Description of the New Eutectic Al-Ca-Cu System in the Aluminum Corner

Abstract

1. Introduction

2. Materials and Methods

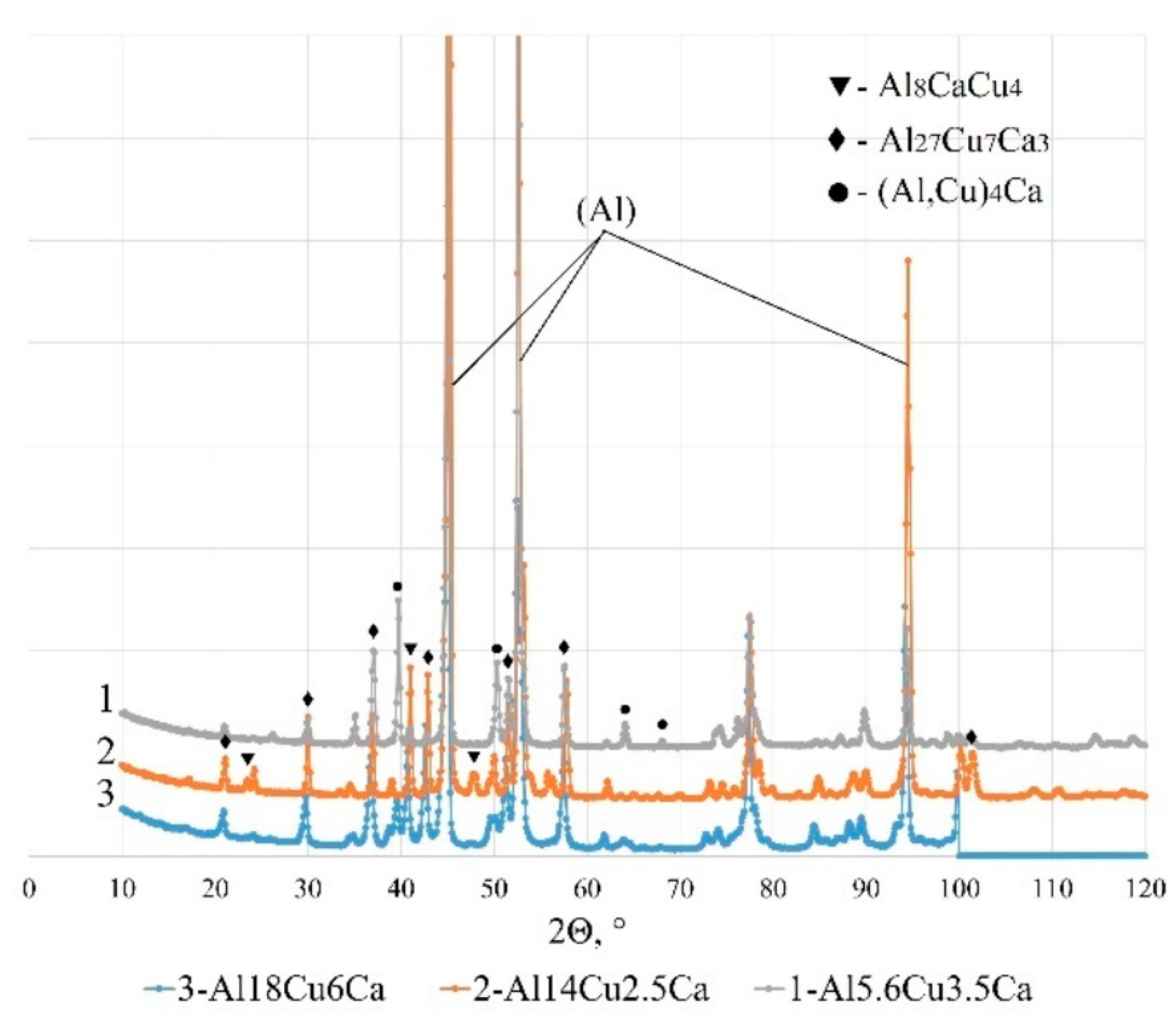

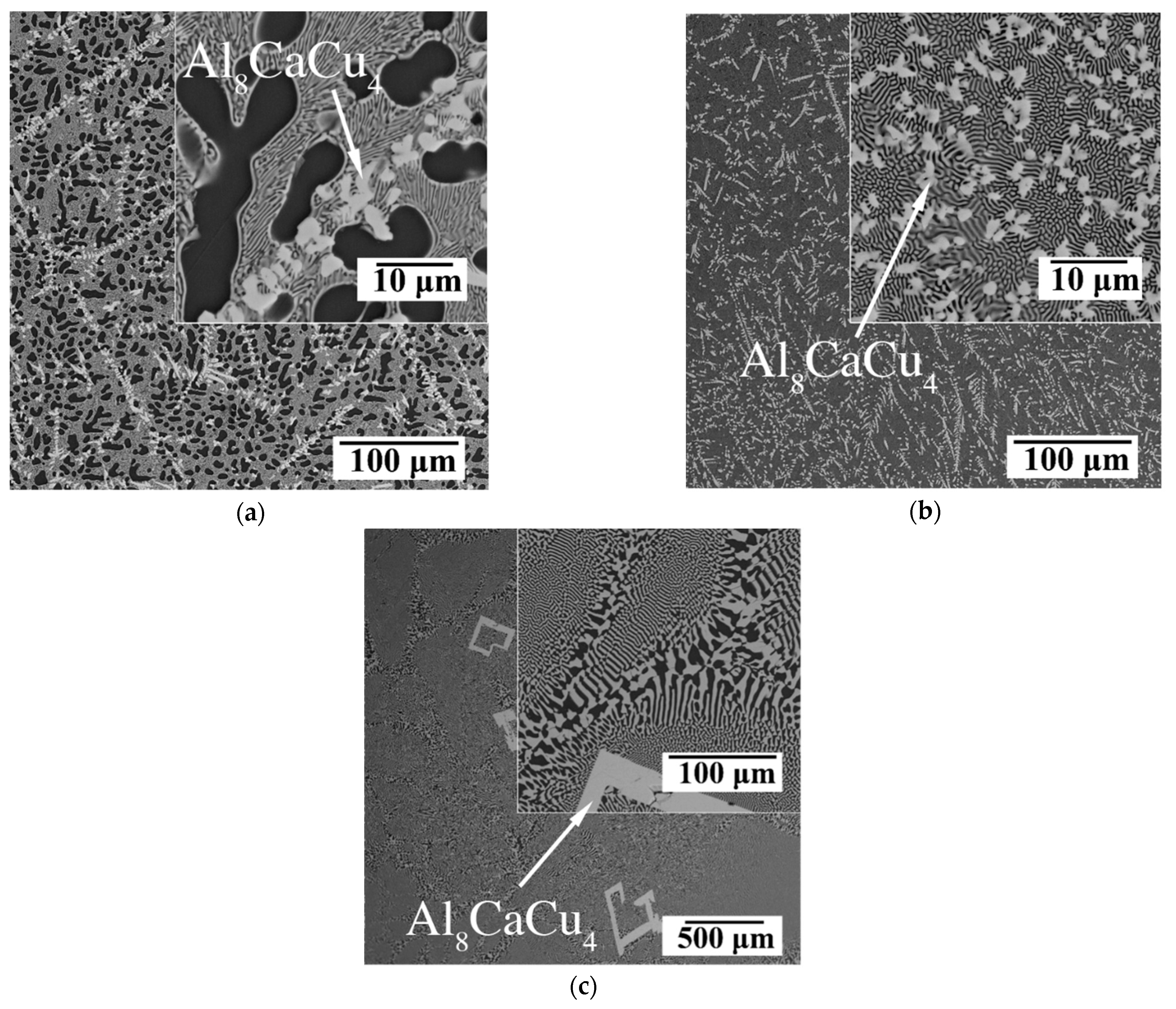

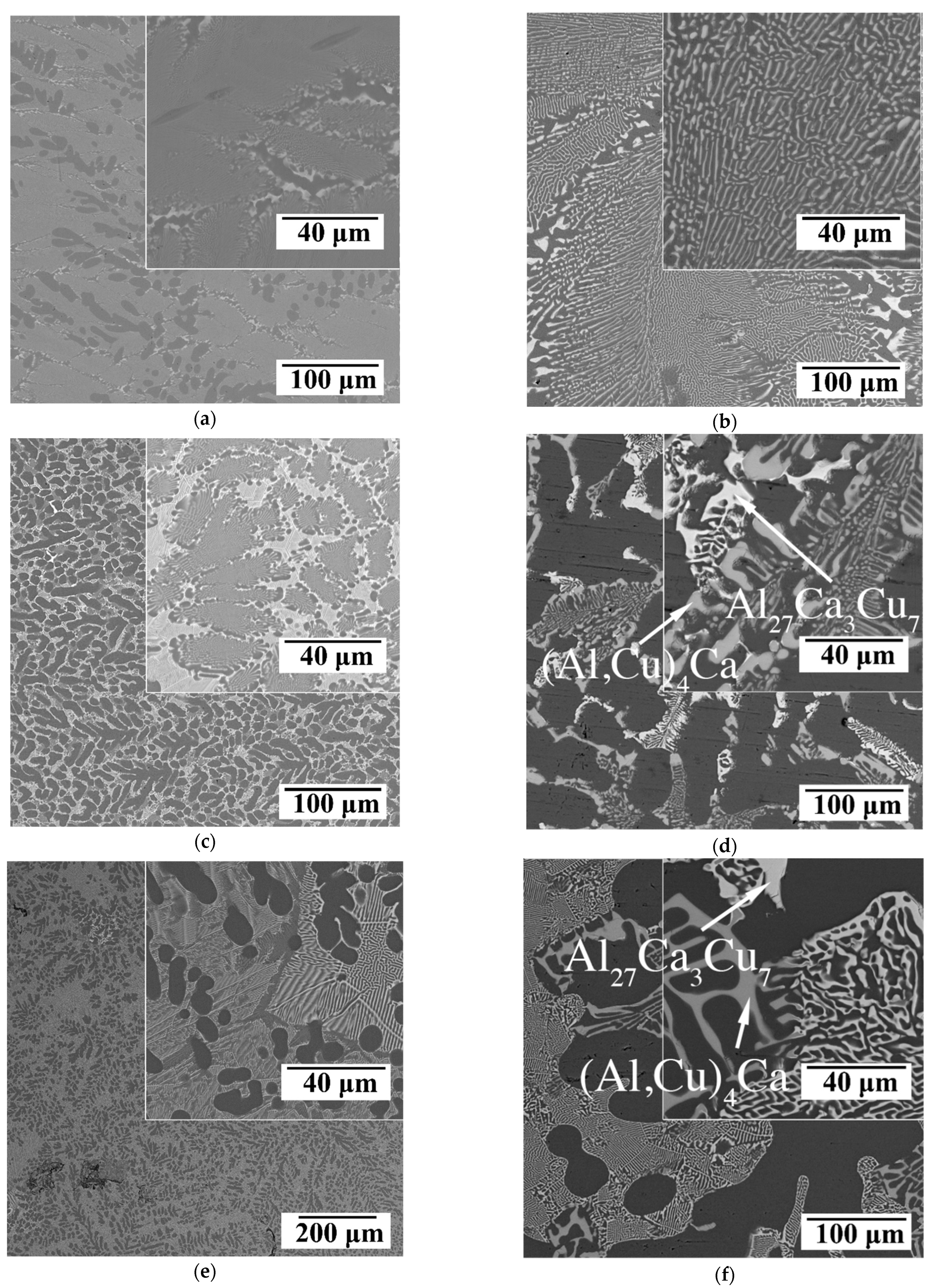

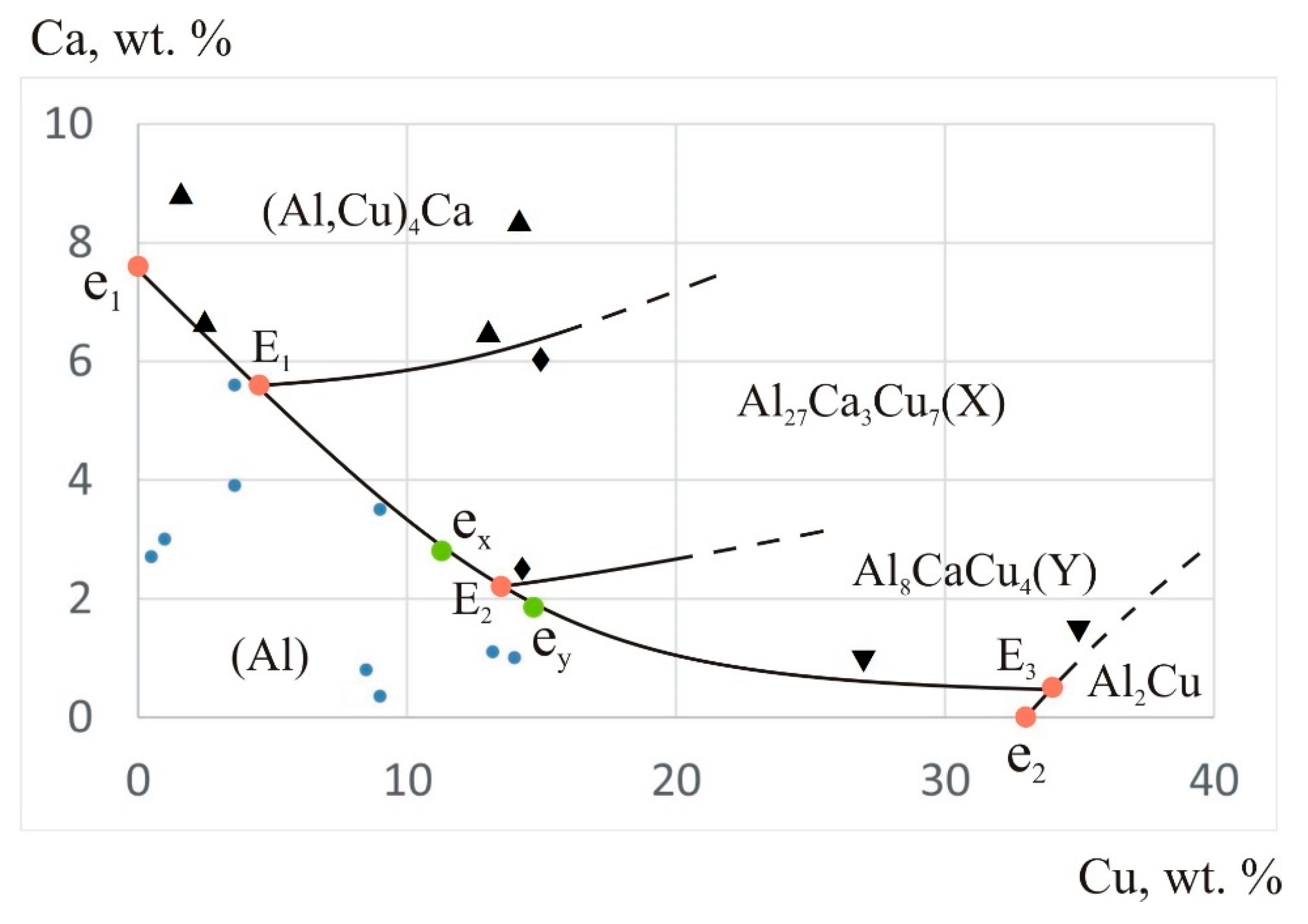

3. Results and Discussion

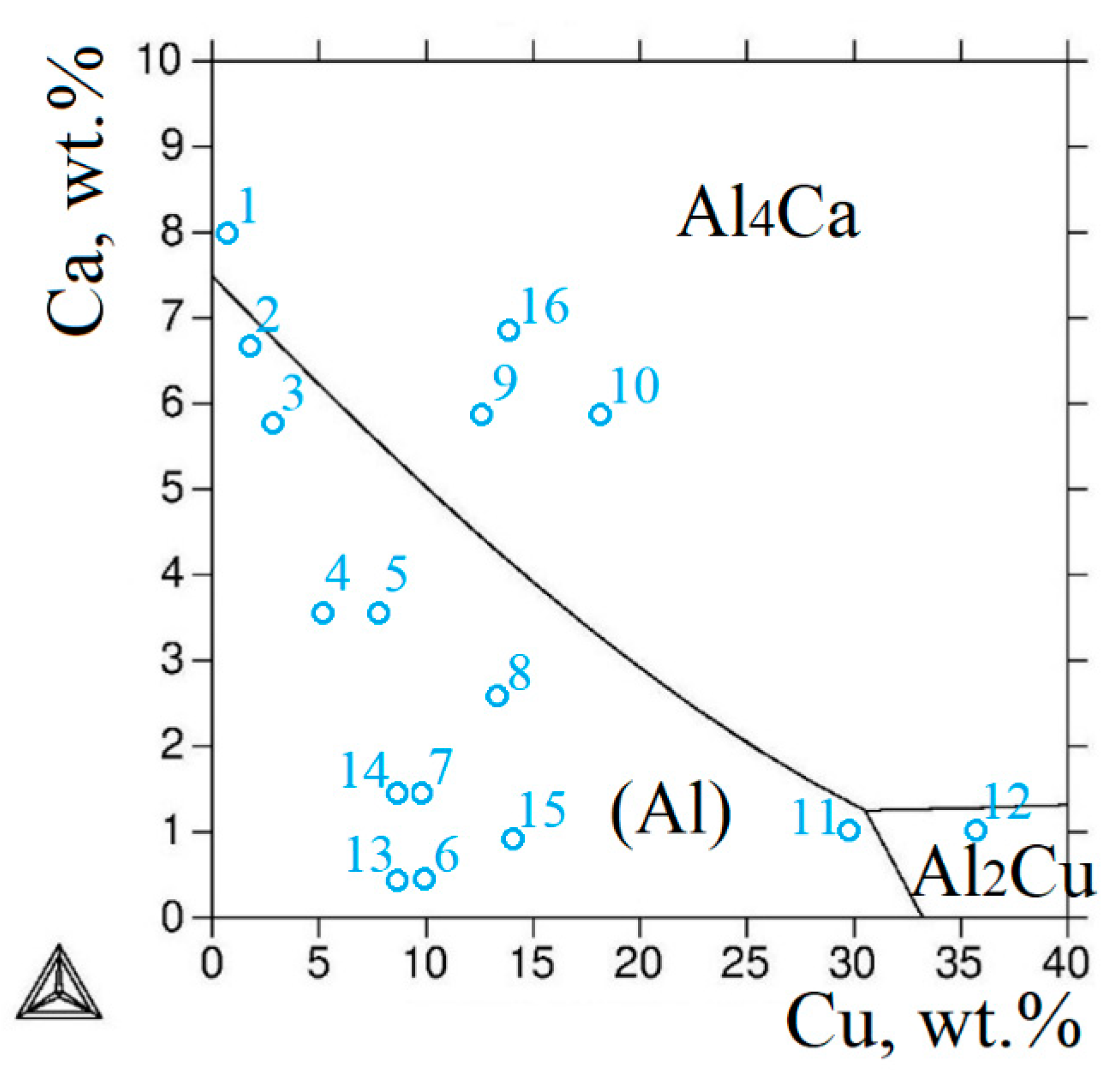

3.1. Liquidus Projection

3.2. Isothermal Section at 530 °C

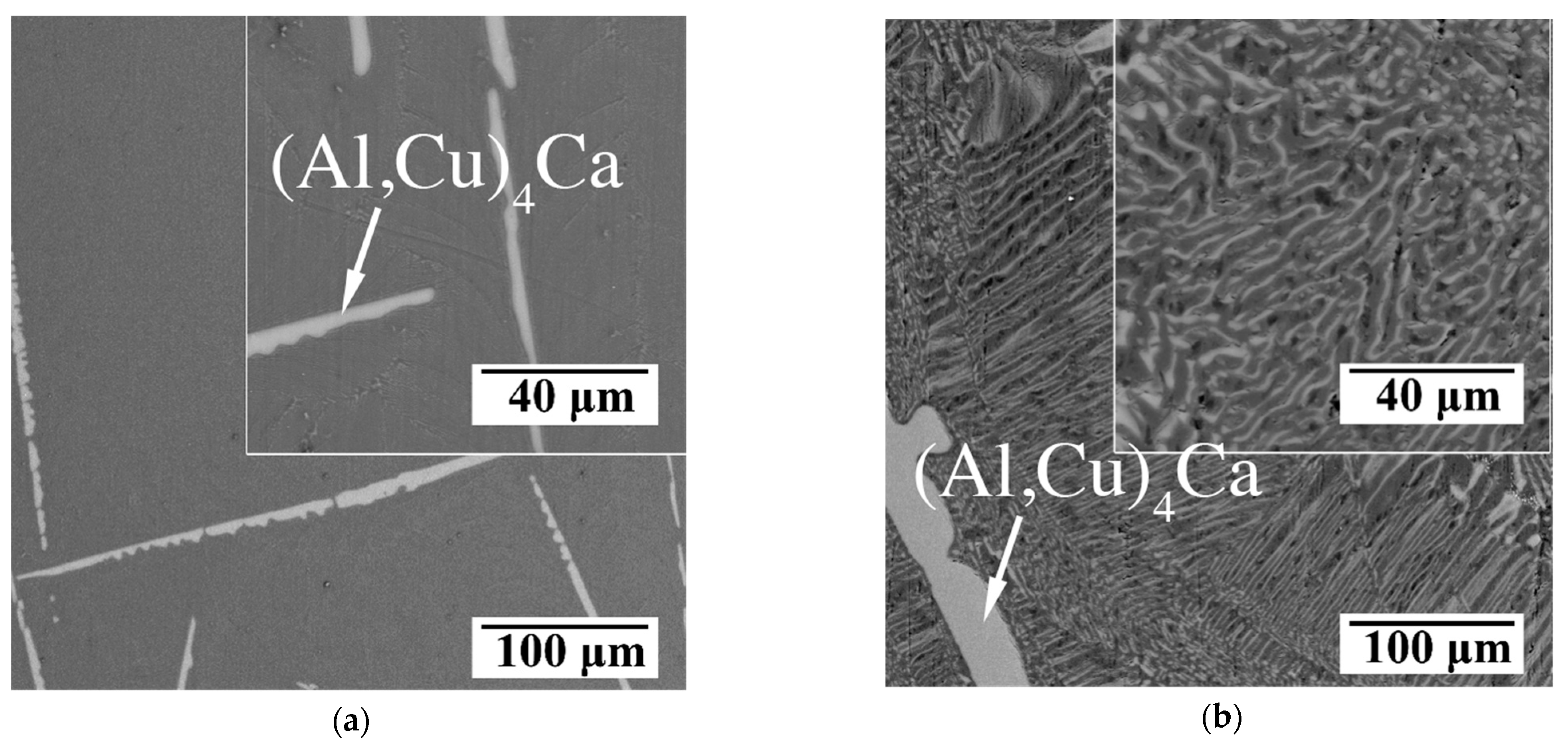

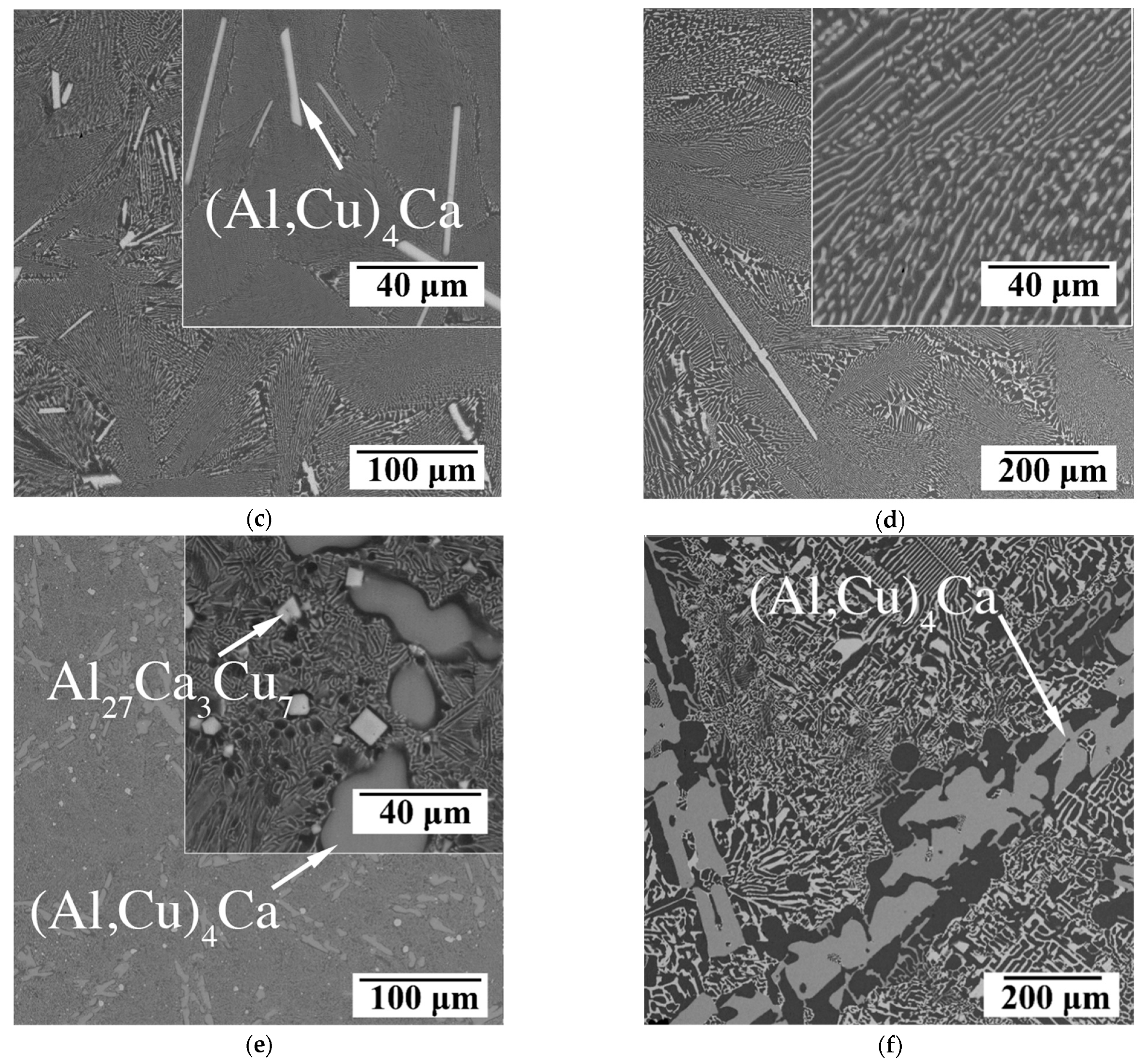

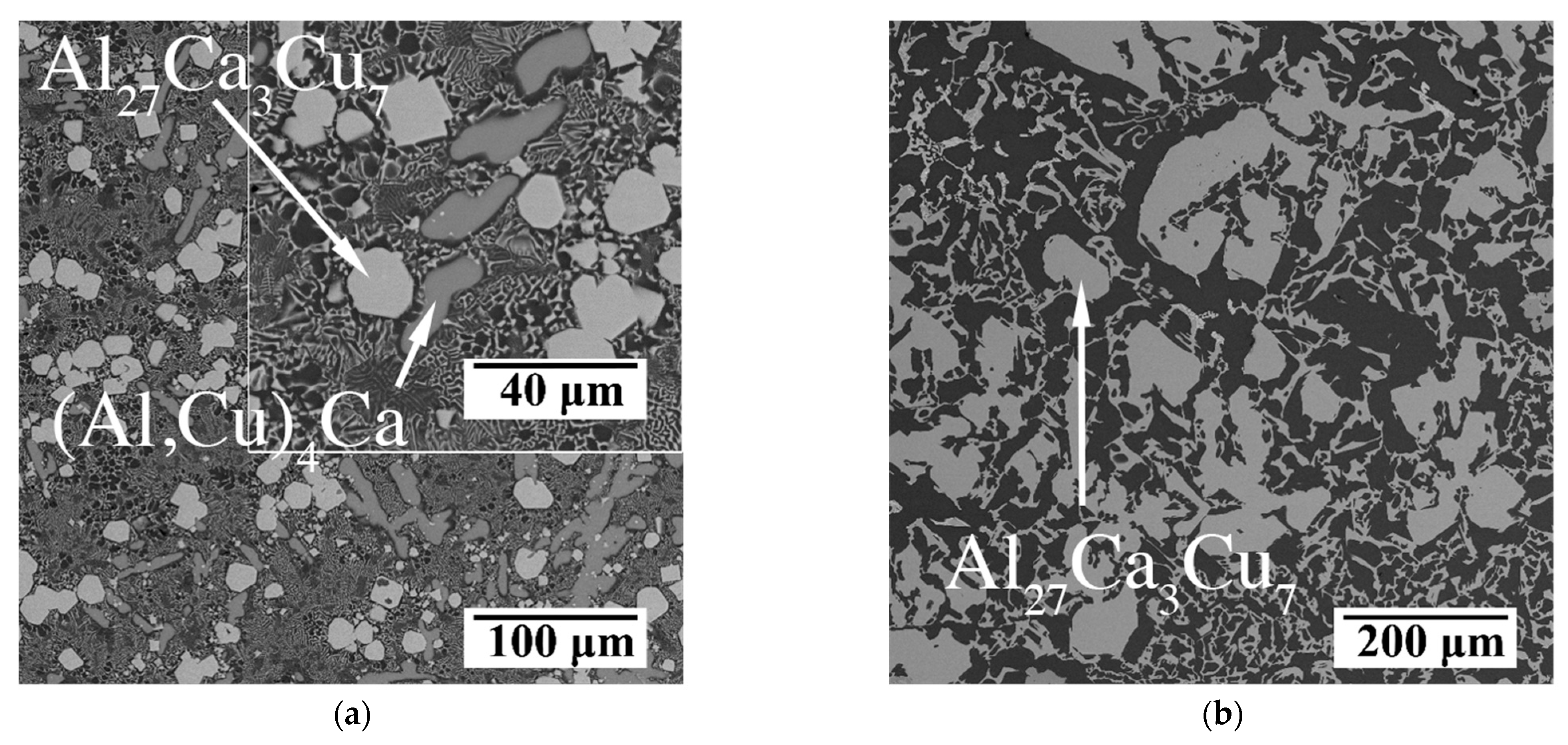

3.3. Alloy Examples

4. Summary

- (1)

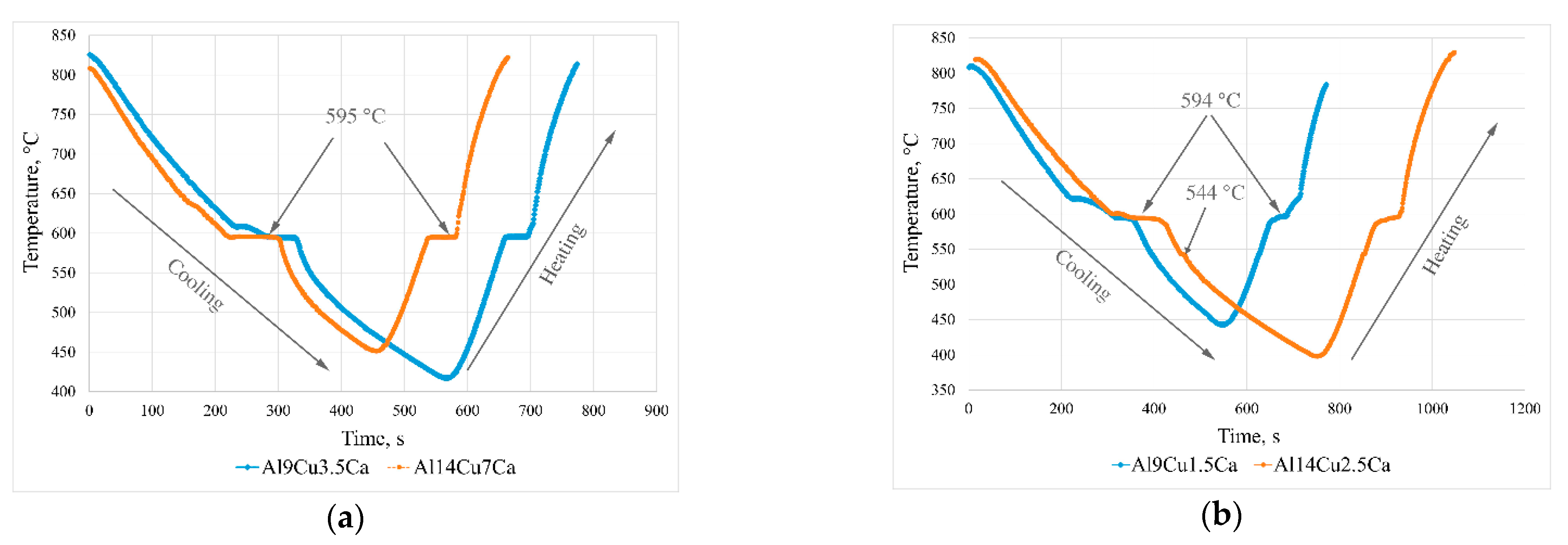

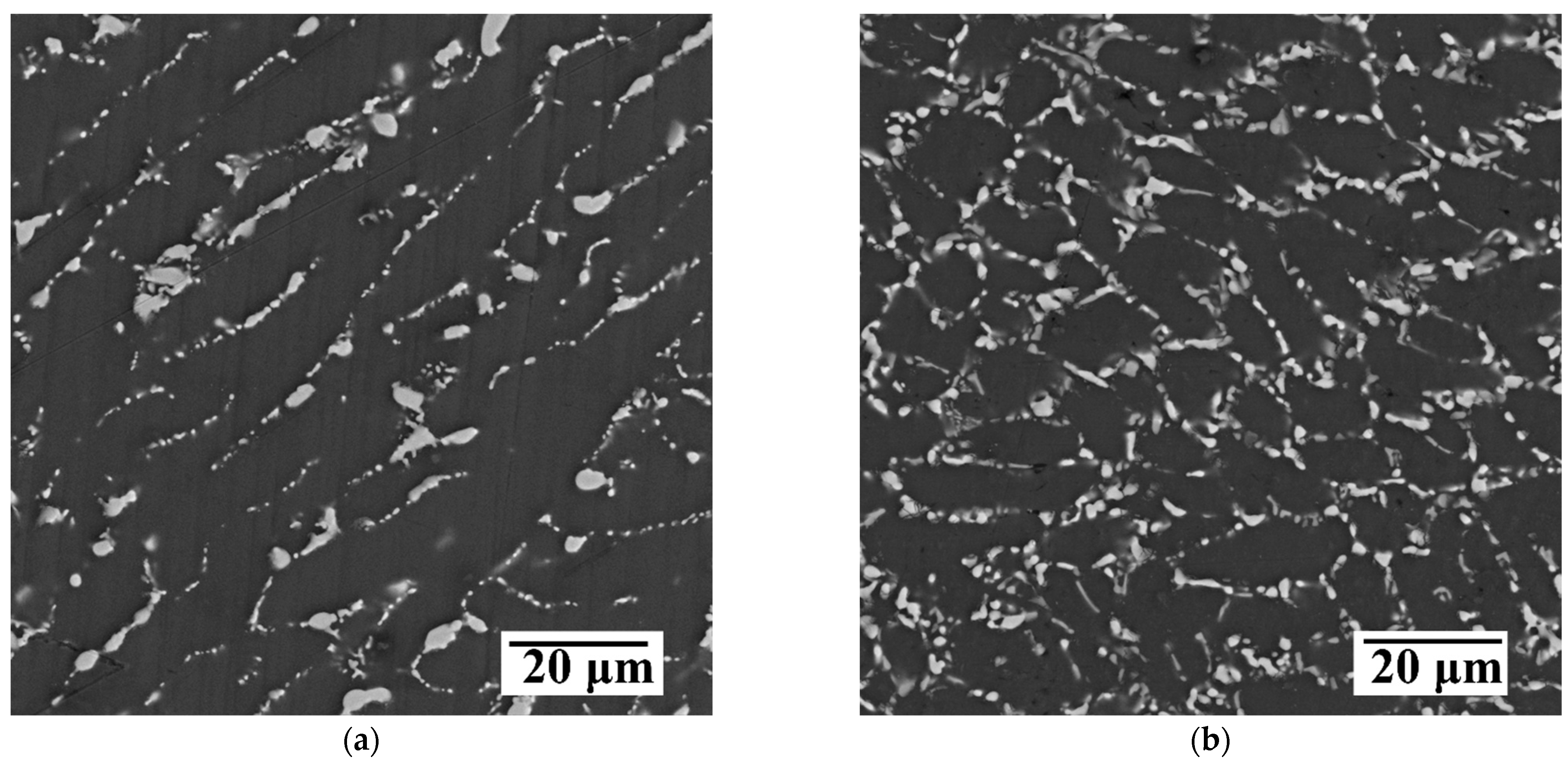

- The liquidus projection of the Al-Ca-Cu system in the aluminum corner was suggested based on experiential studies of the microstructure and phase composition of model alloys. The suggested structure of the diagram has two quasi-binary sections: (Al)-Al27Ca3Cu7 and (Al)-Al8CaCu4, and three invariant ternary eutectic transformations: L→(Al) + (Al,Cu)4Ca + Al27Ca3Cu7 (at 5.6 wt.% Ca, 4.5 wt.% Cu, 595 °C), L→(Al) + Al27Ca3Cu7 +Al8CaCu4 (at 2.2 wt.% Ca, 13.5 wt.% Cu, 594 °C) and L→(Al) + Al8CaCu4 + Al2Cu (at 0.5 wt.% Ca, 34 wt.% Cu, 544 °C). The eutectic point in the quasi-binary sections is accepted to be as follows: L→(Al) + Al27Ca3Cu7 (at 2.8 wt.% Ca, 11.3 wt.% Cu) and L→(Al) + Al8CaCu4 (at 1.8 wt.% Ca, 14.7 wt.% Cu).

- (2)

- A study of the copper solubility limit in (Al) revealed that the copper solubility in the (Al) + Al27Ca3Cu7 + (Al,Cu)4Ca ternary phase filed is small and can be accepted as a few tenths of a percent. In the (Al)+Al27Ca3Cu7+ Al8CaCu4 ternary phase filed, the copper solubility reaches ~2.4 wt.%, while in the other ternary phase filed, (Al) + Al8CaCu4 + Al2Cu is close to the solubility limit, i.e., ~5.1 wt.%, which is close to that for the binary Al-Cu and the ternary Al-Ce-Cu systems. Thus, the alloys pertaining to the (Al) + Al8CaCu4 quasi-binary section and the (Al) + Al8CaCu4 + Al2Cu ternary phase field can be prone to precipitation hardening.

- (3)

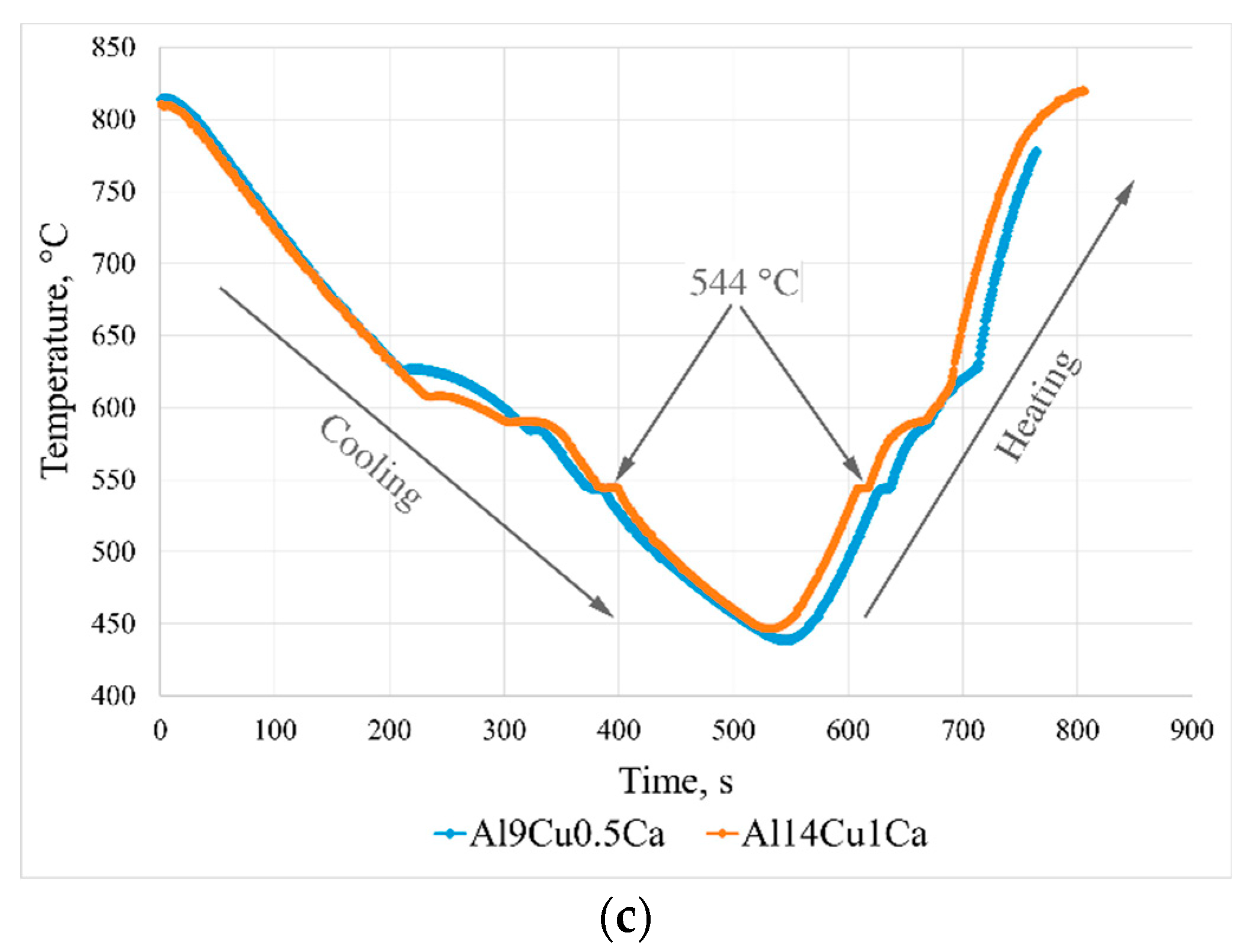

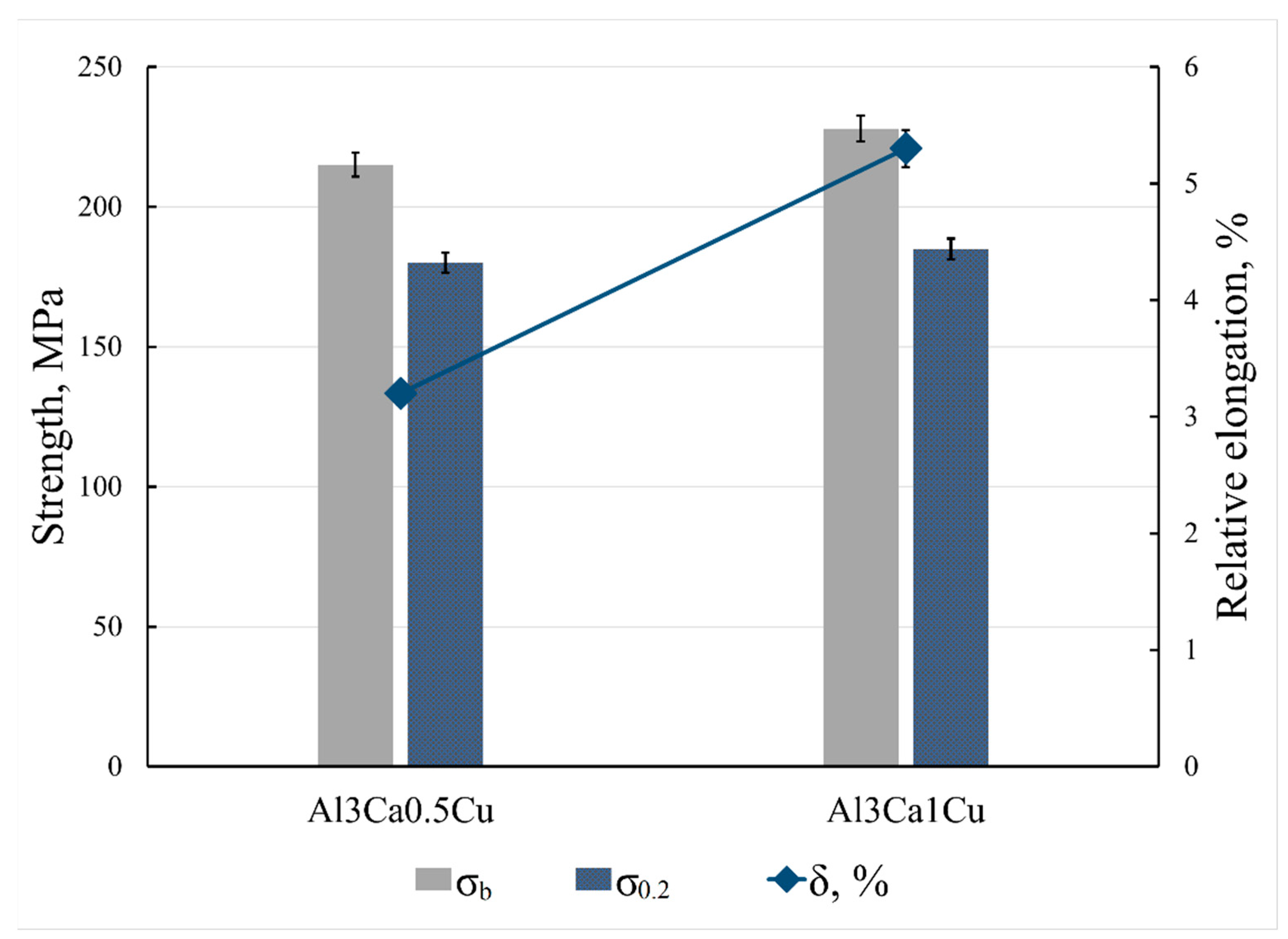

- The prospects of this system for designing new eutectic type alloys with a natural composite structure were demonstrated for the example of the Al3Ca0.5Cu and Al3Ca1Cu alloys. The alloys have an ultra-fine eutectic structure based on the (Al,Cu)4Ca eutectic phase. The alloys showed high manufacturability for moderate temperature hot rolling (300 °C). Uniaxial tensile tests carried out for the obtained 2 mm sheet alloys revealed the following mechanical properties: UTS up to 220 MPa, YS up to 180 MPa, and relative elongation up to 5.5%, which are acceptable for the model alloys.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Polmear, I.J.; Couper, M.J. Design and development of an experimental wrought aluminum alloy for use at elevated temperatures. Metall. Trans. A 1988, 19, 1027–1035. [Google Scholar] [CrossRef]

- Mondol, S.; Kashyap, S.; Kumar, S.; Chattopadhyay, K. Improvement of high temperature strength of 2219 alloy by Sc and Zr addition through a novel three-stage heat treatment route. Mater. Sci. Eng. A 2018, 732, 157–166. [Google Scholar] [CrossRef]

- Bourgeois, L.; Dwyer, C.; Weyland, M.; Nie, J.; Muddle, B.C. Structure and energetics of the coherent interface between the θ′ precipitate phase and aluminium in Al–Cu. Acta Mater. 2011, 59, 7043–7050. [Google Scholar] [CrossRef]

- Ding, H.; Fu, H.Z.; Liu, Z.Y.; Chen, R.Z.; Liu, B.C. Compensation of solidification contraction and hot cracks tendency of alloy. Acta Metall. Sin. 1997, 33, 921–926. [Google Scholar]

- Sims, Z.C.; Weiss, D.; McCall, S.K.; McGuire, M.A.; Ott, R.T.; Geer, T.; Rios, O.; Turchi, P.A.E. Cerium-based, intermetallic-strengthened aluminum casting alloy: High-volume co-product development. JOM 2016, 68, 1940–1947. [Google Scholar] [CrossRef]

- Belov, N.A.; Khvan, A.V.; Alabin, A.N. Microstructure and phase composition of Al-Ce-Cu alloys in the Al-rich corner. Mater. Sci. Forum 2006, 519–521, 395–400. [Google Scholar] [CrossRef]

- Li, M.; Wang, H.; Wei, Z.; Zhu, Z. The effect of Y on the hot-tearing resistance of Al–5 wt.% Cu based alloy. Mater. Des. 2010, 31, 2483–2487. [Google Scholar] [CrossRef]

- Belov, N.A.; Khvan, A.V. The ternary Al–Ce–Cu phase diagram in the aluminum-rich corner. Acta Mater. 2007, 55, 5473–5482. [Google Scholar] [CrossRef]

- Pozdniakov, A.V.; Barkov, R.Y.; Amer, S.M.; Levchenko, V.S.; Kotov, A.D.; Mikhaylovskaya, A.V. Microstructure, mechanical properties and superplasticity of the Al–Cu–Y–Zr alloy. Mater. Sci. Eng. A 2019, 758, 28–35. [Google Scholar] [CrossRef]

- Manca, D.R.; Churyumov, A.Y.; Pozdniakov, A.V.; Prosviryakov, A.S.; Ryabov, D.K.; Krokhin, A.Y.; Korolev, V.A.; Daubarayte, D.K. Microstructure and Properties of Novel Heat Resistant Al–Ce–Cu Alloy for Additive Manufacturing. Met. Mater. Int. 2019, 25, 633–640. [Google Scholar] [CrossRef]

- Shurkin, P.; Akopyan, T.; Korotkova, N.; Prosviryakov, A.; Bazlov, A.; Komissarov, A.; Moskovskikh, D. Microstructure and Hardness Evolution of Al8Zn7Ni3Mg Alloy after Casting at very Different Cooling Rates. Metals 2020, 10, 762–776. [Google Scholar] [CrossRef]

- Chen, B.; Moon, S.K.; Yao, X.; Bi, G.; Shen, J.; Umeda, J.; Kondoh, K. Strength and strain hardening of a selective laser melted AlSi10Mg alloy. Scripta Mater. 2017, 141, 45–49. [Google Scholar] [CrossRef]

- Delahaye, J.; Tchuindjang, J.T.; Lecomte-Beckers, J.; Rigo, O.; Habraken, A.M.; Mertens, A. Influence of Si precipitates on fracture mechanisms of AlSi10Mg parts processed by Selective Laser Melting. Acta Mater. 2019, 175, 160–170. [Google Scholar] [CrossRef]

- Bahl, S.; Plotkowski, A.; Sisco, K.; Leonard, D.N.; Allard, L.F.; Michi, R.A.; Poplawsky, J.D.; Dehoff, R.; Shyam, A. Elevated temperature ductility dip in an additively manufactured Al-Cu-Ce alloy. Acta Mater. 2021, 220, 117285. [Google Scholar] [CrossRef]

- Bahl, S.; Sisco, K.; Yang, Y.; Theska, F.; Primig, S.; Allard, L.F.; Michi, R.A.; Fancher, C.; Stump, B.; Dehoff, R.; et al. Al-Cu-Ce(-Zr) alloys with an exceptional combination of additive processability and mechanical properties. Addit. Manuf. 2021, 48, 102404. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminium Alloys: Structure and Properties, 1st ed.; Butterworths: London, UK, 1976; pp. 29–30. [Google Scholar]

- Akopyan, T.K.; Belov, N.A.; Lukyanchuk, A.A.; Letyagin, N.V.; Sviridova, T.A.; Petrova, A.N.; Fortuna, A.S.; Musin, A.F. Effect of high pressure torsion on the precipitation hardening in Al–Ca–La based eutectic alloy. Mater. Sci. Eng. A 2021, 802, 140633. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Letyagin, N.V.; Sviridova, T.A.; Korotkova, N.O.; Prosviryakov, A.S. New Casting Alloys Based on the Al+Al4(Ca,La) Eutectic. JOM 2020, 72, 3779–3786. [Google Scholar] [CrossRef]

- Belov, N.A.; Naumova, E.A.; Akopyan, T.K.; Doroshenko, V.V. Design of multicomponent aluminium alloy containing 2 wt.% Ca and 0.1 wt.% Sc for cast products. J. Alloys Compd. 2018, 762, 528–536. [Google Scholar] [CrossRef]

- Belov, N.A.; Naumova, E.A.; Akopyan, T.K.; Doroshenko, V.V. Phase Diagram of Al-Ca-Mg-Si System and Its Application for the Design of Aluminum Alloys with High Magnesium Content. Metals 2017, 7, 429. [Google Scholar] [CrossRef]

- Gamin, Y.V.; Belov, N.A.; Akopyan, T.K.; Timofeev, V.N.; Cherkasov, S.O.; Motkov, M.M. Effect of Radial-Shear Rolling on the Structure and Hardening of an Al–8%Zn–3.3%Mg–0.8%Ca–1.1%Fe Alloy Manufactured by Electromagnetic Casting. Materials 2023, 16, 677. [Google Scholar] [CrossRef] [PubMed]

- Belov, N.; Akopyan, T.; Korotkova, N.; Murashkin, M.; Timofeev, V.; Fortuna, A. Structure and Properties of Ca and Zr Containing Heat Resistant Wire Aluminum Alloy Manufactured by Electromagnetic Casting. Metals 2021, 11, 236. [Google Scholar] [CrossRef]

- Letyagin, N.V.; Shurkin, P.K.; Nguen, Z.; Koshmin, A.N. Effect of Thermodeformation Treatment on the Structure and Mechanical Properties of the Al3Ca1Cu1.5Mn Alloy. Phys. Met. Metallogr. 2021, 122, 814–819. [Google Scholar] [CrossRef]

- Letyagin, N.V.; Musin, A.F.; Sichev, L.S. New aluminum-calcium casting alloys based on secondary raw materials. Mater. Today Proc. 2021, 38, 1551–1555. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Sviridova, T.A.; Belov, N.A.; Letyagin, N.V.; Korotitskiy, A.V. Description of intermetallic compounds in equilibrium with aluminum in the new Al–Ca–Cu ternary alloying system. Trans. Nonferrous Met. Soc. China 2023. [Google Scholar]

- Bo, H.; Jin, S.; Zhang, L.G.; Chen, X.M.; Chen, H.M.; Liu, L.B.; Zheng, F.; Jin, Z.P. Thermodynamic assessment of Al-Ce-Cu system. J. Alloys Compd. 2009, 484, 286–295. [Google Scholar] [CrossRef]

- Shelekhov, E.V.; Sviridova, T.A. Programs for X-ray analysis of polycrystalline. Met. Sci. Heat Treat. 2000, 42, 309. [Google Scholar] [CrossRef]

- Andersson, J.O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc and DICTRA, Computational Tools for Materials Science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Glazoff, M.V.; Khvan, A.; Zolotorevsky, V.S.; Belov, N.A. Casting Aluminum Alloys: Their Physical and Mechanical Metallurgy, 2nd ed.; Elsevier: London, UK, 2010; pp. 52–53. [Google Scholar]

- Letyagin, N.V.; Akopyan, T.K.; Nguen, Z.; Sviridova, T.A.; Koshmin, A.N.; Aksenov, A.A. The effect of La on the microstructure and mechanical properties of the (Al) + Al4(Ca,La) wrought alloys. Phys. Met. Metallogr. 2023, 124, 80–86. [Google Scholar]

- Naumova, E.A.; Akopyan, T.K.; Letyagin, N.V.; Vasina, M.A. Investigation of the structure and properties of eutectic alloys of the Al–Ca–Ni system containing REM. Non-Ferr. Met. 2018, 2, 29–36. [Google Scholar] [CrossRef]

| № | Designation | Actual Concentrations, wt.% | ||

|---|---|---|---|---|

| Al | Ca | Cu | ||

| 1 | Al1.0Cu8.0Ca | balance | 8.8 | 1.6 |

| 2 | Al2.2Cu6.7Ca | balance | 6.6 | 2.5 |

| 3 | Al3.4Cu5.6Ca | balance | 5.6 | 3.6 |

| 4 | Al5.6Cu3.5Ca | balance | 3.9 | 6.6 |

| 5 | Al9.0Cu3.5Ca | balance | 3.5 | 9.0 |

| 6 | Al10Cu0.5Ca | balance | 0.35 | 9.0 |

| 7 | Al10Cu1.5Ca | balance | 1.2 | 9.0 |

| 8 | Al14Cu2.5Ca | balance | 2.5 | 14.0 |

| 9 | Al14Cu6.0Ca | balance | 6.5 | 13.0 |

| 10 | Al18Cu6.0Ca | balance | 6.0 | 15.0 |

| 11 | Al30Cu1.0Ca | balance | 1.0 | 27.0 |

| 12 | Al36Cu1.0Ca | balance | 1.5 | 35.0 |

| 13 | Al9.0Cu0.5Ca | balance | 0.4 | 8.2 |

| 14 | Al9.0Cu1.5Ca | balance | 0.8 | 8.5 |

| 15 | Al14Cu1.0Ca | balance | 1.1 | 13.2 |

| 16 | Al14Cu7.0Ca | balance | 8.3 | 14.2 |

| 17 | Al3Ca0.5Cu | balance | 2.7 | 0.5 |

| 18 | Al3Ca1Cu | balance | 3.0 | 1.0 |

| Alloy | Vs, K/s | Chemical Composition, at.% | Phase Identification | ||

|---|---|---|---|---|---|

| Al | Ca | Cu | |||

| Al1.0Cu8.0Ca | 10 | balance | 19.6 | 2.0 | (Al,Cu)4Ca |

| 0.02 | balance | 19.3 | 2.1 | (Al,Cu)4Ca | |

| Al2.2Cu6.7Ca | 10 | balance | 19.3 | 3.3 | (Al,Cu)4Ca |

| 0.02 | balance | 19.0 | 3.8 | (Al,Cu)4Ca | |

| Al14Cu6.0Ca | 10 | balance | 19.0 | 8.0 | (Al,Cu)4Ca |

| balance | 8.0 | 19.0 | Al27Ca3Cu7 | ||

| 0.02 | balance | 19.0 | 8.0 | (Al,Cu)4Ca | |

| balance | 8.0 | 19.0 | Al27Ca3Cu7 | ||

| Al18Cu6.0Ca | 10 | balance | 19.2 | 8.3 | (Al,Cu)4Ca |

| balance | 7.9 | 18.9 | Al27Ca3Cu7 | ||

| 0.02 | balance | 8.0 | 20.0 | Al27Ca3Cu7 | |

| Al14Cu2.5Ca | 10 | balance | 8.0 | 20.0 | Al27Ca3Cu7 |

| 0.02 | balance | 8.0 | 20.0 | Al27Ca3Cu7 | |

| Al30Cu1.0Ca | 10 | balance | 6.6 | 30.1 | Al8CaCu4 |

| Al36Cu1.0Ca | 10 | balance | 6.0 | 30.5 | Al8CaCu4 |

| 0.02 | balance | 7.8 | 33 | Al8CaCu4 | |

| Al3.4Cu5.6Ca | 0.02 | balance | 19.3 | 6.5 | (Al,Cu)4Ca |

| Al5.6Cu3.5Ca | 0.02 | balance | - | 2.0 | (Al) |

| balance | 19.1 | 7.6 | (Al,Cu)4Ca | ||

| balance | 7.8 | 17.6 | Al27Ca3Cu7 | ||

| Al9.0Cu3.5Ca | 0.02 | balance | - | 1.8 | (Al) |

| balance | 19.7 | 8.1 | (Al,Cu)4Ca | ||

| balance | 7.4 | 18.2 | Al27Ca3Cu7 | ||

| Phase Transformation | Point on the Diagram | Chemical Composition, wt.% | T, °C | ||

|---|---|---|---|---|---|

| Al | Ca | Cu | |||

| L→(Al)+ (Al,Cu)4Ca+Al27Ca3Cu7 | E1 | balance | 5.6 | 4.5 | 595 |

| L→(Al)+ Al27Ca3Cu7+Al8CaCu4 | E2 | balance | 2.2 | 13.5 | 594 |

| L→(Al)+ Al8CaCu4+Al2Cu | E3 | balance | 0.5 | 34 | 544 |

| L→(Al)+ Al27Ca3Cu7 | eX | balance | 2.8 | 11.3 | 596 |

| L→(Al)+ Al8CaCu4 | eY | balance | 1.8 | 14.7 | 596 |

| Alloy | Chemical Composition, wt.% | Fractions of Extra Phases, wt.% (vol.%). | ||||

|---|---|---|---|---|---|---|

| Al | Cu | Ca | Al8CaCu4 | Al2Cu | Al27Ca3Cu7 | |

| Al10Cu0.5Ca | balance | 5.1 ± 0.2 | - | 6.2 (3.9) | 3.3 (2.2) | - |

| Al10Cu1.5Ca | balance | 2.4 ± 0.2 | - | 11.0 (7.0) | - | 6.9 (5.7) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akopyan, T.K.; Belov, N.A.; Letyagin, N.V.; Cherkasov, S.O.; Nguen, X.D. Description of the New Eutectic Al-Ca-Cu System in the Aluminum Corner. Metals 2023, 13, 802. https://doi.org/10.3390/met13040802

Akopyan TK, Belov NA, Letyagin NV, Cherkasov SO, Nguen XD. Description of the New Eutectic Al-Ca-Cu System in the Aluminum Corner. Metals. 2023; 13(4):802. https://doi.org/10.3390/met13040802

Chicago/Turabian StyleAkopyan, Torgom K., Nikolay A. Belov, Nikolay V. Letyagin, Stanislav O. Cherkasov, and Xuan D. Nguen. 2023. "Description of the New Eutectic Al-Ca-Cu System in the Aluminum Corner" Metals 13, no. 4: 802. https://doi.org/10.3390/met13040802

APA StyleAkopyan, T. K., Belov, N. A., Letyagin, N. V., Cherkasov, S. O., & Nguen, X. D. (2023). Description of the New Eutectic Al-Ca-Cu System in the Aluminum Corner. Metals, 13(4), 802. https://doi.org/10.3390/met13040802