Life Assessment of Corroded Wire for Prestressing

Abstract

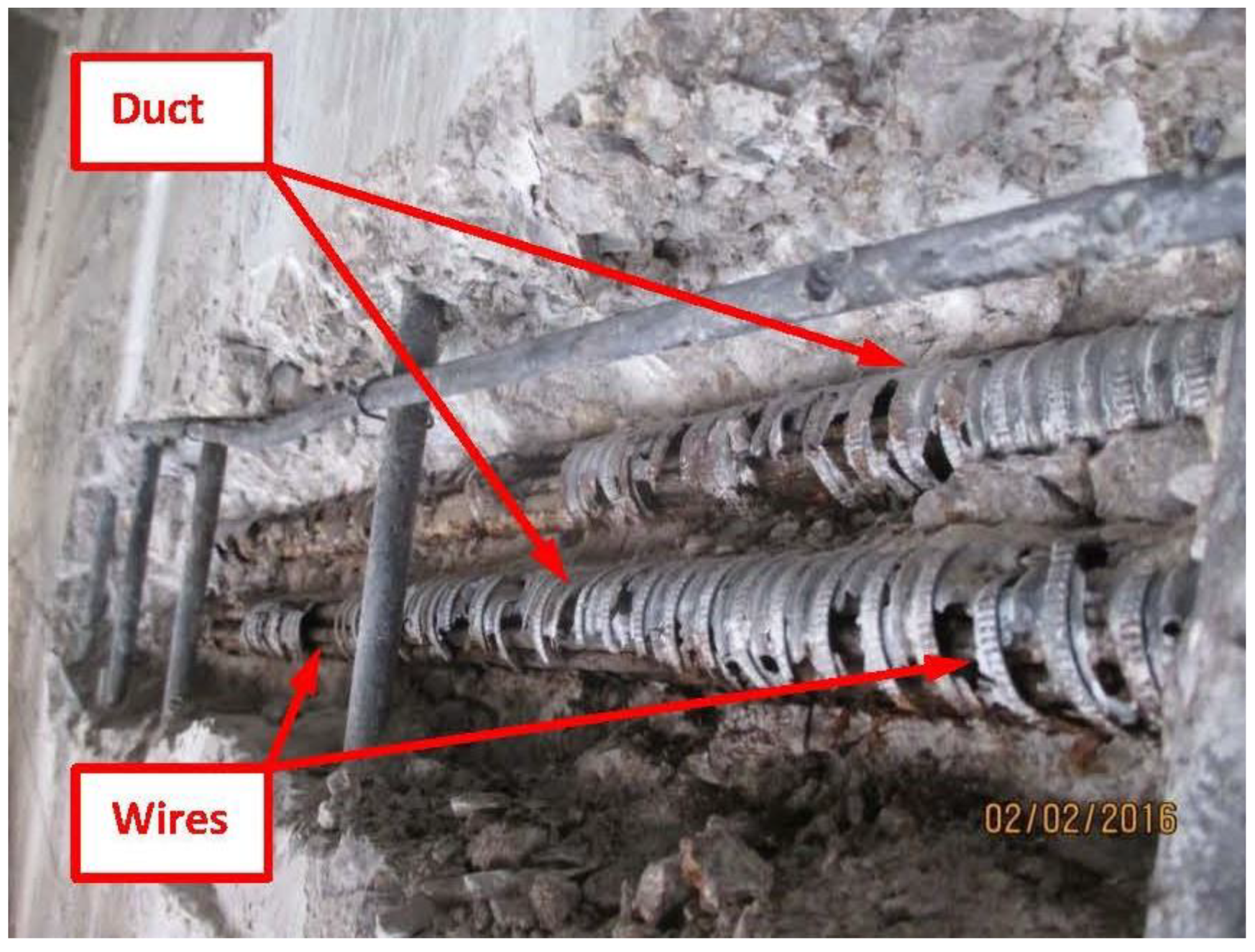

:1. Introduction

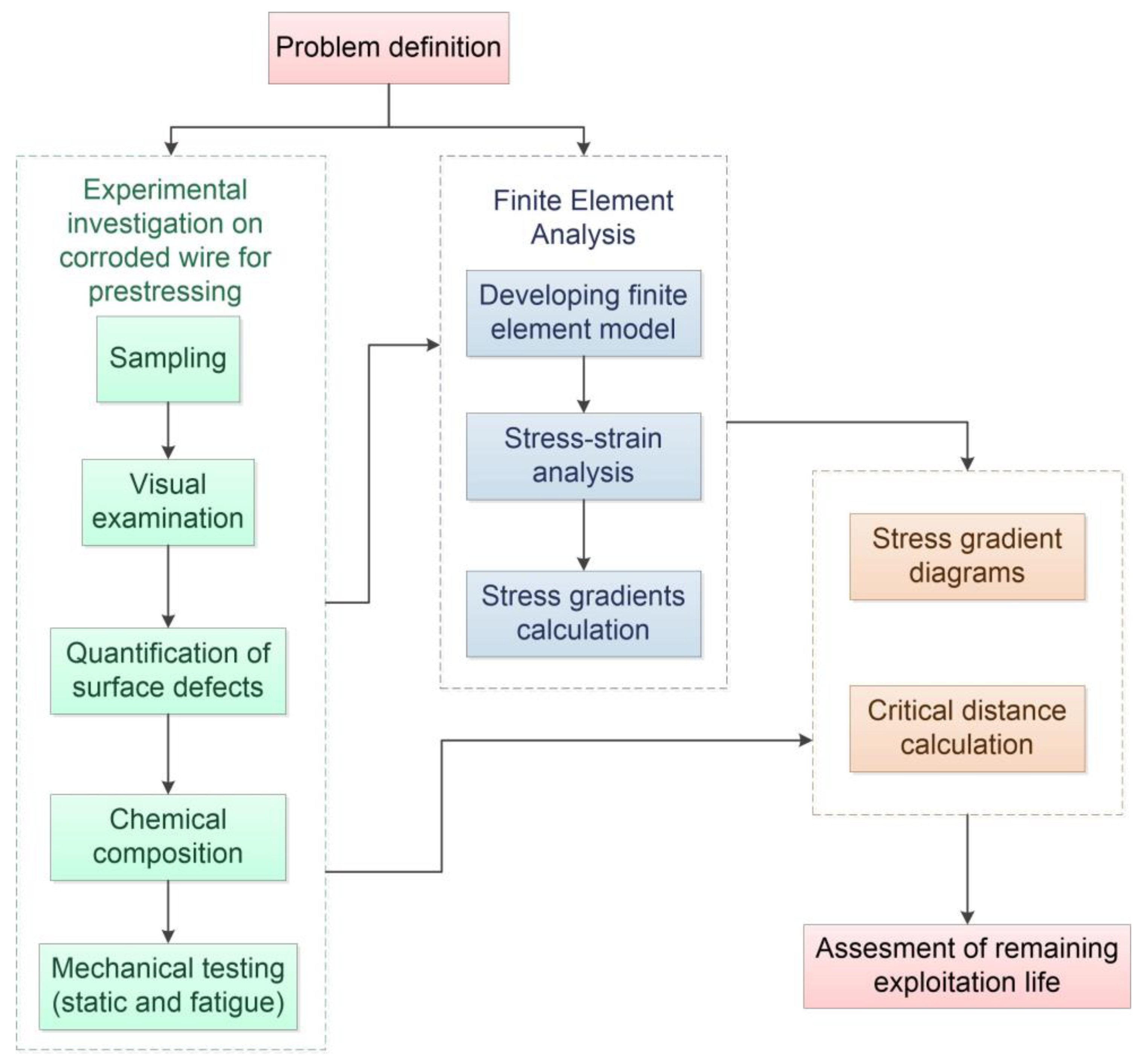

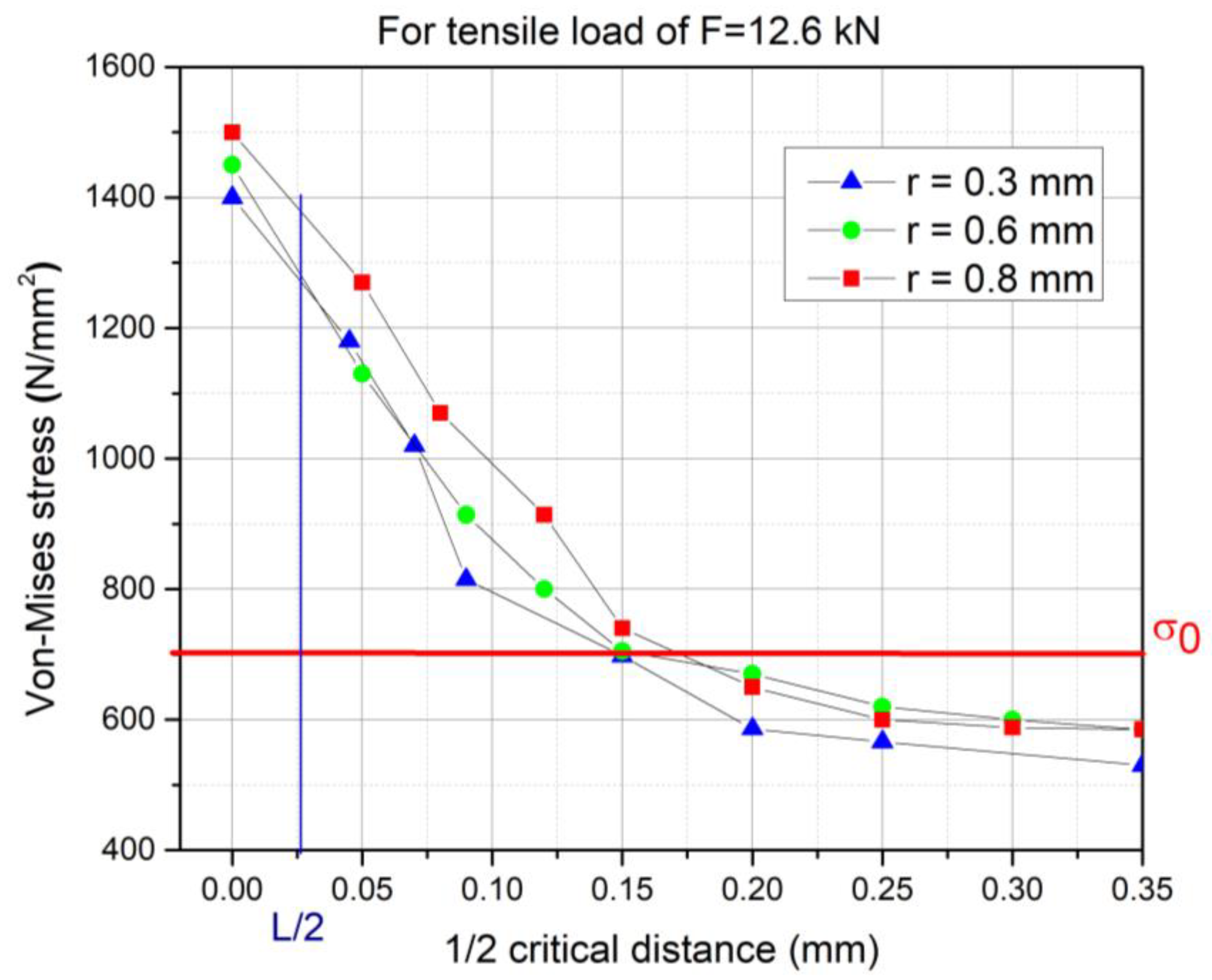

2. Methodology for Life Assessment of Corroded Wire for Prestressing

2.1. Experimental Investigation on Corroded Wire for Prestressing

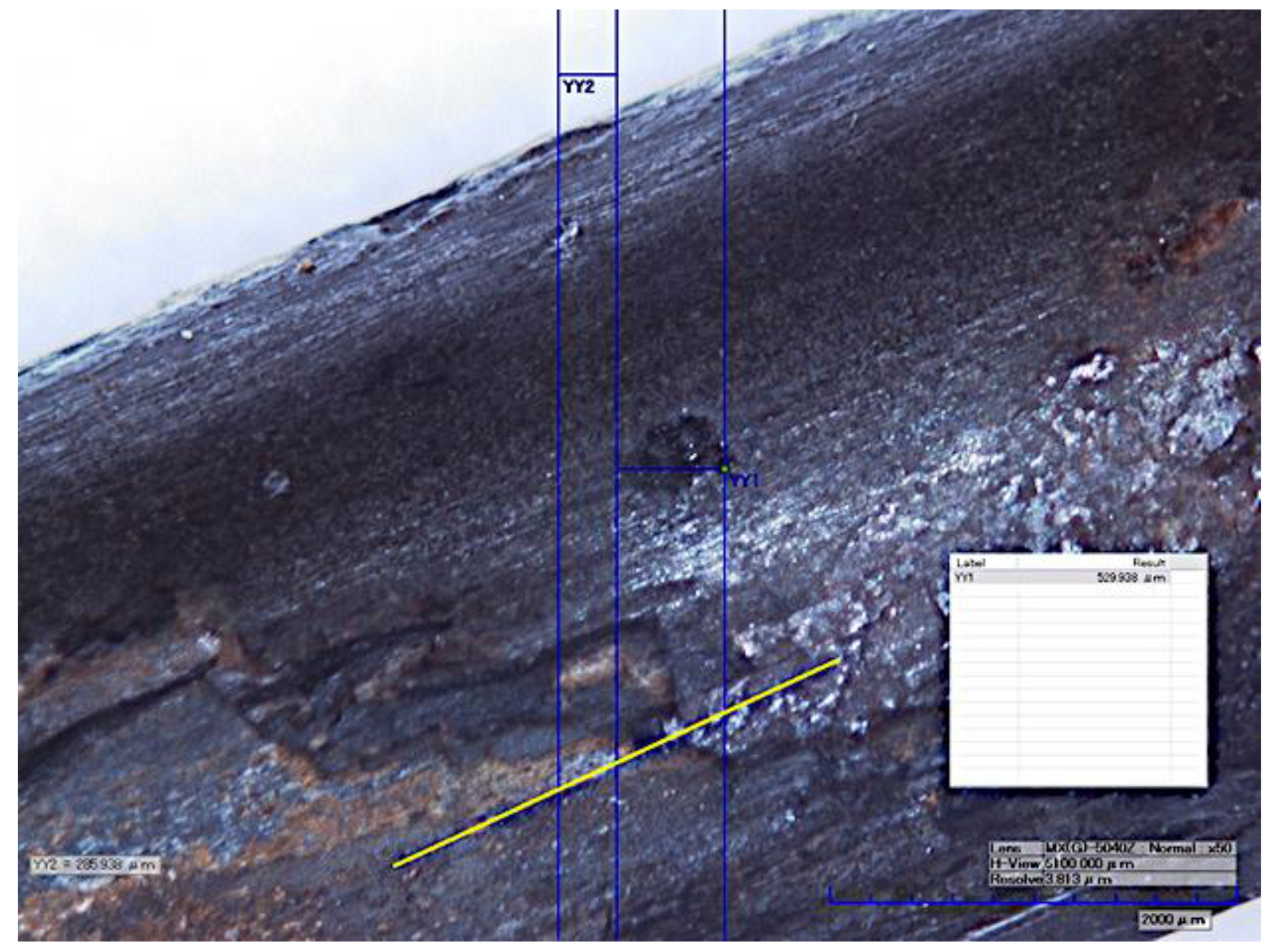

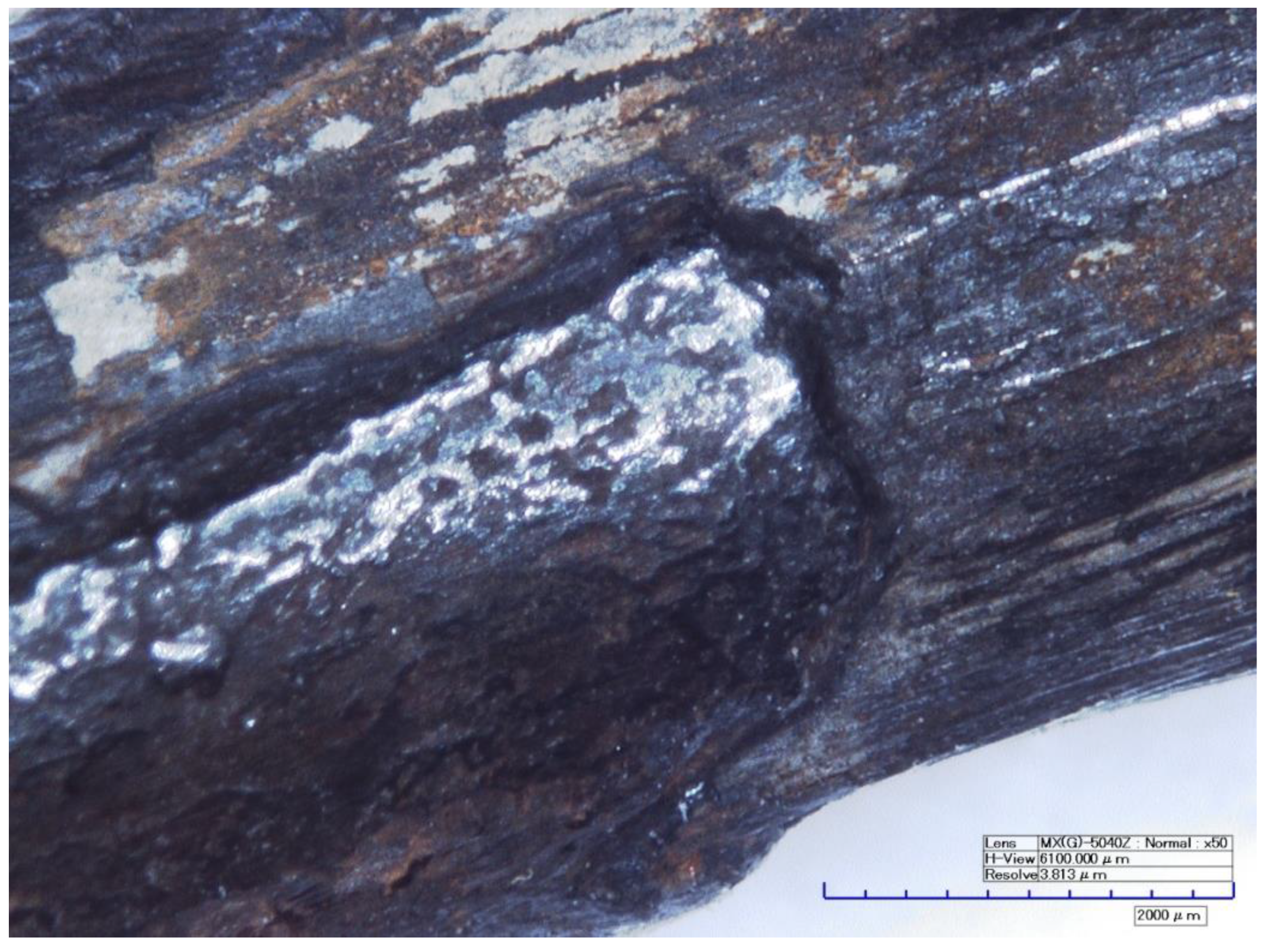

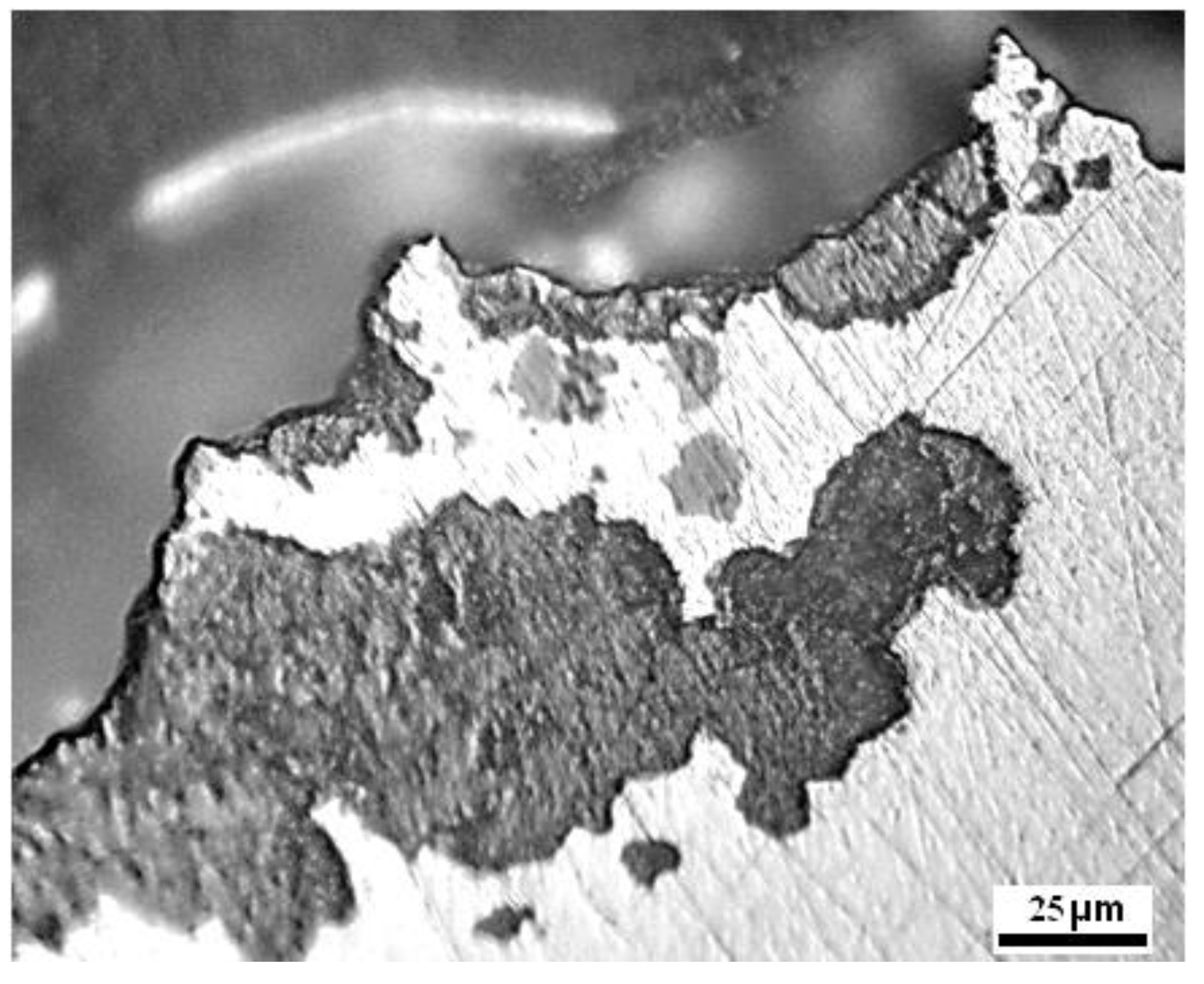

2.1.1. Visual Examination

2.1.2. Experimental Testing

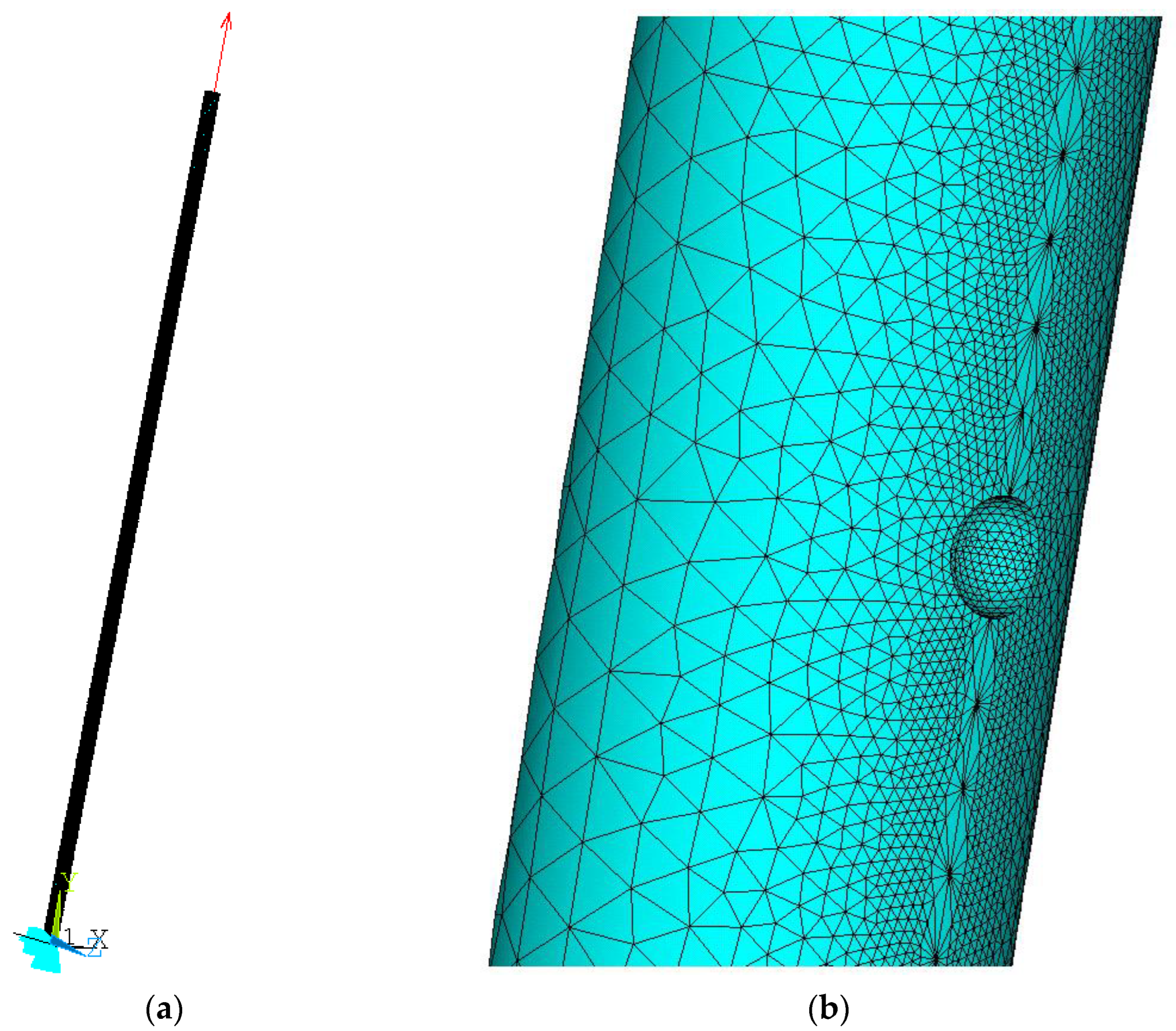

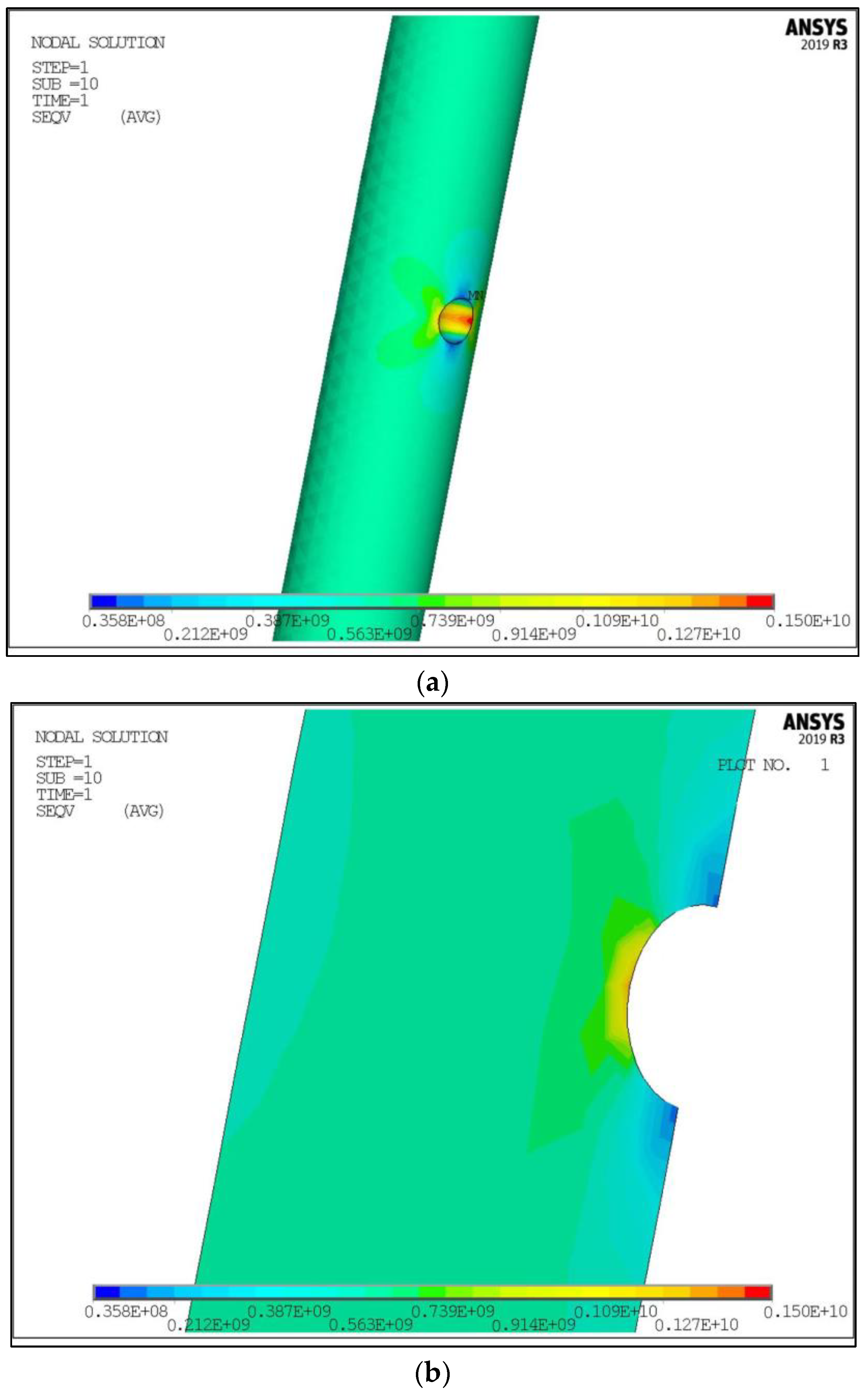

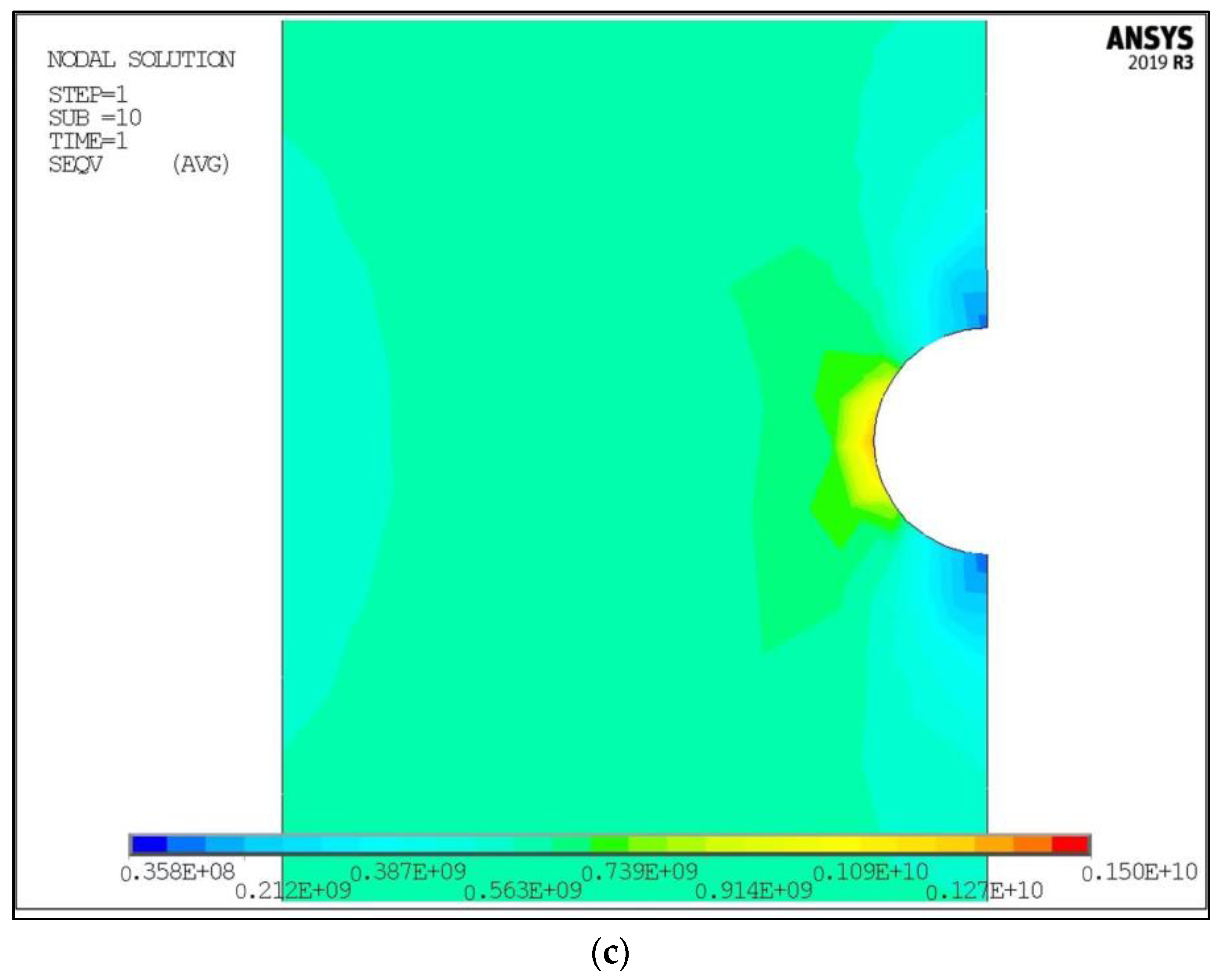

2.2. Finite Element Analysis

2.3. Theory of Critical Distances

3. Results and Discussion

4. Conclusions

- (1)

- The developed methodology has a specific potential for investigation of the elements of concrete prestressing that have already been in use for many years;

- (2)

- The developed methodology presents a unique set of already well-known methods (experimental testing, visual examination, chemical characteristics, tensile testing, Finite Element Analysis, and Theory of Critical Distances), coupled with specific connections in an original methodology for estimation of the remaining life of investigated structures;

- (3)

- The presented procedure gives the possibility for assessing the remaining service life of corroded elements in current use, obtained with consideration of two different loading cases (static and fatigue);

- (4)

- The obtained results in the presented case-study show that the tested corroded wires have reduced load capacity for fatigue loading and high safety for static loading. Because the construction (railway bridge) investigated in this research is not subjected to the fatigue loading case continuously, the static loading case can be considered as the critical loading case. This is in line with the fact that these elements are still in use after 45 years, and is also supported by the experimental results given in this paper, which show that the tensile strength of the tested wire samples is reduced by only 5.5%;

- (5)

- The results can be used for effective determination of the critical size of a pit at the corroded element, i.e., by the periodical implementation of the presented methodology, catastrophic failures can be prevented.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, K.; Liang, K.; Chang, J.; Lau, D. Investigation of the macro performance, mechanism, and durability of multiscale steel fiber reinforced low-carbon ecological UHPC. Constr. Build. Mater. 2022, 327, 126921. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J. Hydration, reinforcing mechanism, and macro performance of multi-layer graphene-modified cement composites. J. Build. Eng. 2022, 57, 104880. [Google Scholar] [CrossRef]

- Broomfield, J.P. Corrosion of Steel in Concrete: Understanding, Investigation and Repair, 3rd ed.; CRC Press: Boca Raton, UK, 2023. [Google Scholar] [CrossRef]

- Dixit, M.; Gupta, A.K. A Review of Different Assessment Methods of Corrosion of Steel Reinforcement in Concrete. Iran J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 735–752. [Google Scholar] [CrossRef]

- Yang, J.; Guo, T.; Chai, S. Experimental and numerical investigation on seismic behaviours of beam-column joints of precast prestressed concrete frame under given corrosion levels. Structures 2020, 27, 1209–1221. [Google Scholar] [CrossRef]

- Kioumarsi, M.; Benenato, A.; Ferracuti, B.; Imperatore, S. Residual Flexural Capacity of Corroded Prestressed Reinforced Concrete Beams. Metals 2021, 11, 442. [Google Scholar] [CrossRef]

- De Queiroz, J.P.T.; Cunha, M.L.; Pavlovic, A.; Rocha, L.A.O.; Dos Santos, E.D.; Troina, G.D.S.; Isoldi, L.A. Geometric evaluation of stiffened steel plates subjected to transverse loading for naval and offshore applications. J. Marine Sci. Eng. 2019, 7, 7. [Google Scholar] [CrossRef]

- Hao Zhang, H.; Wang, L.; Li, J.; Kang, F. Embedded PZT aggregates for monitoring crack growth and predicting surface crack in reinforced concrete beam. Const. Build. Mater. 2023, 364, 129979. [Google Scholar] [CrossRef]

- Chuanjie, C.; Airong, C.; Rujin, M. An improved continuum damage mechanics model for evaluating corrosion–fatigue life of high-strength steel wires in the real service environment. Int. J. Fatigue 2020, 135, 105540. [Google Scholar] [CrossRef]

- Jie, Z.; Berto, F.; Susmel, L. Fatigue behaviour of pitted/cracked high-strength steel wires based on the SED approach. Int. J. Fatigue 2020, 135, 105564. [Google Scholar] [CrossRef]

- Turnbull, A.; Horner, D.A.; Connolly, B.J. Challenges in modelling the evolution of stress corrosion cracks from pits. Eng. Frac. Mech. 2009, 76, 633–640. [Google Scholar] [CrossRef]

- Turnbull, A.; Wright, L.; Crocker, L. New insight into the pit-to-crack transition from finite element analysis of the stress and strain distribution around a corrosion pit. Corr. Sci. 2010, 52, 1492–1498. [Google Scholar] [CrossRef]

- Lan, C.; Xu, Y.; Liu, C.; Li, H.; Spencer, B.F., Jr. Fatigue life prediction for parallel-wire stay cables considering corrosion effects. Int. J. Fatigue 2018, 114, 81–91. [Google Scholar] [CrossRef]

- Wang, G.; Ma, Y.; Wang, L.; Zhang, J. Experimental study and residual fatigue life assessment of corroded high-tensile steel wires using 3D scanning technology. Eng. Fail. Anal. 2021, 124, 105335. [Google Scholar] [CrossRef]

- Susmel, L.; Taylor, D. On the use of the Theory of Critical Distances to predict static failures in ductile metallic materials containing different geometrical features. Eng. Frac. Mech. 2008, 75, 4410–4421. [Google Scholar] [CrossRef]

- Taylor, D. Applications of the theory of critical distances in failure analysis. Eng. Fail. Anal. 2011, 18, 543–549. [Google Scholar] [CrossRef]

- Martínez, J.M.G.; Adriano, V.S.R.; Araújo, J.A.; Ferreira, J.L.A.; da Silva, C.R.M. Geometrical size effect in the fatigue life predictions of aluminum wires with micro holes using methods of the critical distance. Eng. Frac. Mech. 2019, 209, 147–161. [Google Scholar] [CrossRef]

- Jie, Z.; Susmel, L. High-strength steel wires containing corrosion pits: Stress analysis and critical distance based fatigue life estimation. Fatigue Frac. Eng. Mater. Struct. 2020, 43, 1611–1629. [Google Scholar] [CrossRef]

- Terekhina, A.; Kostina, A.; Plekhov, O.; Susmel, L. Elasto-plastic TCD as a method of failure prediction. Proc. Struct. Integ. 2017, 5, 569–576. [Google Scholar] [CrossRef]

- Mitrovic, R.; Momcilovic, D.; Atanasovska, I. Assessment of the effect of pitting corrosion on fatigue crack initiation in hydro turbine shaft. AMR 2013, 633, 186–196. [Google Scholar] [CrossRef]

- Atanasovska, I.; Jelic, M.; Mitrovic, R.; Momcilovic, D. The influence of corrosion on stress concentration factor at shaft to flange radius. In Mechanisms and Machine Science (Book Series); Ceccarelli, M., Ed.; Springer Science: Berlin/Heidelberg, Germany; Business Media Dordrecht: Berlin/Heidelberg, Germany, 2013; Volume 13, pp. 657–666. [Google Scholar] [CrossRef]

- Momcilovic, D.; Mitrovic, R.; Atanasovska, I.; Vuherer, T. Methodology of determination the influence of corrosion pit on decrease of hydro turbine shaft fatigue life. J. Mach. Des. 2012, 4, 231–236. [Google Scholar]

- Atanasovska, I.; Momcilovic, D. Spur gear model for prediction of fatigue damage initiation in contact zone. Int. J. Powertrains 2016, 5, 213–229. [Google Scholar] [CrossRef]

- Momcilovic, D.; Mitrovic, R.; Atanasovska, I. Stress Concentration and Fatigue—Novel Approach on Mechanical Design; Faculty of Mechanical Engineering, University in Belgrade: Belgrade, Serbia, 2016; ISBN 978-86-7083-915-1. (In Serbian) [Google Scholar]

- Hobst, L.; Zajic, J. Anchoring in Rock and Soil; Elsevier: Amsterdam, The Netherlands, 1983. [Google Scholar]

- Rocha, P.H.C.; Díaz, J.I.M.; Silva, C.R.M.; Araújo, J.A.; Castro, F.C. Fatigue of two contacting wires of the ACSR Ibis 397.5 MCM conductor: Experiments and life prediction. Int. J. Fatigue 2019, 127, 25–35. [Google Scholar] [CrossRef]

- Pavlovic, A.; Fragassa, C. Numerical modelling of ballistic impacts on flexible protection curtains used as safety protection in woodworking. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 44–58. [Google Scholar] [CrossRef]

- Taylor, D. The Theory of Critical Distances: A New Perspective in Fracture Mechanics; Elsevier: Oxford, UK, 2007. [Google Scholar]

- Susmel, L.; Taylor, D. A novel formulation of the Theory of Critical Distances to estimate lifetime of notched components in the medium-cycle fatigue regime. Fatigue Frac. Eng. Mater. Struct. 2007, 30, 567–581. [Google Scholar] [CrossRef]

- Susmel, L.; Taylor, D. The Theory of Critical Distances to estimate lifetime of notched components subjected to variable amplitude uniaxial fatigue loading. Int. J. Fatigue. 2011, 33, 900–911. [Google Scholar] [CrossRef]

- Susmel, L. Multiaxial Notch Fatigue: From Nominal to Local Stress-Strain Quantities; Woodhead & CRC: Cambridge, UK, 2009. [Google Scholar]

- Susmel, L. The Theory of Critical Distances: A review of its applications in fatigue. Eng. Frac. Mech. 2008, 75, 1706–1724. [Google Scholar] [CrossRef]

- Louks, R.; Gerin, B.; Draper, J.; Askes, H.; Susmel, L. On the multiaxial fatigue assessment of complex three-dimensional stress concentrators. Int. J. Fatigue 2014, 63, 12–24. [Google Scholar] [CrossRef]

- Cerit, M.; Genel, K.; Eksi, S. Numerical investigation on stress concentration of corrosion pit. Eng. Fail. Anal. 2009, 16, 2467–2472. [Google Scholar] [CrossRef]

- Toribio, J.; Valiente, A. Failure analysis of cold drawn eutectoid steel wires for prestressed concrete. Eng. Fail. Anal. 2006, 13, 301–311. [Google Scholar] [CrossRef]

- Tanaka, K. Engineering formulae for fatigue strength reduction due to crack-like notches. Int. J. Fracture 1983, 22, R39–R45. [Google Scholar] [CrossRef]

- Taylor, D. Geometrical effects in fatigue: A unifying theoretical model. Int. J. Fatigue. 1999, 21, 413–420. [Google Scholar] [CrossRef]

- El Haddad, M.H.; Topper, T.H.; Smith, K.N. Prediction of nonpropagating cracks. Eng. Frac. Mech. 1979, 3, 573–584. [Google Scholar] [CrossRef]

- Toribio, J. Stress-Corrosion of Cold Drawn Prestressing Steels in Simulation of Electrochemical Processes; Wessex Institute of Technology: Ashurst Lodge, UK, 2005; p. 228. [Google Scholar]

- Casagrande, A.; Cammarota, G.P.; Micele, L. Relationship between fatigue limit and Vickers hardness in steels. Mater. Sci. Eng. A 2011, 528, 3468–3473. [Google Scholar] [CrossRef]

- Verpoest, I.; Aernoudt, E.; Deruyttere, A.; De Bondt, M. The fatigue threshold, surface condition and fatigue limit of steel wire. Int. J. Fatigue 1985, 7, 199–214. [Google Scholar] [CrossRef]

- Benes, L.; Mouralova, K.; Midula, P.; Snow, J.; Lysonkova, I.; Pilnaj, D.; Burdova, H.; Prokes, T.; Zahradnicek, R.; Fries, J.; et al. The Corrosion Behavior of WEDM Machined Stainless Steels in a Pyrolysis Environment. Metals 2023, 13, 144. [Google Scholar] [CrossRef]

| Sample Nr. | Cross-Sectional Area of Samples A0 (mm²) | Calculated Diameter d (mm) | Deviation from Nominal Diameter (%) |

|---|---|---|---|

| 1 | 15.9043 | 4.50 | −10.00 |

| 2 | 15.9751 | 4.51 | −9.80 |

| 3 | 16.0460 | 4.52 | −9.60 |

| 4 | 15.9751 | 4.51 | −9.80 |

| 5 | 16.0460 | 4.52 | −9.60 |

| 6 | 15.9043 | 4.50 | −10.00 |

| 7 | 15.9043 | 4.50 | −10.00 |

| 8 | 16.0590 | 4.53 | −9.40 |

| 9 | 15.9751 | 4.51 | −9.80 |

| 10 | 15.9045 | 4.50 | −10.00 |

| Average Values | 15.9893 | 4.51 | −9.76 |

| Nominal Values | 19.234 ÷ 20.019 | 5 ± 0.05 | max ± 1% |

| %C | %Mn | %Si | %P | %S | %Cr | %V | %Al |

|---|---|---|---|---|---|---|---|

| 0.67 | 0.88 | 0.35 | 0.028 | 0.021 | 0.21 | 0.04 | traces |

| Sample Nr. | Elasticity Modulus (GPa) | Tensile Strength σt (MPa) | Elongation (%) |

|---|---|---|---|

| 1 | 196 | 1456 | 5.1 |

| 2 | 197 | 1507 | 4.7 |

| 3 | 196 | 1509 | 4.9 |

| 4 | 196 | 1436 | 5.4 |

| 5 | 198 | 1519 | 4.3 |

| 6 | 197 | 1482 | 5.1 |

| 7 | 196 | 1491 | 5.0 |

| 8 | 199 | 1466 | 5.5 |

| 9 | 198 | 1484 | 5.3 |

| Average Values | 197 | 1483 | 5.0 |

| Reference Value [25] | 200 | 1570 | 4.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Momcilovic, D.; Atanasovska, I.; Vulovic, S.; Pavlovic, A. Life Assessment of Corroded Wire for Prestressing. Metals 2023, 13, 387. https://doi.org/10.3390/met13020387

Momcilovic D, Atanasovska I, Vulovic S, Pavlovic A. Life Assessment of Corroded Wire for Prestressing. Metals. 2023; 13(2):387. https://doi.org/10.3390/met13020387

Chicago/Turabian StyleMomcilovic, Dejan, Ivana Atanasovska, Snezana Vulovic, and Ana Pavlovic. 2023. "Life Assessment of Corroded Wire for Prestressing" Metals 13, no. 2: 387. https://doi.org/10.3390/met13020387

APA StyleMomcilovic, D., Atanasovska, I., Vulovic, S., & Pavlovic, A. (2023). Life Assessment of Corroded Wire for Prestressing. Metals, 13(2), 387. https://doi.org/10.3390/met13020387