Solid-State Welding of Aluminum to Magnesium Alloys: A Review

Abstract

:1. Introduction

2. Solid-State Welding Methods

2.1. Ultrasonic Spot Welding

2.2. Friction Stir Welding

2.3. Diffusion Bonding

2.4. Explosive Welding

2.5. Magnetic Pulse Welding

2.6. Resistance Spot Welding

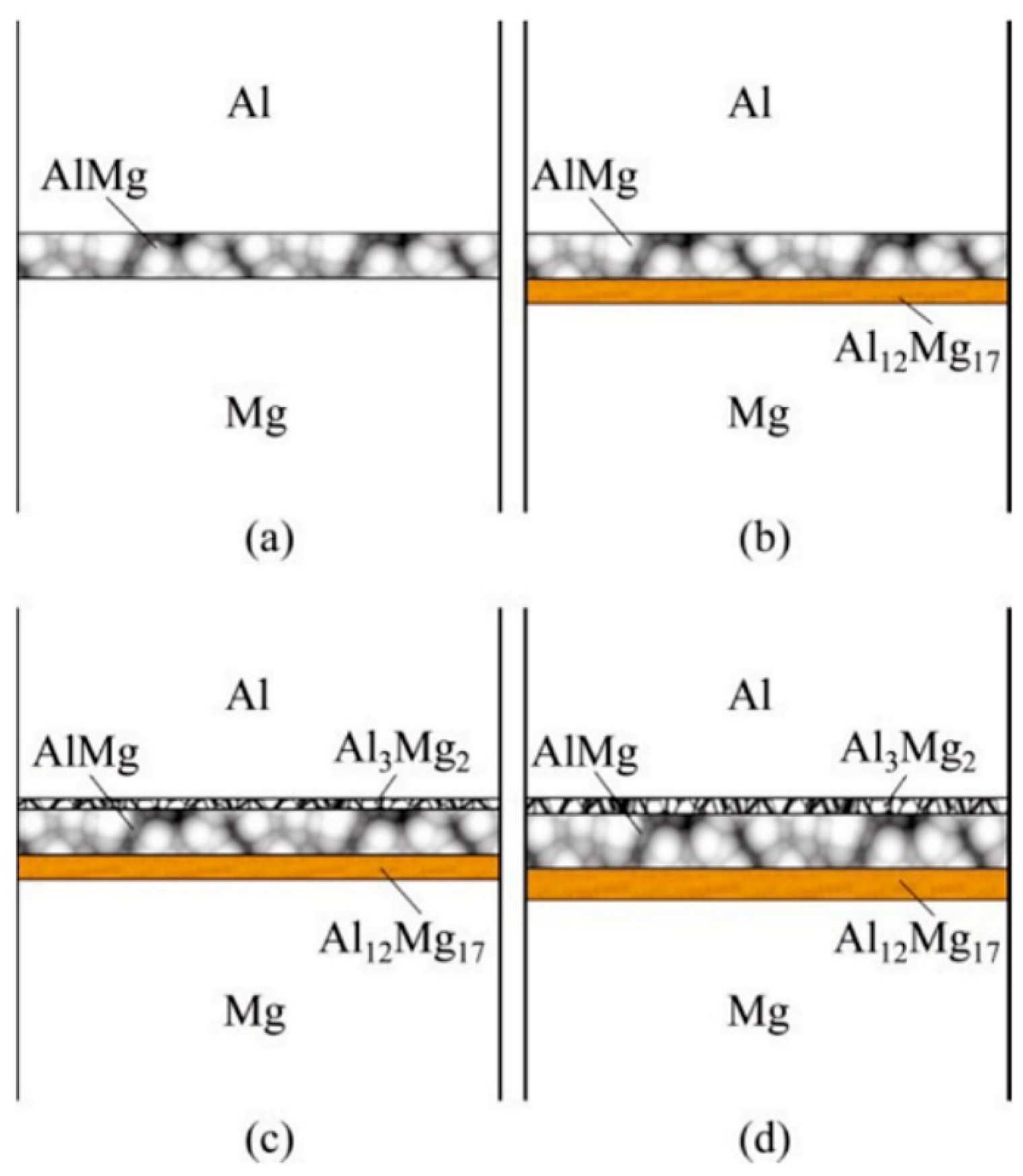

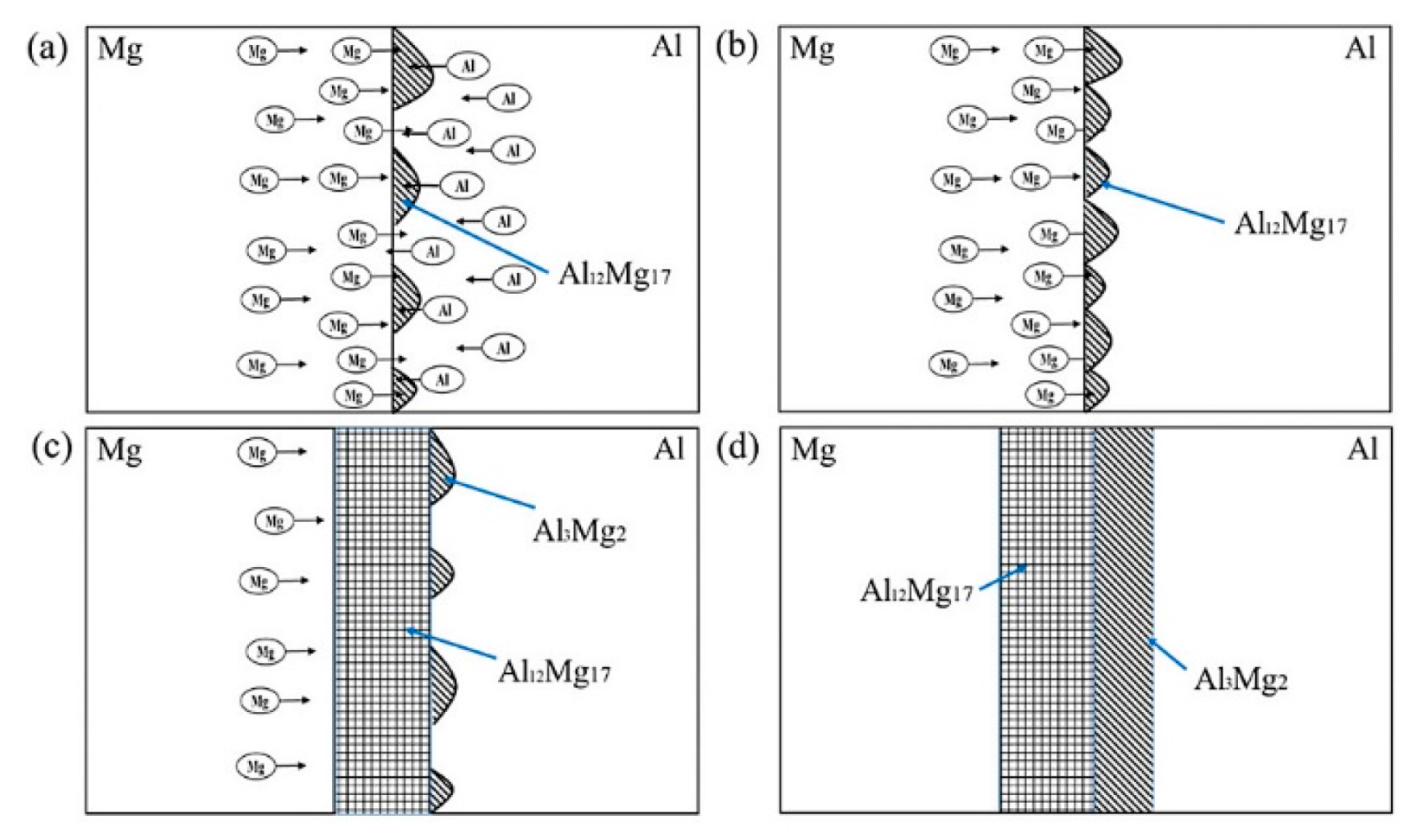

3. Solid-State Welding with Interlayer

4. Hybrid Solid-State Welding Methods

5. Summary and Outlook

- (1)

- Optimizing welding parameters such as current, time, force, tool profile, travel speed, etc., is crucial for enhancing the overall performance of aluminum/magnesium dissimilar alloy welding and has demonstrated successful welding outcomes. Furthermore, refining the welding process itself can also lead to a substantial enhancement in the quality of welds.

- (2)

- In solid phase aluminum/magnesium welding using an intermediate layer, it has been found that metals with a high melting point can effectively resist contact between liquid aluminum and magnesium, thereby hindering the formation of aluminum–magnesium intermetallic compounds. Moreover, by using an intermediate layer metal that undergoes an aluminum–magnesium metallurgical reaction, alloying can be achieved, leading to a change in the composition of the compound phase in the welded joint, making it a promising area for further development.

- (3)

- Hybrid welding methods make effective use of a range of welding approaches, while avoiding the drawbacks of a single method. Of particular importance is the application of ultrasonic waves in composite welding, which opens up new possibilities for dissimilar alloys. Furthermore, the development of composite welding techniques is leading to the creation of new process equipment and technologies for welding dissimilar alloys, making it a highly promising area for future development.

- (4)

- The welding of aluminum/magnesium and other dissimilar metals continues to pose significant challenges in the field of welding engineering. While progress has been made through advancements in welding parameters, intermediate layer use, and composite welding, further efforts are needed to develop lower-cost and more efficient techniques for dissimilar alloy welding.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Callegari, B.; Lima, T.N.; Coelho, R.S. The Influence of Alloying Elements on the Microstructure and Properties of Al-Si-Based Casting Alloys: A Review. Metals 2023, 13, 1174. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D. Climate and energy challenges for materials science. Nat. Mater. 2016, 15, 117–120. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Xin, T.; Zhao, Y.; Mahjoub, R.; Jiang, J.; Yadav, A.; Nomoto, K.; Niu, R.; Tang, S.; Ji, F.; Quadir, Z.; et al. Ultrahigh specific strength in a magnesium alloy strengthened by spinodal decomposition. Sci. Adv. 2021, 7, eabf3039. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.X.; Ahmad, R.; Yin, B.; Sandlöbes, S.; Curtin, W.A. Mechanistic origin and prediction of enhanced ductility in magnesium alloys. Science 2018, 359, 447–452. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Frankel, G.S. Magnesium alloys: Ready for the road. Nat. Mater. 2015, 14, 1189–1190. [Google Scholar] [CrossRef]

- Peng, H.; Jiang, X.; Bai, X.; Li, D.; Chen, D. Microstructure and mechanical properties of ultrasonic spot welded Mg/Al alloy dissimilar joints. Metals 2018, 8, 229. [Google Scholar] [CrossRef] [Green Version]

- Hajjari, E.; Divandari, M.; Razavi, S.H.; Emami, S.M.; Homma, T.; Kamado, S. Dissimilar joining of Al/Mg light metals by compound casting process. J. Mater. Sci. 2011, 46, 6491–6499. [Google Scholar] [CrossRef]

- Wang, P.; Chen, Z.; Huang, H.; Lin, J.; Li, B.; Liu, Q. Fabrication of Ti/Al/Mg laminated composites by hot roll bonding and their microstructures and mechanical properties. Chin. J. Aeronaut. 2020, 34, 192–201. [Google Scholar] [CrossRef]

- Khan, H.A.; Asim, K.; Akram, F.; Hameed, A.; Khan, A.; Mansoor, B. Roll Bonding Processes: State-of-the-Art and Future Perspectives. Metals 2021, 11, 1344. [Google Scholar] [CrossRef]

- Tayyebi, M.; Adhami, M.; Karimi, A.; Rahmatabadi, D.; Alizadeh, M.; Hashemi, R. Effects of strain accumulation and annealing on interfacial microstructure and grain structure (Mg and Al3Mg2 layers) of Al/Cu/Mg multilayered composite fabricated by ARB process. J. Mater. Res. Technol. 2021, 14, 392–406. [Google Scholar] [CrossRef]

- Chen, Y.; Mao, Y.; Lu, W.; He, P. Investigation of welding crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metals joints. Opt. Laser Technol. 2017, 91, 197–202. [Google Scholar] [CrossRef]

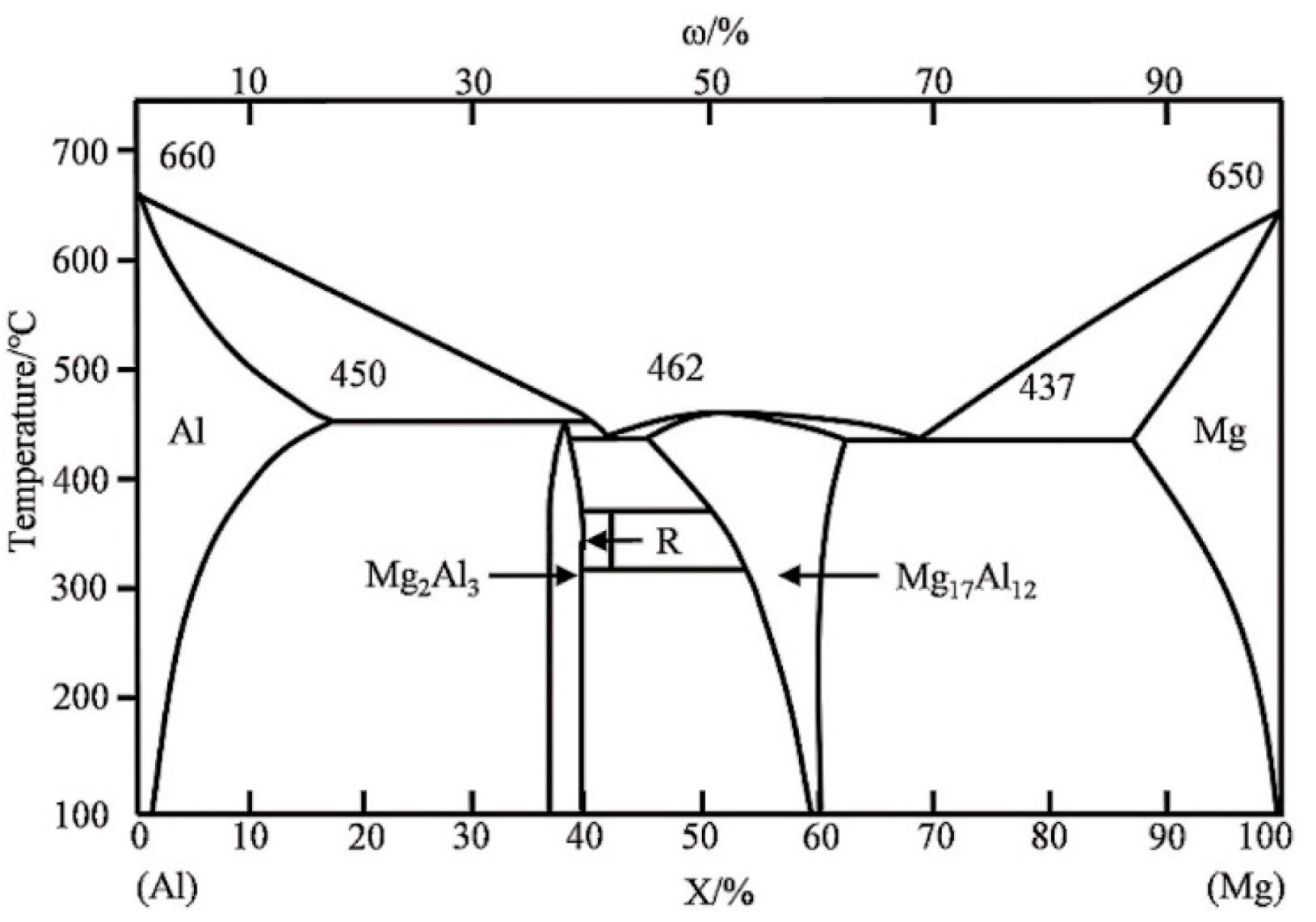

- Sato, Y.S.; Park, S.H.C.; Michiuchi, M.; Kokawa, H. Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys. Scr. Mater. 2004, 50, 1233–1236. [Google Scholar] [CrossRef]

- Xu, Y.; Ke, L.M.; Mao, Y.Q.; Liu, Q.; Xie, J.; Zeng, H.R. Formation investigation of intermetallic compounds of thick plate Al/Mg alloys joint by friction stir welding. Materials 2019, 12, 2661. [Google Scholar] [CrossRef] [Green Version]

- Sanamar, S.; Brokmeier, H.-G.; Schell, N. Formation of the intermetallic phases Al12Mg17 and Al3Mg2 during heating of elemental Al-Mg composites studied by high-energy X-ray diffraction. J. Alloys Compd. 2022, 911, 165114. [Google Scholar] [CrossRef]

- Beygi, R.; Pouraliakbar, H.; Torabi, K.; Eisaabadi B., G.; Fallah, V.; Kim, S.; Shi, R.; da Silva, L. The inhibitory effect of stir zone liquefaction and eutectic-phase formation on the growth of γ/β intermetallics during dissimilar FSW of Al/Mg alloys. J. Manuf. Process. 2021, 70, 152–162. [Google Scholar] [CrossRef]

- Bergmann, J.P.; Petzoldt, F.; Schürer, R.; Schneider, S. Solid-state welding of aluminum to copper—Case studies. Weld. World Le Soudage Dans Le Monde 2013, 57, 541–550. [Google Scholar] [CrossRef]

- Shayakhmetova, E.R.; Murzinova, M.A.; Zadorozhniy, V.S.; Nazarov, A.A. Microstructure of Joints Processed by Ultrasonic Consolidation of Nickel Sheets. Metals 2022, 12, 1865. [Google Scholar] [CrossRef]

- Ni, Z.; Ye, F. Ultrasonic spot welding of aluminum alloys: A review. J. Manuf. Process. 2018, 35, 580–594. [Google Scholar] [CrossRef]

- Padhy, G.; Wu, C.; Gao, S. Friction stir based welding and processing technologies—Processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M. The Influence of the Tool Tilt Angle on the Heat Generation and the Material Behavior in Friction Stir Welding (FSW). Metals 2022, 12, 1837. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Liu, K.; Wang, J.; Jian, S.; Xu, C.; Wang, H.; Wang, L.; Zhu, X.; Okulov, A.; et al. Diffusion bonding, brazing and resistance welding of zirconium alloys: A review. J. Mater. Res. Technol. 2023, 26, 395–416. [Google Scholar] [CrossRef]

- Wang, Q.; Li, X.; Shi, B.; Wu, Y. Experimental and Numerical Studies on Preparation of Thin AZ31B/AA5052 Composite Plates Using Improved Explosive Welding Technique. Metals 2020, 10, 1023. [Google Scholar] [CrossRef]

- Kapil, A.; Mastanaiah, P.; Sharma, A. Comprehensive Weldability Criterion for Magnetic Pulse Welding of Dissimilar Materials. Metals 2022, 12, 1791. [Google Scholar] [CrossRef]

- Emadinia, O.; Ramalho, A.M.; De Oliveira, I.V.; Taber, G.A.; Reis, A. Influence of Surface Preparation on the Interface of Al-Cu Joints Produced by Magnetic Pulse Welding. Metals 2020, 10, 997. [Google Scholar] [CrossRef]

- Martín, Ó.; De Tiedra, P. Advances in the Control and Improvement of Quality in the Resistance Spot Welding Process. Metals 2022, 12, 1810. [Google Scholar] [CrossRef]

- Khedr, M.; Hamada, A.; Järvenpää, A.; Elkatatny, S.; Abd-Elaziem, W. Review on the Solid-State Welding of Steels: Diffusion Bonding and Friction Stir Welding Processes. Metals 2023, 13, 54. [Google Scholar] [CrossRef]

- Moghaddam, N.T.; Rabiezadeh, A.; Khosravifard, A.; Ghalandari, L. Welding of Al–Mg alloy: Solid-State vs. Fusion Welding Techniques. Iran. J. Sci. Technol. Trans. Mech. Eng. 2023, 47, 673–686. [Google Scholar] [CrossRef]

- Singh, V.P.; Patel, S.K.; Ranjan, A.; Kuriachen, B. Recent research progress in solid state friction-stir welding of aluminium–magnesium alloys: A critical review. J. Mater. Res. Technol. 2020, 9, 6217–6256. [Google Scholar] [CrossRef]

- Peng, P.; Wang, W.; Zhang, T.; Liu, Q.; Guan, X.; Qiao, K.; Cai, J.; Wang, K. Effects of interlayer metal on microstructures and mechanical properties of friction stir lap welded dissimilar joints of magnesium and aluminum alloys. J. Mater. Process. Technol. 2022, 299, 117362. [Google Scholar] [CrossRef]

- Song, Q.; Wang, H.; Ji, S.; Ma, Z.; Jiang, W.; Chen, M. Improving joint quality of hybrid friction stir welded Al/Mg dissimilar alloys by RBFNN-GWO system. J. Manuf. Process. 2020, 59, 750–759. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W. Ultrasonic vibration-assisted (UV-A) manufacturing processes: State of the art and future perspectives. J. Manuf. Process. 2020, 51, 174–190. [Google Scholar] [CrossRef]

- Peng, H.; Chen, D.; Jiang, X. Microstructure and mechanical properties of an ultrasonic spot welded aluminum alloy: The effect of welding energy. Materials 2017, 10, 449. [Google Scholar] [CrossRef] [Green Version]

- Cheng, X.M.; Yang, K.; Wang, J.; Xiao, W.T.; Huang, S.S. Ultrasonic system and ultrasonic metal welding performance: A status review. J. Manuf. Process. 2022, 84, 1196–1216. [Google Scholar] [CrossRef]

- Huang, H.; Chen, J.; Lim, Y.C.; Hu, X.; Cheng, J.; Feng, Z.; Sun, X. Heat generation and deformation in ultrasonic welding of magnesium alloy AZ31. J. Mater. Process. Technol. 2019, 272, 125–136. [Google Scholar] [CrossRef]

- Li, H.; Cao, B. Effects of welding pressure on high-power ultrasonic spot welding of Cu/Al dissimilar metals. J. Man-Ufacturing Process. 2019, 46, 194–203. [Google Scholar] [CrossRef]

- Ni, Z.L.; Ye, F.X. Ultrasonic spot welding of Al sheets by enhancing the temperature of weld interface. Mater. Lett. 2017, 208, 69–72. [Google Scholar] [CrossRef]

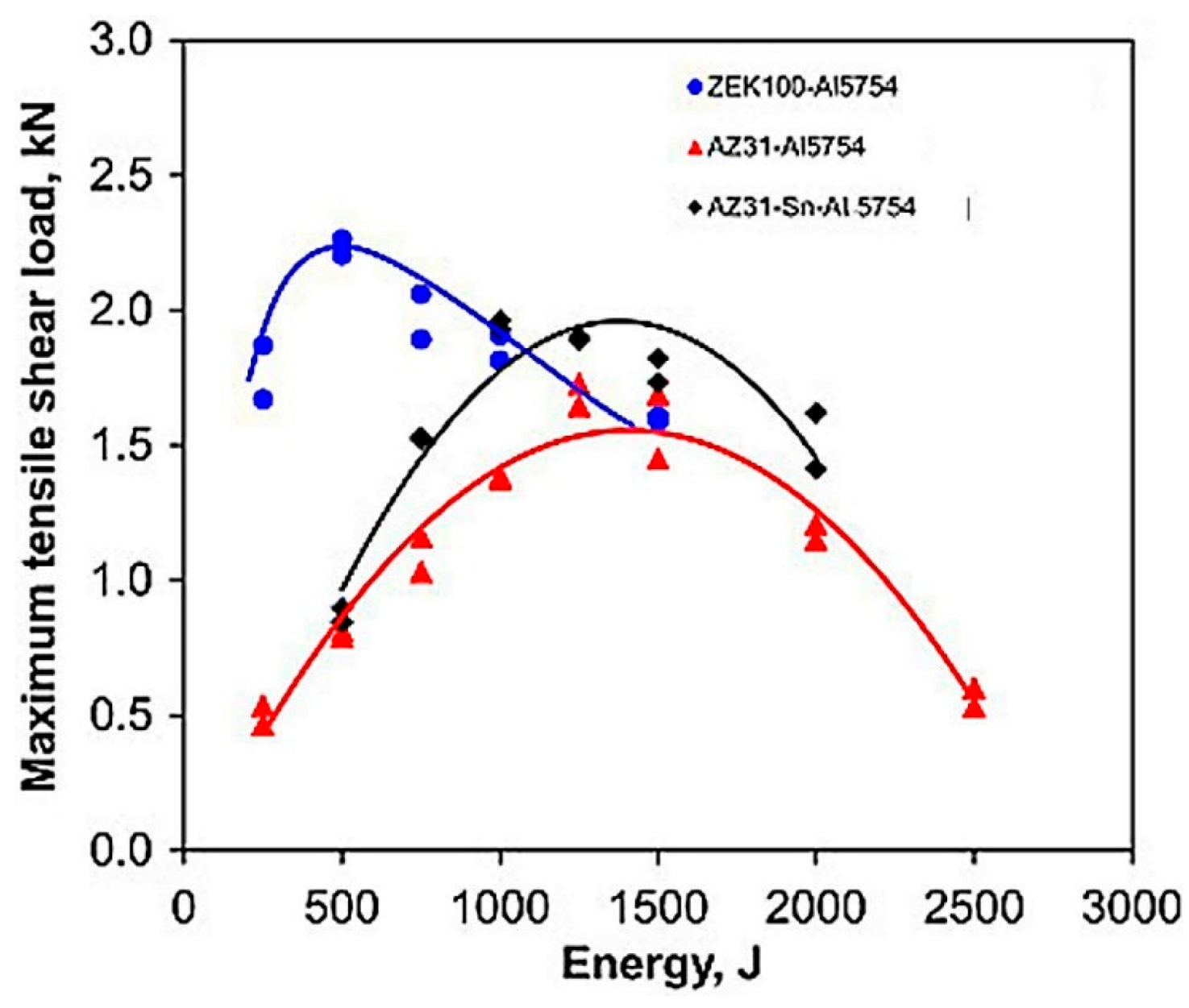

- Macwan, A.; Chen, D.L. Ultrasonic Spot Welding of a Rare-Earth Containing ZEK100 Magnesium Alloy: Effect of Welding En-ergy. Metall. Mater. Trans. A 2016, 47, 1–12. [Google Scholar] [CrossRef]

- Macwan, A.; Chen, D.L. Ultrasonic spot welding of rare-earth containing ZEK100 magnesium alloy to 5754 aluminum alloy. Mater. Sci. Eng. A 2016, 666, 139–148. [Google Scholar] [CrossRef]

- Patel, V.K.; Bhole, S.D.; Chen, D.L. Microstructure and mechanical properties of dissimilar welded Mg-Al joints by ultrasonic spot welding technique. Sci. Technol. Weld. Join. 2012, 17, 202–206. [Google Scholar] [CrossRef]

- Patel, V.K.; Bhole, S.D.; Chen, D.L. Improving weld strength of magnesium to aluminium dissimilar joints via tin interlayer during ultrasonic spot welding. Sci. Technol. Weld. Join. 2012, 17, 342–347. [Google Scholar] [CrossRef]

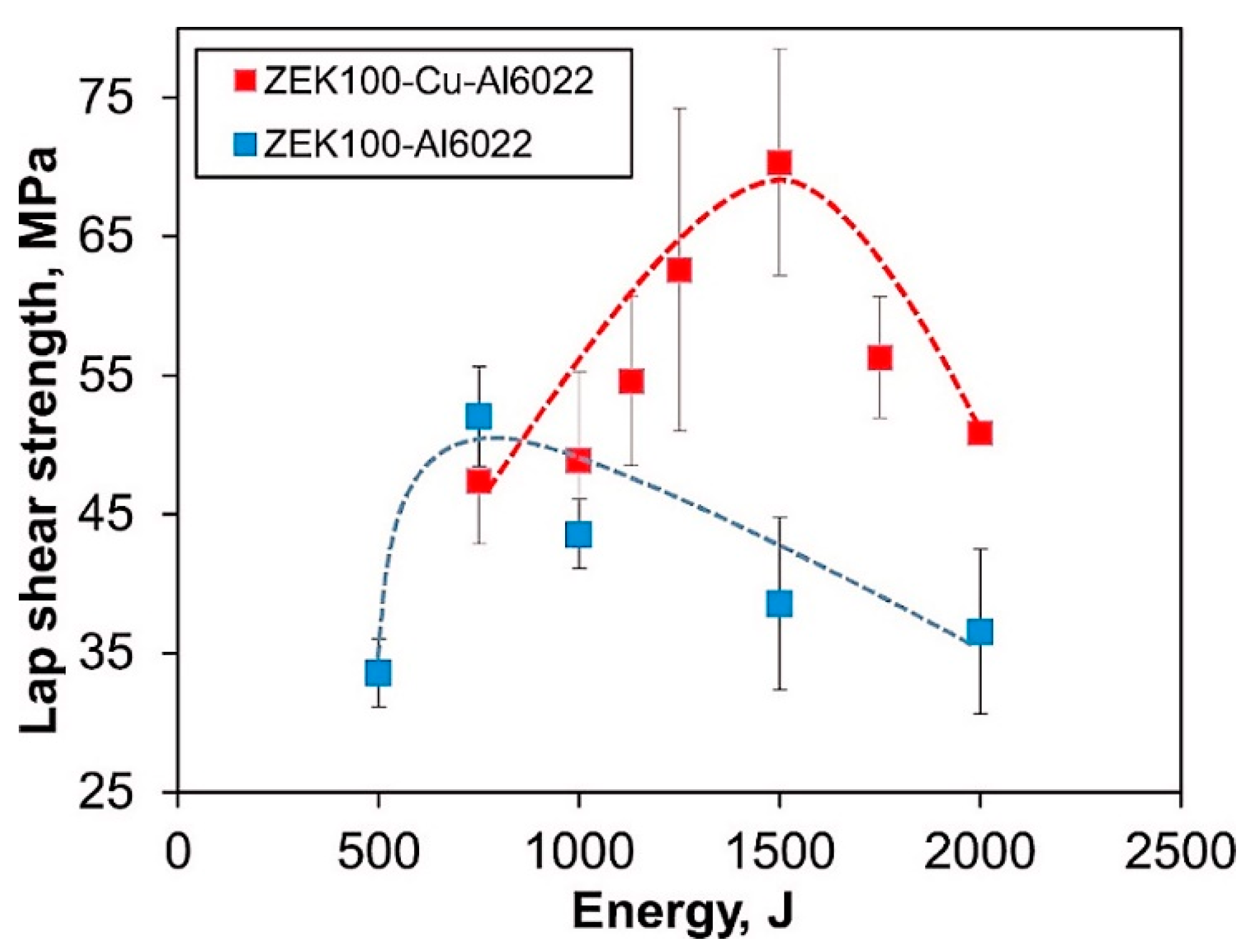

- Peng, H.; Chen, D.L.; Bai, X.F.; She, X.W.; Li, D.Y.; Jiang, X.Q. Ultrasonic spot welding of magnesium-to-aluminum alloys with a copper interlayer: Micro-structural evolution and tensile properties. J. Manuf. Process. 2019, 37, 91–100. [Google Scholar] [CrossRef]

- Peng, H.; Chen, D.L.; Bai, X.F.; Wang, P.Q.; Li, D.Y.; Jiang, X.Q. Microstructure and mechanical properties of Mg-to-Al dissimilar welded joints with an Ag interlayer using ultrasonic spot welding. J. Magnes. Alloys 2020, 8, 552–563. [Google Scholar] [CrossRef]

- Peng, H.; Chen, D.; Guo, S.; Hong, H.; Zheng, K.; Bai, X.; Li, D.; Jiang, X. Dissimilar ultrasonic spot welding of rare-earth containing ZEK100 magnesium-to-aluminum alloy with a zinc interlayer: Microstructural evolution and mechanical properties. J. Manuf. Process. 2023, 92, 422–434. [Google Scholar] [CrossRef]

- Sidhu, R.S.; Kumar, R.; Kumar, R.; Goel, P.; Singh, S.; Pimenov, D.Y.; Giasin, K.; Adamczuk, K. Joining of Dissimilar Al and Mg Metal Alloys by Friction Stir Welding. Materials 2022, 15, 5901. [Google Scholar] [CrossRef]

- Malarvizhi, S.; Balasubramanian, V. Influences of tool shoulder diameter to plate thickness ratio (D/T) on stir zone formation and tensile properties of friction stir welded dissimilar joints of AA6061 aluminum–AZ31B magnesium alloys. Mater. Des. 2012, 40, 453–460. [Google Scholar] [CrossRef]

- Sekhon, S.S.; Kumar, H.; Sehgal, S. Effect of tool pin profile on performance of friction stir welding of brass-copper-based butt welded joint. Int. J. Mater. Eng. Innov. 2016, 7, 236. [Google Scholar] [CrossRef]

- Firouzdor, V.; Kou, S. Al-to-Mg friction stir welding: Effect of material position, travel speed, and rotation speed. Met. Mater. Trans. A 2010, 41, 2914–2935. [Google Scholar] [CrossRef]

- Niu, S.; Ji, S.; Yan, D.; Meng, X.; Xiong, X. AZ31B/7075-T6 alloys friction stir lap welding with a zinc interlayer. J. Mater. Process. Technol. 2019, 263, 82–90. [Google Scholar] [CrossRef]

- Ji, S.; Niu, S.; Liu, J. Dissimilar Al/Mg alloys friction stir lap welding with Zn foil assisted by ultrasonic. J. Mater. Sci. Technol. 2019, 35, 1712–1718. [Google Scholar] [CrossRef]

- Bag, S.; Akinlabi, E.T. Eco Friendly Aspects in Hybridization of Friction Stir Welding Technology for Dissimilar Metallic Materials. Encycl. Renew. Sustain. Mater. 2020, 1, 225–236. [Google Scholar]

- Fernandus, M.J.; Senthilkumar, T.; Balasubramanian, V.; Rajakumar, S. Optimising diffusion bonding parameters to maximize the strength of AA6061 aluminium and AZ31B magnesium alloy joints. Mater. Des. 2012, 33, 31–41. [Google Scholar] [CrossRef]

- Azizi, A.; Alimardan, H. Effect of welding temperature and duration on properties of 7075 Al to AZ31B Mg diffusion bonded joint. Trans. Nonferrous Met. Soc. China 2016, 26, 85–92. [Google Scholar] [CrossRef]

- Liu, W.S.; Long, L.P.; Ma, Y.Z.; Wu, L. Microstructure evolution and mechanical properties of Mg/Al diffusion bonded joints. J. Alloys Compd. 2015, 643, 34–39. [Google Scholar] [CrossRef]

- Afghahi, S.S.S.; Jafarian, M.; Paidar, M.; Jafarian, M. Diffusion bonding of Al 7075 and Mg AZ31 alloys: Process parameters, microstructural analysis and mechanical properties. Trans. Nonferrous Met. Soc. China 2016, 26, 1843–1851. [Google Scholar] [CrossRef]

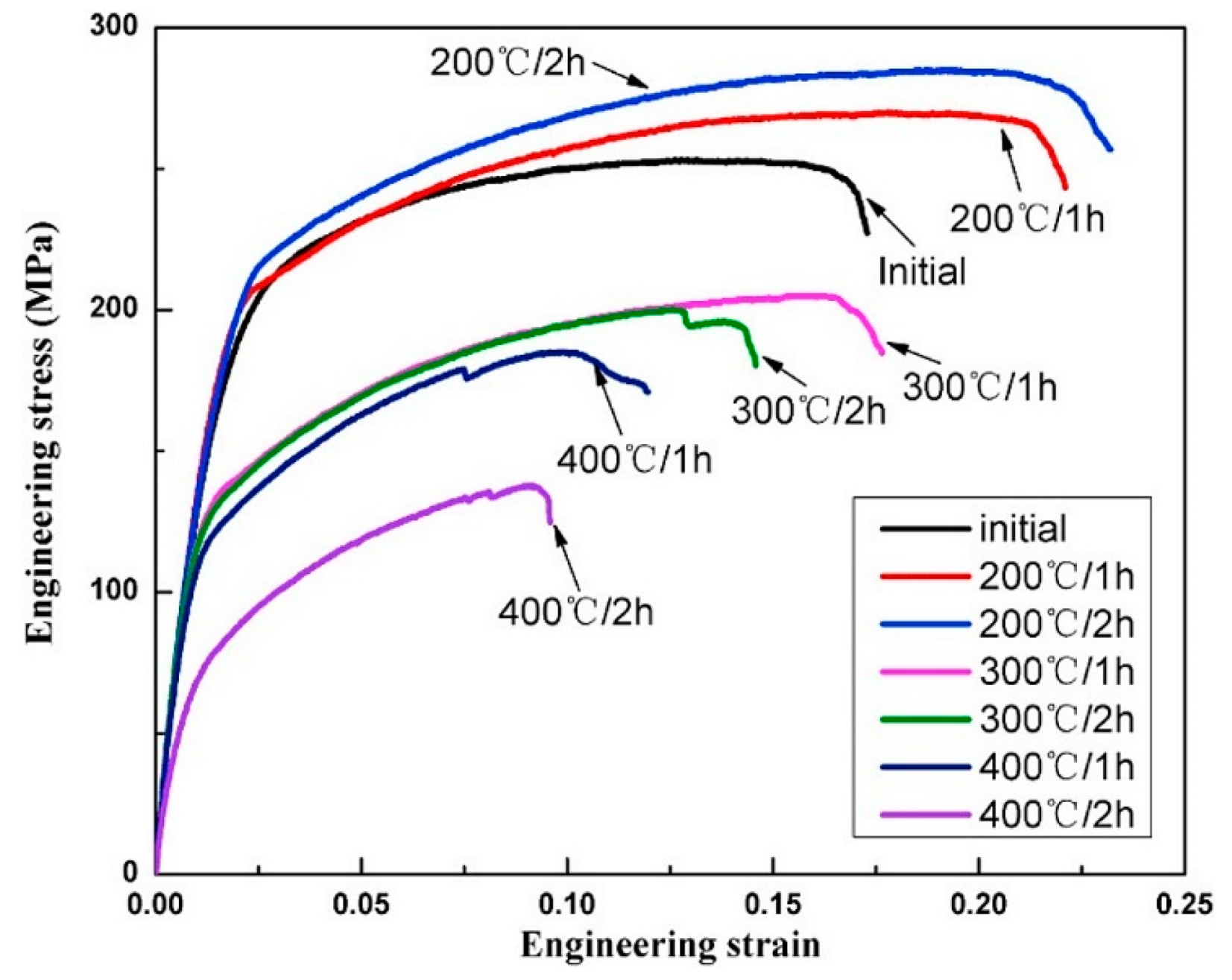

- Jafarian, M.; Rizi, M.S.; Jafarian, M.; Honarmand, M.; Javadinejad, H.R.; Ghaheri, A.; Bahramipour, M.T.; Ebrahimian, M. Effect of thermal tempering on microstructure and mechanical properties of Mg-AZ31/Al-6061 diffusion bonding. Mater. Sci. Eng. A 2016, 666, 372–379. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, L.; Xu, R. Effect of interlayer composition on the microstructure and strength of diffusion bonded Mg/Al joint. Mater. Des. 2009, 30, 4548–4551. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, G.; Wang, Y.; Shen, Q.; Zhang, L. An investigation on diffusion bonding of aluminum and magnesium using a Ni interlayer. Mater. Lett. 2012, 83, 189–191. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, G.; Wang, Y.; Xiao, Y.; Shen, Q.; Zhang, L. Effect of Al thin film and Ni foil interlayer on diffusion bonded Mg–Al dissimilar joints. J. Alloys Compd. 2013, 556, 139–142. [Google Scholar] [CrossRef]

- Varmazyar, J.; Khodaei, M. Diffusion bonding of aluminum-magnesium using cold rolled copper interlayer. J. Alloys Compd. 2018, 773, 838–843. [Google Scholar] [CrossRef]

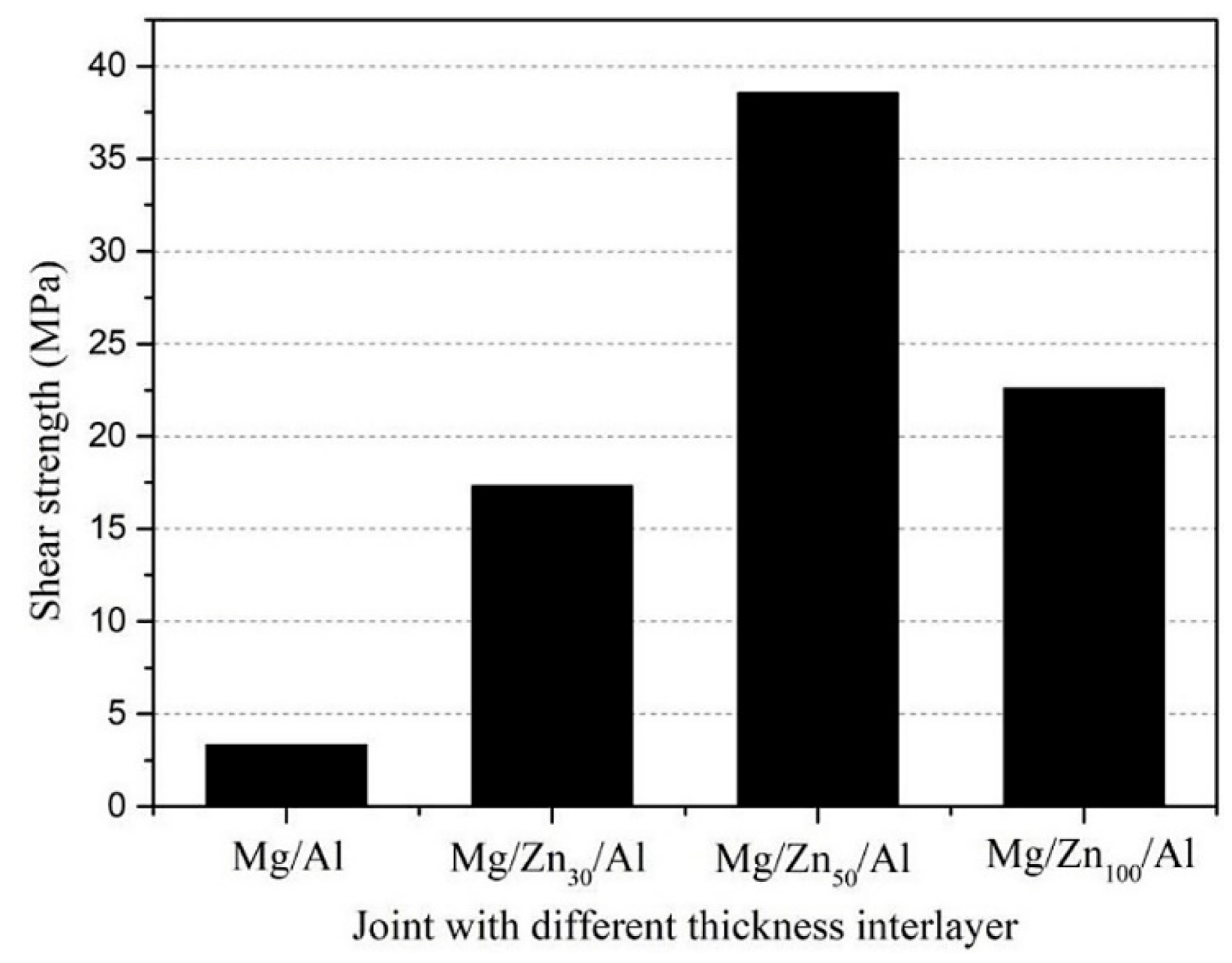

- Guo, Y.; Quan, G.; Ren, L.; Liu, B.; Al-Ezzi, S.; Pan, H. Effect of Zn interlayer thickness on the microstructure and mechanical properties of two-step diffusion bonded joint of ZK60Mg and 5083Al. Vacuum 2018, 161, 353–360. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, Z.; Shen, W.; Wang, J.; Zhang, L.; Chin, B. Microstructure and properties of magnesium AZ31B–aluminum 7075 explosively welded composite plate. Mater. Sci. Eng. A 2010, 527, 2241–2245. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, W.; Yan, Z.; Zhang, J. Interfacial Morphology and Bonding Mechanism of Explosive Weld Joints. Chin. J. Mech. Eng. 2021, 34, 8. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, W.; Zhang, W.; Wei, Y.; Cao, X.; Yan, Z.; Zhou, J. Microstructure evolution and mechanical properties of an AA6061/AZ31B alloy plate fabricated by explosive welding. J. Alloys Compd. 2017, 735, 1759–1768. [Google Scholar] [CrossRef]

- Paul, H.; Petrzak, P.; Chulist, R.; Maj, Ł.; Mania, I.; Prażmowski, M. Effect of impact loading and heat treatment on microstructure and properties of multi-layered AZ31/AA1050 plates fabricated by single-shot explosive welding. Mater. Des. 2022, 214, 110411. [Google Scholar] [CrossRef]

- Zeng, X.-Y.; Wang, Y.-X.; Li, X.-Q.; Li, X.-J.; Zhao, T.-J. Effect of inert gas-shielding on the interface and mechanical properties of Mg/Al explosive welding composite plate. J. Manuf. Process. 2019, 45, 166–175. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, L.; Zhao, G.; Cai, Z.; Zhi, C. Effect of annealing temperature on tensile fracture behavior of AZ31/6061 explosive composite plate. J. Mater. Res. Technol. 2022, 19, 4325–4336. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, W.; Cao, X.; Wu, J. The effect of annealing on the interface microstructure and mechanical characteristics of AZ31B/AA6061 composite plates fabricated by explosive welding. Mater. Des. 2015, 65, 1100–1109. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, D.; Cao, X.; Yang, W.; Wang, W. Influence of multi-pass rolling and subsequent annealing on the interface microstructure and mechanical properties of the explosive welding Mg/Al composite plates. Mater. Sci. Eng. A 2018, 723, 97–108. [Google Scholar] [CrossRef]

- Kapil, A.; Sharma, A. Magnetic pulse welding: An efficient and environmentally friendly multi-material joining technique. J. Clean. Prod. 2015, 100, 35–58. [Google Scholar] [CrossRef]

- Geng, H.; Xia, Z.; Zhang, X.; Li, G.; Cui, J. Microstructures and mechanical properties of the welded AA5182/HC340LA joint by magnetic pulse welding—ScienceDirect. Mater. Charact. 2018, 138, 229–237. [Google Scholar] [CrossRef]

- Jiang, X.; Chen, S. Texture evolution and plastic deformation mechanism in magnetic pulse welding of dissimilar Al and Mg alloys. Weld. World 2018, 62, 1159–1171. [Google Scholar] [CrossRef]

- Zhu, C.; Sun, L.; Gao, W.; Li, G.; Cui, J. The effect of temperature on microstructure and mechanical properties of Al/Mg lap joints manufactured by magnetic pulse welding—ScienceDirect. J. Mater. Res. Technol. 2019, 8, 3270–3280. [Google Scholar] [CrossRef]

- Stern, A.; Aizenshtein, M. Magnetic pulse welding of Al to Mg alloys: Structural–mechanical properties of the interfacial layer. Mater. Sci. Technol. 2011, 27, 1809–1813. [Google Scholar] [CrossRef]

- Li, Y.; Yang, D.; Yang, W.; Wu, Z.; Liu, C. Effect of Annealing Temperature on Microstructure and Properties of Al/Mg Magnetic Pulse Welding Joints. Materials 2022, 15, 5519. [Google Scholar] [CrossRef]

- Bi, J.; Song, J.; Wei, Q.; Zhang, Y.; Li, Y.; Luo, Z. Characteristics of shunting in resistance spot welding for dissimilar unequal-thickness aluminum alloys under large thickness ratio. Mater. Des. 2016, 101, 226–235. [Google Scholar] [CrossRef]

- Hayat, F. The effects of the welding current on heat input, nugget geometry, and the mechanical and fractural properties of resistance spot welding on Mg/Al dissimilar materials. Mater. Des. 2011, 32, 2476–2484. [Google Scholar] [CrossRef]

- Aslanlar, S.; Ogur, A.; Ozsarac, U.; Ilhan, E. Welding time effect on mechanical properties of automotive sheets in electrical resistance spot welding. Mater. Des. 2008, 29, 1427–1431. [Google Scholar] [CrossRef]

- Sun, M.; Niknejad, S.; Gao, H.; Wu, L.; Zhou, Y. Mechanical properties of dissimilar resistance spot welds of aluminum to magnesium with Sn-coated steel interlayer. Mater. Des. 2016, 91, 331–339. [Google Scholar] [CrossRef]

- Sun, M.; Niknejad, S.; Zhang, G.; Lee, M.; Wu, L.; Zhou, Y. Microstructure and mechanical properties of resistance spot welded AZ31/AA5754 using a nickel interlayer. Mater. Des. 2015, 87, 905–913. [Google Scholar] [CrossRef]

- Penner, P.; Liu, L.; Gerlich, A.; Zhou, Y. Feasibility study of resistance spot welding of dissimilar Al/Mg combinations with Ni based interlayers. Sci. Technol. Weld. Join. 2013, 18, 541–550. [Google Scholar] [CrossRef]

- Penner, P.; Liu, L.; Gerlich, A.P.; Zhou, Y. Dissimilar Resistance Spot Welding of Aluminum to Magnesium with Zn-Coated Steel Interlayers. Weld. J. 2014, 93, 225S–231S. [Google Scholar]

- Li, M.; Wang, Y.; Yang, S.; Tao, W.; Zhang, G. Improving mechanical properties and electrode life for joining aluminum alloys with innovatively designated Newton ring electrode. J. Manuf. Process. 2021, 64, 948–959. [Google Scholar] [CrossRef]

- Qi, L.; Zhang, Q.; Ma, Y.; Xu, Y.; Han, X.; Li, Y. A comparative study on mechanical performance of traditional and magnetically assisted resistance spot welds of A7N01 aluminum alloy. J. Manuf. Process. 2021, 66, 133–144. [Google Scholar] [CrossRef]

- Shah, U.; Liu, X. Effects of ultrasonic vibration on resistance spot welding of transformation induced plasticity steel 780 to aluminum alloy AA6061. Mater. Des. 2019, 182, 108053. [Google Scholar] [CrossRef]

- Yamamoto, N.; Liao, J.; Watanabe, S.; Nakata, K. Effect of Intermetallic Compound Layer on Tensile Strength of Dissimilar Friction-Stir Weld of a High Strength Mg Alloy and Al Alloy. Mater. Trans. 2009, 50, 2833–2838. [Google Scholar] [CrossRef] [Green Version]

- Gan, R.; Jin, Y. Friction stir-induced brazing of Al/Mg lap joints with and without Zn interlayer. Sci. Technol. Weld. Join. 2017, 23, 164–171. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zhang, Z.D.; Liu, L.M. The Effect of Galvanized Iron Interlayer on the Intermetallics in the Laser Weld Bonding of Mg to Al Fusion Zone. J. Mater. Eng. Perform. 2013, 22, 351–357. [Google Scholar] [CrossRef]

- Shah, L.H.; Gerlich, A.; Zhou, Y. Design guideline for intermetallic compound mitigation in Al-Mg dissimilar welding through addition of interlayer. Int. J. Adv. Manuf. Technol. 2018, 94, 2667–2678. [Google Scholar] [CrossRef]

- Panteli, A.; Robson, J.D.; Chen, Y.-C.; Prangnell, P.B. The Effectiveness of Surface Coatings on Preventing Interfacial Reaction During Ultrasonic Welding of Aluminum to Magnesium. Met. Mater. Trans. A 2013, 44, 5773–5781. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Luo, G.; Zhang, J.; Shen, Q.; Zhang, L. Microstructure and mechanical properties of diffusion-bonded Mg–Al joints using silver film as interlayer. Mater. Sci. Eng. A 2013, 559, 868–874. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, G.-Q.; Shen, Q.; Zhang, L.-M.; Huang, Z.-J. Characterization of diffusion-bonded joint between Al and Mg using a Ni interlayer. Rare Met. 2016, 35, 537–542. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, Z.; Li, Y.; Liu, Z.; Huang, Z. Microstructure characterization and tensile properties of Mg/Al dissimilar joints manufactured by thermo-compensated resistance spot welding with Zn interlayer. Mater. Des. 2015, 75, 166–173. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, H.; Zhang, H.; Liu, J.; Feng, J. Arc assisted ultrasonic seam welding of Mg/Al joints with Zn interlayer. Mater. Sci. Technol. 2016, 32, 164–172. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, H.; Zhang, H.; Liu, J.; Feng, J. Joining of magnesium and aluminum via arc-assisted ultrasonic seam welding with Sn/Zn composite interlayer. Mater. Lett. 2016, 178, 235–238. [Google Scholar] [CrossRef]

- Xu, R.Z.; Ni, D.R.; Yang, Q.; Liu, C.Z.; Ma, Z.Y. Influence of Zn coating on friction stir spot welded magnesium-aluminium joint. Sci. Technol. Weld. Join. 2016, 22, 512–519. [Google Scholar] [CrossRef]

- Xu, R. Influence of Zn Interlayer Addition on Microstructure and Mechanical Properties of Friction Stir Spot Welded Mg-Al Dissimilar Joints. J. Mech. Eng. 2017, 53, 18–25. [Google Scholar] [CrossRef]

- Abdollahzadeh, A.; Shokuhfar, A.; Cabrera, J.; Zhilyaev, A.; Omidvar, H. The effect of changing chemical composition on dissimilar Mg/Al friction stir welded butt joints using zinc interlayer. J. Manuf. Process. 2018, 34, 18–30. [Google Scholar] [CrossRef] [Green Version]

- Yin, F.; Liu, C.; Zhang, Y.; Qin, Y.; Liu, N. Effect of Ni interlayer on characteristics of diffusion bonded Mg/Al joints. Mater. Sci. Technol. 2018, 34, 1104–1111. [Google Scholar] [CrossRef]

- Gu, X.; Sui, C.; Liu, J.; Li, D.; Meng, Z.; Zhu, K. Microstructure and mechanical properties of Mg/Al joints welded by ultrasonic spot welding with Zn interlayer. Mater. Des. 2019, 181, 108103. [Google Scholar] [CrossRef]

- Zheng, Y.; Pan, X.; Ma, Y.; Liu, S.; Zang, L.; Chen, Y. Microstructure and Corrosion Behavior of Friction Stir-Welded 6061 Al/AZ31 Mg Joints with a Zr Interlayer. Materials 2019, 12, 1115. [Google Scholar] [CrossRef] [Green Version]

- Ji, S.; Niu, S.; Liu, J.; Meng, X. Friction stir lap welding of Al to Mg assisted by ultrasound and a Zn interlayer. J. Mater. Process. Technol. 2019, 267, 141–151. [Google Scholar] [CrossRef]

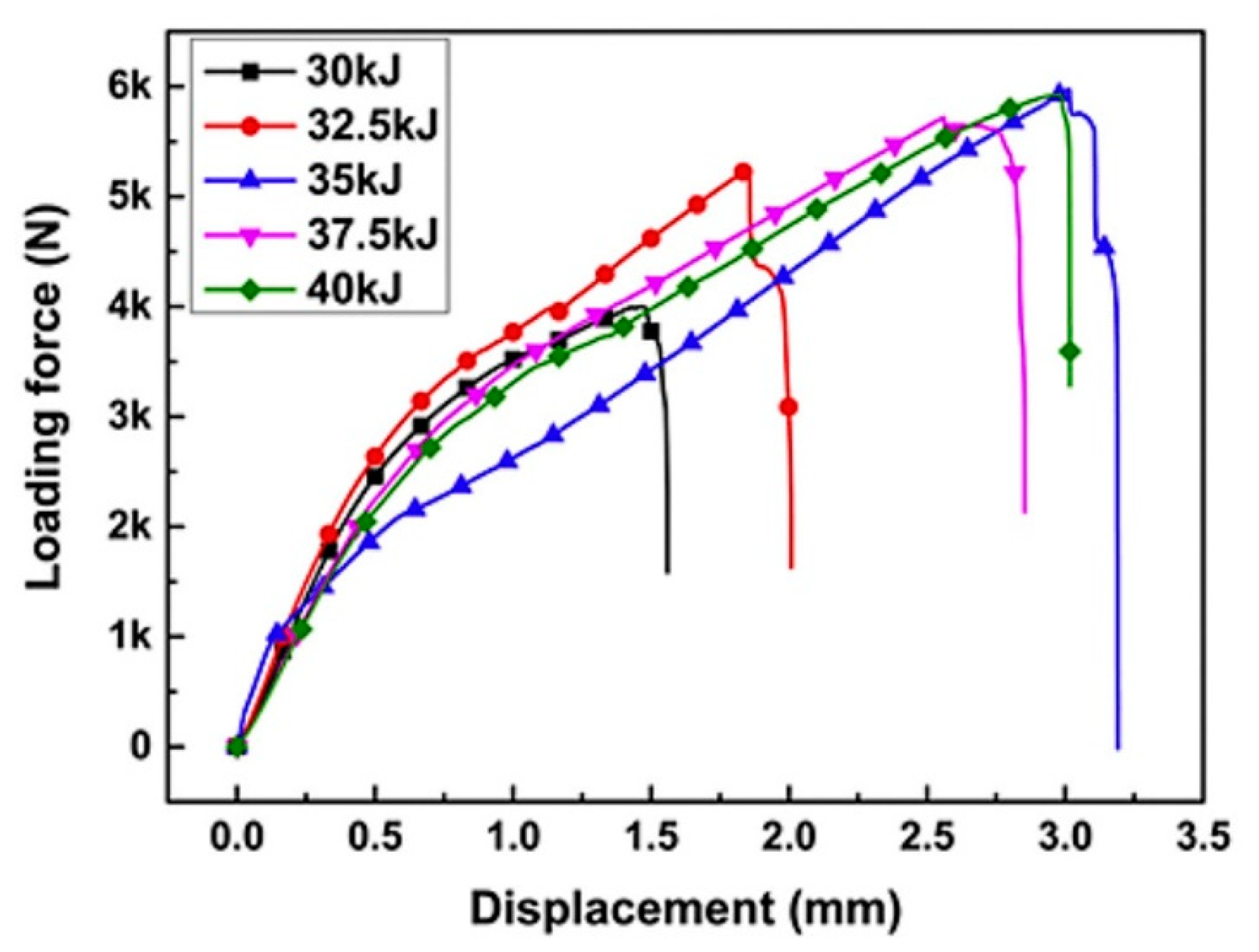

- Liu, J.; Niu, S.; Ren, R.; Ji, S.; Wang, L.; Lv, Z. Improving Joint Morphologies and Tensile Strength of Al/Mg Dissimilar Alloys Friction Stir Lap Welding by Changing Zn Interlayer Thickness. Acta Met. Sin. Engl. Lett. 2019, 32, 1385–1395. [Google Scholar] [CrossRef] [Green Version]

- Zheng, B.; Zhao, L.; Lv, Q.; Wan, G.; Cai, D.; Dong, S.; Hu, B.X. Effect of Sn interlayer on mechanical properties and microstructure in Al/Mg friction stir lap welding with different rotational speeds. Mater. Res. Express 2020, 7, 076504. [Google Scholar] [CrossRef]

- Shakeri, H.; Mofid, M.A. Physical Vapor Deposition Assisted Diffusion Bonding of Al Alloy to Mg Alloy Using Silver Interlayer. Met. Mater. Int. 2020, 27, 4132–4141. [Google Scholar] [CrossRef]

- Kumar, S.; Wu, C. Eliminating intermetallic compounds via Ni interlayer during friction stir welding of dissimilar Mg/Al alloys. J. Mater. Res. Technol. 2021, 15, 4353–4369. [Google Scholar] [CrossRef]

- Karimi-Dermani, O.; Abbasi, A.; Roeen, G.A.; Nayyeri, M.J. Dissimilar friction stir lap welding of AA7075 to AZ31B in the presence of Sn interlayer. J. Manuf. Process. 2021, 68, 616–631. [Google Scholar] [CrossRef]

- Dewangan, S.K.; Tripathi, M.K.; Manoj, M.K. Material Flow Behavior and Mechanical Properties of Dissimilar Friction Stir Welded Al 7075 and Mg AZ31 Alloys Using Cd Interlayer. Met. Mater. Int. 2021, 28, 1169–1183. [Google Scholar] [CrossRef]

- Nimal, R.G.R.; Chenthil, M.; Sangamaeswaran, R.; Hariharan, R.; Esakkimuthu, G. An investigation on microstructural evolution and mechanical properties of Zn coating as interlayer on Mg-Al alloys using diffusion bonding. Mater. Today Proc. 2021, 46, 3512–3516. [Google Scholar] [CrossRef]

- Bandi, A.; Bakshi, S.R. Friction Stir Lap Welding of AZ31B and AA6061 Alloys Using Tin as an Inter-Layer. Met. Mater. Int. 2022, 28, 1678–1696. [Google Scholar] [CrossRef]

- Dong, S.-K.; Lin, S.; Zhu, H.; Wang, C.-J.; Cao, Z.-L. Effect of Ni interlayer on microstructure and mechanical properties of Al/Mg dissimilar friction stir welding joints. Sci. Technol. Weld. Join. 2022, 27, 103–113. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, Y.; Chen, J.; Chen, H.; Zhu, Z.; Li, Y. Control of intermetallic compounds in Ultrasonic-Assisted Sn soldering of Mg/Al alloys. Mater. Des. 2022, 223, 111235. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, W.; Su, Z.; Zhao, Z.; Ren, G.; Niu, W.; Yu, Z.; Zang, L.; Yu, Z. Effects of Zr interlayer on microstructure, mechanical property and corrosion behavior of Al/Mg dissimilar friction stir welding lap joints. Mater. Charact. 2023, 199, 112826. [Google Scholar] [CrossRef]

- Kumar, M.; Das, A.; Ballav, R. Influence of the Zn interlayer on the mechanical strength, corrosion and microstructural behavior of friction stir-welded 6061-T6 aluminium alloy and AZ61 magnesium alloy dissimilar joints. Mater. Today Commun. 2023, 35, 105509. [Google Scholar] [CrossRef]

- Dewangan, S.K.; Banjare, P.N.; Tripathi, M.K.; Manoj, M.K. Effect of vertical and horizontal zinc interlayer on material flow, microstructure, and mechanical properties of dissimilar FSW of Al 7075 and Mg AZ31 alloys. Int. J. Adv. Manuf. Technol. 2023, 126, 4453–4474. [Google Scholar] [CrossRef]

- Yang, T.; Geng, S.; Zhang, D.; Wang, K.; Guo, C.; Zhang, Y. Interface behavior of diffusion bonding AZ31 magnesium alloy to 3003 aluminum alloy using silver-based interlayer. Weld. World 2023, 67, 541–548. [Google Scholar] [CrossRef]

- Zheng, Y.; Ren, G.; Li, L. Improved mechanical and corrosion properties of friction stir welded Al/Mg dissimilar lap joints by Zr interlayer addition. Mater. Lett. 2023, 348, 134710. [Google Scholar] [CrossRef]

- Handa, V.; Goyal, P.; Sehgal, S. Low Cost Joining of Inconel 625 and Super Duplex Stainless Steel 2507 through Novel Technique. J. Mater. Eng. Perform. 2023, 32, 170–175. [Google Scholar] [CrossRef]

- Xiang, R.; Xiong, Z.; Miao, C.; Zhou, L.; Deng, Y.; Zhang, S. The influence of magnetic field on arc behavior, weld geometry, and porosity formation in TIG welding of Al/Mg dissimilar alloys. J. Mater. Process. Technol. 2015, 219, 261–271. [Google Scholar]

- Xie, L.; Shi, W.; Wu, T.; Gong, M.; Cai, D.; Han, S.; He, K. Effect of Hybrid Laser Arc Welding on the Microstructure and Mechanical and Fracture Properties of 316L Sheet Welded Joints. Metals 2022, 12, 2181. [Google Scholar] [CrossRef]

- Yan, S.; Nie, Y.; Zhu, Z.; Chen, H.; Gou, G.; Yu, J.; Wang, G. Characteristics of microstructure and fatigue resistance of hybrid fiber laser-MIG welded Al–Mg alloy joints. Appl. Surf. Sci. 2014, 298, 12–18. [Google Scholar] [CrossRef]

- Lv, X.; Liu, L. Characteristics of laser-offset-TIG hybrid welding of AZ31Mg alloy with 6061Al alloy via Zn filler. Opt. Laser Technol. 2022, 152, 108126. [Google Scholar] [CrossRef]

- Meng, Y.; Lu, Y.; Li, Z.; Zhao, S.; Gao, M. Effects of beam oscillation on interface layer and mechanical properties of laser-arc hybrid lap welded Al/Mg dissimilar metals. Intermetallics 2021, 133, 107175. [Google Scholar] [CrossRef]

- Chang, W.-S.; Rajesh, S.; Chun, C.-K.; Kim, H.-J. Microstructure and Mechanical Properties of Hybrid Laser-Friction Stir Welding between AA6061-T6 Al Alloy and AZ31 Mg Alloy. J. Mater. Sci. Technol. 2011, 27, 199–204. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Casavola, C.; Moramarco, V. Analysis and Comparison of Friction Stir Welding and Laser Assisted Friction Stir Welding of Aluminum Alloy. Materials 2013, 6, 5923–5941. [Google Scholar] [CrossRef] [Green Version]

- Dai, X.; Zhang, H.; Liu, J.; Feng, J. Microstructure and properties of Mg/Al joint welded by gas tungsten arc welding-assisted hybrid ultrasonic seam welding. Mater. Des. 2015, 77, 65–71. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, H.; Wang, B.; Ji, A.; Liu, J.; Feng, J. Improving weld strength of arc-assisted ultrasonic seam welded Mg/Al joint with Sn interlayer. Mater. Des. 2016, 98, 262–271. [Google Scholar] [CrossRef]

- Ji, S.D.; Li, Z.W.; Ma, L.; Yue, Y.M.; Gao, S.S. Investigation of Ultrasonic Assisted Friction Stir Spot Welding of Magnesium Alloy to Aluminum Alloy. Strength Mater. 2016, 48, 2–7. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, C.; Shi, L. Effect of ultrasonic field on microstructure evolution in friction stir welding of dissimilar Al/Mg alloys. J. Mater. Res. Technol. 2022, 17, 1–21. [Google Scholar] [CrossRef]

- Bai, Y.; Su, H.; Wu, C. Enhancement of the Al/Mg Dissimilar Friction Stir Welding Joint Strength with the Assistance of Ultrasonic Vibration. Metals 2021, 11, 1113. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, H.; Wang, B.; Du, R.; Fan, Y.; He, P. Interfacial evolution behavior and mechanical properties of Ti/steel joint via ultrasonic seam assisted resistance spot welding with Cu interlayer. J. Manuf. Process. 2023, 95, 535–550. [Google Scholar] [CrossRef]

- Shah, U.; Liu, X.; Benatar, A.; Kuprienko, A.; Zhang, W. Computational analysis of the ultrasonic effects on resistance spot welding process. J. Manuf. Process. 2022, 81, 191–201. [Google Scholar] [CrossRef]

- Shah, U.; Liu, X. Effect of ultrasonic energy on the spot weldability of aluminum alloy AA6061. Mater. Des. 2020, 192, 108690. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Y.; Xu, Z.; Zhu, K.; Bian, G.; Wang, T.; Fu, X. A new method for fabricating Mg/Al alloy composites by pulse current-assisted rolled welding. Mater. Lett. 2023, 330, 133247. [Google Scholar] [CrossRef]

- Wang, L.; Yuan, T.; Jiang, W.; Jiang, X.; Chen, S.; Liu, Y. Microstructure and Mechanical Properties of Dissimilar Mg Alloy with Cu Interlayer Fabricated by Pulse Current Assisted Friction Stir Welding. J. Mater. Eng. Perform. 2023, 32, 2661–2675. [Google Scholar] [CrossRef]

- Xiaoqing, J.; Yongyong, L.; Tao, Y.; Shujun, C.; Lei, W.; Wang, J. Enhanced mechanical properties of dissimilar Al and Mg alloys fabricated by pulse current assisted friction stir welding. J. Manuf. Process. 2022, 76, 123–137. [Google Scholar] [CrossRef]

| No. | Interlayer | Welding Method | Configuration | Material (Al-Mg) | Author | Year |

|---|---|---|---|---|---|---|

| 1 | Pure Sn interlayer | USW | Lap joint | AA5754(top, t)-AZ31(bottom, b) | V.K. Patel et al. [41] | 2012 |

| 2 | Pure Ni foil interlayer | Diffusion bonding | Lap joint | Pure aluminum and pure magnesium | Jian Zhang et al. [58] | 2012 |

| 3 | Pure Ni/Au-coated Ni interlayer | RSW | Lap joint | AA5754(t)-AZ31B(b) | P. Penner et al. [81] | 2013 |

| 4 | Al/Mn coating | USW + cold spray | Lap joint | AA6011-T4(b)-AZ31-H24(t) | A. Panteli et al. [90] | 2013 |

| 5 | Silver film interlayer | Diffusion bonding | Butt joint | pure Al 1060 and pure magnesium | Yiyu Wang et al. [91] | 2013 |

| 6 | Pure Al foil and pure Ni foil interlayer | Diffusion bonding | Lap joint | Pure Al and pure magnesium | Jian Zhang et al. [59] | 2013 |

| 7 | Pure Zn/Zn-coated steel interlayer | RSW | Lap joint | AA5754(t)-AZ31B(b) | P. Penner et al. [82] | 2014 |

| 8 | Pure Ni foil interlayer | Diffusion bonding | Lap joint | Pure Al 1060(t) and pure magnesium(b) | Zhang J et al. [92] | 2014 |

| 9 | Pure Zn interlayer | RSW | Lap joint | AA5052-H12(t)-AZ31B(b) | Y. Zhang et al. [93] | 2015 |

| 10 | Pure Ni foil interlayer | RSW | Lap joint | AA5754-O(t)-AZ31B-H24(b) | M. Sun et al. [80] | 2015 |

| 11 | Pure Zn interlayer | Arc-assisted ultrasonic seam welding | Lap joint | Al6061(t)-AZ31(b) | X. Dai et al. [94] | 2015 |

| 12 | Sn-coated steel interlayer | RSW | Lap joint | AA5052(t)-AZ31B(b) | M. Sun et al. [79] | 2016 |

| 13 | Sn/Zn composite interlayer | Arc-assisted ultrasonic seam welding | Lap joint | Al6061(t)-AZ31B(b) | Xiangyu Dai et al. [95] | 2016 |

| 14 | Zn-coated All2024 | FSW | Lap joint | Al2024(b)-AZ31(t) | R. Z. Xu et al. [96] | 2016 |

| 15 | Pure Zn foil interlayer | FSW | Lap joint | Al2024-AZ31 | Rongzheng XU et al. [97] | 2017 |

| 16 | Pure Zn interlayer | FSW | Butt joint | Al6061-T6(RS)-AZ31(AS) | A. Abdollahzadeh et al. [98] | 2018 |

| 17 | Pure Ni interlayer | Diffusion bonding | Butt joint | Pure magnesium and pure aluminum | Fuxing Yin et al. [99] | 2018 |

| 18 | Pure Zn interlayer | USW | Lap joint | Al6082-T6(t)-AZ31B(b) | Xiaoyan Gu et al. [100] | 2019 |

| 19 | Pure Zr foil interlayer | FSW | Lap joint | Al6061(t)-AZ31(b) | Yang Zheng et al. [101] | 2019 |

| 20 | Pure Zn interlayer | UaFSW | Lap joint | Al7075-T6(b)-AZ31B(t) | Shude Ji et al. [102] | 2019 |

| 21 | Pure Zn foil interlayer | FSW | Butt joint | Al7075-T6(AS)-AZ31B(RS) | Jinglin Liu et al. [103] | 2019 |

| 22 | Pure copper foil interlayer | USW | Lap joint | Al6022-T43(b)-ZEK100-O(t) | H. Peng et al. [42] | 2019 |

| 23 | Pure zinc foil interlayer | FSW | Lap joint | Al7075-T6(b)-AZ31B(t) | Shiyu Niu et al. [49] | 2019 |

| 24 | Cold rolled copper interlayer | Diffusion bonding | Butt joint | Pure aluminum and pure magnesium | Javad Varmazyar et al. [60] | 2019 |

| 25 | Pure Zn foil interlayer | UaFSW | Lap joint | Al7075-T6(b)-AZ31B(t) | Shude Ji et al. [50] | 2019 |

| 26 | Pure Zn interlayer | Diffusion bonding | Lap joint | Al5083(t)- ZK60(b) | Yangyang Guo et al. [61] | 2019 |

| 27 | Pure Sn foil interlayer | FSW | Lap joint | Al5052H32(t)-AZ31(b) | Bo Zheng et al. [104] | 2020 |

| 28 | pure Ag foil interlayer | USW | Lap joint | Al6022-T43(b)-ZEK100-O(t) | H. Peng et al. [43] | 2020 |

| 29 | Pure Ag foil interlayer | Diffusion bonding | Lap joint | Al 5083(t)-AZ31(b) | Hatef Shakeri et al. [105] | 2020 |

| 30 | Pure Ni foil interlayer | FSW | Lap joint | AA6061-T6(b)-AZ31B(t) | Sachin Kumar et al. [106] | 2021 |

| 31 | Pure tin foil interlayer | FSW | Lap joint | Al7075-T6(t)-AZ31-H24(b) | Omid Karimi-Dermani et al. [107] | 2021 |

| 32 | Cd interlayer | FSW | Butt joint | Al7075(AS)-AZ31(RS) | Satya Kumar Dewangan et al. [108] | 2021 |

| 33 | Zinc-coated AZ80 | Diffusion bonding | Lap joint | Al7075(t)-AZ80(b) | R.J. Golden Renjith Nimal et al. [109] | 2021 |

| 34 | Sn foil interlayer | FSW | Lap joint | AA6061(t)-AZ31(b) | Bandi A et al. [110] | 2021 |

| 35 | Pure Ni foil interlayer | FSW | Butt joint | Al6061-T6(RS)-AZ31B(AS) | Shao-kang Dong et al. [111] | 2022 |

| 36 | Sn and Sn–9Zn solders | USW | Lap joint | Al6061(b)-AZ31(t) | Yingzong Liu et al. [112] | 2022 |

| 37 | Pure Zr foil interlayer | FSW | Lap joint | Al6061(t)-AZ31(b) | Yang Zheng et al. [113] | 2023 |

| 38 | Pure Zn foil interlayer | FSW | Butt joint | Al6061-T6(AS)-AZ61(RS) | Mukesh Kumar et al. [114] | 2023 |

| 39 | Vertical and horizontal zinc interlayer | FSW | Butt joint | Al7075(AS)-AZ31(RS) | Dewangan, S. K et al. [115] | 2023 |

| 40 | AgCuZn (Silver-based) interlayer | Diffusion bonding | Lap joint | Al3003(b)-AZ31(t) | Yang T et al. [116] | 2023 |

| 41 | Zr foil interlayer | FSW | Lap joint | Al6061(t)-AZ31(b) | Yang Zheng et al. [117] | 2023 |

| 42 | pure Zn foil interlayer | USW | Lap joint | AA6022-T43(t)-ZEK100-O(b) | H. Peng et al. [44] | 2023 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Zhu, Z.; Zhu, Y.; Sun, L.; Guo, Y. Solid-State Welding of Aluminum to Magnesium Alloys: A Review. Metals 2023, 13, 1410. https://doi.org/10.3390/met13081410

Chen H, Zhu Z, Zhu Y, Sun L, Guo Y. Solid-State Welding of Aluminum to Magnesium Alloys: A Review. Metals. 2023; 13(8):1410. https://doi.org/10.3390/met13081410

Chicago/Turabian StyleChen, Hao, Zhengqiang Zhu, Yunming Zhu, Liang Sun, and Yukun Guo. 2023. "Solid-State Welding of Aluminum to Magnesium Alloys: A Review" Metals 13, no. 8: 1410. https://doi.org/10.3390/met13081410

APA StyleChen, H., Zhu, Z., Zhu, Y., Sun, L., & Guo, Y. (2023). Solid-State Welding of Aluminum to Magnesium Alloys: A Review. Metals, 13(8), 1410. https://doi.org/10.3390/met13081410