Microstructure and Tribological Behavior of Cr-Mn-N Steel with Age-Hardened Near-Surface Layer including CrN and Fe2N Particles Intended for Use in Orthopedic Implants

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

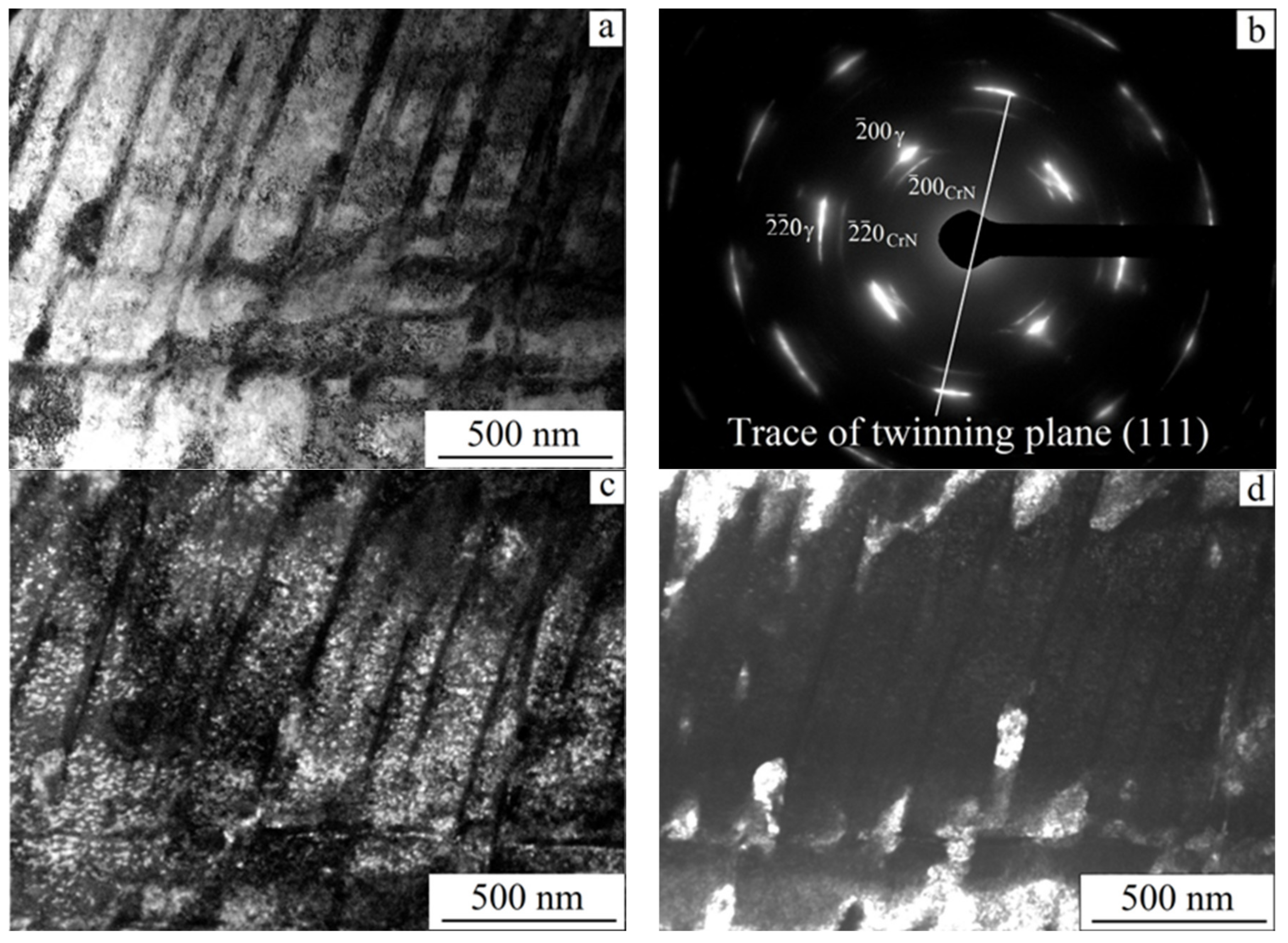

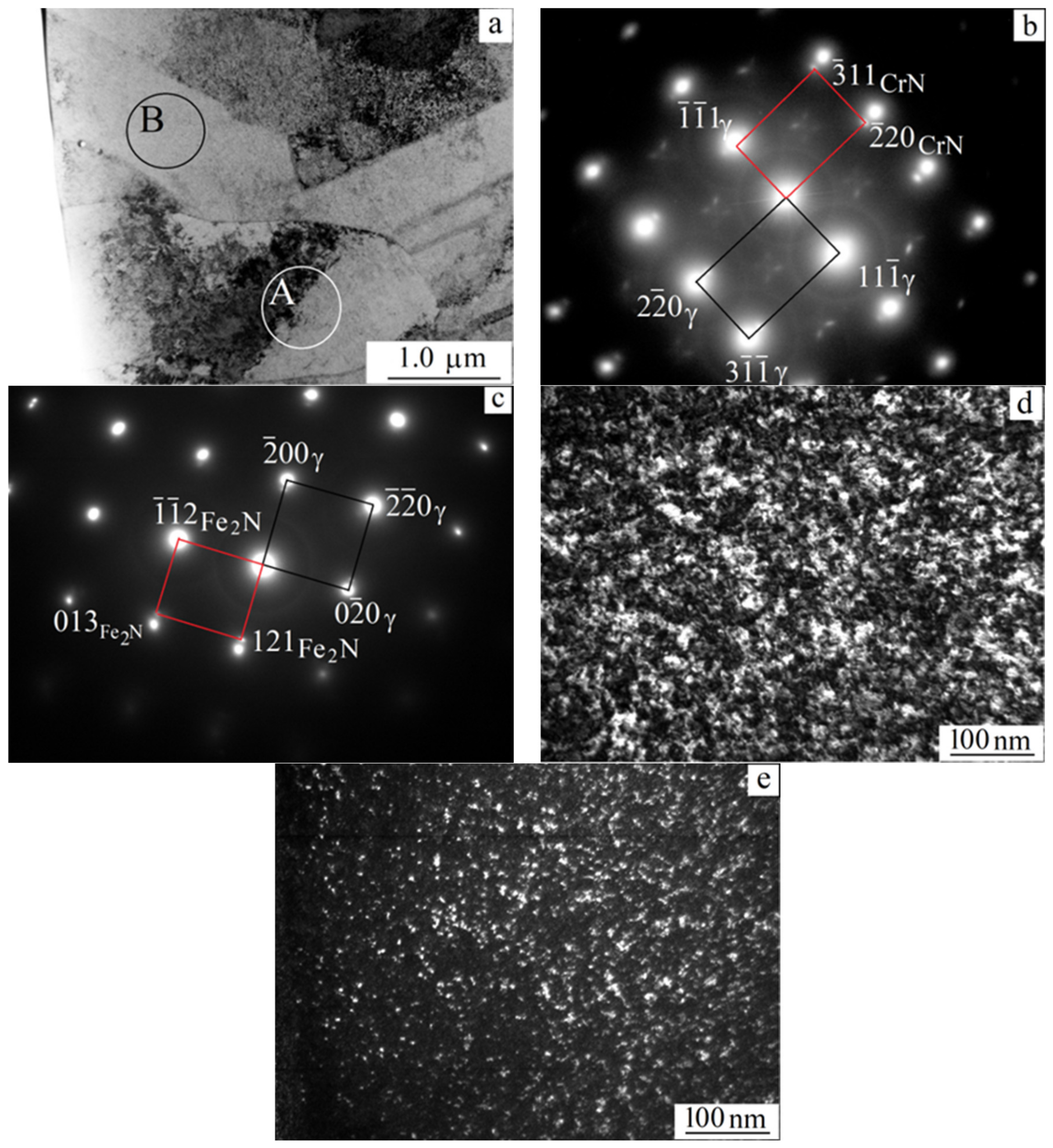

3.1. The Near-Surface Layer Microstructure

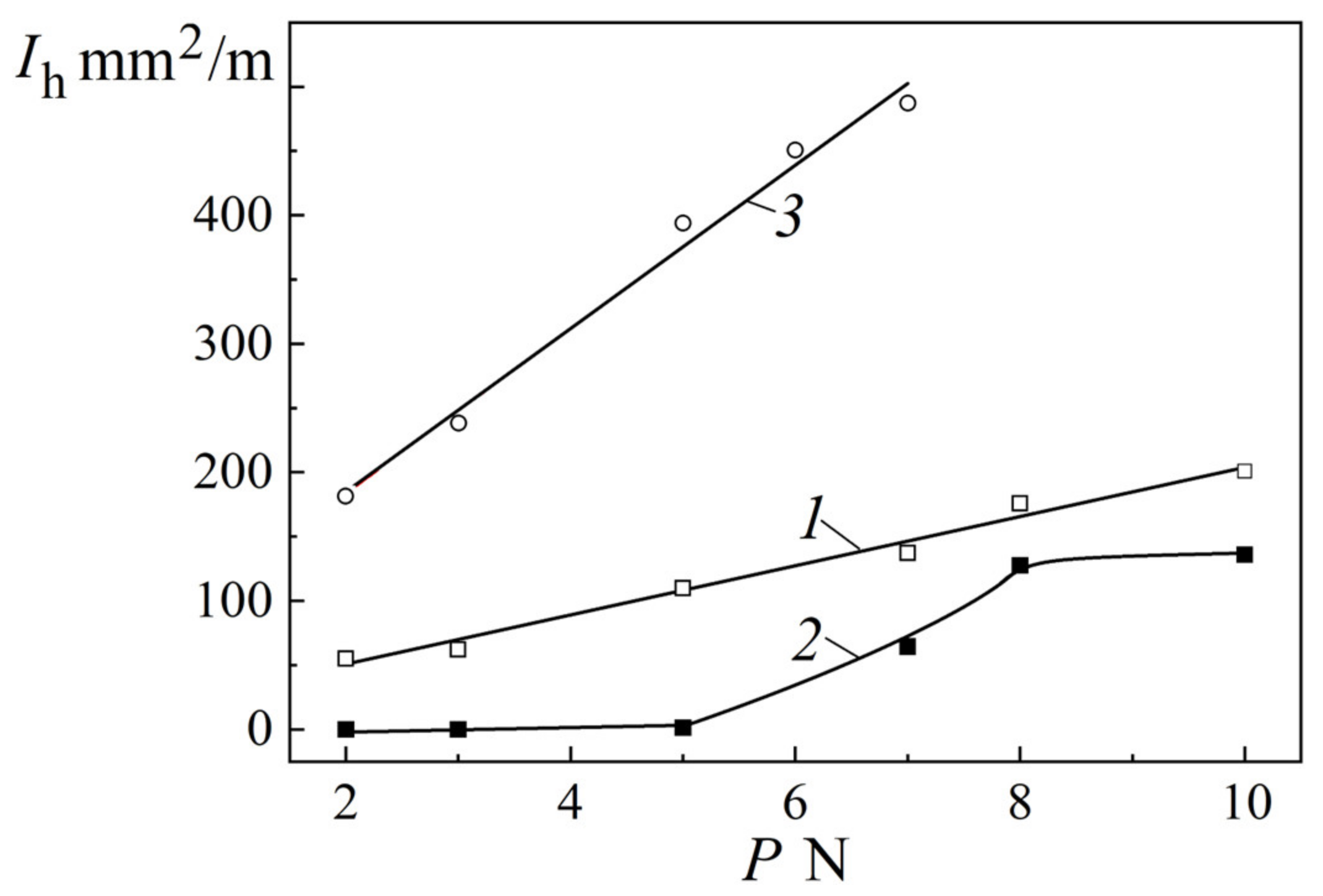

3.2. The Tribological Characteristics

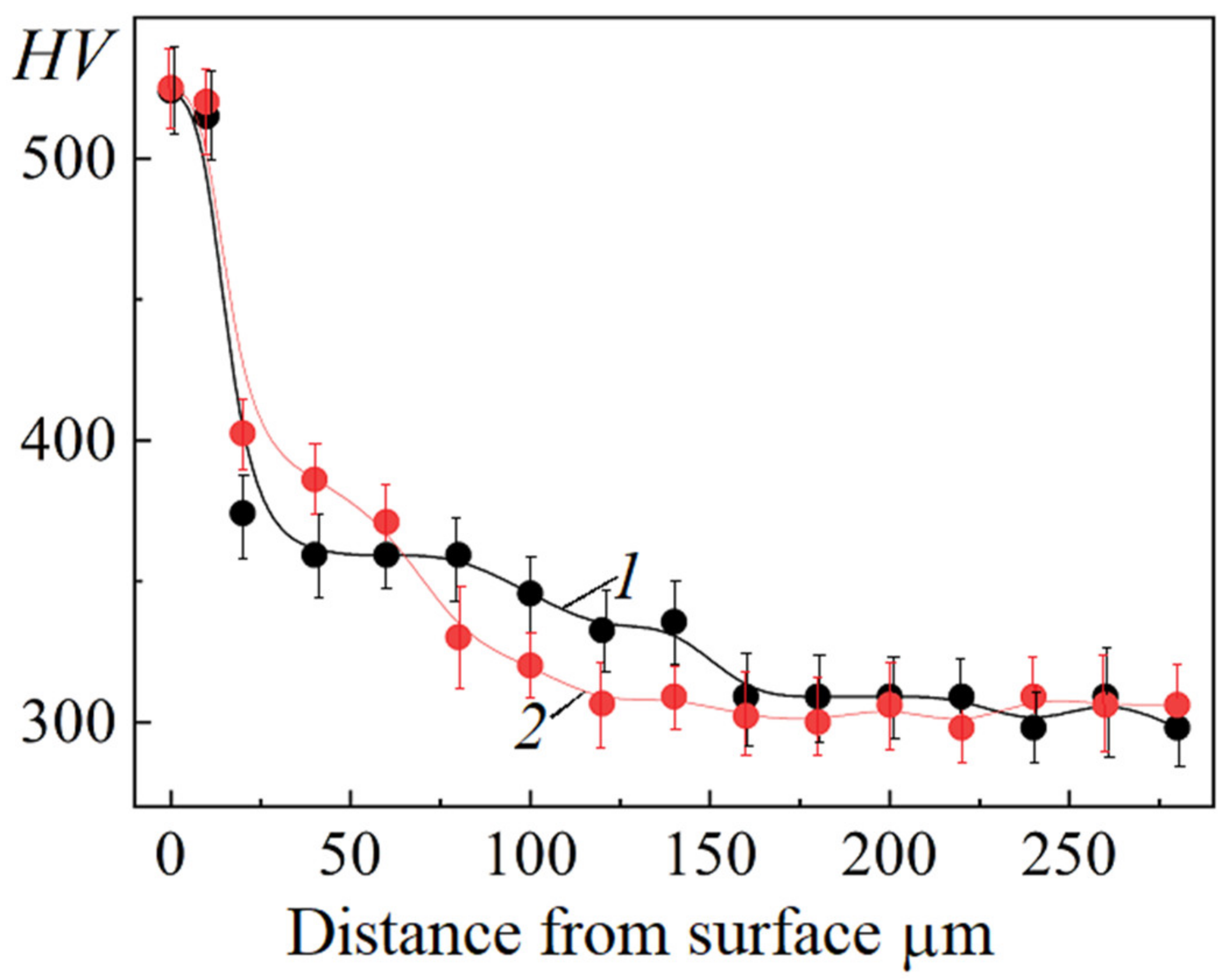

3.3. The Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tigani, D.; Fosco, M.; Bena Ayad, R.; Fantasia, R. Orthopaedic Implant Materials and Design. In Wear of Orthopaedic Implants and Artificial Joints; Affatato, S., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 133–177. [Google Scholar]

- Zhidkov, A.V.; Pashmentova, A.S.; Viun, S.S.; Zhiltsov, M.P.; Mishin, V.V.; Podmasteryev, K.V. The mathematical simulation and study of the electrical resistance of the friction zone of the hip joint endoprosthesis with a metal-metal friction pair. Frict. Wear 2018, 39, 251–258. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Liu, M.; Shi, D.; Hu, N.; Feng, W. Mechanical Properties and in Vivo Assessment of Electron Beam Melted Porous Structures for Orthopedic Applications. Metals 2023, 13, 1034. [Google Scholar] [CrossRef]

- Lang, Y.; Qu, H.; Chen, H.; Weng, Y. Research progress and development tendency of nitrogen-alloyed austenitic stainless steels. J. Iron Steel Res. Int. 2015, 22, 91–98. [Google Scholar] [CrossRef]

- Sumita, M.; Hanawa, T.; Teoh, S.H. Development of nitrogen-containing nickel-free austenitic stainless steels for metallic biomaterials—Review. Mater. Sci. Eng. C 2004, 24, 753–760. [Google Scholar] [CrossRef]

- Ren, Y.; Wan, P.; Liu, F.; Zhang, B.; Yang, K. In vitro study on a new high nitrogen nickel-free austenitic stainless steel for coronary stents. J. Mater. Sci. Technol. 2011, 27, 325–331. [Google Scholar] [CrossRef]

- Li, M.; Yin, T.; Wang, Y.; Du, F.; Zou, X.; Gregersen, H.; Wang, G. Study of biocompatibility of medical grade high nitrogen nickel-free austenitic stainless steel in vitro. Mater. Sci. Eng. C 2014, 43, 641–648. [Google Scholar] [CrossRef]

- Yamamoto, A.; Kohyama, Y.; Kuroda, D.; Hanawa, T. Cytocompatibility evalution of Ni-free stainless steel manufactured by nitrogen adsorption treatment. Mater. Sci. Eng. C 2004, 24, 737–743. [Google Scholar] [CrossRef]

- Ma, T.; Wan, P.; Cui, Y.; Zhang, G.; Li, J.; Liu, J.; Ren, Y.; Yang, K.; Lu, L. Cytocompatibility of high nitrogen stainless steel for orthopedic implants. J. Mater. Sci. Technol. 2012, 28, 647–653. [Google Scholar] [CrossRef]

- Talha, M.; Behera, C.K.; Sinha, O.P. Promising in vitro performances of nickel-free nitrogen-containing stainless steels for orthopaedic applications. Bull. Mater. Sci. 2014, 37, 1321–1330. [Google Scholar] [CrossRef]

- Muley, S.V.; Vidvans, A.N.; Chaudhari, G.P.; Udainiya, S. An assessment of ultra fine grained 319L stainless steel for implant application. Acta Biomater. 2016, 30, 408–419. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; He, H.; Lou, J.; Li, Y.; Li, D.; Chen, Y.; Liu, S. Fabrication, Structure and Mechanical and Ultrasonic Properties of Medical Ti6Al4V Alloys Part I: Microstructure and Mechanical Properties of Ti6Al4V Alloys Suitable for Ultrasonic Scalpe. Materials 2020, 13, 478. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Revankar, G.D.; Shetty, R.; Rao, S.S.; Gaitonde, V.N. Wear resistance enhancement of titanium alloy (Ti–6Al–4V) by ball burnishing process. J. Mater. Res. Technol. 2017, 6, 13–32. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Liu, Z.; Gao, C.; Wong, K.; Ye, S.; Xiao, Z. Modified wear behavior of selective laser melted Ti6Al4V alloy by direct current assisted ultrasonic surface rolling process. Surf. Coat. Technol. 2020, 381, 125122. [Google Scholar] [CrossRef]

- Panin, A.; Kazachenok, M.; Krukovskii, K.; Buslovich, D.; Kazantseva, L.; Martynov, S.; Sklyarova, E. Transformations of the Microstructure and Phase Compositions of Titanium Alloys during Ultrasonic Impact Treatment Part III: Combination with Electrospark Alloying Applied to Additively Manufactured Ti-6Al-4V Titanium Alloy. Metals 2023, 13, 932. [Google Scholar] [CrossRef]

- Feng, S.; Tang, H.; Zhang, S.; Wang, H. Microstructure and wear resistance of laser clad TiB–TiC/TiNi–Ti2Ni intermetallic coating on titanium alloy. Trans. Nonferr. Met. Soc. China 2012, 22, 1667–1673. [Google Scholar] [CrossRef]

- Cui, W.; Qin, G.; Duan, J.; Wang, H. A graded nano-TiN coating on biomedical Ti alloy: Low friction coefficient, good bonding and biocompatibility. Mater. Sci. Eng. C 2017, 71, 520–528. [Google Scholar] [CrossRef]

- Tao, X.; Li, X.; Dong, H.; Matthews, A.; Leyland, A. Evaluation of the sliding wear and corrosion performance of triode-plasma nitrided Fe-17Cr-20Mn-0.5N high-manganese and Fe-19Cr-35Ni-1.2Si high-nickel austenitic stainless steels. Surf. Coat. Technol. 2021, 409, 126890. [Google Scholar] [CrossRef]

- Tao, X.; Rainforth, M.; Matthews, A.; Leyland, A. On the interstitial induced lattice inhomogeneities in nitrogen-expanded austenite. Scr. Mater. 2020, 185, 146–151. [Google Scholar] [CrossRef]

- Narkevich, N.A.; Surikova, N.S.; Mironov, Y.P.; Perevalova, O.B.; Shugurov, A.R.; Shulepov, I.A.; Durakov, V.G.; Mel’nikov, A.G.; Narkevich, V.V. Structure and lattice strains in the surface Cr–Mn–N steel formed by a combination of friction and electron-beam treatments. Phys. Met. Metallogr. 2019, 120, 1071–1077. [Google Scholar] [CrossRef]

- Korshunov, L.G.; Goikhenberg, Y.N.; Chernenko, N.L. Effect discontinuous decomposition on the tribologic properties of high nitrogen chromium manganese austenitic steel G22KH18A0.80. Phys. Met. Metallogr. 2000, 90, 192–198. [Google Scholar]

- Qiao, Y.; Wang, X.; Yang, L.; Wang, X.; Chen, J.; Wang, Z.; Zhou, H.; Zou, J.; Wang, F. Effect of aging treatment on microstructure and corrosion behavior of a Fe-18Cr-15Mn-0. 66N stainless steel. J. Mater. Sci. Technol. 2022, 107, 197–206. [Google Scholar] [CrossRef]

- Narkevich, N.A.; Mironov, Y.P.; Shulepov, I.A. Structure, mechanical and tribotechnical properties of an austenitic nitrogen steel after frictional treatment. Phys. Met. Metallogr. 2017, 118, 399–406. [Google Scholar] [CrossRef]

- Panin, V.E.; Beljuk, S.I.; Durakov, V.G.; Pribytkov, G.A.; Rempe, N.G. Electron beam vacuum surfacing: Equipment, technology and properties of coatings. Weld. Int. 2000, 14, 580–584. [Google Scholar] [CrossRef]

- Shil’ko, S.V.; Chernous, D.A.; Panin, S.V. Modeling of bionically inspired antifriction and connecting layers in a joint endoprosthesis. Phys. Mesomech. 2023, 26, 93–99. [Google Scholar] [CrossRef]

- Narkevich, N.A.; Deryugin, E.E.; Perevalova, O.B.; Vlasov, I.V. Effect of ultrasonic forging strain processing on the nearsurface layer microstructure and temperature-dependent mechanical properties of high nitrogen austenitic steel. Mater. Sci. Eng. A 2022, 834, 142590. [Google Scholar] [CrossRef]

- Narkevich, N.; Vlasov, I.; Volochaev, M.Y.; Mironov, Y.; Panin, S.; Berto, F.; Pavel Maksimov, P.; Deryugin, E. Low-Temperature Deformation and Fracture of Cr-Mn-N Stainless Steel: Tensile and Impact Bending Tests. Metals 2023, 13, 95. [Google Scholar] [CrossRef]

- Ormanova, M.; Petrov, P.; Kovacheva, D. Electron beam surface treatment of tool steels. Vacuum 2017, 135, 7–12. [Google Scholar] [CrossRef]

- Mittemeher, E.J.; Cheng, L.; Van der Schaaf, P.J.; Brakman, C.M.; Korevaar, B.M. Analysis of nonisothermal transformation kinetics; tempering of iron–carbon and iron–nitrogen martensites. Metall. Trans. A 1988, 19, 925–932. [Google Scholar] [CrossRef]

- Kim, J.-M.; Kim, S.-J.; Kang, J.-H. Effects of short-range ordering and stacking fault energy on tensile behavior of nitrogen-containing austenitic stainless steels. Mater. Sci. Eng. A 2022, 836, 142730. [Google Scholar] [CrossRef]

- International Centre for Diffraction Data (ICDD), USA. 2020. Available online: http://www.icdd.com/ (accessed on 1 January 2022).

- Ryu, J.J.; Shrestha, S.; Manogharan, G.; Jung, J.K. Sliding Contact wear damage of EBM built Ti6Al4V: Influence of process induced anisotropic microstructure. Metals 2018, 8, 131. [Google Scholar] [CrossRef] [Green Version]

- Tagil’tseva, D.N.; Narkevicha, N.A.; Shulepov, I.A.; Moiseenko, D.D. Relaxation capacity and cracking resistance of nitrous coating produced by electron-beam facing of 0.6C–24Cr–1N–16Mn steel powder during wear by hard abrasive under heavy loads. J. Frict. Wear 2014, 35, 104–110. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: Nanocomposite coating approach to optimised tribological behavior. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Ojima, M.; Adachi, Y.; Tomota, Y.; Ikeda, K.; Kamiyama, T.; Katada, Y. Work hardening mechanism in high nitrogen austenitic steel studied by in situ neutron diffraction and in situ electron backscattering diffraction. Mater. Sci. Eng. A 2009, 527, 16–24. [Google Scholar] [CrossRef]

| Element | Cr | Mn | Si | Ni | C | N | P | S | Al | V | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr-Mn-N steel | 16.5 | 18.81 | 0.52 | 0.24 | 0.07 | 0.53 | 0.01 | 0.001 | - | - | - | Bal. |

| Ti-6Al-4V | - | - | 0.07 | - | 0.07 | 0.05 | - | - | 5.8 | 3.92 | Bal. | - |

| Phase, Lattice Type | Planes (hkl) | Interplanar Distances d Å | Angles between Directions φ, Grad | Lattice Parameters, Å | Lattice Volume V, Å3 |

|---|---|---|---|---|---|

| Fe2Nexp, orthorhombic | (013) | 1.40 | (013) (121) 48 | a = 6.147 b = 5.034 c = 4.367 | 135.13 |

| (121) | 2.055 | (013) () 42 | |||

| () | 1.86 | () (121) 90 | |||

| Fe2NICDD, orthorhombic | (013) | 1.41 | (013) (121) 48 | a = 5.523 b = 4.83 c = 4.425 | 118.02 |

| (121) | 1.98 | (013) () 45 | |||

| () | 1.89 | () (121) 93.5 |

| Processing | H, GPa | E, GPa | H/E | H3/E2 |

|---|---|---|---|---|

| Quenchig Quenchig + MTT | 3 5 | 200 [36] | 1.5 × 10−2 2.5 × 10−2 | 6.75 × 10−4 31.25 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narkevich, N.; Vlasov, I.; Tolmachev, A. Microstructure and Tribological Behavior of Cr-Mn-N Steel with Age-Hardened Near-Surface Layer including CrN and Fe2N Particles Intended for Use in Orthopedic Implants. Metals 2023, 13, 1328. https://doi.org/10.3390/met13081328

Narkevich N, Vlasov I, Tolmachev A. Microstructure and Tribological Behavior of Cr-Mn-N Steel with Age-Hardened Near-Surface Layer including CrN and Fe2N Particles Intended for Use in Orthopedic Implants. Metals. 2023; 13(8):1328. https://doi.org/10.3390/met13081328

Chicago/Turabian StyleNarkevich, Natalia, Ilya Vlasov, and Aleksey Tolmachev. 2023. "Microstructure and Tribological Behavior of Cr-Mn-N Steel with Age-Hardened Near-Surface Layer including CrN and Fe2N Particles Intended for Use in Orthopedic Implants" Metals 13, no. 8: 1328. https://doi.org/10.3390/met13081328

APA StyleNarkevich, N., Vlasov, I., & Tolmachev, A. (2023). Microstructure and Tribological Behavior of Cr-Mn-N Steel with Age-Hardened Near-Surface Layer including CrN and Fe2N Particles Intended for Use in Orthopedic Implants. Metals, 13(8), 1328. https://doi.org/10.3390/met13081328