Microstructure and Mechanical Properties of High-Strength, Low-Alloy Steel Thin-Wall Fabricated with Wire and Arc Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

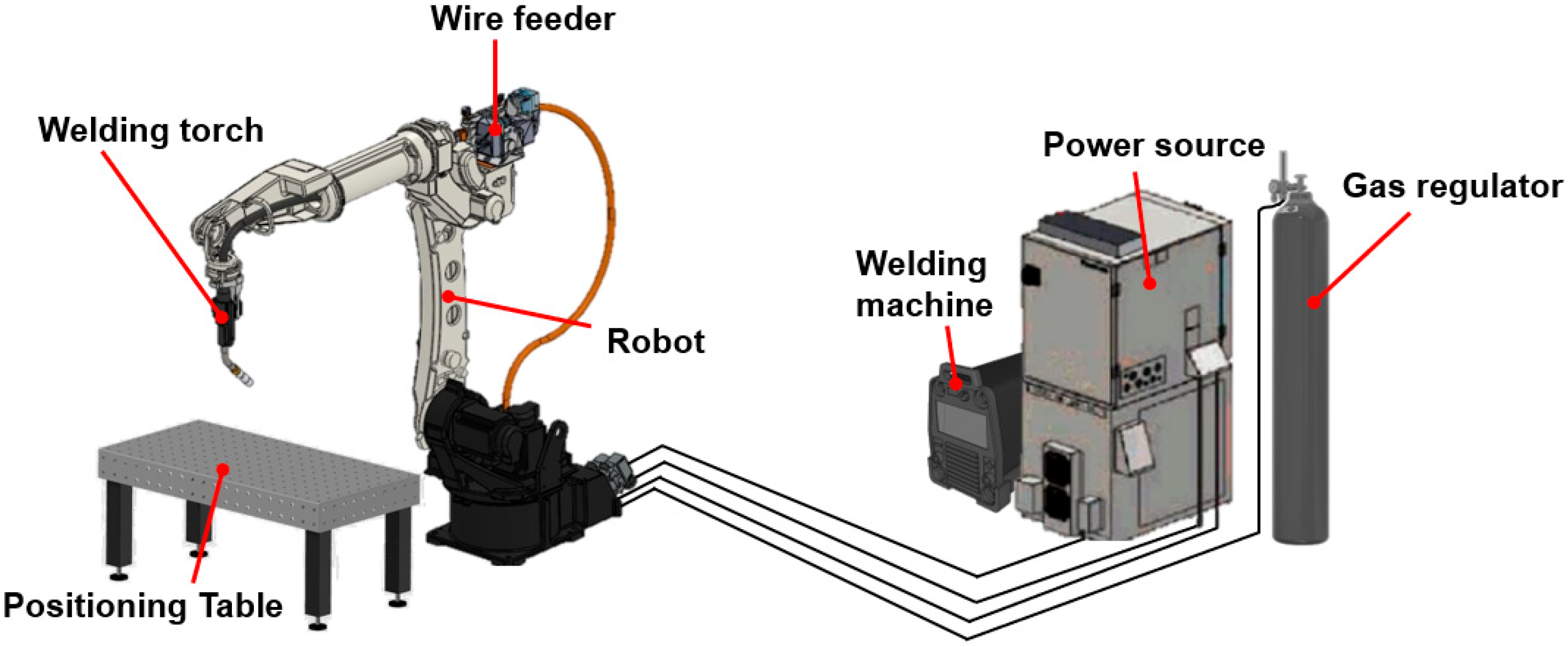

2.1. Experiment Setup

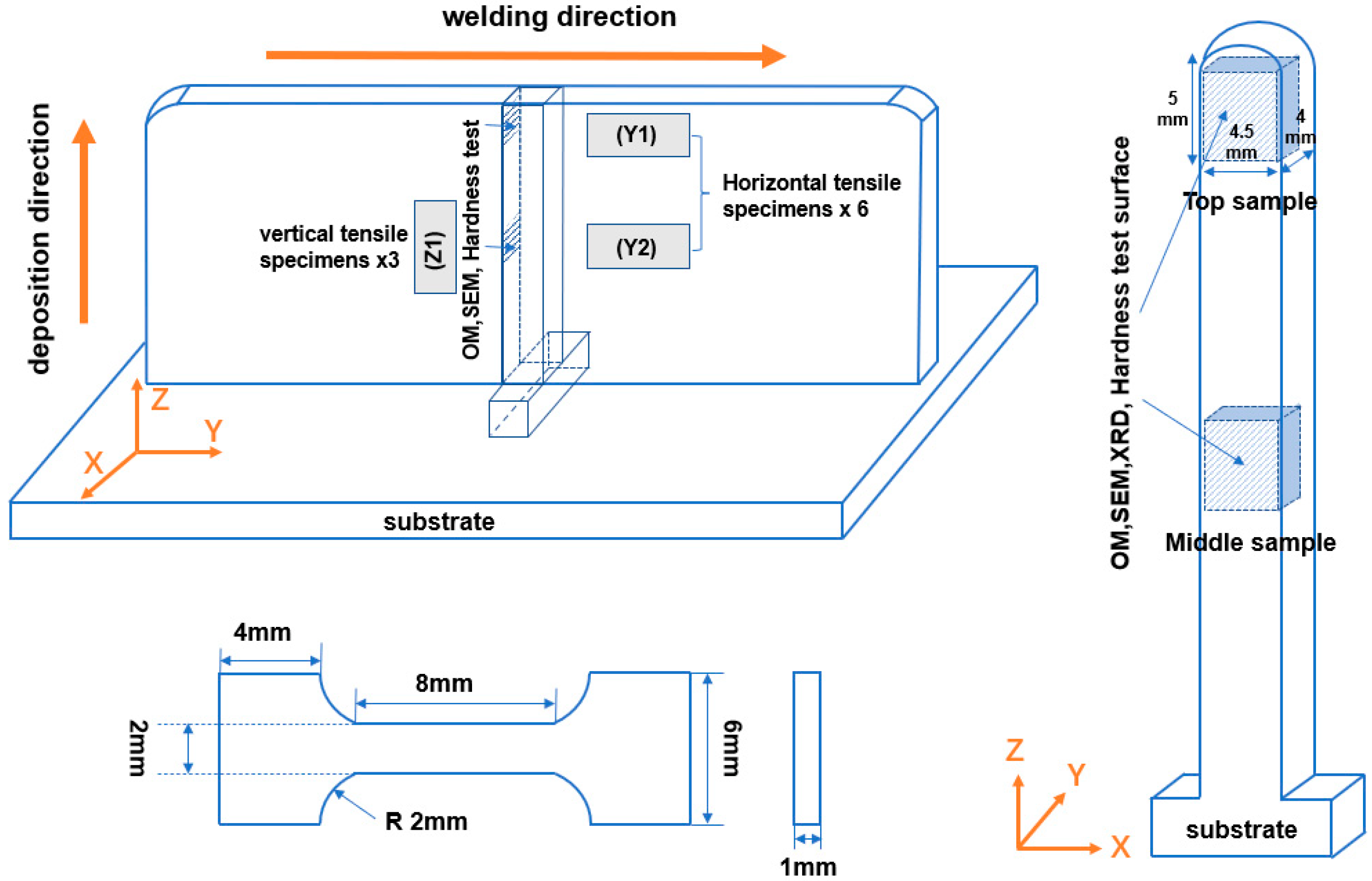

2.2. Characterization of Deposited Walls

3. Results and Discussions

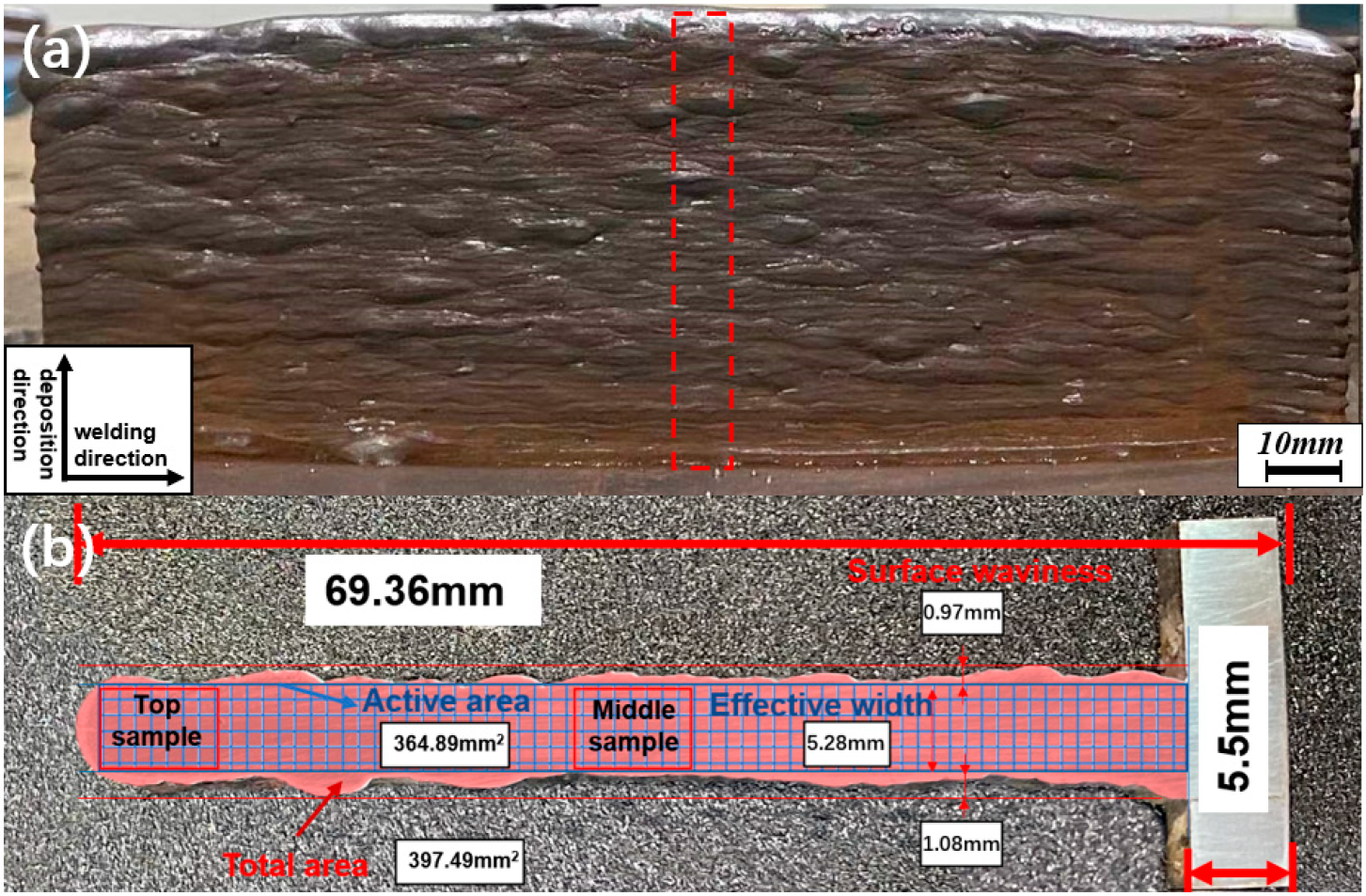

3.1. Macroscopic Characterization

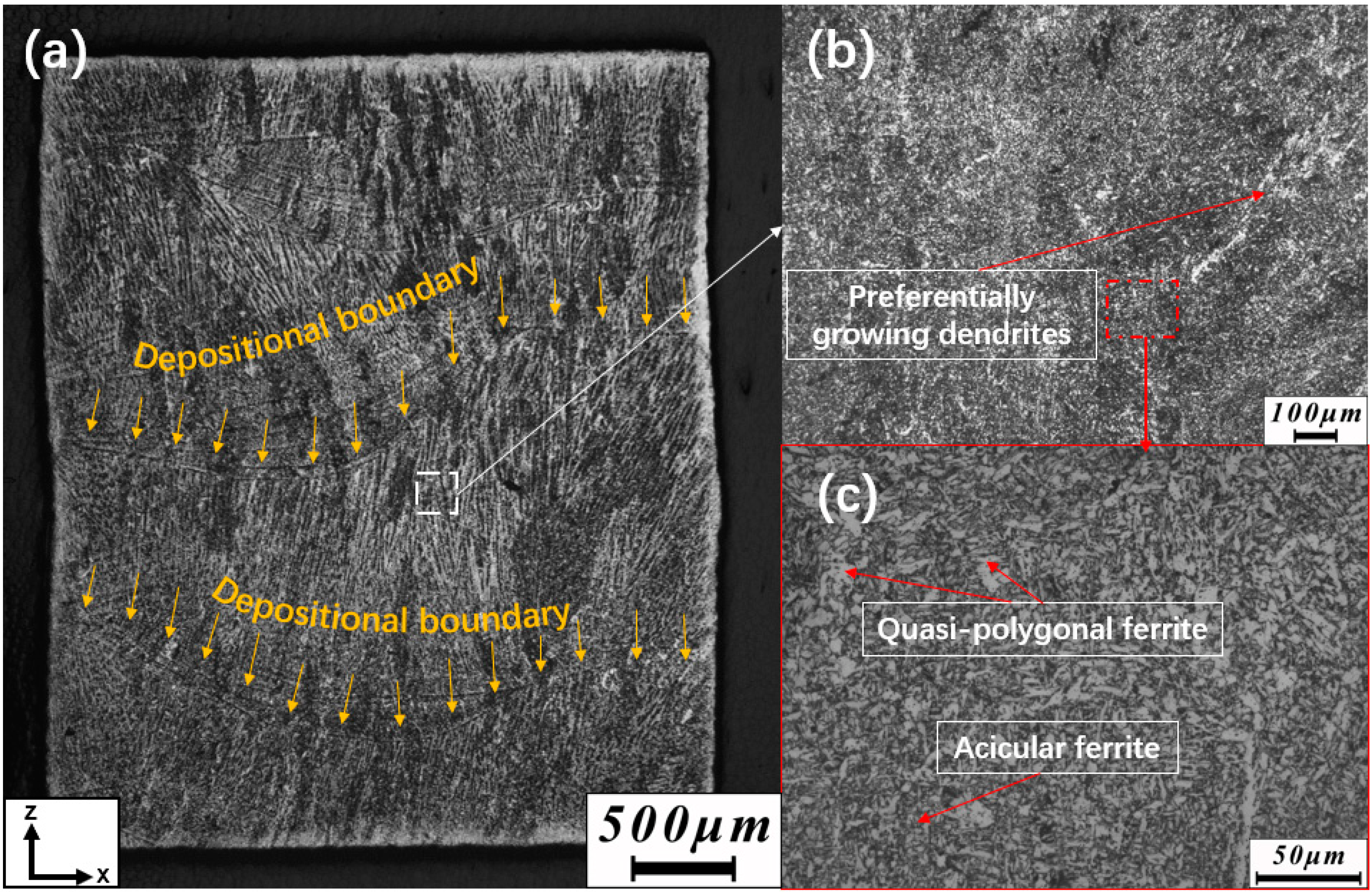

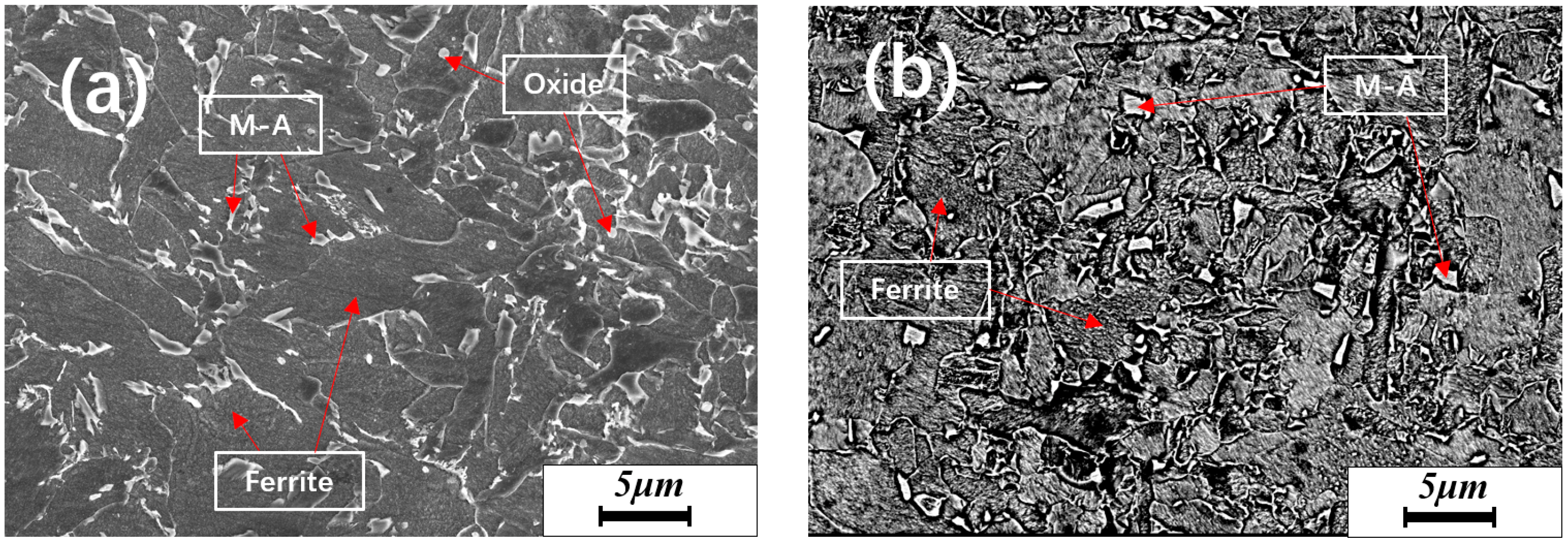

3.2. Microstructure

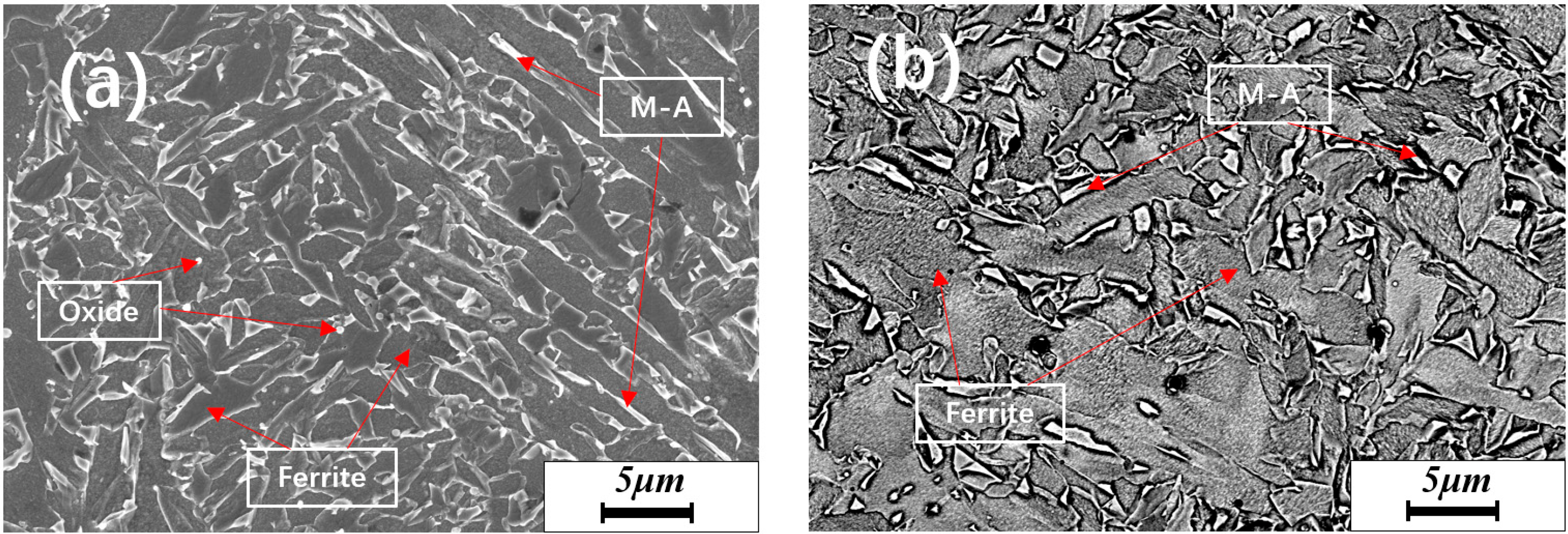

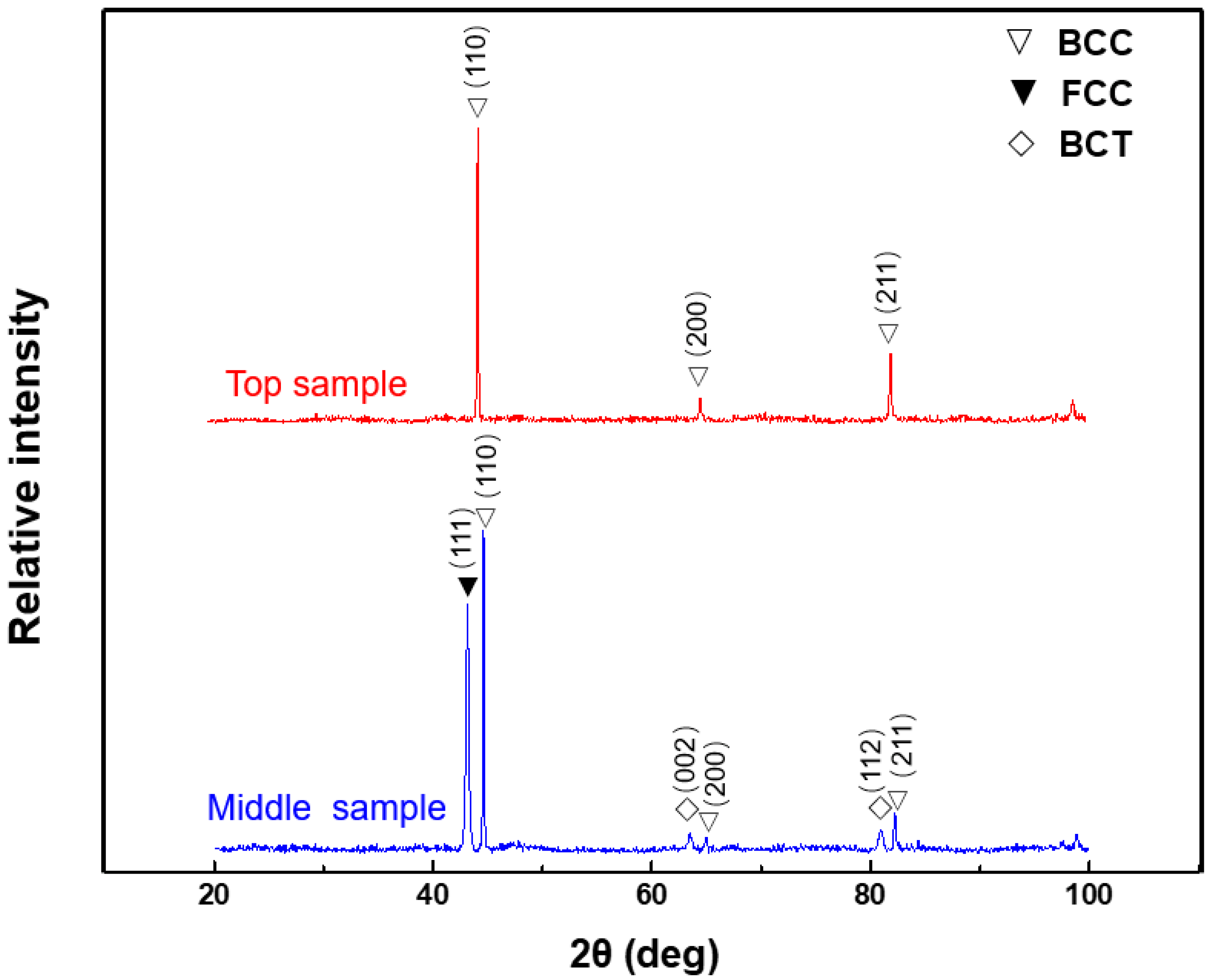

3.3. Phase Composition and Elemental Analysis

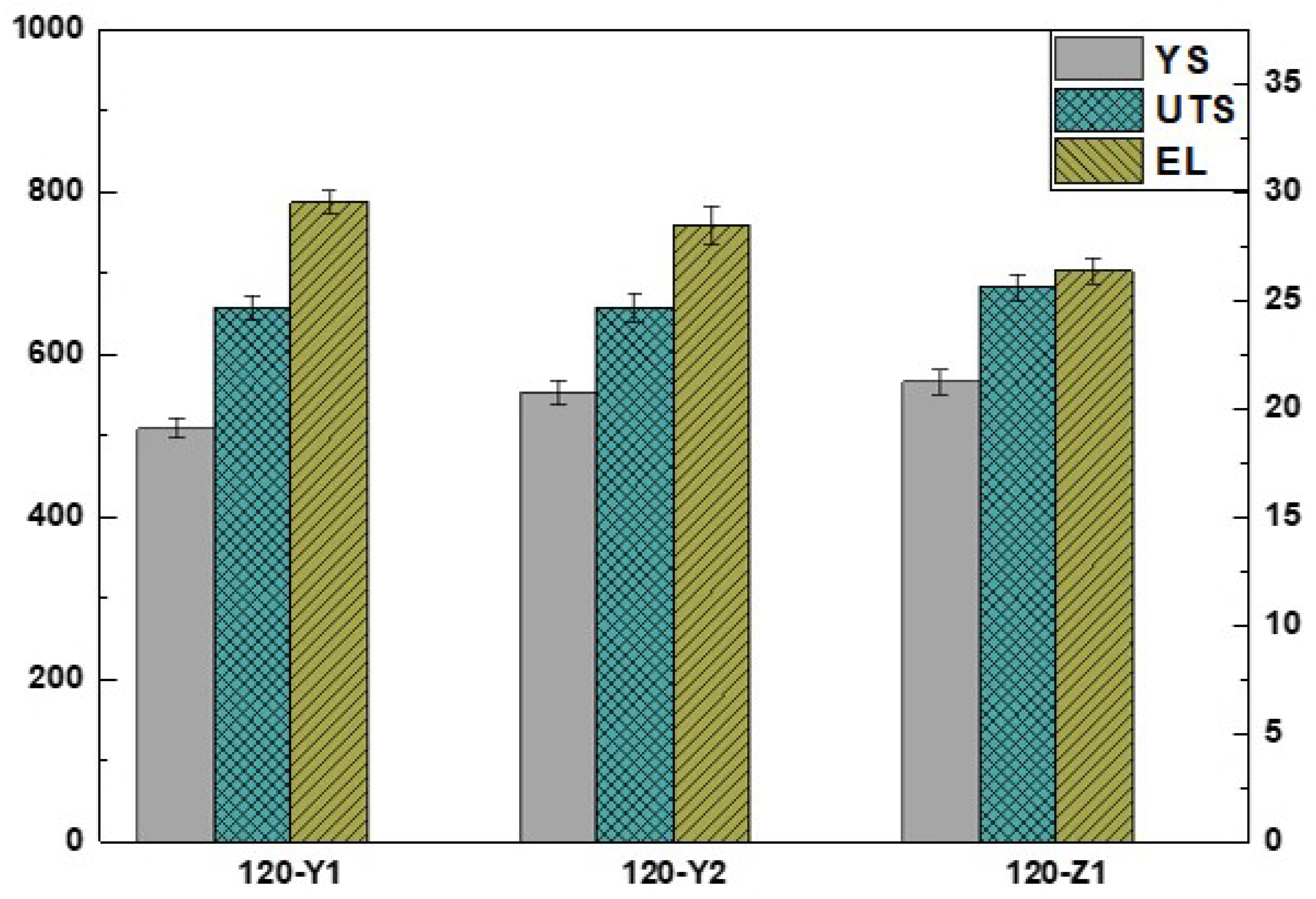

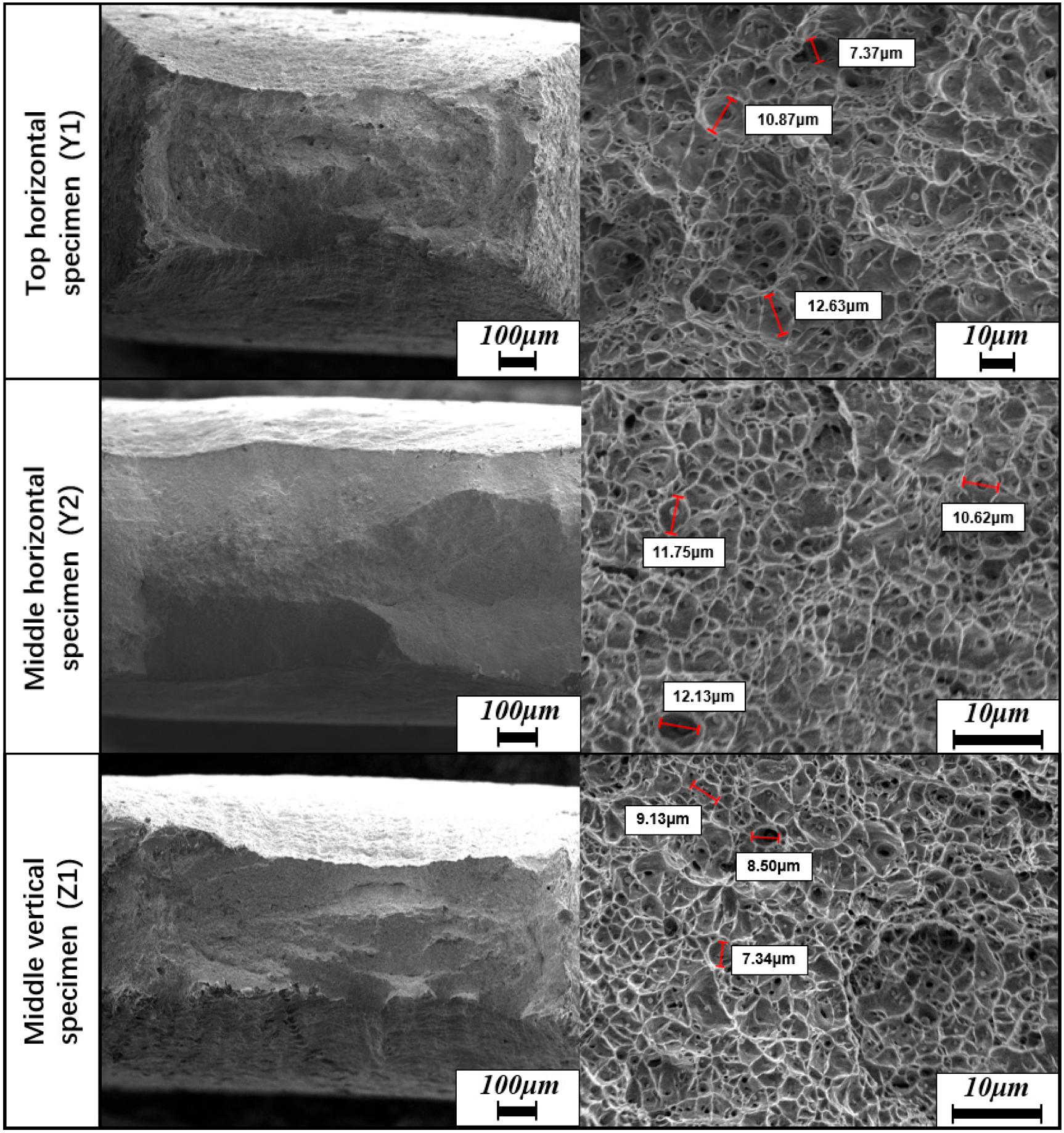

3.4. Mechanical Properties

4. Conclusions

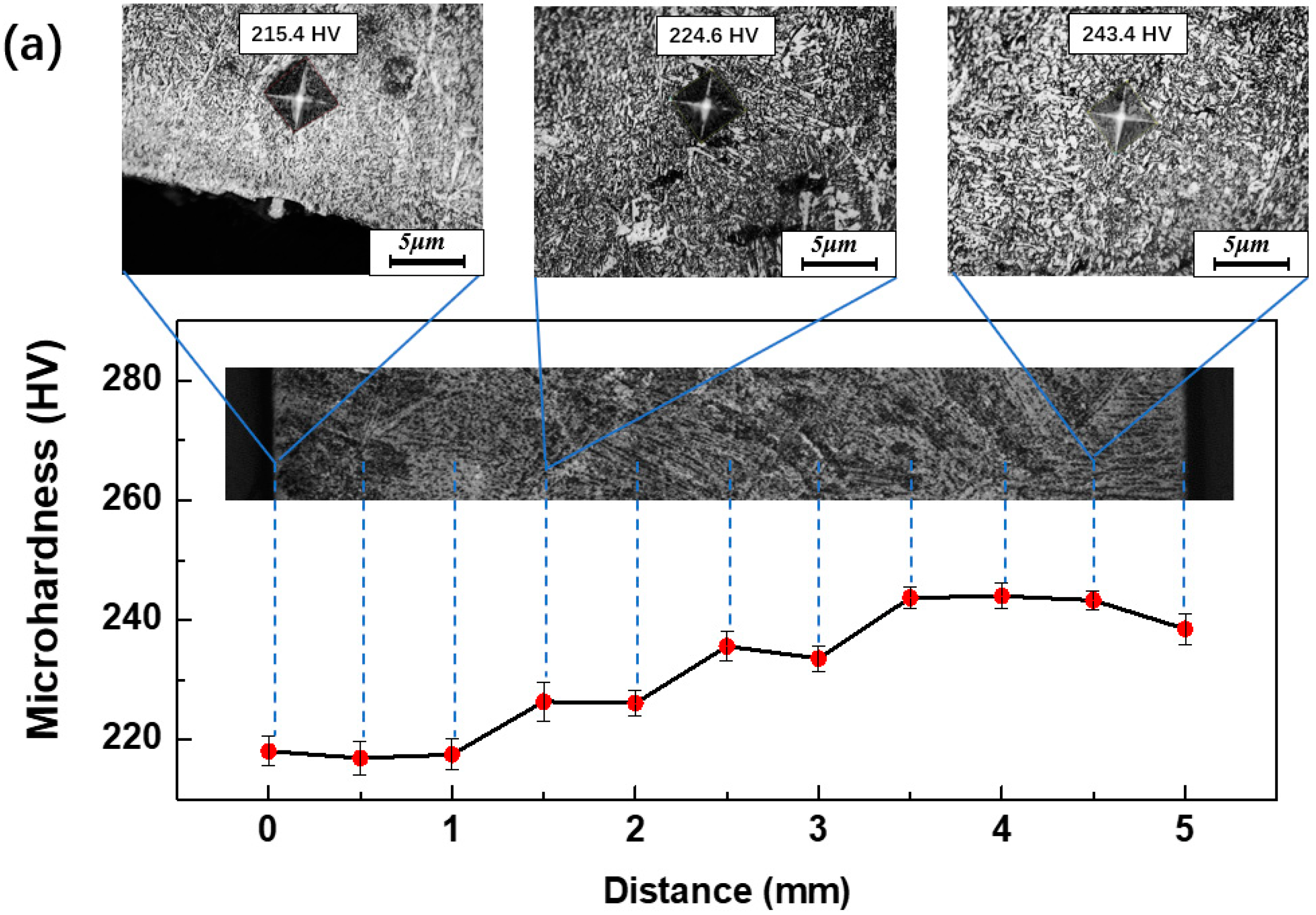

- (a)

- The microstructure of the deposited wall of HSLA is mainly acicular ferrite, and there are longitudinal preferentially growing dendrites along the deposition direction. With the deposition height accumulation, the top sample’s interlayer temperature increases, and the amount of acicular ferrite in the tissue decreases, while the amount of quasi-polygonal ferrite, Widmanstatten ferrite, increases.

- (b)

- Since the deposited samples do not show periodic grain size changes, the microhardness values do not show alternating changes. The hardness of the top sample showed a decreasing trend from bottom to top along the deposition direction, while the hardness of the middle sample was uniform and stable, and the microhardness change was consistent with the corresponding microstructure evolution.

- (c)

- The microstructure gradient in the sample along the deposition direction does not lead to a significant difference in the tensile strength of the sample at different heights. On the contrary, the ductility of the longitudinal sample is less than that of the transverse sample, indicating anisotropy in the deposited sample, which is related to the directional growth of grains along the direction of heat flow.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Skobir, D.A. High-strength low-alloy (HSLA) steels. Mater. Tehnol. 2011, 45, 295–301. [Google Scholar]

- Liu, Y.; Shi, L.; Liu, C.; Yu, L.; Yan, Z.; Li, H. Effect of step quenching on microstructures and mechanical properties of HSLA steel. Mater. Sci. Eng. A 2016, 675, 371–378. [Google Scholar] [CrossRef]

- Ricks, R.; Howell, P.; Barritte, G. The nature of acicular ferrite in HSLA steel weld metals. J. Mater. Sci. 1982, 17, 732–740. [Google Scholar] [CrossRef]

- Kvackaj, T.; Bidulská, J.; Bidulský, R.J.M. Overview of HSS steel grades development and study of reheating condition effects on austenite grain size changes. Materials 2021, 14, 1988. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Song, K.; Di Castri, B.; Ya, W.; Yu, X. Microstructure-gradient approach for effective determination of post-heat treatment temperature of an additive manufactured Ti-6Al-4V sample. J. Alloys Compd. 2022, 921, 165630. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.; Santos, T.G.; Oliveira, J. Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire+ arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, W.; Lin, P.; Zhang, Q.; Zhang, X.; Lin, T.; He, P.; Zhuang, Y. An efficient method to engage oxide ceramics in low-temperature interfacial reactions: Microstructure evolution and kinetics behaviors based on supercooling in a transient liquid phase bonding joint. J. Mater. Sci. Technol. 2023, 151, 234–244. [Google Scholar] [CrossRef]

- Cunningham, C.; Flynn, J.; Shokrani, A.; Dhokia, V.; Newman, S. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, P.; Yu, X. A Literature Review on the Wire and Arc Additive Manufacturing—Welding Systems and Software. Sci. Adv. Mater. 2021, 13, 1391–1400. [Google Scholar] [CrossRef]

- Jafari, D.; Vaneker, T.H.; Gibson, I. Wire and arc additive manufacturing: Opportunities and challenges to control the quality and accuracy of manufactured parts. Mater. Des. 2021, 202, 109471. [Google Scholar] [CrossRef]

- Monteiro, H.; Carmona-Aparicio, G.; Lei, I.; Despeisse, M. Energy and material efficiency strategies enabled by metal additive manufacturing–A review for the aeronautic and aerospace sectors. Energy Rep. 2022, 8, 298–305. [Google Scholar] [CrossRef]

- Aldalur, E.; Veiga, F.; Suárez, A.; Bilbao, J.; Lamikiz, A. High deposition wire arc additive manufacturing of mild steel: Strategies and heat input effect on microstructure and mechanical properties. J. Manuf. Process. 2020, 58, 615–626. [Google Scholar] [CrossRef]

- Jiang, F.; Sun, L.; Huang, R.; Jiang, H.; Bai, G.; Qi, X.; Liu, C.; Su, Y.; Guo, C.; Wang, J. Effects of Heat Input on Morphology of Thin-Wall Components Fabricated by Wire and Arc Additive Manufacturing. Adv. Eng. Mater. 2021, 23, 2001443. [Google Scholar] [CrossRef]

- Rosli, N.A.; Alkahari, M.R.; bin Abdollah, M.F.; Maidin, S.; Ramli, F.R.; Herawan, S.G. Review on effect of heat input for wire arc additive manufacturing process. J. Mater. Res. Technol. 2021, 11, 2127–2145. [Google Scholar] [CrossRef]

- Kornokar, K.; Nematzadeh, F.; Mostaan, H.; Sadeghian, A.; Moradi, M.; Waugh, D.G.; Bodaghi, M.J.M. Influence of heat input on microstructure and mechanical properties of gas tungsten arc welded HSLA S500MC steel joints. Metals 2022, 12, 565. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Avila, J.A.; Santos, T.G.; Miranda, R.; Oliveira, J. Wire and arc additive manufacturing of HSLA steel: Effect of thermal cycles on microstructure and mechanical properties. Addit. Manuf. 2019, 27, 440–450. [Google Scholar] [CrossRef]

- Yildiz, A.S.; Davut, K.; Koc, B.; Yilmaz, O. Wire arc additive manufacturing of high-strength low alloy steels: Study of process parameters and their influence on the bead geometry and mechanical characteristics. Int. J. Adv. Manuf. Technol. 2020, 108, 3391–3404. [Google Scholar] [CrossRef]

- Rodideal, N.; Machado, C.M.; Infante, V.; Braga, D.F.; Santos, T.G.; Vidal, C. Mechanical characterization and fatigue assessment of wire and arc additively manufactured HSLA steel parts. Int. J. Fatigue 2022, 164, 107146. [Google Scholar] [CrossRef]

- Sun, L.; Jiang, F.; Huang, R.; Yuan, D.; Guo, C.; Wang, J. Anisotropic mechanical properties and deformation behavior of low-carbon high-strength steel component fabricated by wire and arc additive manufacturing. Mater. Sci. Eng. A 2020, 787, 139514. [Google Scholar] [CrossRef]

- Panchenko, O.; Kladov, I.; Kurushkin, D.; Zhabrev, L.; Ryl’kov, E.; Zamozdra, M. Effect of thermal history on microstructure evolution and mechanical properties in wire arc additive manufacturing of HSLA steel functionally graded components. Mater. Sci. Eng. A 2022, 851, 143569. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Huang, D.; Zhang, F. Formation and improvement of surface waviness for additive manufacturing 5A06 aluminium alloy component with GTAW system. Rapid Prototyp. J. 2018. [Google Scholar] [CrossRef]

- Bidulsky, R.; Gobber, F.S.; Bidulska, J.; Ceroni, M.; Kvackaj, T.; Grande, M.A.J.M. Coated metal powders for laser powder bed fusion (L-PBF) processing: A review. Metals 2021, 11, 1831. [Google Scholar] [CrossRef]

- Nogi, K.; Ogino, K.; McLean, A.; Miller, W. The temperature coefficient of the surface tension of pure liquid metals. Metall. Trans. B 1986, 17, 163–170. [Google Scholar] [CrossRef]

- Nagalingam, A.P.; Vohra, M.S.; Kapur, P.; Yeo, S.H.J.A.S. Effect of cut-off, evaluation length, and measurement area in profile and areal surface texture characterization of as-built metal additive manufactured components. Appl. Sci. 2021, 11, 5089. [Google Scholar] [CrossRef]

- Zhao, H.; Palmiere, E.J. Effect of austenite grain size on acicular ferrite transformation in a HSLA steel. Mater. Charact. 2018, 145, 479–489. [Google Scholar] [CrossRef]

- Shao, Y.; Liu, C.; Yan, Z.; Li, H.; Liu, Y. Formation mechanism and control methods of acicular ferrite in HSLA steels: A review. J. Mater. Sci. Technol. 2018, 34, 737–744. [Google Scholar] [CrossRef]

- Darivandpour, M.; Dehmolaei, R.; Ranjbar, K. Investigating the heat input effect of the GTAW process upon the microstructure and HAZ extension of HSLA-100 steel weld joints using thermal cycles. Int. J. Iron Steel Soc. Iran 2021, 17, 57–69. [Google Scholar]

- Cho, L.; Tselikova, A.; Holtgrewe, K.; De Moor, E.; Schmidt, R.; Findley, K.O. Critical assessment 42: Acicular ferrite formation and its influence on weld metal and heat-affected zone properties of steels. Mater. Sci. Technol. 2022, 38, 1425–1433. [Google Scholar] [CrossRef]

- Zuo, Z.; Haowei, M.; Yarigarravesh, M.; Assari, A.H.; Tayyebi, M.; Tayebi, M.; Hamawandi, B.J.M. Microstructure, Fractography, and Mechanical Properties of Hardox 500 Steel TIG-Welded Joints by Using Different Filler Weld Wires. Materials 2022, 15, 8196. [Google Scholar] [CrossRef]

- John, M.; Kumar, P.A.; Bhat, K.U. Effect of filler wire strength on high strength low alloy steels. Mater. Today Proc. 2022, 49, 1286–1293. [Google Scholar] [CrossRef]

- Li, X.; Shang, C.; Ma, X.; Gault, B.; Subramanian, S.; Sun, J.; Misra, R.D.K. Elemental distribution in the martensite–austenite constituent in intercritically reheated coarse-grained heat-affected zone of a high-strength pipeline steel. Scr. Mater. 2017, 139, 67–70. [Google Scholar] [CrossRef]

- Rafieazad, M.; Ghaffari, M.; Vahedi Nemani, A.; Nasiri, A. Microstructural evolution and mechanical properties of a low-carbon low-alloy steel produced by wire arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 2121–2134. [Google Scholar] [CrossRef]

- Ghaffari, M.; Nemani, A.V.; Nasiri, A. Microstructure and mechanical behavior of PH 13–8Mo martensitic stainless steel fabricated by wire arc additive manufacturing. Addit. Manuf. 2022, 49, 102374. [Google Scholar] [CrossRef]

- Nemani, A.V.; Ghaffari, M.; Salahi, S.; Lunde, J.; Nasiri, A. Effect of interpass temperature on the formation of retained austenite in a wire arc additive manufactured ER420 martensitic stainless steel. Mater. Chem. Phys. 2021, 266, 124555. [Google Scholar] [CrossRef]

- Wang, Y.; Tomota, Y.; Ohmura, T.; Morooka, S.; Gong, W.; Harjo, S. Real time observation of martensite transformation for a 0.4 C low alloyed steel by neutron diffraction. Acta Mater. 2020, 184, 30–40. [Google Scholar] [CrossRef]

- Ge, J.; Lin, J.; Fu, H.; Lei, Y.; Xiao, R.J.M. A spatial periodicity of microstructural evolution and anti-indentation properties of wire-arc additive manufacturing 2Cr13 thin-wall part. Mater. Des. 2018, 160, 218–228. [Google Scholar] [CrossRef]

- Dirisu, P.; Ganguly, S.; Mehmanparast, A.; Martina, F.; Williams, S. Analysis of fracture toughness properties of wire+ arc additive manufactured high strength low alloy structural steel components. Mater. Sci. Eng. A 2019, 765, 138285. [Google Scholar] [CrossRef]

| Grade | C | Mn | Si | S | P | Cr | Ni | Cu | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| ER120S-G | 0.09 | 1.60 | 0.80 | 0.01 | 0.01 | 0.2 | 1.6 | / | 0.3 | Bal. |

| Q235-B | 0.16 | 0.53 | 0.21 | 0.03 | 0.02 | 0.3 | 0.3 | 0.3 | / | Bal. |

| Parameters | Values |

|---|---|

| Welding current (A) | 170 |

| Welding voltage (V) | ~16 |

| Wire feeding speed (m/min) | 3 |

| Travel speed (m/min) | 0.7 |

| Residence time at the arc extinction (s) | 0.3 |

| Cooling time between layers (S) | 240 |

| Melt drop transition mode | Pulse |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, K.; Lin, Z.; Fa, Y.; Zhao, X.; Zhu, Z.; Ya, W.; Sun, Z.; Yu, X. Microstructure and Mechanical Properties of High-Strength, Low-Alloy Steel Thin-Wall Fabricated with Wire and Arc Additive Manufacturing. Metals 2023, 13, 764. https://doi.org/10.3390/met13040764

Song K, Lin Z, Fa Y, Zhao X, Zhu Z, Ya W, Sun Z, Yu X. Microstructure and Mechanical Properties of High-Strength, Low-Alloy Steel Thin-Wall Fabricated with Wire and Arc Additive Manufacturing. Metals. 2023; 13(4):764. https://doi.org/10.3390/met13040764

Chicago/Turabian StyleSong, Kaijie, Zidong Lin, Yongzhe Fa, Xuefeng Zhao, Ziqian Zhu, Wei Ya, Zhen Sun, and Xinghua Yu. 2023. "Microstructure and Mechanical Properties of High-Strength, Low-Alloy Steel Thin-Wall Fabricated with Wire and Arc Additive Manufacturing" Metals 13, no. 4: 764. https://doi.org/10.3390/met13040764

APA StyleSong, K., Lin, Z., Fa, Y., Zhao, X., Zhu, Z., Ya, W., Sun, Z., & Yu, X. (2023). Microstructure and Mechanical Properties of High-Strength, Low-Alloy Steel Thin-Wall Fabricated with Wire and Arc Additive Manufacturing. Metals, 13(4), 764. https://doi.org/10.3390/met13040764