Solid-State Synthesis of SiC Particle-Reinforced AZ91D Composites: Microstructure and Reinforcement Mechanisms

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composites’ Fabrication

2.3. Microstructure and Property Test

3. Results and Discussion

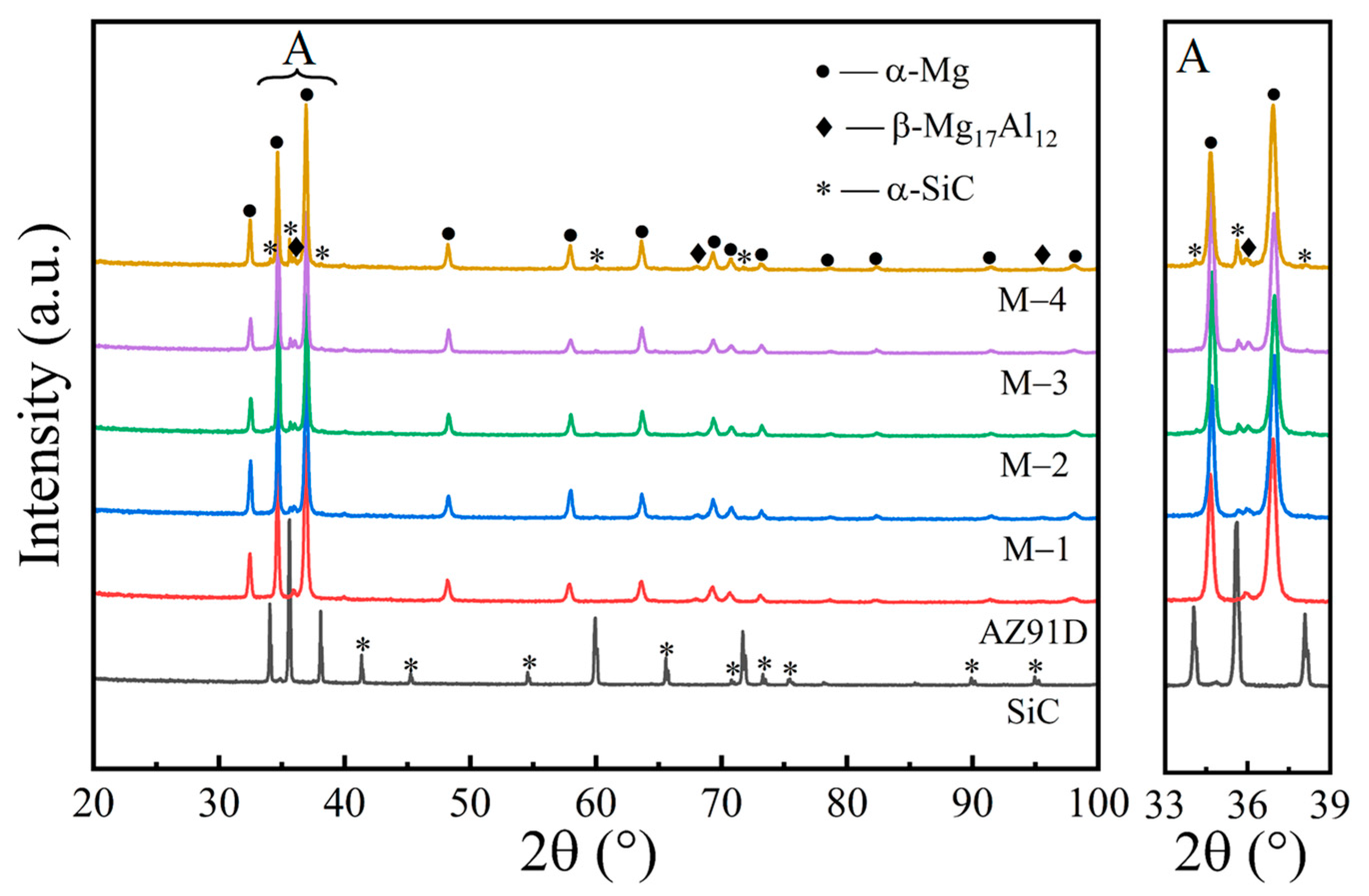

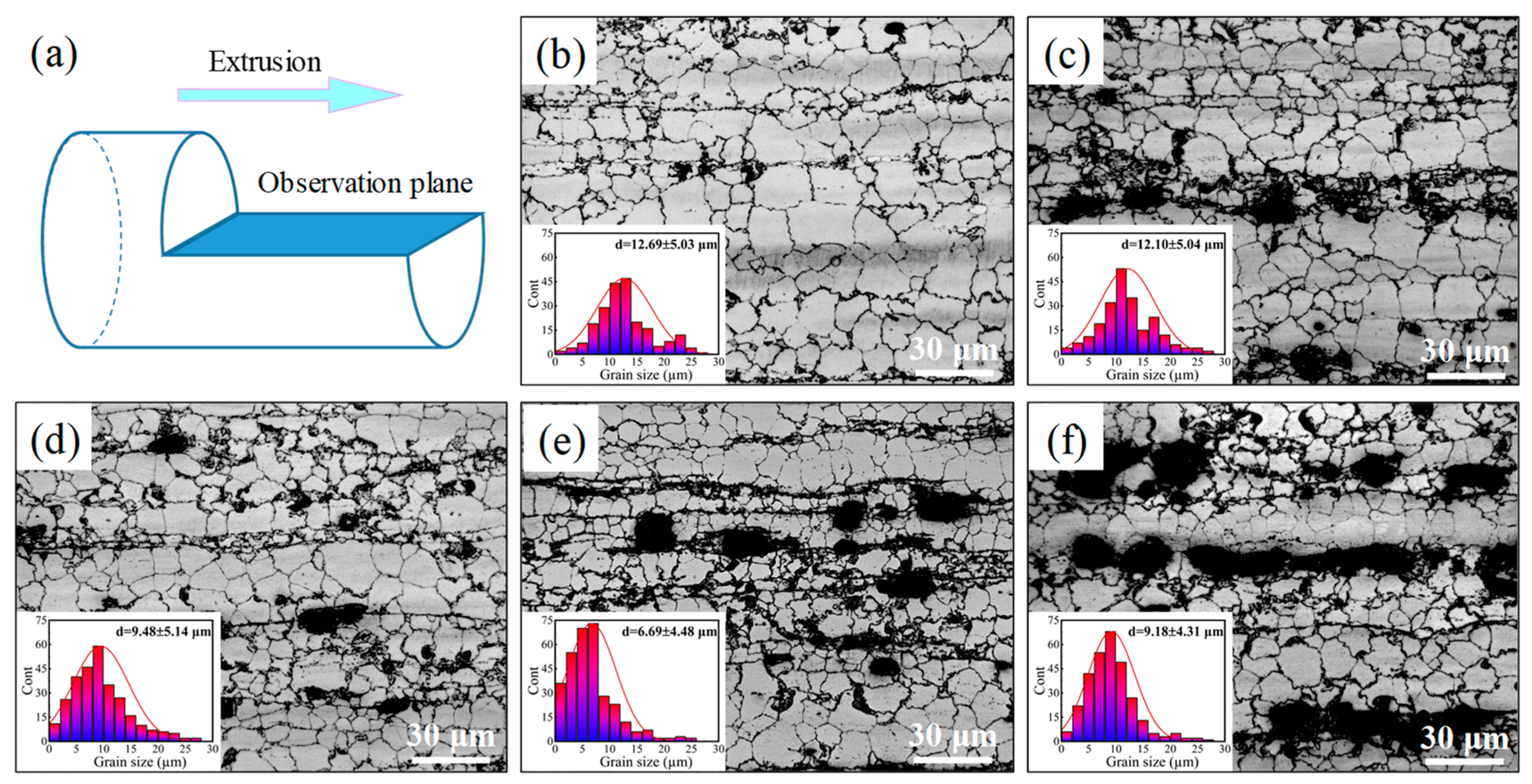

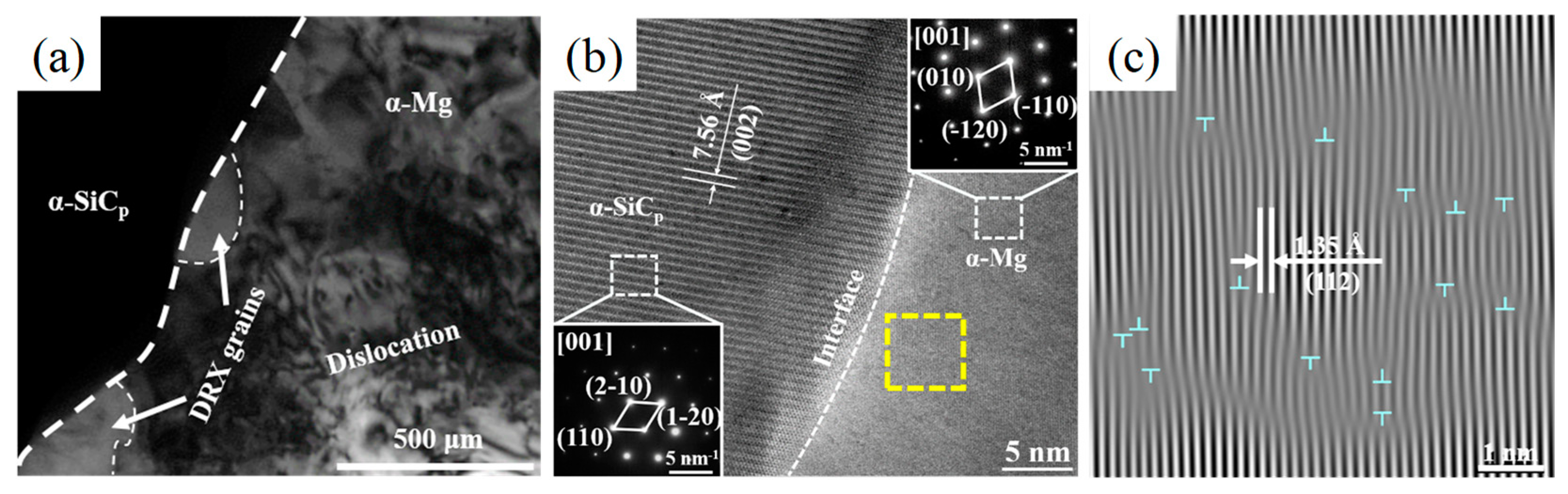

3.1. Microstructure

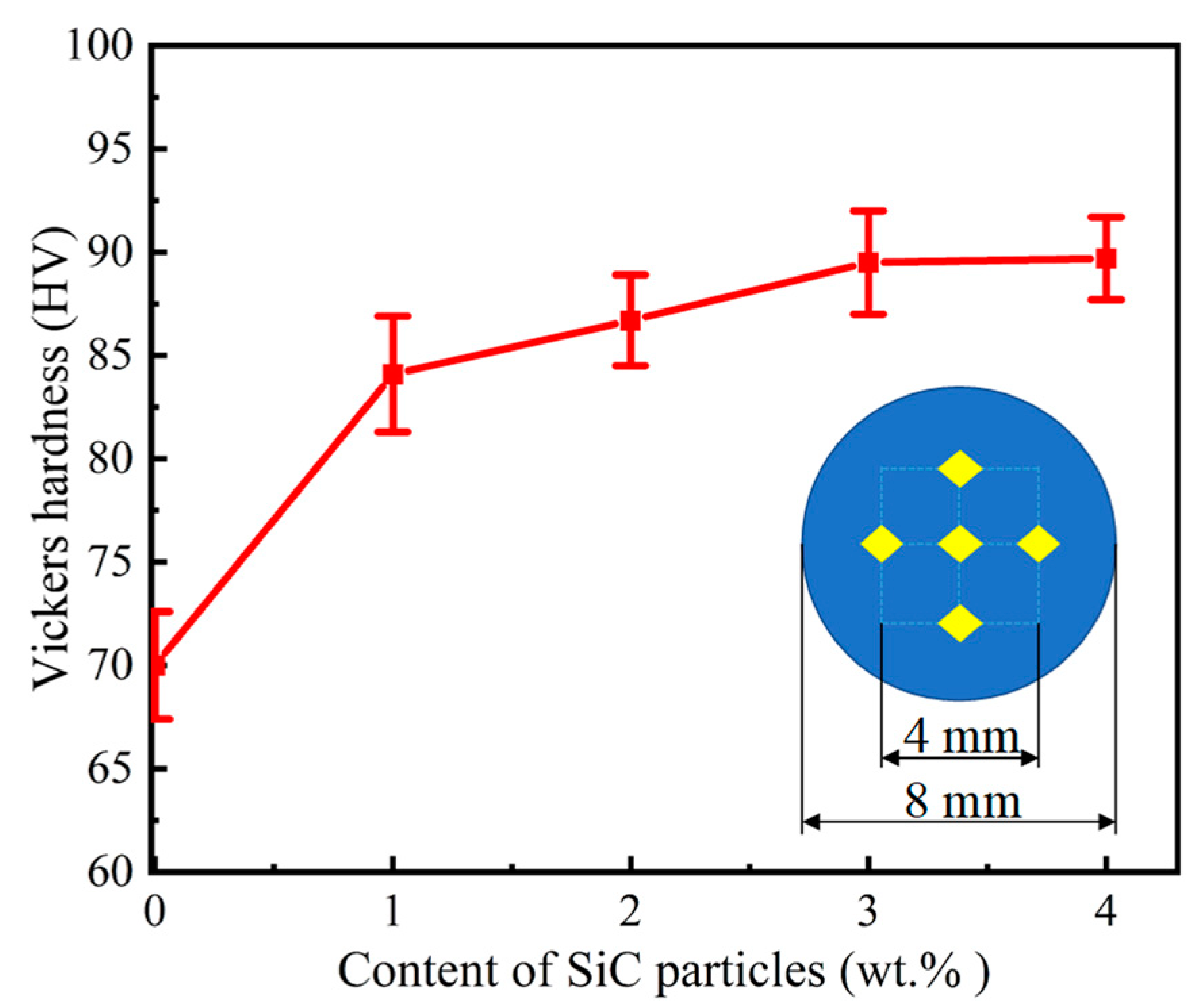

3.2. Mechanical Properties

3.3. Reinforcement Mechanisms

4. Conclusions

- (1)

- AZ91D chips are recycled directly into new magnesium products without pretreatment. The SiCp particles are uniformly dispersed in the SiCp/AZ91D composites through the ball milling process. After hot extrusion, the SiCp are well bonded to the magnesium matrix. Solid-state recovery of magnesium alloy chips is confirmed to be an advanced technology that effectively utilizes waste chips, reduces costs, and achieves resource recycling.

- (2)

- SiCp are able to refine the microstructure of magnesium alloy. When the SiCp content is 3 wt.%, the average grain size of the SiCp/AZ91D composites is the most refined, and the average grain size is reduced from 12.69 ± 5.03 um to 6.69 ± 4.48 μm.

- (3)

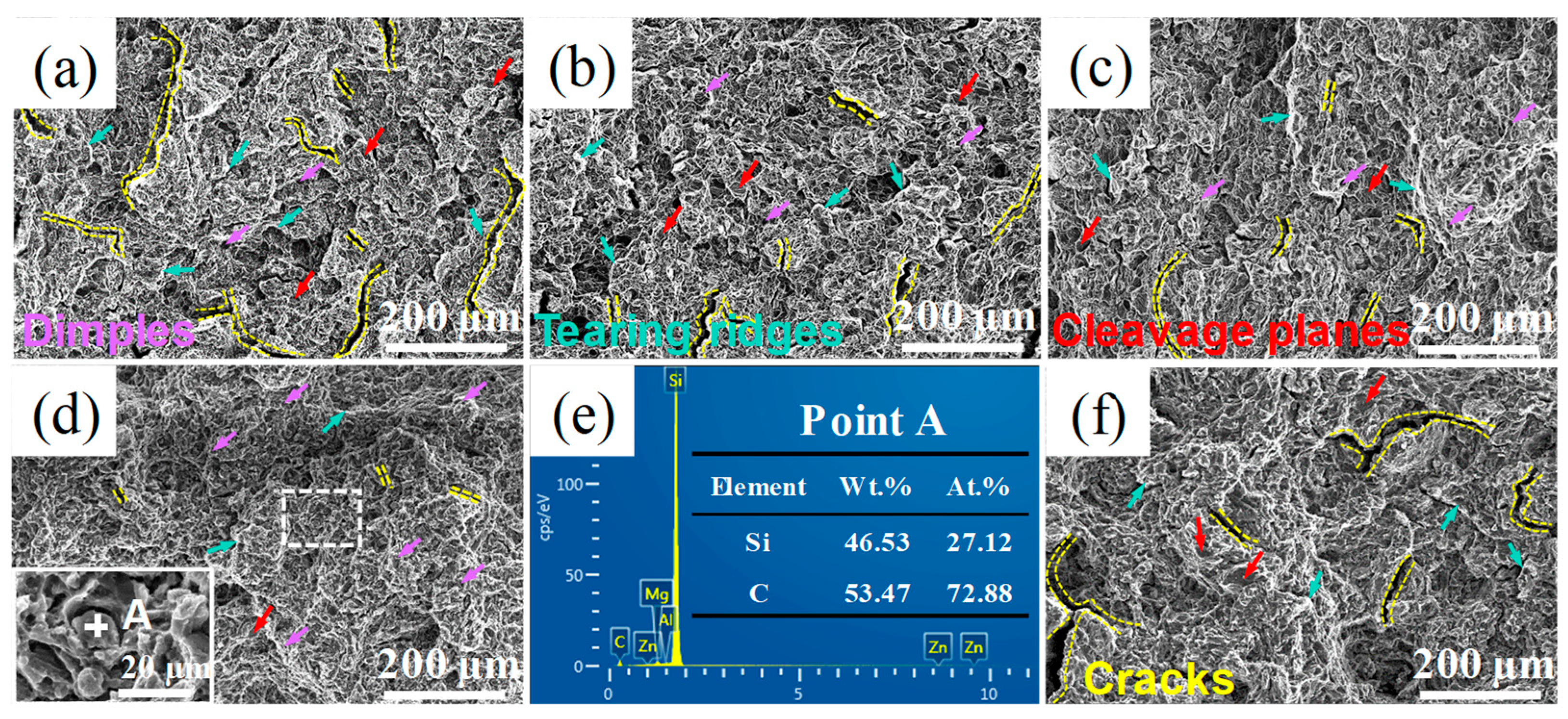

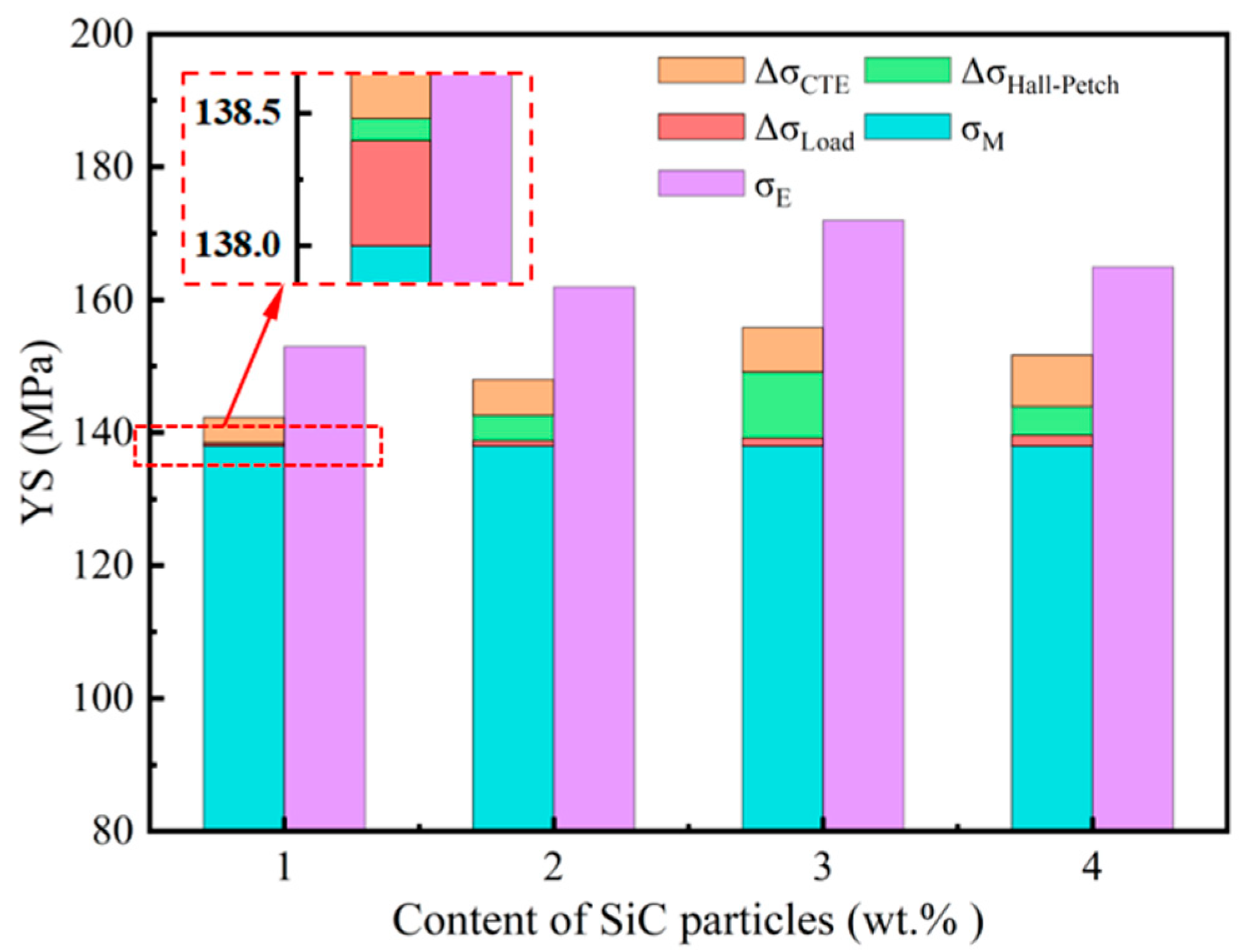

- With the increase in SiCp content, the mechanical properties of the SiCp/AZ91D composites show a trend of increasing and then decreasing. When the content of SiCp is 3 wt.%, the mechanical properties of the SiCp/AZ91D composites are excellent, with Vickers hardness, YS, UTS, and EL of 89.5 ± 2.5 HV, 172 ± 8 MPa, 341 ± 11 MPa, and 4.43 ± 0.18%, respectively. The strong bonding of SiCp with the AZ91D matrix inhibited crack initiation and extension. The fracture mode of the SiCp/AZ91D composites is brittle cleavage fracture.

- (4)

- SiCp improve the strength–toughness of the AZ91D matrix by hindering grain boundary migration, increasing dislocation density, and promoting dynamic recrystallization nucleation. The strengthening mechanisms of the SiCp/AZ91D composites are mainly the grain refinement strengthening mechanism and the dislocation reinforcement mechanism, and the load transfer mechanism has little effect on the mechanical properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, Q.M.; Wu, Y.X.; Wu, Y.Z.; Peng, S.L. Study on the Optimization of Heat Transfer Coefficient of a Rare Earth Wrought Magnesium Alloy in Residual Stress Analysis. Metals 2024, 14, 222. [Google Scholar] [CrossRef]

- Liang, M.J.; Zheng, J.; Liu, H.; Yao, B.X. Microstructure and mechanical properties of AZ31 alloy prepared by cyclic expansion extrusion with asymmetrical extrusion cavity. Trans. Nonferrous Met. Soc. China 2022, 32, 122–133. [Google Scholar] [CrossRef]

- Geng, K.J.; Jiang, H.P.; Zhang, S.Q.; Gao, X.; Wu, J.H.; Sun, C.C.; Zhou, J.X.; Zhang, X.F. Effects of Mold Temperature on the Microstructures and Tensile Properties of the Thixoforged Graphite/AZ91D Composite. Metals 2023, 13, 1000. [Google Scholar] [CrossRef]

- Sarvesha, R.; Chalapathi, D.; Yadava, M.; Jain, J.; Singh, S.S. In-situ studies on deformation and fracture characteristics of AZ91 Mg alloy. Materialia 2021, 18, 101177. [Google Scholar] [CrossRef]

- Farzami, M.; Farahani, M.; Akbari, D.; Tabasi, M. Friction Stir Weld of AZ91 Magnesium Alloy With and Without Nano-SiC Particle. JOM 2019, 71, 4171–4179. [Google Scholar] [CrossRef]

- Lee, T.; Yamasaki, M.; Kawamura, Y.; Go, J.B.; Park, S.H. High-Strength AZ91 Alloy Fabricated by Rapidly Solidified Flaky Powder Metallurgy and Hot Extrusion. Met. Mater. Int. 2019, 25, 372–380. [Google Scholar] [CrossRef]

- Braga, P.L.; de Souza, D.C.P.; de Oliveira, M.C.L.; Antunes, R.A. Effect of Graphene Oxide as an Anodizing Additive for the ZK60A Magnesium Alloy: Correlating Corrosion Resistance, Surface Chemistry and Film Morphology. Metals 2024, 14, 210. [Google Scholar] [CrossRef]

- Du, Z.Q.; Deng, K.K.; Nie, K.B.; Wang, C.J.; Xu, C.; Shi, Q.X. High-Modulus Laminated SiC/AZ91 Material with Adjustable Microstructure and Mechanical Properties Based on the Adjustment of the Densities of the Ceramic Layers. Materials 2023, 16, 6168. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.X.; Wang, Z.H.; Du, X.; Li, S.B.; Du, W.B. Microstructure and Mechanical Properties of Magnesium Matrix Composites Reinforced by In Situ Reduced Graphene Oxide. Materials 2023, 16, 2303. [Google Scholar] [CrossRef]

- Zhou, X.J.; Zhang, Z.F.; Li, X.L.; Zhou, L.Y.; Zhang, X.D.; Chen, M.J. Microstructure and Phase Evolution Characteristics of the In Situ Synthesis of TiC-Reinforced AZ91D Magnesium Matrix Composites. Materials 2022, 15, 1278. [Google Scholar] [CrossRef]

- Zhang, X.L.; Yu, G.K.; Zou, W.B.; Ji, Y.S.; Liu, Y.Z.; Cheng, J.L. Effect of casting methods on microstructure and mechanical properties of ZM5 space flight magnesium alloy. China Foundry 2018, 15, 418–421. [Google Scholar] [CrossRef]

- Nie, K.B.; Wang, X.J.; Deng, K.K.; Hu, X.S.; Wu, K. Magnesium Matrix Composite Reinforced by Nanoparticles—A review. J. Magnes. Alloy. 2021, 9, 57–77. [Google Scholar] [CrossRef]

- Hassana, S.F.; Tunb, K.S.; Guptab, M. Effect of Sintering Techniques on the Microstructure and Tensile Properties of Nano-Yttria Particulates Reinforced Magnesium Nanocomposites. J. Alloys Compd. 2011, 509, 4341–4347. [Google Scholar] [CrossRef]

- Goh, C.S.; Wei, J.; Lee, L.C.; Gupta, M. Properties and deformation behaviour of Mg-Y2O3 nanocomposites. Acta Mater. 2007, 55, 5115–5121. [Google Scholar] [CrossRef]

- Song, J.F.; She, J.; Chen, D.L.; Pan, F.S. Latest Research Advances on Magnesium and Magnesium Alloys Worldwide. J. Magnes. Alloy. 2020, 8, 1–41. [Google Scholar] [CrossRef]

- Zhu, H.D.; Li, X.T.; Guan, X.R.; Shao, Z.C. Effect of Molybdate Conversion Coating of Magnesium Alloy Reinforced by Micro-arc Oxidation. Met. Mater. Int. 2021, 27, 3975–3982. [Google Scholar] [CrossRef]

- Wang, J.Y.; Lin, Y.N.; Chang, T.C.; Lee, S. Recycling the Magnesium Alloy AZ91D in Solid State. Mater. Trans. 2006, 47, 1047–1051. [Google Scholar] [CrossRef]

- Asgari, A.; Sedighi, M.; Krajnik, R. Magnesium alloy-silicon carbide composite fabrication using chips waste. J. Clean. Prod. 2019, 232, 1187–1194. [Google Scholar] [CrossRef]

- Dudek, P.; Piwowońska, J.; Polczyk, T. Microstructure of castings made of magnesium alloys based on recycling of the circulating scrap. J. Mater. Res. Technol. 2021, 14, 2357–2364. [Google Scholar] [CrossRef]

- Schramm, A.; Recksiek, V.; Dudczig, S.; Scharf, C.; Aneziris, C. Immersion Testing of Variously Coated Ceramic Foam Filters in an AZ91 Magnesium Melt. Adv. Eng. Mater. 2021, 24, 2100519. [Google Scholar] [CrossRef]

- Schramm, A.; Nowak, R.; Bruzda, G.; Polkowski, W.; Fabrichnaya, O.; Aneziris, C.G. High temperature wettability and corrosion of ZrO2, Al2O3, Al2O3-C, MgO and MgAlON ceramic substrates by an AZ91 magnesium alloy melt. J. Eur. Ceram. Soc. 2022, 42, 3023–3035. [Google Scholar] [CrossRef]

- Wu, S.Y.; Ji, Z.S.; Hu, M.; Huang, Z.Q.; Tian, C.Y.; Wu, M.Z. Microstructure and Mechanical Properties of AZ31B Magnesium Alloy Prepared by Solid State Recycling. Rare Met. Mater. Eng. 2018, 47, 736–741. [Google Scholar] [CrossRef]

- Hu, M.L.; Wei, S.H.; Shi, Q.; Ji, Z.S.; Xu, H.Y.; Wang, Y. Dynamic Recrystallization Behavior and Mechanical Properties of Bimodal Scale Al2O3 Reinforced AZ31 Composites by Soild State Synthesis. J. Magnes. Alloy. 2020, 8, 841–848. [Google Scholar] [CrossRef]

- Wei, S.H.; Hu, M.L.; Ji, Z.S.; Xu, H.Y.; Wang, Y. Evaluation of microstructure and properties of AZ31/Al2O3 composites prepared by solid-phase synthesis. Mater. Sci. Technol. 2018, 34, 2097–2104. [Google Scholar] [CrossRef]

- TesaŘ, K.; BalÍK, K.; Sucharda, Z.; JÄGer, A. Direct extrusion of thin Mg wires for biomedical applications. Trans. Nonferrous Met. Soc. China 2020, 30, 373–381. [Google Scholar] [CrossRef]

- Zhao, C.; Ma, G.; Liu, T.; Hu, M.; Ji, Z. Effect of Near-Liquidus Squeeze Casting Pressure on Microstructure and Mechanical Property of AZ91D Alloy Differential Support. Materials 2023, 16, 4020. [Google Scholar] [CrossRef]

- Huang, S.J.; Diwan Midyeen, S.; Subramani, M.; Chiang, C.C. Microstructure Evaluation, Quantitative Phase Analysis, Strengthening Mechanism and Influence of Hybrid Reinforcements (β-SiCp, Bi and Sb) on the Collective Mechanical Properties of the AZ91 Magnesium Matrix. Metals 2021, 11, 898. [Google Scholar] [CrossRef]

- Liu, S.S.; Yang, B.P.; Huang, G.S.; Chen, X.H.; Tang, A.t.; Jiang, B.; Zheng, K.H.; Pan, F.S. Effect of dual-heterogeneous microstructures on mechanical properties of AZ91 extruded sheet. Trans. Nonferrous Met. Soc. China 2023, 33, 1086–1097. [Google Scholar] [CrossRef]

- Hong, X.; Meng, L.; Yupeng, W.; Pinkui, M.; Ming, B.; Bo, J.; Zhipeng, G.; Yujie, Z. Refined microstructure and dispersed precipitates in a gradient rolled AZ91 alloy under pulsed current. Materialia 2021, 20, 101245. [Google Scholar] [CrossRef]

- Liu, W.J.; Jiang, B.; Luo, S.Q.; Chen, S.Q.; Pan, F.S. Mechanical properties and failure behavior of AZ61 magnesium alloy at high temperatures. J. Mater. Sci. 2018, 53, 8536–8544. [Google Scholar] [CrossRef]

- Deng, K.K.; Wang, X.J.; Wu, Y.W.; Hu, X.S.; Wu, K.; Gan, W.M. Effect of Particle Size on Microstructure and Mechanical Properties of SiCp/AZ91 Magnesium Matrix Composite. Mater. Sci. Eng. A 2012, 543, 158–163. [Google Scholar] [CrossRef]

- Kandemir, S. Development of Graphene Nanoplatelet-Reinforced AZ91 Magnesium Alloy by Solidification Processing. J. Mater. Eng. Perform. 2018, 27, 3014–3023. [Google Scholar] [CrossRef]

- Wang, X.J.; Wang, X.M.; Hu, X.S.; Wu, K. Effects of hot extrusion on microstructure and mechanical properties of Mg matrix composite reinforced with deformable TC4 particles. J. Magnes. Alloy. 2020, 8, 421–430. [Google Scholar] [CrossRef]

- Meher, A.; Mahapatra, M.M.; Samal, P.; Vundavilli, P.R. Study on effect of TiB2 reinforcement on the microstructural and mechanical properties of magnesium RZ5 alloy based metal matrix composites. J. Magnes. Alloy. 2020, 8, 780–792. [Google Scholar] [CrossRef]

- Poddar, P.; Srivastava, V.C.; De, P.K.; Sahoo, K.L. Processing and Mechanical Properties of SiC Reinforced Cast Magnesium Matrix Composites by Stir Casting Process. Mater. Sci. Eng. A 2007, 460–461, 357–364. [Google Scholar] [CrossRef]

- Rauber, C.; Lohmüller, A.; Opel, S.; Singer, R.F. Microstructure and Mechanical Properties of SiC Particle Reinforced Magnesium Composites Processed by Injection Molding. Mater. Sci. Eng. A 2011, 528, 6313–6323. [Google Scholar] [CrossRef]

- Megahed, M.; Attia, M.A.; Abdelhameed, M.; El-Shafei, A.G. Tribological Characterization of Hybrid Metal Matrix Composites Processed by Powder Metallurgy. Acta Metall. Sin. Engl. 2017, 30, 781–790. [Google Scholar] [CrossRef]

- Pu, B.W.; Lin, X.B.; Li, B.W.; Chen, X.F.; He, C.N.; Zhao, N.Q. Effect of SiC Nanoparticles on the Precipitation Behavior and Mechanical Properties of 7075Al Alloy. J. Mater. Sci. 2020, 55, 6145–6160. [Google Scholar] [CrossRef]

- Wang, X.J.; Hu, X.S.; Wu, K.; Wang, L.Y.; Huang, Y.D. Evolutions of Microstructure and Mechanical Properties for SiCp/AZ91 Pomposites with Different Particle Contents during Extrusion. Mater. Sci. Eng. A 2015, 636, 138–147. [Google Scholar] [CrossRef]

- Wang, W.Z.; Chen, X.; Wang, Q.M.; Huang, G.S.; Li, J.B.; Chen, X.H.; Zheng, K.H.; Jiang, B.; Pan, F.S. Microstructural regulation and mechanical behavior of asymmetrically extruded high-content TC4p reinforced AZ31 composite. Mater. Sci. Eng. A 2024, 892, 146067. [Google Scholar] [CrossRef]

- Li, R.G.; Li, H.R.; Zhao, D.Y.; Dai, Y.Q.; Fang, D.Q.; Zhang, J.H.; Zong, L.; Sun, J. High strength commercial AZ91D alloy with a uniformly fine-grained structure processed by conventional extrusion. Mater. Sci. Eng. A 2020, 780, 139193. [Google Scholar] [CrossRef]

- He, Y.J.; Xu, H.Y.; Liu, Y.; Chen, Y.Y.; Ji, Z.S. Strengthening mechanism of B4C@APC/Al matrix composites reinforced with bimodal-sized particles prepared by hydrothermal carbonized deposition on chips. J. Mater. Sci. Technol. 2022, 123, 60–69. [Google Scholar] [CrossRef]

- Sun, X.F.; Wang, C.J.; Deng, K.K.; Kang, J.W.; Bai, Y.; Nie, K.B.; Shang, S.J. Aging Behavior of AZ91 Matrix Influenced by 5 μm SiCp: Investigation on the Microstructure and Mechanical Properties. J. Alloys Compd. 2017, 727, 1263–1272. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, B.; Kang, Y.H.; Zhao, J.; Zhang, W.W.; Zheng, K.H.; Pan, F.S. Tailoring microstructure and texture of Mg–3Al–1Zn alloy sheets through curve extrusion process for achieving low planar anisotropy. J. Mater. Sci. Technol. 2022, 113, 48–60. [Google Scholar] [CrossRef]

- GB/T228-2002; Metallic Materials-Tensile Testing at Ambient Temperature. General Administration of Quality Supervision, Inspection and Quarantineof the People’s Republic of China: Beijing, China, 2002.

- Chen, Y.; Yao, Y.; Han, S.L.; Feng, X.W.; Luo, T.G.; Zheng, K.H. Study on Microstructure and Mechanical Properties of TC4/AZ31 Magnesium Matrix Nanocomposites. Materials 2023, 16, 1139. [Google Scholar] [CrossRef]

- Shen, M.J.; Wang, X.J.; Zhang, M.F.; Hu, X.S.; Zheng, M.Y.; Wu, K. Fabrication of Bimodal Size SiCp Reinforced AZ31B Magnesium Matrix Composites. Mater. Sci. Eng. A 2014, 601, 58–64. [Google Scholar] [CrossRef]

- Deng, K.K.; Wang, C.J.; Nie, K.B.; Wang, X.J. Recent Research on the Deformation Behavior of Particle Reinforced Magnesium Matrix Composite: A Review. Acta Metall. Sin. Engl. 2019, 32, 413–425. [Google Scholar] [CrossRef]

- Li, Y.Q.; Li, F.; Kang, F.W.; Du, H.Q.; Chen, Z.Y. Recent research and advances in extrusion forming of magnesium alloys: A review. J. Alloys Compd. 2023, 953, 170080. [Google Scholar] [CrossRef]

- Cui, X.F.; Guo, Y.L.; Yang, Y.; Zhu, Y.; Zhou, G.; Cao, T.T.; Luo, Q.; Wei, G.B.; Li, Q.; Jiang, B.; et al. High-ductility Mg-9Li-1Zn-2Gd-1.2Mn alloy prepared via traditional hot extrusion. Mater. Sci. Eng. A 2024, 893, 146094. [Google Scholar] [CrossRef]

- Lv, S.H.; Xie, Z.F.; Yang, Q.; Meng, F.Z.; Qiu, X. Microstructures and mechanical properties of a hot-extruded Mg–8Zn–6Al–1Gd (wt%) alloy. J. Alloys Compd. 2022, 904, 164040. [Google Scholar] [CrossRef]

- Doherty, R.D.; Hughes, D.A.; Humphreys, F.J.; Jonas, J.J.; Jensen, D.J.; Kassner, M.E.; King, W.E.; McNelley, T.R.; McQueen, H.J.; Rollett, A.D. Current Issues in Recrystallization: A Review. Mater. Sci. Eng. A 1997, 238, 219–274. [Google Scholar] [CrossRef]

- Xu, H.Y.; Yang, Z.; Hu, M.L.; Ji, Z.S. Effect of Short Carbon Fiber Content on SCFs/AZ31 Composite Microstructure and Mechanical Properties. Results Phys. 2020, 17, 103074. [Google Scholar] [CrossRef]

- Wu, K.; Deng, K.K.; Nie, K.B.; Wu, Y.W.; Wang, X.J.; Hu, X.S.; Zheng, M.Y. Microstructure and Mechanical Properties of SiCp/AZ91 Composite Deformed Through a Combination of Forging and Extrusion Process. Mater. Des. 2010, 31, 3929–3932. [Google Scholar] [CrossRef]

- Habibnejad Korayem, M.; Mahmudi, R.; Poole, W.J. Enhanced Properties of Mg-Based Nano-Composites Reinforced with Al2O3 Nano-particles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Chang, H.; Wang, X.J.; Hu, X.S.; Wang, Y.Q.; Nie, K.B.; Wu, K. Effects of Reinforced Particles on Dynamic Recrystallization of Mg Base Alloys during Hot Extrusion. Rare Met. Mater. Eng. 2014, 43, 1821–1825. [Google Scholar] [CrossRef]

- Morisada, Y.; Fujii, H.; Nagaoka, T.; Fukusumi, M. Effect of Friction Stir Processing with SiC Particles on Microstructure and Hardness of AZ31. Mater. Sci. Eng. A 2006, 433, 50–54. [Google Scholar] [CrossRef]

- Shang, S.J.; Deng, K.K.; Nie, K.B.; Li, J.C.; Zhou, S.S.; Xu, F.J.; Fan, J.F. Microstructure and Mechanical Properties of SiCp/Mg–Al–Zn Composites Containing Mg17Al12 Phases Processed by Low-Speed Extrusion. Mater. Sci. Eng. A 2014, 610, 243–249. [Google Scholar] [CrossRef]

- Alrasheedi, N.H.; Ataya, S.; El-Sayed Seleman, M.M.; Ahmed, M.M.Z. Tensile Deformation and Fracture of Unreinforced AZ91 and Reinforced AZ91-C at Temperatures up to 300 °C. Materials 2023, 16, 4785. [Google Scholar] [CrossRef]

- Luo, H.; Li, J.; Ye, J.; Lu, Y.; Tan, J.; Song, J.; Chen, X.; Zheng, K.; Pan, F. Influence of Ti-6Al-4V particles on the interfacial microstructure and strength-ductility synergetic mechanism of AZ91 magnesium alloy. Mater. Charact. 2022, 191, 112154. [Google Scholar] [CrossRef]

- Rojas, Á.; Sánchez Torrijos, Y.; Gil-Gómez, A.; Liu, C.H.; Rodríguez Rivas, C.; Ferrer, M.T.; Romero Gómez, M. Performance of different biomarkers for the management of hepatocellular carcinoma. Hepatoma Res. 2018, 4, 31. [Google Scholar] [CrossRef]

- Kumar, B.P.; Birru, A.K. Microstructure and mechanical properties of aluminium metal matrix composites with addition of bamboo leaf ash by stir casting method. Trans. Nonferrous Met. Soc. China 2017, 27, 2555–2572. [Google Scholar] [CrossRef]

- Chai, F.; Ma, Z.; Han, X.; Hu, X.; Chang, Z.; Zhou, J. Effect of strain rates on mechanical behavior, microstructure evolution and failure mechanism of extruded-annealed AZ91 magnesium alloy under room-temperature tension. J. Mater. Res. Technol. 2023, 27, 4644–4656. [Google Scholar] [CrossRef]

- Liu, S.S.; Wang, W.Z.; Chen, X.; Huang, G.S.; Liu, H.; Tang, A.; Jiang, B.; Pan, F.S. Enhanced strength and ductility AZ91 alloy with heterogeneous lamella structure prepared by pre-aging and low-temperature extrusion. Mater. Sci. Eng. A 2021, 812, 141094. [Google Scholar] [CrossRef]

- Whelchel, R.L.; Sanders, T.H.; Thadhani, N.N. Spall and dynamic yield behavior of an annealed aluminum–magnesium alloy. Scr. Mater. 2014, 92, 59–62. [Google Scholar] [CrossRef]

- Wang, D.X.; Jing, Y.; Lin, B.S.; Li, J.P.; Shi, Y.; Misra, R.D.K. On the structure, mechanical behavior, and deformation mechanism of AZ91 magnesium alloy processed by symmetric and asymmetric rolling. Mater. Charact. 2022, 194, 112444. [Google Scholar] [CrossRef]

- Deng, K.K.; Wu, K.; Wu, Y.W.; Nie, K.B.; Zheng, M.Y. Effect of Submicron Size SiC Particulates on Microstructure and Mechanical Properties of AZ91 Magnesium Matrix Composites. J. Alloys Compd. 2010, 504, 542–547. [Google Scholar] [CrossRef]

- Fathi, R.; Ma, A.; Saleh, B.; Xu, Q.; Jiang, J.H. Investigation on mechanical properties and wear performance of functionally graded AZ91-SiCp composites via centrifugal casting. Mater. Today Commun. 2020, 24, 101169. [Google Scholar] [CrossRef]

- Raja, A.; Pancholi, V. Effect of friction stir processing on tensile and fracture behaviour of AZ91 alloy. J. Mater. Process. Technol. 2017, 248, 8–17. [Google Scholar] [CrossRef]

- Yuan, Q.H.; Fu, D.M.; Zeng, X.S.; Liu, Y. Fabrication of carbon nanotube reinforced AZ91D composite with superior mechanical properties. Trans. Nonferrous Met. Soc. China 2017, 27, 1716–1724. [Google Scholar] [CrossRef]

- Nai, M.H.; Wei, J.; Gupta, M. Interface tailoring to enhance mechanical properties of carbon nanotube reinforced magnesium composites. Mater. Des. 2014, 60, 490–495. [Google Scholar] [CrossRef]

- Wang, X.J.; Wu, K.; Huang, W.X.; Zhang, H.F.; Zheng, M.Y.; Peng, D.L. Study on fracture behavior of particulate reinforced magnesium matrix composite using in situ SEM. Compos. Sci. Technol. 2007, 67, 2253–2260. [Google Scholar] [CrossRef]

- Huang, S.J.; Abbas, A. Effects of tungsten disulfide on microstructure and mechanical properties of AZ91 magnesium alloy manufactured by stir casting. J. Alloys Compd. 2020, 817, 153321. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Contribution of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites. Mater. Sci. Eng. A 2008, 483, 148–152. [Google Scholar] [CrossRef]

- Cubides, Y.; Karayan, A.I.; Vaughan, M.W.; Karaman, I.; Castaneda, H. Enhanced mechanical properties and corrosion resistance of a fine-grained Mg-9Al-1Zn alloy: The role of bimodal grain structure and β-Mg17Al12 precipitates. Materialia 2020, 13, 100840. [Google Scholar] [CrossRef]

- Deng, K.K.; Shi, J.Y.; Wang, C.J.; Wang, X.J.; Wu, Y.W.; Nie, K.B. Microstructure and Strengthening Mechanism of Bimodal Size Particle Reinforced Magnesium Matrix Composite. Compos. Part A 2012, 43, 1280–1284. [Google Scholar] [CrossRef]

| Samples | SiCp Contents (wt.%) | SiCp Contents (wt.%) | Cold Pressure (MPa) | Holding Time (s) | Hot Extrusion Pressure (MPa) | Heating Temperature (°C) | Holding Time (min) |

|---|---|---|---|---|---|---|---|

| AZ91D | 0 | 100 | 600 | 15 | 650 | 410 | 30 |

| M-1 | 1 | 99 | |||||

| M-2 | 2 | 98 | |||||

| M-3 | 3 | 97 | |||||

| M-4 | 4 | 96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Q.; Cui, P.; Hu, M.; Wang, F.; Xu, H.; Zhou, X. Solid-State Synthesis of SiC Particle-Reinforced AZ91D Composites: Microstructure and Reinforcement Mechanisms. Metals 2024, 14, 434. https://doi.org/10.3390/met14040434

Shi Q, Cui P, Hu M, Wang F, Xu H, Zhou X. Solid-State Synthesis of SiC Particle-Reinforced AZ91D Composites: Microstructure and Reinforcement Mechanisms. Metals. 2024; 14(4):434. https://doi.org/10.3390/met14040434

Chicago/Turabian StyleShi, Qian, Pengxing Cui, Maoliang Hu, Fei Wang, Hongyu Xu, and Xiaobing Zhou. 2024. "Solid-State Synthesis of SiC Particle-Reinforced AZ91D Composites: Microstructure and Reinforcement Mechanisms" Metals 14, no. 4: 434. https://doi.org/10.3390/met14040434