High-Throughput Investigation of Multiscale Deformation Mechanism in Additively Manufactured Ni Superalloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

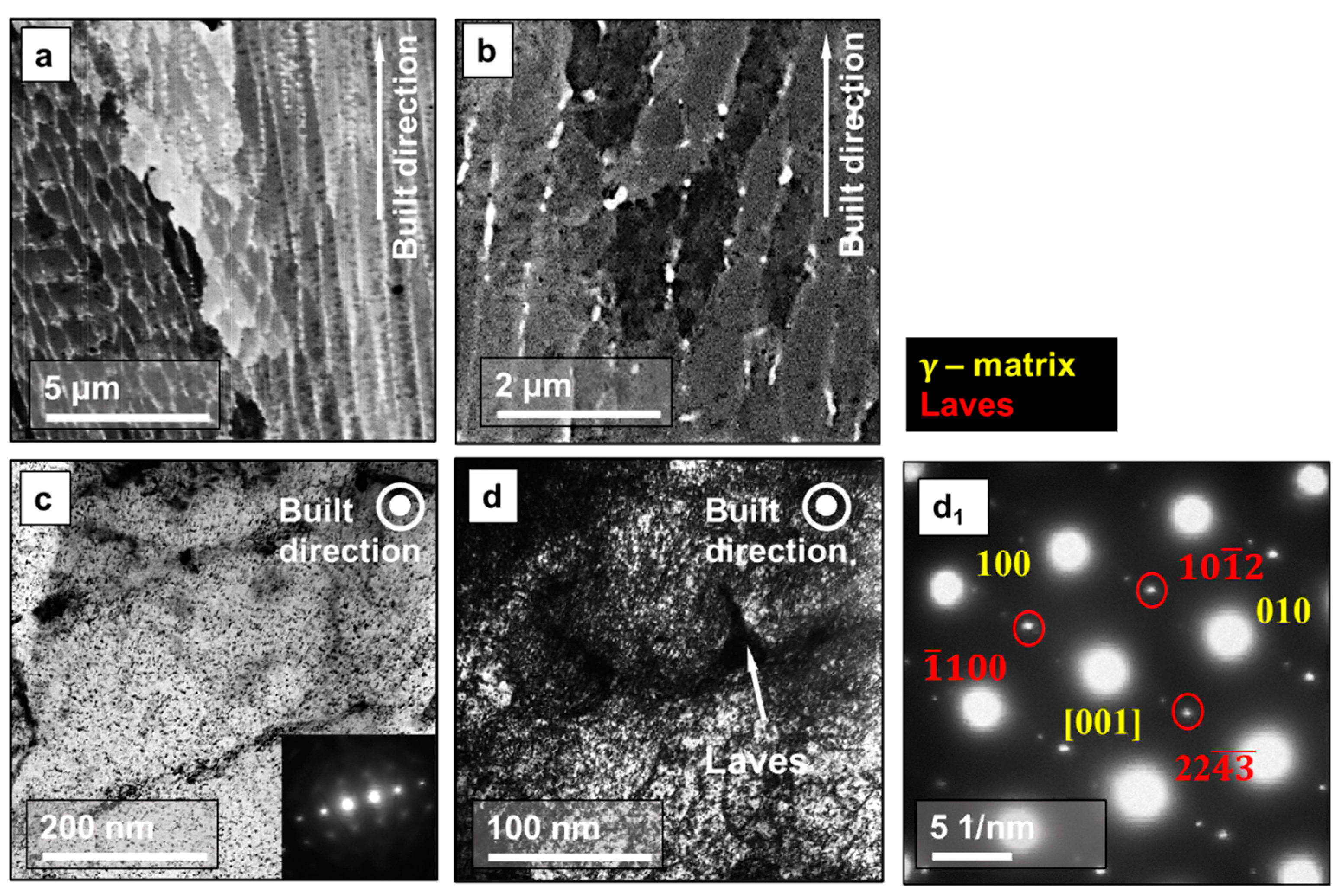

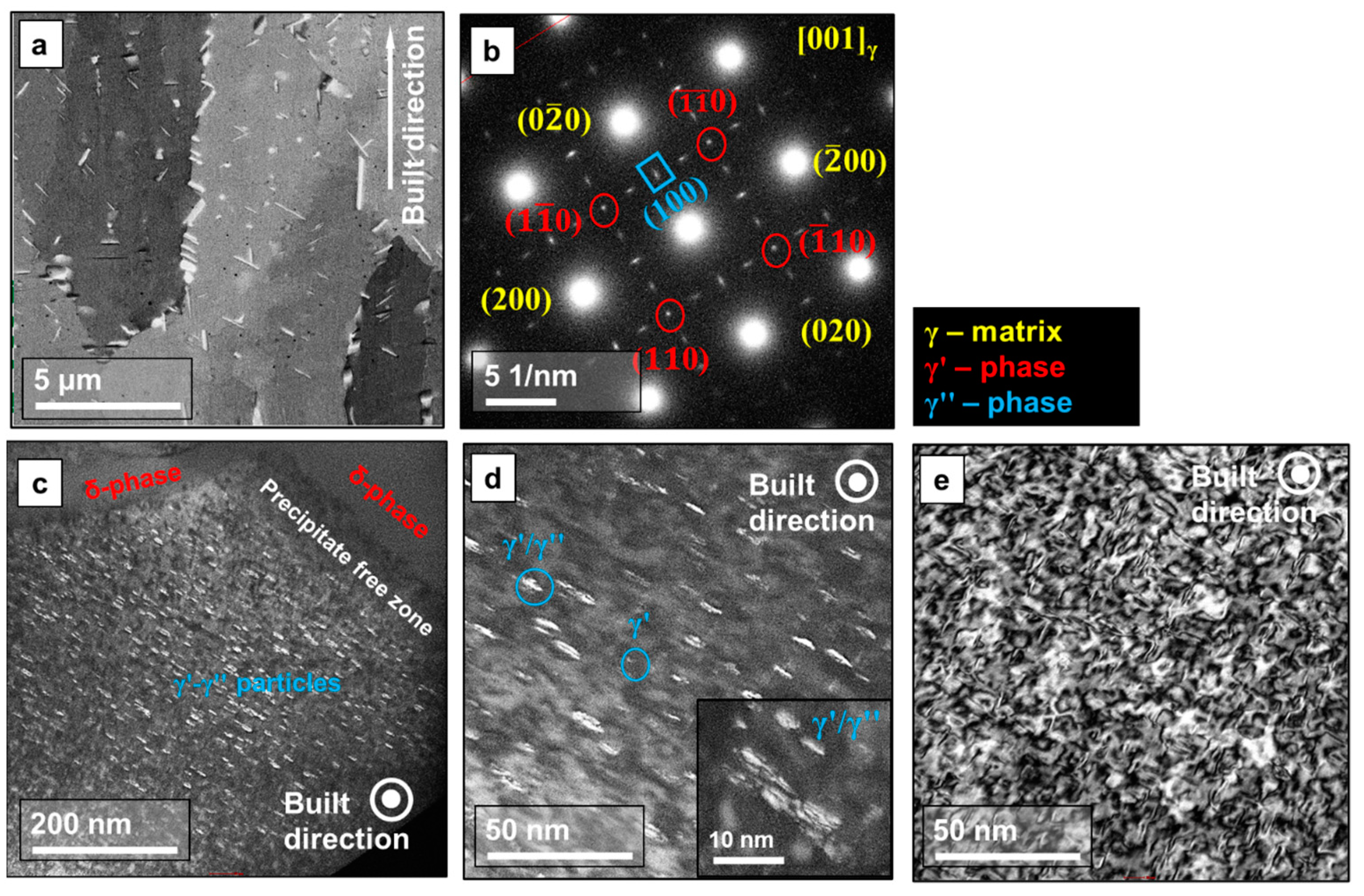

3.1. Microstructure Evolution and Precipitation Phenomenon after L-PBFAM and Heat Treatment

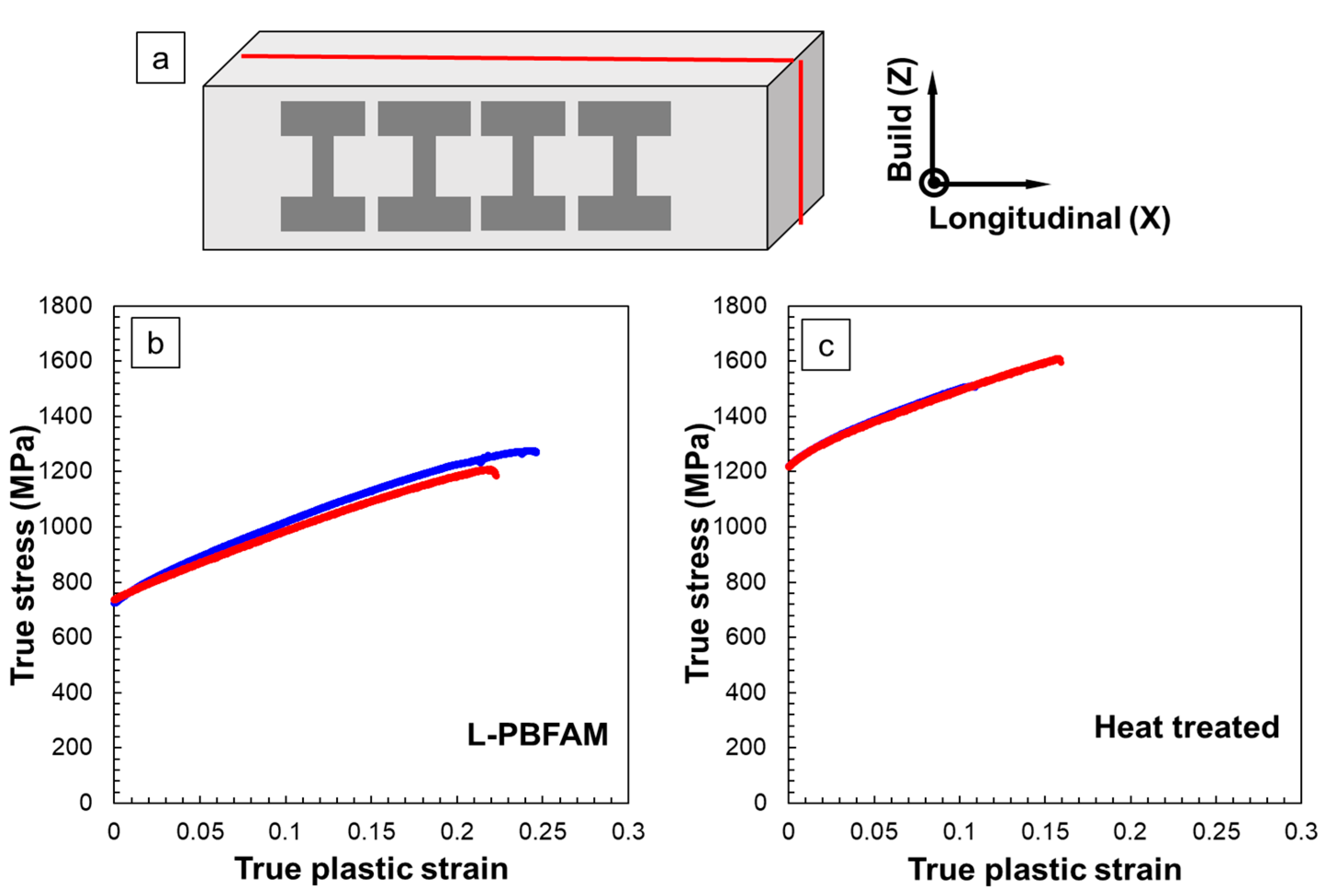

3.2. Investigation of Macroscale Tensile Properties

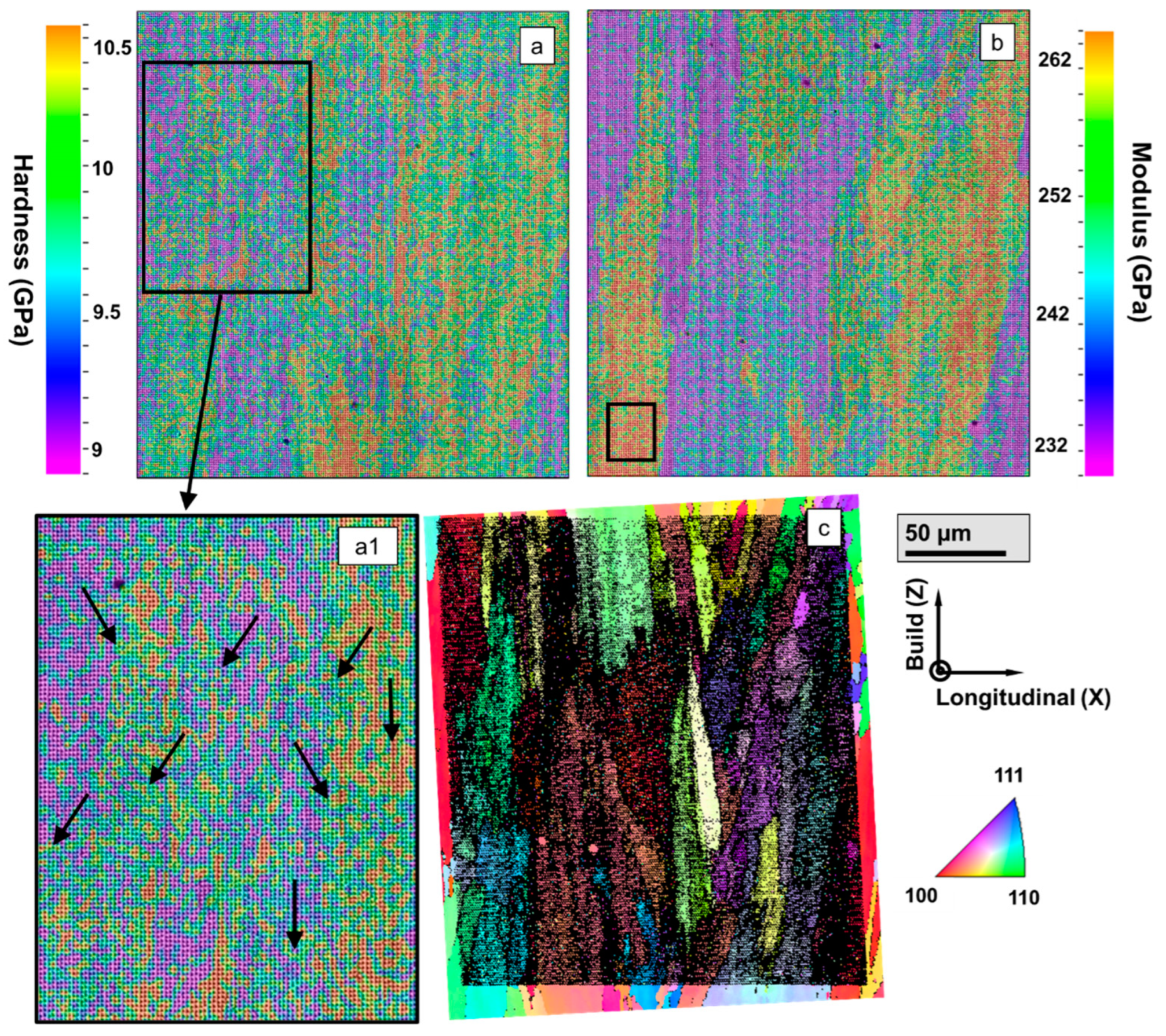

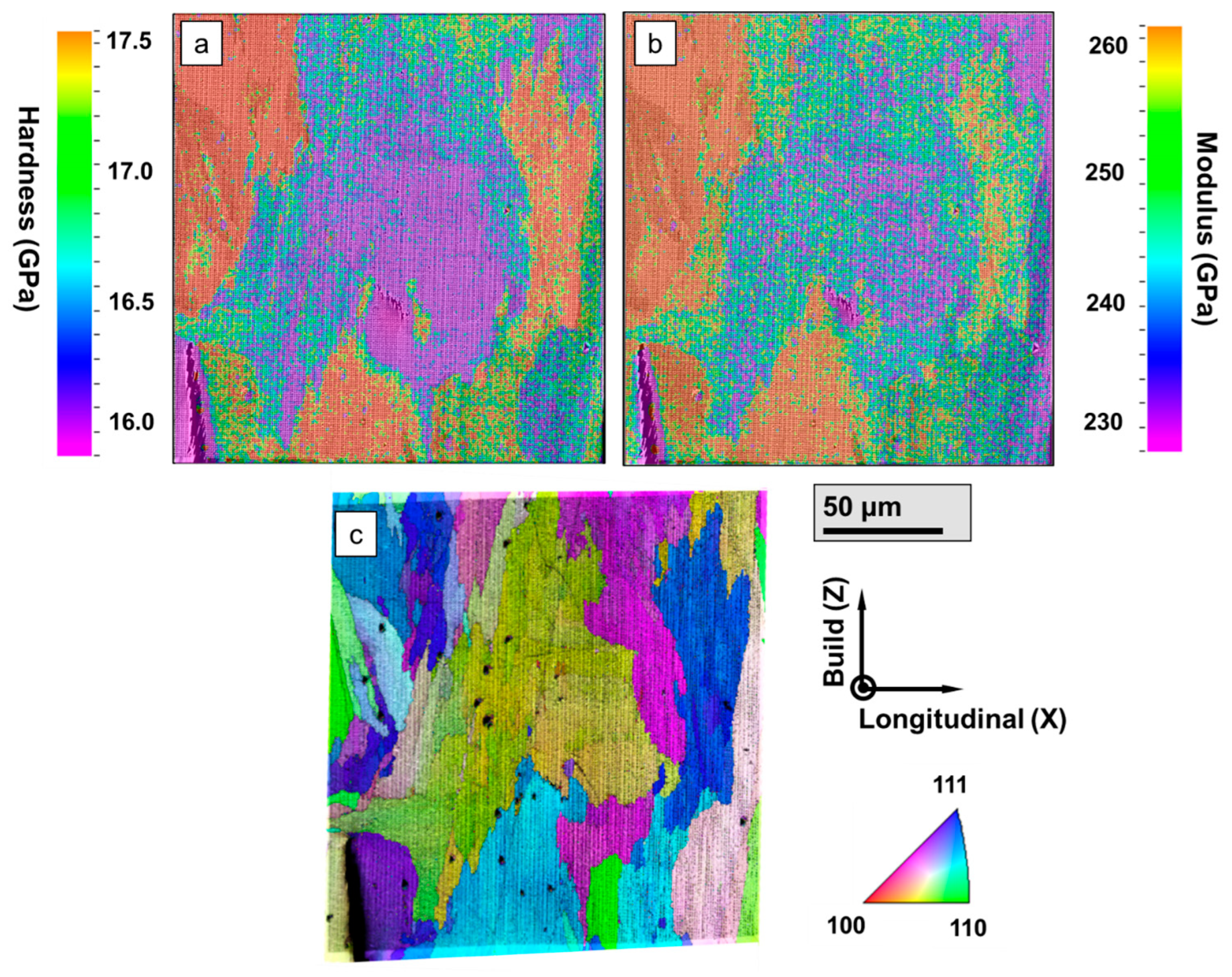

3.3. High-Resolution Nanoindentation Elastoplastic Mapping and Micromechanical Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blackwell, P.L. The Mechanical and Microstructural Characteristics of Laser-Deposited IN718. J. Mater. Process. Technol. 2005, 170, 240–246. [Google Scholar] [CrossRef]

- De Bartolomeis, A.; Newman, S.T.; Jawahir, I.S.; Biermann, D.; Shokrani, A. Future Research Directions in the Machining of Inconel 718. J. Mater. Process. Technol. 2021, 297, 117260. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A Review of Metastable Beta Titanium Alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef] [Green Version]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The Microstructure and Mechanical Properties of Deposited-IN718 by Selective Laser Melting. J. Alloys Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- You, X.; Tan, Y.; Shi, S.; Yang, J.M.; Wang, Y.; Li, J.; You, Q. Effect of Solution Heat Treatment on the Precipitation Behavior and Strengthening Mechanisms of Electron Beam Smelted Inconel 718 Superalloy. Mater. Sci. Eng. A 2017, 689, 257–268. [Google Scholar] [CrossRef]

- Tajyar, A.; Brooks, N.; Holtham, N.; Rowe, R.; Newell, D.J.; Palazotto, A.N.; Davami, K. Effects of a Modified Heat-Treatment on Microstructure and Mechanical Properties of Additively Manufactured Inconel 718. Mater. Sci. Eng. A 2022, 838, 142770. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, Precipitates and Mechanical Properties of Powder Bed Fused Inconel 718 before and after Heat Treatment. J. Mater. Sci. Technol. 2019, 35, 1153–1164. [Google Scholar] [CrossRef]

- Komarasamy, M.; Shukla, S.; Williams, S.; Kandasamy, K.; Kelly, S.; Mishra, R.S. Microstructure, Fatigue, and Impact Toughness Properties of Additively Manufactured Nickel Alloy 718. Addit. Manuf. 2019, 28, 661–675. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.H.; Leary, M.; Sharabian, E.; Cordova, L.; Gibson, I.; Downing, D.; Bateman, S.; Brandt, M.; Rolfe, B. The Effect of Absorption Ratio on Meltpool Features in Laser-Based Powder Bed Fusion of IN718. Opt. Laser Technol. 2022, 153, 108263. [Google Scholar] [CrossRef]

- Jiang, R.; Mostafaei, A.; Pauza, J.; Kantzos, C.; Rollett, A.D. Varied Heat Treatments and Properties of Laser Powder Bed Printed Inconel 718. Mater. Sci. Eng. A 2019, 755, 170–180. [Google Scholar] [CrossRef]

- Ardell, A.J.; Huang, J.C. Antiphase Boundary Energies and the Transition from Shearing to Looping in Alloys Strengthened by Ordered Precipitates. Philos. Mag. Lett. 1988, 58, 189–197. [Google Scholar] [CrossRef]

- Mostafa, A.; Rubio, I.P.; Brailovski, V.; Jahazi, M.; Medraj, M. Structure, Texture and Phases in 3D Printed IN718 Alloy Subjected to Homogenization and HIP Treatments. Metals 2017, 7, 196. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, E.; Popovich, V.A. A Review of Mechanical Properties of Additively Manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Mantri, S.A.; Dasari, S.; Sharma, A.; Alam, T.; Pantawane, M.V.; Pole, M.; Sharma, S.; Dahotre, N.B.; Banerjee, R.; Banerjee, S. Effect of Micro-Segregation of Alloying Elements on the Precipitation Behaviour in Laser Surface Engineered Alloy 718. Acta Mater. 2021, 210, 116844. [Google Scholar] [CrossRef]

- Liu, F.; Lyu, F.; Liu, F.; Lin, X.; Huang, C. Laves Phase Control of Inconel 718 Superalloy Fabricated by Laser Direct Energy Deposition via ı Aging and Solution Treatment. J. Mater. Res. Technol. 2020, 9, 9753–9765. [Google Scholar] [CrossRef]

- Mahadevan, S.; Nalawade, S.; Singh, J.B.; Verma, A.; Paul, B.; Ramaswamy, K. Evolution of δ Phase Microstructure in Alloy 718. In Proceedings of the 7th International Symposium on Superalloy, Pittsburgh, PA, USA, 10–13 October 2010; Volume 2, pp. 737–750. [Google Scholar] [CrossRef]

- Mishra, R.S.; Thapliyal, S. Design Approaches for Printability-Performance Synergy in Al Alloys for Laser-Powder Bed Additive Manufacturing. Mater. Des. 2021, 204, 109640. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, J.; He, B.; Zou, Y. High-Speed Nanoindentation Mapping of a near-Alpha Titanium Alloy Made by Additive Manufacturing. J. Mater. Res. 2021, 36, 2223–2234. [Google Scholar] [CrossRef]

- Dhal, A.; Thapliyal, S.; Gaddam, S.; Agrawal, P.; Mishra, R.S. Multiscale Hierarchical and Heterogeneous Mechanical Response of Additively Manufactured Novel Al Alloy Investigated by High-Resolution Nanoindentation Mapping. Sci. Rep. 2022, 12, 1–8. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Gutierrez, C.; Gan, B.; Molina-Aldareguia, J.M. High-Throughput Nanoindentation Mapping of Cast IN718 Nickel-Based Superalloys: Influence of the Nb Concentration. J. Mater. Res. 2021, 36, 2213–2222. [Google Scholar] [CrossRef]

- Rielli, V.V.; Theska, F.; Yao, Y.; Best, J.P.; Primig, S. Local Composition and Nanoindentation Response of δ-Phase and Adjacent Γ′′-Free Zone in a Ni-Based Superalloy. Mater. Res. Lett. 2022, 10, 301–309. [Google Scholar] [CrossRef]

- Patil, D.A. Effects of Increasing Layer Thickness in the Laser Powder Bed Fusion of Inconel 718; Arizona State University: Tempe, AZ, USA, 2019; Volume 8. [Google Scholar]

- Sadowski, M.; Ladani, L.; Brindley, W.; Romano, J. Optimizing Quality of Additively Manufactured Inconel 718 Using Powder Bed Laser Melting Process. Addit. Manuf. 2016, 11, 60–70. [Google Scholar] [CrossRef]

- Zhong, Q.; Wei, K.; Lu, Z.; Yue, X.; Ouyang, T.; Zeng, X. High Power Laser Powder Bed Fusion of Inconel 718 Alloy: Effect of Laser Focus Shift on Formability, Microstructure and Mechanical Properties. J. Mater. Process. Technol. 2023, 311, 117824. [Google Scholar] [CrossRef]

- ASTM standard UNS N07718; Standard Specification for Precipitation-Hardening Nickel Alloy Plate, Sheet, and Strip for High-Temperature Service 1. ASTM International: West Conshohocken, PA, USA, 2010; Volume 07.

- Rielli, V.V.; Piglione, A.; Pham, M.S.; Primig, S. On the Detailed Morphological and Chemical Evolution of Phases during Laser Powder Bed Fusion and Common Post-Processing Heat Treatments of IN718. Addit. Manuf. 2022, 50, 102540. [Google Scholar] [CrossRef]

- Newell, D.J.; O’Hara, R.P.; Cobb, G.R.; Palazotto, A.N.; Kirka, M.M.; Burggraf, L.W.; Hess, J.A. Mitigation of Scan Strategy Effects and Material Anisotropy through Supersolvus Annealing in LPBF IN718. Mater. Sci. Eng. A 2019, 764, 138230. [Google Scholar] [CrossRef]

- Zhou, Y.Z.; Volek, A.; Green, N.R. Mechanism of Competitive Grain Growth in Directional Solidification of a Nickel-Base Superalloy. Acta Mater. 2008, 56, 2631–2637. [Google Scholar] [CrossRef]

- Pantawane, M.V.; Sharma, S.; Dasari, S.; Mantri, S.A.; Sharma, A.; Banerjee, R.; Banerjee, S.; Dahotre, N.B. Spatial Variation of Thermokinetics and Associated Microstructural Evolution in Laser Surface Engineered IN718: Precursor to Additive Manufacturing. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2021, 52, 2344–2360. [Google Scholar] [CrossRef]

- Doi, M.; Miyazaki, T. Γ′ Precipitate Morphology Formed under the Influence of Elastic Interaction Energies in Nickel-Base Alloys. Mater. Sci. Eng. 1986, 78, 87–94. [Google Scholar] [CrossRef]

- Liu, P.; Wang, Z.; Xiao, Y.; Horstemeyer, M.F.; Cui, X.; Chen, L. Insight into the Mechanisms of Columnar to Equiaxed Grain Transition during Metallic Additive Manufacturing. Addit. Manuf. 2019, 26, 22–29. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Precipitation of the δ-Ni3Nb Phase in Two Nickel Base Superalloys. Metall. Trans. A 1988, 19, 453–465. [Google Scholar] [CrossRef]

- Keiser, D.D. Review of the Physical Metallurgy of Alloy 718; Idaho National Engineering Lab.: Idaho Falls, ID, USA, 1976. [Google Scholar]

- Knezevic, M.; Ghorbanpour, S. Modeling Tensile, Compressive, and Cyclic Response of Inconel 718 Using a Crystal Plasticity Model Incorporating the Effects of Precipitates. In Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications; Springer International Publishing: New York, NY, USA, 2018; pp. 655–668. [Google Scholar] [CrossRef]

- Chaturvedi, M.C.; Han, Y.F. Strengthening Mechanisms in Inconel 718 Superalloy. Met. Sci. 1983, 17, 145–149. [Google Scholar] [CrossRef]

- Zenk, C.H.; Feng, L.; McAllister, D.; Wang, Y.; Mills, M.J. Shearing Mechanisms of Co-Precipitates in IN718. Acta Mater. 2021, 220, 117305. [Google Scholar] [CrossRef]

- Whitmore, L.; Ahmadi, M.R.; Stockinger, M.; Povoden-Karadeniz, E.; Kozeschnik, E.; Leitner, H. Microstructural Investigation of Thermally Aged Nickel-Based Superalloy 718Plus. Mater. Sci. Eng. A 2014, 594, 253–259. [Google Scholar] [CrossRef]

- Oblak, J.M.; Paulonis, D.F.; Duvall, D.S. Coherency Strengthening in Ni Base Alloys Hardened by DO22 Γ′ Precipitates. Metall. Trans. 1974, 5, 143–153. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Shang, S.L.; Wang, W.Y.; Zhou, B.C.; Wang, Y.; Darling, K.A.; Kecskes, L.J.; Mathaudhu, S.N.; Liu, Z.K. Generalized Stacking Fault Energy, Ideal Strength and Twinnability of Dilute Mg-Based Alloys: A First-Principles Study of Shear Deformation. Acta Mater. 2014, 67, 168–180. [Google Scholar] [CrossRef]

- Wang, H.; Dhiman, A.; Ostergaard, H.E.; Zhang, Y.; Siegmund, T.; Kruzic, J.J.; Tomar, V. Nanoindentation Based Properties of Inconel 718 at Elevated Temperatures: A Comparison of Conventional versus Additively Manufactured Samples. Int. J. Plast. 2019, 120, 380–394. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation Size Effects in Crystalline Materials: A Law for Strain Gradient Plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Liu, S.Y.; Li, H.Q.; Qin, C.X.; Zong, R.; Fang, X.Y. The Effect of Energy Density on Texture and Mechanical Anisotropy in Selective Laser Melted Inconel 718. Mater. Des. 2020, 191, 108642. [Google Scholar] [CrossRef]

- Kumara, C.; Deng, D.; Moverare, J.; Nylén, P. Modelling of Anisotropic Elastic Properties in Alloy 718 Built by Electron Beam Melting. Mater. Sci. Technol. 2018, 34, 529–537. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and Mechanical Properties of Inconel 718 Produced by Selective Laser Melting: Sample Orientation Dependence and Effects of Post Heat Treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Krier, J.; Breuils, J.; Jacomine, L.; Pelletier, H. Introduction of the Real Tip Defect of Berkovich Indenter to Reproduce with FEM Nanoindentation Test at Shallow Penetration Depth. J. Mater. Res. 2012, 27, 28–38. [Google Scholar] [CrossRef]

- Zong, W.J.; Wu, D.; He, C.L. Radius and Angle Determination of Diamond Berkovich Indenter. Meas. J. Int. Meas. Confed. 2017, 104, 243–252. [Google Scholar] [CrossRef]

- Ye, C.; Chen, J.; Xu, M.; Wei, X.; Lu, H. Multi-Scale Simulation of Nanoindentation on Cast Inconel 718 and NbC Precipitate for Mechanical Properties Prediction. Mater. Sci. Eng. A 2016, 662, 385–394. [Google Scholar] [CrossRef]

- Luo, W.; Kirchlechner, C.; Li, J.; Dehm, G.; Stein, F. Composition Dependence of Hardness and Elastic Modulus of the Cubic and Hexagonal NbCo2 Laves Phase Polytypes Studied by Nanoindentation. J. Mater. Res. 2020, 35, 185–195. [Google Scholar] [CrossRef]

- Carter, C.B.; Holmes, S.M. The Stacking-Fault Energy of Nickel. Philos. Mag. 1977, 35, 1161–1171. [Google Scholar] [CrossRef]

- Dodaran, M.S.; Guo, S.; Khonsari, M.M.; Shamsaei, N.; Shao, S. A Theoretical Calculation of Stacking Fault Energy of Ni Alloys: The Effects of Temperature and Composition. Comput. Mater. Sci. 2021, 191, 110326. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Deformation Behaviour of Γ″ Strengthened Inconel 718. Acta Metall. 1988, 36, 847–864. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Ni | Cr | Mo | Cu | Al | Ti | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt. % | 0.037 | 0.18 | 0.17 | 52.60 | 18.80 | 3.06 | 0.03 | 0.56 | 0.95 | 5.16 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhal, A.; Agrawal, P.; Haridas, R.S.; Gaddam, S.; Sharma, A.; Parganiha, D.; Mishra, R.S.; Kawanaka, H.; Matsushita, S.; Yasuda, Y.; et al. High-Throughput Investigation of Multiscale Deformation Mechanism in Additively Manufactured Ni Superalloy. Metals 2023, 13, 420. https://doi.org/10.3390/met13020420

Dhal A, Agrawal P, Haridas RS, Gaddam S, Sharma A, Parganiha D, Mishra RS, Kawanaka H, Matsushita S, Yasuda Y, et al. High-Throughput Investigation of Multiscale Deformation Mechanism in Additively Manufactured Ni Superalloy. Metals. 2023; 13(2):420. https://doi.org/10.3390/met13020420

Chicago/Turabian StyleDhal, Abhijeet, Priyanka Agrawal, Ravi Sankar Haridas, Supreeth Gaddam, Aishani Sharma, Digvijay Parganiha, Rajiv S. Mishra, Hirotsugu Kawanaka, Shinji Matsushita, Yusuke Yasuda, and et al. 2023. "High-Throughput Investigation of Multiscale Deformation Mechanism in Additively Manufactured Ni Superalloy" Metals 13, no. 2: 420. https://doi.org/10.3390/met13020420

APA StyleDhal, A., Agrawal, P., Haridas, R. S., Gaddam, S., Sharma, A., Parganiha, D., Mishra, R. S., Kawanaka, H., Matsushita, S., Yasuda, Y., Park, S. H. C., & Yuan, W. (2023). High-Throughput Investigation of Multiscale Deformation Mechanism in Additively Manufactured Ni Superalloy. Metals, 13(2), 420. https://doi.org/10.3390/met13020420