Heterogeneous Microstructure Provides a Good Combination of Strength and Ductility in Duplex Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure Characterization

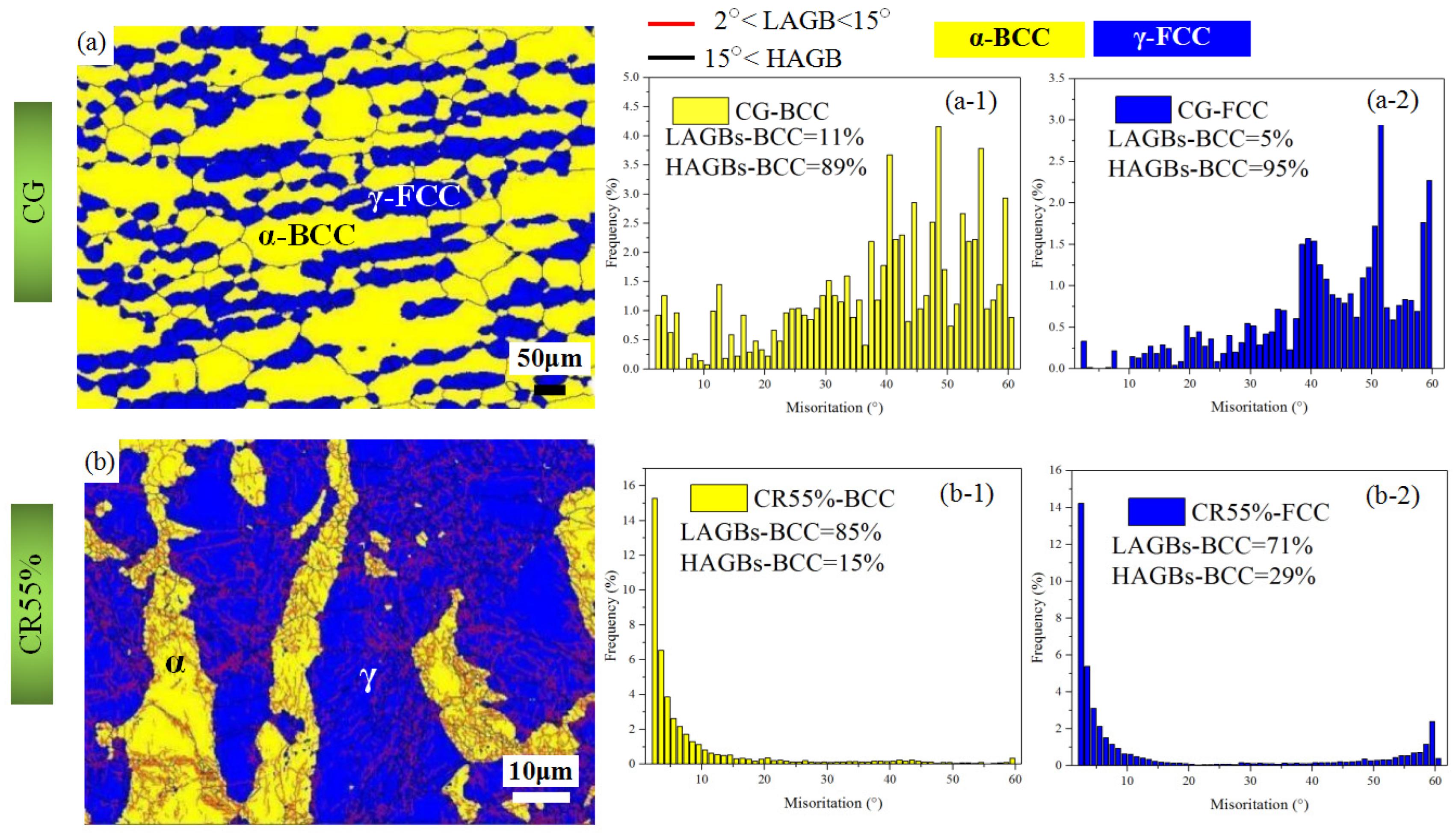

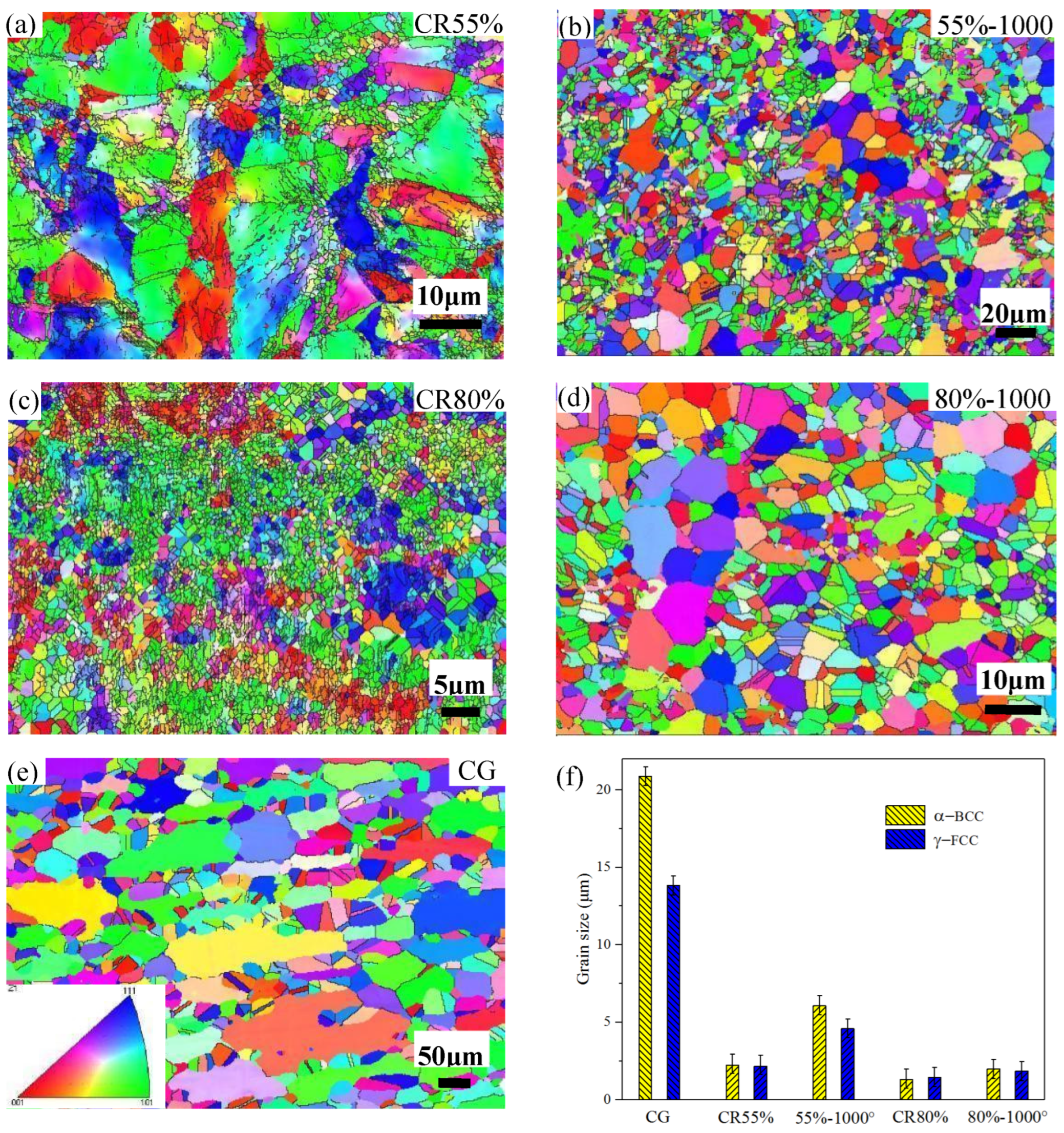

3.1.1. EBSD Analysis

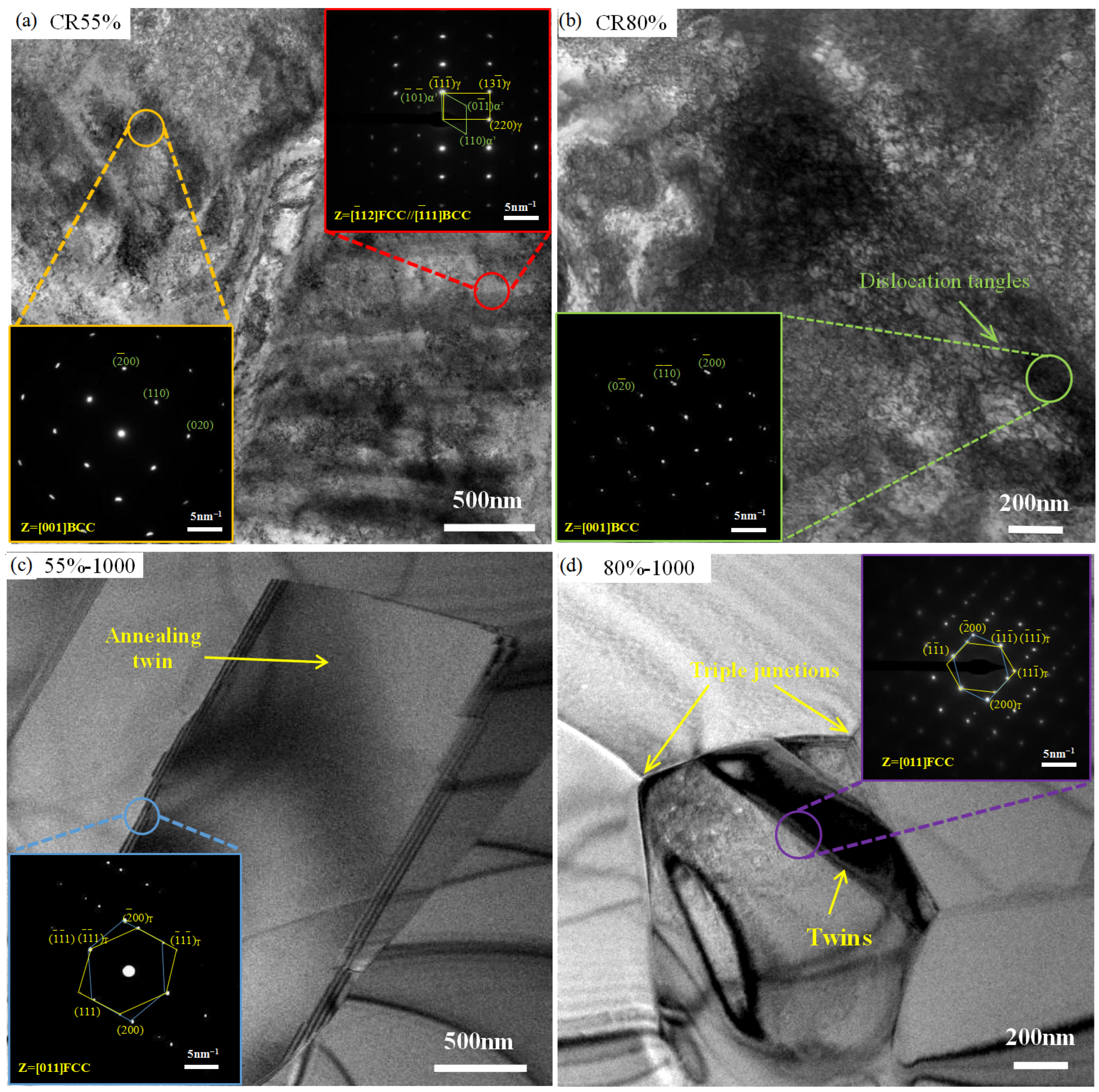

3.1.2. TEM Analysis

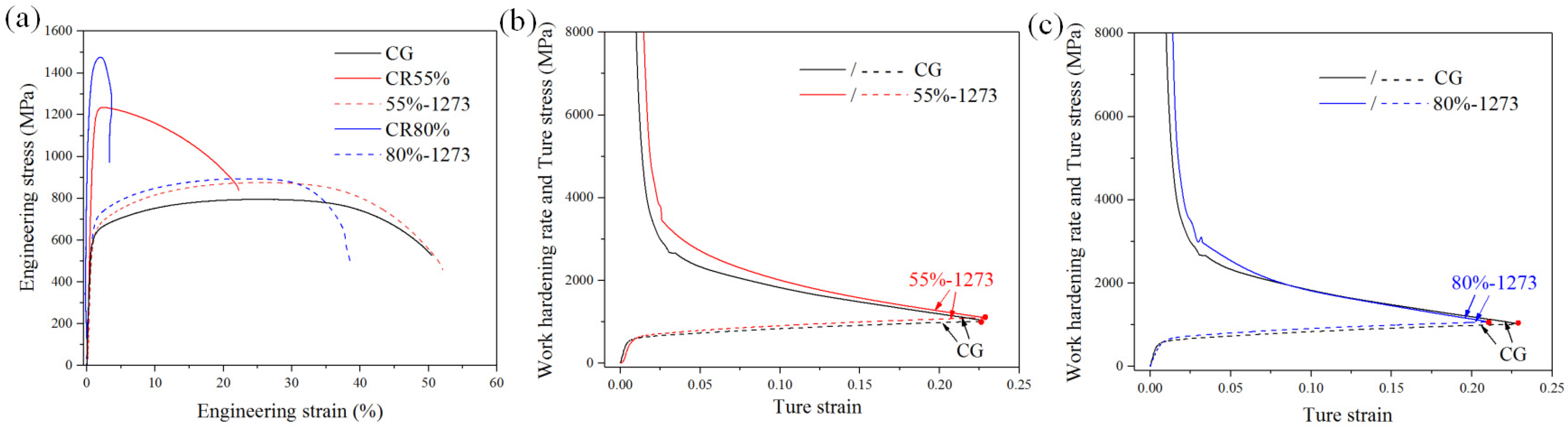

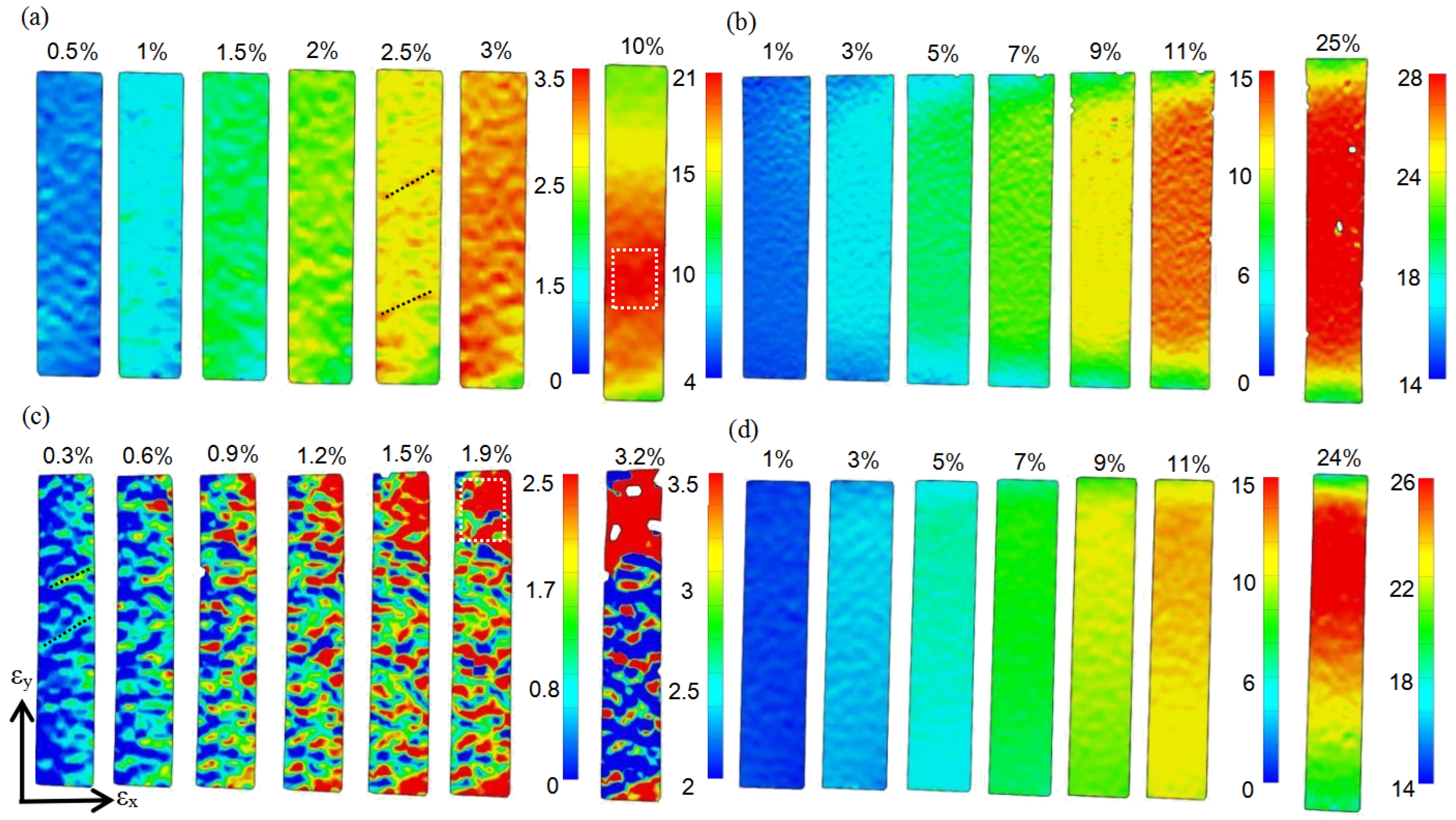

3.2. Mechanical Properties

3.2.1. Tensile Property and Microhardness

3.2.2. HDI Strengthening and HDI Strain Hardening

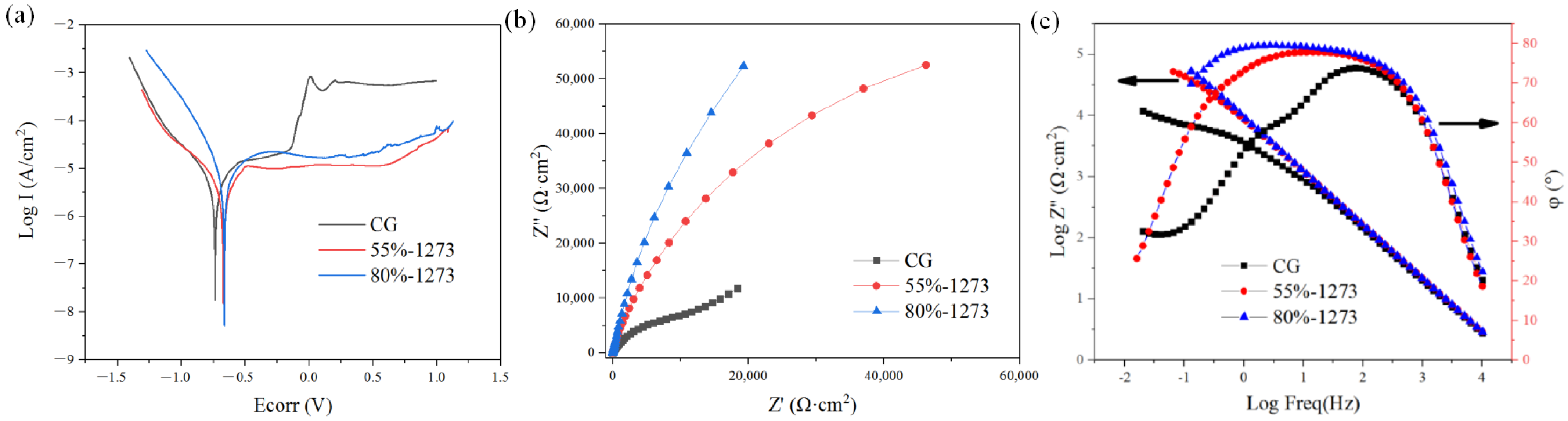

3.3. Corrosion Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Romero-Resendiz, L.; El-Tahawy, M.; Zhang, T.; Rossi, M.C.; Marulanda-Cardona, D.M.; Yang, T.; Amigó-Borrás, V.; Huang, Y.; Mirzadeh, H.; Beyerlein, I.J.; et al. Heterostructured stainless steel: Properties, current trends, and future perspectives. Mater. Sci. Eng. Rep. 2022, 150, 100691. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomaterialia 2012, 8, 3888–3903. [Google Scholar] [CrossRef]

- Ren, Y.B.; Zhao, H.C.; Liu, W.P.; Yang, K. Effect of cold deformation on pitting corrosion of 00Cr18Mn15Mo2N0.86 stainless steel for coronary stent application. Mater. Sci. Eng. C 2016, 60, 293–297. [Google Scholar] [CrossRef] [PubMed]

- Haghdadi, N.; Cizek, P.; Hodgson, P.D.; Beladi, H. Microstructure dependence of impact toughness in duplex stainless steels. Mater. Sci. Eng. A 2019, 745, 369–378. [Google Scholar] [CrossRef]

- Yang, S.F.; Li, C.W.; Chen, A.Y.; Gan, B.; Gu, J.F. Microstructure and corrosion resistance of stainless steel manufactured by laser melting deposition. J. Manuf. Process. 2021, 65, 418–427. [Google Scholar] [CrossRef]

- Fu, Z.R.; Li, X.F.; Li, C.; Pan, H.J.; Bai, Y.H.; Zhang, Z.H.; Liu, Y.; Liu, Y.F.; Yang, J.R.; Gong, Y.L.; et al. Superior mechanical properties of pure Zr with heterogeneous structure. Mater. Charact. 2022, 194, 112437. [Google Scholar] [CrossRef]

- Li, J.S.; Gao, B.; Huang, Z.W.; Zhou, H.; Mao, Q.Z.; Li, Y.S. Design for strength-ductility synergy of 316L stainless steel with heterogeneous lamella structure through medium cold rolling and annealing. Vacuum 2018, 157, 128–135. [Google Scholar] [CrossRef]

- Sun, Y.T.; Kong, X.; Wang, Z.B. Superior mechanical properties and deformation mechanisms of a 304 stainless steel plate with gradient nanostructure. Int. J. Plast. 2022, 155, 103336. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Wu, X.L. Introduction to Heterostructured Materials; Acta Materialia Inc. Publishing: Bethesda, MD, USA, 2023. [Google Scholar]

- Ghosh, S.; Bibhanshu, N.; Suwas, S.; Chatterjee, K. Surface mechanical attrition treatment of additively manufactured 316L stainless steel yields gradient nanostructure with superior strength and ductility. Mater. Sci. Eng. A 2021, 820, 141540. [Google Scholar] [CrossRef]

- Li, J.; Mao, Q.; Chen, M.; Qin, W.; Lu, X.; Liu, T.; She, D.; Kang, J.; Wang, G.; Zhu, X.; et al. Enhanced pitting resistance through designing a high-strength 316L stainless steel with heterostructure. J. Mater. Res. Technol. 2021, 10, 132–137. [Google Scholar] [CrossRef]

- Selvam, K.; Saini, J.; Perumal, G.; Ayyagari, A.; Salloom, R.; Mondal, R.; Mukherjee, S.; Grewal, H.S.; Arora, H.S. Exceptional cavitation erosion-corrosion behavior of dual-phase bimodal structure in austenitic stainless steel. Tribol. Int. 2019, 134, 77–86. [Google Scholar] [CrossRef]

- Sun, G.; Du, L.; Hu, J.; Zhang, B.; Misra, R.D.K. On the influence of deformation mechanism during cold and warm rolling on annealing behavior of a 304 stainless steel. Mater. Sci. Eng. A 2019, 746, 341–355. [Google Scholar] [CrossRef]

- Shirdel, M.; Mirzadeh, H.; Parsa, M.H. Nano/ultrafine grained austenitic stainless steel through the formation and reversion of deformation-induced martensite: Mechanisms, microstructures, mechanical properties, and TRIP effect. Mater. Charact. 2015, 103, 150–161. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Li, S.; Min, N.; Jiang, L.; Zhou, Q.; Jin, X. Ensuring the strength and ductility synergy in an austenitic stainless steel: Single- or multi-phase hetero-structures design. Scr. Mater. 2021, 193, 81–85. [Google Scholar] [CrossRef]

- He, J.S.; Chen, M.; Li, J.S.; Wang, C.X.; Xing, S.L.; Li, Q. Improved Mechanical Property and Corrosion Resistance of SAF2507 Duplex Stainless Steel with Heterogeneous Lamella Structure. Steel Res. Int. 2021, 93, 2100360. [Google Scholar] [CrossRef]

- Gubicza, J.; Chinh, N.Q.; Lábár, J.L.; Hegedűs, Z.; Langdon, T.G. Langdon. Principles of self-annealing in silver processed by equal-channel angular pressing: The significance of a very low stacking fault energy. Mater. Sci. Eng. A 2010, 527, 752–760. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ma, Z.Y. Enhanced strength and ductility of friction stir processed Cu–Al alloys with abundant twin boundaries. Scr. Mater. 2013, 68, 751–754. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Kubin, L.P.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef]

- Li, X.Y.; Lu, L.; Li, J.G.; Zhang, X.; Gao, H.J. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 2020, 5, 706–723. [Google Scholar] [CrossRef]

- Liu, X.L.; Yuan, F.P.; Zhu, Y.T.; Wu, X.L. Extraordinary Bauschinger effect in gradient structured copper. Scr. Mater. 2018, 150, 57–60. [Google Scholar] [CrossRef]

- Lu, W.; Luo, X.; Ning, D.; Wang, M.; Yang, C.; Li, M.; Yang, Y.; Li, P.; Huang, B. Excellent strength-ductility synergy properties of gradient nano-grained structural CrCoNi medium-entropy alloy. J. Mater. Sci. Technol. 2021, 112, 195–201. [Google Scholar] [CrossRef]

- Huang, J.X.; Liu, Y.; Xu, T.; Chen, X.F.; Lai, Q.Q.; Xiao, L.R.; Pan, Z.Y.; Gao, B.; Zhou, H.; Zhu, Y.T. Dual-phase hetero-structured strategy to improve ductility of a low carbon martensitic steel. Mater. Sci. Eng. A 2022, 834, 142584. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Wang, C.Y.; Reddy, K.M.; Li, W.; Wang, X.D. Study on the deformation mechanism of a high-nitrogen duplex stainless steel with excellent mechanical properties originated from bimodal grain design. Acta Mater. 2022, 226, 117670. [Google Scholar] [CrossRef]

- Wu, X.L.; Zhu, Y.T. Heterostructured Materials: Novel Materials with Unprecedented Mechanical Properties; Jenny Stanford Publishing: New York, NY, USA, 2021. [Google Scholar]

- Liang, Z.; Liu, Y.; Wang, X.; Liu, R.; Huang, M. Revealing the individual hardening effects of twins, dislocations, grain boundaries and solid solution in a twinning-induced plasticity steel. Mater. Sci. Forum 2016, 879, 2489–2494. [Google Scholar] [CrossRef]

- Lü, A.Q.; Zhang, Y.; Li, Y.; Liu, G.; Zang, Q.H.; Liu, C.M. Effect of nanocrystalline and twin boundaries on corrosion behavior of 316L stainless steel using SMAT. Acta Met. Sin. (Engl. Lett.) 2006, 19, 183–189. [Google Scholar] [CrossRef]

- Gollapudi, S. Grain size distribution effects on the corrosion behaviour of materials. Corros. Sci. 2012, 62, 90–94. [Google Scholar] [CrossRef]

| Phase | CG | CR55% | 55%-1273 | CR80% | 80%-1273 |

|---|---|---|---|---|---|

| BCC | 45% | 48% | 44% | 49% | 44% |

| FCC | 55% | 52% | 56% | 51% | 56% |

| Sample | YS (MPa) | UE% | UTS (MPa) | YS/UTS | Average Hardness (GPa) | ||

|---|---|---|---|---|---|---|---|

| α | γ | α + γ | |||||

| CG | 541 | 25.2 | 795 | 0.68 | 3.85 | 4.08 | 3.94 |

| CR55% | 1087 | 2.5 | 1236 | 0.88 | 4.45 | 4.83 | 4.64 |

| 55%-1273 | 574 | 25.8 | 874 | 0.66 | 3.91 | 4.12 | 3.98 |

| CR80% | 1342 | 1.9 | 1475 | 0.91 | 4.95 | 5.47 | 5.19 |

| 80%-1273 | 634 | 24.2 | 894 | 0.71 | 3.94 | 4.21 | 4.09 |

| Samples | Ecorr (V) | Icorr (A/cm2) | Ipass (A/cm2) | Epit (V) |

|---|---|---|---|---|

| CG | −0.73109 | 7.9804 × 10−7 | 2.41301 × 10−5 | −0.16262 |

| 55%-1273 | −0.66772 | 4.8292 × 10−7 | 1.17202 × 10−5 | 0.57799 |

| 80%-1273 | −0.66357 | 4.6601 × 10−7 | 2.21371 × 10−5 | 0.54003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Li, X.; Li, C.; Zhou, Z.; Quan, S.; Kang, Z.; Qin, S.; Sun, L.; Gao, B.; Zhu, X. Heterogeneous Microstructure Provides a Good Combination of Strength and Ductility in Duplex Stainless Steel. Metals 2024, 14, 193. https://doi.org/10.3390/met14020193

Yang J, Li X, Li C, Zhou Z, Quan S, Kang Z, Qin S, Sun L, Gao B, Zhu X. Heterogeneous Microstructure Provides a Good Combination of Strength and Ductility in Duplex Stainless Steel. Metals. 2024; 14(2):193. https://doi.org/10.3390/met14020193

Chicago/Turabian StyleYang, Jingran, Xingfu Li, Cong Li, Zhuangdi Zhou, Shuwei Quan, Zhuang Kang, Shen Qin, Lele Sun, Bo Gao, and Xinkun Zhu. 2024. "Heterogeneous Microstructure Provides a Good Combination of Strength and Ductility in Duplex Stainless Steel" Metals 14, no. 2: 193. https://doi.org/10.3390/met14020193

APA StyleYang, J., Li, X., Li, C., Zhou, Z., Quan, S., Kang, Z., Qin, S., Sun, L., Gao, B., & Zhu, X. (2024). Heterogeneous Microstructure Provides a Good Combination of Strength and Ductility in Duplex Stainless Steel. Metals, 14(2), 193. https://doi.org/10.3390/met14020193