Effects of Cold Expansion on Residual Stress of 7050 Aluminium Alloy Frame Forging

Abstract

:1. Introduction

2. Materials and Methods

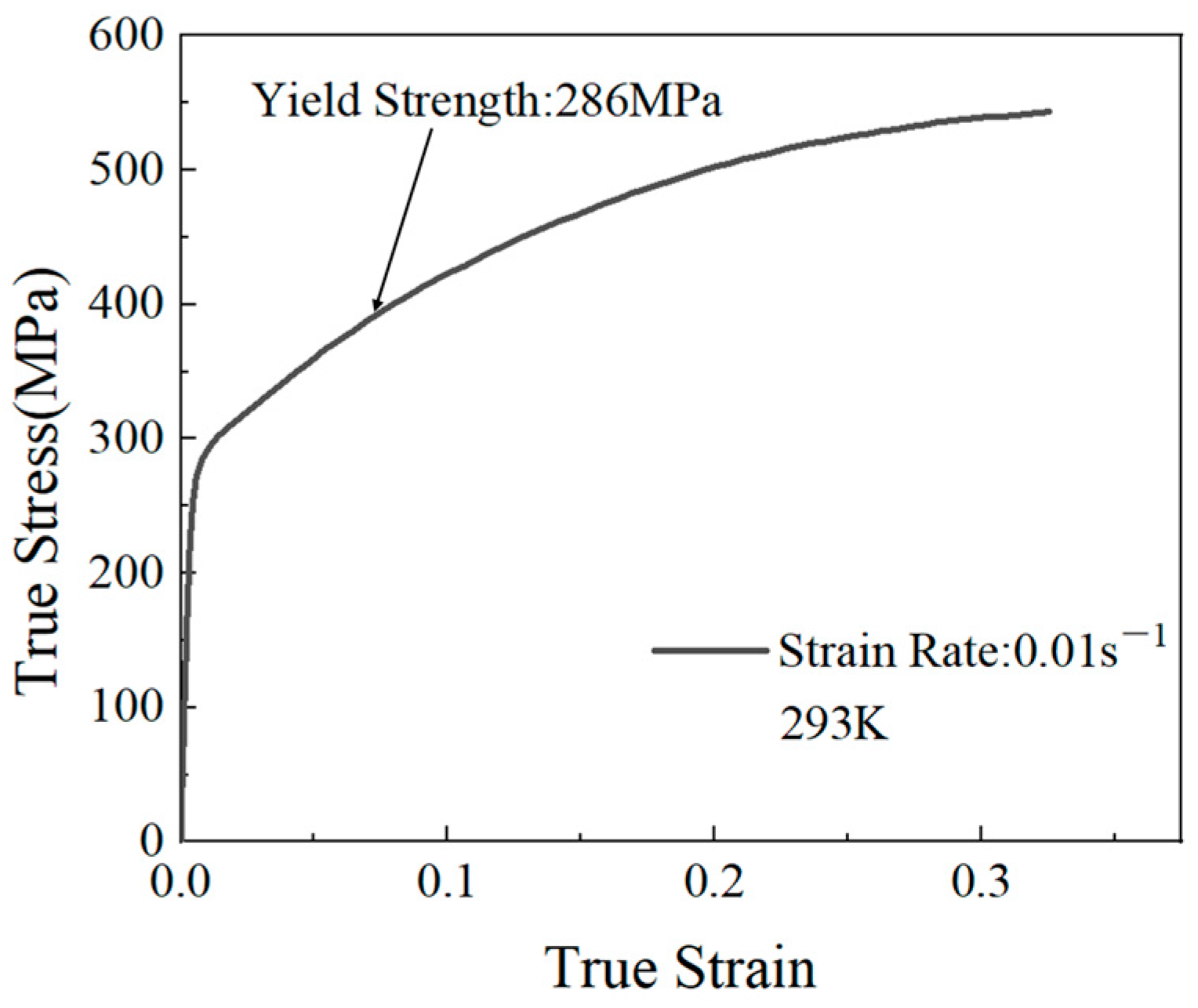

2.1. Material Parameters

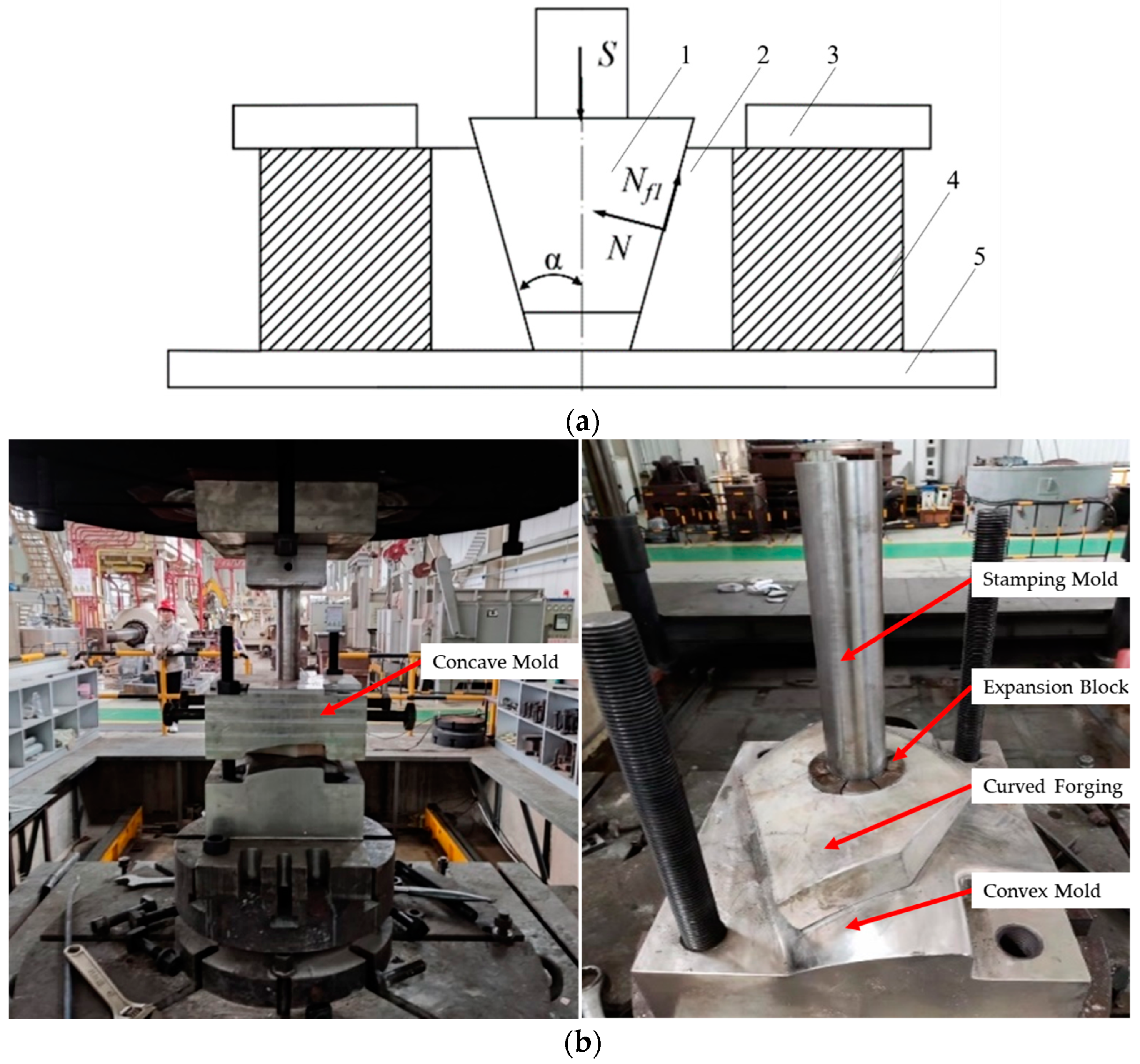

2.2. Cold Expansion Method

- (a)

- Installation: install the convex mold, forging component, concave mold, stamping mold, and expansion block on the forging machine, and fix the convex and concave molds through bolts;

- (b)

- Loading: drive the forging machine to move vertically downward to the specified position and keep 30 s;

- (c)

- Unloading: the forging machine is slowly lifted up to unload the pressure;

- (d)

- Completion: loosen the fastening bolts and remove the forging part, the cold expansion process is completed.

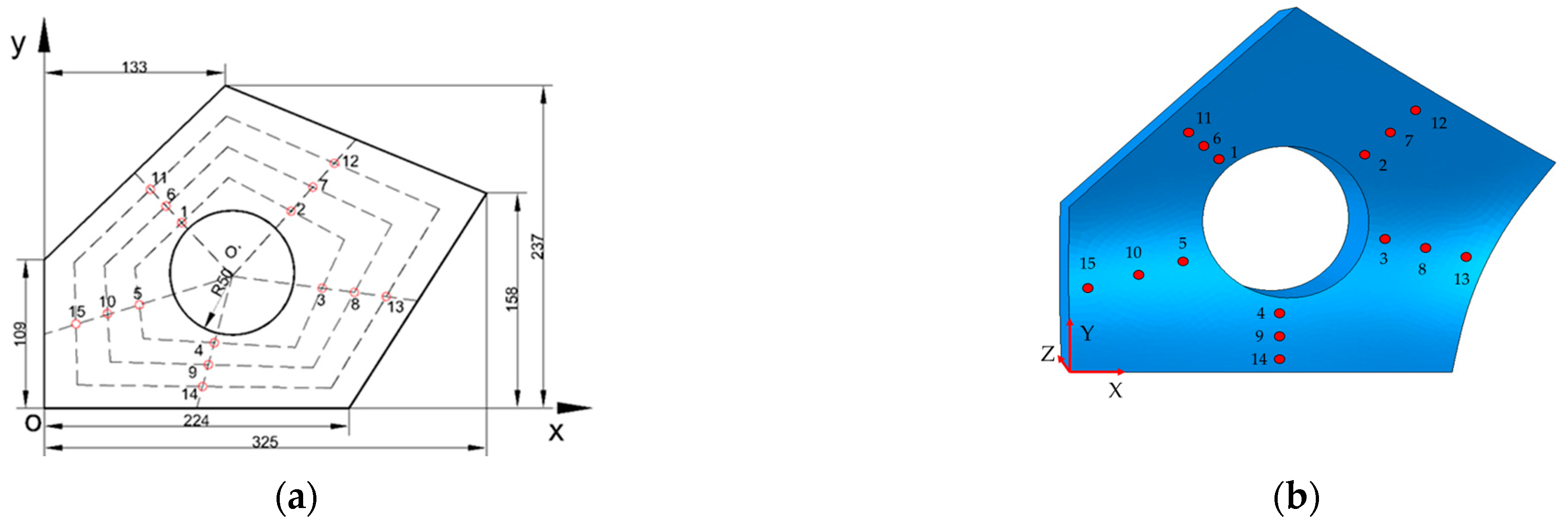

2.3. Residual Stress Measurement Method

3. Models Description

3.1. Quenching Model

- (1)

- The material of the curved frame forging is continuous and isotropic.

- (2)

- The initial temperature field distribution of the curved frame forging is uniform, and the initial residual stress is negligible.

- (3)

- The temperature of the quenching medium remains uniform.

- (4)

- The phase change of the curved frame forging during the quenching process is not considered.

3.2. Cold Expansion Numerical Modelling of Curved Frame Forging

- (1)

- The material of the curved frame forging is continuous and isotropic.

- (2)

- The friction coefficient between the curved frame forging and the mold is constant during the cold expansion process.

- (3)

- The temperature change of the curved frame forging during the cold expansion process is not considered.

4. Results and Discussion

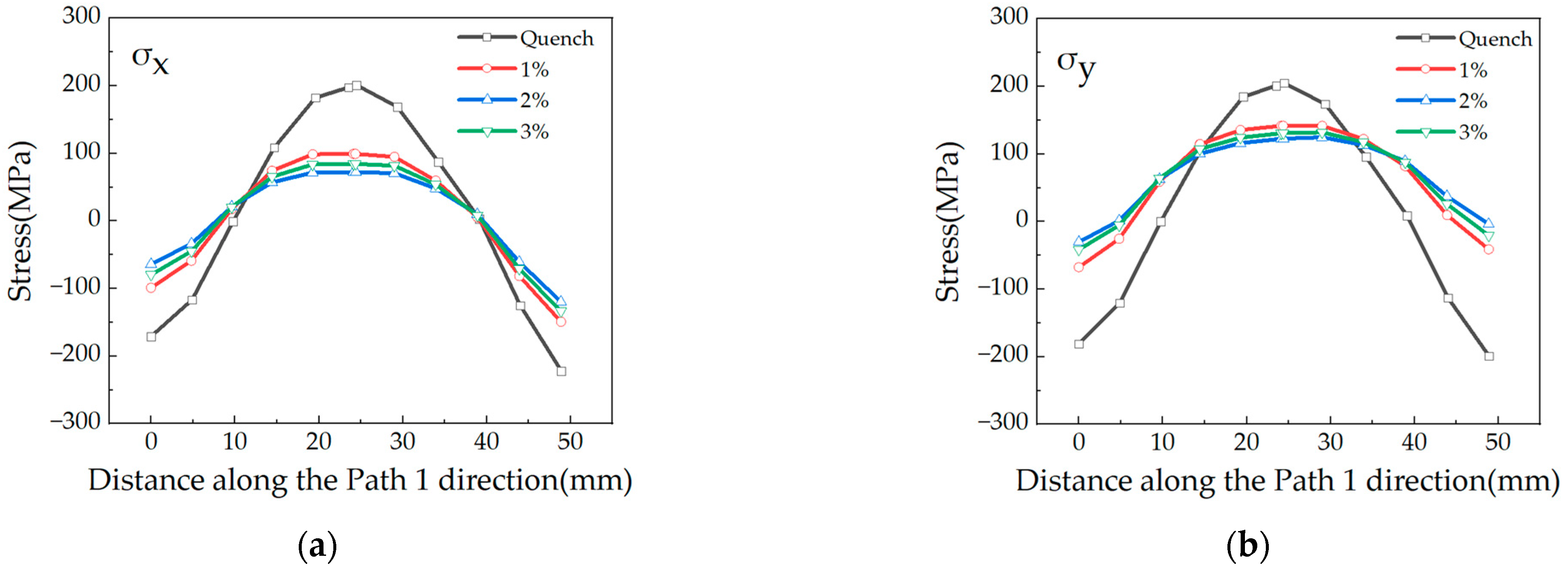

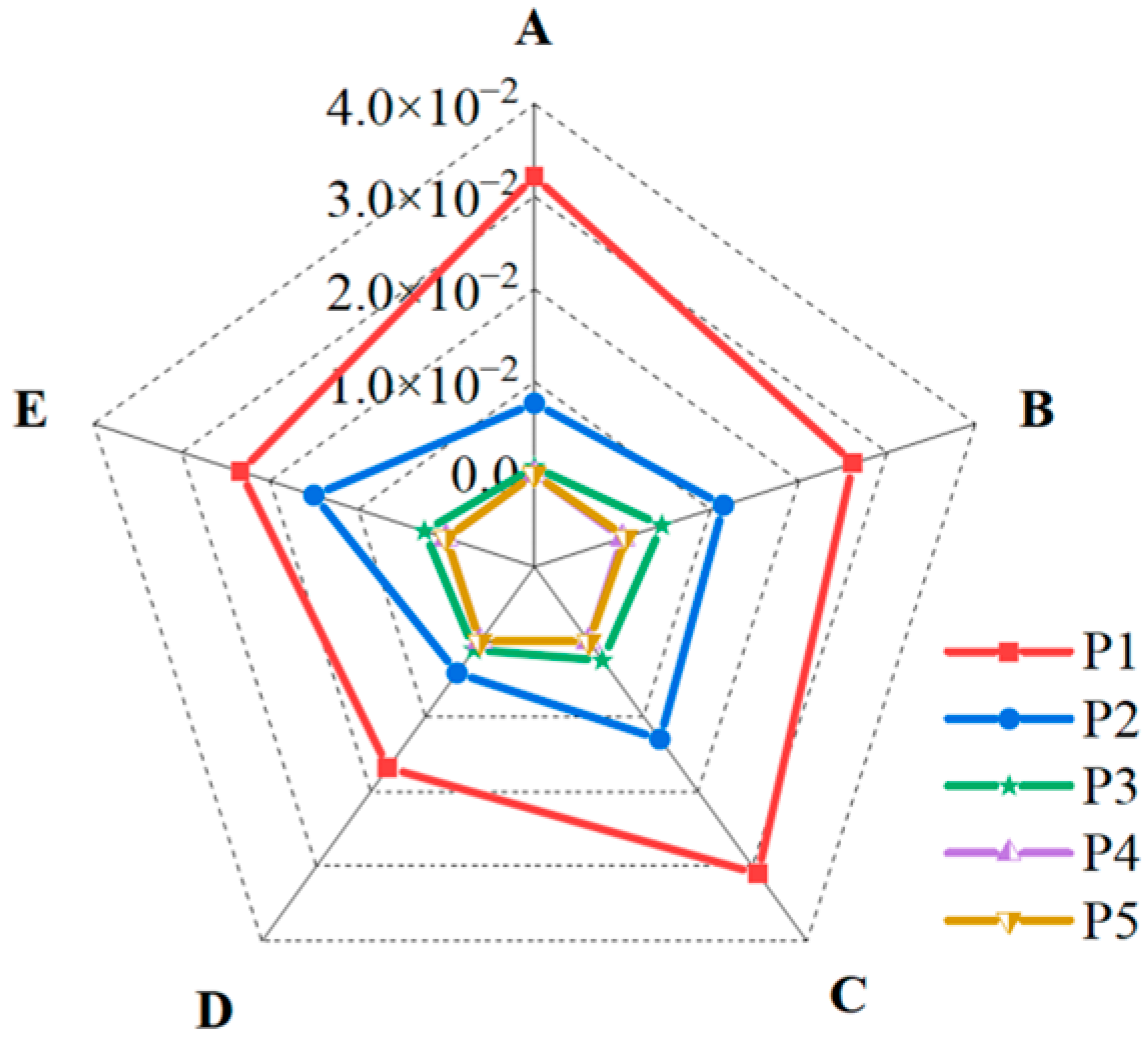

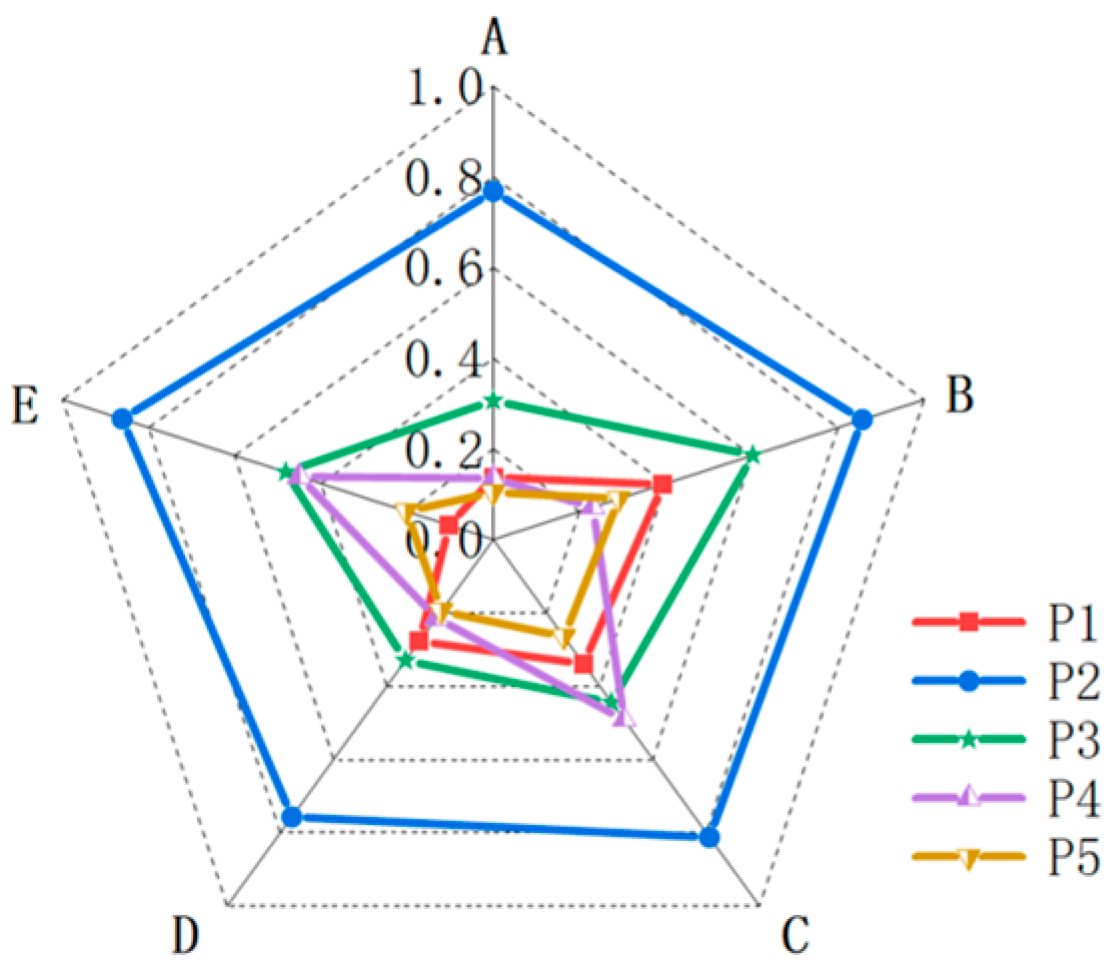

4.1. Effect of Cold Expansion Rate on Residual Stress

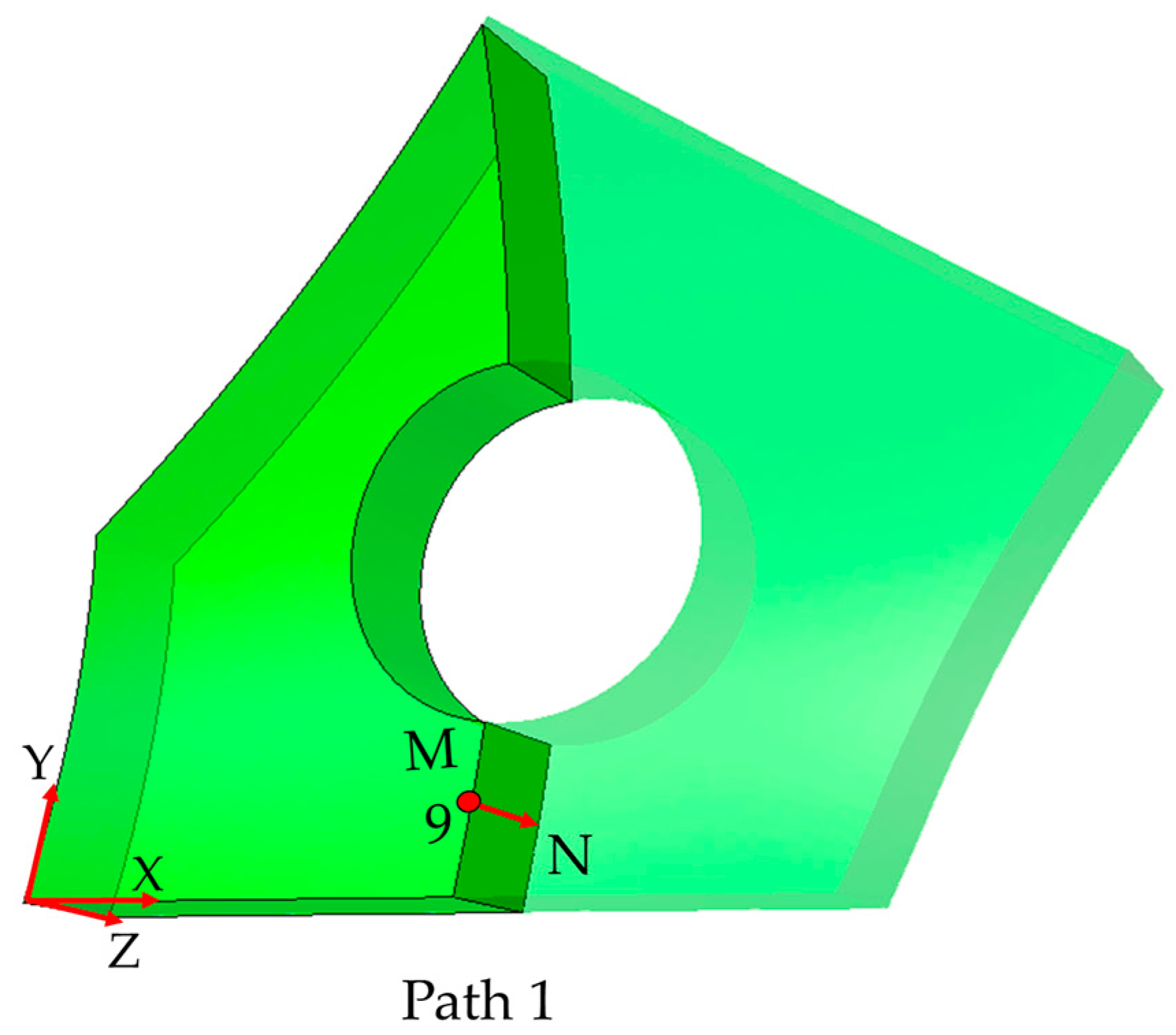

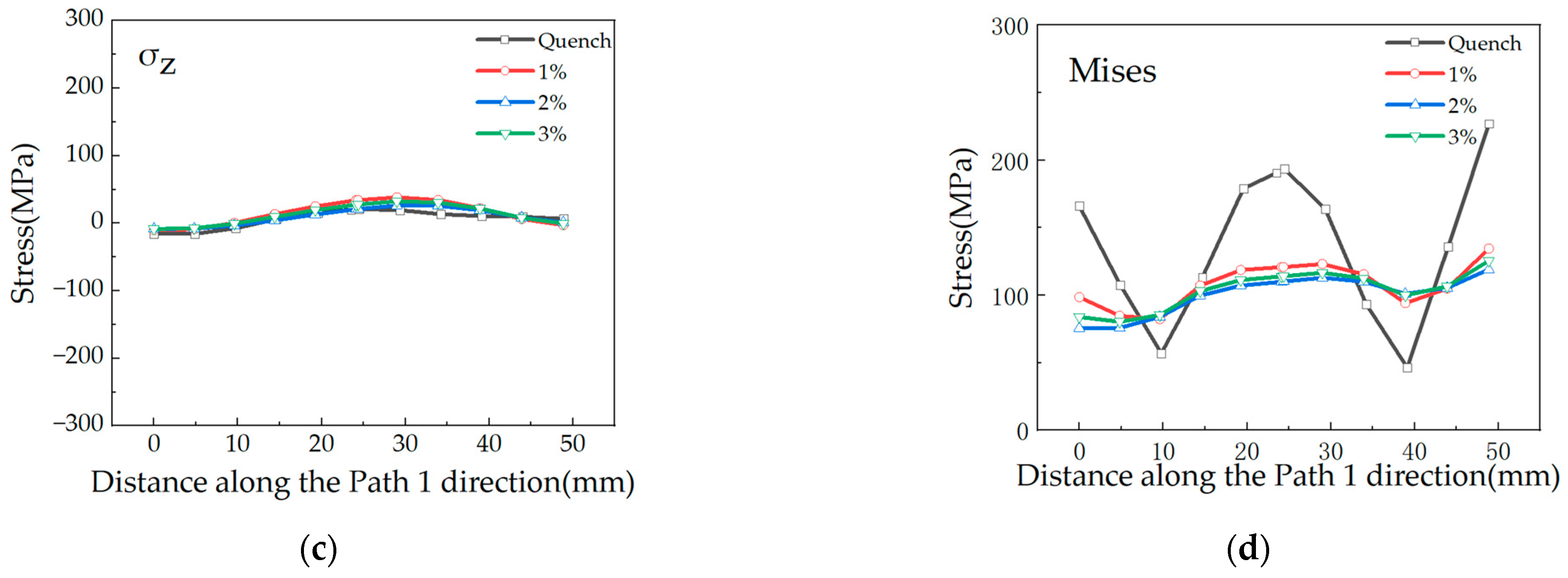

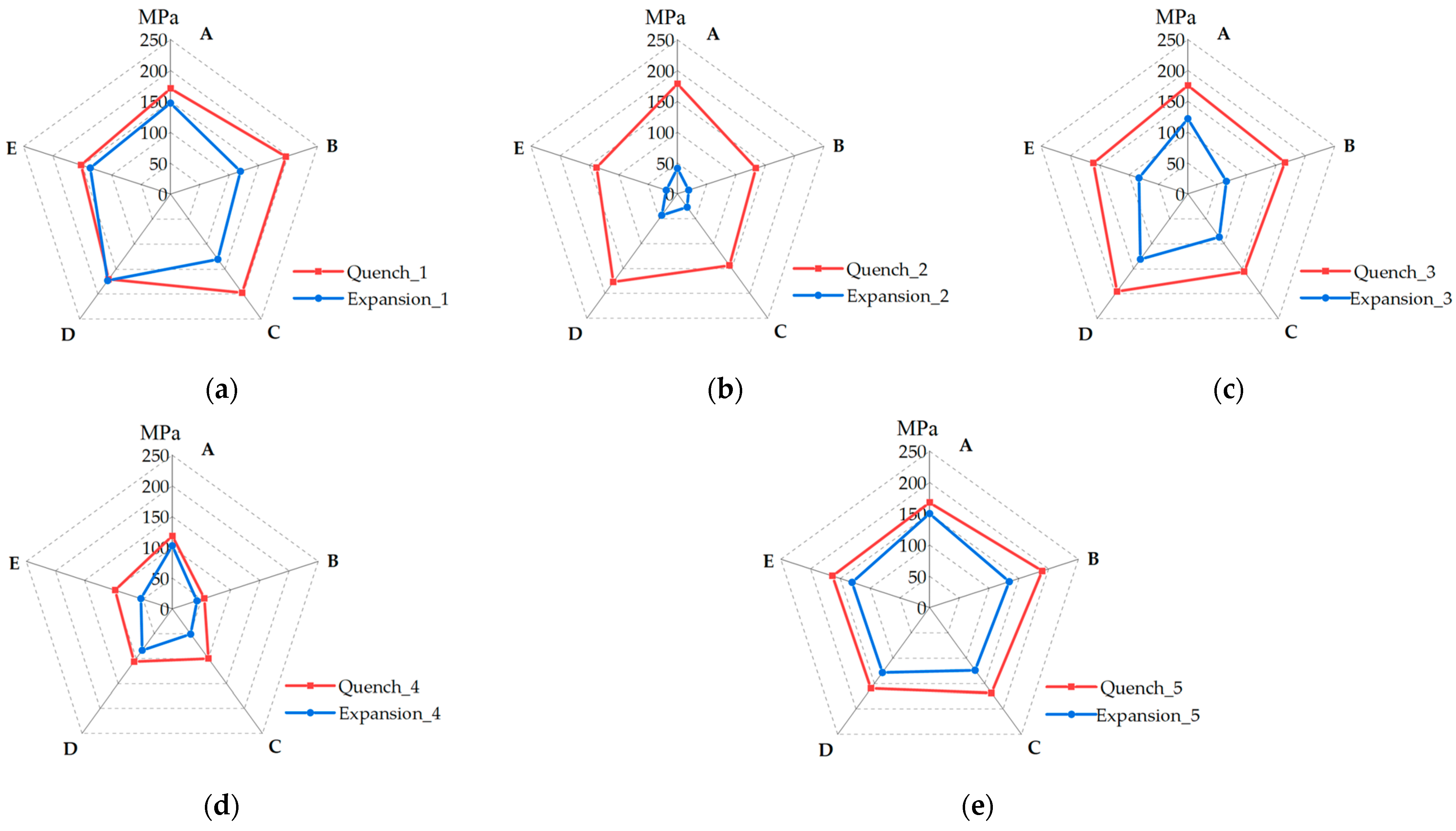

4.2. Residual Stress and Strain Fields after Cold Expansion

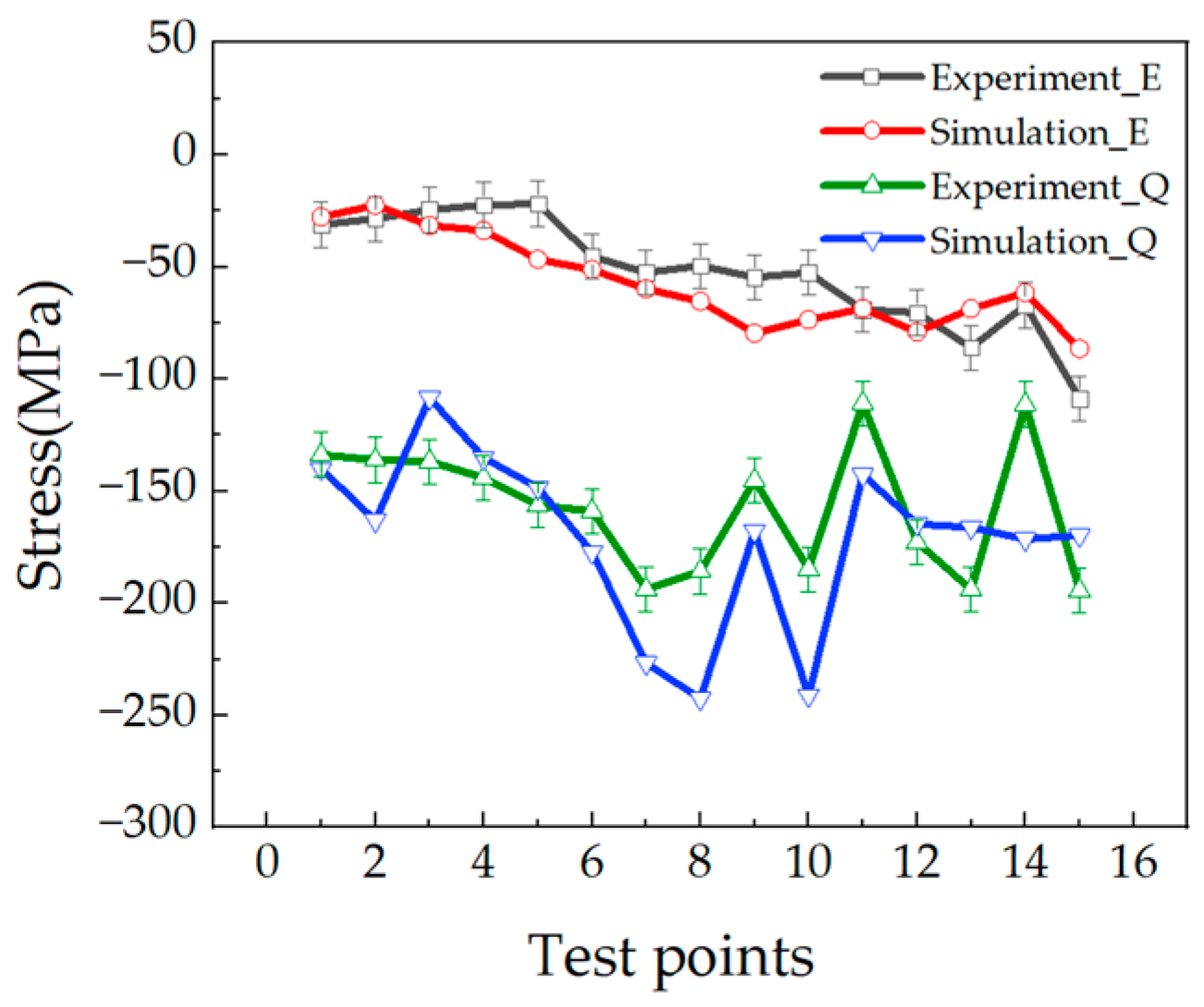

4.3. Results Verification

5. Conclusions

- (1)

- The quenched numerical model results revealed that the quenched residual stress on the surface of the forging was up to 283 MPa, and the residual stress in the central layer was up to 210 MPa, which left a significant safety hazard for the subsequent processing.

- (2)

- The numerical results indicated that cold water quenching the 7050 aluminium alloy frame forgings led to large magnitude residual stress that varied from surface compression (up to 221 MPa) to tension in the core over 205 MPa. After cold expansion, the maximum compressive stress was reduced to 119 MPa, and the maximum tensile stress was reduced to 125 MPa. 2% cold expansion rate was the most efficiently for the reduction of quenched residual stress.

- (3)

- After 2% cold expansion, the residual stress in the forgings was effectively relieved. The von Mises stress on the surface was reduced from 283 MPa to 120 MPa; the von Mises stress at the central thickness was reduced from 153 MPa to 94 MPa. The stress uniformity in the final forming region of the forging was improved.

- (4)

- After cold expansion, extensive plastic deformation occurred in the vast majority of the area near the cold expansion hole, with a maximum plastic strain of 0.032 and a deformation of 0.013 in the smaller areas; the plastic strain in the area of the forging near each side was not significant. The equivalent plastic strain of the forging decreased gradually along the diameter of the expansion hole from the center to each side. However, in the two directions of the minimum thickness, the plastic strain decreased and then increased.

- (5)

- After cold expansion, the highest stress reduction rate of 86.2% was achieved in the region of 0.013 equivalent plastic strain at the center thickness of the forging; the stress reduction effect matched with the distribution of equivalent plastic strain. The XRD method was used to measure the surface stress of the forging after cold expansion, and the distribution was a general agreement with the numerical simulation results, which verified the reliability of the numerical model.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.Q.; Jiang, S.Y.; Zhao, Y.N.; Shan, D.B. Isothermal precision forging of complex-shape rotating disk of aluminum alloy based on processing map and digitized technology. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2013, 580, 294–304. [Google Scholar] [CrossRef]

- Hu, H.E.; Wang, X.Y. Effect of Heat Treatment on the In-Plane Anisotropy of As-Rolled 7050 Aluminum Alloy. Metals 2016, 6, 79. [Google Scholar] [CrossRef]

- Miturska, I. Impact of assembly method on the strength of single-lap joints of aircraft aluminum alloy sheets. Adv. Sci. Technol. Res. J. 2020, 14, 163–170. [Google Scholar] [CrossRef]

- Huang, X.M.; Sun, J.; Li, J.F. Effect of Initial Residual Stress and Machining-Induced Residual Stress on the Deformation of Aluminium Alloy Plate. Strojniski Vestn.-J. Mech. Eng. 2015, 61, 131–137. [Google Scholar] [CrossRef]

- Shan, D.; Xu, W.; Si, C.; Lu, Y. Research on local loading method for an aluminium-alloy hatch with cross ribs and thin webs. J. Mater. Process. Technol. 2007, 187, 480–485. [Google Scholar] [CrossRef]

- Zhang, Y.; Shan, D.; Xu, F. Flow lines control of disk structure with complex shape in isothermal precision forging. J. Mater. Process. Technol. 2009, 209, 745–753. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, B.; Zhang, S.G. The Advancement of 7XXX Series Aluminum Alloys for Aircraft Structures: A Review. Metals 2021, 11, 718. [Google Scholar] [CrossRef]

- Zheng, J.H.; Lin, J.G.; Lee, J.; Pan, R.; Li, C.; Davies, C.M. A novel constitutive model for multi-step stress relaxation ageing of a pre-strained 7xxx series alloy. Int. J. Plast. 2018, 106, 31–47. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, S.C.; Gu, R.Y.; Wang, W.R.; Wei, X.C. Effect of Heat Treatment Conditions on Mechanical Properties and Precipitates in Sheet Metal Hot Stamping of 7075 Aluminum Alloy. J. Mater. Eng. Perform. 2018, 27, 4423–4436. [Google Scholar] [CrossRef]

- Xie, P.; Chen, K.H.; Chen, S.Y.; Ye, S.P.; Jiao, H.B.; Huang, L.P. Study on quenching sensitivity of 7097 aluminum alloy. Mater. Res. Express 2020, 7, 14. [Google Scholar] [CrossRef]

- Weng, Z.J.; Liu, X.Z.; Gu, K.X.; Guo, J.; Cui, C.; Wang, J.J. Modification of residual stress and microstructure in aluminium alloy by cryogenic treatment. Mater. Sci. Technol. 2020, 36, 1547–1555. [Google Scholar] [CrossRef]

- Singh, A.; Agrawal, A. Investigation of surface residual stress distribution in deformation machining process for aluminum alloy. J. Mater. Process. Technol. 2015, 225, 195–202. [Google Scholar] [CrossRef]

- Godlewski, L.A.; Su, X.M.; Pollock, T.M.; Allison, J.E. The Effect of Aging on the Relaxation of Residual Stress in Cast Aluminum. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2013, 44A, 4809–4818. [Google Scholar] [CrossRef]

- Yang, G.H.; Xue, B.; Li, Z.Y.; Zhou, G.; Zhang, S.H.; Lu, N.; Wen, L.; Zhang, D.Z. Influence of Stress Field and Temperature Field on Residual Stress of 2A14 Aluminum Alloy Based on In Situ SAXS Method. Materials 2023, 16, 170. [Google Scholar] [CrossRef]

- Robinson, J.S.; Pirling, T.; Truman, C.E.; Panzner, T. Residual stress relief in the aluminium alloy 7075. Mater. Sci. Technol. 2017, 33, 1765–1775. [Google Scholar] [CrossRef]

- Gong, H.; Sun, Y.J.; Liu, Y.Q.; Wu, Y.X.; He, Y.P.; Sun, X.L.; Zhang, M.H. Effect of Vibration Stress Relief on the Shape Stability of Aluminum Alloy 7075 Thin-Walled Parts. Metals 2019, 9, 27. [Google Scholar] [CrossRef]

- Pan, R.; Shi, Z.S.; Davies, C.M.; Li, C.; Kaye, M.; Lin, J.G. An integrated model to predict residual stress reduction by multiple cold forging operations in extra-large AA7050 T-section panels. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2018, 232, 1319–1330. [Google Scholar] [CrossRef]

- Pan, R.; Pirling, T.; Zheng, J.H.; Lin, J.G.; Davies, C.M. Quantification of thermal residual stresses relaxation in AA7xxx aluminium alloy through cold rolling. J. Mater. Process. Technol. 2019, 264, 454–468. [Google Scholar] [CrossRef]

- Cozzolino, L.D.; Coules, H.E.; Colegrove, P.A.; Wen, S.W. Investigation of post-weld rolling methods to reduce residual stress and distortion. J. Mater. Process. Technol. 2017, 247, 243–256. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Nik, M.A. Edge distance effects on residual stress distribution around a cold expanded hole in Al 2024 alloy. Comput. Mater. Sci. 2009, 45, 1134–1141. [Google Scholar] [CrossRef]

- Amjad, K.; Wang, W.C.; Patterson, E. A comparison of split sleeve cold expansion in thick and thin plates. J. Strain Anal. Eng. Des. 2016, 51, 375–386. [Google Scholar] [CrossRef]

- Seifi, R. Total fatigue lives, crack growth paths and cycles in cold expanded adjacent holes. Int. J. Fatigue 2018, 113, 69–77. [Google Scholar] [CrossRef]

| Element | Zn | Mg | Cu | Zr | Fe | Si | Ti | Mn | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 5.7–6.7 | 1.9–2.6 | 2.0–2.6 | 0.08–0.115 | 0–0.15 | ≤0.12 | ≤0.12 | ≤0.10 | Bal. |

| X-ray Diffraction Parameters | Specification/Values |

|---|---|

| Tube type | Cr |

| Supplied current during the experiment | 6.7 mA |

| Supplied voltage during the experiment | 30 kV |

| Exposure time for the calibration | 8 s |

| Exposure time for measurement | 10 s |

| Collimator diameter | 2 mm |

| Collimator distance | 10.390 mm |

| Detector distance | 50 mm |

| Tilt angle | −45° to 45° |

| Number of tilts | 5/5 |

| Rotation angle | 0° to 90° |

| Number of rotations | 2 |

| Stress resolution | ±10 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, H.; Sun, X.; Zhang, T.; Tang, H. Effects of Cold Expansion on Residual Stress of 7050 Aluminium Alloy Frame Forging. Metals 2023, 13, 732. https://doi.org/10.3390/met13040732

Gong H, Sun X, Zhang T, Tang H. Effects of Cold Expansion on Residual Stress of 7050 Aluminium Alloy Frame Forging. Metals. 2023; 13(4):732. https://doi.org/10.3390/met13040732

Chicago/Turabian StyleGong, Hai, Xiaoliang Sun, Tao Zhang, and Hua Tang. 2023. "Effects of Cold Expansion on Residual Stress of 7050 Aluminium Alloy Frame Forging" Metals 13, no. 4: 732. https://doi.org/10.3390/met13040732