Influence of Organic Acids and Related Organic Compounds on Corrosion Behavior of Stainless Steel—A Critical Review

Abstract

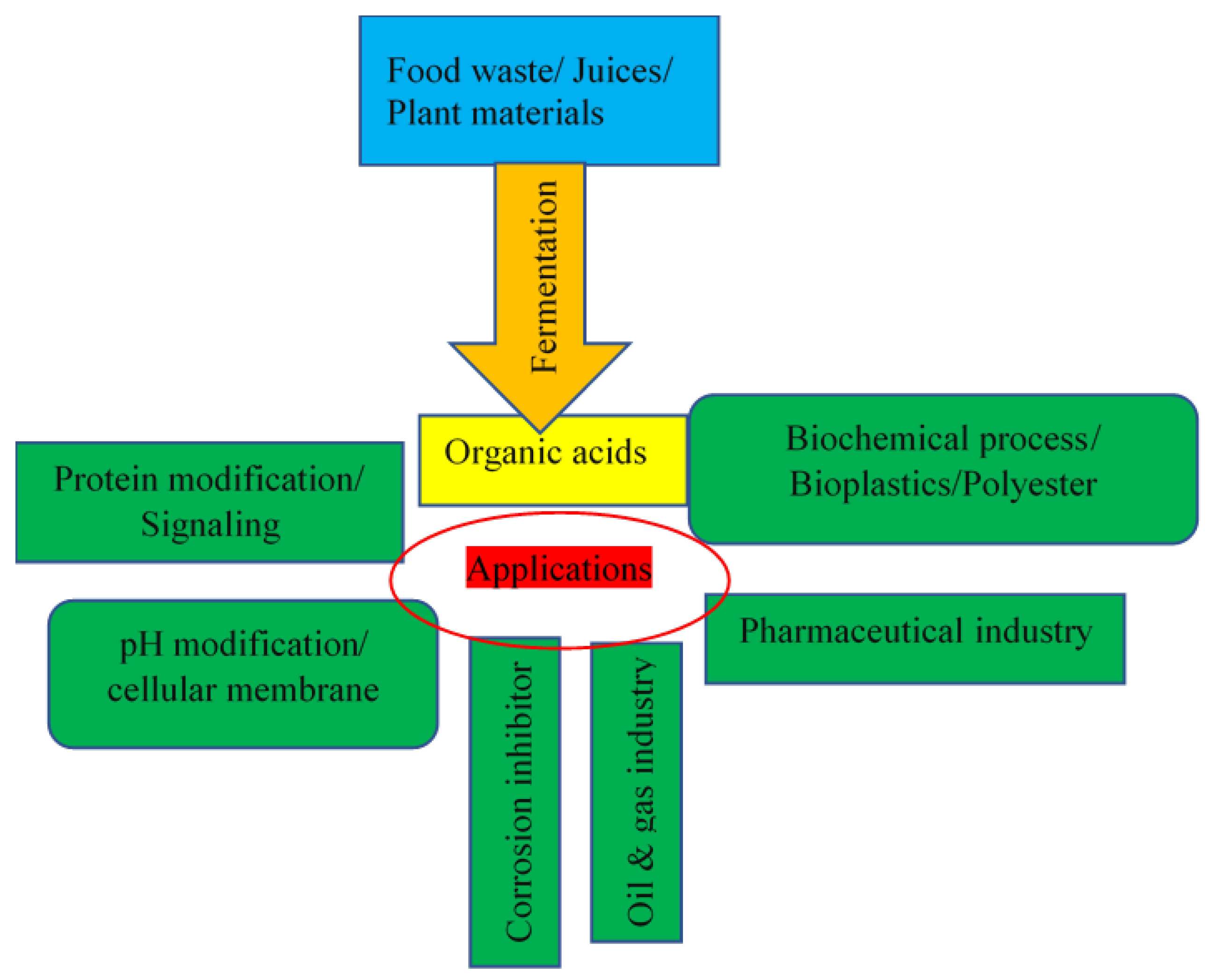

1. Introduction

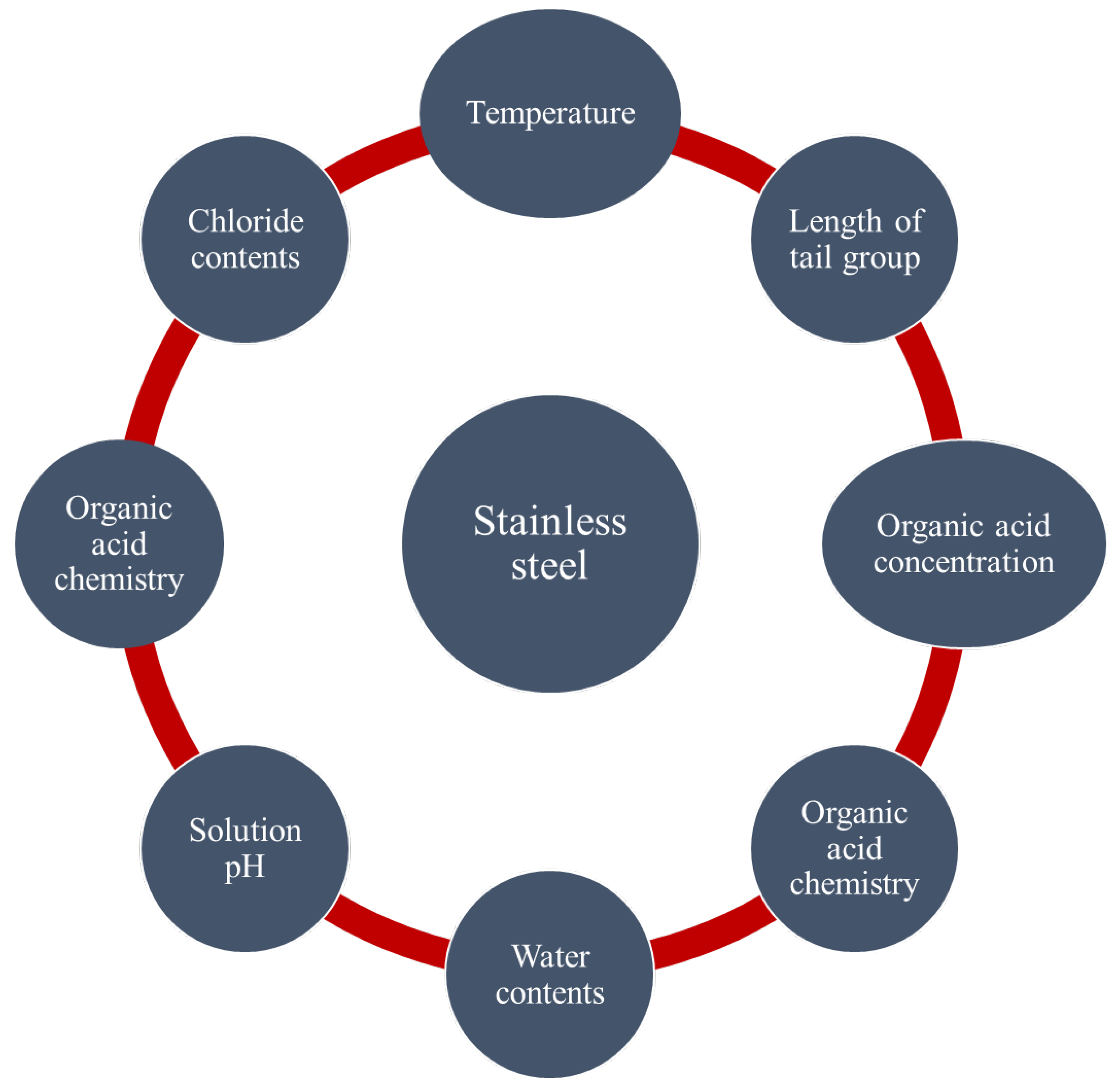

2. Corrosion Behavior of Stainless Steel in Organic Acids and Related Compounds

2.1. Effects of Acetic Acid

2.2. Effects of Formic Acid

2.3. Effects of Citric Acid

2.4. Effects of Oxalic Acid

3. Influence of Alloying Elements on Corrosion Behavior of Steel in Organic Acids and Compounds

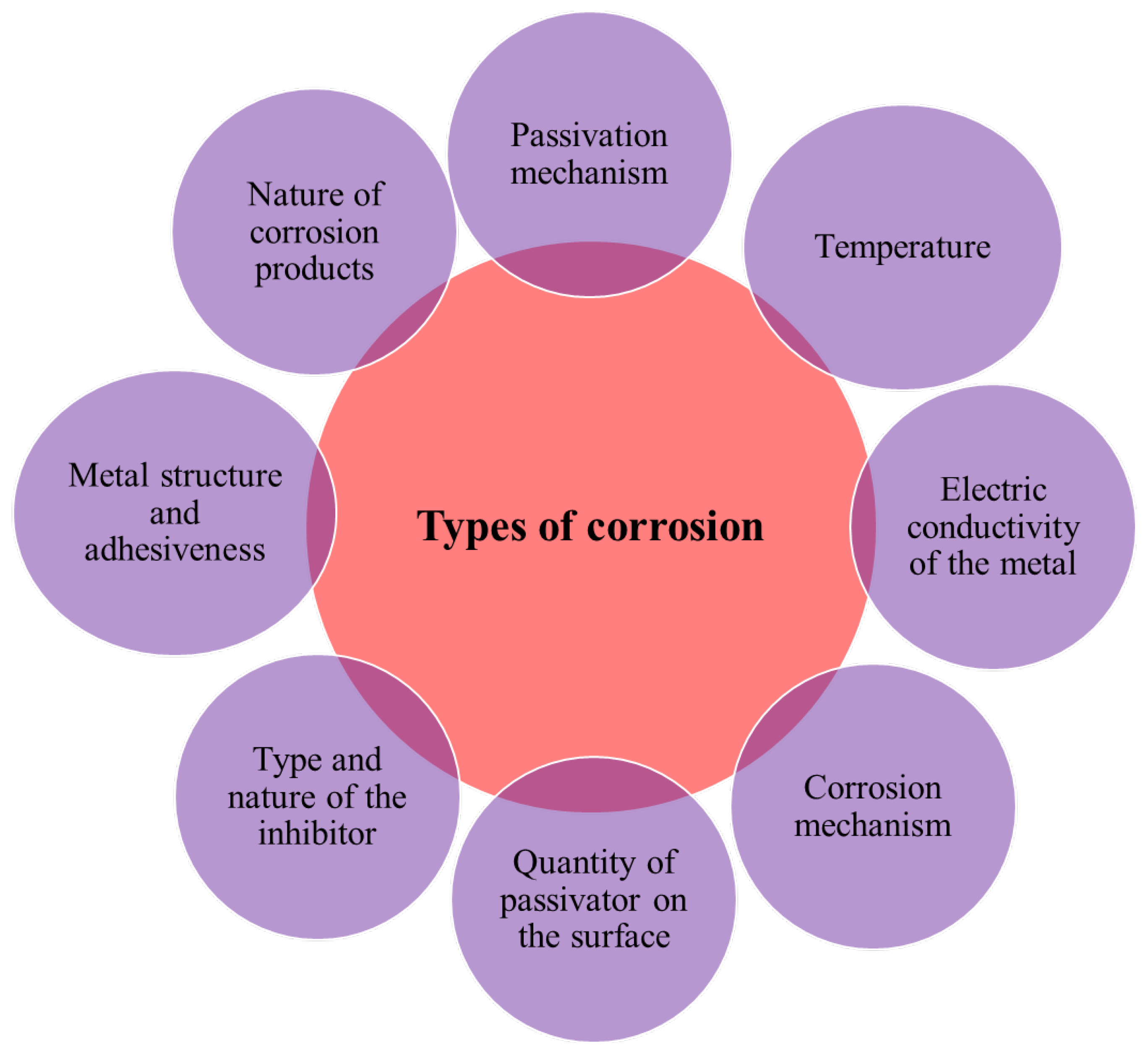

4. Types of Corrosion

4.1. Pitting Corrosion

4.2. General Corrosion

4.3. Stress Corrosion Cracking

4.4. Other Types of Corrosion

4.5. Interaction of Corrosion Types

5. Mechanism of Corrosion

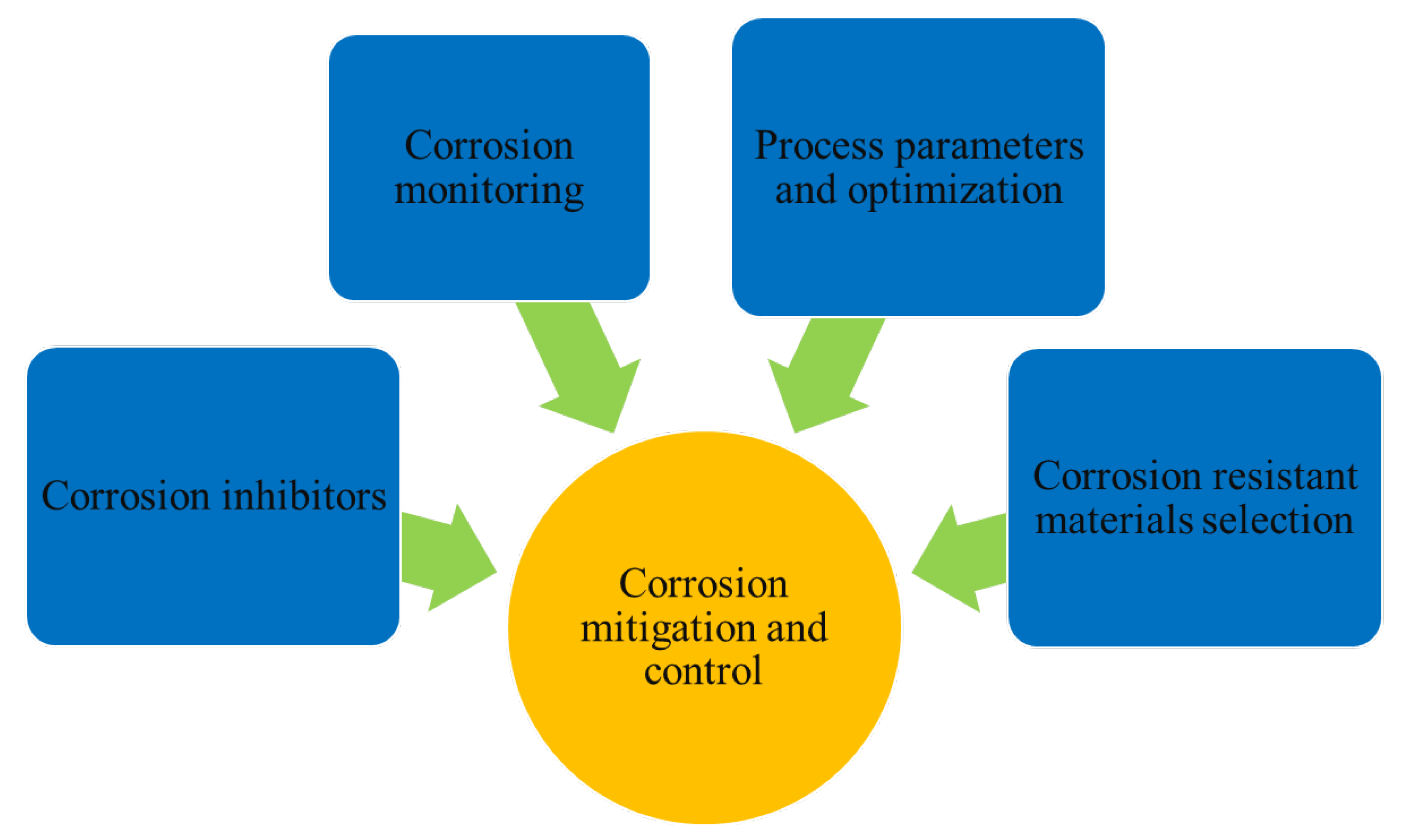

6. Mitigation Methods for Organic Acid Corrosion

6.1. Corrosion Monitoring Methods

6.2. Corrosion-Resistant Material Selection

6.3. Process Parameters and Optimization

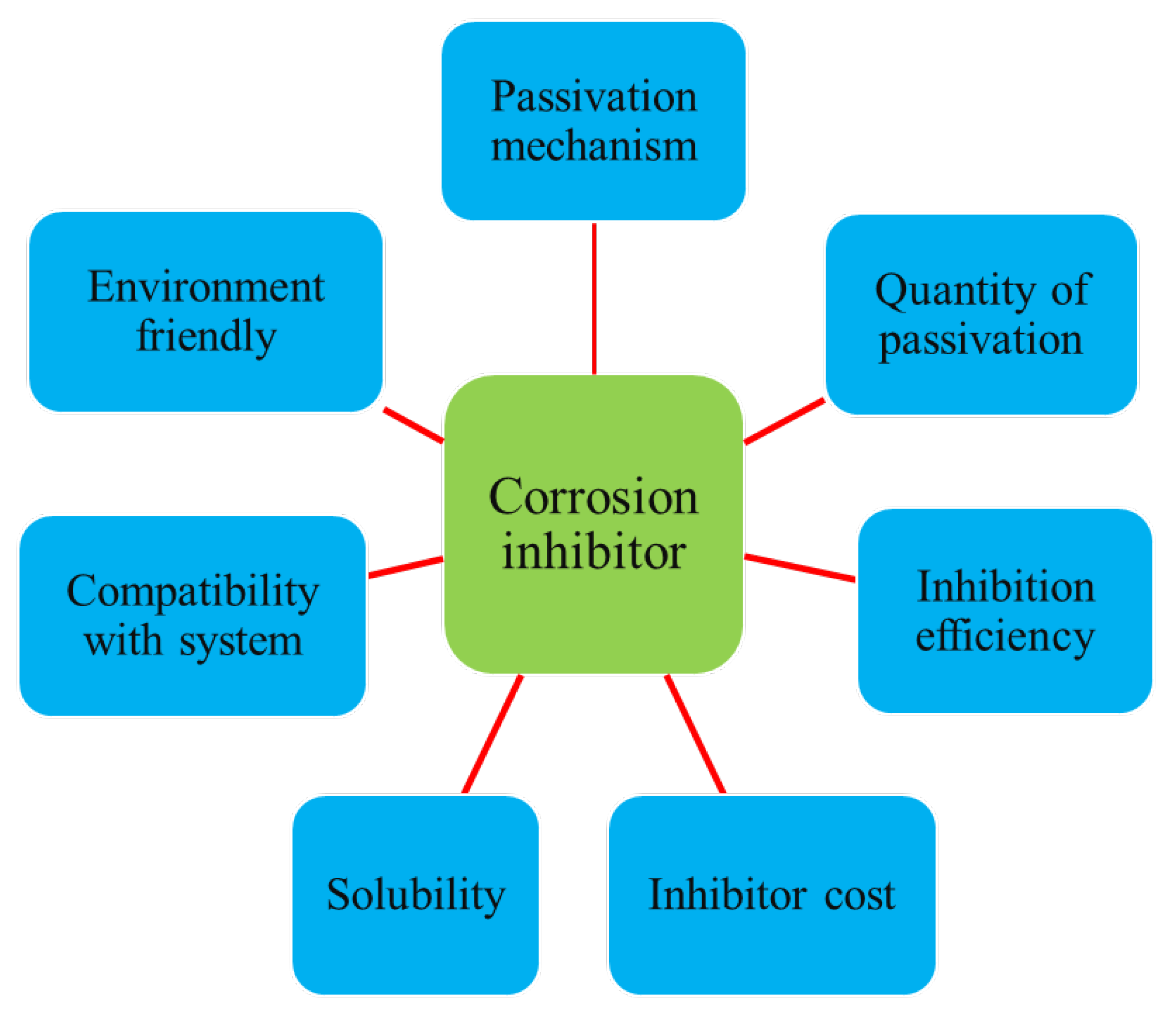

6.4. Corrosion Inhibitors

7. Future Aspects

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pan, Q.; Liu, Q.-Y.; Zheng, J.; Li, Y.-H.; Xiang, S.; Sun, X.-J.; He, X.-S. Volatile and semi-volatile organic compounds in landfill gas: Composition characteristics and health risks. Environ. Int. 2023, 174, 107886. [Google Scholar] [CrossRef] [PubMed]

- Suto, T.; Kawano, N.; Okazaki, K.; Takebuchi, Y.; Shiratori, D.; Fukushima, H.; Kato, T.; Nakauchi, D.; Yanagida, T. Optical and scintillation properties of organic–inorganic perovskite-type compounds with various hydroxyl alkyl amines or alkyl ether amines. Radiat. Phys. Chem. 2023, 209, 110981. [Google Scholar] [CrossRef]

- Wu, C.; Zhu, B.; Liang, W.; Ruan, T.; Jiang, G. Molecular characterization of nitrogen-containing organic compounds in fractionated atmospheric humic-like substances (HULIS) and its relationship with optical properties. Sci. Total. Environ. 2022, 832, 155043. [Google Scholar] [CrossRef] [PubMed]

- Giraudet, S.; Pré, P.; Tezel, H.; Le Cloirec, P. Estimation of adsorption energies using the physical characteristics of activated carbons and the molecular properties of volatile organic compounds. Carbon 2006, 44, 2413–2421. [Google Scholar] [CrossRef]

- Lawrence, G.B.; Roy, K.M. Ongoing increases in dissolved organic carbon are sustained by decreases in ionic strength rather than decreased acidity in waters recovering from acidic deposition. Sci. Total. Environ. 2021, 766, 142529. [Google Scholar] [CrossRef]

- Montaña, M.; Navas, M.B.; Bideberripe, H.P.; Barbelli, M.L.; Lick, I.D.; Casella, M.L. A heterogeneous catalytic process to mitigate the acidity of bio-oils caused by the presence of volatile organic acids. Fuel 2021, 299, 120919. [Google Scholar] [CrossRef]

- Baccichet, I.; Chiozzotto, R.; Spinardi, A.; Gardana, C.; Bassi, D.; Cirilli, M. Evaluation of a large apricot germplasm collection for fruit skin and flesh acidity and organic acids composition. Sci. Hortic. 2022, 294, 110780. [Google Scholar] [CrossRef]

- Mahjoob, M.K.M.; Akbarizadeh, M.; Hasheman, P.; Rattanapan, N.; Moradi-Gholami, A.; Amin, H.I.M.; Jalil, A.T.; Saleh, M.M. Recent advances in metal-organic frameworks synthesis and characterization with a focus on electrochemical determination of biological and food compounds, and investigation of their antibacterial performance. Chin. J. Anal. Chem. 2023, 51, 100286. [Google Scholar] [CrossRef]

- Osorio, V.; Medina, R.; Acuña, J.R.; Pabón, J.; Álvarez, C.I.; Matallana, L.G.; Fernández-Alduenda, M.R. Transformation of organic acids and sugars in the mucilage and coffee beans during prolonged fermentation. J. Food Compos. Anal. 2023, 123, 105551. [Google Scholar] [CrossRef]

- Aslam, R.; Serdaroglu, G.; Zehra, S.; Verma, D.K.; Aslam, J.; Guo, L.; Verma, C.; Ebenso, E.E.; Quraishi, M.A. Corrosion inhibition of steel using different families of organic compounds: Past and present progress. J. Mol. Liq. 2022, 348, 118373. [Google Scholar] [CrossRef]

- Santamaria, M.; Tranchida, G.; Di Franco, F. Corrosion resistance of passive films on different stainless steel grades in food and beverage industry. Corros. Sci. 2020, 173, 108778. [Google Scholar] [CrossRef]

- Korakana, A.; Korakana, S.; Ulmek, N.; Pagare, A.K. Analyzing the effect of the parameters of laser etching process influencing the corrosion resistance and surface roughness of marine grade 316 stainless steel. Mater. Today Proc. 2020, 32, 452–462. [Google Scholar] [CrossRef]

- Zaffora, A.; Di Franco, F.; Santamaria, M. Corrosion of stainless steel in food and pharmaceutical industry. Curr. Opin. Electrochem. 2021, 29, 100760. [Google Scholar] [CrossRef]

- García-Rodríguez, S.; Torres, B.; Pulido-González, N.; Otero, E.; Rams, J. Corrosion behavior of 316L stainless steel coatings on ZE41 magnesium alloy in chloride environments. Surf. Coat. Technol. 2019, 378, 124994. [Google Scholar] [CrossRef]

- Kumar, M.S.; Sujata, M.; Venkataswamy, M.A.; Bhaumik, S.K. Failure analysis of a stainless steel pipeline. Eng. Fail. Anal. 2008, 15, 497–504. [Google Scholar] [CrossRef]

- Xu, Z.; Eduok, U.; Tiamiyu, A.A.; Szpunar, J. Anodic dissolution pattern of magnesium alloy in different media: Effects of solution treatment on its microstructure and corrosion behaviour. Eng. Fail. Anal. 2019, 107, 104234. [Google Scholar] [CrossRef]

- Gu, Y.; Xu, Y.; Shi, Y.; Feng, C.; Volodymyr, K. Corrosion resistance of 316 stainless steel in a simulated pressurized water reactor improved by laser cladding with chromium. Surf. Coat. Technol. 2022, 441, 128543. [Google Scholar] [CrossRef]

- Abd-El-Nabey, B.A.; Khalil, N.; Eisa, M.M.; Sadek, H. Pitting corrosion of stainless steel in water-organic solvent mixtures. Surf. Technol. 1983, 20, 209–217. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, J.; Guo, Q.; Zhang, D.; Luo, J.; Zhu, H.; Zhou, X.; Lu, J.; Yang, J. Body-thorough ultrahigh strength and ductility of austenitic 316L stainless steel by industry-applicable 3-axis stress-released impact. Mater. Sci. Eng. A 2023, 870, 144822. [Google Scholar] [CrossRef]

- Moeinfar, K.; Khodabakhshi, F.; Kashani-Bozorg, S.F.; Mohammadi, M.; Gerlich, A.P. A review on metallurgical aspects of laser additive manufacturing (LAM): Stainless steels, nickel superalloys, and titanium alloys. J. Mater. Res. Technol. 2022, 16, 1029–1068. [Google Scholar] [CrossRef]

- Potgieter, J.H.; Olubambi, P.A.; Cornish, L.; Machio, C.N.; Sherif, E.-S.M. Influence of nickel additions on the corrosion behaviour of low nitrogen 22% Cr series duplex stainless steels. Corros. Sci. 2008, 50, 2572–2579. [Google Scholar] [CrossRef]

- Li, F.; An, M.; Liu, G.; Duan, D. Effects of sulfidation of passive film in the presence of SRB on the pitting corrosion behaviors of stainless steels. Mater. Chem. Phys. 2009, 113, 971–976. [Google Scholar] [CrossRef]

- Shudo, T.; Suzuki, K. Performance improvement in direct methanol fuel cells using a highly porous corrosion-resisting stainless steel flow field. Int. J. Hydrog. Energy 2008, 33, 2850–2856. [Google Scholar] [CrossRef]

- Wang, L.; Kang, B.; Gao, N.; Du, X.; Jia, L.; Sun, J. Corrosion behaviour of austenitic stainless steel as a function of methanol concentration for direct methanol fuel cell bipolar plate. J. Power Sources 2014, 253, 332–341. [Google Scholar] [CrossRef]

- Hu, E.; Xu, Y.; Hu, X.; Pan, L.; Jiang, S. Corrosion behaviors of metals in biodiesel from rapeseed oil and methanol. Renew. Energy 2012, 37, 371–378. [Google Scholar] [CrossRef]

- Sui, P.; Sun, J.; Hua, Y.; Liu, H.; Zhou, M.; Zhang, Y.; Liu, J.; Wang, Y. Effect of temperature and pressure on corrosion behavior of X65 carbon steel in water-saturated CO 2 transport environments mixed with H 2 S. Int. J. Greenh. Gas Control. 2018, 73, 60–69. [Google Scholar] [CrossRef]

- Schwarzenböck, E.; Wiehler, L.; Heidenblut, T.; Hack, T.; Engel, C.; Maier, H.J. Crack initiation of an industrial 7XXX aluminum alloy in humid air analyzed via slow strain rate testing and constant displacement testing. Mater. Sci. Eng. A 2021, 804, 140776. [Google Scholar] [CrossRef]

- Hossain, H.; Hossain, N.; Chowdhury, M.A.; Kowser, A.; Rana, M. Surface synthesization of magnesium alloys for improving corrosion resistance and implant applications. Arab. J. Chem. 2023, 16, 1044665. [Google Scholar] [CrossRef]

- Dudareva, N.; Zaynullina, L.; Kiseleva, S.; Abramova, M. The influence of alloy microstructure on corrosion resistance and other properties of coatings formed by microarc oxidation. Mater. Chem. Phys. 2022, 288, 126379. [Google Scholar] [CrossRef]

- Liu, S.; Sun, H.; Sun, L.; Fan, H. Effects of pH and Cl− concentration on corrosion behavior of the galvanized steel in simulated rust layer solution. Corros. Sci. 2012, 65, 520–527. [Google Scholar] [CrossRef]

- Du, J.; Wang, C.; Wang, W.; Cui, Y.; Zhang, W. Effects of high pressure and temperature on carbon isotope compositions of some acyclic alkanes and preservation of organic matter. High Press. Res. 2012, 32, 220–232. [Google Scholar] [CrossRef]

- Abdelhadi, R.A.; Ahmed, Z.E.; Abouzeid, A.M. Synthesis, spectroscopic analysis and electrochemical studies of novel organic compound based on N-alkylphthalazinone chemistry as corrosion inhibitor for carbon steel in 1M HCl. Int. J. Electrochem. Sci. 2023, 18, 100121. [Google Scholar] [CrossRef]

- Mayerhöfer, T.G.; Spange, S. Understanding Refractive Index Changes in Homologous Series of Unbranched Organic Compounds Based on Beer’s Law. ChemPhysChem 2023, e202300430. [Google Scholar] [CrossRef] [PubMed]

- Meredith, W.; Kelland, S.-J.; Jones, D.M. Influence of biodegradation on crude oil acidity and carboxylic acid composition. Org. Geochem. 2000, 31, 1059–1073. [Google Scholar] [CrossRef]

- Mellmer, M.A.; Sanpitakseree, C.; Demir, B.; Ma, K.; Elliott, W.A.; Bai, P.; Johnson, R.L.; Walker, T.W.; Shanks, B.H.; Rioux, R.M.; et al. Effects of chloride ions in acid-catalyzed biomass dehydration reactions in polar aprotic solvents. Nat. Commun. 2019, 10, 1132. [Google Scholar] [CrossRef]

- Lu, X.; Hasegawa, G.; Kanamori, K.; Nakanishi, K. Hierarchically porous monoliths prepared via sol–gel process accompanied by spinodal decomposition. J. Sol-Gel Sci. Technol. 2020, 95, 530–550. [Google Scholar] [CrossRef]

- Abbas, A.; Huang, S.-J. Investigating the Synergic Effects of WS2 and ECAP on Degradation Behavior of AZ91 Magnesium Alloy. Coatings 2022, 12, 1710. [Google Scholar] [CrossRef]

- Wei, T.; Yan, F.; Tian, J. Characterization and wear- and corrosion-resistance of microarc oxidation ceramic coatings on aluminum alloy. J. Alloy. Compd. 2005, 389, 169–176. [Google Scholar] [CrossRef]

- Subasree, N.; Selvi, J.A.; Pillai, R.S. Effect of alkyl chain length on the corrosion inhibition of mild steel in a simulated hydrochloric acid medium by a phosphonium based inhibitor. J. Adhes. Sci. Technol. 2021, 37, 83–104. [Google Scholar] [CrossRef]

- Nagels, M.; Verhoeven, B.; Larché, N.; Dewil, R.; Rossi, B. Corrosion behaviour of lean duplex stainless steel in advanced oxidation process (AOP) based wastewater treatment plants. Eng. Fail. Anal. 2022, 136, 106170. [Google Scholar] [CrossRef]

- Wan, Y.; Sun, Y.; Cai, D.; Yin, L.; Dai, N.; Lei, L.; Jiang, Y.; Li, J. Influence of Ethanol on Pitting Corrosion Behavior of Stainless Steel for Bioethanol Fermentation Tanks. Front. Chem. 2020, 8, 529. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.X.; El Abedin, S.Z.; Endres, F. Electroplating of mild steel by aluminium in a first generation ionic liquid: A green alternative to commercial Al-plating in organic solvents. Surf. Coat. Technol. 2006, 201, 1352–1356. [Google Scholar] [CrossRef]

- Dastpak, A.; Hannula, P.-M.; Lundström, M.; Wilson, B.P. A sustainable two-layer lignin-anodized composite coating for the corrosion protection of high-strength low-alloy steel. Prog. Org. Coat. 2020, 148, 105866. [Google Scholar] [CrossRef]

- de Moraes, F.P.; Alves, S.F.; Plaut, R.L.; Padilha, A.F. Degradation of microstructure and properties of an AISI 316L steel pipe after more than 100,000 hours usage at 640 °C in a petrochemical industry. Procedia Struct. Integr. 2019, 17, 131–137. [Google Scholar] [CrossRef]

- Paulraj, P.; Garg, R. Effect of intermetallic phases on corrosion behavior and mechanical properties of duplex stainless steel and super-duplex stainless steel. Adv. Sci. Technol. Res. J. 2015, 9, 87–105. [Google Scholar] [CrossRef] [PubMed]

- Chan, K.; Tjong, S. Effect of Secondary Phase Precipitation on the Corrosion Behavior of Duplex Stainless Steels. Materials 2014, 7, 5268–5304. [Google Scholar] [CrossRef]

- Farrell, J.; Melitas, N.; Kason, M.; Li, T. Electrochemical and Column Investigation of Iron-Mediated Reductive Dechlorination of Trichloroethylene and Perchloroethylene. Environ. Sci. Technol. 2000, 34, 2549–2556. [Google Scholar] [CrossRef]

- Alam, A.-M.; Shon, Y.-S. Water-Soluble Noble Metal Nanoparticle Catalysts Capped with Small Organic Molecules for Organic Transformations in Water. ACS Appl. Nano Mater. 2021, 4, 3294–3318. [Google Scholar] [CrossRef]

- Safonov, V.A.; Haruyama, S. Electrochemical impedance of passive iron in sulfuric acid water-organic solutions. Russ. J. Electrochem. 2000, 36, 1108–1116. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, M.-J.; Yang, F.-C.; Gao, C.-W. Study of a Triazole Derivative as Corrosion Inhibitor for Mild Steel in Phosphoric Acid Solution. Int. J. Corros. 2012, 2012, 573964. [Google Scholar] [CrossRef]

- Kuznetsov, Y.I.; Redkina, G.V. Thin Protective Coatings on Metals Formed by Organic Corrosion Inhibitors in Neutral Media. Coatings 2022, 12, 149. [Google Scholar] [CrossRef]

- Frank, M.A.; Meltzer, C.; Braunschweig, B.; Peukert, W.; Boccaccini, A.R.; Virtanen, S. Functionalization of steel surfaces with organic acids: Influence on wetting and corrosion behavior. Appl. Surf. Sci. 2017, 404, 326–333. [Google Scholar] [CrossRef]

- Constantinescu, E.; Heitz, E. On the influence of the water content on corrosion of metals in mono-carboxylic acids. Corros. Sci. 1976, 16, 857–867. [Google Scholar] [CrossRef]

- Lou, X.; Singh, P.M. Role of water, acetic acid and chloride on corrosion and pitting behaviour of carbon steel in fuel-grade ethanol. Corros. Sci. 2010, 52, 2303–2315. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Moura, V.; da Costa, V.C.; Ferreira, M.L.R.; Pardal, J.M. Microstructural changes and corrosion resistance of AISI 310S steel exposed to 600–800 °C. Mater. Charact. 2009, 60, 573–578. [Google Scholar] [CrossRef]

- Li, D.G.; Chen, D.R.; Liang, P. Influences of plastic strain and strain rate on corrosion behavior of 316L stainless steel in simulated cathodic environment of proton exchange membrane fuel cell. Int. J. Hydrog. Energy 2020, 46, 6239–6250. [Google Scholar] [CrossRef]

- Muñoz, A.I.; Antón, J.G.; Guiñón, J.L.; Herranz, V.P. Effects of solution temperature on localized corrosion of high nickel content stainless steels and nickel in chromated LiBr solution. Corros. Sci. 2006, 48, 3349–3374. [Google Scholar] [CrossRef]

- Schmitt, G. Fundamental Aspects of CO2 Metal Loss Corrosion. Part II: Influence of Different Parameters on CO2 Corrosion Mechanism. In Corrosion; NACE: Houston, TX, USA, 2015; Available online: http://onepetro.org/NACECORR/proceedings-pdf/CORR15/All-CORR15/NACE-2015-6033/1343307/nace-2015-6033.pdf/1 (accessed on 15 March 2015).

- Hou, X.; Ren, Q.; Yang, Y.; Cao, X.; Hu, J.; Zhang, C.; Deng, H.; Yu, D.; Li, K.; Lan, W. Effect of temperature on the electrochemical pitting corrosion behavior of 316L stainless steel in chloride-containing MDEA solution. J. Nat. Gas Sci. Eng. 2021, 86, 103718. [Google Scholar] [CrossRef]

- Zhang, N.; Zeng, D.; Xiao, G.; Shang, J.; Liu, Y.; Long, D.; He, Q.; Singh, A. Effect of Cl− accumulation on corrosion behavior of steels in H2S/CO2 methyldiethanolamine (MDEA) gas sweetening aqueous solution. J. Nat. Gas. Sci. Eng. 2016, 30, 444–454. [Google Scholar] [CrossRef]

- Singh, M.M.; Gupta, A.; Deyab, M.A.M.; Sowards, J.W.; Mansfield, E.; Williamson, C.; Weeks, T.; McColskey, J.; Spear, J.; Kappes, M.; et al. Corrosion Behavior of Mild Steel in Acetic Acid Solutions. Corrosion 2000, 56, 371–379. [Google Scholar] [CrossRef]

- El–Maksoud, S.A.A. The Effect of Organic Compounds on the Electrochemical Behaviour of Steel in Acidic Media. A review. Int. J. Electrochem. Sci. 2008, 3, 528–555. [Google Scholar] [CrossRef]

- Qin, R.; Chen, H.; Wen, R.; Li, G.; Meng, Z. Effect of Boric Acid on the Ionization Equilibrium of α-Hydroxy Carboxylic Acids and the Study of Its Applications. Molecules 2023, 28, 4723. [Google Scholar] [CrossRef] [PubMed]

- Wysocka, J.; Cieslik, M.; Krakowiak, S.; Ryl, J. Carboxylic acids as efficient corrosion inhibitors of aluminium alloys in alkaline media. Electrochim. Acta 2018, 289, 175–192. [Google Scholar] [CrossRef]

- Baena, L.M.; Calderón, J.A. Effects of palm biodiesel and blends of biodiesel with organic acids on metals. Heliyon 2020, 6, e03735. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Zheng, L.; Yan, J.; Sun, J.; Gao, J. Effects of AC interference on the corrosion behavior of X70 steel in seawater and acidic solutions. Int. J. Electrochem. Sci. 2023, 18, 59–67. [Google Scholar] [CrossRef]

- Zhang, H.; Cui, J.; Sun, J.; He, W. Corrosion inhibition of methanol towards stainless steel bipolar plate for direct formic acid fuel cell. Int. J. Hydrog. Energy 2020, 45, 30924–30931. [Google Scholar] [CrossRef]

- Badea, G.E.; Ionita, D.; Cret, P. Corrosion and passivation of the 304 stainless steel in formic acid solutions. Mater. Corros. 2014, 65, 1103–1110. [Google Scholar] [CrossRef]

- Invernizzi, A.J.; Sivieri, E.; Trasatti, S.P. Corrosion behaviour of Duplex stainless steels in organic acid aqueous solutions. Mater. Sci. Eng. A 2008, 485, 234–242. [Google Scholar] [CrossRef]

- Qu, Q.; Jiang, S.; Li, L.; Bai, W.; Zhou, J. Corrosion behavior of cold rolled steel in peracetic acid solutions. Corros. Sci. 2008, 50, 35–40. [Google Scholar] [CrossRef]

- Sheng, X.; Ting, Y.-P.; Pehkonen, S.O. The influence of sulphate-reducing bacteria biofilm on the corrosion of stainless steel AISI 316. Corros. Sci. 2007, 49, 2159–2176. [Google Scholar] [CrossRef]

- Cobá-Tec, E.Y.; Pech-Canul, M.A. Corrosion behavior and surface properties of mild steel in aqueous citrate solutions. Chem. Eng. Commun. 2023, 210, 297–313. [Google Scholar] [CrossRef]

- Fekry, A.M. The influence of chloride and sulphate ions on the corrosion behavior of Ti and Ti-6Al-4V alloy in oxalic acid. Electrochim. Acta 2009, 54, 3480–3489. [Google Scholar] [CrossRef]

- Latif, N.; Wahyuadi, M.J.; Triwibowo; Riastuti, R. Erosion corrosion failure on elbow distillate heater system in the petrochemical industry. Mater. Today Proc. 2022, 62, 4235–4241. [Google Scholar] [CrossRef]

- Yang, Y.; Cheng, Y.F. Parametric effects on the erosion–corrosion rate and mechanism of carbon steel pipes in oil sands slurry. Wear 2012, 276–277, 141–148. [Google Scholar] [CrossRef]

- Rezaei, M.; Mahidashti, Z.; Eftekhari, S.; Abdi, E. A corrosion failure analysis of heat exchanger tubes operating in petrochemical refinery. Eng. Fail. Anal. 2021, 119, 105011. [Google Scholar] [CrossRef]

- Heitz, E. Corrosion of Metals in Organic Solvents. In Advances in Corrosion Science and Technology: Volume 4; Springer: Boston, MA, USA, 1974; pp. 149–243. [Google Scholar] [CrossRef]

- Ekilik, V.V.; Grigor’Ev, V.P. Metal Corrosion in Organic and Aqueous-Organic Media. Prot. Met. 2002, 38, 124–131. [Google Scholar] [CrossRef]

- Mandel, M.; Kietov, V.; Hornig, R.; Vollmer, M.; Frenck, J.-M.; Wüstefeld, C.; Rafaja, D.; Niendorf, T.; Krüger, L. On the polarisation and Mott-Schottky characteristics of an Fe-Mn-Al-Ni shape-memory alloy and pure Fe in NaCl-free and NaCl-contaminated Ca(OH)2,sat solution—A comparative study. Corros. Sci. 2021, 179, 109172. [Google Scholar] [CrossRef]

- Tan, L.; Ren, X.; Allen, T.R. Corrosion behavior of 9–12% Cr ferritic–martensitic steels in supercritical water. Corros. Sci. 2010, 52, 1520–1528. [Google Scholar] [CrossRef]

- Ai, Z.; Sun, W.; Jiang, J.; Song, D.; Ma, H.; Zhang, J.; Wang, D. Passivation Characteristics of Alloy Corrosion-Resistant Steel Cr10Mo1 in Simulating Concrete Pore Solutions: Combination Effects of pH and Chloride. Materials 2016, 9, 749. [Google Scholar] [CrossRef]

- Sekine, I.; Masuko, A.; Senoo, K. Corrosion Behavior of AISI 316 Stainless Steel in Formic and Acetic Acid Solutions. Corrosion 1987, 43, 553–560. [Google Scholar] [CrossRef]

- Kriaa, A.; Hamdi, N.; Jbali, K.; Tzinmann, M. Corrosion of iron in highly acidic hydro-organic solutions. Corros. Sci. 2009, 51, 668–676. [Google Scholar] [CrossRef]

- Mubarak, N.M.; Anwar, M.; Debnath, S.; Sudin, I. Corrosion. In Fundamentals of Biomaterials; Springer: Singapore, 2023; pp. 91–99. [Google Scholar] [CrossRef]

- Li, S.; Zuo, Y.; Tang, Y.; Zhao, X. The electroplated Pd–Co alloy film on 316L stainless steel and the corrosion resistance in boiling acetic acid and formic acid mixture with stirring. Appl. Surf. Sci. 2014, 321, 179–187. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Tang, Z.; Zhang, S.; Qiu, J. The potential influence of high uric acid exposure on surface and corrosion susceptibility of pure titanium. J. Mater. Sci. Mater. Med. 2022, 33, 44. [Google Scholar] [CrossRef] [PubMed]

- Gouda, V.K.; Rizkalla, E.N.; Abd-El-Wahab, S.; Ibrahim, E.M. Corrosion behaviour in organic acid solutions—I. Tin electrode. Corros. Sci. 1981, 21, 1–15. [Google Scholar] [CrossRef]

- Shi, Y.Y.; Zhang, Z.; Cao, F.H.; Zhang, J.Q. Dimensional analysis applied to pitting corrosion measurements. Electrochim. Acta 2008, 53, 2688–2698. [Google Scholar] [CrossRef]

- Radi, P.A.; Vieira, A.; Manfroi, L.; de Farias Nass, K.C.; Ramos, M.A.R.; Leite, P.; Martins, G.V.; Jofre, J.B.F.; Vieira, L. Tribocorrosion and corrosion behavior of stainless steel coated with DLC films in ethanol with different concentrations of water. Ceram. Int. 2019, 45, 9686–9693. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Coy, A.E.; Viejo, F.; Arrabal, R.; Matykina, E. Pitting corrosion behaviour of austenitic stainless steels—Combining effects of Mn and Mo additions. Corros. Sci. 2008, 50, 1796–1806. [Google Scholar] [CrossRef]

- Cai, C.; Zhang, Z.; Cao, F.; Gao, Z.; Zhang, J.; Cao, C. Analysis of pitting corrosion behavior of pure Al in sodium chloride solution with the wavelet technique. J. Electroanal. Chem. 2005, 578, 143–150. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N. Effect of Grain Size on Corrosion: A Review. Corrosion 2010, 66, 075005. [Google Scholar] [CrossRef]

- Rao, A.C.U.; Vasu, V.; Govindaraju, M.; Srinadh, K.V.S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review. Trans. Nonferrous Met. Soc. China 2016, 26, 1447–1471. [Google Scholar] [CrossRef]

- Hong, J.H.; Lee, S.H.; Kim, J.G.; Yoon, J.B. Corrosion behaviour of copper containing low alloy steels in sulphuric acid. Corros. Sci. 2012, 54, 174–182. [Google Scholar] [CrossRef]

- Dias, D.; Nakamatsu, S.; Della Rovere, C.A.; Otubo, J.; Mariano, N.A. Characterization and Corrosion Resistance Behavior of Shape Memory Stainless Steel Developed by Alternate Routes. Metals 2019, 10, 13. [Google Scholar] [CrossRef]

- Dong, B.; Wen, X.-D.; Feng, L. Temperature Effect on Corrosion Behavior of 304LN Stainless Steel and Carbon Steel Rebars in Chloride Contaminated Concrete Pore Solution Using Electrochemical Method. Int. J. Electrochem. Sci. 2020, 15, 10844–10853. [Google Scholar] [CrossRef]

- Dehghani, A.; Bahlakeh, G.; Ramezanzadeh, B.; Ramezanzadeh, M. Potential role of a novel green eco-friendly inhibitor in corrosion inhibition of mild steel in HCl solution: Detailed macro/micro-scale experimental and computational explorations. Constr. Build. Mater. 2020, 245, 118464. [Google Scholar] [CrossRef]

- Nogara, J.; Zarrouk, S.J. Corrosion in geothermal environment Part 2: Metals and alloys. Renew. Sustain. Energy Rev. 2018, 82, 1347–1363. [Google Scholar] [CrossRef]

- Ren, L.; Jiang, T.; Jia, Z.; Li, D.; Yuan, C.; Li, H. Pipeline corrosion and leakage monitoring based on the distributed optical fiber sensing technology. Measurement 2018, 122, 57–65. [Google Scholar] [CrossRef]

- Gloria, N.B.S.; Areiza, M.C.L.; Miranda, I.V.J.; Rebello, J.M.A. Development of a magnetic sensor for detection and sizing of internal pipeline corrosion defects. NDT E Int. 2009, 42, 669–677. [Google Scholar] [CrossRef]

- Raja, S.; Saranya, R.; SaiYaswanth, V.; SachinAdithya, A.; Kumar, M.B.R. A Review on Influencing Welding Parameters of Super Alloys. IOP Conf. Ser. Mater. Sci. Eng. 2020, 995, 012041. [Google Scholar] [CrossRef]

- Jafari, H.; Idris, M.H.; Ourdjini, A.; Rahimi, H.; Ghobadian, B. EIS study of corrosion behavior of metallic materials in ethanol blended gasoline containing water as a contaminant. Fuel 2011, 90, 1181–1187. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Joshi, V.; Pandit, S.; Agrawal, M.; Kumar, O.S.; Periwal, S.; Manikandan, M.; Arivazhagan, N. Investigations on the microstructure and mechanical properties of multi-pass pulsed current gas tungsten arc weldments of Monel 400 and Hastelloy C276. Mater. Des. 2014, 64, 775–782. [Google Scholar] [CrossRef]

- Takeuchi, M.; Nakajima, Y.; Hoshino, K.; Kawamura, F. Controls of chromium and third element contents in nickel-base alloys for corrosion resistant alloys in hot HNO3–HF mixtures. J. Alloy. Compd. 2010, 506, 194–200. [Google Scholar] [CrossRef]

- Bhaskaran, R.; Palaniswamy, N.S.; Rengaswamy, N.; Jayachandran, M. A review of differing approaches used to estimate the cost of corrosion (and their relevance in the development of modern corrosion prevention and control strategies). Anti-Corros. Methods Mater. 2005, 52, 29–41. [Google Scholar] [CrossRef]

- Farmer, J.; Farmer, C.J. Highway Infrastructure Focus Area Next-Generation Infrastructure Materials Volume I—Technical Proposal & Management Enhancement of Transportation Infrastructure with Iron-Based Amorphous-Metal and Ceramic Coatings; U.S. Department of Energy Office of Scientific and Technical Information: Livermore, CA, USA, 2007. [Google Scholar] [CrossRef][Green Version]

- Glass, G.K.; Page, C.L.; Short, N.R. Factors affecting the corrosion rate of steel in carbonated mortars. Corros. Sci. 1991, 32, 1283–1294. [Google Scholar] [CrossRef]

- Vidyasagar, K.E.C.; Rana, A.; Kalyanasundaram, D. Optimization of laser parameters for improved corrosion resistance of nitinol. Mater. Manuf. Process. 2020, 35, 1661–1669. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H. A review on the influence of process parameters and heat treatment on the corrosion performance of Ni-based thermal spray coatings. Surf. Rev. Lett. 2022, 29, 2230001. [Google Scholar] [CrossRef]

- Popoola, A.P.I.; Fatoba, O.S.; Popoola, O.M.; Pityana, S.L. The Influence of Heat Treatment and Process Parameters Optimization on Hardness and Corrosion Properties of Laser Alloyed X12CrNiMo Steel. Silicon 2016, 8, 579–589. [Google Scholar] [CrossRef]

- Songur, F.; Arslan, E.; Dikici, B. Taguchi optimization of PEO process parameters for corrosion protection of AA7075 alloy. Surf. Coat. Technol. 2022, 434, 128202. [Google Scholar] [CrossRef]

- Ettefagh, A.H.; Guo, S.; Raush, J. Corrosion performance of additively manufactured stainless steel parts: A review. Addit. Manuf. 2021, 37, 101689. [Google Scholar] [CrossRef]

- Xu, X.; Lu, H.; Qiu, J.; Luo, K.; Su, Y.; Xing, F.; Lu, J. High-speed-rate direct energy deposition of Fe-based stainless steel: Process optimization, microstructural features, corrosion and wear resistance. J. Manuf. Process. 2022, 75, 243–258. [Google Scholar] [CrossRef]

- Ramesh, S.; Kudva, S.A.; Anne, G.; Manne, B.; Arya, S. Optimization of ball-burnishing process parameters on surface roughness, micro hardness of Mg–Zn–Ca alloy and investigation of corrosion behavior. Mater. Res. Express 2019, 6, 1065e8. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.; Singh, J.P. Investigation on wall thickness reduction of hydropower pipeline underwent to erosion-corrosion process. Eng. Fail. Anal. 2021, 127, 105504. [Google Scholar] [CrossRef]

- Ramesh, N.R.; Kumar, V.S.S. Experimental erosion-corrosion analysis of friction stir welding of AA 5083 and AA 6061 for sub-sea applications. Appl. Ocean Res. 2020, 98, 102121. [Google Scholar] [CrossRef]

- Mehta, R.K.; Yadav, M. Corrosion inhibition properties of expired Broclear medicine and its carbon dot as eco-friendly inhibitors for mild steel in 15% HCl. Mater. Sci. Eng. B 2023, 295, 116566. [Google Scholar] [CrossRef]

- Farahati, R.; Mousavi-Khoshdel, S.M.; Ghaffarinejad, A.; Behzadi, H. Experimental and computational study of penicillamine drug and cysteine as water-soluble green corrosion inhibitors of mild steel. Prog. Org. Coat. 2020, 142, 105567. [Google Scholar] [CrossRef]

- Umoren, S.A.; Solomon, M.M. Effect of halide ions on the corrosion inhibition efficiency of different organic species—A review. J. Ind. Eng. Chem. 2015, 21, 81–100. [Google Scholar] [CrossRef]

- Cheng, X.; Feng, Z.; Li, C.; Dong, C.; Li, X. Investigation of oxide film formation on 316L stainless steel in high-temperature aqueous environments. Electrochim. Acta 2011, 56, 5860–5865. [Google Scholar] [CrossRef]

- Xi, T.; Shahzad, M.B.; Xu, D.; Sun, Z.; Zhao, J.; Yang, C.; Qi, M.; Yang, K. Effect of copper addition on mechanical properties, corrosion resistance and antibacterial property of 316L stainless steel. Mater. Sci. Eng. C 2017, 71, 1079–1085. [Google Scholar] [CrossRef]

- Luo, H.; Li, X.G.; Dong, C.F.; Xiao, K. The influence of Cu on the electrochemical behaviour of 304 stainless steel in 0.1M H3 PO4 solution. Surf. Interface Anal. 2013, 45, 793–799. [Google Scholar] [CrossRef]

- Oguzie, E.E.; Li, J.; Liu, Y.; Chen, D.; Li, Y.; Yang, K.; Wang, F. The effect of Cu addition on the electrochemical corrosion and passivation behavior of stainless steels. Electrochim. Acta 2010, 55, 5028–5035. [Google Scholar] [CrossRef]

- Singh, A.; Ansari, K.R.; Chauhan, D.S.; Quraishi, M.A.; Kaya, S. Anti-corrosion investigation of pyrimidine derivatives as green and sustainable corrosion inhibitor for N80 steel in highly corrosive environment: Experimental and AFM/XPS study. Sustain. Chem. Pharm. 2020, 16, 100257. [Google Scholar] [CrossRef]

- Carranza, M.S.S.; Reyes, Y.I.A.; Gonzales, E.C.; Arcon, D.P.; Franco, F.C. Electrochemical and quantum mechanical investigation of various small molecule organic compounds as corrosion inhibitors in mild steel. Heliyon 2021, 7, e07952. [Google Scholar] [CrossRef] [PubMed]

- Abd El Haleem, S.M.; Abd El Wanees, S.; Abd El Aal, E.E.; Farouk, A. Factors affecting the corrosion behaviour of aluminium in acid solutions. I. Nitrogen and/or sulphur-containing organic compounds as corrosion inhibitors for Al in HCl solutions. Corros. Sci. 2013, 68, 1–13. [Google Scholar] [CrossRef]

- Chen, L.; Lu, D.; Zhang, Y. Organic Compounds as Corrosion Inhibitors for Carbon Steel in HCl Solution: A Comprehensive Review. Materials 2022, 15, 2023. [Google Scholar] [CrossRef] [PubMed]

- Mahdavian, M.; Attar, M.M. Another approach in analysis of paint coatings with EIS measurement: Phase angle at high frequencies. Corros. Sci. 2006, 48, 4152–4157. [Google Scholar] [CrossRef]

- Al-Sabbagh, A.M.; Osman, M.M.; Omar, A.M.A.; El-Gamal, I.M. Organic corrosion inhibitors for steel pipelines in oilfields. Anti-Corros. Methods Mater. 1996, 43, 11–16. [Google Scholar] [CrossRef]

- Ramgopal, T. Localized Corrosion of Tantalum in Chloride-Containing Methanol Solutions—Effect of Water Concentration. Corrosion 2005, 61, 757–765. [Google Scholar] [CrossRef]

- Hiraide, N.; Sakamoto, S.; Yakawa, A. Corrosion Resistance Test of Stainless Steels in the Biofuel Environment. Int. J. Automot. Eng. 2019, 10, 144–149. [Google Scholar] [CrossRef][Green Version]

| Organic Compound | Application | Organic Compound | Application |

|---|---|---|---|

| Gammexene | Insecticide/germicide | Urotropin | Urological disease treatment |

| Carbon-tetrachloride | Fire extinguishers | Ether | Coolant, solvent, anesthesia, and in alcohol production, etc. |

| Benzene Sulphonic acid | In the production of sulfa drugs, colored solutes, saccharin, etc. | Benzoic acid | In the food industry for preservation and drug production, etc. |

| Benzaldehyde | In perfume manufacturing and the color industry | Phenol | Used in the production of aspirin, predestine, insecticides, carbolic soap, etc. |

| Aniline | In drug manufacturing and colors etc. | Nitro benzene | In polishes and soap production, etc. |

| Chloro benzene | Used in phenol, aniline, etc., manufacturing. | Toluene | In the explosive industry, medicine production, dry cleaning, solvents, etc. |

| Benzene | Used as fuel in engines, solvents in dry cleaning, etc. | Glucose | In fruit/juices preservation, production of wines and medicines, etc. |

| Oxalic acid | Used in leather bleaching, printing, and colorization of clothes, making ink colors, cleaning ink spots with 10% solution, etc. | Urea | Used in the production of medicines, urea plastic, and formaldehyde. Used in the form of fertilizer, etc. |

| Ethyl acetate | Used in artificial perfumes and medicines, etc. | Acetamide | In misting paper and pulp, in softening cloth, and leather. |

| Acetic anhydride | Used in the making of medicine like aspirin, in the production of synthetic/artificial silk from cellulose, in the color industry, etc. | Glycerol | In wine and fruit preservation, cosmetics, and shoe polishes, medicines for pain relievers, watches for cleaning, in making nitro-glycerine, etc. |

| Acetic acid | In making jelly and sauces; in the laboratory, and food industry in the form of vinegar, etc. | Formic acid | In food preservation, used in insecticide production, in rubber, leather trade, etc. |

| Acetone | In making of chloroform, chloretone, sulfone, synthetic rubber, artificial silk, clodian cellulose, varnish, etc. | Acetaldehyde | Used in the production of plastic, metal acetaldehyde medicine, colors, etc. |

| Formaldehyde | Used in making waterproof clothes, gelatin film, insecticides, etc. | Acetyl chloride | In the production of acetic anhydride, acetamide, etc. |

| Ethyl alcohol | Used as insecticides for cleaning wounds, in stoves and spirit lamps, making artificial scents/colors in fruits and perfumes, solvents in methylated spirits, in varnishes and polish, in making wines and alcoholic drinking stuff, etc. | Methane | Used in the production of chloroform, formaldehyde, methyl alcohol, making tires, inks, and colors. Used as fuel for energy production, etc. |

| Methyl alcohol | In making polish, varnish, artificial color, methylated spirit, used as fuel in engines by mixing with petrol, etc. | Chloroform | Used as anesthesia in surgical operations, solvents for lac, fats, rubber, used as insecticides, etc. |

| Ethyl bromine | Used in surgical operations as local anesthesia. | Polystyrene | Used in making accumulator cells, caps of acid bottles, etc. |

| Polythene | Used in the production of uncrackable bottles, electrical resistance in cables and wires, etc. | Acetylene | Used for artificial ripening, Marcelin anesthesia, in producing artificial rubber, etc. |

| Ethylene | Used for anesthesia, fruit ripening, and preservation, in oxy-ethylene flame. | Butane | Used as fuel in liquid state in the form of LPG, etc. |

| Firmament | In the production of chewing tablets and medicines for the throat, etc. |

| Metal | Corrosion Medium | Type of Corrosion | Temperature | Prevention Method |

|---|---|---|---|---|

| Carbon steel | Dimethyl formamide | Uniform | 100 °C | 0.1% H2O) |

| AISI316 | Acetic acid (30%) + propyl acetate (9%) + butyl acetate (42%) + propionic acid (18%) | Pitting | Boiling | Add titanium |

| Ti | Methyl acetate+acetals + HCl + H2O | Intergranular stress corrosion | Boiling | Enamel coating |

| Al | Ethyl dibromide | High rate uniform | 25 °C | Use galvanized steel |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, A.; Adesina, A.Y.; Suleiman, R.K. Influence of Organic Acids and Related Organic Compounds on Corrosion Behavior of Stainless Steel—A Critical Review. Metals 2023, 13, 1479. https://doi.org/10.3390/met13081479

Abbas A, Adesina AY, Suleiman RK. Influence of Organic Acids and Related Organic Compounds on Corrosion Behavior of Stainless Steel—A Critical Review. Metals. 2023; 13(8):1479. https://doi.org/10.3390/met13081479

Chicago/Turabian StyleAbbas, Aqeel, Akeem Yusuf Adesina, and Rami K. Suleiman. 2023. "Influence of Organic Acids and Related Organic Compounds on Corrosion Behavior of Stainless Steel—A Critical Review" Metals 13, no. 8: 1479. https://doi.org/10.3390/met13081479

APA StyleAbbas, A., Adesina, A. Y., & Suleiman, R. K. (2023). Influence of Organic Acids and Related Organic Compounds on Corrosion Behavior of Stainless Steel—A Critical Review. Metals, 13(8), 1479. https://doi.org/10.3390/met13081479