct. 2016, 49, 3785–3800. [Google Scholar] [CrossRef]

- Connal, J. Second Gateway Bridge, Brisbane, Australia. IABSE Symp. Rep. 2010, 97, 78–85. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Structural performance of stainless steel reinforced concrete members: A review. Constr. Build. Mater. 2022, 325, 126673. [Google Scholar] [CrossRef]

- Cramer, S.D.; Covino, B.S.; Bullard, S.J.; Holcomb, G.R.; Russell, J.H.; Nelson, F.J.; Laylor, H.M.; Soltesz, S.M. Corrosion prevention and remediation strategies for reinforced concrete coastal bridges. Cem. Concr. Compos. 2002, 24, 101–117. [Google Scholar] [CrossRef]

- Sánchez-Deza, A.; Bastidas, D.M.; La Iglesia, A.; Mora, E.M.; Bastidas, J.M. Service life prediction for 50-year-old buildings in marine environments. Rev. Metal. 2018, 54, 111. [Google Scholar] [CrossRef]

- Castorena-González, J.H.; Martin, U.; Gaona-Tiburcio, C.; Núñez-Jáquez, R.E.; Almeraya-Calderón, F.M.; Bastidas, J.M.; Bastidas, D.M. Modeling steel corrosion failure in reinforced concrete by cover crack width 3D FEM analysis. Front. Mater. 2020, 7, 41. [Google Scholar] [CrossRef]

- Yang, Y.; Nakamura, H.; Yamamoto, Y.; Miura, T. Numerical simulation of bond degradation subjected to corrosion-induced crack by simplified rebar and interface model using RBSM. Constr. Build. Mater. 2020, 247, 118602. [Google Scholar] [CrossRef]

- Li, M.; Shen, D.; Yang, Q.; Cao, X.; Huang, C.; Cui, Z.; Qi, Y. Effect of reinforcement corrosion on the seismic performance of reinforced concrete shear walls. Constr. Build. Mater. 2023, 377, 130977. [Google Scholar] [CrossRef]

- He, Z.; He, C.; Ma, G.; Yang, W.; Xu, G. Performance assessment of deteriorated RC shield tunnels integrated with stochastic field-based modeling for nonuniform steel corrosion. Eng. Fail. Anal. 2023, 148, 107196. [Google Scholar] [CrossRef]

- Hong, S.; Qin, S.; Dong, P.; Li, G.; Zhang, Y.; Xing, F.; Dong, B. Quantification of rust penetration profile in reinforced concrete deduced by inverse modeling. Cem. Concr. Compos. 2020, 111, 103622. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, L. Prediction of corrosion-induced cracking of concrete cover: A critical review for thick-walled cylinder models. Ocean Eng. 2020, 213, 107688. [Google Scholar] [CrossRef]

- Dangwal, S.; Singh, H. Behavior of corrosion damaged non-seismically and seismically detailed reinforced concrete beam-column sub-assemblages under cyclic loading. Eng. Fail. Anal. 2023, 146, 107135. [Google Scholar] [CrossRef]

- Briz, E.; Biezma, M.V.; Bastidas, D.M. Stress corrosion cracking of new 2001 lean–duplex stainless steel reinforcements in chloride contained concrete pore solution: An electrochemical study. Constr. Build. Mater. 2018, 192, 1–8. [Google Scholar] [CrossRef]

- Martin, U.; Bastidas, D.M. Stress corrosion cracking mechanisms of UNS S32205 duplex stainless steel in carbonated solution induced by chlorides. Metals 2023, 13, 10645. [Google Scholar] [CrossRef]

- Martin Diaz, U.; Birbilis, N.; Macdonald, D.D.; Bastidas, D.M. Passivity breakdown and crack propagation mechanisms of lean duplex (UNS S32001) stainless steel reinforcement in high alkaline solution under stress corrosion cracking. Corrosion 2023, 79, 4229. [Google Scholar] [CrossRef]

- Martin, U.; Bastidas, D.M. Stress corrosion cracking failure analysis of aisi 1018 carbon steel reinforcing bars in carbonated and chloride contaminated environment. Eng. Fail. Anal. 2023, 146, 107159. [Google Scholar] [CrossRef]

- Yu, X.; Al-Saadi, S.; Kohli, I.; Zhao, X.; Singh Raman, R.K. Austenitic Stainless-Steel Reinforcement for Seawater Sea Sand Concrete: Investigation of Stress Corrosion Cracking. Metals 2021, 11, 500. [Google Scholar] [CrossRef]

- Briz, E.; Martin, U.; Biezma, M.V.; Calderon-Uriszar-Aldaca, I.; Bastidas, D.M. Evaluation of the mechanical behavior of 2001 LDSS and 2205 DSS reinforcements exposed to simultaneous load and corrosion in chloride contained concrete pore solution. J. Build. Eng. 2020, 31, 101456. [Google Scholar] [CrossRef]

- Ahmed, I.I.; Adebisi, J.A.; Abdulkareem, S.; Sherry, A.H. Investigation of surface residual stress profile on martensitic stainless steel weldment with X-ray diffraction. J. King Saud Univ. Eng. Sci. 2018, 30, 183–187. [Google Scholar] [CrossRef]

- ASTM G129-21; Standard Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted Cracking. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Hurley, M.F.; Scully, J.R. Threshold chloride concentrations of selected corrosion-resistant rebar materials compared to carbon steel. Corrosion 2006, 62, 892–904. [Google Scholar] [CrossRef]

- Bautista, A.; Pomares, J.C.; González, M.N.; Velasco, F. Influence of the microstructure of TMT reinforcing bars on their corrosion behavior in concrete with chlorides. Constr. Build. Mater. 2019, 229, 116899. [Google Scholar] [CrossRef]

- Sandim, M.J.R.; Souza Filho, I.R.; Mota, C.F.G.S.; Zilnyk, K.D.; Sandim, H.R.Z. Microstructural and magnetic characterization of a lean duplex steel: Strain-induced martensite formation and austenite reversion. J. Magn. Magn. Mater. 2021, 517, 167370. [Google Scholar] [CrossRef]

- Park, I.; Kim, E.-Y.; Yang, W.-J. Microstructural investigation of stress corrosion cracking in cold-formed AISI 304 reactor. Metals 2020, 11, 7. [Google Scholar] [CrossRef]

- Toribio, J.; Ayaso, F.-J. Cleavage stress producing notch-induced anisotropic fracture and crack path deflection in cold drawn pearlitic steel. Metals 2021, 11, 451. [Google Scholar] [CrossRef]

- Katona, R.M.; Karasz, E.K.; Schaller, R.F. A Review of the governing factors in pit-to-crack transitions of metallic structures. Corrosion 2023, 79, 72–96. [Google Scholar] [CrossRef] [PubMed]

- Mu, Z.; Yang, Y.; Gao, Z.; Jiang, Z. Mechanical behavior of special-shaped double-web steel-reinforced concrete column joints. Metals 2023, 13, 601. [Google Scholar] [CrossRef]

- Lun, P.Y.; Zhang, X.G.; Jiang, C.; Ma, Y.F.; Fu, L. Modelling of corrosion-induced concrete cover cracking due to chloride attacking. Materials 2021, 14, 1440. [Google Scholar] [CrossRef] [PubMed]

- Cojocaru, E.M.; Raducanu, D.; Vintila, A.N.; Alturaihi, S.S.; Serban, N.; Berbecaru, A.C.; Cojocaru, V.D. Influence of ageing treatment on microstructural and mechanical properties of a solution treated UNS S32750/EN 1.4410/F53 super duplex stainless steel (SDSS) alloy. J. Mater. Res. Technol. 2020, 9, 8592–8605. [Google Scholar] [CrossRef]

- Örnek, C.; Léonard, F.; McDonald, S.A.; Prajapati, A.; Withers, P.J.; Engelberg, D.L. Time-dependent in situ measurement of atmospheric corrosion rates of duplex stainless steel wires. NPJ Mater. Degrad. 2018, 2, 10. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, Z.; Chen, J.; Yao, Y.; Li, D. Characterisation of stress corrosion durability and time-dependent performance of cable bolts in underground mine environments. Eng. Fail. Anal. 2023, 150, 107292. [Google Scholar] [CrossRef]

- Singh Raman, R.K.; Jones, R. Distinct advantages of circumferential notch tensile (CNT) testing in the determination of a threshold for stress corrosion cracking (KISCC). Materials 2021, 14, 5620. [Google Scholar] [CrossRef]

- Robl, T.; Wölfle, C.H.; Shahul Hameed, M.Z.; Rappl, S.; Krempaszky, C.; Werner, E. An Approach to Predict Geometrically and Thermo-Mechanically Induced Stress Concentrations in Ribbed Reinforcing Bars. Metals 2022, 12, 411. [Google Scholar] [CrossRef]

- Groza, J.R.; Eslamloo-Grami, M.; Bandy, R. The effect of thermo-mechanical treatment on the pitting corrosion of reinforcing carbon steel bars. Werkst. Und Korros. 1993, 44, 359–366. [Google Scholar] [CrossRef]

- Truschner, M. Effect of cold deformation on the stress corrosion cracking resistance of a high-strength stainless steel. J. Mater. Sci. 2022, 57, 20447–20461. [Google Scholar] [CrossRef]

- González-Velázquez, J.L.; Rivas-López, D.I.; Beltrán-Zúñiga, M.A.; Villagómez-Ortega, J.; Dorantes-Rosales, H.J. Fracture mechanics analysis of the stress corrosion cracking failure of stainless steel hexagonal head screws in a marine-industrial environment. Eng. Fail. Anal. 2023, 146, 107098. [Google Scholar] [CrossRef]

- Ponciano Gomes, J.A.C.; Silva, S.C.; Campos, T. Stress corrosion cracking susceptibility of armour layers in CO2 annulus environments—SSRT experimental simulation. Eng. Fail. Anal. 2022, 139, 106451. [Google Scholar] [CrossRef]

- Abe, S.; Kojima, M.; Hosoi, Y. Stress corrosion cracking susceptibility index, ISCC, of austenitic stainless steels in constant strain-rate test. In Stress Corrosion Cracking; The Slow Strain-Rate Technique; Ugiansky, G.M., Payer, J.H., Eds.; ASTM International: West Conshohocken, PA, USA, 1979; pp. 294–304. ISBN 978-0-8031-5548-0. [Google Scholar]

- Kordina, K.R.; Mancini, G.; Schäfer, K.; Schieβl, A.; Zilch, K. FIB Bulletin No. 55, Model Code 2010—First Complete Draft, Volume 1; Balázs, G.L., Ed.; The International Federation for Structural Concrete: Lausanne, Switzerland, 2010; ISBN 9782883940949. [Google Scholar]

- ASTM A615/A615M; Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ACI 318-19; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2022; ISBN 9781641950565.

- Medina, E.; Medina, J.M.; Cobo, A.; Bastidas, D.M. Evaluation of mechanical and structural behavior of austenitic and duplex stainless steel reinforcements. Constr. Build. Mater. 2015, 78, 1–7. [Google Scholar] [CrossRef]

- Yu, Q.-Q.; Gu, X.-L.; Zeng, Y.-H.; Zhang, W.-P. Flexural behavior of Corrosion-Damaged prestressed concrete beams. Eng. Struct. 2022, 272, 114985. [Google Scholar] [CrossRef]

- Cui, C.; Ma, R.; Martínez-Pañeda, E. A generalised, multi-phase-field theory for dissolution-driven stress corrosion cracking and hydrogen embrittlement. J. Mech. Phys. Solids 2022, 166, 104951. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).