Neural Network as a Tool for Design of Amorphous Metal Alloys with Desired Elastoplastic Properties

Abstract

:1. Introduction

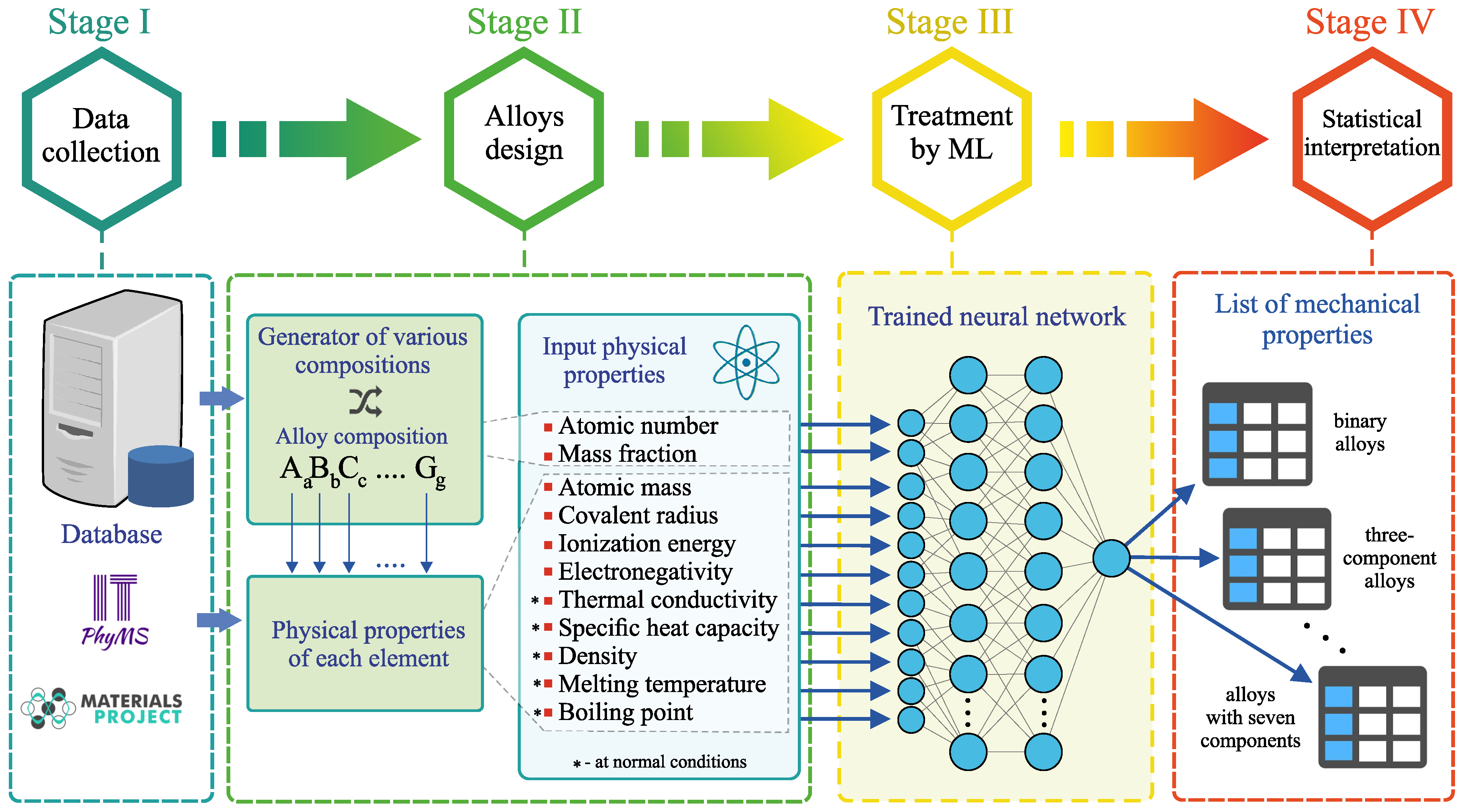

2. Method for Determining the Mechanical Properties of Amorphous Metal Alloys

2.1. General Strategy of the Method

- Stage I. This stage includes the process of data collection and systematization of information about the properties of multicomponent amorphous metal alloys based on Al, Au, Ca, Co, Cu, Fe, La, Hf, Mg, Ni, Pd, Pt, Sc, Ti, W, Zr, etc., as well as information about the properties of the other additional chemical elements involved in the formation of these alloys. Among these properties are the atomic mass , the covalent radius , the ionization energy and the electronegativity , which characterize the nature of the chemical element [see Table 1]. This choice is due to the following reasons. First, these parameters most clearly define the possible physical and chemical bonds between the elements, which can either promote or inhibit the formation of an amorphous structure. For example, according to the empirical rule proposed by Inone et al. in the early 1990’s [44], the difference in atomic sizes must be greater than 12% for good amorphization of a liquid. Secondly, most of the intrinsic properties of chemical elements (especially of the same type) are correlated. In addition, the thermal conductivity , the specific heat capacity , the density , the melting temperature and the boiling temperature of chemical elements at normal conditions are used. The atomic number Z and the mass fraction of each chemical element in the alloy are used to characterize the alloy composition. The Young’s modulus E and the yield strength are also applied, whose values are known for the considered amorphous alloys. The values of all the listed physical properties are taken from the database ITPhyMS (Information technologies in physical materials science) [45] and the database Materials Project [46] as well as from Refs. [36,47,48,49,50] [see Supplementary data of the present work]. These properties are characterized by different physical dimensions and by different ranges of values. Therefore, the properties are calibrated so that their values vary in the range [0; 1]. The calibration is done according to the rulewhere “” and “” are the smallest and largest known values of the “Property”. Moreover, all these listed properties correlate with the mechanical properties of materials. For example, Xiong et al. have shown that the accuracy of predicting the mechanical properties of amorphous metal alloys is improved when the quantities , Z, , , , and are considered in a machine learning model [37]. In addition, the results obtained by Wang based on the analysis of a large set of empirical data for amorphous alloys allow one to establish the existence of correlation between elastic moduli (i.e., Young’s modulus, shear modulus, bulk modulus), microstructural features, rheological properties, the glass transition temperature, the melting temperature and the boson peak [47,48].

- Stage II. Alloys with different compositions are generated. Taking into account the number of possible components, combinations of all chemical elements and their mass fraction, up to different compositions can be determined simultaneously. When obtaining alloys, those chemical elements are selected that are included on the alloys in the training dataset. In the present work, 32 chemical elements were used including transition metals (Fe, Co, Ni, Cu, etc.), semimetals (B, Al, Sn, etc.), lanthanides (La, Gd, Er, etc.) and alkali and alkaline earth metals (Li, Be, Mg, Ca, etc.). A list of all the considered chemical elements is given on Table S1 in Supplementary data. The mass fraction of the chemical elements in a generated alloy is also set randomly so that the total mass fraction of all chemical elements is equal to 100%. A set of physical properties is created for each chemical element [see Table 1].

- Stage III. Information about the alloy composition and the physical properties of all the chemical elements is processed by the pre-trained neural network. This neural network evaluates the Young’s modulus E and the yield strength for all generated alloys. The training procedure of the neural network is discussed in more details in the subsection “Machine learning model: structure and training”.

- Stage IV. Statistical interpretation of machine learning results is performed.

2.2. Machine Learning Model: Structure and Training

2.3. Validation of the Machine Learning Model

3. Properties Importance Scores

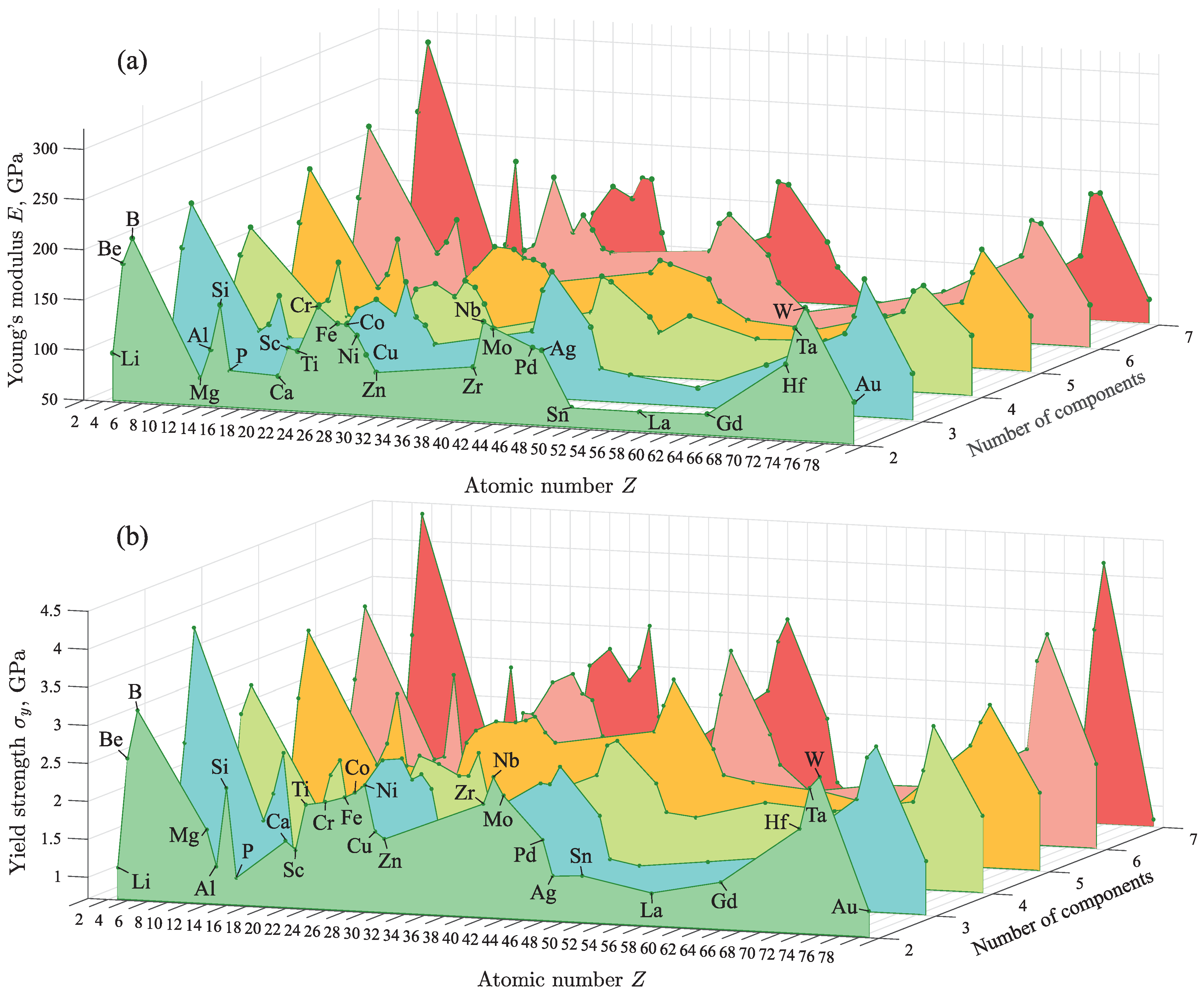

4. Statistical Interpretation of the Results

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. R Rep. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Chen, M. A brief overview of bulk metallic glasses. NPG Asia Mater. 2011, 3, 82–90. [Google Scholar] [CrossRef]

- Yeh, P.-Y.; Huang, J.C.; Jang, J.S.C.; Pan, C.-T.; Chen, C.-H.; Lin, C.-H. Recent Developments in Additive-Manufactured Intermetallic Compounds for Bio-Implant Applications. J. Med. Biol. Eng. 2022, 42, 800–815. [Google Scholar] [CrossRef]

- Huang, L.J.; Lin, H.J.; Wang, H.; Ouyang, L.Z.; Zhu, M. Amorphous alloys for hydrogen storage. J. Alloys Compd. 2023, 941, 168945. [Google Scholar] [CrossRef]

- Kruzic, J.J. Bulk Metallic Glasses as Structural Materials: A Review. Adv. Eng. Mater. 2016, 18, 1308–1331. [Google Scholar]

- Louzguine-Luzgin, D.V.; Polkin, V.I. Properties of bulk metallic glasses. Russ. J. Non-Ferr. Met. 2017, 58, 80–92. [Google Scholar] [CrossRef]

- Li, H.X.; Lu, Z.C.; Wang, S.L.; Wu, Y.; Lu, Z.P. Fe-based bulk metallic glasses: Glass formation, fabrication, properties and applications. Prog. Mater. Sci. 2019, 103, 235–318. [Google Scholar] [CrossRef]

- Malygin, G.A. Strength and plasticity of nanocrystalline materials and nanosized crystals. Phys. Usp. 2011, 54, 1091–1116. [Google Scholar] [CrossRef]

- Galimzyanov, B.N.; Doronina, M.A.; Mokshin, A.V. Excellent glass former Ni62Nb38 crystallizing under combined shear and ultra-high pressure. J. Non-Cryst. Solids 2021, 572, 121102. [Google Scholar] [CrossRef]

- Anikeev, S.G.; Artyukhova, N.V.; Shabalina, A.V.; Kulinich, S.A.; Hodorenko, V.N.; Kaftaranova, M.I.; Promakhov, V.V.; Gunter, V.E. Preparation of porous TiNi-Ti alloy by diffusion sintering method and study of its composition, structure and martensitic transformations. J. Alloys Compd. 2022, 900, 163559. [Google Scholar] [CrossRef]

- Galimzyanov, B.N.; Mokshin, A.V. Mechanical response of mesoporous amorphous NiTi alloy to external deformations. Int. J. Solids Struct. 2021, 224, 111047. [Google Scholar] [CrossRef]

- Lesz, S. Effect of cooling rates on the structure, density and micro-indentation behavior of the Fe, Co-based bulk metallic glass. Mater. Charact. 2017, 124, 97–106. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.V. Structural Changes in Metallic Glass-Forming Liquids on Cooling and Subsequent Vitrification in Relationship with Their Properties. Materials 2022, 15, 7285. [Google Scholar] [CrossRef]

- Tournier, R.F.; Ojovan, M.I. Multiple Melting Temperatures in Glass-Forming Melts. Sustainability 2022, 14, 2351. [Google Scholar] [CrossRef]

- Ojovan, M.I.; Tournier, R.F. On Structural Rearrangements Near the Glass Transition Temperature in Amorphous Silica. Materials 2021, 14, 5235. [Google Scholar] [CrossRef]

- Galimzyanov, B.N.; Yarullin, D.T.; Mokshin, A.V. Kinetics of inherent processes counteracting crystallization in supercooled monatomic liquid. J. Phys. Condens. Matter 2022, 34, 454002. [Google Scholar]

- Kramer, J. Der amorphe Zustand der Metalle. Z. Phys. 1937, 106, 675–691. [Google Scholar] [CrossRef]

- Brenner, A.; Couch, D.E.; Williams, E.K. Electrodeposition of alloys of phosphorus with nickel or cobalt. J. Res. Nat. Bur. Stand. 1950, 44, 109–122. [Google Scholar] [CrossRef]

- Duwez, P. Structure and Properties of Alloys Rapidly. Quenched from the Liquid State. Trans. Am. Soc. Metals 1967, 60, 607–633. [Google Scholar]

- Pond, R., Jr.; Maddin, R. A method of producting rapidly solidified filamentary castings. Trans. TMS-AIME 1969, 245, 2475. [Google Scholar]

- Peker, A.; Johnson, W.L. A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl. Phys. Lett. 1993, 63, 2342–2344. [Google Scholar] [CrossRef]

- Demetriou, M.D.; Kaltenboeck, G.; Suh, J.-Y.; Garrett, G.; Floyd, M.; Crewdson, C.; Hofmann, D.C.; Kozachkov, H.; Wiest, A.; Schramm, J.P.; et al. Glassy steel optimized for glass-forming ability and toughness. Appl. Phys. Lett. 2009, 95, 041907. [Google Scholar] [CrossRef]

- Conner, R.D.; Li, Y.; Nix, W.D.; Johnson, W.L. Shear band spacing under bending of Zr-based metallic glass plates. Acta Mater. 2004, 52, 2429–2434. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.L.; Chang, C.T. Fe- and Co-based bulk glassy alloys with ultrahigh strength of over 4000 MPa. Intermetallics 2006, 14, 936–944. [Google Scholar] [CrossRef]

- Zhang, H.W.; Subhash, G.; Jing, X.N.; Kecskes, L.J.; Dowding, R.J. Evaluation of hardness–yield strength relationships for bulk metallic g lasses. Philos. Mag. Lett. 2006, 86, 333–345. [Google Scholar] [CrossRef]

- Yuan, C.C.; Xi, X.K. On the correlation of Young’s modulus and the fracture strength of metallic glasses. J. Appl. Phys. 2011, 109, 033515. [Google Scholar] [CrossRef]

- Mokshin, A.V.; Mokshin, V.V.; Mirziyarova, D.A. Formation of Regression Model for Analysis of Complex Systems Using Methodology of Genetic Algorithms. Nonlinear Phenom. Complex Syst. 2020, 23, 317–326. [Google Scholar]

- Mokshin, A.V.; Khabibullin, R.A. Is there a one-to-one correspondence between interparticle interactions and physical properties of liquid? Phys. A Stat. Mech. Appl. 2022, 608, 128297. [Google Scholar] [CrossRef]

- White, A.A. Big data are shaping the future of materials science. MRS Bull. 2013, 38, 594–595. [Google Scholar] [CrossRef]

- Rodrigues, J.F., Jr.; Florea, L.; de Oliveira, M.C.F.; Diamond, D.; Oliveira, O.N., Jr. Big data and machine learning for materials science. Discov. Mater. 2021, 1, 12. [Google Scholar] [CrossRef]

- Agrawal, A.; Choudhary, A. Perspective: Materials informatics and big data: Realization of the “fourth paradigm” of science in materials science. APL Mater. 2016, 4, 053208. [Google Scholar] [CrossRef]

- Tripathi, M.K.; Kumar, R.; Tripathi, R. Big-data driven approaches in materials science: A survey. Mater. Today Proc. 2020, 26, 1245–1249. [Google Scholar] [CrossRef]

- Shokrollahi, Y.; Dong, P.; Gamage, P.T.; Patrawalla, N.; Kishore, V.; Mozafari, H.; Gu, L. Finite Element-Based Machine Learning Model for Predicting the Mechanical Properties of Composite Hydrogels. Appl. Sci. 2022, 12, 10835. [Google Scholar] [CrossRef]

- Merayo, D.; Rodríquez-Prieto, A.; Camacho, A.M. Prediction of Mechanical Properties by Artificial Neural Networks to Characterize the Plastic Behavior of Aluminum Alloys. Materials 2020, 13, 5227. [Google Scholar] [CrossRef] [PubMed]

- Ciupan, E.; Ciupan, M.; Jucan, D.C. Determining the Mechanical Properties of a New Composite Material using Artificial Neural Networks. TJETT 2018, 66, 103–108. [Google Scholar]

- Galimzyanov, B.N.; Doronina, M.A.; Mokshin, A.V. Arrhenius Crossover Temperature of Glass-Forming Liquids Predicted by an Artificial Neural Network. Materials 2023, 16, 1127. [Google Scholar] [CrossRef]

- Xiong, J.; Shi, S.-Q.; Zhang, T.-Y. A machine-learning approach to predicting and understanding the properties of amorphous metallic alloys. Mater. Des. 2020, 187, 108378. [Google Scholar] [CrossRef]

- Khakurel, H.; Taufique, M.F.N.; Roy, A.; Balasubramanian, G.; Ouyang, G.; Cui, J.; Johnson, D.D.; Devanathan, R. Machine learning assisted prediction of the Young’s modulus of compositionally complex alloys. Sci. Rep. 2021, 11, 17149. [Google Scholar] [CrossRef]

- Amigo, N.; Palominos, S.; Valencia, F.J. Machine learning modeling for the prediction of plastic properties in metallic glasses. Sci. Rep. 2023, 13, 348. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, T.Y.; Shi, S.Q. Machine learning prediction of elastic properties and glass-forming ability of bulk metallic glasses. MRS Commun. 2019, 9, 576–585. [Google Scholar] [CrossRef]

- Galimzyanov, B.N.; Doronina, M.A.; Mokshin, A.V. Machine learning-based prediction of elastic properties of amorphous metal alloys. Phys. A Stat. Mech. Appl. 2023, 617, 128678. [Google Scholar] [CrossRef]

- Johnson, W.L.; Samwer, K. A Universal Criterion for Plastic Yielding of Metallic Glasses with a (T/Tg)2/3 Temperature Dependence. Phys. Rev. Lett. 2005, 95, 195501. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.; Seo, N.; Kim, H.-J.; Lee, M.-H.; Lim, H.-K.; Son, S.B.; Lee, S.-J. Inverse Design of Fe-Based Bulk Metallic Glasses Using Machine Learning. Metals 2021, 11, 729. [Google Scholar] [CrossRef]

- Inone, A. Bulk Amorphous Alloys: Preparation and Fundamental Characteristics (Materials Science Foundations); Trans Tech Publications: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Material Properties Database of the “Information Technologies in Physical Materials Science” Laboratory of Kazan Federal University. Available online: http://itphyms.int.kpfu.ru/ (accessed on 27 March 2023).

- Scientific Database of Materials and Their Properties from Lawrence Berkeley National Laboratory. Available online: https://materialsproject.org/ (accessed on 27 March 2023).

- Wang, W.H. Correlations between elastic moduli and properties in bulk metallic glasses. J. Appl. Phys. 2006, 99, 093506. [Google Scholar] [CrossRef]

- Wang, W.H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 2012, 57, 487–656. [Google Scholar] [CrossRef]

- Chen, X.-Q.; Niu, H.; Li, D.; Li, Y. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics 2011, 19, 1275–1281. [Google Scholar] [CrossRef]

- Qu, R.T.; Liu, Z.Q.; Wang, R.F.; Zhang, Z.F. Yield strength and yield strain of metallic glasses and their correlations with glass transition temperature. J. Alloys Compd. 2015, 637, 44–54. [Google Scholar] [CrossRef]

- Chumachenko, K.; Iosifidis, A.; Gabbouj, M. Feedforward neural networks initialization based on discriminant learning. Neural Netw. 2022, 146, 220–229. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, S.; Athaiya, A. Activation functions in neural networks. IJEAST 2020, 4, 310–316. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks and Learning Machines, 3rd ed.; Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- Li, J.; Cheng, J.; Shi, J.; Huang, F. Brief Introduction of Back Propagation (BP) Neural Network Algorithm and Its Improvement. Adv. Comput. Sci. Inf. Eng. 2012, 169, 553–558. [Google Scholar]

- Yan, Z.; Zhong, S.; Lin, L.; Cui, Z. Adaptive Levenberg-Marquardt Algorithm: A New Optimization Strategy for Levenberg-Marquardt Neural Networks. Mathematics 2021, 9, 2176. [Google Scholar] [CrossRef]

- Sobhanifar, N.; Ahmadloo, E.; Azizi, S. Prediction of Two-Phase Heat Transfer Coefficients in a Horizontal Pipe for Different Inclined Positions with Artificial Neural Networks. J. Heat Transf. 2015, 137, 061009. [Google Scholar] [CrossRef]

- Šter, B. Selective Recurrent Neural Network. Neural Process. Lett. 2012, 38, 1–15. [Google Scholar] [CrossRef]

- Turco, C.; Funari, M.F.; Teixeira, E.; Mateus, R. Artificial Neural Networks to Predict the Mechanical Properties of Natural Fibre-Reinforced Compressed Earth Blocks (CEBs). Fibers 2021, 9, 78. [Google Scholar] [CrossRef]

- Marques, A.E.; Prates, P.A.; Pereira, A.F.G.; Oliveira, M.C.; Fernandes, J.V.; Ribeiro, B.M. Performance Comparison of Parametric and Non-Parametric Regression Models for Uncertainty Analysis of Sheet Metal Forming Processes. Metals 2020, 10, 457. [Google Scholar] [CrossRef]

- Jetly, V.; Chaudhury, B. Extracting electron scattering cross sections from swarm data using deep neural networks. Mach. Learn. Sci. Technol. 2021, 2, 035025. [Google Scholar] [CrossRef]

- Malyshev, V.; Makasheva, A. The Relation between the Heat of Melting Point, Boiling Point, and the Activation Energy of Self-Diffusion in Accordance with the Concept of Randomized Particles. Open J. Phys. Chem. 2014, 4, 166–172. [Google Scholar] [CrossRef]

- Kanematsu, N.; Inaniwa, T.; Nakao, M. Modeling of body tissues for Monte Carlo simulation of radiotherapy treatments planned with conventional X-ray CT systems. Phys. Med. Biol. 2016, 61, 5037–5050. [Google Scholar] [CrossRef]

- Karpechev, E.V.; Pshenichnov, I.A.; Karavicheva, T.L.; Kurepin, A.B.; Golubeva, M.B.; Guber, F.F.; Maevskaya, A.I.; Reshetin, A.I.; Tiflov, V.V.; Topilskaya, N.S.; et al. Emission of forward neutrons by 158A GeV indium nuclei in collisions with Al, Cu, Sn and Pb. Nucl. Phys. A 2014, 921, 60–84. [Google Scholar] [CrossRef]

- Agmon, N. Covalent radii from ionization energies of isoelectronic series. Chem. Phys. Lett. 2014, 595–596, 214–219. [Google Scholar] [CrossRef]

- Matovi, B.; Yano, T. Silicon Carbide and Other Carbides. Handb. Adv. Ceram. 2013, 225–244. [Google Scholar] [CrossRef]

- Braithwaite, E.R.; Haber, J. Molybdenum: An Outline of Its Chemistry and Uses; Elsevier Science B. V.: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Barnhart, J. Occurrences, uses and properties of chromium. Regul. Toxicol. Pharmacol. 1997, 26, S3–S7. [Google Scholar] [CrossRef] [PubMed]

- Rieth, M.; Dudarev, S.L.; Gonzalez de Vicente, S.M.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.E.J.; Balden, M.; Baluc, N.; Barthe, M.F.; et al. Recent progress in research on tungsten materials for nuclear applications in Europe. J. Nucl. Mater. 2013, 432, 482–500. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Kuramoto, K.; Chiba, A. Development of new Co–Cr–W-based biomedical alloys: Effects of microalloying and thermomechanical processing on microstructures and mechanical properties. Mater. Des. 2014, 55, 987–998. [Google Scholar] [CrossRef]

- Baldinozzi, G.; Pontikis, V. Phenomenological potentials for the refractory metals Cr, Mo and W. J. Phys. Condens. Matter 2022, 34, 315702. [Google Scholar] [CrossRef] [PubMed]

- Sanin, V.V.; Kaplansky, Y.Y.; Aheiev, M.I.; Levashov, E.A.; Petrzhik, M.I.; Bychkova, M.Y.; Samokhin, A.V.; Fadeev, A.A.; Sanin, V.N. Structure and Properties of Heat-Resistant Alloys NiAl-Cr-Co-X (X = La, Mo, Zr, Ta, Re) and Fabrication of Powders for Additive Manufacturing. Materials 2021, 14, 3144. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Shen, J. Effect of heat treatment on the microstructure and elevated temperature tensile property of Fe-doped NiAl–Cr(Mo)–(Hf, Dy) eutectic alloy. Mater. Sci. Eng. A 2016, 654, 177–183. [Google Scholar] [CrossRef]

| Property | Symbol | Unit |

|---|---|---|

| Atomic number | Z | – |

| Mass fraction of elements | % | |

| Atomic mass | a.e.m. | |

| Covalent radius | pm | |

| Ionization energy | eV | |

| Electronegativity | – | |

| Thermal conductivity | W/(m·K) | |

| Specific heat capacity | J/(g·K) | |

| Density | g/cm | |

| Melting temperature | K | |

| Boiling temperature | K |

| Number of Components | Alloy | E, GPa | Alloy | , GPa |

|---|---|---|---|---|

| 2 | CrB | 305 | PdB | |

| WHf | 271 | WHf | ||

| 3 | MoBW | 319 | MoBSi | |

| NbHfB | 289 | NiBSc | ||

| NiBW | 280 | PdBP | ||

| 4 | AgBScTa | 302 | CoBBeAl | |

| ZrNiBBe | 285 | NbWLaB | ||

| CrBZrHf | 271 | TiWPdB | ||

| 5 | TiFeBSnBe | 296 | CoBAgGdSi | |

| PdBSiPHf | 289 | FeBMoTaAg | ||

| 6 | CrBNbPdTaSi | 310 | CrMoWPdGdB | |

| PdBeMoTiBFe | 306 | MoWPdGdBCr | ||

| WBAuBeNbAg | 296 | TaNbAlAuBW | ||

| 7 | WCoNbAgBBeMg | 284 | WBAgNbSiCoPd | |

| CrAgTiBGdBeMg | 234 | CrFeWCaBSnBe |

| Alloy | E, GPa | Alloy | E, GPa |

|---|---|---|---|

| CrB | 305 | CuMg | 60 |

| WMoB | 318 | CuMo | 154 |

| NiCrCo | 58 | WAgB | 234 |

| NiZrSi | 108 | CrBGd | 217 |

| NiMoW | 183 | CrNbLa | 196 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galimzyanov, B.N.; Doronina, M.A.; Mokshin, A.V. Neural Network as a Tool for Design of Amorphous Metal Alloys with Desired Elastoplastic Properties. Metals 2023, 13, 812. https://doi.org/10.3390/met13040812

Galimzyanov BN, Doronina MA, Mokshin AV. Neural Network as a Tool for Design of Amorphous Metal Alloys with Desired Elastoplastic Properties. Metals. 2023; 13(4):812. https://doi.org/10.3390/met13040812

Chicago/Turabian StyleGalimzyanov, Bulat N., Maria A. Doronina, and Anatolii V. Mokshin. 2023. "Neural Network as a Tool for Design of Amorphous Metal Alloys with Desired Elastoplastic Properties" Metals 13, no. 4: 812. https://doi.org/10.3390/met13040812

APA StyleGalimzyanov, B. N., Doronina, M. A., & Mokshin, A. V. (2023). Neural Network as a Tool for Design of Amorphous Metal Alloys with Desired Elastoplastic Properties. Metals, 13(4), 812. https://doi.org/10.3390/met13040812