Effect of Friction Stir Welding and Tempering on the Microstructure and Strength of a Tempformed Low-Alloy Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results

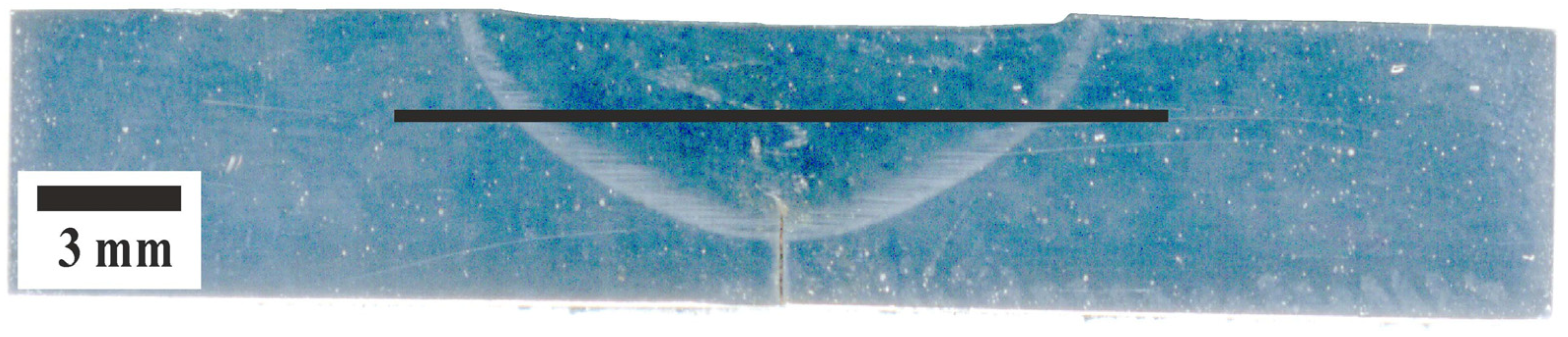

3.1. Hardness Distribution

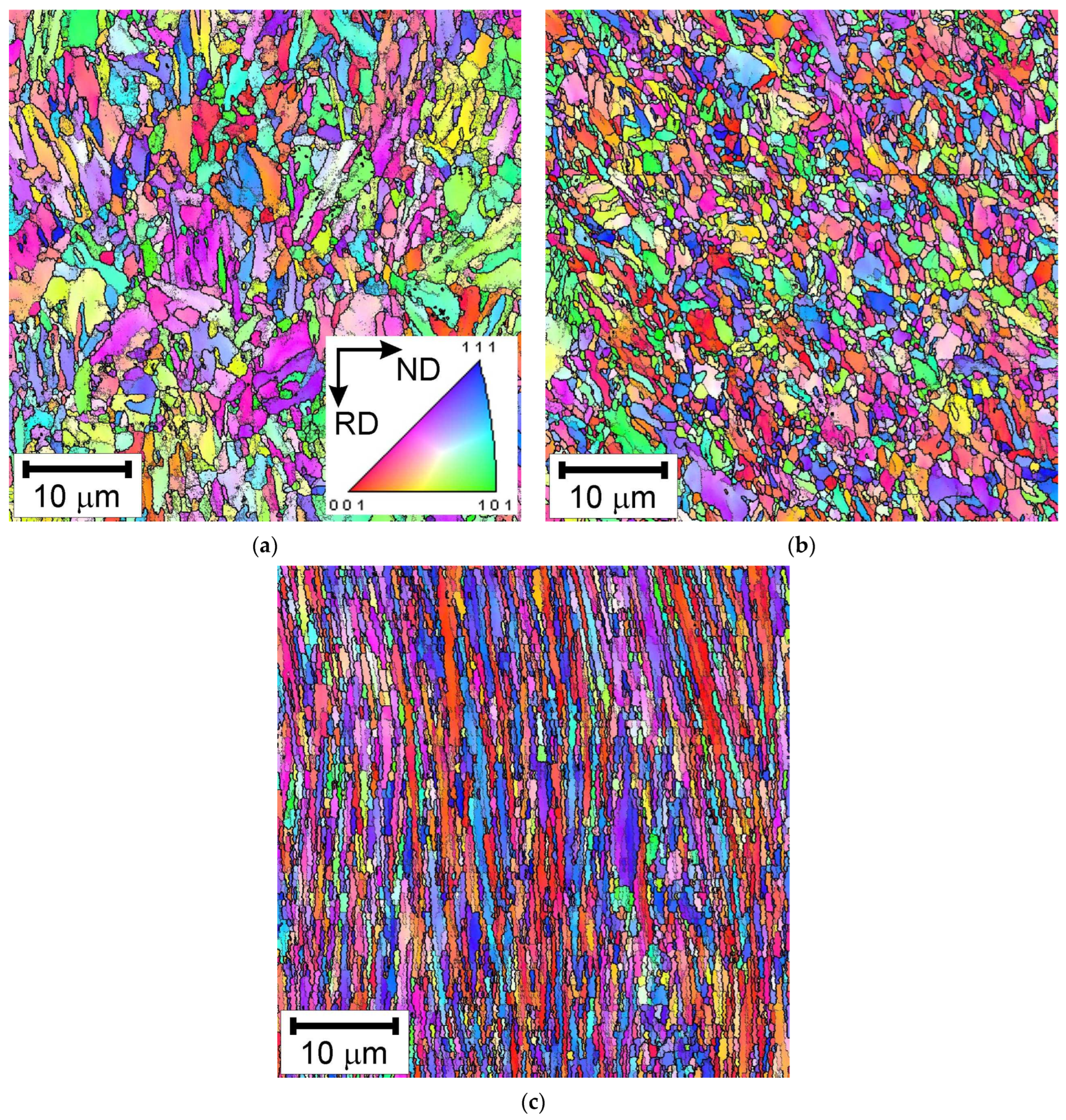

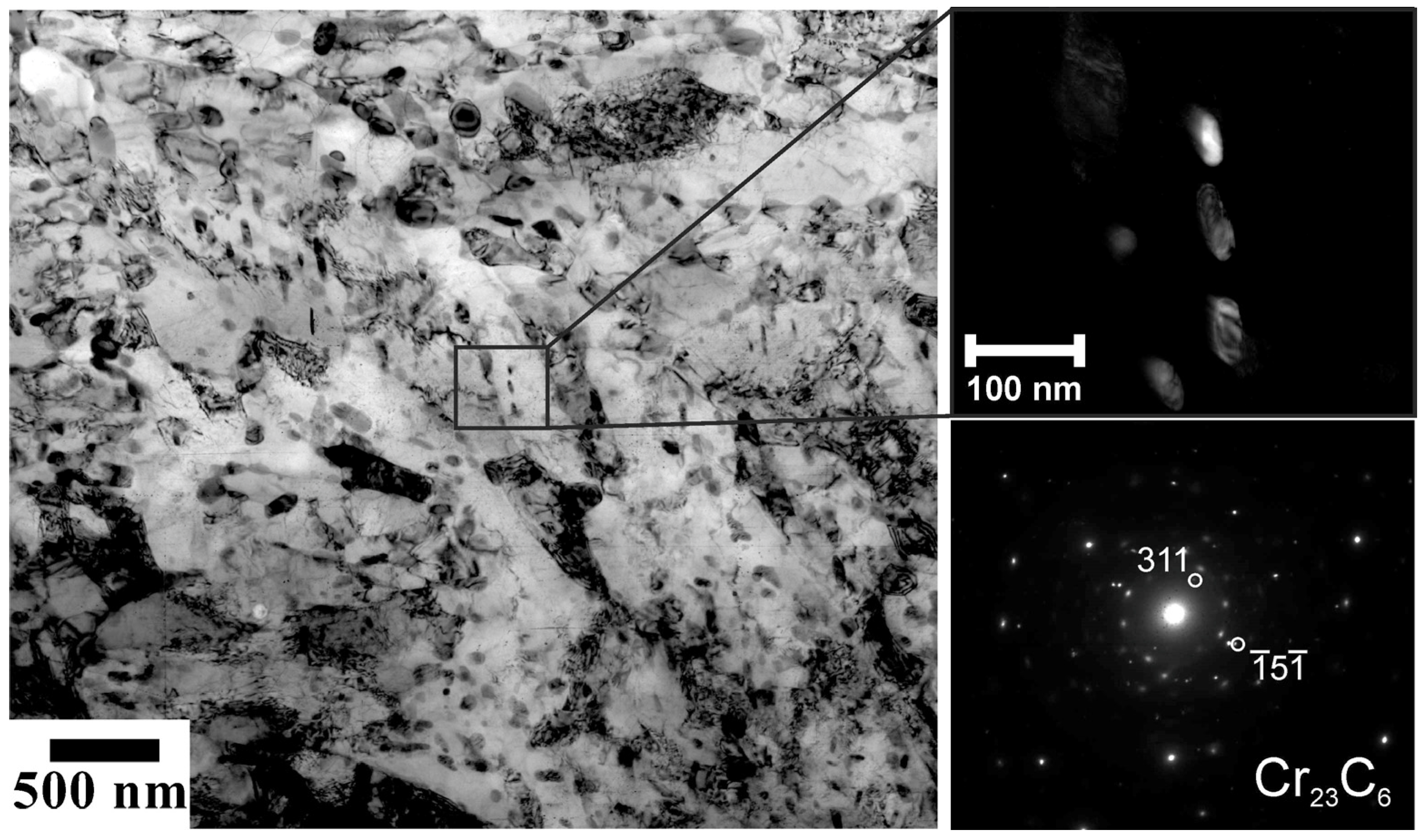

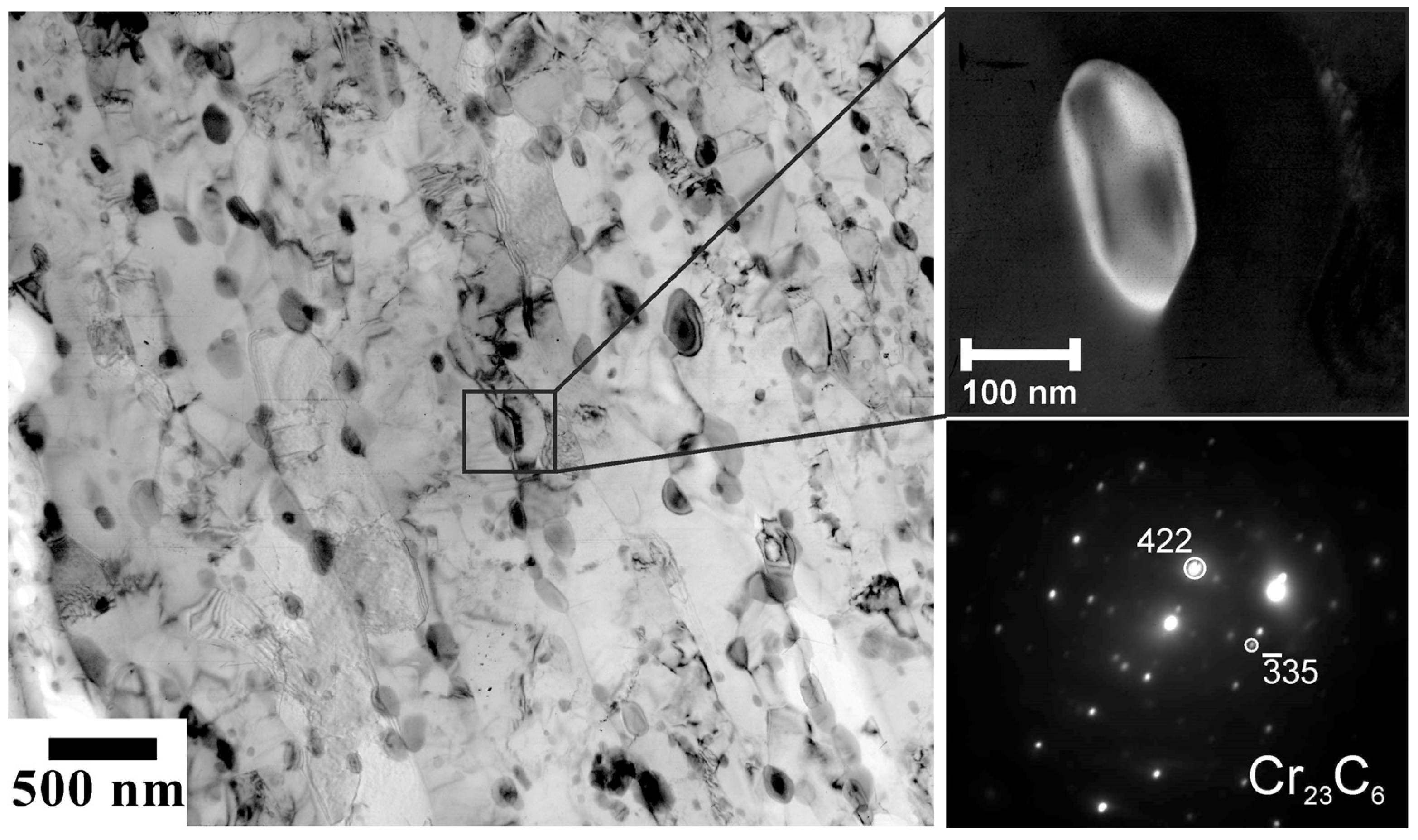

3.2. Microstructure Evolution

3.3. Tensile Tests

4. Discussion

5. Conclusions

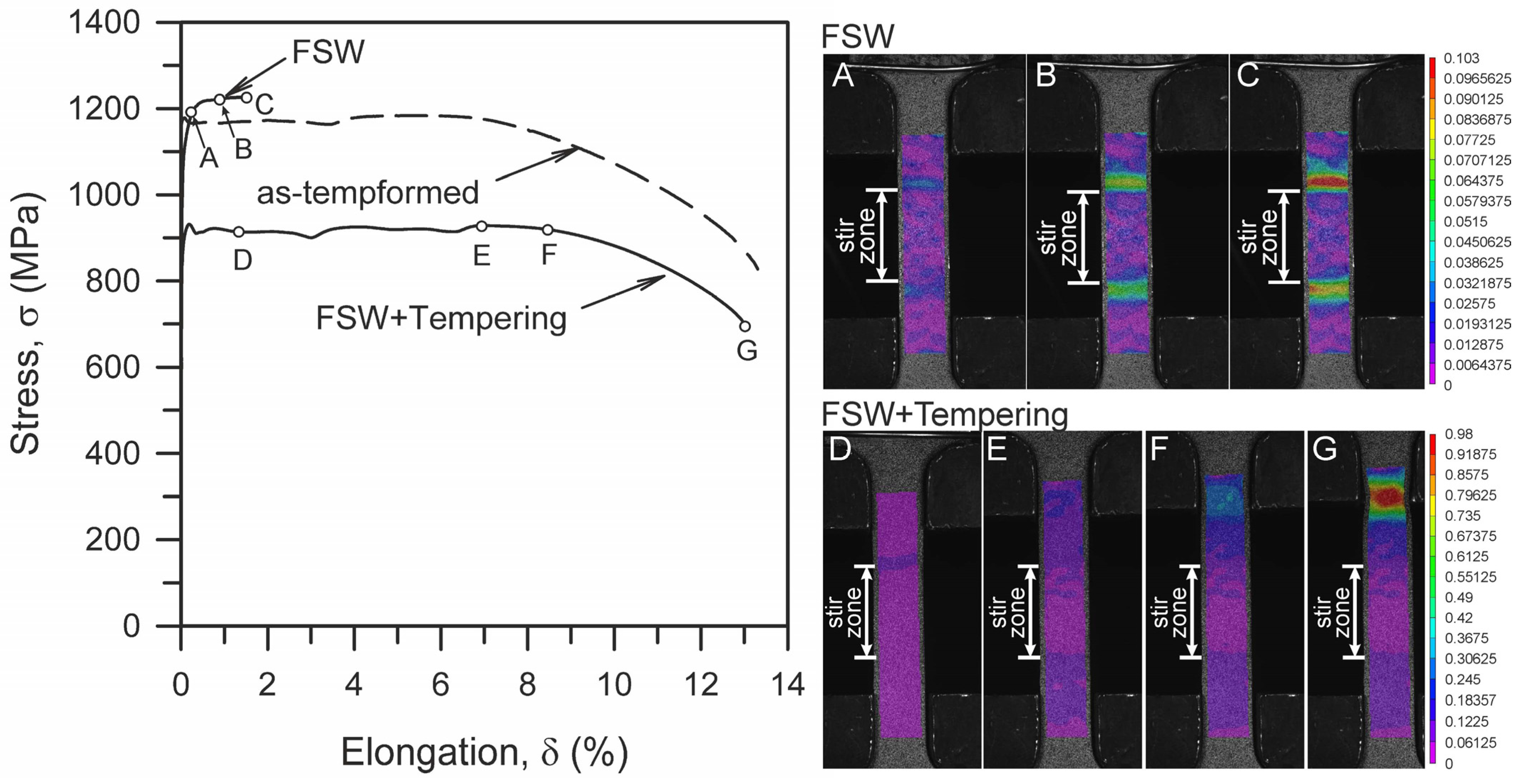

- The stir zone of the FSW joint sample is characterized by a lath martensite microstructure due to heating up to the austenite region and rapid cooling after the FSW. Owing to the high dislocation density inside the martensite laths, the hardness of the stir zone increases two-fold, reaching 7000 MPa. The yield strength of the FSW joint sample was 1170 MPa, which is comparable with that of about 1200 MPa of the base-tempformed material. The strain localization takes place in the heat-affected zone close to the stir zone upon tensile testing of the FSW joint sample, leading to a small total elongation of about 1.5%.

- Post-weld tempering at 650 °C for 1 h results in a decrease in the hardness of the weld joint to the level of the base material of about 3000 MPa. However, the strain localization followed by fracture upon tensile testing of the welded and tempered sample occurs in the base material. The yield strength of the FSW joint sample after tempering was 930 MPa, with a total elongation of 13%. This increase in elongation is attributed to further tempering and improving the plasticity of the base material. The yield strength is controlled by the dislocation density, which provides strengthening similar to that from grain size and dispersed particles.

- FSW, followed by a post-weld tempering treatment, can be used to join high-strength low-alloy steels with an ultrafine-grained microstructure produced by tempforming.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goodwin, F.; Guruswamy, S.; Kainer, K.U.; Kammer, C.; Knabl, W.; Leichtfried, G.; Schlamp, G.; Stickler, R.; Warlimont, H. Metals. In Springer Handbook of Condensed Matter and Materials Data; Martienssen, W., Warlimont, H., Eds.; Springer: Berlin, Germany, 2005; pp. 161–430. [Google Scholar]

- Krauss, G. Steels: Processing Structure and Performance; ASM International: Phoenix, AZ, USA, 2015; 681p. [Google Scholar]

- Faucher, B.; Dogan, B. Evaluation of the fracture toughness of hot-rolled low-alloy Ti-V plate steel. Metall. Trans. A 1988, 19, 505–516. [Google Scholar] [CrossRef]

- Tomita, Y. Low temperature mechanical properties of quenched and tempered 04C–Ni–Cr–Mo steel after controlled rolling. Mater. Sci. Technol. 1988, 4, 613–620. [Google Scholar] [CrossRef]

- Tomita, Y. Low-temperature improvement of mechanical properties of AISI 4340 steel through high-temperature thermomechanical treatment. Metall. Trans. A 1991, 22, 1093–1102. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T.; Yin, F.; Sitdikov, O.; Tsuzaki, K. Toughening of a 1500 MPa class steel through formation of an ultrafine fibrous grain structure. Scripta Mater. 2007, 57, 465–468. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T.; Yin, F.; Tsuzaki, K. Inverse temperature dependence of toughness in an ultrafine grain-structure steel. Science 2008, 320, 1057–1060. [Google Scholar] [CrossRef] [PubMed]

- Dolzhenko, A.; Kaibyshev, R.; Belyakov, A. Tempforming as an advanced processing method for carbon steels. Metals 2020, 10, 1566. [Google Scholar] [CrossRef]

- Inoue, T.; Qiu, H.; Ueji, R.; Kimura, Y. Ductile-to-brittle transition and brittle fracture stress of ultrafine-grained low-carbon steel. Materials 2021, 14, 1634. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Kaibyshev, R.; Belyakov, A. Tempforming Strengthening of a Low-Alloy Steel. Materials 2022, 15, 5241. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T. Influence of annealing on delamination toughening of Mo-bearing medium-carbon steel with ultrafine elongated grain structure processed by warm tempforming. ISIJ Int. 2022, 62, 402–404. [Google Scholar] [CrossRef]

- Al-Sabur, R. Tensile strength prediction of aluminium alloys welded by FSW using response surface methodology—Comparative review. Mater. Today Proc. 2021, 45, 4504–4510. [Google Scholar] [CrossRef]

- Santella, M.; Hovanski, Y.; Pan, T.-Y. Friction stir spot welding (FSSW) of advanced high strength steel (AHSS). SAE Int. J. Mater. Manuf. 2012, 5, 382–387. [Google Scholar] [CrossRef]

- Lee, H.; Kim, C.; Song, J.H. An evaluation of global and local tensile properties of friction-stir welded DP980 dual-phase steel joints using a digital image correlation method. Materials 2015, 8, 8424–8436. [Google Scholar] [CrossRef]

- You, H.; Kang, M.; Yi, S.; Hyun, S.; Kim, C. Comprehensive Analysis of the Microstructure and Mechanical Properties of Friction-Stir-Welded Low-Carbon High-Strength Steels with Tensile Strengths Ranging from 590 MPa to 1.5 GPa. Appl. Sci. 2021, 11, 5728. [Google Scholar] [CrossRef]

- Abhilash, V.; Lakshminarayanan, A.K. Friction stir lap joining techniques effects on microstructure and tensile properties of high strength automotive steel top hat sections. Mater. Res. Express 2023, 10, 026505. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Lugovskaya, A.; Belyakov, A. Failure of friction stir welded joint of a tempformed high-strength low-alloy steel. In Proceedings of the 16th Sino-Russia Symposium on Advanced Materials and Technologies; The Nonferrous Metals Society of China: Beijing, China, 2023; pp. 240–244. [Google Scholar]

- Hughes, D.A.; Hansen, N. Microstructure and strength of nickel at large strains. Acta Mater. 2000, 48, 2985–3004. [Google Scholar] [CrossRef]

- Williams, D.B.; Carter, C.B. Transmission Electron Microscopy; Plenum Press: New York, NY, USA, 1996; pp. 289–318. [Google Scholar]

- The VIC-3D System. Available online: https://www.correlatedsolutions.com/vic-3d/ (accessed on 15 December 2023).

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; Dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Ohashi, R.; Fujimoto, M.; Mironov, S.; Sato, Y.S.; Kokawa, H. Microstructural characterization of high-strength steel lap joint produced by friction spot joining. Metall. Mater. Trans. A 2009, 40A, 2033–2035. [Google Scholar] [CrossRef]

- Hua, P.; Mironov, S.; Sato, Y.S.; Kokawa, H.; Park, S.H.C.; Hirano, S. Crystallography of martensite in friction-stir-welded 12 Cr heat-resistant steel. Metall. Mater. Trans. A 2019, 50A, 3158–3163. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Ueda, M.; Tsuji, N.; Minamino, Y. Crystallographic analysis of plate martensite in Fe–28.5at.% Ni by FE-SEM/EBSD. Mater. Charact. 2005, 54, 378–386. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Tikhonova, M.; Kaibyshev, R.; Belyakov, A. Microstructures and Mechanical Properties of Steels and Alloys Subjected to Large-Strain Cold-to-Warm Deformation. Metals 2022, 12, 454. [Google Scholar] [CrossRef]

- Belyakov, A.; Kimura, Y.; Adachi, Y.; Tsuzaki, K. Microstructure Evolution in Ferritic Stainless Steels during Large Strain Deformation. Mater. Trans. 2004, 45, 2812–2821. [Google Scholar] [CrossRef]

- De Ardo, A.J.; Hua, M.J.; Cho, K.G.; Garcia, C.I. On strength of micro alloyed steels: An interpretive review. Mater. Sci. Technol. 2009, 25, 1074–1082. [Google Scholar] [CrossRef]

- Xiong, Z.; Timokhina, I.; Pereloma, E. Clustering, nano-scale precipitation and strengthening of steels. Prog. Mater. Sci. 2021, 118, 100764. [Google Scholar] [CrossRef]

- Mecking, H.; Kocks, U. Kinetics of flow and strain-hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Tanaka, Y.; Takaki, S.; Tsuchiyama, T.; Uemori, R. Effect of grain size on the yield stress of cold worked iron. ISIJ Int. 2018, 58, 1927–1933. [Google Scholar] [CrossRef]

- Frost, H.; Ashby, M. Deformation Mechanism Maps; Pergamon Press: Oxford, UK, 1982; p. 166. [Google Scholar]

- Hall, E.O. The deformation and ageing of mild steel: III Discussion of results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Lesuer, D.R.; Syn, C.K.; Sherby, O.D. Influence of Iron Oxide Particles on the Strength of Ball-Milled Iron. Mater. Trans. 2006, 47, 1508–1517. [Google Scholar] [CrossRef]

- Belyakov, A.; Tsuzaki, K.; Kimura, Y.; Mishima, Y. Tensile behaviour of submicrocrystalline ferritic steel processed by large-strain deformation. Philos. Mag. Lett. 2009, 89, 201–212. [Google Scholar] [CrossRef]

- Harrell, T.J.; Topping, T.D.; Wen, H.; Hu, T.; Schoenung, J.M.; Lavernia, E.J. Microstructure and strengthening mechanisms in an ultrafine grained Al-Mg-Sc alloy produced by powder metallurgy. Metall. Mater. Trans. A 2014, 45A, 6329–6343. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Pydrin, A.; Gaidar, S.; Kaibyshev, R.; Belyakov, A. Microstructure and Strengthening Mechanisms in an HSLA Steel Subjected to Tempforming. Metals 2022, 12, 48. [Google Scholar] [CrossRef]

- Takaki, S. Yielding behavior of polycrystalline ferritic steel. In THERMEC’2021 Book of Abstracts, Proceedings of the International Conference on Processing & Manufacturing of Advanced Materials, Online, 1–5 June 2021; Graz University of Technology: Graz, Austria, 2021; pp. 33–34. [Google Scholar]

| Sample | D, nm | ρOIM, m−2 | ρTEM, m−2 | ρ, m−2 | d, nm |

|---|---|---|---|---|---|

| As-tempformed | 360 ± 30 | (2.5 ± 0.2) × 1015 | (0.8 ± 0.2) × 1015 | 3.3 × 1015 | 53 ± 8 |

| FSW, stir zone | 850 ± 80 | (0.9 ± 0.1) × 1015 | (3.0 ± 0.6) × 1015 | 3.9 × 1015 | - |

| FSW, stir zone, tempered | 850 ± 80 | (0.8 ± 0.1) × 1015 | (0.8 ± 0.2) × 1015 | 1.6 × 1015 | 61 ± 5 |

| FSW, base material, tempered | 570 ± 50 | (1.3 ± 0.1) × 1015 | (0.3 ± 0.1) × 1015 | 1.6 × 1015 | 77 ± 8 |

| Sample | σ0.2, MPa | Δσρ, MPa | ΔσD, MPa | ΔσOr, MPa |

|---|---|---|---|---|

| As-tempformed | 1180 ± 35 | 1050 | 400 | 495 |

| FSW, stir zone | 1170 ± 35 | 1140 | 260 | - |

| FSW, stir zone, tempered | 930 ± 20 | 730 | 260 | 455 |

| FSW, base material, tempered | 930 ± 20 | 730 | 320 | 380 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolzhenko, A.S.; Lugovskaya, A.S.; Malopheyev, S.; Dudko, V.; Tikhonova, M.; Kaibyshev, R.; Belyakov, A. Effect of Friction Stir Welding and Tempering on the Microstructure and Strength of a Tempformed Low-Alloy Steel. Metals 2024, 14, 114. https://doi.org/10.3390/met14010114

Dolzhenko AS, Lugovskaya AS, Malopheyev S, Dudko V, Tikhonova M, Kaibyshev R, Belyakov A. Effect of Friction Stir Welding and Tempering on the Microstructure and Strength of a Tempformed Low-Alloy Steel. Metals. 2024; 14(1):114. https://doi.org/10.3390/met14010114

Chicago/Turabian StyleDolzhenko, Anastasiia S., Anna S. Lugovskaya, Sergey Malopheyev, Valeriy Dudko, Marina Tikhonova, Rustam Kaibyshev, and Andrey Belyakov. 2024. "Effect of Friction Stir Welding and Tempering on the Microstructure and Strength of a Tempformed Low-Alloy Steel" Metals 14, no. 1: 114. https://doi.org/10.3390/met14010114

APA StyleDolzhenko, A. S., Lugovskaya, A. S., Malopheyev, S., Dudko, V., Tikhonova, M., Kaibyshev, R., & Belyakov, A. (2024). Effect of Friction Stir Welding and Tempering on the Microstructure and Strength of a Tempformed Low-Alloy Steel. Metals, 14(1), 114. https://doi.org/10.3390/met14010114