Metadynamic Recrystallization Behavior of Cr-Ni-Mo Alloy Steel

Abstract

:1. Introduction

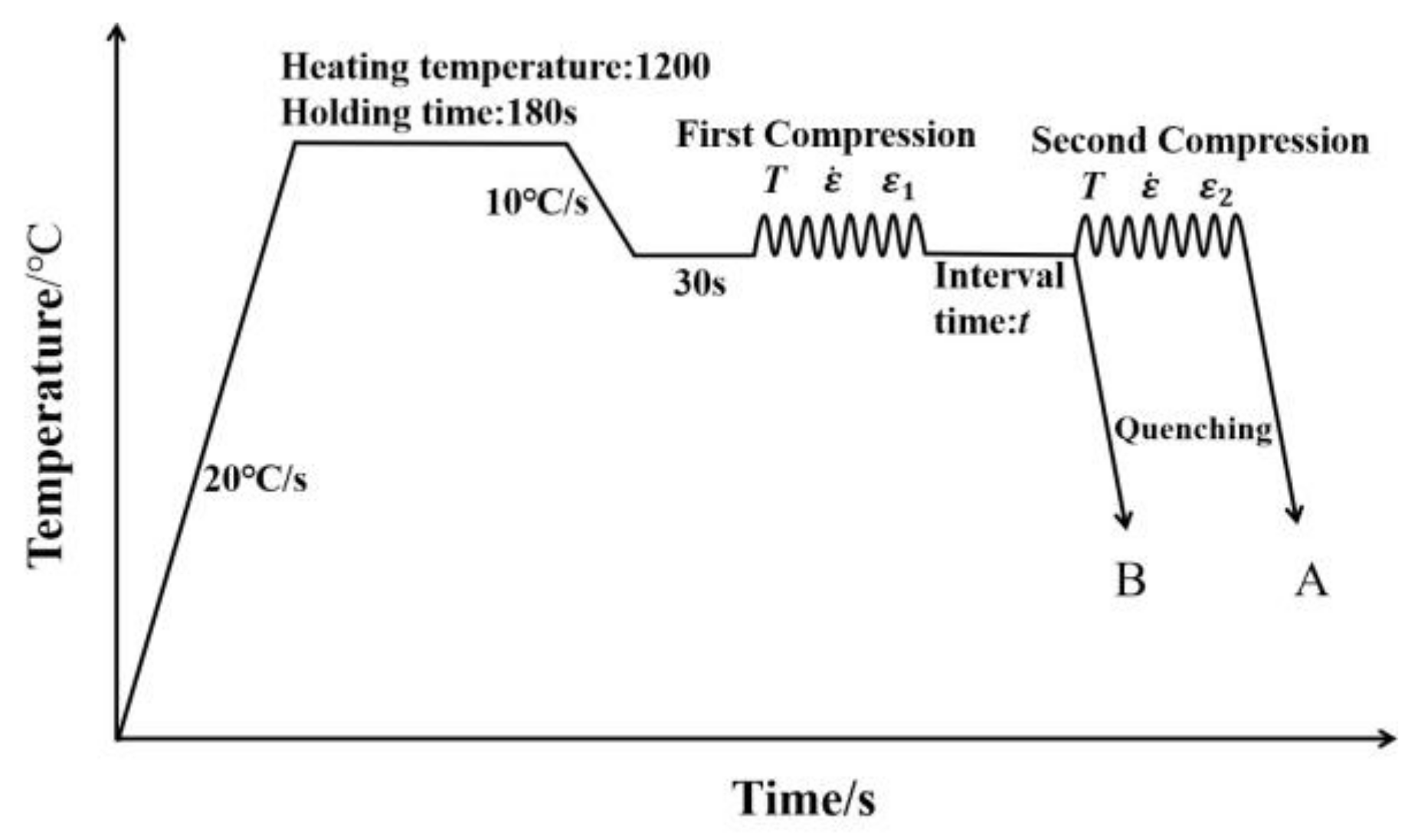

2. Experiment

3. Results and Discussion

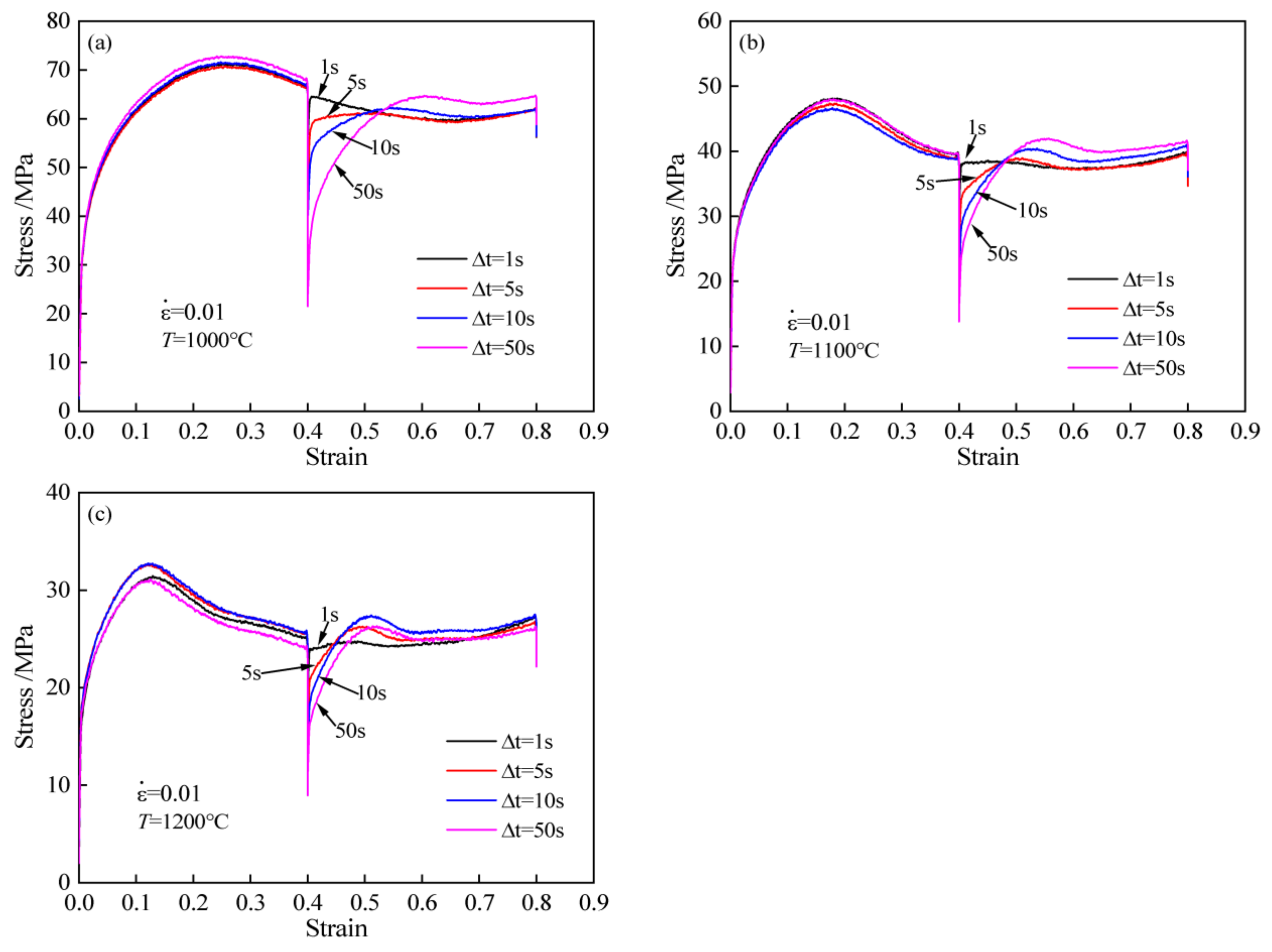

3.1. Flow Behavior

3.2. Effect of Process Parameters on the Metadynamic Recrystallization Softening Rate and Grain Size of 34CrNi3MoV Steel

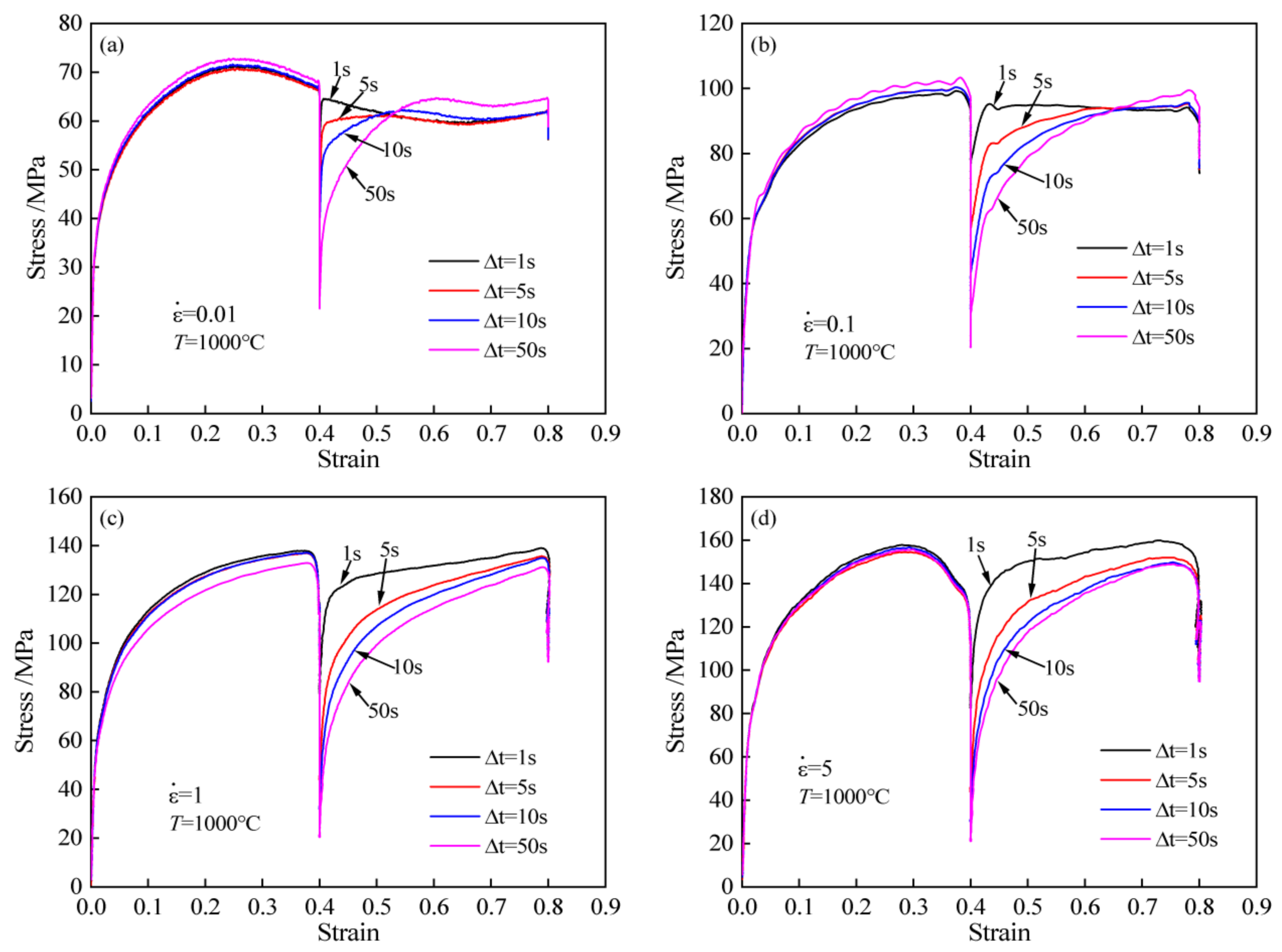

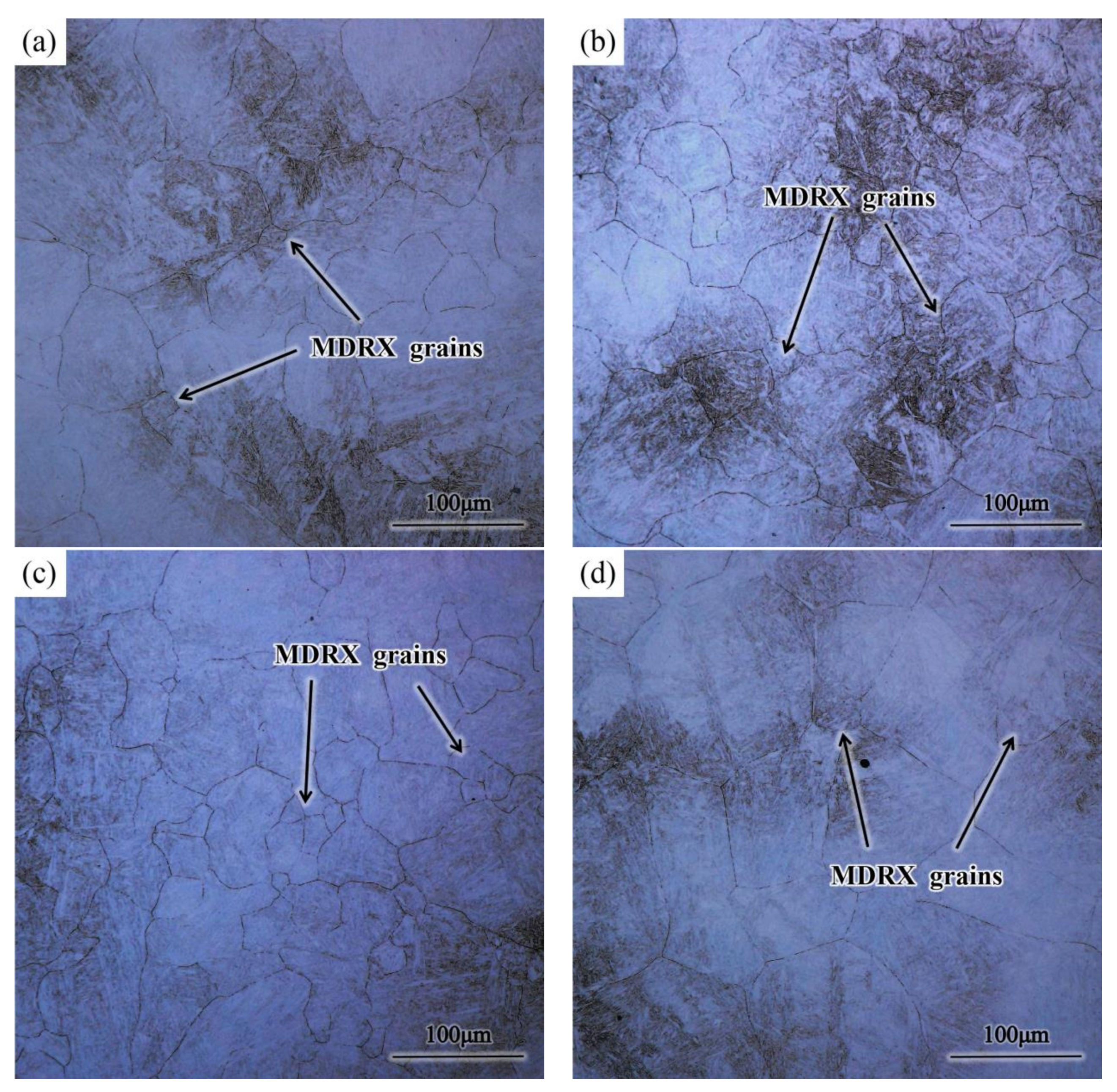

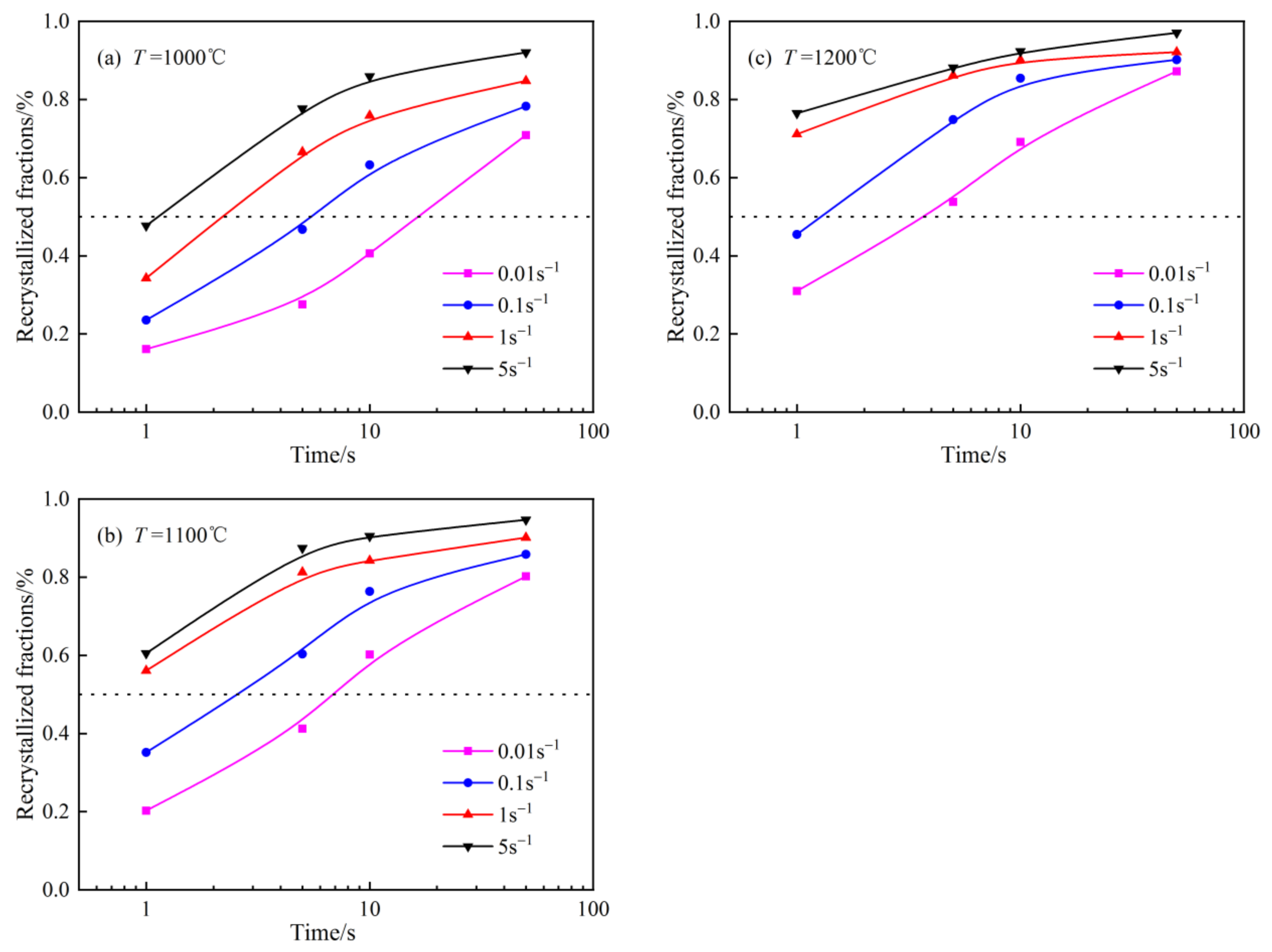

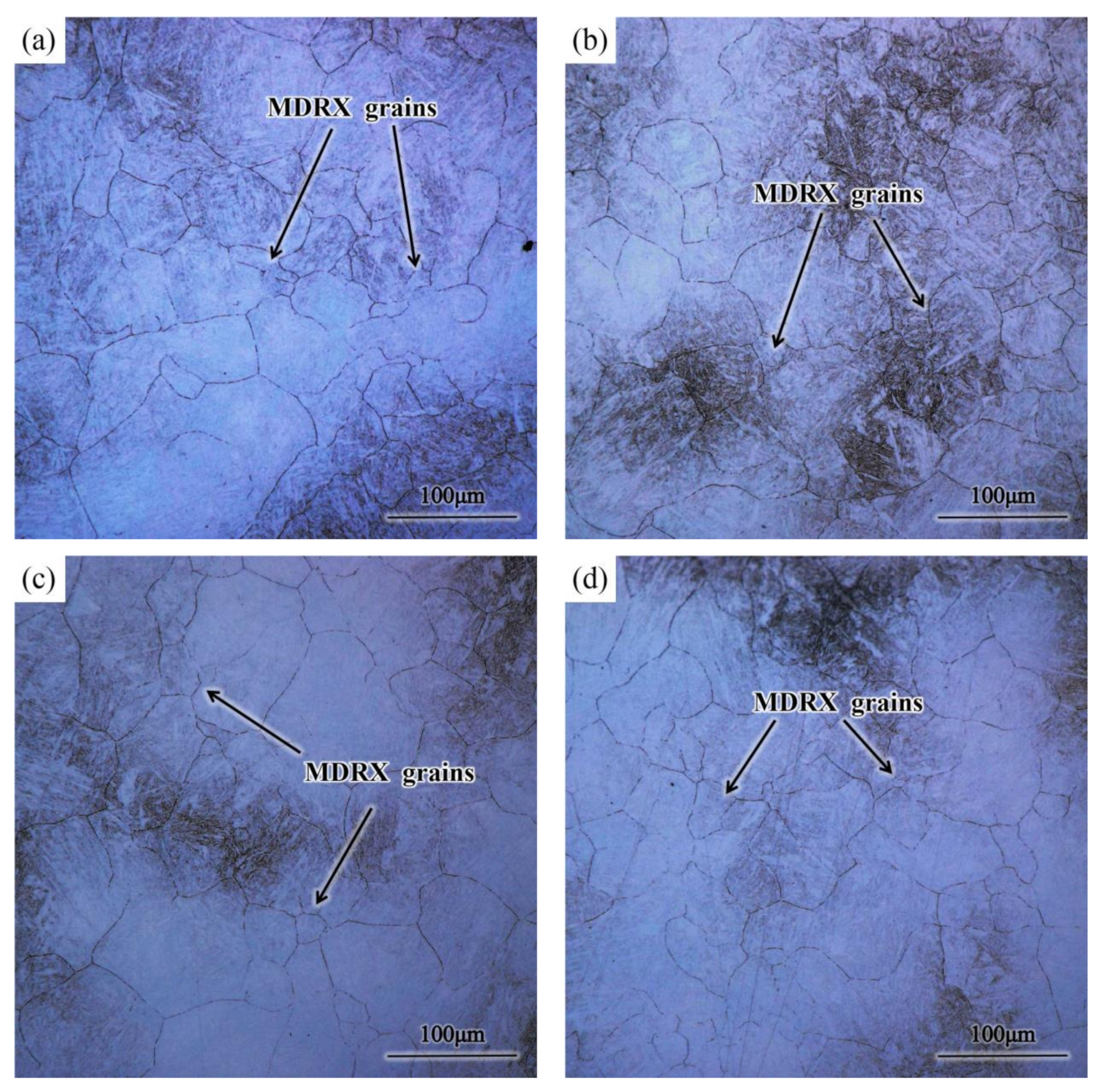

3.2.1. Effect of Deformation Temperature and Interval Time on Metadynamic Recrystallization Softening Rate and Grain Size

3.2.2. Effect of Strain Rate on Metadynamic Recrystallization Softening Rate and Grain Size

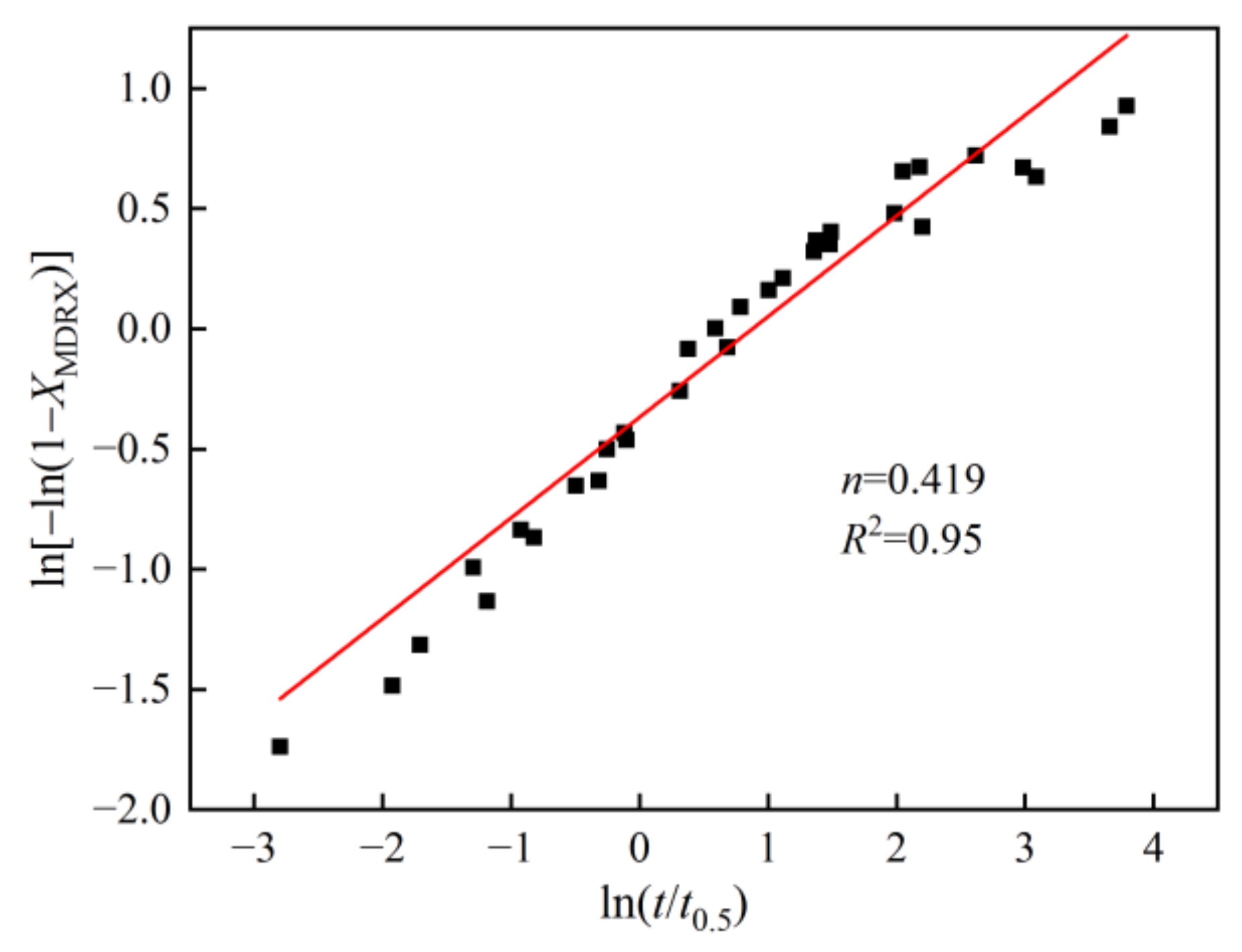

3.3. Establishment of Metadynamic Recrystallization Model for 34CrNi3MoV Steel

3.3.1. Determination of t0.5 Formula

3.3.2. Determination of the Dynamical Model

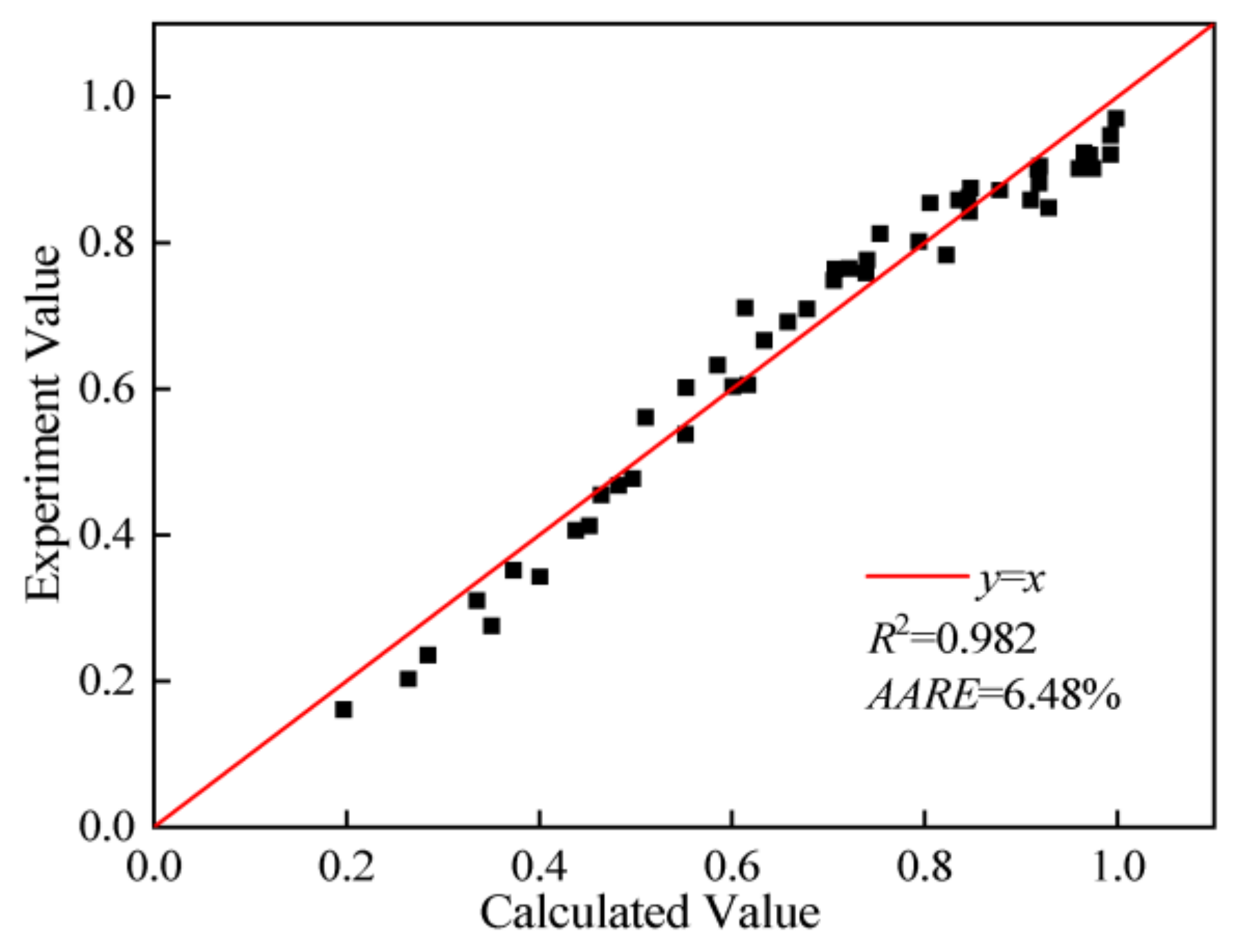

3.3.3. Validation of the Model

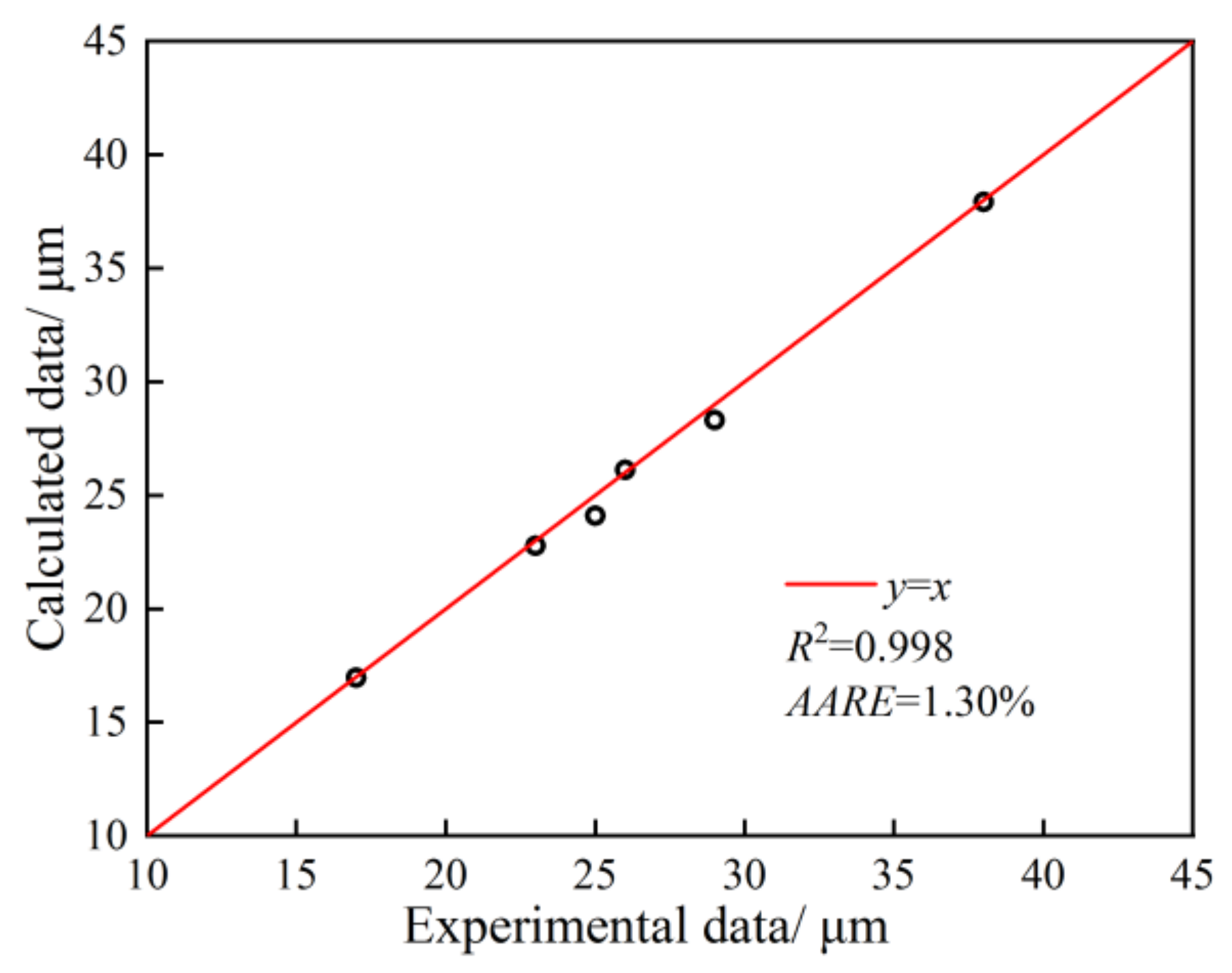

3.4. Grain Size Equation Establishment

4. Conclusions

- (1)

- Increasing the deformation temperature, extending the interval time, and increasing the strain rate are all beneficial to the improvement of the metadynamic recrystallization softening rate, and fine and uniform new grains can be obtained under a high strain rate. However, in high-temperature conditions, mixed crystallization can easily occur, which is not conducive to grain refinement.

- (2)

- The MDRX kinetic model for 34CrNi3MoV steel can be described as:

- (3)

- The MDRX grain size model for 34CrNi3MoV steel can be described as:

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.G.; Li, P.J.; Yin, X.Y.; Wu, F.Y.; Xiong, L.T.; Gao, H.T. Effects of Deformation Parameters on the Superplastic Behavior and Microstructure Evolution of TA32 Alloy. Rare Met. Mater. Eng. 2018, 47, 3473–3481. [Google Scholar]

- Lei, L.; Yang, Q.B.; Zhang, Z.Q.; Fan, X.Z.; Li, X.; Yang, M.; Deng, Z.H. Multi-pass Compression Behavior and Microstructure Evolution of AA2195 Aluminum Lithium Alloy. Mater. Rep. 2019, 33, 348–352. [Google Scholar]

- Gan, H.Y.; Cheng, M.; Song, H.W.; Chen, Y.; Zhang, S.H.; Vladimir, P. Dynamic Recrystallization and texture evolution of GH4169 alloy during cross wedge rolling. J. Mater. Eng. 2020, 48, 114–122. [Google Scholar]

- Qiao, S.B.; He, X.K.; Liu, J.J.; Zhao, D.L.; Liu, Z.D. Microstructure evolution and flow stress modeling of SA508Gr.4N steel during hot deformation process. J. Mater. Eng. 2021, 49, 67–77. [Google Scholar]

- Pan, L.B.; Chu, T.; Zhang, S.; Jiang, J.; Cheng, C.J.; Xie, Q.Z.; Xing, X.Q.; Si, T.Z. Dynamic recrystallization behaviors of 30CrNi3MoV steel and its mathematical models. Heat Treat. Met. 2021, 46, 23–30. [Google Scholar]

- Wu, C.H.; Feng, D.; Zang, Q.H.; Fan, S.C.; Zhang, H.; Li, Y.S. Microstructure Evolution and Recrystallization Behavior During Hot Deformation of Spray Formed AlSiCuMg Alloy. Acta Metall. Sin. 2022, 58, 932–942. [Google Scholar]

- Zhao, M.J.; Huang, L.; Zeng, R.; Su, H.L.; Wen, D.X.; Li, J.J. In-situ observations and modeling of metadynamic recrystallization in 300M steel. Mater. Charact. 2020, 159, 109997. [Google Scholar] [CrossRef]

- Shen, W.F.; Zhang, C.; Zhang, L.W.; Xia, Y.N.; Xu, Y.F.; Shi, X.H. Metadynamic recrystallization of Nb–V microalloyed steel during hot deformation. J. Mater. Res. 2017, 32, 656–665. [Google Scholar] [CrossRef]

- Wang, Y.S.; Hu, Z.Q.; Wang, K.K.; Li, H. Investigation on meta-dynamic recrystallization behavior of 5CrNiMoV hot-working die steel. J. Plast. Eng. 2021, 28, 118–125. [Google Scholar]

- Chen, W.X.; Hu, B.J.; Jia, C.N.; Zheng, C.W.; Li, D.Z. Post-Dynamic Softening of Austenite in a Ni-30%Fe Model Alloy After Hot Deformation. Acta Metall. Sin. 2020, 56, 874–884. [Google Scholar]

- Ma, Q.; Wei, K.; Tang, H.B.; Dong, X.J. Softening behavior and equiaxed α phase microstructure evolution of TA15 titanium alloy during double-pass hot compression deformatiion. Trans. Mater. Heat Treat. 2021, 42, 40–47. [Google Scholar]

- Zhang, C.; Zhang, L.W.; Shen, W.F.; Liu, C.R.; Xia, Y.N. The Kinetics of Metadynamic Recrystallization in a Ni-Cr-Mo-Based Superalloy Hastelloy C-276. J. Mater. Eng. Perform. 2016, 25, 545–552. [Google Scholar] [CrossRef]

- Chen, X.M.; Lin, Y.C.; Li, X.H.; Chen, M.S.; Yuan, W.Q. lnvestigation on strain dependence of metadynamic recrystallization behaviors of GH4169 superalloy. Vacuum 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Niu, W.L.; Guo, J.; Ma, S.W.; Zhang, M.C. Maicang Sub-dynamic Recrystallization Kinetics Model of the New Type Alloy of High-Quality GH738. Rare Met. Mater. Eng. 2022, 51, 183–189. [Google Scholar]

- Wang, Y.J.; Liu, Z.C.; Duan, B.Y. Microstructure of refined 34CrNi3MoV steel. Ordnance Mater. Sci. Eng. 2013, 36, 128–132. [Google Scholar]

- Zhao, Y.T.; Liu, Z.C.; Wang, Y.F. Mixed Grain and Elimination Measure of 34CrNi3MoV Steel. Heat Treat. Met. 2007, 25, 75–77. [Google Scholar]

- Xu, Y.; Jiao, Y.X.; Liu, J.S. Modeling of Metadynamic Recrystallization Kinetics and Recrystallization Mechanisms of V-Containing 12Cr Rotor Steel. J. Mater. Eng. Perform. 2020, 29, 4754–4765. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, J.; Han, Y.; Liu, R.; Zou, D.N.; Qiao, G.J. Metadynamic Recrystallization Behavior of As-cast 904L Superaustenitic Stainless Steel. J. Iron Steel Res. Int. 2016, 23, 151–159. [Google Scholar] [CrossRef]

- Cheng, Y.; Du, H.Y.; Wei, Y.H.; Hou, L.F.; Liu, B.S. Metadynamic recrystallization behavior and workability characteristics of HR3C austenitic heat-resistant stainless steel with processing map. J. Mater. Process. Tech. 2016, 235, 134–142. [Google Scholar] [CrossRef]

- Liang, M.Q.; Li, X.X.; Zhang, Y.L.; Zhang, W.; Huang, D.C. Analysis on sub-dynamic recrystallization and establishment of mathematic model for non-quenched and tempered steel. Forg. Stamp. Technol. 2021, 46, 175–178. [Google Scholar]

- Zhang, C.; Zhang, L.W.; Shen, W.F.; Xia, Y.N. The kinetics and microstructural evolution during metadynamic recrystallization of medium carbon Cr–Ni–Mo alloyed steel. J. Mater. Res. 2017, 32, 1367–1375. [Google Scholar] [CrossRef]

- Liu, D.H.; Chen, J.D.; Chai, H.R.; Jiang, Y.H.; Li, Z.; Qiu, W.Q.; Guo, Z.H. Study of meta-dynamic recrystallization behavior of GH5188 superalloy. J. Mater. Res. Technol. 2021, 15, 1179–1189. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | V | Cu | P | S |

|---|---|---|---|---|---|---|---|---|---|

| 0.3 | 0.25 | 0.65 | 1.4 | 3.1 | 0.4 | 0.15 | ≤0.02 | ≤0.015 | ≤0.001 |

| Deformation Temperature (°C) | Strain Rate (s−1) | t0.5 (s) |

|---|---|---|

| 1000 | 0.01 | 16.42 |

| 1000 | 0.1 | 5.54 |

| 1000 | 1 | 2.28 |

| 1000 | 5 | 1.13 |

| 1100 | 0.01 | 6.88 |

| 1100 | 0.1 | 2.53 |

| 1200 | 0.01 | 3.66 |

| 1200 | 0.1 | 1.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, B.; Zou, Z.; Xu, D.; Wang, Y.; Wang, X.; Zhao, H.; Ju, D. Metadynamic Recrystallization Behavior of Cr-Ni-Mo Alloy Steel. Metals 2023, 13, 696. https://doi.org/10.3390/met13040696

Zheng B, Zou Z, Xu D, Wang Y, Wang X, Zhao H, Ju D. Metadynamic Recrystallization Behavior of Cr-Ni-Mo Alloy Steel. Metals. 2023; 13(4):696. https://doi.org/10.3390/met13040696

Chicago/Turabian StyleZheng, Bing, Zhipeng Zou, Dong Xu, Yiqun Wang, Xuexi Wang, Hongyang Zhao, and Dongying Ju. 2023. "Metadynamic Recrystallization Behavior of Cr-Ni-Mo Alloy Steel" Metals 13, no. 4: 696. https://doi.org/10.3390/met13040696

APA StyleZheng, B., Zou, Z., Xu, D., Wang, Y., Wang, X., Zhao, H., & Ju, D. (2023). Metadynamic Recrystallization Behavior of Cr-Ni-Mo Alloy Steel. Metals, 13(4), 696. https://doi.org/10.3390/met13040696