On the Competition between Pores and Hidden Entrainment Damage during In Situ Tensile Testing of Cast Aluminum Alloy Components

Abstract

1. Introduction

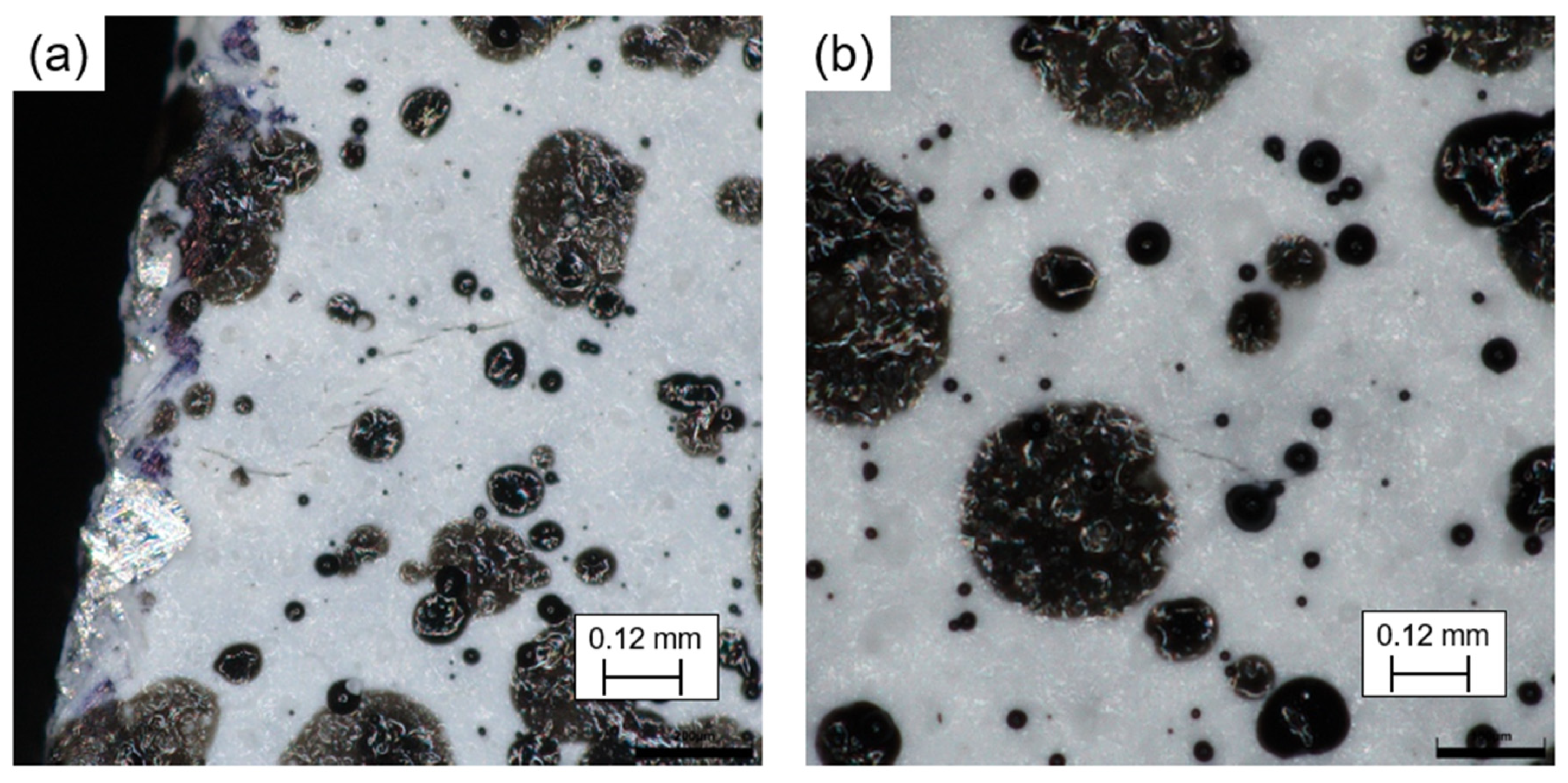

2. Materials and Methods

3. Results and Discussion

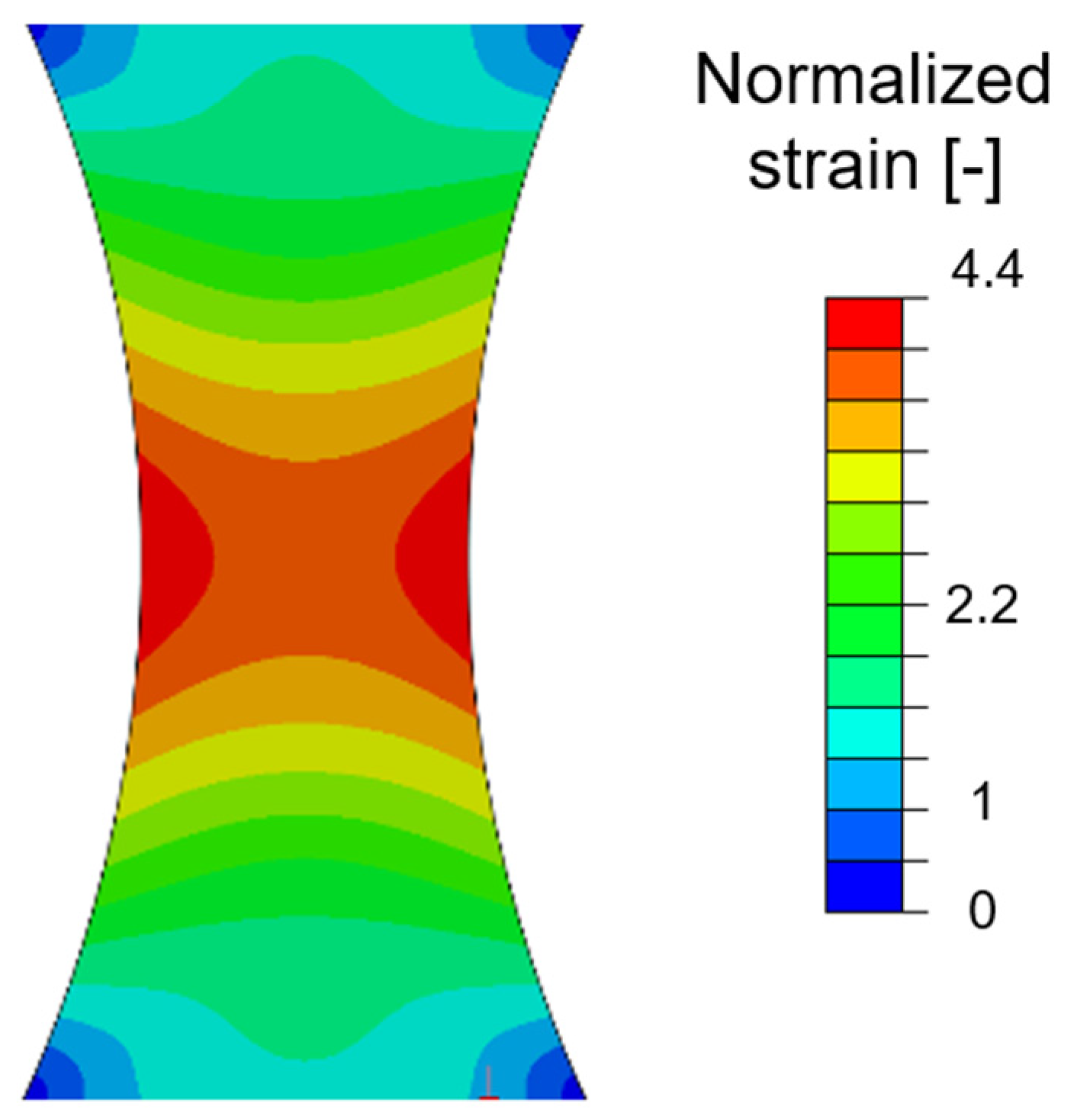

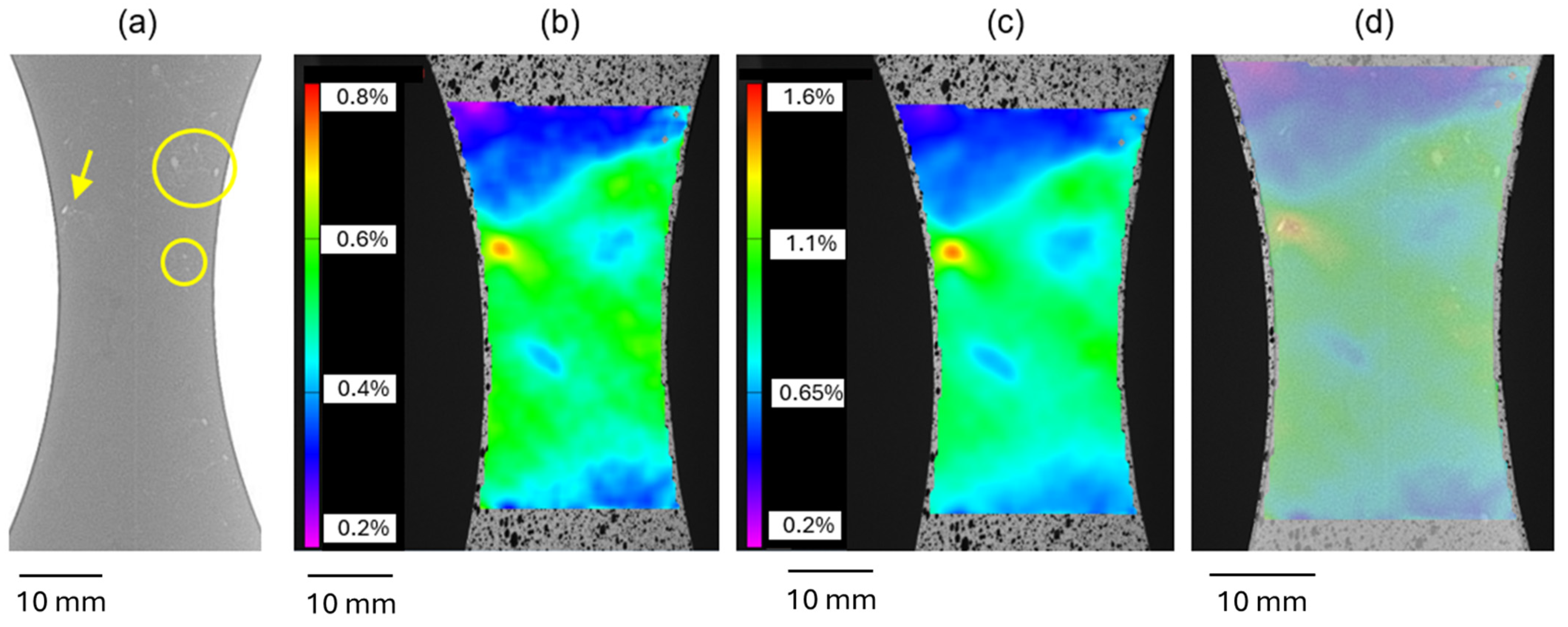

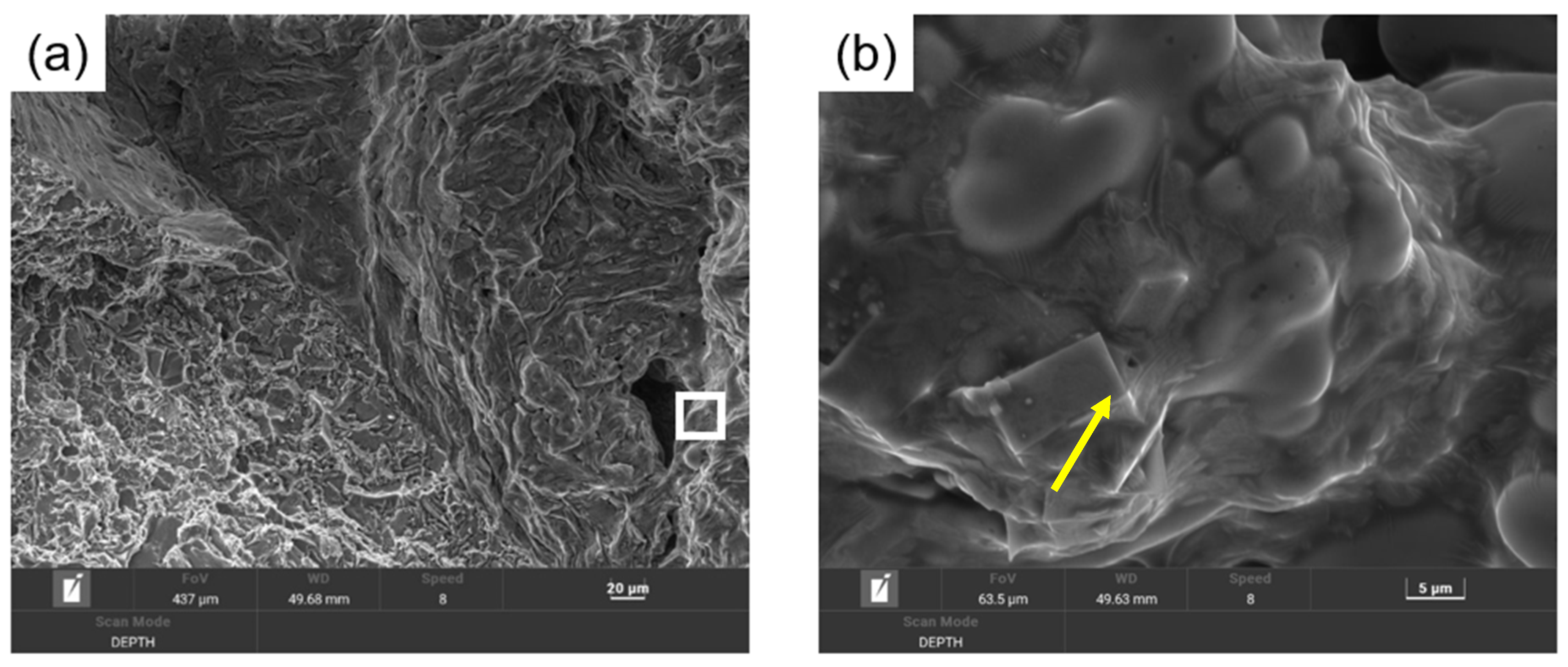

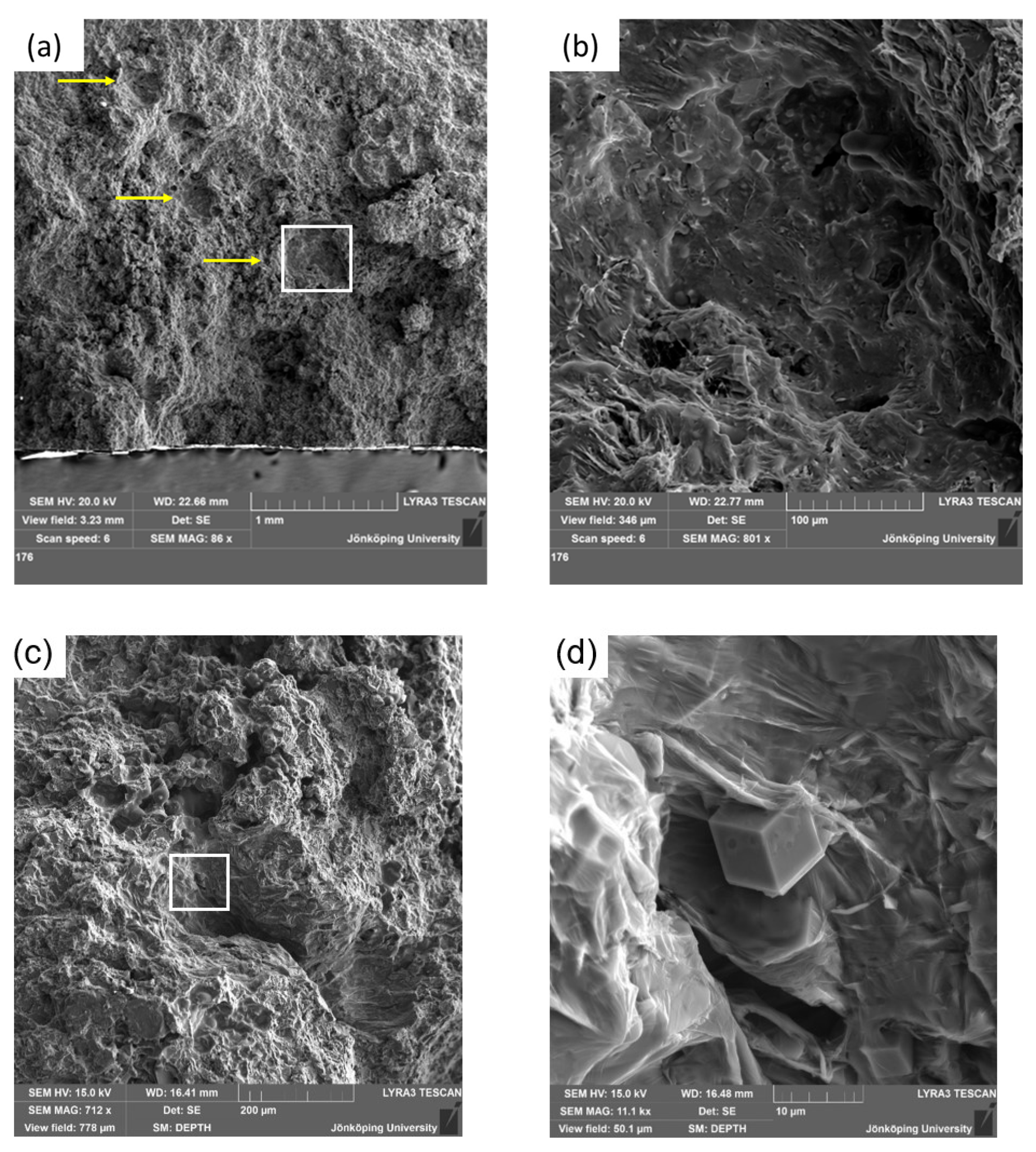

3.1. Competition with an Early Leader

3.2. Competition with a Late Leader

3.3. Competition to the End

4. Conclusions

- There is always competition between multiple strain concentrations during tensile testing of HPDC Al-alloys. Visible (pores) and hidden (invisible bifilms) damage competes in the early stages of tensile deformation. This competition for the final fracture can have an early winner or it can continue till the end.

- Strain concentration around a pore does not necessarily have the uniformity taught in mechanical engineering textbooks. This is due to bifilms that remain hidden near pores and that open during tensile deformation.

- Pores provide stress concentration around them, causing bifilms in their vicinity to open earlier than in areas without pores.

- Hidden bifilms can win the competition even when there are pores in the casting.

- Battling pores is the first step of quality improvement efforts, but definitely not the last.

- Current quality assurance systems that assess the quality of casting based solely on pores are outdated and should be updated immediately.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mil-a-21180 d. In Aluminum-Alloy Castings; Department of Defense: Washington, DC, USA, 1984.

- Wang, Q.; Crepeau, P.; Davidson, C.; Griffiths, J. Oxide films, pores and the fatigue lives of cast aluminum alloys. Metall. Mater. Trans. B 2006, 37, 887–895. [Google Scholar] [CrossRef]

- Katgerman, L.; Eskin, D.G. In search of prediction of hot cracking in aluminium alloys. In Hot Cracking Phenomena in Welds II; Böllinghaus, T., Herold, H., Cross, C.E., Lippold, J.C., Eds.; Springer: Berlin, Germany, 2008; pp. 3–18. [Google Scholar]

- Nazarboland, A.; Elliott, R. The effect of intrinsic casting defects on the mechanical properties of austempered, alloyed ductile iron. Int. J. Cast Met. Res. 1997, 10, 87–97. [Google Scholar] [CrossRef]

- Campbell, J. Pore nucleation in solidifying metals. In Proceedings of the Conference on the Solidification of Metals, Brighton, UK, 4–7 December 1967; Institute of Metals Publication: London, UK, 1968; pp. 18–26. [Google Scholar]

- Yousefian, P.; Tiryakioğlu, M. Pore formation during solidification of aluminum: Reconciliation of experimental observations, modeling assumptions, and classical nucleation theory. Metall. Mater. Trans. A 2018, 49, 563–575. [Google Scholar] [CrossRef]

- Tiryakioğlu, M. On the heterogeneous nucleation pressure for hydrogen pores in liquid aluminium. Int. J. Cast Met. Res. 2020, 33, 153–156. [Google Scholar] [CrossRef]

- Campbell, J. Entrainment defects. Mater. Sci. Technol. 2006, 22, 127–145. [Google Scholar] [CrossRef]

- Yousefi, E.; Sun, Y.; Kunwar, A.; Guo, M.; Moelans, N.; Seveno, D. Surface tension of aluminum-oxygen system: A molecular dynamics study. Acta Mater. 2021, 221, 117430. [Google Scholar] [CrossRef]

- Stucki, F.; Erbudak, M.; Kostorz, G. The initial oxidation of solid and liquid aluminium. Appl. Surf. Sci. 1987, 27, 393–400. [Google Scholar] [CrossRef]

- Bedair, S.; Smith, H.P., Jr. Leed studies of oxygen adsorption on the (111) and (110) surfaces of aluminum. J. Appl. Phys. 1971, 42, 3616–3618. [Google Scholar] [CrossRef]

- Reichel, F.; Jeurgens, L.; Richter, G.; Mittemeijer, E. Amorphous versus crystalline state for ultrathin Al2O3 overgrowths on al substrates. J. Appl. Phys. 2008, 103, 093515. [Google Scholar] [CrossRef]

- Men, H.; Fan, Z. Transition of amorphous to crystalline oxide film in initial oxide overgrowth on liquid metals. Mater. Sci. Technol. 2011, 27, 1033–1039. [Google Scholar] [CrossRef]

- Cox, M.; Harding, R.A.; Campbell, J. Optimised running system design for bottom filled aluminium alloy 2l99 investment castings. Mater. Sci. Technol. 2003, 19, 613–625. [Google Scholar] [CrossRef]

- Lai, N.; Griffiths, W.; Campbell, J. Modelling of the potential for oxide film entrainment in light metal alloy castings. In Proceedings of the Tenth International Conference on Modeling of Casting, Welding and Advanced Solidification Processes, Destin, FL, USA, 25–30 May 2003; pp. 415–422. [Google Scholar]

- Campbell, J. The origin of Griffith cracks. Metall. Mater. Trans. B 2011, 42, 1091–1097. [Google Scholar] [CrossRef]

- Erzi, E.; Tiryakioğlu, M. A simple procedure to determine incoming quality of aluminum alloy ingots and its application to a356 alloy ingots. Int. J. Met. 2020, 14, 999–1004. [Google Scholar] [CrossRef]

- Gyarmati, G.; Kéri, Z.; Mende, T.; Molnár, D. Analysis of the quality of incoming alsi9mn alloy ingots. Int. J. Met. 2024, 18, 1723–1738. [Google Scholar] [CrossRef]

- Bogdanoff, T.; Tiryakioglu, M.; Jarfors, A.E.W.; Ghassemali, E. A simple procedure to assess the complete melt quality in aluminium castings: Implementation in a die-casting and a rheo-casting. Int. J. Cast Met. Res. 2023, 37, 71–79. [Google Scholar] [CrossRef]

- Dai, X.; Yang, X.; Campbell, J.; Wood, J. Effects of runner system design on the mechanical strength of al–7si–mg alloy castings. Mater. Sci. Eng. A 2003, 354, 315–325. [Google Scholar] [CrossRef]

- Tiryakioǧlu, M.; Campbell, J.; Staley, J.T. The influence of structural integrity on the tensile deformation of cast al–7wt.%si–0.6 wt.%mg alloys. Scr. Mater. 2003, 49, 873–878. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Staley, J.T.; Campbell, J. The effect of structural integrity on the tensile deformation characteristics of a206-t71 alloy castings. Mater. Sci. Eng. A 2008, 487, 383–387. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Campbell, J.; Alexopoulos, N.D. On the ductility of cast al-7 pct si-mg alloys. Metall. Mater. Trans. A 2009, 40, 1000–1007. [Google Scholar] [CrossRef]

- Hu, M.-L.; Guo, H.-M.; Yang, K.-Y.; Chang, W.-J.; Deng, B.; Luo, J.-T. Bifilm defects in alsi10mgmn alloy castings. Int. J. Met. 2023, 18, 2944–2957. [Google Scholar] [CrossRef]

- Campbell, J.; Tiryakioğlu, M. Fatigue failure in engineered components and how it can be eliminated: Case studies on the influence of bifilms. Metals 2022, 12, 1320. [Google Scholar] [CrossRef]

- Staley, J.T., Jr.; Tiryakioğlu, M.; Campbell, J. The effect of hot isostatic pressing (hip) on the fatigue life of a206-t71 aluminum castings. Mater. Sci. Eng. A 2007, 465, 136–145. [Google Scholar] [CrossRef]

- Campbell, J. The Mechanisms of Metallurgical Failure: On the Origin of Fracture; Butterworth-Heinemann: Oxford, UK, 2020. [Google Scholar]

- Campbell, J. Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design; Elsevier Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Campbell, J. Mini Casting Handbook; Aspect Design: Malvern, UK, 2018. [Google Scholar]

- Olofsson, J.; Bogdanoff, T.; Tiryakioğlu, M. On revealing hidden entrainment damage during in situ tensile testing of cast aluminum alloy components. Mater. Charact. 2024, 208, 113647. [Google Scholar] [CrossRef]

- Yang, B.-C.; Chen, S.-F.; Song, H.-W.; Zhang, S.-H.; Chang, H.-P.; Xu, S.-W.; Zhu, Z.-H.; Li, C.-H. Effects of microstructure coarsening and casting pores on the tensile and fatigue properties of cast a356-t6 aluminum alloy: A comparative investigation. Mater. Sci. Eng. A 2022, 857, 144106. [Google Scholar] [CrossRef]

- Olofsson, J. Integrated Fatigue Life Predictions of Aluminium Castings Using Simulated Local Microstructure and Defects. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Banff, AB, Canada, 18–23 June 2023; IOP Publishing: Bristol, UK, 2023; p. 012067. [Google Scholar]

- Divandari, M.; Campbell, J. Mechanisms of bubble trail formation in castings. Trans. AFS 2001, 109, 433–442. [Google Scholar]

- Tiryakioğlu, M. On estimating the hydrogen solubility in solid aluminium alloys and the hydrogen solubility difference between the liquidus and solidus temperatures. Int. J. Cast Met. Res. 2021, 34, 83–87. [Google Scholar] [CrossRef]

- Nyahumwa, C.; Green, N.R.; Campbell, J. Influence of casting technique and hot isostatic pressing on the fatigue of an al-7si-mg alloy. Metall. Mater. Trans. A 2001, 32, 349–358. [Google Scholar] [CrossRef]

- Miresmaeili, S.M.; Campbell, J.; Shabestari, S.G.; Boutorabi, S.M.A. Precipitation of sr-rich intermetallic particles and their influence on pore formation in sr-modified a356 alloy. Metall. Mater. Trans. A 2005, 36, 2341–2349. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. Morphology of β-al5fesi phase in al-si cast alloys. Mater. Trans. 2006, 47, 1303–1312. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. The solidification characteristics of fe-rich intermetallics in al-11.5si-0.4mg cast alloys. Metall. Mater. Trans. A 2004, 35, 1425–1435. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. Effect of sr on primaryα-fe phase in liquid al-11.5si-0.4mg cast alloy. Mater. Sci. Technol. 2004, 20, 514–520. [Google Scholar] [CrossRef]

- Cao, X.; Saunders, N.; Campbell, J. Effect of iron and manganese contents on convection-free precipitation and sedimentation of primary α-al(femn)si phase in liquid al-11.5si-0.4mg alloy. J. Mater. Sci. 2004, 39, 2303–2314. [Google Scholar] [CrossRef]

- Nayebi, B.; Divandari, M. Characteristics of dynamically formed oxide films on molten aluminium. Int. J. Cast Met. Res. 2012, 25, 270–276. [Google Scholar] [CrossRef]

- Divandari, M.; Campbell, J. Oxide film characteristics of al–7si–mg alloy in dynamic conditions in casting. Int. J. Cast Met. Res. 2004, 17, 182–187. [Google Scholar] [CrossRef]

- Azarmehr, S.; Divandari, M.; Arabi, H. Investigation on thickness of short time oxide films in al–1mg and al–2mg alloys. Mater. Sci. Technol. 2012, 28, 1295–1300. [Google Scholar] [CrossRef]

- Mirak, A.R.; Divandari, M.; Boutorabi, S.M.A.; Campbell, J. Oxide film characteristics of az91 magnesium alloy in casting conditions. Int. J. Cast Met. Res. 2007, 20, 215–220. [Google Scholar] [CrossRef]

- Fox, S.; Campbell, J. Visualisation of oxide film defects during solidification of aluminium alloys. Scr. Mater. 2000, 43, 881–886. [Google Scholar] [CrossRef]

- Ferraro, S.; Fabrizi, A.; Timelli, G. Evolution of sludge particles in secondary die-cast aluminum alloys as function of fe, mn and cr contents. Mater. Chem. Phys. 2015, 153, 168–179. [Google Scholar] [CrossRef]

- Ferraro, S.; Bjurenstedt, A.; Seifeddine, S. On the formation of sludge intermetallic particles in secondary aluminum alloys. Metall. Mater. Trans. A 2015, 46, 3713–3722. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Toschi, S.; Bjurenstedt, A.; Seifeddine, S. Influence of sludge particles on the fatigue behavior of al-si-cu secondary aluminium casting alloys. Metals 2018, 8, 268. [Google Scholar] [CrossRef]

- Griffiths, W.D.; Raiszadeh, R. Hydrogen, porosity and oxide film defects in liquid al. J. Mater. Sci. 2009, 44, 3402–3407. [Google Scholar] [CrossRef]

- Hwang, J.Y.; Doty, H.W.; Kaufman, M.J. The effects of mn additions on the microstructure and mechanical properties of al–si–cu casting alloys. Mater. Sci. Eng. A 2008, 488, 496–504. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Yousefian, P.; Eason, P.D. Quantification of entrainment damage in a356 aluminum alloy castings. Metall. Mater. Trans. A 2018, 49, 5815–5822. [Google Scholar] [CrossRef]

- Zhang, Q.; Liljenfors, T.; Jonsson, S.; Jarfors, A.E.W. On the application of reduced pressure test for the prediction of ductility of 46000 alloy: Role of pore’s morphology and distribution. J. Mater. Res. Technol. 2024, 31, 927–934. [Google Scholar] [CrossRef]

- Song, J.; Xiong, S.-M.; Li, M.; Allison, J. In situ observation of tensile deformation of high-pressure die-cast specimens of am50 alloy. Mater. Sci. Eng. A 2009, 520, 197–201. [Google Scholar] [CrossRef]

- Doglione, R. In situ investigations on the ductility of an al-si-mg casting alloy. JOM 2012, 64, 51–57. [Google Scholar] [CrossRef]

- Caceres, C. Particle cracking and the tensile ductility of a model al-si-mg composite system. Alum. Trans. 2006, 1, 1–13. [Google Scholar]

- Bogdanoff, T.; Börjesson, J.; Seifeddine, S.; Tiryakioğlu, M.; Ghassemali, E. On the secondary cracks during crack propagation in an al-si-cu-mg alloy: An in-situ study. Mater. Charact. 2023, 203, 113046. [Google Scholar] [CrossRef]

- Bogdanoff, T.; Lattanzi, L.; Merlin, M.; Ghassemali, E.; Jarfors, A.E.W.; Seifeddine, S. The complex interaction between microstructural features and crack evolution during cyclic testing in heat-treated al–si–mg–cu cast alloys. Mater. Sci. Eng. A 2021, 825, 141930. [Google Scholar] [CrossRef]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Al |

|---|---|---|---|---|---|---|---|---|

| Content | 10.2 | 1.05 | 3.14 | 0.26 | 0.16 | 0.04 | 0.63 | Bal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olofsson, J.; Bogdanoff, T.; Tiryakioğlu, M. On the Competition between Pores and Hidden Entrainment Damage during In Situ Tensile Testing of Cast Aluminum Alloy Components. Metals 2024, 14, 1175. https://doi.org/10.3390/met14101175

Olofsson J, Bogdanoff T, Tiryakioğlu M. On the Competition between Pores and Hidden Entrainment Damage during In Situ Tensile Testing of Cast Aluminum Alloy Components. Metals. 2024; 14(10):1175. https://doi.org/10.3390/met14101175

Chicago/Turabian StyleOlofsson, Jakob, Toni Bogdanoff, and Murat Tiryakioğlu. 2024. "On the Competition between Pores and Hidden Entrainment Damage during In Situ Tensile Testing of Cast Aluminum Alloy Components" Metals 14, no. 10: 1175. https://doi.org/10.3390/met14101175

APA StyleOlofsson, J., Bogdanoff, T., & Tiryakioğlu, M. (2024). On the Competition between Pores and Hidden Entrainment Damage during In Situ Tensile Testing of Cast Aluminum Alloy Components. Metals, 14(10), 1175. https://doi.org/10.3390/met14101175